Abstract

This paper reports the improved thermal and drying performance of a solar air heater powered by real solar irradiance and equipped with a tree-like fractal-based cylindrical pin (SAH-TFCP) as a turbulator for drying applications. The main purpose of this work is to demonstrate the SAH-TFCP’s improvement potential based on its thermal and drying performance as compared with a conventional solar air heater based on a flat-plate absorber (SAH-FP). The test was implemented based on solar time from 8:30 to 17:30 under Thailand’s climatic conditions at a latitude angle of 14° and a longitude angle of 100°. Turmeric slices were used to evaluate the SAH’s drying performance. The thermal efficiency, moisture content wet basis (MCwb), drying rate (DR), and drying efficiency were measured as parameters of interest to assess the improvement potential of the SAH-TFCP over the SAH-FP. The results indicate that the SAH-TFCP provides better thermal and drying performance than the SAH-FP. A higher flow rate yields a higher thermal efficiency and a greater improvement potential. The improvement potential is around 44–85%. The drying efficiency of the SAH-TFCP is always higher than that of the SAH-FP and has an improvement potential of 32–44%, depending on the airflow rate.

1. Introduction

Utilizing renewable energy sources is an efficient way to address the fossil fuel shortage in the near future. At the same time, it can also mitigate the environmental impacts of burning fossil fuels to generate useful thermal energy or electricity [1]. The most widely used renewable source is solar energy because of its abundance, especially in tropical countries. Hence, many researchers have focused on methods for converting solar irradiance into useful energy, such as wall-mounted solar heating for houses [2]; heating through stored thermal energy via solar power [3]; and drying applications via solar air heaters, indirect solar air dryers [4], hybrid SAHs [5], and forced convection solar dryers [6].

In the food preservation and herb production industry, drying is an important process for removing water from products (moisture content). This process mainly requires thermal energy to perform the water removal process via evaporation. In large-scale agricultural drying, the thermal energy used in the drying process mostly comes from electrical air heaters and heat pumps. Winans et al. [7] focused on the drying process via an electrical heater, while Cop et al. [8] and Hu et al. [9] discussed the drying of agricultural products via heat pumps. Their drying machines require quite high electrical energy per unit mass of dried product. This means that the increasing need for drying comes with an increased energy demand, which leads to problems such as primary energy shortages and environmental impacts. Therefore, many researchers have proposed alternative technologies to reduce the energy consumption of agricultural drying. One of the most suitable technologies is the solar air heater (SAH). The SAH can convert solar irradiance into useful thermal energy (hot air supplied for the drying process). This has encouraged many researchers to design and propose the development of solar air heaters for agricultural drying applications, as proposed by Afzal et al. [10], Karwa et al. [11], and Singh, V.P et al. [12]. They aimed to make energy usage more sustainable and to mitigate the environmental impacts of using fossil energy.

Jongpluempiti et al. [13] developed and tested a solar air heater with a conventional flat-plate absorber and investigated the thermal performance and hot air supplied when drying tofu with the spray-drying method. Their prototype solar air heater was tested using real solar irradiance. Y. He et al. [14] performed a numerical investigation of a solar air heater with a flat-plate absorber. Their main focus was on its convective heat transfer performance. They concluded that the key performance parameter in producing hot air is the convective heat transfer mechanism, which is significantly dependent on the Nusselt number, Reynolds number, and Pranthl number. Boulemtafes-Boukadoum et al. [15] also investigated the performance of a solar air heater based on heat transfer and aimed to demonstrate the influence of the convective heat transfer coefficient on energy conversion efficiency. Their findings indicated that the energy conversion of the solar air heater significantly depends on the airflow rate, the gap between the absorber plate and glass cover (aspect ratio), and its ability to generate a turbulent flow (or recirculation) of the air stream flowing through the absorber plate. The solar air heater based on the conventional flat-plate absorber had relatively low energy efficiency due to the lower turbulent flow of the air stream (laminar boundary layer flow) because the air stream flows over a smooth surface. This results in poor heat transfer performance and consequently results in poor drying performance, as supported by [16]. This has encouraged some researchers to propose an alternative design technique to enhance the heat transfer performance by means of installing a turbulator in the absorber plate. Previous research that focused on solar air heaters equipped with a turbulator is summarized in Table 1.

Table 1.

Summary of research focusing on the turbulator-enhanced performance of SAHs.

The surveyed literature listed in Table 1 shows that the thermal and drying efficiency of solar air heaters for drying applications can be increased by installing a turbulator. Hence, energy usage becomes more efficient. A key way to improve performance is to intensify the turbulent flow of the air stream as it flows through the absorber plate. A higher turbulence intensity can promote better convective heat transfer. Previous research that supports this was conducted by Naef A.A. Qasem et al. [30] and N. Jayranaiwachira et al. [31]. Their experiments showed that a higher convective heat transfer coefficient is obtained when a turbulator is installed on a smooth surface; however, it comes with a larger pressure drop across the absorber, which increases the energy consumption of an air blower or fan [32]. Therefore, the trade-off between enhanced heat transfer and a higher pressure drop has been studied in detail by researchers to investigate the value of using a turbulator [33]. Similarly, Sureandhar et al. [34] studied the arc-rib fin turbulator arrangement installed in an absorber plate with a fixed arc-rib fin configuration (e/De = 0.0422) and one with varying sizes (e/De = 0.0422–0.0541). The results showed that the varied arc-rib fin significantly improved the heat transfer process and provided better thermo-hydraulic characteristics than the fixed arc-rib fin. The friction factors of the varied arc-rib and fixed arc-rib are not much different; hence, the thermal enhancement factor of the varied arc-rib fin is higher than that of the fixed one.

Some researchers have applied fractal theory to formulate specific turbulator shapes to enhance heat transfer. Zhang [35] studied heat transfer augmentation with novel truncated ribs designed using fractal theory. Their aim was to propose new turbulator shapes (coral, elliptical, cylindrical, etc.) with sizes that could be varied. This resulted in heat transfer enhancement, which they investigated in detail. They found numerically and experimentally that the fractal turbulator could increase the Nusselt number and the convective heat transfer coefficient with the same flow Reynolds number. A slight increase in the pressure drop was found when using the fractal turbulator, which resulted in a higher thermal enhancement factor as compared with other turbulators [36]. However, the available literature has few studies investigating a fractal installed in a solar air heater. Yu et al. [37] proposed a fractal technique to improve an energy storage system with tree-like fractal fins. Zhang et al. [38] employed fractal theory to create a tree-like fractal formation, the aim of which was to improve heat transfer performance. They concluded that the fractal can be used as a tool for heat transfer enhancement due to its shape. The fractal technique makes the large-scale design of a heat exchanger easier and more efficient [39].

However, to the best of the authors’ knowledge, fractal theory applied to a solar air heater for drying applications has not been reported in the available literature. This is a major research gap that is addressed in this work. It is expected that a solar air heater equipped with a fractal working as a turbulator will have significant improvements in both thermal and drying performance. This is because it can improve convective heat transfer between the air stream and absorber, which results in better energy conversion (converting solar radiation into thermal energy). However, a reasonably accurate case study must first be performed based on solar time to assess the performance improvement potential. This will be useful as a base case for designing further SAHs equipped with fractal-shaped pins for larger-scale solar drying.

As explained earlier, this work investigates the performance of a solar air heater equipped with a tree-like fractal-based cylindrical pin (SAH-TFCP) with the aim of demonstrating the improvement potential of the thermal and drying performance as compared with the conventional solar air heater based on a flat-plate absorber (SAH-FP). The test was implemented based on solar time from 8:30 to 17:30 under Thailand’s climatic conditions at a latitude angle of 14° and a longitude angle of 100°. Turmeric slices were used as samples to evaluate the drying performance. The thermal efficiency, moisture content wet basis (MCwb), drying rate (DR), and drying efficiency were measured as the parameters of interest for analyzing the improvement potential of the SAH-TFCP over the SAH-FP. The test results demonstrate the feasibility of using the TFCP to improve the thermal and drying performance. The major contribution of this work is that it provides a reference case for improving solar drying performance. The novelty of this work is characterized below:

- A tree-like fractal-based cylindrical pin was designed and constructed to be installed in the absorber plate of the solar air heater and work as a turbulator. This has not been reported in the available literature for solar drying applications.

