1. Introduction

With the advancement of coalbed methane well construction technology, the development well patterns for CBM extraction have diversified. The multi-branch horizontal well technology has demonstrated numerous advantages in the CBM extraction field [

1]. Its long horizontal section and multi-branch structure can expand the control area per well, enhance extraction efficiency, reduce the number of drilling operations, and lower comprehensive costs [

2,

3,

4]. This technology is particularly suitable for CBM extraction in areas with simple geological structures, stable coal seam thickness, and high-permeability coal seams. In China, the application and promotion of multi-branch horizontal wells have long been carried out in regions such as the Qinshui Basin and the Ordos Basin, yielding extensive theoretical and technical achievements to support their large-scale implementation.

For instance, Jian Kuo et al. proposed optimizing well locations, stabilizing the pressure drawdown rate, and enhancing production continuity based on the successful development experience of multi-branch horizontal wells in the Zhengzhuang Block of the Qinshui Basin, aiming to achieve high and stable production [

5]. Luan Fei analyzed the advantages of feather-shaped multi-branch horizontal wells in the Gujiao Block of the Qinshui Basin and provided optimal selection schemes for fracturing fluids, proppants, and fracturing parameters, offering a solid basis for subsequent development [

6]. Liu Zhan et al. conducted a systematic comparison of the gas production performance of different multi-branch horizontal wells in the Sanjiao Block of the Ordos Basin, identifying the main controlling factors affecting their productivity and proposing countermeasures for yield improvement and stability [

7]. Additionally, Chen et al. studied the well structure for high-yield multi-branch horizontal wells and analyzed the mechanisms through which geological and engineering factors influence well productivity, yet failed to quantify the impact degree of these factors [

8]. Wei and Yan comprehensively analyzed the effects of engineering factors on the productivity of multi-branch horizontal wells but neglected discussions on geological factors [

9]. Although progress has been made in optimizing the design and enhancing the productivity of multi-branch horizontal wells, due to significant variations in coal seam properties under different geological conditions, research on the geological adaptability of this technology remains insufficient. Currently, most studies have not fully recognized or visually demonstrated the impacts of CBM geological and engineering conditions on the productivity of multi-branch horizontal wells, making it particularly crucial to clarify these influencing factors, especially in regions with limited historical multi-branch horizontal well operations.

Southwestern China, represented by Guizhou Province, is one of the favorable CBM enrichment areas and has emerged as a new hotspot for CBM exploration and development after the Qinshui Basin and the eastern margin of the Ordos Basin [

10]. The Zhina Coalfield, the largest anthracite production area in Guizhou, holds a total CBM resource volume of 6367.771 × 10

8 m

3. After nearly two decades of CBM exploration and development, the extraction models in this area have gradually matured. Currently, well-established development models in the Zhina Coalfield include vertical wells and cluster well groups [

11], while multi-branch horizontal well extraction is still in its infancy. In 2022, the first multi-branch horizontal well in Guizhou Province was drilled in the Wenjiaba Block of the Zhina Coalfield. Gas production and drainage experiments verified the feasibility of CBM extraction using multi-branch horizontal wells in complex tectonic regions. However, due to the limited number of multi-branch horizontal wells and short extraction durations in the area, a systematic understanding of production-increasing factors remains elusive. The applicable conditions and engineering optimization directions of multi-branch horizontal wells in Guizhou remain unclear, severely hindering their popularization and application in southwestern China.

