Dry Anaerobic Digestion of Selectively Collected Biowaste: Technological Advances, Process Optimization and Energy Recovery Perspectives

Abstract

1. Introduction

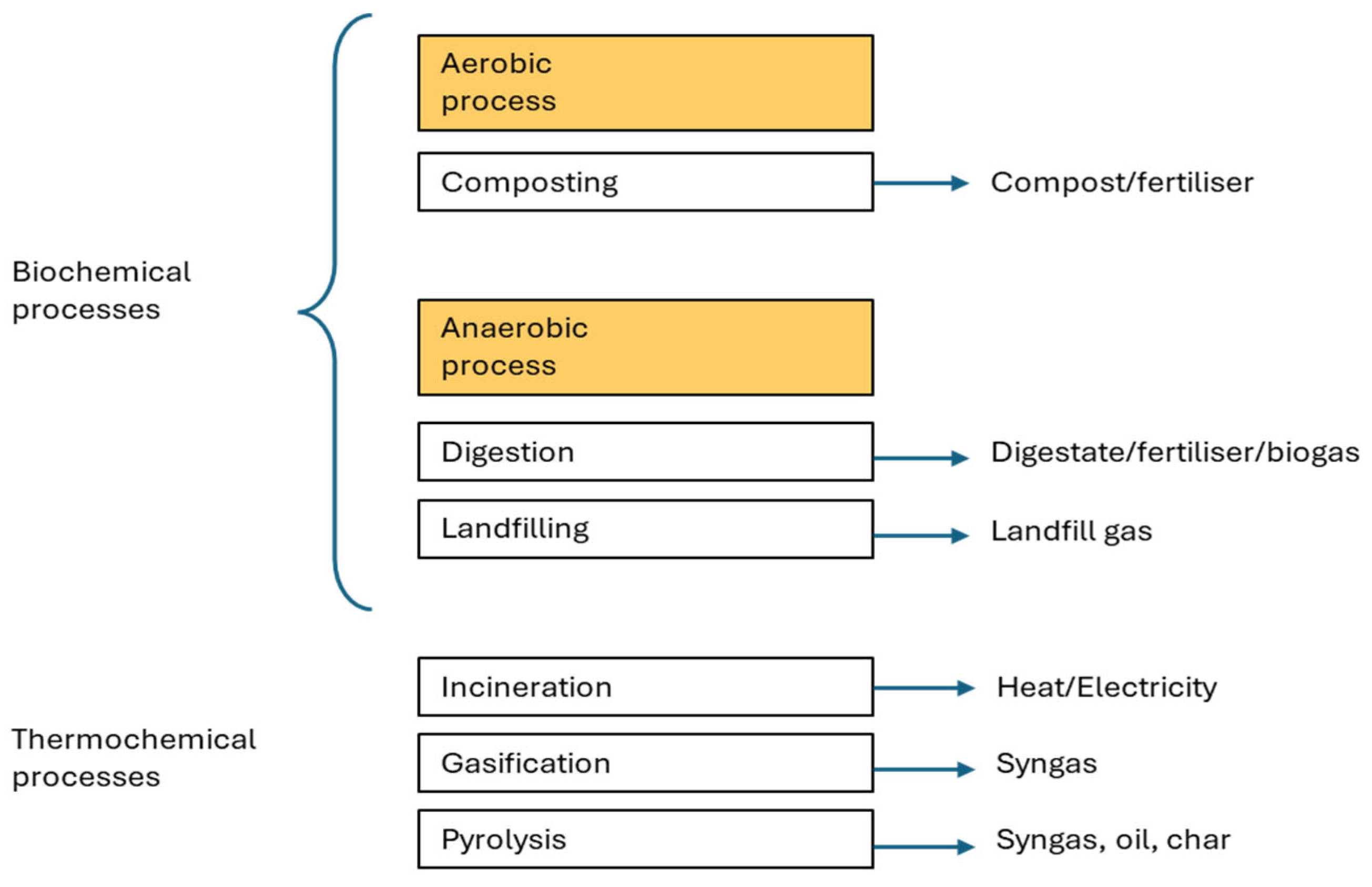

2. Characterization and Pretreatment of Organic Waste for Dry Anaerobic Digestion

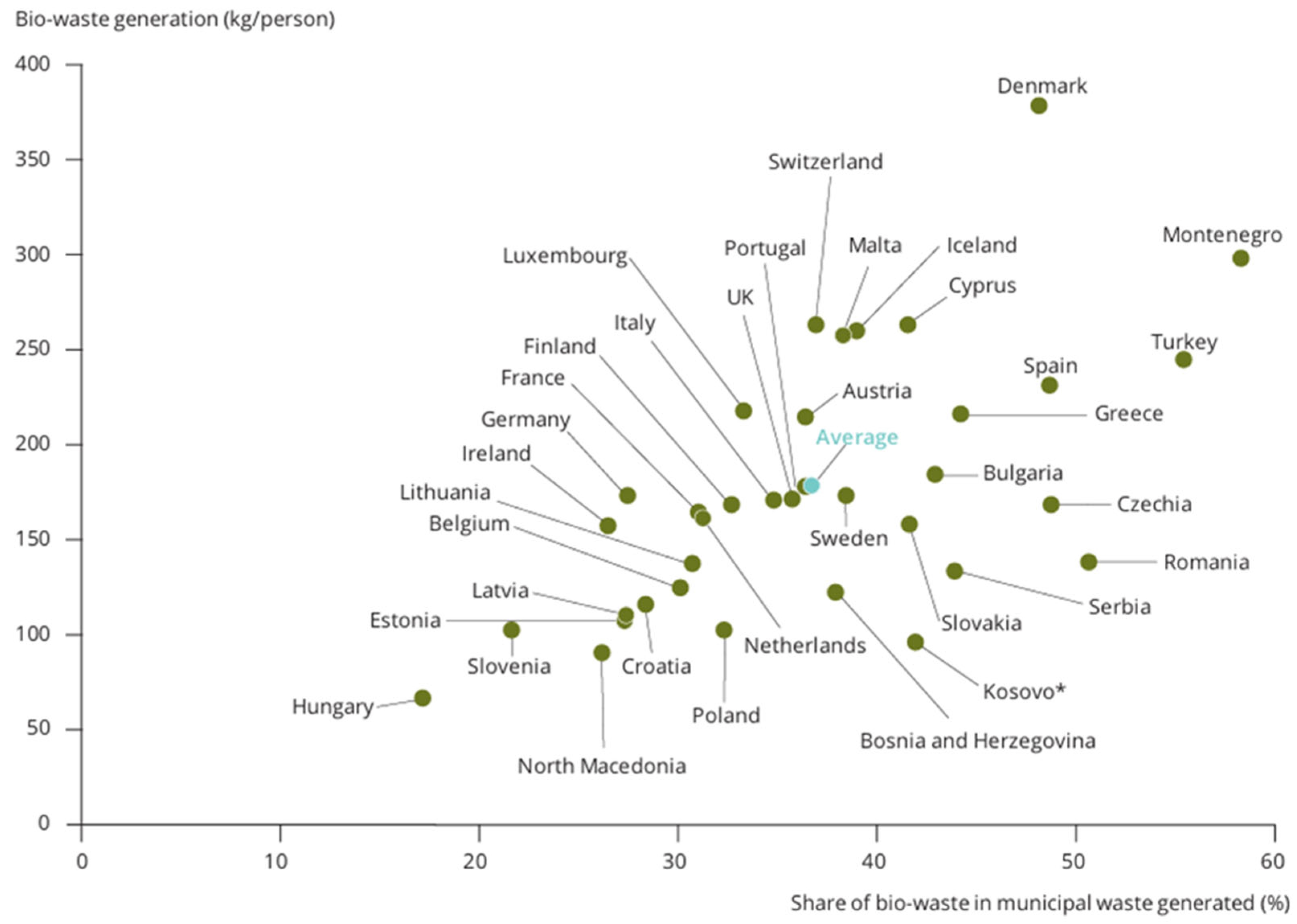

2.1. Quantitative Aspects of Selective Biowaste Collection in Municipal Waste Management

2.2. Biochemical Characteristics of Organic Waste Streams and Their Potential for Anaerobic Digestion

2.3. Pre-Treatment Methods for Organic Waste Prior to Anaerobic Digestion

3. Key Technological Aspects of Dry Anaerobic Digestion

3.1. Overview of Used Digesters and Feeding/Unloading Techniques

3.2. Comparison of Dry and Wet Fermentation

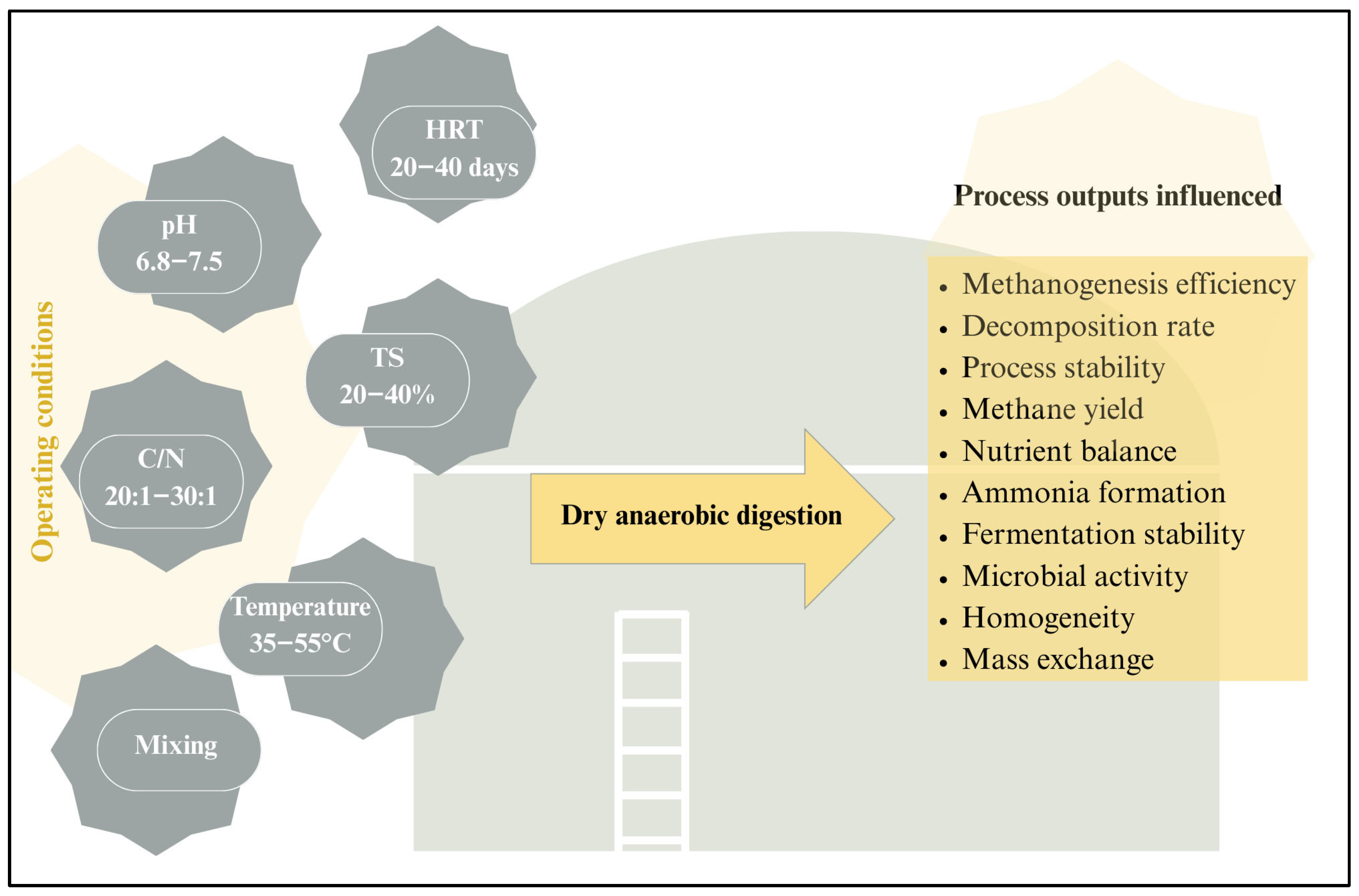

3.3. Process Parameters Overview

3.4. Analysis of Factors Limiting Process Performance

3.5. Selected Intensification Techniques

4. Energy Efficiency and Economic Aspects of Dry Anaerobic Digestion

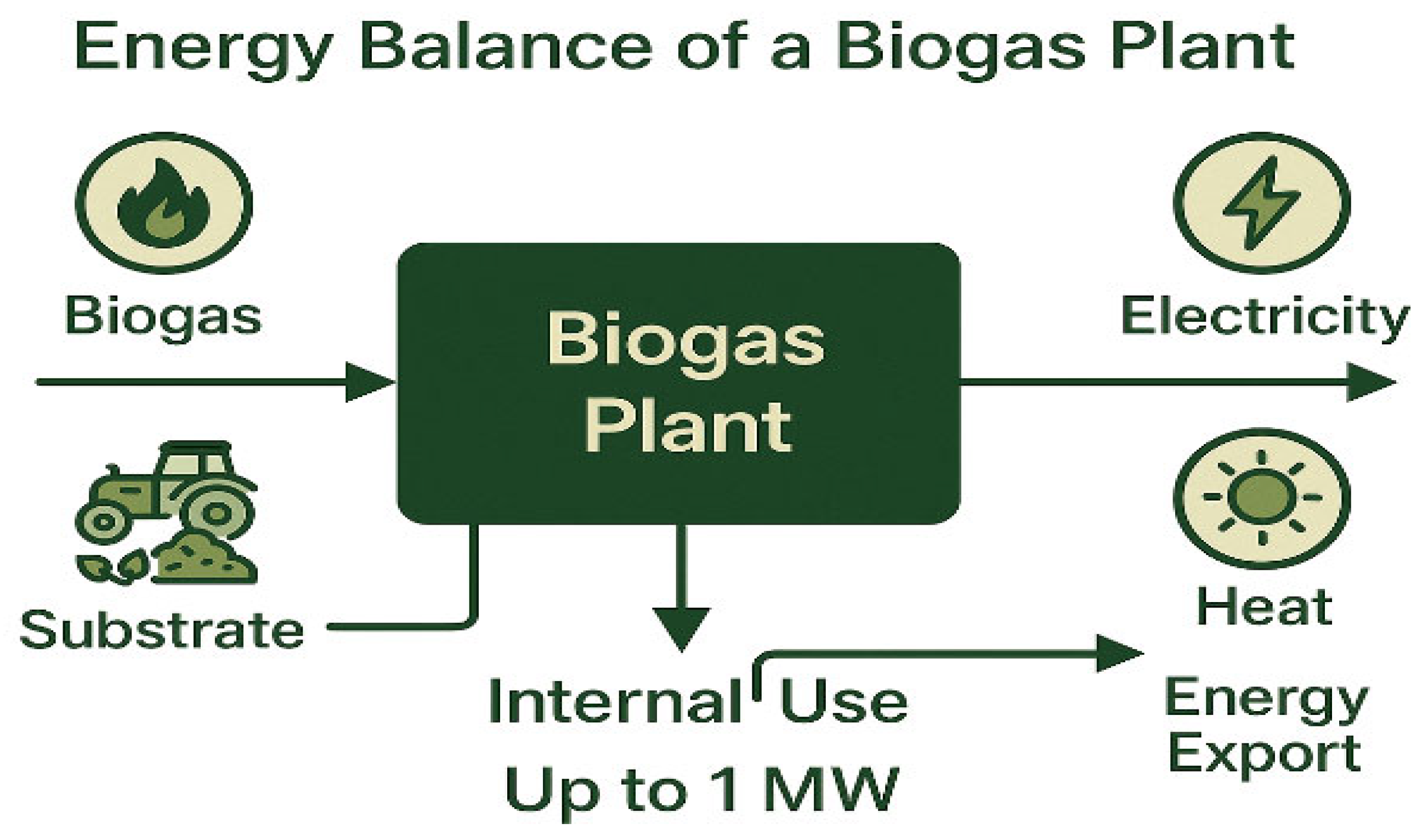

4.1. Biogas Plant Energy Balance

4.2. Cost and Revenue Analysis

4.3. The Importance of Biogas in the Energy Transformation

5. Environmental Impact and Legal Regulations

5.1. Comparison of the Carbon Footprint of Dry Anaerobic Digestion and Other Organic Waste Treatment Methods (Composting, Landfilling, Wet Anaerobic Digestion)

5.2. Legal Framework for Waste Management in the European Union and Globally

5.3. The Role of Dry Anaerobic Digestion in the Circular Economy: Soil Carbon Sequestration and Greenhouse Gas Emission Reduction

- Methane emissions reduction from organic waste: Diverting biowaste from landfilling to DAD prevents uncontrolled anaerobic decomposition, which would otherwise generate significant amounts of methane (CH4) [117].

- Replacement of synthetic fertilizers: The use of digestate reduces reliance on mineral fertilizers, the production of which is associated with high carbon dioxide (CO2) emissions [161].

- Production of green energy: Biogas generated through DAD can be converted into electricity, heat, or upgraded to biomethane, thereby reducing dependence on fossil fuels.

