Abstract

The environmental challenges posed by global warming have significantly increased the global pursuit of renewable and clean energy sources. Among these, solar energy stands out due to its abundance, renewability, low environmental impact, and favorable long-term economic viability. However, its intermittent nature and dependence on weather conditions hinder consistent and efficient utilization. To address these limitations, nanoparticle-enhanced phase change materials (NPCMs) have emerged as a promising solution for enhancing thermal energy storage in solar thermal systems. NPCMs incorporate superior-performance nanoparticles within traditional phase change material matrices, resulting in improved thermal conductivity, energy storage density, and phase change efficiency. This review systematically examines the recent advances in NPCMs for solar energy applications, covering their classification, structural characteristics, advantages, and limitations. It also explores in-depth analytical approaches, including mechanism-oriented analysis, simulation-based modelling, and algorithm-driven optimization, that explain the behavior of NPCMs at micro and macro scales. Furthermore, the techno-economic implications of NPCM integration are evaluated, with particular attention to cost-benefit analysis, policy incentives, and market growth potential, which collectively support broader adoption. Overall, the findings highlight NPCMs as a frontier in materials innovation and enabling technology for achieving low-carbon, environmentally responsible energy solutions, contributing significantly to global sustainable development goals.

1. Introduction

Traditional fossil fuel combustion releases substantial carbon dioxide emissions, constituting the dominant source of greenhouse gases. These emissions drive global warming, ecosystem disruptions [1], and extreme weather events [2]. Simultaneously, in accordance with the 2024 United Nations World Population Prospects, the global population is projected to reach 10.1 billion by 2061 and continue its growth trajectory, which directly causes a relentless increase in energy demand [3]. Due to the dual pressures of rapid population growth and surging energy demands, the adoption of abundant, clean, and eco-friendly renewable energy has become imperative.

Solar energy, which possesses notable advantages in terms of its environmental friendliness, abundant supply, and high degree of independence, has been widely used in energy systems such as photovoltaic (PV) power generation [4], solar thermal conversion [5,6], solar cooling [7,8], and solar still [9], thereby offering tremendous potential for sustainable energy systems. In the domain of solar energy utilization, the intermittent and non-stable nature of solar energy poses significant challenges, so high-efficiency heat storage technology has emerged as a pivotal breakthrough for enhancing the utilization efficiency of solar energy [10]. In solar energy systems, solar radiant energy is first converted into thermal energy via heat collection devices, so heat storage technology becomes essential for the spatio-temporal transfer and stable output of this energy [11,12]. Among various heat storage strategies, the latent heat storage technology founded upon phase change material (PCM) has set itself apart due to its distinctive operational mechanism [13,14]. The PCM materials listed in Table 1 were selected for comparison due to their diverse chemical structures (paraffins, salt hydrates, and eutectic mixtures), varied phase change temperatures, and widespread use in thermal storage. This selection enables the systematic evaluation of nanoparticle (NP) dispersion effects on key PCM parameters, such as thermal conductivity and latent heat.

Table 1.

Properties of some PCM.

The incorporation of high-performance nanoparticles, such as Cu for reducing melting time, Al2O3 for accelerating solidification, and graphite for enhancing thermal conductivity (TC), into phase change materials to form nanocomposite phase change materials can significantly improve solar energy conversion efficiency and thermal storage capacity [31,32]. Their core advantages are mainly reflected in the following aspects. The high heat storage density enables the efficient accumulation of thermal energy within confined spaces, thereby maximizing the utilization of available volume [33,34]. The isothermal behavior during the phase change process ensures the thermal stability of the heat storage system, which is crucial for solar-thermal applications that require a consistent heat source [35,36]. Meanwhile, the minimal phase change temperature difference significantly mitigates heat losses during the heat storage cycle, leading to enhanced energy utilization efficiency [37].

Based on the analysis above, NPCM materials have been widely and intensively studied and analyzed in the scientific research community. However, the research gaps lie in the lack of a review paper that summarizes the latest applications of NPCM in high-temperature thermal energy storage systems, particularly in terms of energy performance through mechanism analysis, simulation, and algorithm. Therefore, the general aim of this review article is to systematically introduce various research and analysis methods from the perspective of NPCM models.

This review is primarily divided into six sections. Section 1 covers the latest developments in NPCMs reported in recent literature. Section 2 focuses on introducing various structural characteristics of NPCMs. Section 3 concentrates on the mechanisms and simulation analysis methods of NPCMs, spanning from the material’s microscopic structure to its comprehensive applications. Section 4 demonstrates the algorithm-driven optimization of NPCMs, including machine learning methods and uncertainty analysis. Section 5 discusses techno-economic analysis, including cost-benefit analysis, and policy incentives. Finally, the conclusions and future research directions in the field of NPCMs are proposed in Section 6.

2. Nano-Enhanced Phase Change Material (NPCM)

NPCM has high heat storage density for efficient limited space energy storage, isothermal phase change thermal stability, and a minimal phase—change temperature difference that cuts heat storage cycle losses. These unique properties give PCM-based latent heat storage technology extensive application potential across a wide range of fields, including solar thermal power generation, building energy-efficiency improvements, and electronic thermal management. As such, it represents a crucial technological pathway for addressing the intermittent issue of solar energy and facilitating the efficient utilization of renewable energy resources. From a structural perspective, NPCM can be classified based on the configuration of the nanomaterial within the composite: thermophysical NPCM (dispersed NPs), photonic NPCM (NPs with light-responsive surfaces), NPCM fluids (NP suspensions), nano-encapsulated PCM (core-shell nanostructures), and phase-engineered nanomaterials (NPs with designed phase interfaces).

2.1. Thermophysical NPCM

Thermophysical NPCM enhances PCM properties by incorporating nanoparticles (NPs) like graphene and metal compounds, which strengthen thermal conductivity [38]. Abdolahimoghadam designed a bio-based NPCM composed of coconut oil, beeswax, and graphene-Cu hybrid NPs. Research shows that the addition of graphene nanosheets (GNP) to the material can significantly increase the melting rate by 5.05% [39]. Gopi selected bismuth oxychloride, CuO, and their mixture (composite) as NPs and stearic acid as the PCM. They found that the latent heats of NPCMs containing 0.5 wt% bismuth oxychloride, CuO, and the composite were 204.6 kJ·kg−1, 198.3 kJ·kg−1, and 201.7 kJ·kg−1, respectively, and the thermal conductivities increased to 0.19 W/(m·°C), 0.22 W/(m·°C), and 0.20 W/(m·°C), respectively, which were 5.9%, 29.4%, and 17.6% higher than those of the pure PCM [40].

2.2. Photonic NPCM

Photonic NPCM enhances photovoltaic-thermal system performance when combined with nanofluids, improving light absorption [41]. Ahmed used 0.6% silicon carbide-enhanced nanofluid and silicon carbide to enhance the PCM in photovoltaic systems, thereby improving the photovoltaic-thermal efficiency. The research results show that the maximum energy power increased from 17.512 W to 26 W [42]. Under the working conditions of 47.94 °C and a flow rate of 5 L/min, Maseer studied a semi-circular absorber-tube-type solar photovoltaic-thermal (PVT) system with combined cooling of nanofluid and NPCM. The research results of this study show that the power-generation efficiency was 12.70%, the heat generation efficiency was 78.99%, and the total efficiency was 91.83% [43]. Máñez has developed a simple yet effective reconfigurable all-dielectric metasurface design that enables full control of the electromagnetic response, including electrical, magnetic, and electromagnetic coupling, by changing the refractive index of the PCM layer [44].

2.3. NPCM Fluids

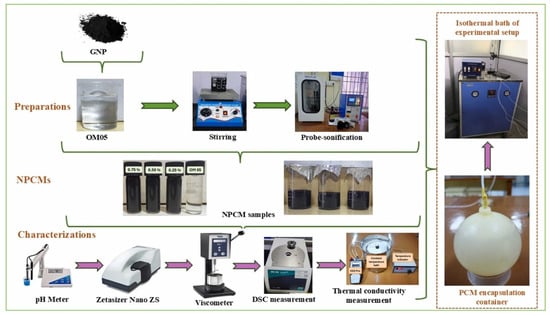

NPCM fluids are liquid-phase composite materials formed by dispersing NPs, particularly molten salt compounds, within PCM or base fluids, demonstrating superior specific heat capacity. Sathishkumar formed NPCM clusters by using the fatty-acid-based PCM OM05 and a GNP suspension, which led to research results showing that for the Oleic-acid-modified (OM) 05-based NPCM with 0.75 wt% GNP, its TC increased significantly at 30 °C, the total solidification time was shortened by 32%, and as a result, a more efficient cooling and charging rate was achieved (Shown in Figure 1) [45]. Baiju devised a conical-fin latent heat storage system utilizing HS-89 hydrated salt as the matrix, incorporating 0.5 wt% graphene nanoplatelets (GNP) and 0.5 wt% nano-alumina (nAl2O3), achieving a 56% reduction in charging time [46]. Wu added 5 wt% of OM and nanoAl (3:1) to binary alkanes, which caused TC to increase to 0.31 W/(m·K) and the melting time to decrease by 38.3% [47].

Figure 1.

The preparation process of the OM05-based NPCM. (Reproduced with permission from [45], Elsevier, 2025).

2.4. Encapsulated NPCM

Encapsulated NPCM is a composite PCM that combines NPs or nanomaterials with PCM, which can effectively prevent liquid leakage during equipment operation. Shijina added the developed GNE-PCM to an ethylene-glycol-water mixture to prepare a graphene nano-encapsulated composite material, and the research showed that TC, specific heat capacity, and cooling efficiency of the material were all improved [48]. To study the effect of GNP on the thermal properties of NPCM for encapsulated heat sinks, Sivashankar added different concentrations of GNP to the OM35 base to prepare NPCM. The research results showed that 0.5 vol% of GNP led to a significant increase in both TC and thermal diffusivity of NPCM [49]. Sutheesh encapsulated tetradecan-1-ol with polymethyl methacrylate to form NPCM for thermal regulation of Lithium-ion Battery (LIB). The research results showed that for LIB with added NPCM, heat generation was reduced, and both the convective heat transfer coefficient and the discharge rate were improved [50].