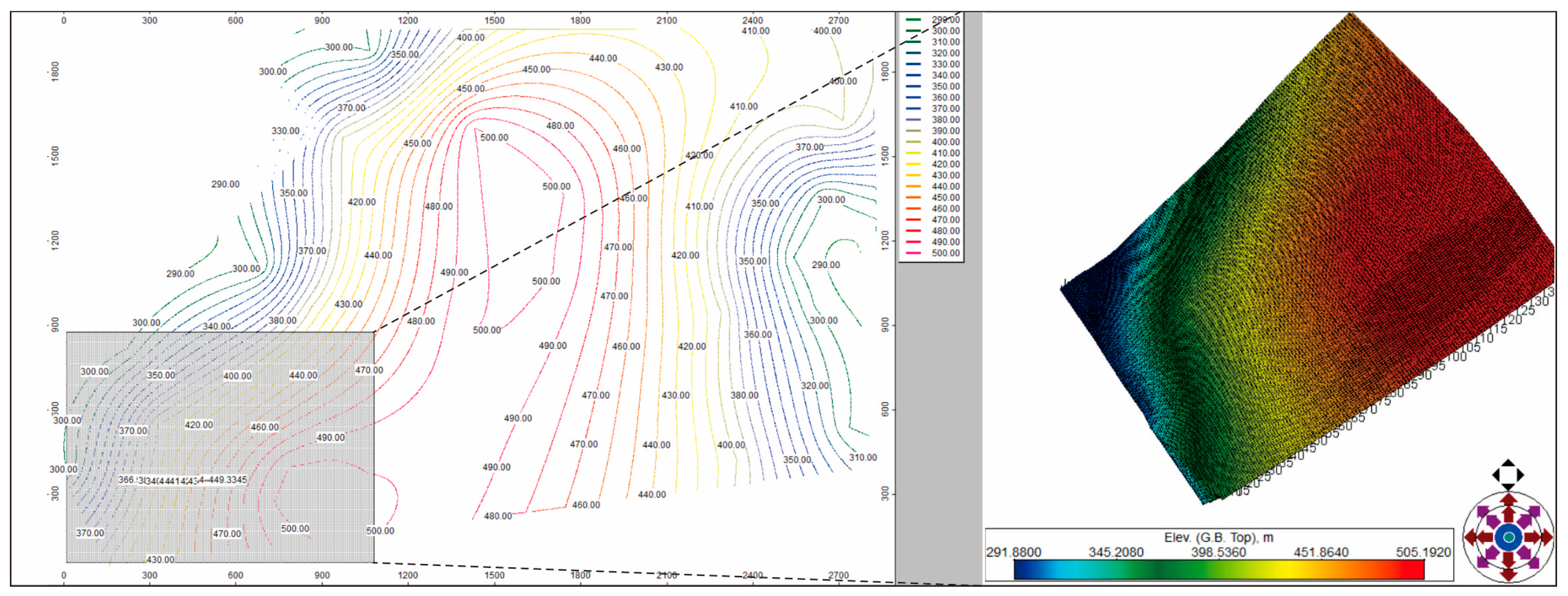

This study focuses on the Wenjiaba Coal Mine Area within the Zhina Coalfield, Guizhou, taking Well W1, the only multi-branch horizontal well in the area, as the research object. Based on geological and engineering data, a geological model of coal reservoirs was constructed, and simulation extraction schemes were designed. Through comparative analysis of reservoir numerical simulation results, the impacts of geological and engineering factors on the gas production capacity of multi-branch horizontal wells were evaluated, providing a theoretical basis for the optimized design, promotion, and application of multi-branch horizontal wells in the Zhina Coalfield.

2. Geological and Engineering Background of the Study Area

2.1. Geological Background

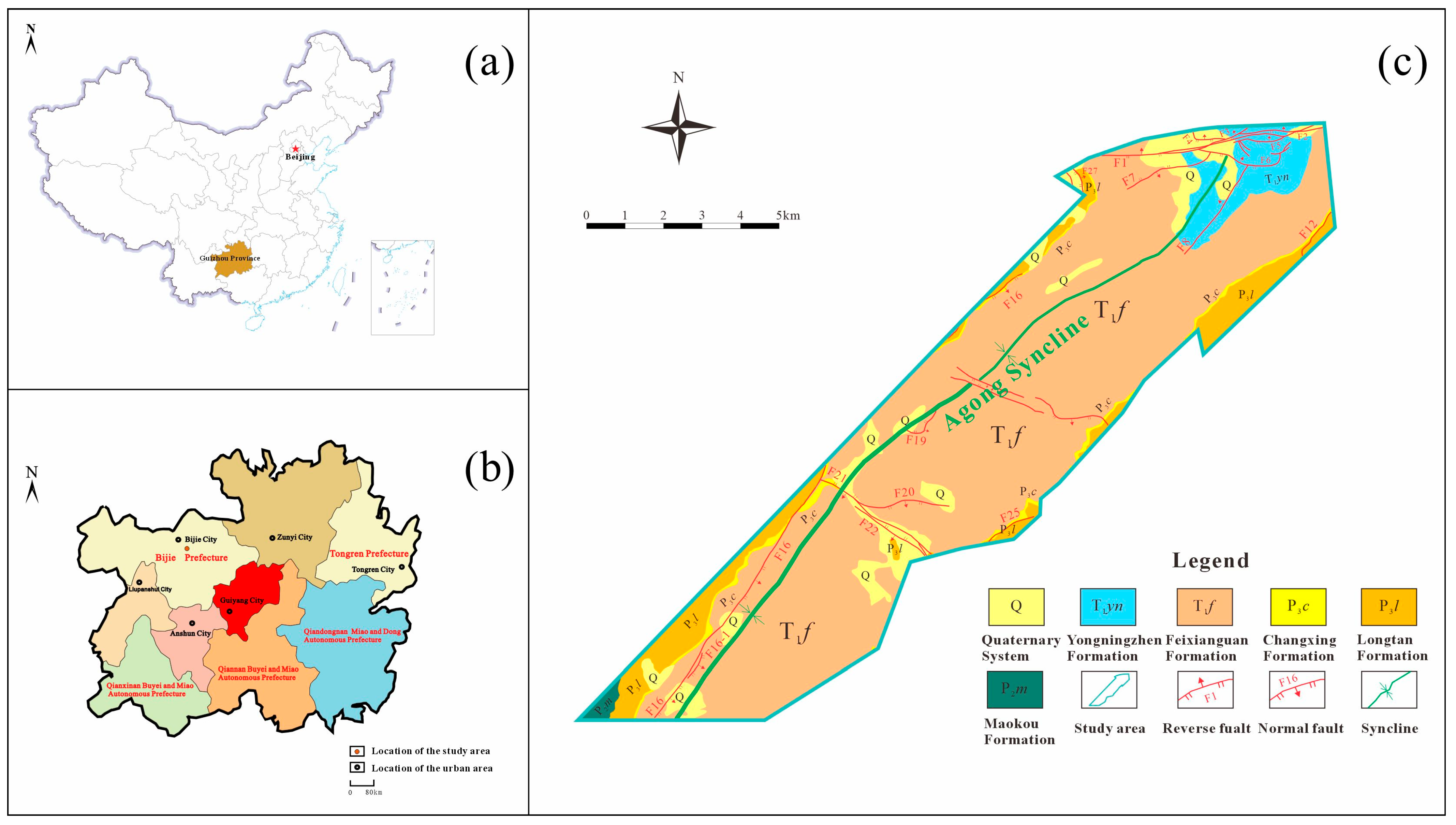

The Wenjiaba Coal Mine Area in the Zhina Coalfield is located in the western part of Zhijin County, Bijie City, Guizhou Province, China. The strata develop from old to new as the Middle Permian Maokou Formation (P

2m), Upper Permian Emeishan Basalt Formation (P

3β), Longtan Formation (P

3l), Changxing Formation (P

3c), Lower Triassic Feixianguan Formation (T

1f), Yongningzhen Formation (T

1yn), and Quaternary (Q) [

12]. The mine area is situated in the middle of the northern segment of the Agong Syncline, presenting an arc-shaped asymmetric syncline structure.