6. Priority Research Directions and Policy and Strategic Planning Recommendations for Municipal Integration of DAD Systems

6.1. Overview of Mature DAD Technologies and Emerging Hybrid Optimization Methods

6.2. Holistic Process Optimization in DAD: Addressing Limitations Through Synergistic Engineering

6.3. From Waste to Value: Economic and Governance Pathways for Circular DAD Integration

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AD | Anaerobic Digestion |

| BCM | Billion Cubic Meters |

| CCS | Carbon Capture and Storage |

| CCU | Carbon Capture and Utilization |

| CE | Circular Economy |

| C/N | Carbon-to-Nitrogen Ratio |

| CSTR | Continuous Stirred-Tank Reactor |

| DAD | Dry Anaerobic Digestion |

| EfW | Energy from Waste |

| EU27 | European Union Countries |

| F/T | Freezing/Thawing |

| GHG | Greenhouse Gas |

| HRT | Hydraulic Retention Time |

| LCA | Life Cycle Assessment |

| KPGO | Polish National Waste Management Plan |

| MW | Megawatt |

| OFMSW | Organic Fraction of Municipal Solid Waste |

| OLR | Organic Loading Rate |

| PFR | Plug-Flow Reactor |

| PLN | Polish Zloty (currency) |

| PP MP | Polypropylene Microplastics |

| PPP | public-private partnership |

| ROS | Reactive Oxygen Species |

| S/I | Substrate To Inoculum Ratio |

| SOC | Soil Organic Carbon |

| SRB | Sulphate-Reducing Bacteria |

| SRT | Solid Retention Time |

| TPA | Tons per Annum |

| TS | Total Solids |

| TWh | Terawatt-hour |

| VFA | Volatile Fatty Acids |

| VS | Volatile Solids |

| WAD | Wet Anaerobic Digestion |

| WtE | Waste to Energy |

References

- Guisado, J.M.; Becerra, J.A.; Chacartegui, R. Scenarios for Energy Recovery from Slaughterhouse Wastes in Europe. iScience 2025, 28, 112943. [Google Scholar] [CrossRef]

- Yangin-Gomec, C.; Dalkılıç, K.; Perendeci, A.; Güngörmüşler, M.; Somorin, T.; Roussel, J.; Varol, M.; Ramos, A.; Van Hullebusch, E.D.; Trubetskaya, A.; et al. Thermochemical Processing of Organic Wastes for Sustainable Valorisation and Energy Recovery: A Review of Recent Contributions to the Field. Biomass Bioenergy 2025, 201, 108122. [Google Scholar] [CrossRef]