- The improvement potential of the SAH-TFCP over the conventional SAH was demonstrated in tests under real climatic conditions.

- The performance of the two systems under real solar irradiance is detailed and evaluated.

- Thermal and drying performance is discussed and compared to indicate the advantages of using a tree-like fractal.

This work is composed of four sections. The research problem and literature review demonstrating the research gap are presented in Section 1. The test setup and the construction details of the SAH equipped with/without the tree-like fractal-based cylindrical pin (SAH-TFCP) are provided in Section 2, which also describes the data collected and the details of system control. Section 3 provides a discussion of the results based on thermal and drying performance to demonstrate the improvement potential of the SAH-TFCP over the conventional SAH. Concluding remarks on the significant findings of this work are summarized in Section 4.

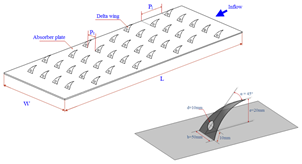

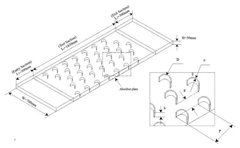

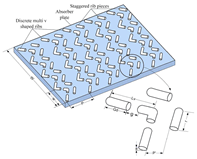

2. Test Setup of Solar Air Heater

This research aims to investigate the thermal and drying performance enhancement of a solar air heater for drying applications by installing a tree-like fractal-based cylindrical pin in the absorber plate (SAH-TFCP). The thermal and drying performance indicators of the SAH-TFCP are compared with those of the conventional flat-plate solar air heater (SAH-FP). An empirical test of the solar-driven air heater under Thailand’s climatic conditions was implemented to analyze the improvement potential of the SAH-TFCP over the SAH-FP. Turmeric was used as the sample product to demonstrate the drying performance. The test was implemented based on real solar time, as this demonstrates the real thermal and drying performance of the solar-driven SAH. The test stand unit was located at a latitude angle of 14° and a longitude angle of 100° (Lopburi province, Thailand). During the test, the airflow rate and solar irradiance were measured as the variable parameters to investigate the thermal performance and drying efficiency. This section provides the details of the test setup of the SAH (Section 2.1) and the detailed development of the tree-like fractal-based cylindrical pin, which was installed in the absorber of the SAH (Section 2.2). The data collected during empirical tests are described in Section 2.3.

2.1. Construction and Test Setup of Solar Air Heater for Drying Applications

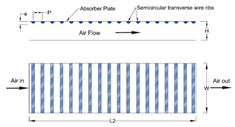

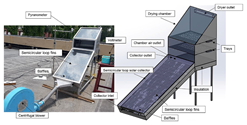

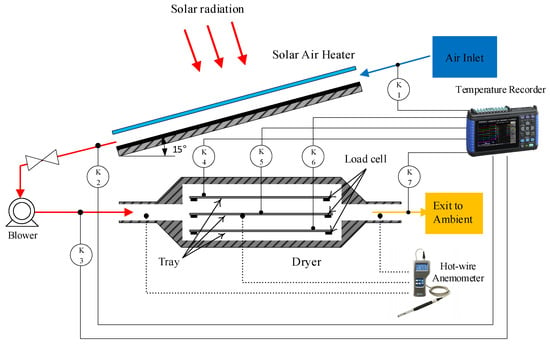

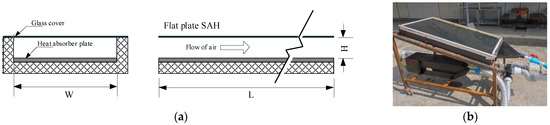

Figure 1 shows the solar-driven air heater test unit, which is mainly composed of an absorber plate, a drying chamber, and measuring devices. The absorber plate was designed to be easily exchanged so that the performance of the SAH with and without the TFCP can be fairly compared using the same major hardware. The airflow through the absorber was supplied using an air blower, in which the flow rate can be precisely regulated by an inverter.

Figure 1.

Schematic of the experimental setup.

The operation of the SAH for drying turmeric begins when solar irradiance falls on the absorber plate. At the same time, ambient air can enter the absorber (point 1) via the air blower. As the air stream flows through the absorber, convective heat transfer takes place, resulting in hot air produced at the outlet of the absorber (point 2). This hot airflow then enters the drying chambers to perform the drying process (points 4–6) of the agricultural product (turmeric slices). The water contained within the turmeric slices (moisture content) is evaporated from their surface as hot air flows through the drying chamber. Thereafter, air with higher humidity (higher moisture) leaves the drying chamber at point 7 to complete the operation. The temperature at the points of interest, the airflow rate, and the weight loss of the dried product are important parameters for this investigation.

The absorber plate was constructed based on ASHARE 93-77 recommendations [40]. The dimensions (W × L × H) are 150 × 75 × 4 cm, as shown in Figure 2 and Table 2. The absorber plate was fabricated from aluminum alloy (AA-1060) with a 3 mm thickness. This aluminum alloy was commercially available in Thailand market. Smart wood was placed behind the absorber plate to support the test stand. The absorber plate was painted matte black to maximize its ability to absorb solar irradiance (high absorbability). A neoprene foam insulator was used to prevent heat loss from the absorber plate to its surroundings, and a polycarbonate plate was placed behind the insulator to support the test stand. A glass cover with a 3 mm thickness was installed over the absorber plate to form an airflow gap to generate hot air via a convective heat transfer mechanism. The gap height is 40 mm, which corresponds to an aspect ratio (r, W/H) of around 19; this r value optimizes the trade-off between the pressure drop and heat transfer performance, as supported by [41].

Figure 2.

The geometrical drawing of the absorber plate of the SAH. (a) The sectional view of the absorber (b) Photograph of the test unit.

Table 2.

Dimensions of the SAH.

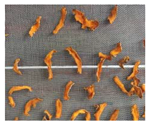

Based on the criteria recommended in [42], the drying chamber was designed so that the agricultural products can be dried by supplied hot air. This makes agricultural products and herbs more economical. The dimensions are shown in Table 2. The hot air from the absorber enters the drying chamber at point (3) by means of an air blower and discharges to the ambient environment at point (7). In this work, turmeric slices were selected to demonstrate the drying performance of the SAH. They were prepared with approximately 3 mm thickness, as shown in Figure 3.

Figure 3.

The drying chamber and trays. (a) Drying samples on the dryer tray, (b) Turmeric slices as samples.

The air blower is electrically driven by an AC motor (220 V, 0.35 kW), and its flow rate can be regulated precisely by an inverter. This allows the airflow rate to remain constant at the desired point. An empirical test was implemented at three different mass flow rates: 0.016, 0.034, and 0.05 kg/s. The mass flow rate was the only parameter that varied during the tests. These mass flow rates were proven to provide acceptable performance for this particular absorber size in previous work by the authors of [43], where it was proven that an acceptable thermal enhancement factor (trade-off between heat transfer enhancement and the increased pressure drop (higher energy consumption)) can be obtained with mass flow rates of 0.016–0.05 kg/s. In addition, the investigated range of mass flow rates is consistent with the published work by Abushanab et al. [44].

To maintain the mass flow rate at a certain value, a hot-wire anemometer was used to measure the air velocity within a constant-area duct installed at the absorber inlet. The constant-area duct has a diameter of 45 mm and a length of 600 mm. The air velocity can be varied by fine-tuning the inverter frequency until the air flowing through the constant-area duct reaches a constant velocity, and hence, the mass flow rate can be calculated via Equation (4). Solar irradiance, ambient temperature, and relative humidity vary with the daytime period, which is a common manner of field testing of solar drying. Such parameters are beyond the control of the researcher. Therefore, in this work, the performance of the SAH was evaluated using a practical solar drying application.