The general strike of the strata is NE-SW, locally varying to nearly EW or SN. The SE limb dips northwest with a dip angle of 4–38°: the outcrop area of coal seams is steeper, with angles of 18–38° (typically 21–26°), while the strata gradually become gentler toward the synclinal axis, with angles of 4–12°. The NW limb dips southeast, featuring steeper strata with dip angles of 30–60° (

Figure 1). In the complex tectonic region of the Wenjiaba mining area in the Zhina Coalfield, the arc-shaped asymmetrical structure of the Agong Syncline and its secondary faults significantly affect the occurrence of coalbed methane. The differential dip angles of the southeast and northwest flanks result in a heterogeneous distribution of the thickness of Coal Seam 16, ranging from 0 to 2.89 m. Tectonic stress, on one hand, promotes the development of endogenous fractures in primary structure coal, while on the other hand, it causes the cleats in the steeply dipping sections to close, reducing permeability. The sealing environment of the syncline core and the gas escape pathways along the fault zones together lead to uneven gas content, which directly impacts the production performance of multi-branch horizontal wells.

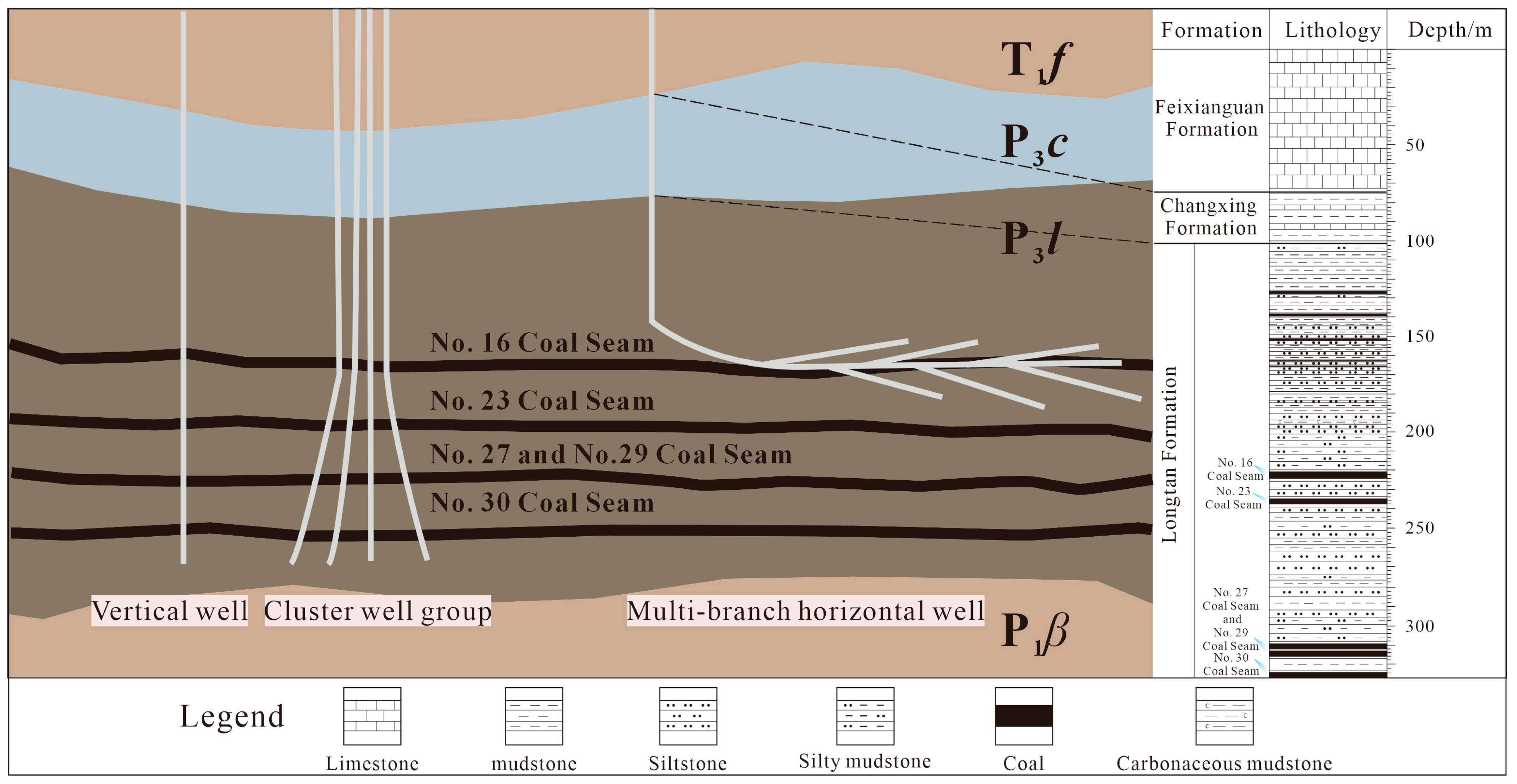

The Zhina Coalfield currently has mature vertical well and cluster well group CBM exploration and mining models, while the multi-branch horizontal well technology is still in its infancy. Among them, the main target coal seams for vertical wells and cluster well groups include Coal Seams No. 16, 23, 27, 29, and 30, whereas multi-branch horizontal wells are used to extract CBM from Coal Seam No. 16. The study area’s stratigraphy includes the Feixianguan Formation, Changxing Formation, and Longtan Formation, with the Longtan Formation containing multiple main coal seams in direct conformable contact with the Changxing Formation (

Figure 2).

The main coal-bearing stratum in the Wenjiaba Coal Mine Area is the Upper Permian Longtan Formation, which contains 30–33 coal seams, including 6 minable seams with a total minable thickness of 7.17–25.93 m (average 16.26 m). The No. 6, 7, 16, 27, and 30 coal seams are minable throughout the area, while the No. 23 coal seam is mostly minable, all of which are primary structure coals. The macroscopic petrographic types are dominated by semi-bright coal and semi-dark to semi-bright coal, intercalated with a small amount of vitrain and fusain. The microscopic petrographic components are mainly vitrinite, followed by inertinite, with a vitrinite reflectance of 2.8–4.1%, belonging to anthracite No. 3.