2.5. Phase-Engineered Nanomaterials

Phase-Engineered Nanomaterials refer to the optimization of the physical and chemical properties of materials themselves by designing the crystal-phase structure of nanomaterials [51,52]. Liu used palladium-selenide as a model system, which was then transformed into Pd17Se15 and Pd4Se phases by thermally regulating the component ratio. Through precise control of the electrode thickness and spacing, different phase-configuration arrangements could be obtained, which enabled multiple in-situ functions and extended to 29 elemental combinations between metals and chalcogens, as reported in reference [53]. Zang developed an amorphous-crystalline CuxS–Ag2S composite with a significant temperature gradient, which achieved a synergistic enhancement of optimal thermoelectric therapy and multi-enzyme activity, as indicated in reference [54]. Yang developed a bismuth-doped ruthenium oxide single-atom alloy oxide catalyst, which achieved a current density of 1.0 A cm−2 at only 1.59 V under industrial conditions, according to reference [55]. Some NPCM performance improvements are listed in Table 2.

Table 2.

Properties of some NPCM.

3. Analytical Methods for NPCMs

In this section, we will concisely discuss the key methods pivotal for NPCM performance analysis. These mainly include Mechanism-oriented Analysis, which delves into fundamental interactions. Then there is Simulation-based Analysis, using computational models to accurately predict properties. Finally, Algorithm-driven optimization leverages algorithms to efficiently find optimal configurations for NPCM. Each method significantly contributes to a comprehensive understanding and enhances NPCM performance.

3.1. Mechanism-Oriented Analysis

Mechanism-Oriented Analysis is a crucial approach in understanding the behavior of NPCM in high-temperature thermal energy storage systems. This method delves deep into the fundamental mechanisms underlying the material’s performance, aiming to establish a clear connection between its microscopic structure and macroscopic properties. At the microscopic level, NPCM consists of a base PCM embedded with NPs. These NPs can significantly alter the properties of PCMs. For example, they may enhance heat transfer by increasing the effective TC [56]. The mechanism-oriented analysis aims to explore how the size, shape, and distribution of these NPs interact with the molecular structure of the PCM, studying the interactions between NPs and the PCM which can affect the atomic morphology, pore structure, and chemical bond interactions within the PCM, thereby influencing its heat storage and heat release capabilities [57,58]. By understanding these mechanisms, researchers can predict and optimize the performance of relevant NPCM. Commonly used mechanism-analysis methods for studying NPCM include molecular dynamics (MD) simulation, density functional theory (DFT), and stochastic simulation approaches, for which a review and analysis of the most recent relevant literature will be conducted hereinafter.

3.1.1. Molecular Dynamics (MD) Simulation

MD simulation has become an important tool for studying NPCMs with excellent performance. In research, MD enables researchers to delve deep into the complex atomic and molecular-level behaviors underlying the macroscopic properties of materials [59]. As shown in Figure 2, the corresponding atomic arrangement characteristics can be observed. For composite materials that are typically composed of matrix PCMs embedded with NPs, MD can accurately model the interactions between PCM molecules and NPs, which are of crucial importance as they significantly influence the thermal, mechanical, and phase change characteristics of the composite materials [60]. Additionally, MD assists in understanding the phase change processes in NPCM, which involve the complex phenomenon of PCMs transitioning from the solid to the liquid state or vice versa [61]. With the help of MD, researchers can track the energy changes, atomic displacements, and intermolecular forces during these phase transitions. The analysis of these principles is vital for optimizing the design of NPCM-based thermal energy storage systems, as it enables the optimization and regulation of phase change temperature, latent heat capacity, and other key parameters. In conclusion, MD plays a key role in uncovering the change mechanisms of NPCM and promoting the development of advanced thermal energy storage solutions. The following is an overview of the research on the application of the latest MD analysis method to the analysis of NPCM.

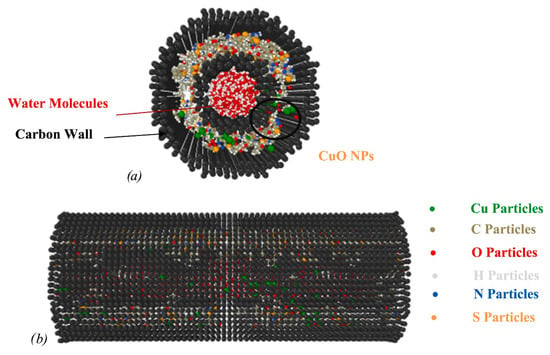

Figure 2.

Schematic diagram of the atomic arrangement of SA-paraffin of CuO NPs. (Reproduced with permission from [60], Elsevier, 2025). (a) front view; (b) side view.

Cu NPs are frequently added to PCMs with the aim of enhancing the latter’s thermal properties. Cu NPs are frequently added to PCMs due to their balanced cost, thermal conductivity, and chemical stability. Karimipour added Cu NPs to paraffin and analyzed the trends of TC and energy-efficiency transformation of paraffin-Cu-NFs placed between parallel plates under the influence of different panel temperatures [59]. Liu also used the same materials in his study, where it was found that when the concentration of Cu NPs increased from 1% to 7%, the maximum density decreased by 1.62%, the maximum velocity increased to 0.00493 Å/fs, the maximum temperature increased by 3.9%, the heat transfer flux increased by 2.1%, the conductivity increased to 0.68 W/m·K, the charging time decreased by approximately 1.42%, and the discharging time decreased by approximately 0.14%, yet as the concentration of Cu NPs continued to increase to 10%, these parameters rebounded [62]. Singh’s research also confirmed that different concentrations of Cu NPs had an impact on both TC and heat flux, but the turning-point concentration in the research results was 3%, which differed to some extent from previous studies, a difference caused by factors such as the setup of the simulation model and the force-field analysis method [63]. Cao carried out molecular-dynamics simulation and analysis using two types of PCM (hydrocarbon-water composite and paraffin) and three wall-metals (Pt, Cu, and Al), and found that the thermal performance of the combination of paraffin and Cu NPs was superior to that of other combinations [64]. Huang added Cu NPs to Sodium sulfate decahydrate and analyzed the heat and mass transfer process and phonon process [65].

CuO is also a high-quality NP. Gao analyzed the changing trends of the maximum velocity, temperature, TC, and heat flux of the SA/PCM/CuO nanostructure within a cylindrical pipe [66]. Yang considered the influence of the concentration of Cuo NPs on the thermal-performance parameters of the composite material, including density, maximum velocity, maximum temperature, heat flux, TC, charging time, and discharging time [67]. Ru discovered that when the atomic radius increased from 4 Å to 10 Å, the maximum density decreased to 0.0825 atoms/Å3, the maximum velocity decreased, the maximum temperature dropped, TC decreased by 1.57 W/m·K, the charging time shortened by 6.09 ns, and the discharging time decreased by 8.28 ns [68]. An analysis was also conducted to evaluate the influence of the radius of NPs on these parameters. Notably, the charging time increased to 6.28 ns, which was contrary to the previous research results, so the study on the influence mechanism of the atomic radius on the charging time of the material still warrants further in-depth analysis [69]. Yu analyzed the influence of CuO NPs on the density, TC, and melting enthalpy of the lauric-acid PCM (as shown in Figure 3) [70]. Fang added SiO2 NPs to the fundamental molten salt (a mixture of Na2CO3 and K2CO3) and analyzed the thermal conductivity and shear viscosity using MD [71]. The main materials and research contents of the above-mentioned study are listed in Table 3.

Figure 3.

Schematic diagram of Lauric acid-CuO model (Reproduced with permission from [70], Elsevier, 2024).

Table 3.

The main materials and research contents about MD.

3.1.2. Density Functional Theory

In the research of NPCMs, DFT is an important quantum-mechanical method. At its core, it takes the electron density as the fundamental variable, positing that the ground-state energy of a system is a functional of the electron density [72]. Solving the relevant equations to determine the electron density significantly simplifies the computational complexity of multi-electron systems [73]. In the study of NPCM, DFT can precisely analyze the interactions between the base PCM and NPs at the atomic scale [74]. This helps in understanding how these interactions alter the heat transfer capabilities and other properties of NPCM. Moreover, DFT can delve deep into its phase change processes, facilitating the optimization of its applications in thermal energy storage and other aspects. Overall, DFT provides crucial support for unlocking the potential of NPCM in various applications.

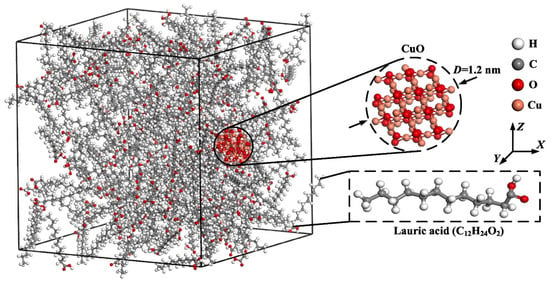

As shown in Figure 4, Liang employed DFT to reveal enhanced van der Waals interactions and elevated non-covalent energy in acetylated lignin/fatty acid systems, achieving 40.8% particle yield, 57.2% fatty acid loading, and 70 °C phase transition temperature [75]. Zhang used DFT to demonstrate that graphitized carbon coating transforms non-uniform electric fields around Ni0 NPs into spherical uniformity under solar irradiation [76]. Yao applied DFT to confirm 8.9 nm mesopore concentration in NPCM skeletons, aligning with scanning electron microscope (SEM) data [77]. Tan leveraged DFT-based quantum chemistry to prove modified lotus root starch enhances hydrogen bonding in sodium acetate trihydrate–sodium thiosulfate pentahydrate clusters, boosting water retention and thermal storage [78]. Yuan utilized DFT to characterize MIL-101(Fe) pore structures, identifying dominant 1.19 nm micropores and 15.17 nm mesopores [79]. Additional DFT studies include Wang’s pore distribution analysis of a Zeolitic Imidazolate Framework-8 based biocompatible porous material of micron-size [80], Zeng’s calculation of higher formation energy for C-substituted Sb7Se3 superlattices [81], and Xin’s electronic density of states examination of Design and synthesize a composite PCM of Na2HPO4·12H2O (DHPD)—vermiculite nanosheets (VMTNS) systems [82]. The main materials and research contents of the above-mentioned study are listed in Table 4.