- Lu, C.-C.; Lin, Y.-P.; Hwu, F.-Y. Impact of Organic Biomass Waste Composition on Anaerobic Acid Fermentation. Biomass Bioenergy 2025, 200, 108004. [Google Scholar] [CrossRef]

- Jasińska, A.; Grosser, A.; Meers, E.; Piłyp, D. Stimulating Methane Production from Poultry Manure Digest with Sewage Sludge and Organic Waste by Thermal Pretreatment and Adding Iron or Sodium Hydroxide. Energies 2024, 17, 2679. [Google Scholar] [CrossRef]

- Macherzyński, B.; Popowska-Nowak, E.; Włodarczyk-Makuła, M.; Bień, B.; Wszelaka-Rylik, M. Intensification of Energy Production in the Anaerobic Digestion Process of Sewage Sludge Using Enzymatic Disintegration. Energies 2024, 18, 11. [Google Scholar] [CrossRef]

- Cai, Y.; Cheng, M.; Liu, X.; Qu, G.; Zou, H.; Li, H.; Zhao, S.; Ren, N. Effects of Copper and Zinc on Three Stages-Anaerobic Fermentation of Organic Wastes. Environ. Res. 2025, 284, 122216. [Google Scholar] [CrossRef]

- Zawieja, I. Comparison of the Efficiency of Organic Compounds Decomposition in Sewage Sludge Using Selected Physical, Chemical and Biological Methods. Desalination Water Treat. 2023, 301, 277–288. [Google Scholar] [CrossRef]

- Sobhi, M.; Elsamahy, T.; Zakaria, E.; Gaballah, M.S.; Zhu, F.; Hu, X.; Zhou, C.; Guo, J.; Huo, S.; Dong, R. Characteristics, Limitations and Global Regulations in the Use of Biogas Digestate as Fertilizer: A Comprehensive Overview. Sci. Total Environ. 2024, 957, 177855. [Google Scholar] [CrossRef] [PubMed]

- Adnane, I.; Taoumi, H.; Lahrech, K.; Fertahi, S.E.; Ghodbane, M. From Waste to Resource: Biogas and Digestate Valorization Strategies for Sustainable Energy and Agriculture. Biomass Bioenergy 2025, 200, 108006. [Google Scholar] [CrossRef]

- Grobelak, A.; Bień, B.; Sławczyk, D.; Bień, J. Conditioning Biomass for Biogas Plants: Innovative Pre-Treatment and Digestate Valorization Techniques to Enhance Soil Health and Fertility. Sustainability 2025, 17, 3289. [Google Scholar] [CrossRef]

- Chen, J.; Ye, X.; Jiang, M.; Xia, B.; Skitmore, M.; Liu, Y. Impact of Video Information Intervention on Public Perceptions of Waste-to-Energy Incineration Facilities: An Information Processing Theory Perspective. Waste Manag. 2025, 203, 114890. [Google Scholar] [CrossRef]

- Baxter, J.; Maclaren, V.; Bayne, J. How Energy from Waste (EFW) Facilities Impact Waste Diversion Behavior: A Case Study of Ontario, Canada. Resour. Conserv. Recycl. 2020, 158, 104759. [Google Scholar] [CrossRef]

- Strobel, R.; Waldner, M.H.; Gablinger, H. Highly Efficient Combustion with Low Excess Air in a Modern Energy-from-Waste (EfW) Plant. Waste Manag. 2018, 73, 301–306. [Google Scholar] [CrossRef]

- Levidow, L.; Upham, P. Linking the Multi-Level Perspective with Social Representations Theory: Gasifiers as a Niche Innovation Reinforcing the Energy-from-Waste (EfW) Regime. Technol. Forecast. Soc. Chang. 2017, 120, 1–13. [Google Scholar] [CrossRef]

- Sanjaya, E.; Abbas, A. Plasma Gasification as an Alternative Energy-from-Waste (EFW) Technology for the Circular Economy: An Environmental Review. Resour. Conserv. Recycl. 2023, 189, 106730. [Google Scholar] [CrossRef]

- Tahir, M.H.; Vasudev, V.; Ibrahim, M.; Alotaibi, M.O.; Abbas, F.M.; Asseri, T.A.Y.; Irfan, R.M. Optimizing Waste Valorization: Catalytic Co-Pyrolysis of Cabbage Waste and Tire Waste for Enhanced Bio-Oil and Syngas Production Utilizing Char as a Reforming Catalyst. RSC Adv. 2025, 15, 19937–19946. [Google Scholar] [CrossRef]

- Galavote, T.; Yamane, L.H.; Cano, N.S.D.S.L.; Chaves, G.D.L.D.; Siman, R.R. Waste Management Policies and Impact of Landfill Diversion Goals in Gas-to-Energy Recovery. Proc. Inst. Civ. Eng.-Waste Resour. Manag. 2024, 177, 122–138. [Google Scholar] [CrossRef]

- Siddiqui, F.Z.; Rafey, A.; Pandey, S.; Khan, M.E. Pilot Demonstration of Clean Technology for Landfill Gas Recovery in India—A Case Study. Clean. Chem. Eng. 2022, 2, 100024. [Google Scholar] [CrossRef]

- Ma, H.; Chen, P.; Hong, F.; Shi, Y.; Lu, H.; Jiang, W.; Wang, C.; Si, B. Food Waste Valorization Using a Novel System Integrated Dry Fermentation, Fractionation and Torrefaction. Chem. Eng. J. 2025, 513, 163117. [Google Scholar] [CrossRef]

- Lyu, H.; Ma, H.; Hong, F.; Si, B.; Lu, H.; Jiang, W. Promoting Dry Anaerobic Fermentation for Biohydrogen and Volatile Fatty Acids Production via Adding Milli-Magnetite. Int. J. Hydrogen Energy 2025, 109, 1081–1089. [Google Scholar] [CrossRef]

- Li, D.; Sun, M.; Xu, J.; Gong, T.; Ye, M.; Xiao, Y.; Yang, T. Effect of Biochar Derived from Biogas Residue on Methane Production during Dry Anaerobic Fermentation of Kitchen Waste. Waste Manag. 2022, 149, 70–78. [Google Scholar] [CrossRef]

- Yesil, H.; Calli, B.; Tugtas, A.E. A Hybrid Dry-Fermentation and Membrane Contactor System: Enhanced Volatile Fatty Acid (VFA) Production and Recovery from Organic Solid Wastes. Water Res. 2021, 192, 116831. [Google Scholar] [CrossRef]

- European Environmental Agency. Biowaste in Europe—Turning Challenges into Opportunities; European Environmental Agency: Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Separate Collection of Bio-Waste in Europe. Available online: https://www.compostnetwork.info/policy/biowaste-in-europe/separate-collection/ (accessed on 20 June 2025).

- Gilbert, J.; Siebert, S. Compost and Digestate for a Circular Bioeconomy; European Compost Network: Bochum, Germany, 2022. [Google Scholar]

- Favoino, E.; Giavini, M. Bio-Waste Generation in the EU: Current Capture Levels and Future Potentials; Bio-Based Industries Consortium: Brussels, Belgium, 2020. [Google Scholar]

- Ana, J.B.; Moreno, R.; Gomes, M.I.; Silveira, A. Decision Making Methodology for Biowaste Management Planning Support: Addressing an EU Directive. J. Clean. Prod. 2025, 517, 145826. [Google Scholar] [CrossRef]

- Statistics Poland. Local Data Bank—Municipal Waste; Statistics Poland: Warsaw, Poland, 2024.

- den Boer, E. Bioodpady—Wyzwanie nie Tylko dla Gmin—Recykling—Tom nr 2 (2017)—BazTech—Yadda; Biorecycling: Wrocław, Poland, 2017; Volume 2. [Google Scholar]

- Czekała, W. Selective Collection and Management of Biowaste from the Municipal Sector in Poland: A Review. Appl. Sci. 2023, 13, 11015. [Google Scholar] [CrossRef]

- Bernat, K.; Waszczyłko-Miłkowska, B.; Kamińska-Borak, J.; Zaborowska, M.; Godlewska, A.; Dębowska, D.; Napiórkowski, K.; Jóżwiak, M.; Łaba, R. Bioodpady Komunalne Posegregowane i Poddawane Recyklingowi u Źródła w Polsce; Instytut Ochrony Środowiska—Państwowy Instytut Badawczy: Warsaw, Poland, 2025. [Google Scholar]

- Ribić, B.; Voća, N. Biowaste as a Feedstock for Biogas Production—A Case Study. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 3970–3979. [Google Scholar] [CrossRef]

- Mrosso, R.; Mecha, A.C.; Kiplagat, J. Characterization of Kitchen and Municipal Organic Waste for Biogas Production: Effect of Parameters. Heliyon 2023, 9, e16360. [Google Scholar] [CrossRef]

- Chiumenti, A.; Pezzuolo, A.; Boscaro, D.; da Borso, F. Exploitation of Mowed Grass from Green Areas by Means of Anaerobic Digestion: Effects of Grass Conservation Methods (Drying and Ensiling) on Biogas and Biomethane Yield. Energies 2019, 12, 3244. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, X.; Sun, C.; Chen, Y.; Xi, Z.; Ma, G.; Zhang, T.; Zhang, Y.; Zhou, X.; Li, Y.-Y.; et al. New Insights into Anaerobic Digestion of Lignocellulosic Wastes towards Carbon Neutrality: A Review of Current Advancement and Future Prospects. J. Water Process Eng. 2024, 68, 106584. [Google Scholar] [CrossRef]

- Agregán, R.; Lorenzo, J.M.; Kumar, M.; Shariati, M.A.; Khan, M.U.; Sarwar, A.; Sultan, M.; Rebezov, M.; Usman, M. Anaerobic Digestion of Lignocellulose Components: Challenges and Novel Approaches. Energies 2022, 15, 8413. [Google Scholar] [CrossRef]