2.2. Coal Reservoir Characteristics

The main target coal seam of the CBM multi-branch horizontal well W1 is the No. 16 coal seam. In the mine area, the minable thickness of the coal seam is 0–2.89 m (average 1.83 m), with a burial depth of 221 m. The air-dried basis Langmuir volume of the coal seam is 22.57–34.84 m3/t (average 25.30 m3/t), the Langmuir pressure is 0.62–1.66 MPa (average 1.34 MPa), and the air-dried basis gas content is 12.03–17.52 m3/t (average 14.68 m3/t). The coal seam shows strong gas storage capacity but low Langmuir pressure. The mercury injection porosity is 4.72%. The well test permeability for Coal Seam No. 16 is 0.77 × 10−3 μm2. The well test permeability is a reservoir permeability parameter measured through field well testing using the slug method and essentially belongs to the category of effective permeability; the reservoir pressure is 2.95–6.86 MPa (average 4.84 MPa), and the pressure gradient is 0.77–1.11 MPa/100 m (average 0.93 MPa/100 m).

Within the coal mining range, the No. 16 coal seam is shallowly buried, featuring high gas content, high gas saturation, high porosity, low-to-medium permeability, and subnormal-to-normal reservoir pressure. Based on core analysis, the No. 16 coal seam has a mercury injection porosity of 4.72%. Well test data show permeability of 0.77 × 10−3 μm2, which is sufficient to allow proppant placement. The reservoir pressure ranges from 2.95 to 6.86 MPa, and the pressure gradient is between 0.77 and 1.11 MPa/100 m. The moderate formation pressure can drive the fracturing fluid to propagate towards the distal fractures, thereby enhancing the treatment range. Comprehensive evaluation shows that this coal seam has good development potential for CBM.

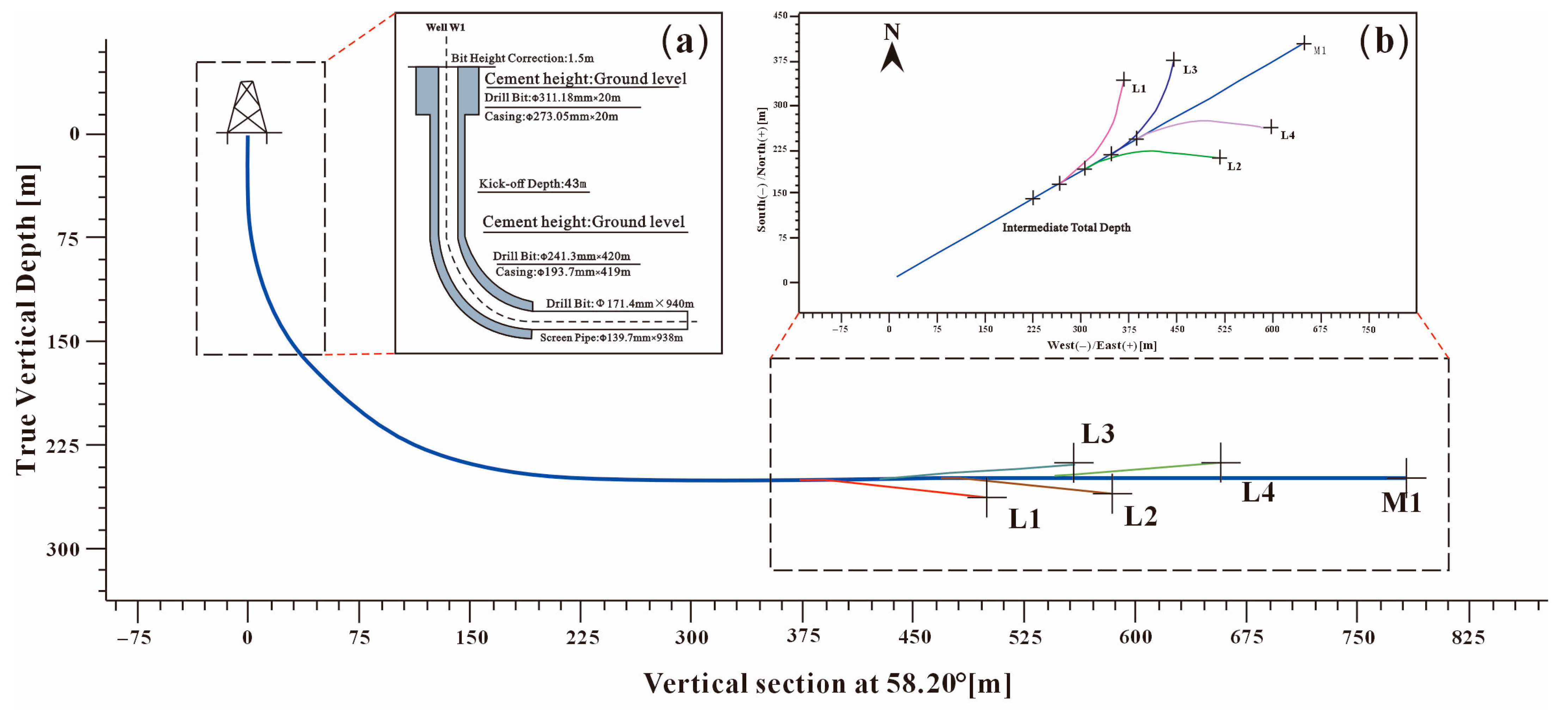

2.3. Construction Status of Multi-Branch Horizontal Well

In 2020, Guizhou Shuikuang Aorui’an Clean Energy Co., Ltd. took the lead in drilling the Wen 1L-1H multi-branch horizontal well in the Wenjiaba No.1 Coal Mine Block. This well integrates drilling, well completion, and stimulation measures, with a main horizontal wellbore as the core and two or more branch wells drilled on both sides, using these bores as flow channels for coalbed methane. The main horizontal wellbore undergoes three-stage drilling: the first spud drills and runs surface casing to seal collapsible and leak-prone formations; the second spud drills to the landing point (target coal seam) and runs technical casing to seal strata above the coal seam; the third spud drills the main horizontal wellbore and branch bores, followed by gas production through screen or open-hole completion (

Figure 3).