Figure 4.

Analysis diagram of the formation mechanism of lignin-stearic acid capsules (Reproduced with permission from [75], Elsevier, 2025). (a) 31P NMR spectra of EHL and ACEHL; (b) acetylation of GCA; (c–e) Isosurface and (f–h) scatter graph of independent gradient model based on Hirshfeld partitioning (IGMH) of the unacetylated lignin (GCA) dimer (c,f), acetylated lignin (AGCA) dimer (d,g), AGCA combined with stearic acid (e,h).

Table 4.

The main materials and research contents about DFT.

3.1.3. Characterization Method

Characterization methods, which involve using experimental equipment to collect relevant signals and conduct principled analyses of specific material properties, are employed to better observe the microstructure and performance characteristics of NPCMs when applied to their analysis. This provides crucial support for developing new high—heat and high—stability NPCMs. Multiple experimental approaches are often combined with modeling techniques for analyzing a single NPCM material. Common characterization techniques include SEM, TEM, XRD, FTIR, DSC, TGA, and Temperature history methods (T-history methods). SEM is commonly employed to observe the microstructure and offers a high-resolution surface view [83,84]. TEM is also utilized for microstructure observation, but it enables internal-structure analysis at the micro-scale [85,86]. XRD is utilized to determine the crystal structure of NPCM components [87,88]. FTIR identifies functional groups by detecting chemical bond vibrations [89,90]. DSC was employed to characterize its unique thermal properties, including thermal hysteresis, phase transition temperature, latent heat, and thermal stability [91,92]. TGA is employed to investigate its phase change characteristics [93,94]. The T-history method is used to analyze the temperature curves of NPCM and further derive the thermophysical properties of the materials [95,96]. The main materials and research contents of the above-mentioned study are listed in Table 5.

Table 5.

The main materials and research contents about characterization methods.

3.2. Simulation-Based Analysis

Simulation-based analysis plays a pivotal role in the study of NPCM within high-temperature thermal energy storage systems. This approach utilizes computational models to replicate and analyze the complex behaviors of NPCM, offering insights that are often difficult to obtain through experimental means alone. In Simulation-Based Analysis, various physical phenomena such as heat transfer, phase transitions [97], and fluid flow within the NPCM are numerically modeled. For heat transfer, models consider the enhanced TC imparted by the NPs in NPCM. They simulate how heat diffuses through the composite material, taking into account the interactions between the base PCM and the NPs. When it comes to phase transitions, simulations can precisely capture the temperature-dependent behavior of NPCM. By inputting the thermo-physical properties of the components, these models can predict the onset and duration of phase changes, which are crucial for understanding the energy storage and release processes. Moreover, in systems where NPCM might be used in flowing configurations, fluid-flow simulations help analyze how the presence of NPs affects the flow characteristics. This information is valuable for designing efficient heat exchange systems. Overall, Simulation-Based Analysis provides a cost-effective and time-efficient way to explore different scenarios, optimize NPCM-based systems, and guide experimental research. Commonly used simulation-based analyses for studying NPCM include finite element analysis (FEA), computational fluid dynamics (CFD), stochastic simulation approaches, and multiphysics coupling models, for which a review and analysis of the most recent relevant literature will be conducted hereinafter.

3.2.1. Finite Element Analysis

FEA discretizes complex structures into finite elements to build simulation models, predicting the temperature field, stress distribution, and energy transfer efficiency of materials during phase transitions [98,99]. FEA can quantitatively analyze the impact of NP dispersibility on the thermal performance parameters of PCMs, thereby optimizing the design of porous encapsulation to reduce the leakage rate. Meanwhile, it simulates the regulatory mechanism of nanoscale interfacial thermal resistance on phase—change kinetics at the micro—scale, providing theoretical support for the efficient thermal management of NPCMs in scenarios such as electronic heat dissipation and intelligent buildings. The following is an overview of the research on the application of the latest FEA analysis method to the analysis of NPCM.

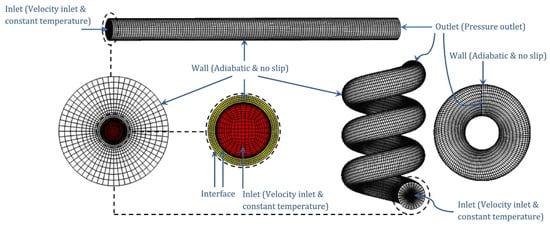

Gürsoy investigated the thermal performance of RT58-based composites incorporating spherical, square, and elliptical dimpled fins with varied Al2O3 NP concentrations [100]. Hekmat explored heat transfer enhancement in a spiral circular thermal storage system (as shown in Figure 5) using RT-50 with differently dosed NPs [101]. Dora developed a hierarchical composite by blending nano-silica/coconut fiber with decanol-ethanol-treated exfoliated vermiculite PCM, subsequently integrating it into foam concrete for building thermal analysis [102]. Yang engineered graded-porosity foam Cu/paraffin NPCMs to optimize structural configurations based on porosity uniformity, thermal response, and energy storage dynamics [103]. Lastly, Zhao quantified Herringbone Graphite Nanofiber agglomeration effects in paraffin via spherical clustering and linear percolation models, revealing enhanced TC in linear networks under high interfacial conditions [104]. Sun used artificially cultivated diatom microcrystals to modulate carbilose nanofibers to fabricate porous frameworks to fabricate PCMs with stable shapes, and modeled and studied the influence of pore properties on leakage resistance (as shown in Figure 6) [105]. Çiçek established a symmetric radiator model to analyze the effects of different NP concentrations and heat flux on thermal performance [56]. Saleh modeled the flexible structure of a square cavity using the Arbitrary Lagrangian–Eulerian method and analyzed the effects of temperature, Stefan number, and other factors on the system’s overall performance [106]. Egami added CuO nano-powders to PCM in a rectangular container with H-shaped fins, analyzing the effects of nano-powders’ concentration and shape factor on freezing performance [107]. The main materials and research contents of the above-mentioned study are listed in Table 6.

Figure 5.

Schematic diagram of the three-dimensional spiral circular structure (Reproduced with permission from [101], Elsevier, 2025).

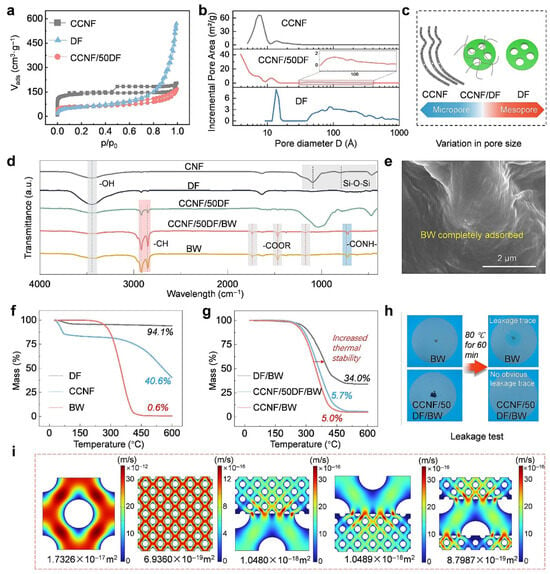

Figure 6.

Simulation analysis of carbilose nanofibers and the impact on leaks (Reproduced with permission from [105], Elsevier, 2025). (a) N2 isothermal adsorption–desorption curves; (b) pore size distribution of CCNF, DF, and CCNF/50DF; (c) pore size regulation; (d) FTIR spectra of the CCNF composite porous framework and BW composites; (e) SEM image of CCNF/50DF/BW. TGA curves of (f) CCNF, BW and DF as well as (g) the prepared ss-PCMs. (h) Schematic diagram of liquid flow in the porous framework, along with (i) simplified 2D models constructed.

Table 6.

The main materials and research contents about FEA approaches.

3.2.2. Computational Fluid Dynamics

CFD plays a key role in the study of NPCM applications as a powerful tool for simulating fluid flow and heat transfer phenomena [108,109]. NPCMs use the phase transformation process to absorb or release a large amount of latent heat, but their thermal properties are highly dependent on the nanoscale structure of the material itself, its dispersion stability, and its interaction with the surrounding fluid. By simulating complex multiphase flow systems containing NPCM particles or capsules, CFD can reveal micro/macroscale flow, heat transfer, and phase transition coupling mechanisms to guide the design of NPCMs and evaluate their thermal management performance in energy storage systems. The following is an overview of the research on the application of the latest CFD analysis method to the analysis of NPCM.