- Ryniecki, A.; Pilarski, K.; Pilarska, A. Wykorzystanie fermentacji metanowej do zagospodarowania wybranych produktów odpadowych przemysłu spożywczego [The use of methane fermentation in the development of selected waste products of food industry]. Uniw. Ekon. We Wrocławiu 2014, 4, 100–111. [Google Scholar] [CrossRef][Green Version]

- Hinterholz, B.; Costa, M.S.S.D.M.; Lucas Junior, J.D.; Pereira, E.D.S.; Buligon, E.L.; Lima, J.C.D.; Marostica, R. Anaerobic Mono-and Co-Digestion of Fruit and Vegetable Residues: Effects on Biogas Yield and Biofertilizer. Rev. Bras. Eng. Agríc. Ambient. 2024, 28, e280349. [Google Scholar] [CrossRef]

- González, R.; Peña, D.C.; Gómez, X. Anaerobic Co-Digestion of Wastes: Reviewing Current Status and Approaches for Enhancing Biogas Production. Appl. Sci. 2022, 12, 8884. [Google Scholar] [CrossRef]

- Zhang, L.; Tsui, T.-H.; Loh, K.-C.; Dai, Y.; Zhang, J.; Tong, Y.W. Biogas Production from High-Solid Anaerobic Digestion of Food Waste and Its Co-Digestion with Other Organic Wastes. In Biogas Plants; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2024; pp. 85–99. ISBN 978-1-119-86394-6. [Google Scholar]

- Poulsen, T.G.; Adelard, L. Improving Biogas Quality and Methane Yield via Co-Digestion of Agricultural and Urban Biomass Wastes. Waste Manag. 2016, 54, 118–125. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Su, H.; Baeyens, J.; Tan, T. Reviewing the Anaerobic Digestion of Food Waste for Biogas Production. Renew. Sustain. Energy Rev. 2014, 38, 383–392. [Google Scholar] [CrossRef]

- Pavi, S.; Kramer, L.E.; Gomes, L.P.; Miranda, L.A.S. Biogas Production from Co-Digestion of Organic Fraction of Municipal Solid Waste and Fruit and Vegetable Waste. Bioresour. Technol. 2017, 228, 362–367. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Loh, K.-C. Synergistic Effect of Activated Carbon and Encapsulated Trace Element Additive on Methane Production from Anaerobic Digestion of Food Wastes—Enhanced Operation Stability and Balanced Trace Nutrition. Bioresour. Technol. 2019, 278, 108–115. [Google Scholar] [CrossRef]

- Liu, X.; Khalid, H.; Amin, F.R.; Ma, X.; Li, X.; Chen, C.; Liu, G. Effects of Hydraulic Retention Time on Anaerobic Digestion Performance of Food Waste to Produce Methane as a Biofuel. Environ. Technol. Innov. 2018, 11, 348–357. [Google Scholar] [CrossRef]

- Kotarska, K.; Dziemianowicz, W.; Świerczyńska, A. Study on the Sequential Combination of Bioethanol and Biogas Production from Corn Straw. Molecules 2019, 24, 4558. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, Y.; Wang, S.; Wu, G.; Zhan, X. A Critical Review on Dry Anaerobic Digestion of Organic Waste: Characteristics, Operational Conditions, and Improvement Strategies. Renew. Sustain. Energy Rev. 2023, 176, 113208. [Google Scholar] [CrossRef]

- Arelli, V.; Juntupally, S.; Begum, S.; Anupoju, G. Significance of Pretreatment in Enhancing the Performance of Dry Anaerobic Digestion of Food Waste: An Insight on Full Scale Implementation Strategy with Theoretical Analogy. Processes 2020, 8, 1018. [Google Scholar] [CrossRef]

- Pilarska, A.A.; Kulupa, T.; Kubiak, A.; Wolna-Maruwka, A.; Pilarski, K.; Niewiadomska, A. Anaerobic Digestion of Food Waste—A Short Review. Energies 2023, 16, 5742. [Google Scholar] [CrossRef]

- He, K.; Liu, Y.; Tian, L.; He, W.; Cheng, Q. Review in Anaerobic Digestion of Food Waste. Heliyon 2024, 10, e28200. [Google Scholar] [CrossRef]

- Wu, H.-M.; Li, X.; Chen, J.-N.; Yan, Y.-J.; Kobayashi, T.; Hu, Y.; Zhang, X. Food Waste Anaerobic Digestion Under High Organic Loading Rate: Inhibiting Factors, Mechanisms, and Mitigation Strategies. Processes 2025, 13, 2090. [Google Scholar] [CrossRef]

- Luning, L.; van Zundert, E.H.M.; Brinkmann, A.J.F. Comparison of Dry and Wet Digestion for Solid Waste. Water Sci. Technol. 2003, 48, 15–20. [Google Scholar] [CrossRef] [PubMed]

- Sayara, T.; Sánchez, A. A Review on Anaerobic Digestion of Lignocellulosic Wastes: Pretreatments and Operational Conditions. Appl. Sci. 2019, 9, 4655. [Google Scholar] [CrossRef]

- Orlando, M.-Q.; Borja, V.-M. Pretreatment of Animal Manure Biomass to Improve Biogas Production: A Review. Energies 2020, 13, 3573. [Google Scholar] [CrossRef]

- Rocamora, I.; Wagland, S.T.; Villa, R.; Simpson, E.W.; Fernández, O.; Bajón-Fernández, Y. Dry Anaerobic Digestion of Organic Waste: A Review of Operational Parameters and Their Impact on Process Performance. Bioresour. Technol. 2020, 299, 122681. [Google Scholar] [CrossRef]

- Vigueras-Carmona, S.E.; Velasco-Pérez, A.; Montes-García, M.M.; Puebla, H.; Rodríguez-Jara, M.; Vian, J. Particle Size Effect on Biodegradability and Kinetics During Anaerobic Digestion of Fruit and Vegetable Waste. Processes 2025, 13, 937. [Google Scholar] [CrossRef]

- Mozhiarasi, V. Overview of Pretreatment Technologies on Vegetable, Fruit and Flower Market Wastes Disintegration and Bioenergy Potential: Indian Scenario. Chemosphere 2022, 288, 132604. [Google Scholar] [CrossRef]

- Mozhiarasi, V.; Weichgrebe, D.; Srinivasan, S.V. Enhancement of Methane Production from Vegetable, Fruit and Flower Market Wastes Using Extrusion as Pretreatment and Kinetic Modeling. Water Air Soil Pollut. 2020, 231, 126. [Google Scholar] [CrossRef]

- Heller, R.; Brandhorst, C.; Hülsemann, B.; Lemmer, A.; Oechsner, H. Comparison of Different Mechanical Pretreatment Methods for the Anaerobic Digestion of Landscape Management Grass. Energies 2023, 16, 8091. [Google Scholar] [CrossRef]

- Van Vlierberghe, C.; Escudié, R.; Bernet, N.; Frédéric, S.; Carrere, H. Long Term Alkaline Storage and Pretreatment Process of Cover Crops for Anaerobic Digestion. Bioresour. Technol. 2021, 330, 124986. [Google Scholar] [CrossRef]

- Khor, W.C.; Rabaey, K.; Vervaeren, H. Low Temperature Calcium Hydroxide Treatment Enhances Anaerobic Methane Production from (Extruded) Biomass. Bioresour. Technol. 2015, 176, 181–188. [Google Scholar] [CrossRef]

- Gueri, M.V.D.; Buratto, W.G.; Nied, A.; Schirmer, W.N.; Frare, L.M.; Furtado, A.C. Alkaline Pretreatment of Food Waste and Grass Clippings for the Enhancement of Methane Production in Anaerobic Digestion Processes. J. Mater. Cycles Waste Manag. 2025, 27, 2652–2665. [Google Scholar] [CrossRef]

- Sato, A.; Widjaja, A. Soeprijanto Hydrothermal Pretreatment of Rice Straw with Alkaline Addition for Enhancing Biogas Production in Semicontinuous Anaerobic Digester. J. Phys. Conf. Ser. 2021, 2117, 012034. [Google Scholar] [CrossRef]

- Sato, A.; Widjaja, A. Influence of Alkaline Hydrothermal Pretreatment of Rice Straw on Biomass Composition|Sato|. Int. Energy J. 2019, 19, 115–124. [Google Scholar]

- Xiang, C.; Tian, D.; Hu, J.; Huang, M.; Shen, F.; Zhang, Y.; Yang, G.; Zeng, Y.; Deng, S. Why Can Hydrothermally Pretreating Lignocellulose in Low Severities Improve Anaerobic Digestion Performances? Sci. Total Environ. 2021, 752, 141929. [Google Scholar] [CrossRef]

- Abdelsalam, E.M.; Samer, M.; Amer, M.A.; Amer, B.M.A. Biogas Production Using Dry Fermentation Technology through Co-Digestion of Manure and Agricultural Wastes. Environ. Dev. Sustain. 2021, 23, 8746–8757. [Google Scholar] [CrossRef]

- Rossi, E.; Pecorini, I.; Ferrara, G.; Iannelli, R. Dry Anaerobic Digestion of the Organic Fraction of Municipal Solid Waste: Biogas Production Optimization by Reducing Ammonia Inhibition. Energies 2022, 15, 5515. [Google Scholar] [CrossRef]

- Hayyat, U.; Khan, M.U.; Sultan, M.; Zahid, U.; Bhat, S.A.; Muzamil, M. A Review on Dry Anaerobic Digestion: Existing Technologies, Performance Factors, Challenges, and Recommendations. Methane 2024, 3, 33–52. [Google Scholar] [CrossRef]

- Sganzerla, W.G.; Costa, J.M.; Tena-Villares, M.; Buller, L.S.; Mussatto, S.I.; Forster-Carneiro, T. Dry Anaerobic Digestion of Brewer’s Spent Grains toward a More Sustainable Brewery: Operational Performance, Kinetic Analysis, and Bioenergy Potential. Fermentation 2022, 9, 2. [Google Scholar] [CrossRef]