For Well W1, the first spud used a large-diameter PDC bit to drill 13.67 m below the bedrock, forming the wellbore foundation after casing running. The second spud was drilled to 397.00 m to enter the No. 16 coal seam, and technical casing was run after completion to ensure wellbore stability. The third spud adopted a steering drilling tool assembly for sequential multi-branch horizontal drilling. Each branch was precisely positioned within the coal seam to achieve effective penetration and coverage, with a horizontal section length of 500.81 m in the third spud stage. Finally, the main branch and all branches completed the scheduled drilling tasks, and a prefabricated screen was run for completion in the third-spud main branch.

5. Impacts of Engineering Factors on Productivity

5.1. Branch Angle

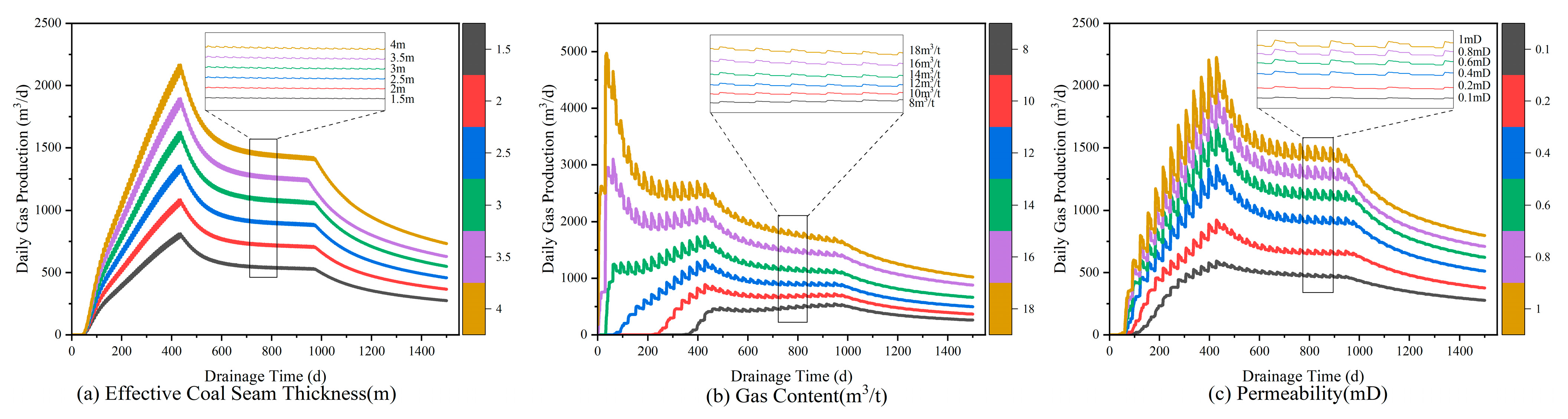

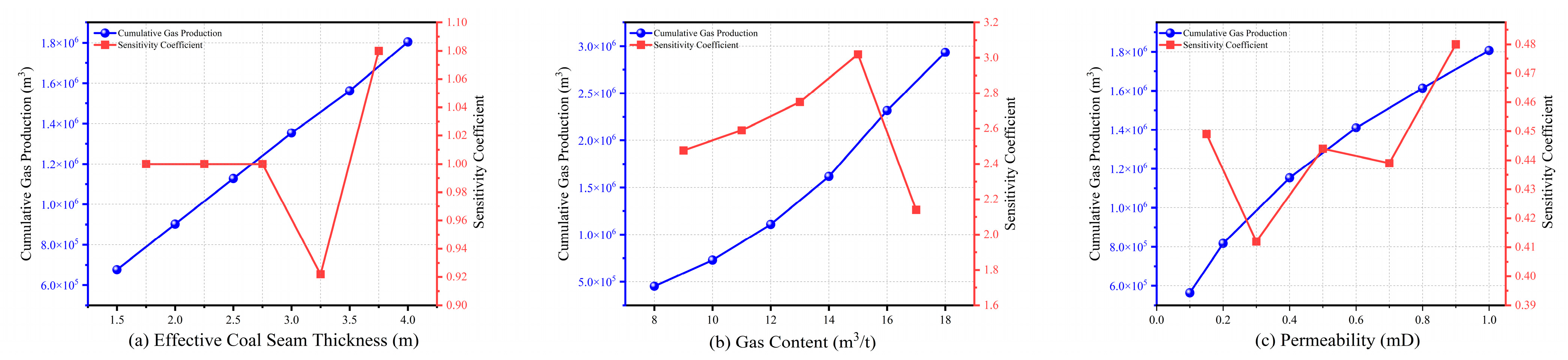

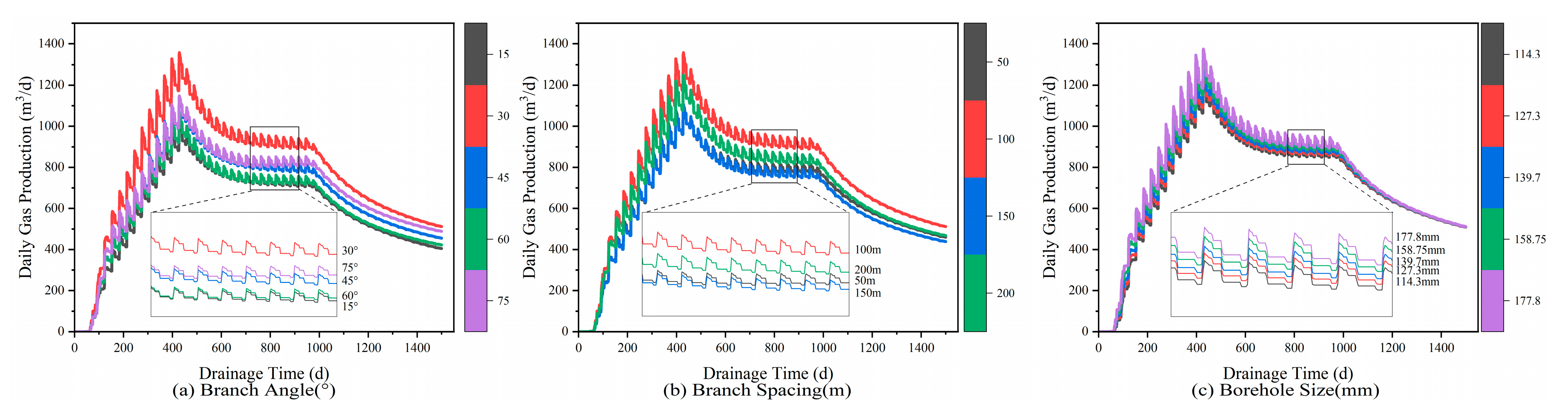

As shown in the 1500-day daily gas production under different branch angles (

Figure 8a) and the sensitivity coefficient diagram of cumulative gas production (

Figure 9a), gas production performance varies significantly with different branch angles. The trends of daily gas production at 15° and 60° branch angles are similar to those of cumulative gas production; the gas production at the 75° branch angle is the lowest, only 0.83 × 10

6 m

3; the cumulative gas production of the well with a 30° branch angle reaches 1.1535 × 10

6 m

3. There is a favorable interval for branch angles, as both low and high branch angles inhibit productivity improvement, so appropriate branch angles need to be selected in actual construction. The cumulative gas production at a 30° branch angle is the highest, while those at 15° and 45° are lower than that at 30°, confirming that a 30° branch angle is the favorable one.

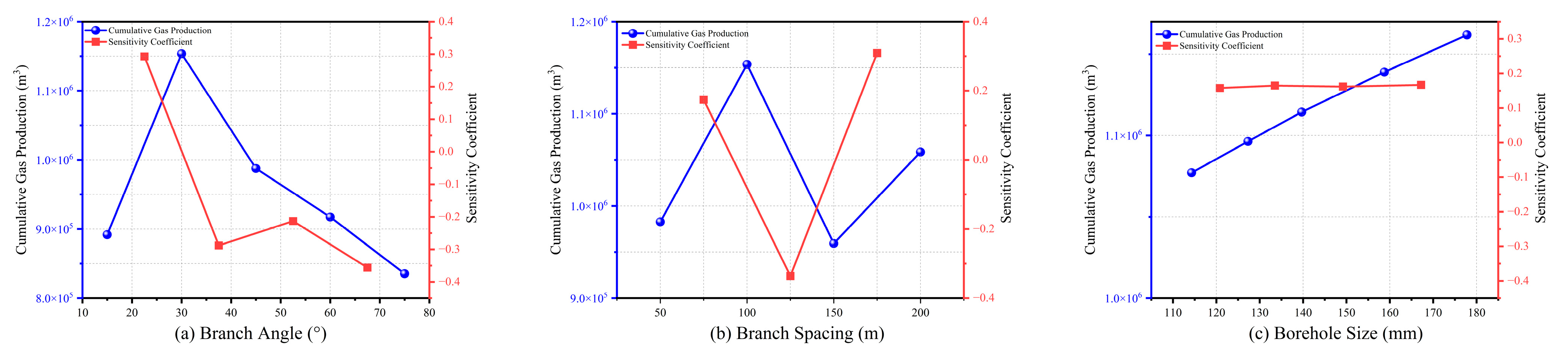

The cumulative gas production of low-branch-angle wells (15°) and high-branch-angle wells (75°) after 1500 days of production is at a low level, while that of multi-branch horizontal wells with medium branch angles is generally higher. Among them, the cumulative gas production at a 30° branch angle is the highest, reaching 1.1535 × 10

6 m

3. Calculations of sensitivity coefficients show that when the branch angle increases from 15° to 30°, gas production shows a positive increase, while from 30° to 75°, gas production decreases to varying degrees. To quantitatively analyze the influence of branch angles on gas production, the absolute values of sensitivity coefficients in each branch angle interval were averaged, resulting in an average sensitivity coefficient of 0.2875. The results of engineering parameter optimization show that a 30° branch angle is the optimal value, which is consistent with the conclusion of Tang et al. [