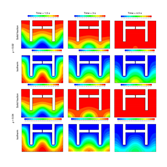

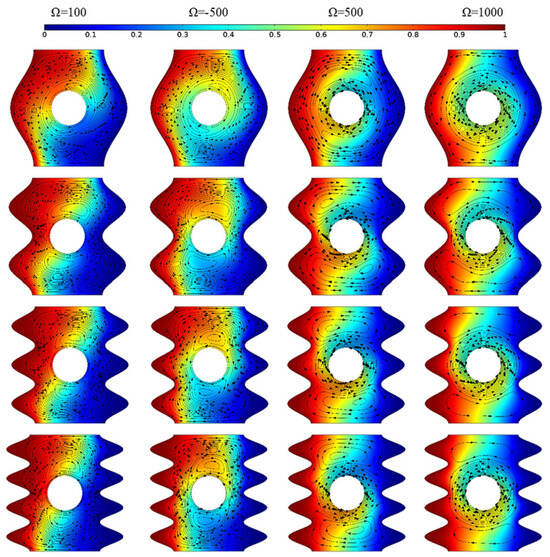

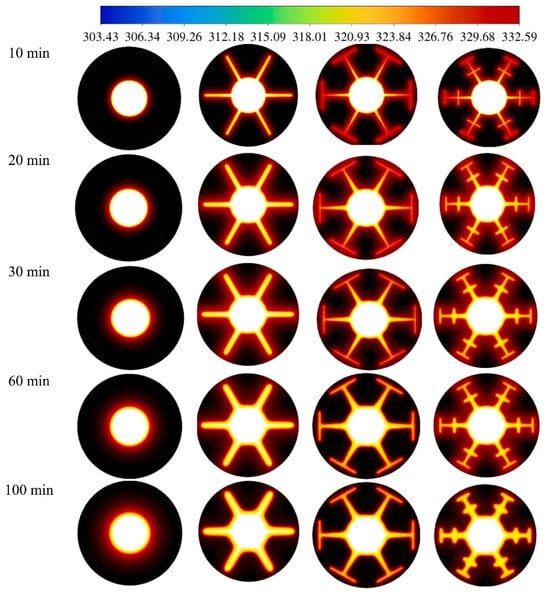

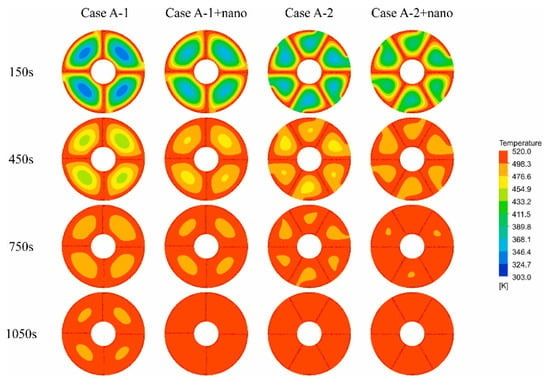

Olivares-Robles designed a ring thermoelectric cooler composed of semiconductors, PCM (OM32 and Polyethylene glycol 1500), base fluid (water), and Al2O3 NPs, and analyzed the effects of NP concentration and temperature on the thermal performance of the cooler [110]. Benyahia developed a simulation model of a finned triangular inner tube and paraffin PCM enhanced with Cu NPs to analyze the effects of different NP concentrations, tube eccentricity, and inclination on the thermal properties of materials [111]. Bouzennada established a simulation model of NPCM fluids contained in different wave side wall cavities to analyze the influence mechanism of different wall structures, cylindrical radii, and rotational speed (as shown in Figure 7), and NPs concentration on thermal performance [112]. Glolami built Cu fins and Al heat sinks, analyzed the phase transformation process of Na2SO4·10H2O, paraffin, and eicosane, and analyzed the efficiency of photovoltaic panels [113]. Nandi used CuO NPs, lauric acid, RT35HC, and P58 materials to analyze the affected mechanism of improved solar irradiation by designing a rectangular geometry with different parallel structure shapes [114]. Shaik used CuO NPs, RT82, to analyze the effects of different liquid fractions and shapes on melting time and melting rate by designing a modified fin (as shown in Figure 8) with different vertical structure shapes [115]. Waqas used multi-walled carbon nanotube (MWCNT), TiO2, and molten-salt PCM materials to design different rotationally symmetrical fin structures in hollow cylinders (as shown in Figure 9) to analyze the thermal performance of tubular heat exchangers [116]. Mahdavi designed PV laminates using Cu NPs, porous Cu media, and RT35-HC paraffin, and analyzed the effects of water pipe placement, NP concentration, and porous media on the thermal and electrical energy of the PV panels [117]. Alam analyzed the melting performance of latent heat thermal energy storage units made of different materials and shaped PCM [118]. Kiyak analyzed the effect mechanism of curvature and different concentrations of Cu NPs on the melting and solidification processes of thermal energy storage systems [119]. The main materials and research contents of the above-mentioned study are listed in Table 7.

Figure 7.

Simulation results under different wall structures and speeds (Reproduced with permission from [112], Elsevier, 2024).

Figure 8.

Simulation results of modified fin with different parallel structure shapes (Reproduced with permission from [115], Elsevier, 2025).

Figure 9.

Simulation results of different rotationally symmetrical fin structures (Reproduced with permission from [116], Elsevier, 2025).

Table 7.

The main materials and research contents about CFD approaches.

3.2.3. System Performance Simulation

System performance simulation provides core support for design optimization by building a highly integrated system simulation coupling model to efficiently simulate the overall dynamic response and comprehensive performance of complex systems in an experimental or simulation environment. With its high thermal conductivity, latent heat of phase change, and fast response, NPCMs are often used in the design of various photothermal conversion system materials, which enhance the performance characteristics of the system in thermal management or electrical efficiency management, accelerate the research and development of photothermal systems, and improve the reliability of the system. The following is an overview of the research on the application of the latest system performance simulation analysis method to the analysis of NPCM.

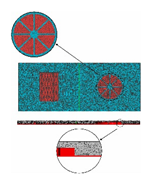

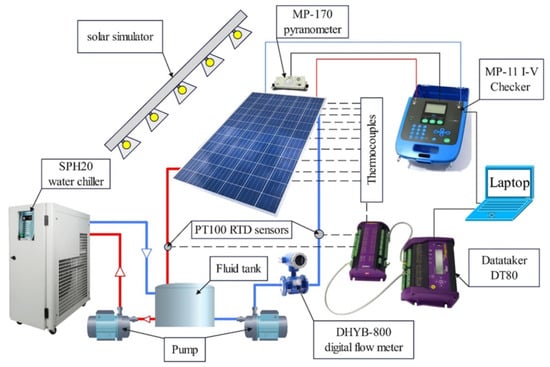

Amin added graphene to beeswax to make distillation tubes and designed an experimental system for analyzing freshwater production performance by combining K-type thermocouples, insolation intensity meters, graduated cylinders, and data collectors [120]. Singh added different concentrations of Al2O3 particles to OM37 to make NPCMs for the analysis of the thermal performance of solar ponds [121]. Emara integrated the design of a freshwater system by adding different concentrations of TiO2 and Al2O3 nanofluids to paraffin with a melting temperature of 62 °C [122]. Al-Karboly integrated a twisted band absorber, a twisted absorption tube, a 1% SiC NP-reinforced paraffin preparation vessel, and a silicon carbide nanofluid, comprehensively designed a photovoltaic system (Shown in Figure 10), and analyzed its thermal efficiency [123]. Kamrava used ZnO, CuO, and Al2O3 in paraffin wax as NPCM to further construct the floor heating system and analyzed the thermal performance characteristics of the floor temperature and heat flux of the floor heating system [124]. Gür added B4C to the RT35HC to design the heat sink, further constructed an ultra-low energy consumption home heat sink simulation system, and analyzed the thermal performance factors such as room temperature and water temperature [125]. Sathishkumar used GNP and strong nitric acid to prepare NPCM materials to design the energy storage tank system, and analyzed the thermal performance parameters such as stored energy and solidification time [126]. Bassam used nanofluids (SiC and water preparation) and NPCM (SiC and paraffin preparation) to design micro-finned tubes, and the comprehensive design of the photovoltaic system showed a 77.5% increase in thermal efficiency and an increase in output power to 14.5 W [127,128]. Kibria used NPCM (paraffin wax with Al2O3 and ZnO NPs) to design a photovoltaic thermal system, and the analysis results showed that the surface temperature of the system was reduced by 5.4 °C, the power was increased by 2.75%, the electrical efficiency was increased by 2.71%, the maximum heat output power was increased by 17.4%, and the overall efficiency was increased by 15.82% [129]. Bharathiraja designed a collector system incorporating MWCNTs and SiO and discovered that this design led to a higher output temperature and a longer duration for hot water production [130]. The main materials and research contents of the above-mentioned study are listed in Table 8.

Figure 10.

Photovoltaic system (Reproduced with permission from [123], Elsevier, 2025).

Table 8.

The main materials and research contents about system performance simulation approaches.

3.2.4. Magnetic Field Coupling Models

The magnetic field changes the Lorentz and Kelvin forces in the convective heat transfer process through the coupling of the changes in magnetic induction intensity with the conductivity and magnetism of different NPs. This regulates the melting and solidification behaviors in the phase transformation process of the NPCM, further altering the relevant thermodynamic characteristic parameters of the NPCM. Additionally, the coupling effect can also impact the dynamic behavior between NPs and PCM, resulting in current changes that adjust the system’s charging and discharging processes, thereby optimizing the system’s power characteristic parameters [131]. The following is an overview of the research on the application of the latest magnetic field coupling models analysis method to the analysis of NPCM.

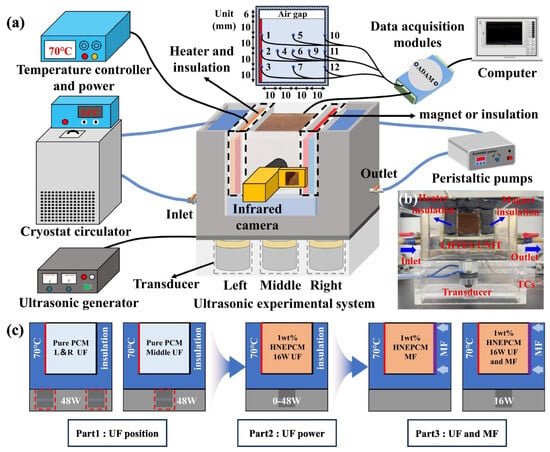

Izadi added different concentrations of Al2O3 nanoadditives to paraffin wax to construct a hexagonal heat storage unit and analyzed the convective melting mechanism of the tilt angle and magnetic field strength [132]. Hassan designed a U-shaped baffle cavity for the nano-encapsulated PCMs and analyzed the mechanism of the natural convection effect of the inclined magnetic field on the structure [133]. Younis designed a cavity structure to analyze the mechanism by which magnetic field strength affects the thermal properties of nano-encapsulated PCMs [134]. Selimefendigil designed a triangular-shaped structure containing Ag-MgO hybrid nanofluids to analyze the convective influence mechanism in a heterogeneous magnetic field [135]; designed a multi-jet impingement system to study the numerical effects of Ag-MgO nanofluids on the thermal properties of PCMs under different magnetic field strengths and clarity [136]; studied the phase transition and convective heat transfer mechanisms of different types of NPs and encapsulated PCMs under magnetic fields [137]. Nguyen designed an external magnetic field for the analysis of the thermal performance effects of NPCM capsules incorporated into roof structures [138]. Lu designed a stable rotating magnetic field applied to paraffin wax doped with Fe3O4 to analyze the effect of the magnetic field on the melting mechanism [139]. Li added Al2O3 and Fe3O4 to paraffin wax to prepare NPCMs, and analyzed the melting and energy storage mechanisms inside the materials using ultrasonic and magnetic fields (Shown in Figure 11) [140]. Zhuang added Al2O3 and Fe3O4 to paraffin wax to prepare NPCMs, and analyzed the heat transfer mechanism of NPs to the materials by thermochromic liquid crystal combined with a magnetic field [141]. Farahani analyzed the effects of fin factors and Fe3O4 EMPs concentration on the thermal performance of energy storage systems under the application of magnetic fields [142]. The main materials and research contents of the above-mentioned study are listed in Table 9.