- Zhen, F.; Xing, T.; Li, L.; Sun, Y.; Zhang, H. Optimization of the Methane Production in Batch Anaerobic Digestion of Maize Straw by Adjustment of Total Solid and Substrate-to-Inoculum Ratio Based on Kinetics. Int. J. Agric. Biol. Eng. 2024, 17, 225–231. [Google Scholar] [CrossRef]

- Donoso-Bravo, A.; Sadino-Riquelme, C.; Gómez, D.; Segura, C.; Valdebenito, E.; Hansen, F. Modelling of an Anaerobic Plug-Flow Reactor. Process Analysis and Evaluation Approaches with Non-Ideal Mixing Considerations. Bioresour. Technol. 2018, 260, 95–104. [Google Scholar] [CrossRef]

- Chiumenti, A.; da Borso, F.; Limina, S. Dry Anaerobic Digestion of Cow Manure and Agricultural Products in a Full-Scale Plant: Efficiency and Comparison with Wet Fermentation. Waste Manag. 2018, 71, 704–710. [Google Scholar] [CrossRef]

- Sievers, D.A.; Kuhn, E.M.; Thompson, V.S.; Yancey, N.A.; Hoover, A.N.; Resch, M.G.; Wolfrum, E.J. Throughput, Reliability, and Yields of a Pilot-Scale Conversion Process for Production of Fermentable Sugars from Lignocellulosic Biomass: A Study on Feedstock Ash and Moisture. ACS Sustain. Chem. Eng. 2020, 8, 2008–2015. [Google Scholar] [CrossRef]

- Stolze, Y.; Zakrzewski, M.; Maus, I.; Eikmeyer, F.; Jaenicke, S.; Rottmann, N.; Siebner, C.; Pühler, A.; Schlüter, A. Comparative Metagenomics of Biogas-Producing Microbial Communities from Production-Scale Biogas Plants Operating under Wet or Dry Fermentation Conditions. Biotechnol. Biofuels 2015, 8, 14. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Liu, J.; Chen, M.; Zheng, J.; Gui, S.; Wei, Y. Application of Mixture Design to Optimize Organic Composition of Carbohydrate, Protein, and Lipid on Dry Anaerobic Digestion of OFMSW: Aiming Stability and Efficiency. Biochem. Eng. J. 2021, 172, 108037. [Google Scholar] [CrossRef]

- Angelonidi, E.; Smith, S.R. A Comparison of Wet and Dry Anaerobic Digestion Processes for the Treatment of Municipal Solid Waste and Food Waste. Water Environ. J. 2015, 29, 549–557. [Google Scholar] [CrossRef]

- Hossain, M.S.; Karim, T.U.; Onik, M.H.; Kumar, D.; Rahman, M.A.; Yousuf, A.; Uddin, M.R. Impact of Temperature, Inoculum Flow Pattern, Inoculum Type, and Their Ratio on Dry Anaerobic Digestion for Biogas Production. Sci. Rep. 2022, 12, 6162. [Google Scholar] [CrossRef] [PubMed]

- Saady, N.M.C.; Massé, D.I. Starting-up Low Temperature Dry Anaerobic Digestion of Cow Feces and Wheat Straw. Renew. Energy 2016, 88, 439–444. [Google Scholar] [CrossRef]

- Li, D.; Huang, X.; Wang, Q.; Yuan, Y.; Yan, Z.; Li, Z.; Huang, Y.; Liu, X. Kinetics of Methane Production and Hydrolysis in Anaerobic Digestion of Corn Stover. Energy 2016, 102, 1–9. [Google Scholar] [CrossRef]

- Rouf, M.; Islam, M.; Rabeya, T.; Mondal, A. Anaerobic Digestion of Mixed Dried Fallen Leaves by Mixing with Cow Dung. Bangladesh J. Sci. Ind. Res. 2015, 50, 163–168. [Google Scholar] [CrossRef][Green Version]

- André, L.; Zdanevitch, I.; Pineau, C.; Lencauchez, J.; Damiano, A.; Pauss, A.; Ribeiro, T. Dry Anaerobic Co-Digestion of Roadside Grass and Cattle Manure at a 60 L Batch Pilot Scale. Bioresour. Technol. 2019, 289, 121737. [Google Scholar] [CrossRef]

- Wang, J.; Tang, X.; Yang, H.; Zhao, Q.; Wang, H.; Deng, L.; Wang, W. Fixing Collapsed Dry Anaerobic Digestion System of Kitchen Waste Caused by Severe VFAs Accumulation. Renew. Energy 2024, 237, 121589. [Google Scholar] [CrossRef]

- Bokhary, A.; Ale Enriquez, F.; Garrison, R.; Ahring, B.K. Advancing Thermophilic Anaerobic Digestion of Corn Whole Stillage: Lignocellulose Decomposition and Microbial Community Characterization. Fermentation 2024, 10, 306. [Google Scholar] [CrossRef]

- Tang, F.; Tian, J.; Zhu, N.; Lin, Y.; Zheng, H.; Xu, Z.; Liu, W. Dry Anaerobic Digestion of Ammoniated Straw: Performance and Microbial Characteristics. Bioresour. Technol. 2022, 351, 126952. [Google Scholar] [CrossRef]

- Manyi-Loh, C.E.; Lues, R. Anaerobic Digestion of Lignocellulosic Biomass: Substrate Characteristics (Challenge) and Innovation. Fermentation 2023, 9, 755. [Google Scholar] [CrossRef]

- Wang, X.; Liu, T.; Liu, Y.; Sun, Y. Effects of Stirring Time on Anaerobic Digestion of Cattle Manure-Corn Stover: Microbial Diversity and Metabolic Pathways. Fuel 2024, 367, 131468. [Google Scholar] [CrossRef]

- Shapovalov, Y.; Zhadan, S.; Bochmann, G.; Salyuk, A.; Nykyforov, V. Dry Anaerobic Digestion of Chicken Manure: A Review. Appl. Sci. 2020, 10, 7825. [Google Scholar] [CrossRef]

- Xiao, Y.; Yang, H.; Jiang, X.; Wang, W.; Deng, L. Mitigation of Ammonia and Volatile Fatty Acids Inhibition in Dry Anaerobic Digestion of Chicken Manure by Biochar Prepared at Varying Pyrolysis Temperatures. Bioresour. Technol. 2025, 428, 132465. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Niu, Q.; Nie, W.; Li, X.; Yang, C. Effects of Heavy Metals and Antibiotics on Performances and Mechanisms of Anaerobic Digestion. Bioresour. Technol. 2022, 361, 127683. [Google Scholar] [CrossRef]

- Zubair, M.; Li, Z.; Zhu, R.; Wang, J.; Liu, X.; Liu, X. The Antibiotics Degradation and Its Mechanisms during the Livestock Manure Anaerobic Digestion. Molecules 2023, 28, 4090. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Zhang, Y.; Liang, J.; Li, Y.; Zhang, J.; Fang, W.; Zhang, P.; Zhang, G.; Hao Ngo, H. Improvement of Anaerobic Digestion Containing Sulfur with Conductive Materials: Focusing on Recent Advances and Internal Biological Mechanisms. Chem. Eng. J. 2023, 472, 144867. [Google Scholar] [CrossRef]

- Tzenos, C.A.; Kalamaras, S.D.; Economou, E.-A.; Romanos, G.E.; Veziri, C.M.; Mitsopoulos, A.; Menexes, G.C.; Sfetsas, T.; Kotsopoulos, T.A. The Multifunctional Effect of Porous Additives on the Alleviation of Ammonia and Sulfate Co-Inhibition in Anaerobic Digestion. Sustainability 2023, 15, 9994. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Y.; Li, B.; Zhang, J.; Guan, D.; Hu, Y.; Fan, H.; Sun, Y.; Wang, H.; Guo, L. New Insights into Microplastics Inhibiting Kitchen Waste Dry Digestion: Digestion Efficiency, Microbial Communities and Microplastic Aging Mechanisms. Chem. Eng. J. 2025, 508, 160907. [Google Scholar] [CrossRef]

- Mohammad Mirsoleimani Azizi, S.; Hai, F.I.; Lu, W.; Al-Mamun, A.; Ranjan Dhar, B. A Review of Mechanisms Underlying the Impacts of (Nano)Microplastics on Anaerobic Digestion. Bioresour. Technol. 2021, 329, 124894. [Google Scholar] [CrossRef]

- Lin, M.; Wang, A.; Ren, L.; Qiao, W.; Wandera, S.M.; Dong, R. Challenges of Pathogen Inactivation in Animal Manure through Anaerobic Digestion: A Short Review. Bioengineered 2022, 13, 1149–1161. [Google Scholar] [CrossRef] [PubMed]

- Machnicka, A.; Grübel, K. The Effect of Pre-Treatment and Anaerobic Digestion for Pathogens Reduction in Agricultural Utilization of Sewage Sludge. Environ. Sci. Pollut. Res. 2022, 30, 13801–13810. [Google Scholar] [CrossRef]

- Rahman, M.S.; Hoque, M.N.; Puspo, J.A.; Islam, M.R.; Das, N.; Siddique, M.A.; Hossain, M.A.; Sultana, M. Microbiome Signature and Diversity Regulates the Level of Energy Production under Anaerobic Condition. Sci. Rep. 2021, 11, 19777. [Google Scholar] [CrossRef]

- Forster-Carneiro, T.; Pérez, M.; Romero, L.I.; Sales, D. Dry-Thermophilic Anaerobic Digestion of Organic Fraction of the Municipal Solid Waste: Focusing on the Inoculum Sources. Bioresour. Technol. 2007, 98, 3195–3203. [Google Scholar] [CrossRef]