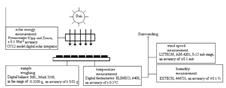

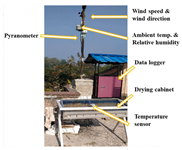

Uncertainty Analysis

During the test, temperatures at the points of interest (points 1–7) were measured using a thermocouple probe (K-type) with an uncertainty of ±0.25 °C, and the real-time temperature was recorded using a data logger (Hioki-LR8431). The air velocity was detected using a hot-wire anemometer with an uncertainty of 2.0% of the read value. The solar irradiance falling on the absorber plate was monitored via a pyrometer. The weight of the sample was recorded using a digital load cell (uncertainty of 1.0%). All measuring devices and their uncertainties are listed in Table 3.

Table 3.

List of instruments applied during experiments. (a) The measuring devices with their uncertainties; (b) the uncertainties of the parameters of interest (during the test).

The uncertainty of the experimental setup was analyzed based on the method described in [45]. Let the independent variables be , …, and let the dependent variable be Y. Thus,

The uncertainty is calculated as

where is the uncertainty in the function , is the partial derivative of the corresponding , and is the uncertainty in the parameter.

The results for the uncertainties in the parameters of interest are tabulated in Table 3—(b).

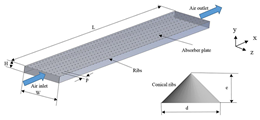

2.2. Construction of Tree-like Fractal-Based Cylindrical Pin (TFCP)

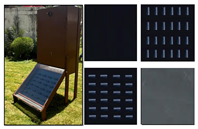

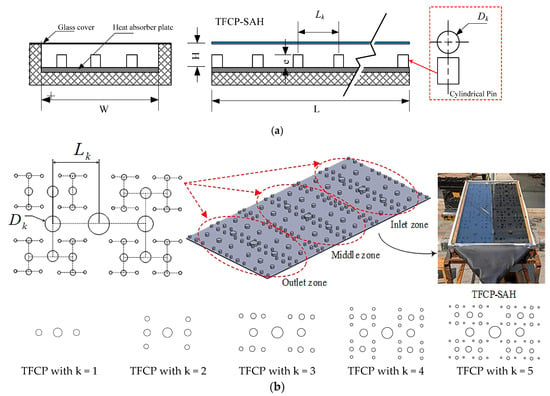

The major purpose of this work is to compare the thermal and drying performance of the solar-driven air heater equipped with/without a tree-like fractal (TFCP). The conventional absorber plate (flat plate) and that equipped with the TFCP (SAH-TFCP) were constructed for empirical solar drying tests. The dimensions of the conventional flat plate are 1.5 × 0.75 m2, and its thickness is 1.5 mm. It was fabricated from aluminum alloy AA-1060. The absorber plate of the SAH-TFCP was designed to have similar dimensions to the conventional plate, but the tree-like fractal-based cylindrical pin is placed on the top of the absorber plate, as shown in Figure 4. As a result of installing the fractal in the absorber plate, heat transfer enhancement is made possible by the fractal working as a turbulator to facilitate the heat transfer mechanism. Its improvement potential will be addressed in Section 3.

Figure 4.

The construction of the SAH-TFCP. (a) Details of SAH-TFCP, (b) The formulation of the TFCP with an increase in branching order.

To indicate the location for installing the tree-like fractal and the diameter of the cylindrical pin, the fractal formula is used, which is stated in a tree-like fractal equation. This formula was previously proposed by C. Xia et al. [46]:

where is the length of the initial branches of the fractal.

Here, is the length of the initial diameter of the pin. According to Murray’s law, the optimal values of parameters and provide the minimum flow resistance.

In constructing the TFCP, a bifurcation angle of 90° was used to create the cylindrical pin fractal (pin diameter and position), as shown in Figure 4b. The branching order (k) of the fractal is key to identifying the cylindrical pin’s installation location and dimensions, calculated using Equations (3) and (4). A branching order of 5 (k = 5) was used to construct the fractal [47]. In the initial design, the absorber was separated into three zones, as shown in Figure 2. An initial length of 250 mm ( = 250 mm) and an initial diameter of 50 mm ( = 50 mm) were used to calculate the fractal TFCP for each zone. The branching order is key to generating the fractal TFCP. The formulation of the TFCP with increasing branching order (k = 1–5) is indicated in Figure 4b.

In this work, the height ratio (e/H) was fixed at 0.5 throughout the experiment (the cylindrical pin fractal height is 20 mm). The absorber equipped with the TFCP was fabricated as shown in Figure 4a. The TFCP was made of aluminum alloy AA-1060, which is similar to the absorber plate.

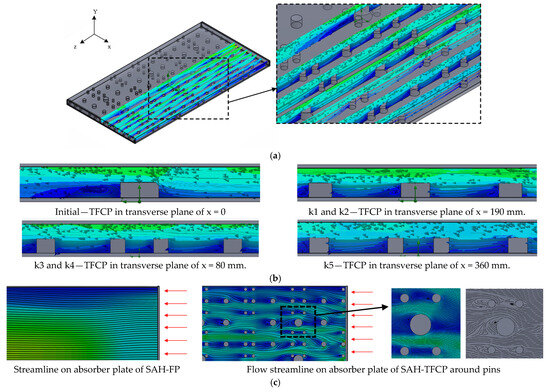

The installation of a tree-like fractal can enhance heat transfer performance because the air stream flowing through the fractal becomes more turbulent. This can improve heat transfer performance by eliminating the boundary layer flow (laminar sub-layer flow). The authors implemented CFD simulations to visualize the flow pathline with/without the TFCP and determine whether the TFCP could provide a more turbulent flow, as described in [48]. The simulation was implemented at an airflow velocity of 5 m/s as the inlet boundary condition. The velocity contour representing the flow physics with/without the TFCP is schematically shown in Figure 5. It is clearly seen that the air stream flowing through the absorber equipped with the TFCP is much more turbulent, and the recirculation zone of the air stream is established. This can enhance the convective heat transfer performance due to an increased Nusselt number [49]. In other words, the fractal (TFCP) works as a turbulator to increase the turbulence of the air stream flow. The use of a tree-like fractal based on a cylindrical shape for solar drying applications has not been reported in the available literature. This is proposed and discussed in this work.

Figure 5.

Comparison of typical flow physics of the air stream flowing through SAH-FP and SAH-TFCP. (a) Flow contour of air stream at various sections, (b) Velocity contours in transverse plane of x (different sections), (c) Velocity streamline on absorber plate of SAH.

2.3. Data Collected and Determination of Performance Parameters

2.3.1. Thermal Performance Parameter

During the test, solar irradiance is absorbed by the absorber plate (via short-wave radiation), and then, the absorbed heat is transferred to the air as it flows through the air gap between the absorber plate and the glass cover. The heat transfer rate can be calculated using Equation (3) [50]:

where

Meanwhile, the absorbed heat from the solar irradiance falling on the absorber with a certain surface area can be estimated using Equation (6):

Therefore, the thermal efficiency [51] of the SAH can be determined by

where is the useful energy generated by the SAH, and is the solar irradiance falling on the absorber plate.

Since this paper reports thermal performance based on the real-time operation of the SAH, thermal efficiency is key to demonstrating the improvement in the performance of the SAH equipped with/without the TFCP.

2.3.2. Drying Performance Parameters

The objective of the drying process is to remove water from the product (moisture content). This can be indicated by the moisture content’s wet basis, as stated in Equation (9) [52]:

where is the moisture content (wet basis), is the initial product weight (g) (before drying), and is the weight of the dried product (g).

The drying rate is recognized as a significant parameter for indicating drying performance improvement and can be determined using Equation (10) [53]:

where is the initial mass of the product (before drying), is the final mass of the product (after drying), and is the time interval for drying (hour).