Figure 11.

Ultrasonic experimental system diagram (Reproduced with permission from [140], Elsevier, 2024). (a) Schematic diagram; (b) experimental setup of the ultrasonic and magnetic fields experimental system; (c) Boundary conditions under different cases.

Table 9.

The main materials and research contents about the magnetic field.

4. Algorithm-Driven Optimization

Algorithm-driven optimization has become an important research strategy for enhancing the performance of NPCMs in high-temperature thermal storage systems [143]. This strategy utilizes the powerful computational capability of algorithms to finely optimize parameters such as the composition and structural design of NPCM, in pursuit of maximizing thermal efficiency and thermal stability. In the NPCM field, algorithms play a critical role in determining the ideal mass ratio of the base PCMs to NPs. They filter optimal solutions from numerous combinations of NP characteristics and PCM properties based on preset material performance benchmarks, which may encompass multiple dimensions ranging from maximizing thermal conductivity and energy storage capacity to enhancing thermal and electrical efficiency [144]. Furthermore, algorithm-driven optimization extends to the manufacturing processes of NPCM. During the synthesis of composite materials, algorithms take into account parameters such as mixing intensity, temperature regulation, and pressure control. By optimizing these factors, it is possible to enhance the performance of NPCM while also reducing costs, making NPCM more attractive for large-scale applications in high-temperature thermal storage and thus promoting the development of more efficient and sustainable energy solutions [145].

4.1. Machine Learning Methods

Machine learning methods serve as a system analysis and prediction paradigm based on the inherent laws of massive data. By deeply mining the hidden correlations within complex systems, these methods break through the simplification dependence of traditional physical models on complex boundary conditions and multi-field coupling mechanisms. In the thermal performance study of NPCMs, this approach demonstrates significant advantages: through high-dimensional data analysis of the synergistic effects of multiple parameters, it can accurately capture the distribution of NPs, the evolution of phase change interfaces, and the nonlinear response patterns of flow within porous media, revealing cross-scale coupling mechanisms that are difficult to quantify with traditional theoretical models. This data-centric research paradigm not only optimizes the thermal management performance prediction of nano PCM in complex geometric structures but also provides a new pathway for the intelligent design of industrial-grade phase change energy storage systems. The following is an overview of the research on the application of the latest machine learning methods to the analysis of NPCM.

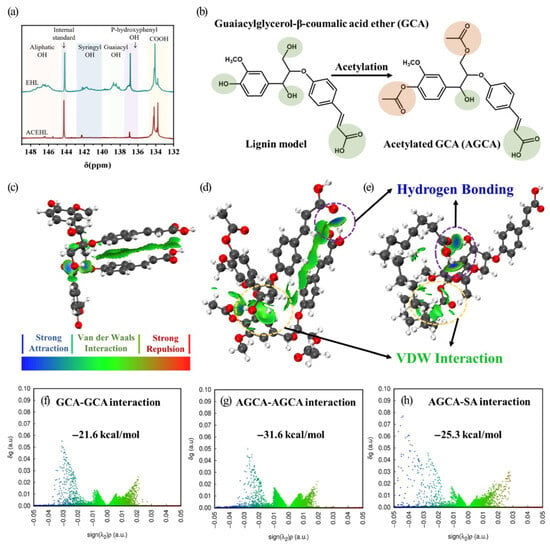

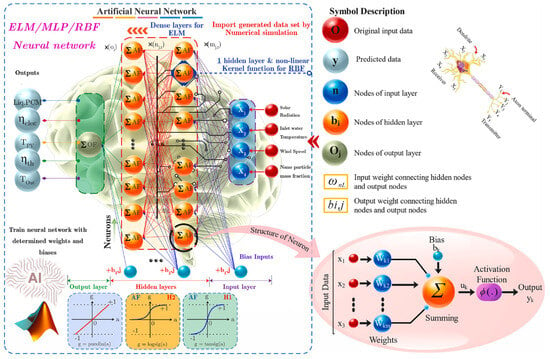

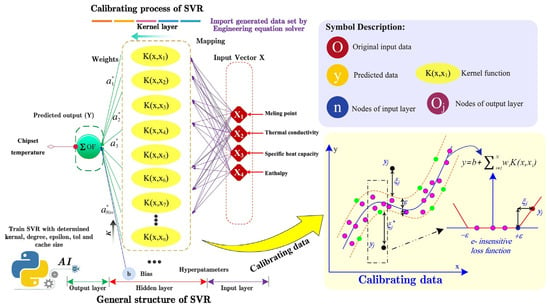

Shakibi uses CFD simulation to design key factors, construct an Artificial neural network (ANN) model (Shown in Figure 12), and integrate long short-term memory (LSTM), grey wolf optimizer (GWO), Particle swarm optimization (PSO) and other methods to analyze and solve the intelligent model of the optimal thermal performance parameters [146]. Aly explored the heat and mass transfer properties of NPCM in a wave porous cavity using the incompressible smoothed particle hydrodynamics method and the extreme gradient boosting (XGBoost) machine learning model, Darcy number, Rayleigh number, Fusion temperature, Soret number, Dufour number, Hot zone length, Hot zone Key parameters such as height reveal the influencing characteristics of internal thermal performance [147]. Abdolahimoghamad established the multilayer perceptron (MLP)-ANN model for estimating the optimal melting and solidification time of Gr-Cu hybrid NPs and latent heat, thermal conductivity of bio-based NPCMs [148,149]. Gao established an automatic correlation determination model to predict liquid-state thermal conductivity, k-nearest neighbor and polynomial regression composite models to predict the thermal conductivity of NPCMs, and minimum absolute shrinkage and choice operators to predict freezing-state latent heat [150]. Ghasemi established an ANN model and input heat flux, Reynolds number, and concentration to predict performance evaluation criterion and average Nu [151]. Kiaghadi used four models: linear regression, lasso regression, polynomial regression, and auto-regressive integrated moving average to verify the correlation between time and liquid fraction, and confirmed that the data analysis method can be effectively applied to the prediction of phase transition behavior [152]. The auto-regressive integrated moving average algorithm was used to predict parameters such as solar unit time, PV temperature, melting fraction, NPCM temperature, electrical efficiency, and other parameters based on historical data [153]. Yang established an ANN model with Reynolds number and porosity of nickel foam as inputs, which could effectively predict the maximum temperature of LIB [154]. Xu established an ANN model with shear rate and mass fraction as inputs, which could effectively predict the dynamic viscosity, density, and shear stress of the LIB of the NPCM [155]. Salari established a Harris Hawks optimizer model optimized by a random forest algorithm to predict printed circuit board (PCB) temperature [156]. Khadem established a GWO-support vector regression with a hybrid composite model (Shown in Figure 13), and predicted the chipset temperature parameters through the melting point, thermal conductivity, specific heat capacity, and enthalpy parameters of the system [157]. Fini developed a composite model of an ANN-multiobjective genetic algorithm for predicting the Nu and pressure drop of microencapsulated PCM fluid [158]. The main materials and research contents of the above-mentioned study are listed in Table 10.

Figure 12.

Schematic diagram of machine learning model (Reproduced with permission from [146], Elsevier, 2023).

Figure 13.

Support vector regression with hybrid model (Reproduced with permission from [157], Elsevier, 2023).

Table 10.

The main materials and research contents about the machine learning methods.

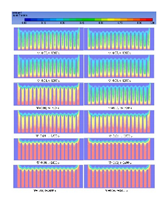

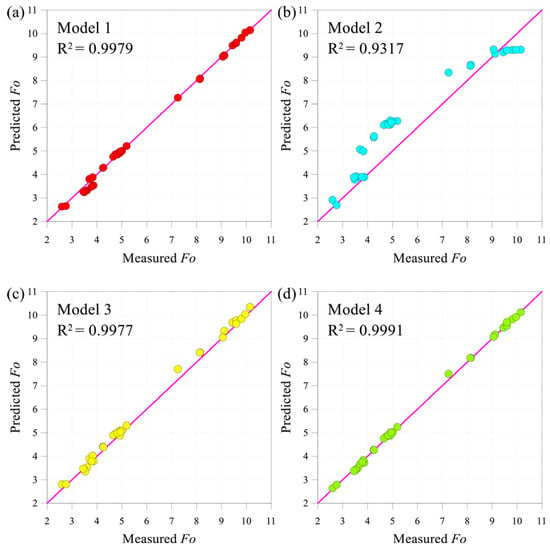

Monte Carlo methods, which often conduct research by leveraging the Bayesian approach optimized by Markov chain Monte Carlo, play a crucial role. Regarding data processing, the distribution of independent variables, such as normal distribution or log-normal distribution, is set according to different scenarios, and the corresponding dependent variables are determined [159]. Multiple models are established, and a large amount of input—output data is utilized, with the training set and the test set divided in a specific proportion, and metrics such as mean squared error, root mean squared error, and coefficient of determination are employed to analyze the prediction accuracy of the models [160]. Some studies also use the mean value, the standard deviation of the number of iterations, and the standard deviation for precise data analysis. In the research on the dispersion of highly conductive nanomaterials in D-mannitol to enhance heat transfer in the LHTES system, parameters related to the thermophysical properties of NPCM and the inlet conditions of the heat-conducting fluid are set as independent variables following a normal distribution, with the Fourier number (Fo) as the dependent variable. Based on 153 CFD data, four models are established by dividing the training set and the test set into an 8:2 ratio. The curves of the Fo values predicted and the actual Fo values by the four models are shown in Figure 14. Eventually, a model that can best predict the Fo of the actual dataset is constructed based on relevant metrics [161]. In the study of graphite nanosheets reinforcing dodecanol (C12H26O), the melting rate and the surface-average Nu are set as independent variables with a normal or log-normal distribution, and the Stefan number, Grashof number, and Fo are set as dependent variables. Based on 573 melting-rate datasets and 516 surface-average Nu-number datasets, five models are established by dividing the training set and the test set in a 7:3 ratio. Subsequently, the models that can best predict the dataset values and the Nu values are analyzed, fully demonstrating the application of the Monte Carlo method in practical research [162]. The main materials and research contents of the above-mentioned study are listed in Table 11.