3] that “25° to 35° is an efficient branch angle range” in the simulation of feather-shaped branch horizontal wells in the Ordos Basin. This confirms the mechanical mechanism that medium angles can balance the pressure drop range and efficiency.

Nonlinear Effects of Branch Angle and Physical Mechanisms

To analyze the mechanism by which branch angles affect multi-branch horizontal wells, reservoir pressure monitoring points were set up 50 m away from the main stem and branch wells, with an initial reservoir pressure of 2950 kPa. The reservoir pressure at 1500 days was recorded, and pressure distribution maps at three time points—547 days, 1004 days, and 1500 days—are shown in

Figure 10. It can be observed that throughout the production period, the pressure reduction effect in low-angle reservoirs is better than that in medium- and high-branch-angle reservoirs. High-angle reservoirs reach a near-saturated state of pressure reduction within the first 547 days, with subsequent pressure reductions being less than those in low and medium angles, and the final reservoir pressure is also higher than that in other angles. Wells with low branch angles are affected by the superposition effect of drawdown funnels between the main stem and branches, promoting rapid reservoir pressure decline, resulting in a better pressure reduction effect during the early drainage period compared to medium and high branch angles. However, due to the narrow fan-shaped desorption range, this leads to reduced cumulative gas production [

3]. Although wells with high branch angles have the potential for large-area pressure relief, the pressure reduction rate per unit area significantly attenuates, characterized by a slow pressure drop rate, and the final pressure is higher than that of other branch angles. The reason is that the diffusion of the pressure drop funnel is hindered, and the pressure reduction in the distal reservoir is insufficient to reach the critical desorption pressure, resulting in low desorption efficiency. Wells with medium branch angles (30–60°) form a continuous pressure depletion zone within the well control range through the synergistic effect of pressure reduction between branches, offering excellent pressure reduction effects while also having a large diffusion area. This balances the pressure relief range and reservoir pressure reduction effects well, thereby increasing gas production. The design of branch angles for multi-branch horizontal wells should optimize the dynamic balance between the pressure relief range and pressure reduction rate to maximize reservoir stimulation efficiency [

3,

25].