The parameter that indicates the overall energy efficiency for solar drying applications is the drying efficiency. It can be determined using Equation (11) [54].

Additionally,

The aforementioned parameters were determined to analyze the performance improvement of the solar air heater equipped with the TFCP (SAH-TFCP) for drying applications. This is discussed in the next section.

3. Test Results and Discussion

This paper aims to demonstrate the thermal and drying performance of a solar air heater equipped with/without a TFCP when the system is driven by real solar irradiance under Thailand’s climatic conditions. The main purpose is to demonstrate the improvement potential of a solar air heater equipped with a tree-like fractal (SAH-TFCP) as compared with the conventional flat-plate absorber (SAH-FP), which is not reported in the available literature. The tests were implemented within a daytime period of 8.30–17.30 (drying time of 9 h). The air temperature, humidity, and solar irradiance at the points of interest during the operating time were measured so that the thermal and drying performance of the SAH could be analyzed comprehensively. Moreover, the initial weight of the turmeric slices and their real-time weight were recorded (every 15 min) to assess the drying performance. Subsequently, the thermal and drying performance of the SAH-TFCP was compared with that of the SAH-FP (conventional SAH) to determine the improvement potential of the SAH-TFCP.

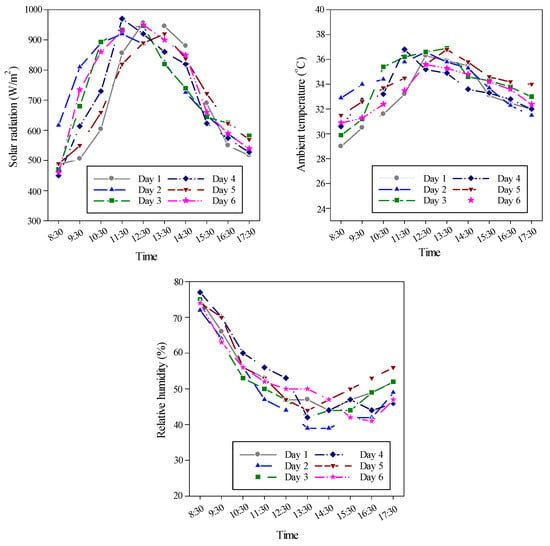

3.1. Comparison of Thermal Performance of SAH-TFCP and SAH-FP

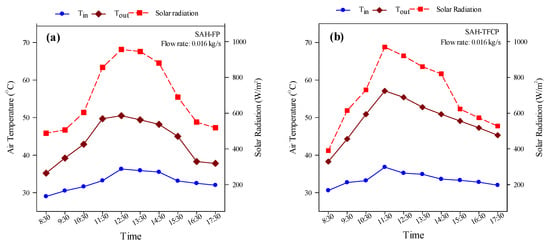

In comparative experiments, the airflow rate of the SAH was held constant in each test case (this was the only control variable parameter of the investigations) by carefully adjusting the rotational speed of the blower. To determine the desired mass flow rate, a hot-wire anemometer installed at the inlet of the absorber was used to measure the air velocity within the constant-area duct. The air mass flow rate was then determined using Equation (6). The initial weight of turmeric was recorded, and real-time weight was monitored via a digital load cell and recorded using a data acquisition unit. The test started at 8.30 and finished at 17.30 (9 h) under clear-sky test conditions. The environmental conditions during the test periods are depicted in Figure 6. The parameters of interest were recorded every 15 min via the data acquisition unit. Additionally, comparative tests were implemented using different airflow rates ranging from 0.016 to 0.05 kg/s. The test results of the SAH are depicted in Figure 7.

Figure 6.

Environmental conditions during the test period.

Figure 7.

(a,b) Test results at the airflow rate of 0.016 kg/s; (c,d) Test results at the airflow rate of 0.034 kg/s; (e,f). Test results at the airflow rate of 0.05 kg/s.

Figure 7a–f show the ambient air temperatures at the absorber inlet (or Tamb), the absorber outlet (Thot-air), the inlet/outlet of the drying chamber, and variations in solar irradiance with time. These results are also depicted for different airflow rates (0.016–0.050 kg/s). It can be seen that for a mass flow rate of 0.016 kg/s (Figure 7a,b), the SAH-TFCP can produce a much higher air temperature at the outlet of the absorber than the SAH-FP. The highest possible Thot-air produced by the SAH-TFCP is 57.3 °C with solar irradiance of around 985 W/m2. Meanwhile, that produced by the SAH-FP is 48.5 °C with solar irradiance of around 980 W/m2. This indicates that a higher hot-air temperature (Thot-air) is made possible by the SAH-TFCP. This results in a better drying process (discussed later in the next section).

The results for mass flow rates of 0.034 and 0.05 kg/s, as shown in Figure 7c,d and Figure 7e,f, respectively, show that the air temperature at the absorber outlet increases significantly with increasing solar irradiance and vice versa. In other words, a higher Thot-air is produced when solar irradiance increases and vice versa. Increasing Thot-air leads to a higher drying rate and better drying performance (which will be discussed in the next section). A higher Thot-air is the result of better heat transfer via the convection process due to the working absorber temperature being increased with solar irradiance. It is interesting to see that the Thot-air produced by the SAH-TFCP is always higher than that produced by the SAH-FP. Since the air velocity is fixed for a particular test case, a larger temperature differential between the absorber surface and the air is the result of an increased heat transfer rate. As a result, a higher air temperature at the absorber outlet is produced. However, the test was conducted at different solar times (day-by-day variations), and hence, fair comparisons of the thermal efficiency of the two absorbers (demonstrating the trade-off between useful thermal energy and solar irradiance) must be employed for accurate results. Comparisons of the thermal efficiency of the two systems and the percent improvement are shown in Figure 8.

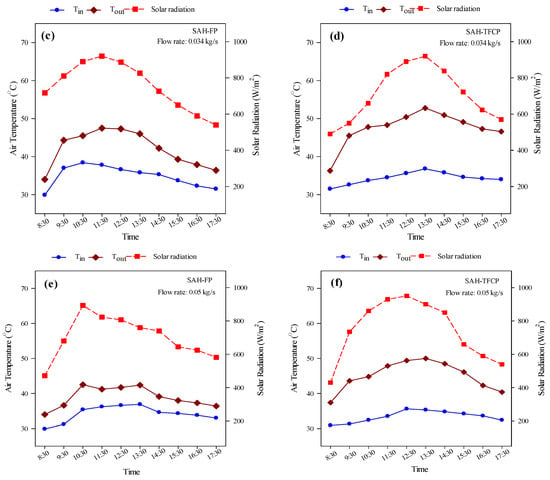

Figure 8.

Thermal efficiency of the SAH-TFCP compared with the SAH-FP at different air flow rates of (a) 0.016 kg/s (b) 0.034 kg/s (c) 0.05 kg/s (d) Improvement potential of thermal efficiency of SAH.

It is clearly seen in Figure 8a–c that, for a given airflow rate, the thermal efficiency of the SAH-TFCP is higher than that of the SAH-FP throughout the test period. The improvement potential (%IMP) is found to vary with the airflow rate and solar time, and a higher improvement potential is found when the airflow rate is increased, as shown in Figure 8d.

As previously shown in Figure 7a–f, the air temperature at the absorber outlet (Thot-air) produced by the SAH-TFCP is much higher than that produced by the SAH-FP throughout the test period. Notably, the two systems were tested with the same airflow rate (same flow Reynolds number), and thermal efficiency was used as a key parameter for comparison. This shows that heat transfer performance is significantly enhanced after the cylindrical fractal (TFCP) is installed in the absorber plate. The key to the heat transfer enhancement is that the TFCP can generate more turbulence in the air stream that flows through the absorber plate (as previously shown in Figure 5). A higher turbulence intensity can enhance the convective heat transfer mechanism, in which the Nusselt number increases (or the convective heat transfer coefficient increases) even when the flow Reynolds number is identical.