Figure 14.

The curves of the Fo values by the four models (Reproduced with permission from [161], Elsevier, 2022). (a) Model 1; (b) Model 2; (c) Model 3; (d) Model 4.

Table 11.

The main materials and research contents about the Monte Carlo Method.

4.2. Uncertainty Quantification Techniques

The uncertainty quantification techniques are uncertain to comprehensively assess the impact of uncertainty factors in systems on outcomes [163]. By meticulously identifying and precisely quantifying various sources of uncertainty, including measurement errors, model assumptions, and parameter variability, they provide strong assurance for the accuracy and reliability of models, enabling effective improvements on this basis [164]. In many fields, uncertainty quantification techniques play a crucial role, particularly in the research and application of complex systems based on NPCM materials. They assist researchers in gaining a deeper understanding of the intrinsic uncertainty mechanisms within the system, thereby allowing for a full consideration of uncertainty factors in model construction, optimization, and decision-making processes, ensuring the scientific and rational nature of the results. The following is an overview of the research on the application of the latest uncertainty quantification techniques to the analysis of NPCM.

Al-Aasam calculated that the error value of the PVT system caused by temperature, mass glow rate, solar irradiance, voltage, and current is 3.83% [165]. Daneshazarian determined that the error value of the ground source heat pump system resulting from temperature outlet, temperature inlet, and flow rate is 0.5% [166]. Gür analyzed the error value of the electronics system attributed to the temperatures of the PCM and the temperatures of the empty system, which is 1.5% [167]. Venkatesh conducted an analysis of the error in the heat exchanger system using parameters of radiation, temperature, wind velocity, and flow rate [168]. Ganeshkumar examined the error values of parameters such as mass flow rate, Nu, Convective heat transfer coefficient (CHTC), heat gain, solar energy, and energy efficiency for the solar air heater [169]. Amin adopted the Holman method to calculate the error values caused by solar radiation, temperature, and productivity in the freshwater production system, which were ±1.55%, ±1.2%, and ±1.58%, respectively [120]. Singh analyzed that the total error of the thermal performance system of solar ponds using NPCM was 2.59% [121]. Al-Karboly integrated the design of the photovoltaic system and analyzed that the total error caused by sensors or instruments was less than 4% [123]. Bassam utilized SiC and water to prepare nanofluids, and SiC and paraffin to prepare NPCMs, comprehensively designed photovoltaic systems, and analyzed the error values caused by temperature, radiation, voltage, and flow measurements [127,128]. The main materials and research contents of the above-mentioned study are listed in Table 12.

Table 12.

The main materials and research contents about uncertainty quantification techniques.

5. Techno-Economic Analysis

The techno-economic analysis within the framework of NPCM is a comprehensive evaluation that combines considerations of both technological and economic feasibility [170]. This analysis delves deeply into the specifics of NPCM-related technologies, exploring everything from fundamental scientific principles to practical applications, and accurately assesses the costs and potential benefits associated with research and development, production, and maintenance. It not only predicts short-term financial impacts but also evaluates long-term economic sustainability. By integrating technological and economic dimensions, techno-economic analysis provides stakeholders with a holistic view, assisting them in making informed investment decisions in NPCM projects and ensuring the efficient allocation of resources in this emerging field [171].

5.1. Cost-Benefit Analysis

Cost-benefit analysis is a systematic decision-making tool, the core logic of which lies in quantifying and comparing all expected costs and benefits of an NPCM product over its entire lifecycle, while considering the time value of the product [172,173]. Ultimately, it calculates key indicators to evaluate the economic feasibility of the product as well as the relative advantages of different proposals [174]. For NPCM products, cost-benefit analysis effectively avoids resource waste by preemptively identifying projects where expected benefits will not cover costs, thus preventing the allocation of valuable funds to inherently unprofitable innovations. Furthermore, in the context of limited resources, it optimizes resource allocation by horizontally comparing the net benefit priorities of various NPCM proposals, ensuring investments are directed towards the avenues with the highest economic potential. This transforms innovation risks into measurable investment propositions, maximizing the likelihood of creating long-term value [175]. The following is an overview of the research on the application of the latest cost-benefit analysis method to the analysis of NPCM.

Sharshir analyzed that the hemispherical solar still device with metal organic framework is the most cost-effective and efficient, with the highest unit production cost and life cycle cost for producing fresh water [176]. Rasaiah studied multiple nanofluid improved double slope solar still devices and found that CuO nanofluid has the highest cost-effectiveness in terms of economy and environmental protection [177]. Kumar’s study found that the configuration of aluminum foam and PCM with microchannels helps maintain efficient flow conditions but has higher maintenance costs [178]. Gürbüz designed a collector embedded with S NPs and analyzed it from multiple perspectives, such as efficiency, energy, and cost [179]. Mohtasim studied the energy recovery period and economic and environmental factors, such as CO2 reduction of solar still systems and PVT systems with different structures [180]. Singh combined multiple NPCMs, the configuration of the device, and the analysis of daily freshwater production and investment payback period parameters under various conditions were carried out [181]. Anika comprehensively analyzed the performance, economy, environment, and other factors of the distiller constructed with mixed NPCMs and proposed improvement suggestions [182]. Rad designed a PVT system using nanofluid as a coolant and found that the unit production cost was 0.134 $/kWh [183]. Essa placed PCM and Ag NPs under the absorber to design the best-performing solar still, and the research results showed that the use of the device increased freshwater productivity by 245% [184]. Paul regarded different NPs as important factors affecting the thermal and environmental economic performance of the solar distiller [185]. Elamy combined Ag NPs for comprehensive solar still research; the results showed that the productivity of the slipped material increased by 233%, and both the environmental and economic cost-effectiveness were improved [186]. Attia’s work demonstrated that incorporating graphene materials into the design of solar stills led to a remarkable 574.1% enhancement in energy efficiency [187]. El-Gazar combined the characteristics of TiO2 and SiO2 to design a solar still system and found that the production cost of distilled water was lower in summer than in winter [188]. The main materials and research contents of the above-mentioned study are listed in Table 13.

Table 13.

The main materials and research contents about cost-benefit analysis.

After delving into a series of cases where the latest cost-benefit analysis method was applied to NPCM analysis, the remarkable practical advantages and potential of this method are evident. These cases span multiple industries like freshwater, photovoltaic, and electric power, and involve complex NPCM scenarios. They offer decision-makers clear, intuitive, and actionable references. This approach effectively overcomes the blind spots and limitations of conventional analysis. By applying it, businesses can optimize resource allocation in NPCM implementation. This, in turn, enhances economic efficiency while advancing sustainable development goals.

5.2. Policy Incentives and Market Growth Potential

Policy incentives are constructing a multi-level environmental governance system, driving the global green transition. Under the UN framework, conference of the parties (COP) 29 established the climate finance target, mandating developed countries to provide $300 billion annually in public funds by 2035 to leverage $1.3 trillion in support for developing countries’ infrastructure development [189]; COP30 proposes establishing a carbon tariff revenue-sharing mechanism and a deforestation accountability mechanism to ensure biofuel and mineral development do not harm the ecological rights of developing countries [190]. At the international institutional level, the International Energy Agency (IEA) demonstrated through its Strategy for an Affordable and Fair Clean Energy Transition that renewable energy costs are lower than fossil fuels [191], and its 2023 Energy Efficiency Report requires doubling the global annual energy efficiency improvement rate to 4% by 2030 [192]; the tripling renewable energy capacity target (to 11.2 TW by 2030) jointly advanced by the IEA and International Renewable Energy Agency (IRENA) has shown tangible results that China contributed 64% of the 585 GW global new installations in 2024 [193]. The EU established a 40% minimum domestic clean energy production capacity target by 2030 through its Net Zero Industry Act [194], complemented by the Batteries and Waste Batteries Regulation mandating full lifecycle carbon footprint disclosure (implementing a battery passport by 2027) [195], combined with the Carbon Border Adjustment Mechanism imposing comprehensive tariffs on six high-carbon import sectors [196]. Supported by the Critical Raw Materials Act aiming to increase strategic raw material processing to 40% and recycling rates to 25% [197], and augmented by the EU Wind Power Action Plan streamlining permitting processes (targeting 120 GW for North Sea wind power by 2030) [198], this forms a tripartite “technological autonomy-supply chain decarbonization-resource circularity” system. The US revised the Inflation Reduction Act, raising clean electricity tax credits to 35% (with domestic manufacturing requirements) and removing battery mineral restrictions [199], while New York State enacted the Climate Change Superfund Act, imposing a $75 billion levy on fossil fuel companies [200]. Developing countries are advancing concurrently: China’s Energy Law established a renewable energy consumption guarantee mechanism and initiated a unified energy market [201], while its Draft Ecological Environment Code consolidated over 30 laws to create a dedicated “Green and Low-Carbon” chapter [202]; India launched a national carbon market covering power and petrochemical sectors, paired with a 280 GW solar target [203]; Vietnam’s Revised Electricity Law introduced direct green power purchase agreements exempting them from bidding [204]; Brazil invested R$21 billion in its National Hydrogen Program [205]; the UAE’s National Biofuel Policy established production standards promoting waste cooking oil conversion, targeting a 20% increase in biodiesel consumption by 2050 [206]. These policies, relying on mandatory fund allocation, technical standards, market mechanism restructuring, and ecological rights protection, transform global environmental commitments into enforceable binding rules, highlighting the critical role of policy-driven approaches in environmental governance. The main research contents of the above-mentioned study are listed in Table 14.