The impact of branch angles on gas production in multi-branch horizontal wells for coalbed methane is essentially the result of a dynamic balance between the depressurization area and the interference effect. As the angle increases, the spatial distribution of the branch boreholes can significantly expand the reservoir control range. This is due to the increased spacing at the ends of the branches and the enhanced efficiency of fracture communication, especially in reservoirs with anisotropic permeability. A branch angle of around 45° can intersect the main permeability direction diagonally, maximizing the desorption coverage area. For example, in the spindle-shaped wells of the Wenjiaba block, when the angle increased from 60° to 80°, the peak daily gas production increased by 51%.

However, after the angle exceeds 45°, the overlapping area at the ends of the branches expands, leading to intensified interference effects. The interference intensity of a 60° branch is 2.3 times higher than that of a 30° branch. Meanwhile, the flow resistance of fluids converging into the main wellbore increases. When the angle is greater than 60°, the frictional pressure drop loss increases sharply by 15–20%, offsetting the gains from the increased depressurization area. This is highly consistent with the simulation results of this study, where wells with medium branch angles have greater gas production potential.

5.2. Branch Spacing

Figure 8b shows the daily gas production results of multi-branch horizontal wells under different branch spacings. Multi-branch horizontal wells with different branch spacings all exhibit a trend of initial increase, followed by stabilization, and then decrease. The cumulative gas production of 50 m and 150 m branch spacings is the lowest, being 0.9827 × 10

6 m

3 and 0.9593 × 10

6 m

3, respectively, while that of 100 m branch spacing is the highest, reaching 1.1535 × 10

6 m

3 (

Figure 9b). Starting from 50 m, with each 50 m increase in branch spacing up to 200 m, the corresponding sensitivity coefficients are 0.174, −0.336, and 0.309, with an average absolute sensitivity coefficient of 0.273. When the branch spacing increases from 50 m to 100 m, gas production shows a positive trend, while when the spacing is greater than 100 m, the sensitivity coefficient is negative, indicating that an increase in branch spacing has a negative impact on gas production. The optimal branch spacing for multi-branch horizontal wells is around 100 m (

Figure 8b). However, the production advantage of a 100 m branch spacing in this study differs from the 150 m spacing recommended in simulations of the Surat Basin in Australia. The reason for this difference lies in the fact that the coal seams in the Zhina Coalfield are relatively thin. In thinner coal seams, a dense branch layout is more conducive to controlling the limited reservoir volume. In contrast, the main coal seams in the Surat Basin have a thickness of 5 to 8 m, necessitating a larger spacing to avoid the superposition loss due to pressure drop funnels. In the Zhina Coalfield, thin coal seams require more densely spaced branches primarily because they naturally have a higher density of fractures, forming a high-permeability network. A smaller well spacing can efficiently cover the gas production area, and thin coal seams are often interbedded with sandstone, which accelerates drainage and pressure reduction. Dense well spacing can quickly form a pressure drawdown funnel. In contrast, the thick coal seams in the Surat Basin of Australia require a larger branch spacing. The core contradiction lies in the fact that the thick coal layers are mostly deposited in deeper areas where higher stress leads to a sharp decrease in permeability. The low permeability increases the resistance to fluid flow significantly, and a larger well spacing can prevent competition in pressure reduction between wells and the risk of well flooding caused by the rapid advance of highly mineralized water from deep areas. At the same time, a “fewer wells, higher production” model can balance the economic viability of the low-permeability thick coal seams.

CBM is produced through a series of processes such as “drainage-pressure reduction-desorption-diffusion-seepage” [

26,

27]. During production, as the bottom-hole pressure decreases, the difference between the fluid pressure and wellbore pressure continues to increase, with the largest pressure difference around the wellbore decreasing outward, forming a drawdown funnel near the wellbore. By monitoring the reservoir pressure between branches at a position 100 m parallel from the main stem under different branch spacings, the reservoir pressure curves are plotted as

Figure 11. It can be seen that the pressure drop effect of 50 m branch spacing is higher than that of 100 m and 200 m branch spacings [

28], while the pressure drop effect of large branch spacing is hindered in the middle, but its coal seam desorption range is higher than that of medium and low branch spacings. Correspondingly, the pressure drop effect of low branch spacing wells is far better than the other two, but the desorption range is limited. This is because when the branch spacing is too small, the drawdown funnels formed in the reservoir overlap, causing the reservoir pressure to drop rapidly. Low-spacing wells are limited by the desorption range of the coal reservoir, resulting in lower productivity than high-spacing multi-branch horizontal wells. For multi-branch horizontal wells with too large branch spacing, although the desorption area can be expanded, the drawdown funnel diffuses slowly, leading to insufficient pressure drop within the well control range and difficult CBM desorption. Therefore, appropriate branch spacing can promote the synergistic effect between branches, achieve effective reservoir pressure reduction, and improve the recovery rate within the well control range [

29,

30].

Nonlinear Effects of Branch Spacing and Physical Mechanisms

The impact of branch spacing on gas production in multi-branch horizontal wells for coalbed methane is essentially the result of a dynamic balance between depressurization area control and inter-branch interference effects. When the branch spacing is too small, the pressure drawdown zones formed by each branch borehole overlap significantly, intensifying the “inter-branch interference” phenomenon. This interference significantly reduces the effective depressurization range of a single branch and weakens the pressure gradient in the overlapping areas at the branch ends, thereby lowering the desorption rate of coalbed methane.

Hydrodynamic simulation experiments have shown that when the number of branches exceeds four and the spacing is less than 150 m, the intensity of inter-branch interference increases sharply. The underlying mechanism is that dense branches create local low-pressure “shadow zones,” reducing the desorption driving pressure difference. Meanwhile, the convergence of fluids into the main wellbore exacerbates frictional pressure drop losses, further suppressing production enhancement.