It is also found that when the airflow rate increases (or the flow Reynolds number increases), the improvement potential increases (please see Figure 8d). This is due to the fact that the convective heat transfer coefficient increases with the flow Reynolds number, as supported by [55]. In this case, a more turbulent air stream is achieved with a higher flow velocity at the absorber plate. As a result, the SAH-TFCP can produce a higher improvement potential when the airflow rate is increased. This analysis has demonstrated that installing the TFCP in the absorber plate can greatly enhance the heat transfer mechanism of the solar air heater, resulting in improved thermal performance.

It is also seen that the air temperature at the absorber outlet (Thot-air) decreases when the airflow rate is increased (seen in Figure 7). This is because a higher convective heat transfer coefficient is obtained due to being operated with a higher mass flow rate (or higher air velocity). In this case, the Nusselt number (or convective heat transfer coefficient) is increased due to an increase in the flow Reynolds number when the air mass flow rate is increased. However, a lower temperature differential between the absorber surface and the airflow causes Thot-air to decrease. This is a common convective heat transfer mechanism that occurs when operating with a higher convective heat transfer coefficient, as supported by [56].

The above analysis has shown that the thermal performance improvement of the solar air heater is made possible by installing the tree-like fractal in the absorber. The key to this heat transfer enhancement is the more turbulent flow of the airflow stream. The results reported in this section were obtained under Thailand’s climatic conditions, and the SAH was powered by real-time solar irradiance. This can serve as a reference case for further improving and validating the design model of the SAH. This will benefit the drying performance, which will be discussed in the next section.

3.2. Comparative Drying Performance of SAH-TFCP with SAH-FP

This section demonstrates the drying performance improvement of the SAH-TFCP as compared with the SAH-FP. The impact of the airflow rate on the drying performance is explored and discussed. In this test, the hot air produced at the absorber outlet was supplied to the drying chamber to produce dried turmeric. In this case, drying samples and turmeric slices were used to evaluate the drying performance. The percent decrease in moisture content (wet basis), drying rate, and drying efficiency are used as drying performance indicators to demonstrate the improvement potential of the SAH-TFCP in the drying process. The test was implemented based on real solar irradiance and carried out from 8:30 to 17:30 (9 h drying time).

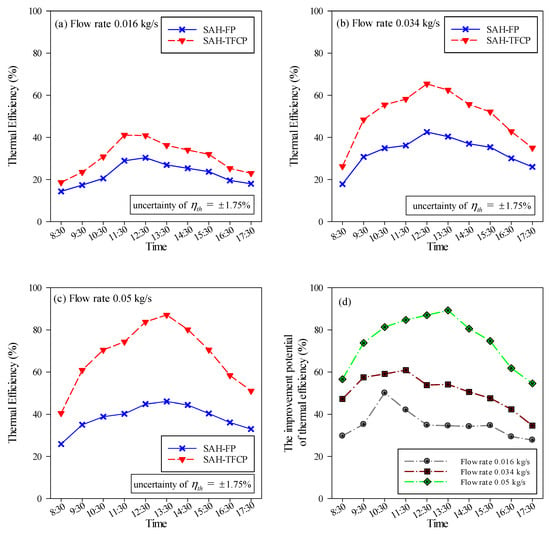

Figure 9 depicts the moisture content wet basis (MCw) over the drying period at various airflow rates (Figure 9a–c). The results clearly show that for a given airflow rate, the MCw with the SAH-TFCP is always lower than that with the SAH-FP for the same drying time. This means that the sample dries faster when the SAH-TFCP is used. A lower MCw with the same drying time reflects better water removal from the drying sample, meaning that the water in the sample (moisture content) is removed faster when using the SAH-TFCP. In the first four hours of the drying period, the MCw of both systems drops sharply with the same trend. This is because the drying sample still contains quite high moisture, resulting in a higher evaporation rate of water at the surface of the drying sample. Notably, the MCw obtained with the SAH-TFCP is always higher than that with the SAH-FP, which reflects a higher water evaporation rate. After four hours of drying, the MCw decreased slightly with the drying time in all cases.

Figure 9.

Moisture content produced by the SAH-TFCP compared with that produced by the SAH-FP at different air mass flow rates of (a) 0.016 kg/s (b) 0.034 kg/s (c) 0.05 kg/s (d) Improvement potential of the produced moisture content.

Figure 9d shows that in the first four hours of drying, the percent improvement in MCw increases with the drying time until it reaches its maximum value after 240 min of drying. Then, the percent improvement of MCw decreases continuously until the drying period ends. In addition, for the same drying time, a higher percent improvement in MCw was found when the airflow rate was increased. From the test, the maximum percent improvement of MCw is as follows: 54.03% at a flow rate of 0.05 kg/s, 40.29% at a flow rate of 0.034 kg/s, and 34.52% at a flow rate of 0.016 kg/s.

For a given airflow rate, the faster water removal from the drying sample is caused by enhanced heat transfer via the SAH-TFCP (by producing a higher Thot-air), as discussed in the previous section. In this case, a higher air temperature yields a higher water evaporation rate at the surface of the sample (due to a larger temperature differential between the hot air and the sample surface). This causes a sharp decrease in MCw with the same drying time. It is noticeable in Figure 9d that operating the SAH at a higher airflow rate increases the improvement potential. However, the previous section has shown that Thot-air (seen in Figure 7) decreases significantly when the airflow rate is increased. Hence, the airflow rate seems to have a greater impact on the moisture removal rate than the drying temperature (Tdry = Thot-air). A possible reason for this is that a higher airflow rate can accelerate the water evaporation rate more than a higher drying temperature can because the water in the sample (turmeric slice) is dehydrated by the evaporation process. Hence, a higher velocity of air flowing over the sample surface can yield a higher water evaporation rate at the sample surface, resulting in a lower MCw with the same drying time. This is because the airflow has a relatively low relative humidity.

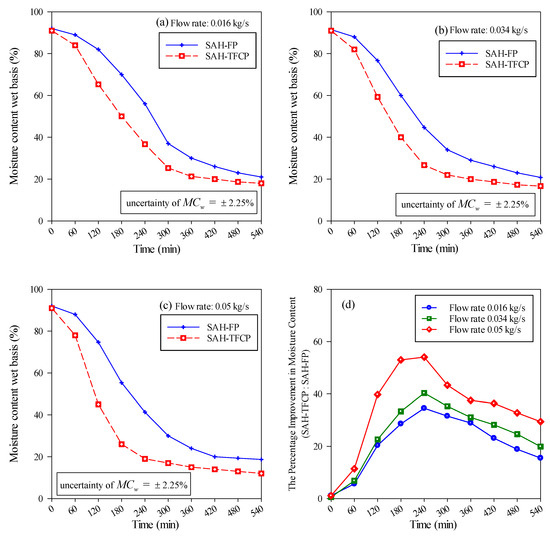

The above results demonstrate the benefit of using a tree-like fractal as the turbulator for performance enhancement in drying applications based on the moisture removal rate. However, to provide a different perspective on drying performance, the drying rate and drying efficiency during the drying period are demonstrated in Figure 10 and Figure 11. The drying rate involves latent heat transfer based on the evaporation of water in the drying sample. A higher latent heat transfer rate yields a higher drying rate. The drying efficiency represents the efficiency of energy usage, and hence, a higher drying efficiency is preferable.

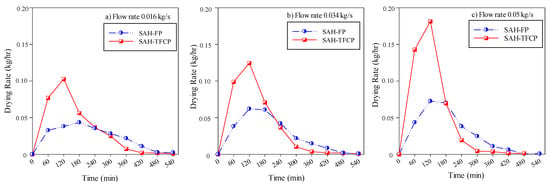

Figure 10.

Comparisons of the drying rate at different flow rates.