Table 14.

The main research content about policy.

6. Conclusions and Future Work

This review comprehensively analyzes NPCM’s high thermal performance research methods and economic benefits, delves into its melting mechanisms, and optimal design configurations. Starting with the fundamental types of NPCM, it offers in-depth explanations of these mechanisms and designs, highlighting their advantages in thermal energy management. The review also incorporates cost-benefit analyses of application systems and the latest international environmental policies to fully assess NPCM’s energy-saving and eco-friendly attributes. These findings demonstrate NPCM’s great potential in materials innovation and low-carbon environmental protection, strongly supporting sustainable development.

6.1. Key Findings and Contributions

- (1)

- NPCMs improve thermal conductivity, reduce supercooling, and accelerate melting/solidification rates.

- (2)

- Various NPCM structures, such as thermophysical, photonic, fluid-based, encapsulated, and phase-engineered, enable targeted applications across different solar thermal systems.

- (3)

- Mechanism-level analysis using MD and DFT provides critical insights into nanoparticle-PCM interactions and nano-scale heat transfer behavior.

- (4)

- Techno-economic analyses confirm that NPCMs offer high cost-effectiveness, improved energy efficiency, and extended lifecycle benefits for solar energy systems.

- (5)

- The identical Cu NPs and paraffin-based NPCM structure exhibit analogous thermal property inflection points at significantly disparate Cu NP concentrations. Consequently, it is imperative to establish a rigorous simulation model to analyze the correlation between nanoparticle concentration and the thermal performance characteristics of NPCM.

- (6)

- The unit production cost of distilled water for solar distillers using NPCM can be as low as $0.00713/L, and other models of solar distillers also demonstrate good, low-carbon, and environmentally friendly economic performance.

- (7)

- The combined use of mechanistic analysis methods and simulation methods is more conducive to studying the phase change mechanism of NPCM during the melting process.

- (8)

- The combination of a finite element analysis model and experimental data is more advantageous for the analysis of the melting phase transition mechanism of NPCM under the action of a magnetic field.

- (9)

- The application of algorithm optimization and analysis methods, particularly integrated algorithmic models based on artificial neural networks (ANNs), can be harnessed to more effectively project the material configurations of devices or systems that achieve high thermal efficiency performance.

- (10)

- The incorporation of graphene materials significantly enhances the performance characteristics of PCMs. For instance, in solar still applications, it improves energy efficiency by 574.1%. Therefore, graphene and other high-performance materials should be prioritized in future NPCM research.

- (11)

- Increasing policy incentives, clean energy mandates, and investments in renewable infrastructure are accelerating the commercial potential of NPCM-based solutions.

6.2. Remaining Challenges and Future Opportunities

Although NPCM exhibits strong thermal performance in melt heat transfer, the design and selection of its nano materials or structures face challenges in practical applications. As different researchers have discussed NPCM from various research perspectives, integrating innovative research ideas into the design of NPCM application systems has become a mainstream research direction. Research on NPCM holds extensive promise, and future leading research methods are likely to be associated with it.

- (1)

- The accuracy of ideal model simulation methods, which is related to mesh size, models, quantities, and solution methods, necessitates further research to design high-precision physical simulation models and reduce interference from inaccuracies in real-world models.

- (2)

- In algorithm optimization analysis, which demands extensive data collection with accuracy being critical, the impact of varying parameter choices in different algorithms on model outcomes necessitates further exploration into constructing high-quality datasets and developing efficient, accurate algorithmic models.

- (3)

- During the experiment, the inaccuracy caused by measuring devices is inevitable, highlighting the necessity for more precise system accuracy control and making it necessary to conduct uncertainty analysis on key steps.

- (4)

- In actual solar energy system applications, unforeseen circumstances often arise during operation, so future research could integrate simulations of additional weather factors to develop a more realistic and production-oriented simulation model.

- (5)

- An intelligent optimization model for solar-powered freshwater production systems should be established, since the study of nanomaterials within a single system is limited in scope, failing to take into account the substitutability of materials and the acceptability of economic costs.

- (6)

- Although significant progress has been made in the research of thermodynamic melting associated with magnetic field convection across various fields, it is necessary to further explore the economic benefits of these findings and address the insufficient studies on the impact of eddy current characteristics in magnetic fields on the thermal properties of materials.

Author Contributions

Conceptualization, J.W. and W.L.; methodology, W.L.; software, M.W.; validation, M.W., J.Y. and D.M.; formal analysis, W.L.; investigation, W.L. and M.W.; resources, J.Y.; data curation, W.L.; writing—original draft preparation, W.L. and J.W.; writing—review and editing, E.H. and J.W.; visualization, D.M.; supervision, J.W.; project administration, J.W.; funding acquisition, J.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| ANN | Artificial neural network |

| BA | Bat algorithm |

| BBO | Optimization based on biogeography |

| BET | Brunauer–Emmett–Teller |

| CFD | Computational fluid dynamic |

| CHTC | Convective heat transfer coefficient |

| COP | Conference of the parties |

| DFT | Density functional theory |

| DHPD | Na2HPO4·12H2O |

| DSC | Differential scanning calorimetry |

| F | Furfural |

| FEA | Finite element analysis |

| Fo | Fourier number |

| FTIR | Fourier transform infrared spectroscopy |

| GNP | Graphene nanosheets |

| GWO | Grey wolf optimization |

| IEA | International energy agency |

| IRENA | International renewable energy agency |

| L | Liquid |

| LHTES | Latent heat thermal energy storage |

| LIB | Lithium-ion battery |

| LSTM | Long short-term memory |

| MA | Myristic acid |

| MD | Molecular dynamics |

| MLP | Multilayer perceptron |

| MWCNT | Multi-walled carbon nanotube |

| NG | Nano-graphite |

| Ni@C/C | The hierarchically porous carbon structure infiltrated with Ni@graphite |

| NP | Nanoparticle |

| NPCM | Nanoparticle-enhanced phase change material |

| Nu | Nusselt |

| ODA | Octadecanol |

| OM | Oleic-acid-modified |

| PCB | Printed circuit board |

| PCM | Phase change material |

| PSO | Particle swarm optimization |

| PV | Photovoltaic |

| PVT | Photovoltaic-thermal |

| R | Resorcinol |

| RBF | Radial basis function |

| S | Solid |

| SA | Silica aerogel |

| SEM | Scanning electron microscope |

| SIMPLE | Semi-implicit method for pressure linked equations |

| SH | Sherwood number |

| TC | Thermal conductivity |

| TEM | Transmission electron microscope |

| TGA | Thermogravimetric analysis |

| TLC | Thermochromic liquid crystal |

| VMTNS | Vermiculite nanosheets |

| XGBoost | Extreme gradient boosting |

| XPS | X–ray photoelectron spectroscopy |

| XRD | X–ray diffractometer |

References

- Wang, J.; Gullo, P.; Ramezani, H. Review on the trend of ultra-low-GWP working fluids for small-capacity vapour-compression systems. Sustain. Energy Technol. Assess. 2024, 66, 103803. [Google Scholar] [CrossRef]

- Alizadeh, O. A review of ENSO teleconnections at present and under future global warming. WIREs Clim. Change 2024, 15, e861. [Google Scholar] [CrossRef]

- Rodés-Guirao, H.R.a.L. Peak Global Population and Other Key Findings from the 2024 UN World Population Prospects. Available online: https://ourworldindata.org/un-population-2024-revision?weekend-reading-link-040824/ (accessed on 1 May 2025).

- Ngagoum Ndalloka, Z.; Vijayakumar Nair, H.; Alpert, S.; Schmid, C. Solar photovoltaic recycling strategies. Sol. Energy 2024, 270, 112379. [Google Scholar] [CrossRef]

- Yu, J.; Cheng, H.; Wang, Y.; He, C.; Zhou, B.; Liu, C.; Feng, Y. Multiple shearing-induced high alignment in polyethylene/graphene films for enhancing thermal conductivity and solar-thermal conversion performance. Chem. Eng. J. 2024, 480, 148062. [Google Scholar] [CrossRef]

- Wang, J.; Hu, E.; Blazewicz, A.; Ezzat, A.W. Investigation on the long-term performance of solar thermal powered adsorption refrigeration system based on hourly accumulated daily cycles. Heat Mass Transf. 2021, 57, 361–375. [Google Scholar] [CrossRef]

- Ali, F.H.; Al-Amir, Q.R.; Hamzah, H.K.; Alahmer, A. Unveiling the potential of solar cooling technologies for sustainable energy and environmental solutions. Energy Convers. Manag. 2024, 321, 119034. [Google Scholar] [CrossRef]

- Wang, J.; Hu, E.; Blazewicz, A.; Ezzat, A.W. Simulation of accumulated performance of a solar thermal powered adsorption refrigeration system with daily climate conditions. Energy 2018, 165, 487–498. [Google Scholar] [CrossRef]

- Kasaeian, A.; Nazari, N.S.; Masoumi, A.; Shabestari, S.T.; Jadidi, M.; Fereidooni, L.; Bidhendi, M.E. A review on phase change materials in different types of solar stills. J. Energy Storage 2024, 99, 113430. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Y.; Wang, D.; Song, C.; Fu, Z.; Zhang, C. A review of the photothermal-photovoltaic energy supply system for building in solar energy enrichment zones. Renew. Sustain. Energy Rev. 2024, 191, 114100. [Google Scholar] [CrossRef]

- Pintaldi, S.; Perfumo, C.; Sethuvenkatraman, S.; White, S.; Rosengarten, G. A review of thermal energy storage technologies and control approaches for solar cooling. Renew. Sustain. Energy Rev. 2015, 41, 975–995. [Google Scholar] [CrossRef]