- Musluoğlu, A.; Dereli, R.K.; Arıkan, O.A.; Övez, S.S. Comprehensive Experiences on the Operation of a Full-Scale Continuous Dry Anaerobic Digestion Plant Treating Mechanically Sorted OFMSW. Water Sci. Technol. 2025, 91, 1157–1171. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, J.; Fu, Z.; Wang, Y.; Guan, D.; Xie, J.; Zhang, Q.; Liu, Q.; Wang, D.; Sun, Y. Metagenomic Approach Reveals the Mechanism of Calcium Oxide Improving Kitchen Waste Dry Anaerobic Digestion. Bioresour. Technol. 2023, 387, 129647. [Google Scholar] [CrossRef]

- Ottoni, J.R.; Bernal, S.P.F.; Marteres, T.J.; Luiz, F.N.; Dos Santos, V.P.; Mari, Â.G.; Somer, J.G.; De Oliveira, V.M.; Passarini, M.R.Z. Cultured and Uncultured Microbial Community Associated with Biogas Production in Anaerobic Digestion Processes. Arch. Microbiol. 2022, 204, 340. [Google Scholar] [CrossRef]

- Fernandez, H.C.; Buffiere, P.; Bayard, R. Understanding the Role of Mechanical Pretreatment before Anaerobic Digestion: Lab-Scale Investigations. Renew. Energy 2022, 187, 193–203. [Google Scholar] [CrossRef]

- Weiland, P. Biogas Production: Current State and Perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef] [PubMed]

- Bauer, F.; Hulteberg, C.; Persson, T.; Tamm, D. (PDF) Biogas Upgrading—Review of Commercial Technologies. Available online: https://lucris.lub.lu.se/ws/portalfiles/portal/5465492/4580054.pdf (accessed on 21 July 2025).

- Dronia, W.; Kostecki, J.; Połomka, J.; Jędrczak, A. Bio-Waste from Urban and Rural Areas as a Source of Biogas and Methane—A Case Study from Poland. Energies 2024, 17, 317. [Google Scholar] [CrossRef]

- Pöschl, M.; Ward, S.; Owende, P. Evaluation of Energy Efficiency of Various Biogas Production and Utilization Pathways. Appl. Energy 2010, 87, 3305–3321. [Google Scholar] [CrossRef]

- Naegele, H.-J.; Lemmer, A.; Oechsner, H.; Jungbluth, T. Electric Energy Consumption of the Full Scale Research Biogas Plant “Unterer Lindenhof”: Results of Longterm and Full Detail Measurements. Energies 2012, 5, 5198–5214. [Google Scholar] [CrossRef]

- Krell, K.; Severin, A. Financing & Business Models for Biogas Plants: Concepts. Available online: https://www.interregeurope.eu/sites/default/files/inline/Biogas_financing_concepts_ASeverin_15062020.pdf (accessed on 21 July 2025).

- Vachkova, R.M. Poland to Co-Finance Renewable Energy Projects in Rural Areas|Renewable Energy News|Renewables Now. Available online: https://renewablesnow.com/news/poland-to-co-finance-renewable-energy-projects-in-rural-areas-811697/ (accessed on 11 July 2025).

- Ciuła, J.; Wiewiórska, I.; Banaś, M.; Pająk, T.; Szewczyk, P. Balance and Energy Use of Biogas in Poland: Prospects and Directions of Development for the Circular Economy. Energies 2023, 16, 3910. [Google Scholar] [CrossRef]

- Motola, V.; Scarlat, N.; Buffi, M.; Hurtig, O.; Rejtharova, J.; Georgakaki, A.; Mountraki, A.; Letout, S.; Salvucci, R.; Rózsai, M.; et al. Clean Energy Technology Observatory, Bioenergy in the European Union: Status Report on Technology Development, Trends, Value Chains and Markets: 2024; Publications Office of the European Union: Luxembourg, 2024; ISBN 978-92-68-20961-5. [Google Scholar]

- Gustafsson, M.; Ammenberg, J. A Perspective on the State of the Biogas Industry from Selected Member Countries of IEA Bioenergy Task 37—Bioenergy 2022. IEA_T37_CountryReportSummary_2021.pdf. Available online: https://www.ieabioenergy.com/blog/publications/a-perspective-on-the-state-of-the-biogas-industry-from-selected-member-countries-of-iea-bioenergy-task-37/ (accessed on 21 July 2025).

- Wiedmann, T.; Minx, J. A Definition of Carbon Footprint. Ecol. Econ. Res. Trends 2008, 2, 55–65. [Google Scholar]

- Boldrin, A.; Andersen, J.K.; Møller, J.; Christensen, T.H.; Favoino, E. Composting and Compost Utilization: Accounting of Greenhouse Gases and Global Warming Contributions. Waste Manag. Res. 2009, 27, 800–812. [Google Scholar] [CrossRef]

- Kusch, S.; Oechsner, H.; Jungbluth, T. Biogas Production with Horse Dung in Solid-Phase Digestion Systems. Bioresour. Technol. 2008, 99, 1280–1292. [Google Scholar] [CrossRef]

- De Bere, L. Anaerobic Digestion of Solid Waste: State-of-the-Art. Water Sci. Technol. 2000, 41, 283–290. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Fahl, F. Biogas: Developments and Perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Biogas Digestate Quality and Utilization. In The Biogas Handbook; Elsevier: Amsterdam, The Netherlands, 2013; pp. 267–301. ISBN 978-0-85709-498-8.

- Abu, R.; Ab Aziz, M.A.; Che Hassan, C.H.; Zainon Noor, Z.; Abd Jalil, R. A Comparative Life Cycle Assessment of Dry and Wet Anaerobic Digestion Technologies for Food Waste Management. J. Kejuruter. 2023, 35, 317–349. [Google Scholar] [CrossRef]

- Holm-Nielsen, J.B.; Al Seadi, T.; Oleskowicz-Popiel, P. The Future of Anaerobic Digestion and Biogas Utilization. Bioresour. Technol. 2009, 100, 5478–5484. [Google Scholar] [CrossRef]

- Poeschl, M.; Ward, S.; Owende, P. Environmental Impacts of Biogas Deployment—Part II: Life Cycle Assessment of Multiple Production and Utilization Pathways. J. Clean. Prod. 2012, 24, 184–201. [Google Scholar] [CrossRef]

- Möller, K.; Müller, T. Effects of Anaerobic Digestion on Digestate Nutrient Availability and Crop Growth: A Review. Eng. Life Sci. 2012, 12, 242–257. [Google Scholar] [CrossRef]

- Eldem, N.Ö.; Ozturk, I.; Soyer, E.; Callı, B.; Akgiray, Ö. Ammonia and pH Inhibition in Anaerobic Treatment of Wastewaters, Part I: Experimental. J. Environ. Sci. Health Part A 2004, 39, 2405–2420. [Google Scholar] [CrossRef]

- Rehl, T.; Müller, J. Life Cycle Assessment of Biogas Digestate Processing Technologies. Resour. Conserv. Recycl. 2011, 56, 92–104. [Google Scholar] [CrossRef]

- Hamelin, L.; Naroznova, I.; Wenzel, H. Environmental Consequences of Different Carbon Alternatives for Increased Manure-Based Biogas. Appl. Energy 2014, 114, 774–782. [Google Scholar] [CrossRef]

- Lamolinara, B.; Pérez-Martínez, A.; Guardado-Yordi, E.; Guillén Fiallos, C.; Diéguez-Santana, K.; Ruiz-Mercado, G.J. Anaerobic Digestate Management, Environmental Impacts, and Techno-Economic Challenges. Waste Manag. 2022, 140, 14–30. [Google Scholar] [CrossRef]

- Haug, R.T. The Practical Handbook of Compost Engineering, 1st ed.; Routledge: London, UK, 2018; ISBN 978-0-203-73623-4. [Google Scholar]

- Bernal, M.P.; Alburquerque, J.A.; Moral, R. Composting of Animal Manures and Chemical Criteria for Compost Maturity Assessment. A Review. Bioresour. Technol. 2009, 100, 5444–5453. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2021—The Physical Science Basis: Working Group I Contribution to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change, 1st ed.; Cambridge University Press: Cambridge, UK, 2023; ISBN 978-1-009-15789-6. [Google Scholar]

- Andersen, J.K.; Boldrin, A.; Christensen, T.H.; Scheutz, C. Greenhouse Gas Emissions from Home Composting of Organic Household Waste. Waste Manag. 2010, 30, 2475–2482. [Google Scholar] [CrossRef]

- Amlinger, F.; Peyr, S.; Cuhls, C. Green House Gas Emissions from Composting and Mechanical Biological Treatment. Waste Manag. Res. 2008, 26, 47–60. [Google Scholar] [CrossRef]

- Containers, P.; Good, N.D. Documentation for Greenhouse Gas Emission and Energy Factors Used in the Waste Reduction Model (WARM)—Management Practices Chapters; US Environmental Protection Agency: Washington, DC, USA, 2019.

- Pérez, T.; Vergara, S.E.; Silver, W.L. Assessing the Climate Change Mitigation Potential from Food Waste Composting. Sci. Rep. 2023, 13, 7608. [Google Scholar] [CrossRef]

- Regulation—2019/1009—EN—EUR-Lex. Available online: https://eur-lex.europa.eu/eli/reg/2019/1009/oj/eng (accessed on 21 July 2025).