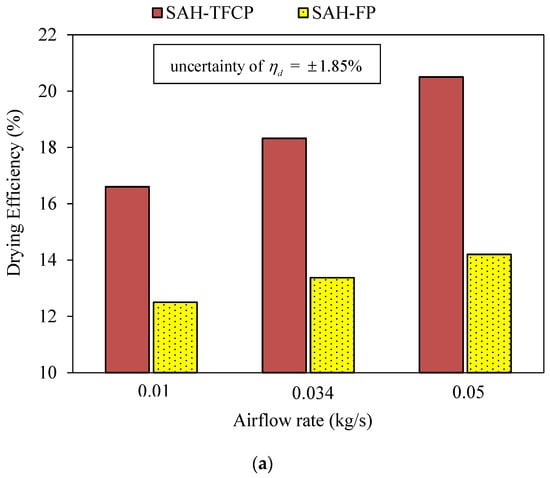

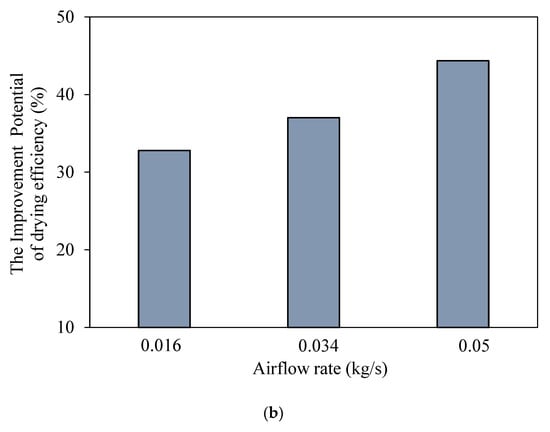

Figure 11.

The drying efficiency and improvement potential at different airflow rates. (a) The drying efficiency at different airflow rates, (b) The improvement potential at different airflow rates.

It is seen in Figure 10 that at a fixed airflow rate, the drying rate of the SAH-TFCP is much higher than that of the SAH-FP in the first two hours. This is due to a higher moisture removal rate, as discussed earlier for MCw. However, after three hours, the drying rate of the SAH-TFCP becomes lower than that of the SAH-FP. The reason is that the moisture content of the product (after three hours) dried by the SAH-TFCP is lower than that dried by the SAH-FP, and the surface area of the dried product for water evaporation is reduced significantly (seen in Table 4). These are the reasons that the drying rate of the SAH-TFCP is lower than that of the SAH-FP after three hours.

Table 4.

The drying process of turmeric slices using the SAH-TFCP at a 0.05 kg/s mass flow rate.

Figure 11a shows that at a fixed airflow rate, the drying efficiency obtained using the SAH-TFCP is much higher than that using the SAH-FP. It also shows that the drying efficiency of the two systems increases with an increase in the airflow rate. The SAH-TFCP always has a higher drying efficiency throughout the investigated range of mass flow rates. The improvement potential (or percent improvement) is depicted in Figure 11b. The improvement in drying efficiency is the result of heat transfer performance enhancement by the TFCP, which works as a turbulator to increase the turbulence of the air stream flowing through the absorber plate, which results in a higher Thot-air at a fixed flow rate. In addition, when increasing the airflow rate, the turbulent flow of the air stream is more intense because the air velocity is increased as it flows through the fractal. This results in a higher heat transfer rate, which results in better energy conversion. As a result, it has a high potential to have better drying performance, which is indicated by the drying efficiency improvement shown in Figure 11b.

The results in this section show that the drying performance, in terms of the drying rate and drying efficiency, can be improved by installing the tree-like fractal-based cylindrical pin in the absorber plate of the solar air heater. A significant drying performance improvement is obtained with solar energy radiation under Thailand’s climatic conditions. Hence, the results reported in this section can be used as a base reference case for further developing a more accurate mathematical model to predict the drying performance of the SAH operating with a turbulator.

4. Conclusions

The improvement potential of a solar air heater equipped with a TFCP was investigated under Thailand’s climatic conditions. The thermal and drying performance of the SAH-TFCP was compared with that of the SAH-FP (conventional one) for analysis. Turmeric slices were used as drying samples for the drying performance assessment. The tests were conducted at different airflow rates ranging from 0.016 to 0.050 kg/s under real solar irradiance. The findings of this work can be summarized as follows:

- At a fixed airflow rate, the temperature of hot air (Thot-air) produced by the SAH-TFCP is much higher than that produced by the SAH-FP. This is due to convective heat transfer enhancement via the tree-like fractal-based cylindrical pin.

- The temperature of hot air from both systems decreases when increasing the airflow rate; however, the Thot-air produced by the SAH-TFCP is always higher than that produced by the SAH-FP.

- The thermal efficiency of the two systems varies significantly with solar irradiance. The thermal efficiency of the SAH-TFCP is higher than that of the SAH-FP. The percent improvement in thermal efficiency is 44–85%, depending on the airflow rate. A higher improvement potential is found when increasing the airflow rate.

- The moisture content wet basis (MCw) of the SAH-TFCP is lower than that of the SAH-FP with the same drying time. This indicates that the turmeric slices are dried faster via the SAH-TFCP. A lower MCw with the same drying time is made possible by increasing the mass flow rate.

- The drying efficiency of the SAH-TFCP is much higher than that of the SAH-FP throughout the test period. The improvement potential is 32–44%. An increase in the airflow rate yields a higher improvement potential.

Hopefully, the test results of the solar air heater for drying applications proposed in this work are useful for researchers who are interested in developing high-performance SAHs for drying applications. The test results show that installing the tree-like fractal cylindrical pin is an efficient way to improve the thermal and drying performance of the SAH. This is evidence that solar drying applications can be made more sustainable with lower energy usage. Since the thermal and drying performance of the SAH was acceptable under hot and humid conditions (Thailand’s climatic conditions), the improvement technique proposed in this work is expected to further increase thermal and drying efficiency in low-humidity conditions.

Author Contributions

Conceptualization, C.P., T.T., and K.S.; methodology, C.P., T.T., and K.S.; software, C.P.; validation, C.P., T.T., and K.S.; formal analysis, C.P., T.T., and K.S.; investigation, C.P.; data curation, C.P., T.T., and K.S.; writing—original draft preparation, C.P., T.T., and K.S.; writing—review and editing, C.P., T.T., and K.S.; supervision, T.T., and K.S.; funding acquisition, K.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research budget was allocated by the National Science, Research and Innovation Fund (NSRF) and King Mongkut’s University of Technology North Bangkok (Project No. KMUTNB-FF-67-B-41).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to thank Pornjit Pratumsuwan at department of Department of Teacher Training in Mechanical Engineering, King Mongkut’s University of Technology North Bangkok for his generous guidance and valuable comments.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| SAH | Solar air heater |

| TFCP | Tree-like fractal cylindrical pins |

| FP | Flat plate |

| IP | Improvement potential |

| Nomenclature | |

| A | Cross-sectional area of the duct, m2 |

| Aabsorb | Surface area of collector plate, m2 |

| Cp | Specific heat of air at constant pressure, kJ/(kg K) |

| Dh | Hydraulic diameter of the air passage, m |

| Dk | Diameter of the kth branching level |

| DR | Drying rate |

| e | Roughness height, mm |

| e/D | Height ratio |

| H | Height of air channel, m |

| h | Heat transfer coefficient, W m−2 K−1 |

| I | Solar irradiance, W/m2 |

| k | Thermal conductivity of air, W m−2 K−1 |

| L | Duct length, m |

| Lk | Length of the kth branching level |

| MC | Moisture content |

| Mt | Total moisture content |

| m | Mass flow rate of air, kg/s |

| mi | Initial product weight, kg |

| md | Weight of the dried product, kg |

| mw | Mass of evaporated water, kg |

| Qin | The solar irradiance falling on absorber plate, W |

| Qout | Useful heat gain, W |

| Tamb | Ambient air temperature |

| Thot-air | Air temperature of solar air heater outlet |

| V | Velocity of air through the duct |

| W | Duct width, m |

| Greek letters | |

| Thermal efficiency, % | |

| Drying efficiency, % | |

| Air density, kg/m3 | |

| Diameter exponent | |

References

- Panda, S.; Panda, B.; Kumar, R.; Jena, C. Energy & Exergy Analysis of a PV Panel with Passive cooling mechanism. Suranaree J. Sci. Technol. 2023, 30, 6. [Google Scholar]