- Suresh, C.; Saini, R.P. Review on solar thermal energy storage technologies and their geometrical configurations. Int. J. Energy Res. 2020, 44, 4163–4195. [Google Scholar] [CrossRef]

- Carnie, J.-T.; Hardalupas, Y.; Sergis, A. Decarbonising building heating and cooling: Designing a novel, inter-seasonal latent heat storage system. Renew. Sustain. Energy Rev. 2024, 189, 113897. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, C.; Zhang, C. Advances in latent heat storage technology for electronic cooling. Renew. Sustain. Energy Rev. 2025, 215, 115614. [Google Scholar] [CrossRef]

- Ou, S.; Wang, P.; Yang, S.; Su, H. Thermal characteristics and energy-saving research of P-PCM FinTwall in hot summer and cold winter regions. Energy 2025, 329, 136670. [Google Scholar] [CrossRef]

- Karaağaç, M.O. Experimental investigation of a novel PCM-enhanced underfloor heating system for energy-efficient sustainable buildings. Appl. Therm. Eng. 2025, 275, 126891. [Google Scholar] [CrossRef]

- Chen, X.; Su, Y.; Zhang, Y.; Shen, J.; Xu, X.; Wang, X.; Zhou, F. Performance of thermal management system based on PCM/forked liquid-cold plate for 18650 cylindrical battery. J. Energy Storage 2024, 91, 112071. [Google Scholar] [CrossRef]

- Kurşun, B.; Balta, M.; Karabulut, K. Exploring the impact of inner and middle channel geometries on the melting rate of PCM-metal foam composition in a triplex tube heat exchanger. Therm. Sci. Eng. Prog. 2024, 51, 102621. [Google Scholar] [CrossRef]

- Palaniappan, M.; El-Shafay, A.S.; Shanmugan, S. Improving heat retention properties of steeped M-shape basin solar distillers utilizing paraffin RT50-enhanced silver nanoparticles and Manihot esculenta extracts. Desalination 2024, 586, 117836. [Google Scholar] [CrossRef]

- Gürbüz, H.; Demirtürk, S.; Akçay, H.; Topalcı, Ü. Experimental investigation on electrical power and thermal energy storage performance of a solar hybrid PV/T-PCM energy conversion system. J. Build. Eng. 2023, 69, 106271. [Google Scholar] [CrossRef]

- Manikandan, S.; Muthuvairavan, G.; Samykano, M.; Natarajan, S.K. Numerical simulation of various PCM container configurations for solar dryer application. J. Energy Storage 2024, 86, 111294. [Google Scholar] [CrossRef]

- Ji, C.; Liu, D.; Waqas, H.; Sun, S.-L.; Jalili, B.; Abdelmohimen, M.A.H. Melting performance of Molten Salt with nanoparticles in a novel triple tube with leaf-shaped fins. Case Stud. Therm. Eng. 2024, 61, 105063. [Google Scholar] [CrossRef]

- Ma, T.; Li, Z.; Lv, K.; Chang, D.; Hu, W.; Zou, Y. Design and performance analysis of deep peak shaving scheme for thermal power units based on high-temperature molten salt heat storage system. Energy 2024, 288, 129557. [Google Scholar] [CrossRef]

- Reddy, B.D.; Rahul, S.V.S.; Harish, R. Impact of fin number and nanoparticle size on molten salt NanoPCM melting in finned annular space. J. Energy Storage 2023, 72, 108705. [Google Scholar] [CrossRef]

- Gui, X.; Wang, S.; Ding, L. Simulation study of a novel phase change cooling garment for electricians in a high-temperature environment. Int. J. Refrig. 2024, 168, 79–88. [Google Scholar] [CrossRef]

- Anter, A.G.; Sultan, A.A.; Hegazi, A.A.; El Bouz, M.A. Thermal performance and energy saving using phase change materials (PCM) integrated in building walls. J. Energy Storage 2023, 67, 107568. [Google Scholar] [CrossRef]

- Madurai Elavarasan, R.; Nadarajah, M.; Pugazhendhi, R.; Gangatharan, S. An experimental investigation on coalescing the potentiality of PCM, fins and water to achieve sturdy cooling effect on PV panels. Appl. Energy 2024, 356, 122371. [Google Scholar] [CrossRef]

- Zhan, H.; Mahyuddin, N.; Sulaiman, R.; Khayatian, F. Phase change material (PCM) integrations into buildings in hot climates with simulation access for energy performance and thermal comfort: A review. Constr. Build. Mater. 2023, 397, 132312. [Google Scholar] [CrossRef]

- Gado, M.G. Thermal management and heat transfer enhancement of electronic devices using integrative phase change material (PCM) and triply periodic minimal surface (TPMS) heat sinks. Appl. Therm. Eng. 2025, 258, 124504. [Google Scholar] [CrossRef]

- Madurai Elavarasan, R.; Pugazhendhi, R.; Shafiq, S.; Gangatharan, S.; Nadarajah, M.; Shafiullah, G.M. Efficiency enhancement of PV panels with passive thermal management using PCM: An exhaustive review on materials, designs and effective techniques. Appl. Energy 2025, 382, 125217. [Google Scholar] [CrossRef]

- Anya, B.; Mohammadpourfard, M.; Akkurt, G.G.; Mohammadi-Ivatloo, B. Exploring geothermal energy based systems: Review from basics to smart systems. Renew. Sustain. Energy Rev. 2025, 210, 115185. [Google Scholar] [CrossRef]

- Suo, Y.; Tang, C.; Jia, Q.; Zhao, W. Influence of PCM configuration and optimization of PCM proportion on the thermal management of a prismatic battery with a combined PCM and air cooling structure. J. Energy Storage 2024, 80, 110340. [Google Scholar] [CrossRef]

- Al-Amayreh, M.I.; Alahmer, A. Efficiency enhancement in direct thermal energy storage systems using dual phase change materials and nanoparticle additives. Case Stud. Therm. Eng. 2024, 59, 104577. [Google Scholar] [CrossRef]

- Murali, G.; Ramani, P.; Murugan, M.; Elumalai, P.V.; Ranjan Goud, N.U.; Prabhakar, S. Improved solar still productivity using PCM and nano-PCM composites integerated energy storage. Sci. Rep. 2024, 14, 15609. [Google Scholar] [CrossRef]

- Kazaz, O.; Abu-Nada, E. Thermal performance of nano-architected phase change energetic materials for a next-generation solar harvesting system. Energy Convers. Manag. 2025, 327, 119541. [Google Scholar] [CrossRef]

- Ulker, N.; Bulut, H.; Demircan, G. Comparative study on the effect of surface-modified nanoparticles on PCM for solar energy applications. J. Therm. Anal. Calorim. 2024, 149, 12053–12070. [Google Scholar] [CrossRef]

- Bestas, S.; Aktas, I.S.; Bayrak, F. A bibliometric and performance evaluation of nano-PCM-integrated photovoltaic panels: Energy, exergy, environmental and sustainability perspectives. Renew. Energy 2024, 226, 120383. [Google Scholar] [CrossRef]

- Goel, V.; Dwivedi, A.; Kumar, R.; Kumar, R.; Pandey, A.K.; Chopra, K.; Tyagi, V.V. PCM-assisted energy storage systems for solar-thermal applications: Review of the associated problems and their mitigation strategies. J. Energy Storage 2023, 69, 107912. [Google Scholar] [CrossRef]

- Abdolahimoghadam, M.; Rahimi, M. The effect of the number of tubes on the charging and discharging performances of a novel bio-nPCM within a vertical multi-tube TES system. Energy 2025, 319, 135010. [Google Scholar] [CrossRef]

- Dhivagar, R.; Singh, P.K.; Nandhakumar, E. Synergistic effect of stearic acid/bismuth oxychloride/cupric oxide for thermal storage applications: Preparation, stability, rheological and thermophysical analysis. Phys. Scr. 2024, 99, 065039. [Google Scholar]

- Azeez, H.L.; Ibrahim, A.; Ahmed, B.O.; Dol, S.S.; Al-Waeli, A.H.A.; Jaber, M. Experimental evaluation of a novel photovoltaic thermal System: Energy, economic, and exergy-based sustainability analysis. Case Stud. Therm. Eng. 2025, 71, 106167. [Google Scholar] [CrossRef]

- Ahmed, B.O.; Ibrahim, A.; Azeez, H.L.; Dol, S.S.; Al-Waeli, A.H.A.; Jaber, M. Energy and exergy analysis of a newly designed photovoltaic thermal system featuring ribs, petal array, and coiled twisted tapes: Experimental analysis. Case Stud. Therm. Eng. 2024, 63, 105388. [Google Scholar] [CrossRef]

- Maseer, M.M.; Ismail, F.B.; Kazem, H.A.; Hachim, D.M.; Al-Gburi, K.A.H.; Chaichan, M.T. Performance enhancement of photovoltaic/thermal collector semicircle absorber tubes using nanofluid and NPCM. Renew. Energy 2024, 233, 121152. [Google Scholar] [CrossRef]

- Máñez-Espina, L.M.; Díaz-Rubio, A. Control of the local and nonlocal electromagnetic response in all-dielectric reconfigurable metasurfaces. Phys. Rev. Appl. 2024, 22, 054022. [Google Scholar] [CrossRef]

- Sathishkumar, A.; Sundaram, P.; Prabakaran, R.; Kim, S.C. Graphene based fatty acid phase change material as an alternative to water: An experimental investigation on thermal energy storage characteristics. Colloids Surf. A Physicochem. Eng. Asp. 2025, 715, 136589. [Google Scholar] [CrossRef]

- Baiju, V.; Priya, K.L.; Shafi, K.A.; Shahid, P.A.M.; Lamba, R.; Singh, H.; Ichiyanagi, M.; Suzuki, T.; Shajan, S. Enhanced latent heat storage for solar thermal applications using tapered fins and hybrid nano-additives. J. Energy Storage 2025, 118, 116308. [Google Scholar] [CrossRef]