- Seadi, T.A.; Lukehurst, C. (PDF) Quality Management of Digestate from Biogas Plants Used as Fertiliser; IEA Bioenergy: Paris, France, 2012; Volume 40. [Google Scholar]

- IPCC. AR4 Climate Change 2007: Mitigation of Climate Change; IPCC: Geneva, Switzerland, 2007. [Google Scholar]

- Mønster, J.; Kjeldsen, P.; Scheutz, C. Methodologies for Measuring Fugitive Methane Emissions from Landfills—A Review. Waste Manag. 2019, 87, 835–859. [Google Scholar] [CrossRef]

- Bogner, J.; Spokas, K. Landfill CH4: Rates, Fates, and Role in Global Carbon Cycle. Chemosphere 1993, 26, 369–386. [Google Scholar] [CrossRef]

- Ko, J.H.; Xu, Q.; Jang, Y.-C. Emissions and Control of Hydrogen Sulfide at Landfills: A Review. Crit. Rev. Environ. Sci. Technol. 2015, 45, 2043–2083. [Google Scholar] [CrossRef]

- Kjeldsen, P.; Barlaz, M.A.; Rooker, A.P.; Baun, A.; Ledin, A.; Christensen, T.H. Present and Long-Term Composition of MSW Landfill Leachate: A Review. Crit. Rev. Environ. Sci. Technol. 2002, 32, 297–336. [Google Scholar] [CrossRef]

- Friedrich, E.; Trois, C. Quantification of Greenhouse Gas Emissions from Waste Management Processes for Municipalities—A Comparative Review Focusing on Africa. Waste Manag. 2011, 31, 1585–1596. [Google Scholar] [CrossRef]

- Directive—2008/98—EN—Waste Framework Directive—EUR-Lex. Available online: https://eur-lex.europa.eu/eli/dir/2008/98/oj/eng (accessed on 21 July 2025).

- Directive—2018/851—EN—EUR-Lex. Available online: https://eur-lex.europa.eu/eli/dir/2018/851/oj/eng (accessed on 21 July 2025).

- The Rotterdam Convention on the Prior Informed Consent Procedure for Certain Hazardous Chemicals and Pesticides in International Trade 1998. In Multilateral Environmental Treaties; Edward Elgar Publishing: Cheltenham, UK, 2017; pp. 343–353.

- Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal—Main Page. Available online: https://legal.un.org/avl/ha/bcctmhwd/bcctmhwd.html (accessed on 21 July 2025).

- Regulation—2020/852—EN—Taxonomy Regulation—EUR-Lex. Available online: https://eur-lex.europa.eu/eli/reg/2020/852/oj/eng (accessed on 21 July 2025).

- EUR-Lex—52020DC0098—EN—EUR-Lex. A New Circular Economy Action Plan. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:9903b325-6388-11ea-b735-01aa75ed71a1.0017.02/DOC_1&format=PDF (accessed on 21 July 2025).

- ISO 14001:2015; Environmental Management Systems—Requirements with Guidance for Use. ISO: Geneva, Switzerland, 2015. Available online: https://www.iso.org/standard/60857.html (accessed on 21 July 2025).

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 21 July 2025).

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 21 July 2025).

- ISO 24187:2023; Principles for the Analysis of Microplastics Present in the Environment. ISO: Geneva, Switzerland, 2023. Available online: https://www.iso.org/standard/78033.html (accessed on 21 July 2025).

- Regulation—2021/1056—EN—EUR-Lex. Available online: https://eur-lex.europa.eu/eli/reg/2021/1056/oj/eng (accessed on 21 July 2025).

- European Commission. Communication from the Commission to the European Parliament and the Council Sustainable Carbon Cycles; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions the European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Wu, L.; Zhang, J.; Jia, D.; Wang, S.; Yan, Y. Performance Evaluation of Multistage Fractured Horizontal Wells in Tight Gas Reservoirs at Block M, Ordos Basin. Energies 2022, 15, 613. [Google Scholar] [CrossRef]

- Muhammad Nasir, I.; Mohd Ghazi, T.I.; Omar, R. Production of Biogas from Solid Organic Wastes through Anaerobic Digestion: A Review. Appl. Microbiol. Biotechnol. 2012, 95, 321–329. [Google Scholar] [CrossRef]

- Tambone, F.; Scaglia, B.; D’Imporzano, G.; Schievano, A.; Orzi, V.; Salati, S.; Adani, F. Assessing Amendment and Fertilizing Properties of Digestates from Anaerobic Digestion through a Comparative Study with Digested Sludge and Compost. Chemosphere 2010, 81, 577–583. [Google Scholar] [CrossRef]

- Tataridas, A.; Kanatas, P.; Chatzigeorgiou, A.; Zannopoulos, S.; Travlos, I. Sustainable Crop and Weed Management in the Era of the EU Green Deal: A Survival Guide. Agronomy 2022, 12, 589. [Google Scholar] [CrossRef]

- Bukovszki, V.; Magyari, Á.; Braun, M.K.; Párdi, K.; Reith, A. Energy Modelling as a Trigger for Energy Communities: A Joint Socio-Technical Perspective. Energies 2020, 13, 2274. [Google Scholar] [CrossRef]

- Lal, R. Sequestering Carbon in Soils of Agro-Ecosystems. Food Policy 2011, 36, S33–S39. [Google Scholar] [CrossRef]

- Börjesson, P.; Berglund, M. Environmental Systems Analysis of Biogas Systems—Part I: Fuel-Cycle Emissions. Biomass Bioenergy 2006, 30, 469–485. [Google Scholar] [CrossRef]

- Hijazi, O.; Munro, S.; Zerhusen, B.; Effenberger, M. Review of Life Cycle Assessment for Biogas Production in Europe. Renew. Sustain. Energy Rev. 2016, 54, 1291–1300. [Google Scholar] [CrossRef]

- Tyagi, V.K.; Fdez-Güelfo, L.A.; Zhou, Y.; Álvarez-Gallego, C.J.; Garcia, L.I.R.; Ng, W.J. Anaerobic Co-Digestion of Organic Fraction of Municipal Solid Waste (OFMSW): Progress and Challenges. Renew. Sustain. Energy Rev. 2018, 93, 380–399. [Google Scholar] [CrossRef]

- De Baere, L. The DRANCO Technology: A Unique Digestion Technology for Solid Organic Waste. Available online: https://dranco.be/publication/the-dranco-technology-a-unique-digestion-technology-for-solid-organic-waste-de-baere-l-2/ (accessed on 14 July 2025).

- André, L.; Pauss, A.; Ribeiro, T. Solid Anaerobic Digestion: State-of-Art, Scientific and Technological Hurdles. Bioresour. Technol. 2018, 247, 1027–1037. [Google Scholar] [CrossRef]

- Akinbomi, J.G.; Patinvoh, R.J.; Taherzadeh, M.J. Current Challenges of High-Solid Anaerobic Digestion and Possible Measures for Its Effective Applications: A Review. Biotechnol. Biofuels Bioprod. 2022, 15, 52. [Google Scholar] [CrossRef] [PubMed]

- Fagbohungbe, M.O.; Dodd, I.C.; Herbert, B.M.J.; Li, H.; Ricketts, L.; Semple, K.T. High Solid Anaerobic Digestion: Operational Challenges and Possibilities. Environ. Technol. Innov. 2015, 4, 268–284. [Google Scholar] [CrossRef]

- Yumpu.com Feasibility of Generating Green Power Through Anaerobic Digestion. Available online: https://www.yumpu.com/en/document/view/5144591/feasibility-of-generating-green-power-through-anaerobic-digestion- (accessed on 14 July 2025).

- Negi, S.; Chai, J.-Y.; Tjhin, A.C.T.; Pan, S.-Y. Electro-Anaerobic Digestion as Carbon–Neutral Solutions. Chem. Biol. Technol. Agric. 2025, 12, 64. [Google Scholar] [CrossRef]

- Panaro, D.B.; Trucchia, A.; Luongo, V.; Mattei, M.R.; Frunzo, L. Global Sensitivity Analysis and Uncertainty Quantification for a Mathematical Model of Dry Anaerobic Digestion in Plug-Flow Reactors. Math. Biosci. Eng. MBE 2024, 21, 7139–7164. [Google Scholar] [CrossRef]

- Maxhayi, S.; Mukumba, P.; Obileke, K.; Mzobotshe, M.; Lethole, N. Temperature Effect of Biogas Production from a Greenhouse Biogas Digester. Edelweiss Appl. Sci. Technol. 2024, 8, 3872–3885. [Google Scholar] [CrossRef]

- Oliveira, M.; Miguel, M.; Van Langen, S.K.; Ncube, A.; Zucaro, A.; Fiorentino, G.; Passaro, R.; Santagata, R.; Coleman, N.; Lowe, B.H.; et al. Circular Economy and the Transition to a Sustainable Society: Integrated Assessment Methods for a New Paradigm. Circ. Econ. Sustain. 2021, 1, 99–113. [Google Scholar] [CrossRef]

- Taron, A.; Majumder, A.; Bodach, S.; Agbefu, D. Public-Private Partnerships for the Circular Bioeconomy in the Global South: Lessons Learned; International Water Management Institute: Colombo, Sri Lanka, 2023. [Google Scholar]

- Smith, S.J.; Satchwell, A.J.; Kirchstetter, T.W.; Scown, C.D. The Implications of Facility Design and Enabling Policies on the Economics of Dry Anaerobic Digestion. Waste Manag. 2021, 128, 122–131. [Google Scholar] [CrossRef]