- Matsunaga, J.; Kikuta, K.; Hirakawa, H.; Mizuno, K.; Tajima, M.; Hayashi, M.; Fukushima, A. An Assessment of Heating Load Reduction by a Solar Air Heater in a Residential Passive Ventilation System. Energies 2021, 14, 7651. [Google Scholar] [CrossRef]

- Sornek, K.; Papis-Fraczek, K. Development and Tests of the Solar Air Heater with Thermal Energy Storage. Energies 2022, 15, 6583. [Google Scholar] [CrossRef]

- Qamar, Z.; Munir, A.; Langrish, T.; Ghafoor, A.; Tahir, M. Experimental and Numerical Simulations of a Solar Air Heater for Maximal Value Addition to Agricultural Products. Agriculture 2023, 13, 387. [Google Scholar] [CrossRef]

- Hao, W.; Liu, S.; Mi, B.; Lai, Y. Mathematical Modeling and Performance Analysis of a New Hybrid Solar Dryer of Lemon Slices for Controlling Drying Temperature. Energies 2020, 13, 350. [Google Scholar] [CrossRef]

- Karami, H.; Kaveh, M.; Golpour, I.; Khalife, E.; Rusinek, R.; Dobrzański, B., Jr.; Gancarz, M. Thermodynamic Evaluation of the Forced Convective Hybrid-Solar Dryer during Drying Process of Rosemary (Rosmarinus officinalis L.). Leaves Energ. 2021, 14, 5835. [Google Scholar] [CrossRef]

- Winans, K.; Brodt, S.; Kendall, A. Life cycle assessment of California processing tomato: An evaluation of the effects of evolving practices and technologies over a 10-year (2005–2015) time frame. Life Cycle Assess. 2020, 25, 538–547. [Google Scholar] [CrossRef]

- Cop, M.; Barta, R.B.; Thomas, C.; Hesse, U. Experimental investigation of a heat pump tumble dryer with a zeotropic refrigerant mixture. Int. J. Refrig. 2024, 158, 190–201. [Google Scholar] [CrossRef]

- Hu, Z.; Li, Y.; El-Mesery, H.S.; Yin, D.; Qin, H.; Ge, F. Design of new heat pump dryer system: A case study in drying characteristics of kelp knots. Case Stud. Therm. Eng. 2022, 32, 101912. [Google Scholar] [CrossRef]

- Afzal, A.; Iqbal, T.; Ikram, K.; Anjum, M.N.; Umair, M.; Azam, M.; Akram, S.; Hussain, F.; Zaman, M.A.; Ali, A.; et al. Development of a hybrid mix-mode solar air heater for product drying. Heliyon 2023, 9, e14144. [Google Scholar] [CrossRef]

- Karwa, R. Thermo-Hydraulic performance of solar air heater with finned absorber plate forming multiple rectangular air flow passages in parallel under laminar flow conditions. Appl. Therm. Eng. 2023, 221, 119673. [Google Scholar] [CrossRef]

- Singh, V.P.; Jain, S.; Karn, A.; Kumar, A.; Dwivedi, G.; Meena, C.S.; Dutt, N.; Ghosh, A. Recent Developments and Advancements in Solar Air Heaters: A Detailed Review. Sustainability 2022, 14, 12149. [Google Scholar] [CrossRef]

- Jongpluempiti, J.; Pannucharoenwong, N.; Benjapiyaporn, C.; Vengsungnle, P. Design and Construction of the Flat Plate Solar Air Heater for Spray Dryer. Energy Procedia 2017, 138, 288–293. [Google Scholar] [CrossRef]

- He, Y.; Yu, H.; Duan, G.; Wang, Y.; Yang, Q.; Feng, L.; Zhang, J. Thermal performance and experimental analysis of stainless steel flat plate solar collector with full-flow channels. Heliyon 2024, 10, e28255. [Google Scholar] [CrossRef] [PubMed]

- Boulemtafes-Boukadoum, A.; Abid, C.; Benzaoui, A. 3D Numerical study of the effect of aspect ratio on mixed convection air flow in upward solar air heater. Int. J. Heat Fluid. Flow 2020, 84, 108570. [Google Scholar] [CrossRef]

- Lingayat, A.B.; Chandramohan, V.P.; Raju, V.R.K.; Meda, V. A review on indirect type solar dryers for agricultural crops—Dryer setup, its performance, energy storage and important highlights. Appl. Energy 2020, 258, 114005. [Google Scholar] [CrossRef]

- Baissi, M.T.; Brima, A.; Aoues, K.; Khanniche, R.; Moummi, N. Thermal behavior in a solar air heater channel roughened with delta-shaped vortex generators. Appl. Therm. Eng. 2020, 165, 113563. [Google Scholar] [CrossRef]

- Saravanan, S.; Murugan, M.; Reddy, M.S.; Ranjit, P.S.; Elumalai, P.V. Thermo-hydraulic performance of a solar air heater with staggered C-shape finned absorber plate. Int. J. Therm. Sci. 2021, 168, 107068. [Google Scholar] [CrossRef]

- Ravi, R.K.; Saini, R.P. Nusselt number and friction factor correlations for forced convective type counter flow solar air heater having discrete multi V shaped and staggered rib roughness on both sides of the absorber plate. Appl. Therm. Eng. 2018, 129, 735–746. [Google Scholar] [CrossRef]

- Alam, T.; Meena, C.S.; Balam, N.B.; Kumar, A.; Cozzolino, R. Thermo-Hydraulic Performance Characteristics and Optimization of Protrusion Rib Roughness in Solar Air Heater. Energies 2021, 14, 3159. [Google Scholar] [CrossRef]

- Yadav, A.S.; Alam, T.; Gupta, G.; Saxena, R.; Gupta, N.K.; Allamraju, K.V.; Kumar, R.; Sharma, N.; Sharma, A.; Pandey, U. A Numerical Investigation of an Artificially Roughened Solar Air Heater. Energies 2022, 15, 8045. [Google Scholar] [CrossRef]

- Khanlari, A.; Guler, H.O.; Tuncer, A.D.; Sirin, C.; Bilge, Y.A.C.; Yilmaz, Y.; Gungor, A. Experimental and numerical study of the effect of integrating plusshaped perforated baffles to solar air collector in drying application. Renew. Energy 2020, 145, 1677–1692. [Google Scholar] [CrossRef]

- Hassan, A.; Nikbahkt, A.; Welsh, Z.; Yarlagadda, P.; Fawzia, S. Experimental and thermodynamic analysis of solar air dryer equipped with V-groove double pass collector: Techno-economic and exergetic measures. Energy Convers. Manag. X 2022, 16, 100296. [Google Scholar] [CrossRef]

- Tefera, E.; Damtie, E.G.; Bezzie, Y.M.; Admass, Z. Experimental testing of mixed-mode double pass solar air heater integrated with aluminium cans for red pepper drying. Case Stud. Therm. Eng. 2023, 50, 103379. [Google Scholar] [CrossRef]

- Mohammed, S.A.; Alawee, W.H.; Chaichan, M.T.; Abdul-Zahra, A.S.; Fayad, M.A.; Ajiuwaya, T.M. Optimized solar food dryer with varied air heater designs. Case Stud. Therm. Eng. 2024, 53, 103961. [Google Scholar] [CrossRef]

- Rani, P.; Tripathy, P.P. CFD coupled heat and mass transfer simulation of pineapple drying process using mixed-mode solar dryers integrated with flat plate and finned collector. Renew. Energy 2023, 217, 119210. [Google Scholar] [CrossRef]