As the branch spacing increases, the depressurization area controlled by a single branch expands significantly. This “area superposition effect” is due to the matching of branch spacing with the propagation characteristics of the coalbed pressure wave. When the spacing is close to the radius of pressure wave propagation, the pressure drawdown interference between branches is reduced, and the overall controlled volume achieves seamless coverage. In the Qinshui Basin, wells with optimized spacing of 250 m have a 40% higher peak gas production and an extended stable production period of eight months compared to wells with 150 m spacing. However, there is a critical threshold: when the spacing exceeds 300 m, “island areas” that are not affected by the pressure wave are formed between branches, leading to fragmented controlled areas.

5.3. Borehole Size

Simulation results of multi-branch horizontal wells under different borehole sizes (

Figure 8c) show that borehole size has a minimal impact on daily gas production, with similar trends in daily gas production curves. The cumulative gas production after 1500 days of production reaches a maximum of 1.161 × 10

6 m

3 and a minimum of 1.07 × 10

6 m

3, with a small range between the maximum and minimum values. Starting from 114.3 mm, as the size increases to 177.8 mm, the corresponding sensitivity coefficients are 0.158, 0.165, 0.162, and 0.167, with an average sensitivity coefficient of 0.163 (

Figure 9c). The influence of borehole size on gas production is less significant than that of branch angles and spacing. Larger diameters are more favorable for CBM production.

Small-diameter branch boreholes significantly increase flow resistance and are prone to wellbore collapse and coal powder plugging in the coal seam section [

31]. Larger-diameter branch boreholes reduce frictional losses of gas–water two-phase flow in the wellbore and enhance pressure drop transmission efficiency [

32,

33]. Additionally, borehole size regulates the reservoir stress sensitivity effect: smaller boreholes exacerbate stress concentration, leading to permeability decline in the near-wellbore area, while larger boreholes reduce stress gradients and delay permeability decline by expanding the contact area between the wellbore and coal matrix. Borehole size also affects stimulation efficiency by influencing fracturing fluid performance: larger boreholes provide more flow space for fracturing fluids, improving proppant transport efficiency and enhancing fracture conductivity. In summary, borehole size is positively correlated with productivity, but an economic threshold exists, requiring comprehensive consideration of drilling costs, reservoir properties, and fracturing parameters. Additionally, the weak sensitivity of wellbore size to production capacity in this study aligns with the viewpoint of Yu et al. [

34], who proposed that “there is an economic threshold for the impact of wellbore size.” Their numerical simulations indicated that after the diameter exceeds 177.8 mm, the increase in production capacity is less than 5%, while drilling costs rise by more than 20%. This suggests that in practical engineering, it is necessary to consider both technical feasibility and economic viability.

Although the borehole size has a relatively low sensitivity to the production capacity of multi-branch horizontal wells, the economic trade-off between production enhancement and drilling cost remains a core consideration in the design and construction. The production capacity mainly increases with the increase in wellbore length or the number of branches, but there is a significant diminishing effect: while the extension of wellbore length can significantly improve the initial production capacity, the additional revenue per meter gradually decreases. Similarly, increasing the number of branches also faces declining marginal benefits. With a fixed wellbore length, the cost increases rigidly with the addition of branches, and drilling costs climb linearly with the length or number of branches. Therefore, the construction of multi-branch horizontal wells should focus on design optimization to avoid blindly increasing the number of branches or wellbore length, cost control through technological iteration to reduce costs and increase efficiency, and dynamic evaluation by establishing a simple dynamic model to calculate marginal cost and marginal revenue in real time.

5.4. Engineering Parameters Economic Feasibility Analysis

The optimization of engineering parameters for multi-branch horizontal wells depends not only on the enhancement of production capacity but also on economic rationality, balancing drilling costs with production benefits. Based on the engineering data from the Zhina Coalfield in 2023, conducting an economic feasibility analysis of engineering parameters is very necessary for industry practitioners.

A cost–benefit analysis of branch angles shows that, based on local engineering data, the drilling cost per branch at a 30° branch angle is 12% higher than that at a 15° angle, mainly due to the increased complexity and torque requirements of high-angle directional drilling; however, over a 1500-day simulation period, the cumulative gas production at a 30° angle is 23% higher than at a 15° angle. At a natural gas price of 1.8 yuan/m3, this can bring an additional revenue of 414,000 yuan. After considering both costs and benefits, the net present value (NPV) of the 30° angle is 1.8 times that of the 15° angle, confirming its economic optimality.

Regarding branch spacing, when reducing the spacing from 150 m to 100 m, the total drilling cost per well increases due to the addition of more branches, but when increasing from 50 m to 100 m, the cost decreases due to the reduction in redundant branches; in terms of production capacity, the cumulative gas production at a spacing of 100 m is 17% higher than at 150 m and only 8% lower than at 50 m. Ultimately, the NPV of the 100 m spacing is 1.5 times that of the 50 m spacing and 1.3 times that of the 150 m spacing, achieving the best balance between cost control and production capacity utilization.

When the size increases from 114.3 mm to 177.8 mm, the cumulative gas production over 1500 days increases by approximately 8.5%. This is mainly because larger wellbores can reduce friction losses in two-phase flow of gas and water, enhance the efficiency of pressure drop transmission, and alleviate the decrease in permeability caused by stress sensitivity. However, in terms of costs, increasing the wellbore size significantly increases drilling costs. The cost per meter for larger wellbores is 18% higher than that for smaller ones, and beyond 177.8 mm, the cost increase exceeds 20% while the production capacity improvement is less than 5%, creating a clear cost–benefit imbalance. Considering the characteristics of thin coal seams in the Zhina Coalfield, a wellbore size of around 158.75 mm is the optimal choice: its cost is controllable, production capacity is improved compared to the smallest size, and it can meet the stability requirements of thin coal seam wellbores. Larger sizes, due to cost increases far exceeding production benefits, are not economically feasible in this study area.