- Akpinae, E.K. Drying of mint leaves in a solar dryer and under open sun: Modelling, performance analyses. Energy Convers. Manag. 2010, 51, 2407–2418. [Google Scholar] [CrossRef]

- Patel, V.; Judal, K.B.; Panchal, H.; Singh, B.; Jomde, A.; Kumar, A.; Patel, A.; Jain, R.; Sadasivuni, K.K. Investigation on drying kinetics analysis of gooseberry slices dried under open sun. Environ. Chall. 2023, 13, 100778. [Google Scholar] [CrossRef]

- Prajapati, C.; Sheorey, T. Exploring the efficacy of natural convection in a cabinet type solar dryer for drying gooseberries: An experimental analysis. J. Agric. Food Res. 2023, 14, 100684. [Google Scholar] [CrossRef]

- Qasem, N.A.A.; Arnous, M.N.; Zubair, S.M. A comprehensive thermal-hydraulic assessment of solar flat-plate air heaters. Energy Convers. Manag. 2020, 215, 112922. [Google Scholar] [CrossRef]

- Jayranaiwachira, N.; Promvong, P.; Thianpong, C.; Skullong, S. Thermal-hydraulic performance of solar receiver duct with inclined punched-ribs and grooves. Case Stud. Therm. Eng. 2022, 39, 102437. [Google Scholar] [CrossRef]

- Altun, A.H.; Gurdal, M.; Berber, A. Effects of sinusoidal turbulator in cylindrical channel on heat transfer and flow characteristics. Maejo Int. J. Sci. Technol. 2020, 14, 27–42. [Google Scholar]

- Said, Z.; Bellos, E.; Ali, H.M.; Rahman, S.; Tzivanidid, C. Nanofluids, turbulators, and novel working fluids for heat transfer processes and energy applications: Current status and prospective. Appl. Therm. Eng. 2025, 258, 124478. [Google Scholar] [CrossRef]

- Sureandhar, G.; Srinivasan, G.; Muthukumar, P.; Senthilmurugan, S. Performance analysis of arc rib fin embedded in a solar air heater. Therm. Sci. Eng. Prog. 2021, 23, 100891. [Google Scholar] [CrossRef]

- Zhang, G.Z.; Sunden, B.; Xie, G. Combined experimental and numerical investigations on heat transfer augmentation in truncated ribbed channels designed by adopting fractal theory. Int. Commun. Heat Mass Transf. 2021, 121, 105080. [Google Scholar] [CrossRef]

- Sureandhar, G.; Srinivasan, G.; Muthukumar, P.; Senthilmurugan, S. Investigation of thermal performance in a solar air heater having variable arc ribbed fin configuration. Sustain. Energy Technol. Assess. 2022, 52, 102069. [Google Scholar] [CrossRef]

- Yu, C.; Wu, S.; Huang, Y.; Yao, F.; Liu, X. Charging performance optimization of a latent heat storage unit with fractal tree-like fins. J. Energy Storage 2020, 30, 101498. [Google Scholar] [CrossRef]

- Zhang, C.; Li, J.; Chen, Y. Improving the energy discharging performance of a latent heat storage (LHS) unit using fractal-tree-shaped fins. Appl. Energy 2020, 259, 114102. [Google Scholar] [CrossRef]

- Zhuang, D.; Yang, Y.; Ding, G.; Du, X.; Hu, Z. Optimization of Microchannel Heat Sink with Rhombus Fractal-like Units for Electronic Chip Cooling. Int. J. Refrig. 2020, 116, 108–118. [Google Scholar] [CrossRef]

- ASHRAE Standard 93–77; Method of Testing to Determine the Thermal Performance of Solar Collectors. American Society for Heating, Refrigeration, and Air Conditioning Press: Beijing, China, 2011.

- Mzad, H.; Bennour, F. On the effect of the transversal aspect ratio on the double-glazed solar air heater performance. Heat Transf. 2023, 52, 2771–2795. [Google Scholar] [CrossRef]

- Osodo, B.; Nyaanga, D.; Kiplagat, J. Simulation of grain quantity, fan and solar collector sizes for an experimental forced convection grain dryer, Agric. Food Sci. 2019, 6, 98–108. [Google Scholar]

- Hassan, H.; Elfadl, S.A.; El-Dosoky, M.F. An experimental investigation of the performance of new design of solar air heater (tubular). Renew. Energy 2020, 151, 1055–1066. [Google Scholar] [CrossRef]

- Abushanab, W.S.; Zaywd, M.E.; Sathyamurthy, R.; Moustafa, E.B.; Elsheikh, A.H. Performance evaluation of a solar air heater with staggered/longitudinal finned absorber plate integrated with aluminium sponge porous medium. J. Build. Eng. 2023, 73, 106841. [Google Scholar] [CrossRef]

- Kline, S.J. Describing uncertainty in single sample experiments. Mech. Eng. 1953, 75, 3–8. [Google Scholar]

- Xia, C.; Fu, J.; Lai, J.; Yao, X.; Chen, Z. Conjugate heat transfer in fractal tree-like channels network heat sink for high-speed motorized spindle cooling. Appl. Therm. Eng. 2015, 90, 1032–1042. [Google Scholar] [CrossRef]

- Prasopsuk, C.; Thongtip, T.; Pratumsuwan, P.; Sutthivirode, K. Experimental study of Thermo-Hydraulic Performance for Solar Air Heater with varied Cylindrical Pins using Tree-like Fractal arrangements. In Proceedings of the 11th International Conference on Technical Education, Bangkok, Thailand, 6–7 June 2024. [Google Scholar]

- Promthaisong, P.; Eiamsa-ard, S. Fully developed periodic and thermal performance evaluation of a solar air heater channel with wavy-triangular ribs placed on an absorber plate. Int. J. Therm. Sci. 2019, 140, 413–428. [Google Scholar] [CrossRef]

- Dong, Z.; Lui, P.; Xiao, H.; Liu, Z.; Liu, W. A study on heat transfer enhancement for solar air heaters with ripple surface. Renew. Energy 2021, 172, 477–487. [Google Scholar] [CrossRef]

- Sexena, A.; Varun; El-Sebaii, A. A thermodynamic review of solar air heaters. Renew. Sustain. Energy Rev. 2015, 43, 863–890. [Google Scholar] [CrossRef]

- Jia, B.; Lui, F.; Wang, D. Experimental study on the performance of spiral solar air heater. Sol. Energy 2019, 182, 78–88. [Google Scholar] [CrossRef]

- Abubakar, S.; Umaru, S.; Kaisan, M.U.; Umar, U.A.; Ashok, B.; Nanthagopal, K. Development and performance comparison of mixed-mode solar crop dryers with and without thermal storage. Renew. Energy 2018, 128, 285–298. [Google Scholar] [CrossRef]

- Ramirez, C.; Palacio, M.; Carmona, M. Reduced Model and Comparative Analysis of the Thermal Performance of Indirect Solar Dryer with and without PCM. Energies 2020, 13, 5508. [Google Scholar] [CrossRef]

- Matias Gonçalves, L.; Mendoza-Martinez, C.; Alves Rocha, E.P.; Coutinho de Paula, E.; Cardoso, M. Solar Drying of Sludge from a Steel-Wire-Drawing Industry. Energies 2023, 16, 6314. [Google Scholar] [CrossRef]

- Barik, A.K.; Mohanty, A.; Senapati, J.R.; Awad, M.M. Constructal design of different ribs for thermo-fluid performance enhancement of a solar air heater (SAH). Int. J. Therm. Sci. 2021, 160, 106655. [Google Scholar] [CrossRef]

- An, B.-H.; Choi, K.-H.; Choi, H.-U. Heat Transfer Augmentation and Friction Factor Due to the Arrangement of Rectangular Turbulators in a Finned Air Channel of a Solar Air Heater. Energies 2023, 16, 6891. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).