- Matheri, A.N.; Sethunya, V.L.; Belaid, M.; Muzenda, E. Analysis of the Biogas Productivity from Dry Anaerobic Digestion of Organic Fraction of Municipal Solid Waste. Renew. Sustain. Energy Rev. 2018, 81, 2328–2334. [Google Scholar] [CrossRef]

| Year | Total Mass of Collected Municipal Waste (Thousand Tons) | Amount of Municipal Waste Generated per Capita (kg/a) | The Mass of Separately Collected Biodegradable Waste (Thousand Tons) | Relative Share of Separately Collected Biodegradable Waste to the Total Municipal Waste Stream (%) | The Amount of Biodegradable Waste Collected per Capita (kg/a) | Proportion of Separately Collected Biowaste in Relation to the Total Biodegradable Waste Generated (%) |

|---|---|---|---|---|---|---|

| 2015 | 10,863.5 | 283 | 657.0 | - | - | 25.9 |

| 2020 | 13,116.9 | 344 | 1610.0 | 12.3 | 42 | 32.4 |

| 2021 | 13,673.6 | 360 | 1843.0 | 13.5 | 49 | 33.9 |

| 2022 | 13,420.3 | 355 | 1913.6 | 14.3 | 51 | 35.7 |

| 2023 | 13,447.9 | 357 | 2042.6 | 15.2 | 54 | 37.4 |

| Waste Type | Biogas Yield (mL/g VS) | Methane Yield (mL/g VS) | Fermentation Time (days) | C/N Ratio | pH | Experimental Parameters | Source |

|---|---|---|---|---|---|---|---|

| Kitchen waste | |||||||

| Cooked rice | 2821 | ~1770 | 28 | 30.9 | 7.2 | Lab-scale batch BMP (1 L serum bottles), mesophilic 37 °C, TS ≈ 8%, S/I 1:1 (w/w) | |

| Cooked beans | 983 | ~590 | 11 | - | - | [33] | |

| Cabbage | 800 | ~480 | 10 | 13.9 | 6.2 | ||

| Green waste | |||||||

| Fresh grass | 639.7 | ~384 | - | - | - | Lab BMP, mesophilic 37 °C; freshly harvested; TS ≈ 20% | |

| Dried grass | 565.9 | ~339 | - | - | - | Lab BMP, mesophilic 37 °C; sun-dried; TS ≈ 90% | [34] |

| Ensiled grass | 573.4 | ~344 | - | - | - | Lab BMP, mesophilic 37 °C; ensiled 60 d; TS ≈ 30% | |

| Agrofood industry | |||||||

| Fruit-vegetable mix | 720 | ~436 | - | - | - | Batch co-digestion test with dairy sludge; mesophilic 35 °C; TS ≈ 12% | [38] |

| Corn straw | 330 | ~250 | 8 | - | 7.5 | Batch BMP, mesophilic 37 °C; alkaline-adjusted; TS ≈ 25% | [46] |

| Waste Type | Dry Matter Content (%) | Optimal Temperature (°C) | Retention Time (Days) | Advantages | Challenges | Experimental Parameters | Source |

|---|---|---|---|---|---|---|---|

| Kitchen waste | 8–33 | 35–40 | 15–30 | High biodegradability, easy availability | Low carbon content, possible acidification | Mesophilic 35–37 °C; TS adjusted to ≥15% | [33] |

| Green waste | 20–40 | 35–40 | 20–35 | Stable structure, good biodegradability | Seasonal availability | mesophilic 37 °C; batch mode | [34] |

| Food industry | 10–30 | 35–40 | 15–25 | Diverse organic composition | Variable chemical composition | mesophilic 35 °C; codigestion | [37] |

| Lignocellulose | 85–95 | 35–55 | 25–45 | Low water content, easy storage | High biodegradation resistance | mesophilic 37 °C; pH adjusted 7.5; TS 25–30% | [46] |

| Method | Mechanism | Description | Source |

|---|---|---|---|

| Mechanical shredding | Increased specific surface area, rupture of cell walls, shorter diffusion path for enzymes, substrate homogenization, removal of contaminants (glass, metals) | Shredding to <10 mm, often using hammer or knife mills. | [47,56,57,58,59] |

| Alkaline treatment | Deacetylation and loosening of lignin fibers, increase in soluble sugars. | Biomass treated with alkaline solution (e.g., NaOH, Ca(OH)2). | [60,61,62] |

| Hydrothermal hydrolysis | Decomposition of hemicellulose into simple sugars, partial degradation or redeposition of lignin. | Biomass decomposition in hot pressurized water without chemical additives. | [63,64,65] |

| Parameter | Dry Anaerobic Digestion (DAD) | Wet Anaerobic Digestion (WAD) |

|---|---|---|

| Dry matter content (TS) | High solids content: 20–40% TS | Low solids content: <10–20% TS |

| Water and energy demand | Low—pre-treatment of feedstocks does not require mechanical particle size reduction or dilution | High—preparation of substrates requires dilutions, energy demand during mixing |

| Methane yield | Typically higher methane yield | Typically lower methane yield |

| Foaming problem | Not applicable | Occurs |

| Space requirements | Reactors with smaller working volumes | Reactors are usually larger than in DAD due to the dilute feedstocks |

| Process stability | Often lower process stability resulting from, among others, the risk of acidification | More stable process |

| Percolate recycling rate | High | Low or lack |

| Investment and operating costs | Possible higher costs of mechanical processes, lower energy costs—no mixing equipment required | Higher water and energy costs |

| Parameter | 0.5 MW | 1.0 MW |

|---|---|---|

| Capital expenditure (CAPEX) | PLN 6.5–7 million | PLN 13–14 million |

| Annual operating costs (OPEX) | PLN ~2 million | PLN ~4 million |

| Revenue from the sale of electricity | PLN ~1.8 million/year | PLN ~3.6 million/year |

| Revenue from the sale of heat | PLN ~1.2 million/year | PLN ~2.4 million/year |

| Revenue from digestate | PLN ~0.2 million/year | PLN ~0.4 million/year |

| Available subsidies | 45–65% of CAPEX | up to 65% of investment costs |

| Country | Estimated Number of Biogas Installations | Biogas Production (TWh/Year) |

|---|---|---|

| Germany | >10,000 | 87 |

| France | ~1600 | 25 |

| Italy | - | 22 |

| Denmark | - | 7 |

| Strengths | Weaknesses | Opportunities | Threats |

|---|---|---|---|

| High energy efficiency and potential for negative carbon footprint | Higher initial investment compared to composting | Alignment with circular economy and climate neutrality targets | Policy or market instability affecting renewable energy support |

| Reduced leachate and condensate compared to wet AD | Limited applicability for very high-moisture feedstocks | Development of biomethane markets and energy system integration | Competition from other waste treatment technologies (e.g., incineration, composting) |

| Production of digestate usable as organic fertilizer | Technical complexity requiring skilled operation | Access to EU and global green funding instruments | Public acceptance issues related to odor or local siting |

| Closed system minimizes fugitive GHG emissions | Lower experience base compared to wet AD in some regions | Potential role in energy security and regional bioeconomy strategies | Risks related to feedstock availability and contamination |

| Technology | Reactor Type | Operating Temp. | Mixing Strategy | Advantages | Limitations | Reference |

|---|---|---|---|---|---|---|

| Dranco | vertical plug-flow | thermophilic (~50 °C) | none (gravity) | simple design, low OPEX, good for high TS | no mixing may cause channeling; limited flexibility | [164] |

| Valorga | vertical with gas injection | mesophilic/thermophilic | gas injection | handles heterogeneous waste, stable performance | mixing energy costs; risk of sedimentation | [165] |

| Kompogas | horizontal plug-flow | thermophilic (~55 °C) | slow internal paddles | effective mixing, high reliability | maintenance of mechanical parts | [68] |

| Bekon | batch (garage-type) | mesophilic (~37 °C) | none | low-tech, suitable for decentralized use | lower throughput; risk of local inhibition | [166] |

| Aikan | integrated dry digestion + composting | thermophilic + aerobic stage | combined stages | maximizes recovery, integrates composting | high CAPEX; system complexity | [68] |

| Linde BRV | horizontal plug-flow with percolate recirculation | thermophilic | percolate recirculation | good efficiency, moderate energy needs | clogging risk in recirculation | [68] |

| BioPercolat | leach-bed | mesophilic | percolate irrigation | low water demand, modular design | uneven percolate flow; inert buildup | [167] |

| Iska | two-stage (dry + wet) | mesophilic + wet methanogenesis | separate dry/wet | improved hydrolysis and methane yield | more space and complexity needed | [168] |

| Step No. | Technical Optimization Framework |

|---|---|

| 1 | Pretreatment strategy |

| Goal: improve feedstock properties before entering the reactor | |

| |

| Effect: improves substrate rheology, reduces energy needs for mixing and heating. | |

| 2 | Reactor design optimization |

| Goal: Adapt reactor to handle high-solids content and improve heat/mass transfer. | |

| |

| Effect: ensures homogeneity, stabilizes temperature, reduces dead zones. | |

| 3 | Smart monitoring & control |

| Goal: enable real-time process optimization and fault detection. | |

| |

| Effect: Increases reliability, reduces downtime, supports automation. | |

| 4 | Integration & feedback loop |

| All three areas are interconnected: | |

| |

| Effect: | |

| Enhanced process synergy: integration ensures that modifications in one area (e.g., pretreatment) immediately benefit the others (e.g., reactor efficiency, monitoring accuracy). Real-time adaptability: smart monitoring provides continuous data, enabling dynamic adjustments to pretreatment intensity or reactor settings in response to operational changes. Improved system stability: stable temperature and consistent mixing achieved through adaptive feedback reduce microbial stress and increase biogas yield. Resource efficiency: optimized energy use across pretreatment and reactor operations; reduced water input due to better rheology; overall lowered environmental footprint. Learning-based optimization: AI-driven control systems learn from historical performance, leading to predictive maintenance and optimal scheduling. Closed-loop circularity: continuous refinement of parameters leads to higher substrate conversion, lower residue generation, and improved recovery of energy and nutrients. | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bień, B.; Grobelak, A.; Bień, J.; Sławczyk, D.; Kozłowski, K.; Wysokowska, K.; Rak, M. Dry Anaerobic Digestion of Selectively Collected Biowaste: Technological Advances, Process Optimization and Energy Recovery Perspectives. Energies 2025, 18, 4475. https://doi.org/10.3390/en18174475

Bień B, Grobelak A, Bień J, Sławczyk D, Kozłowski K, Wysokowska K, Rak M. Dry Anaerobic Digestion of Selectively Collected Biowaste: Technological Advances, Process Optimization and Energy Recovery Perspectives. Energies. 2025; 18(17):4475. https://doi.org/10.3390/en18174475

Chicago/Turabian StyleBień, Beata, Anna Grobelak, Jurand Bień, Daria Sławczyk, Kamil Kozłowski, Klaudia Wysokowska, and Mateusz Rak. 2025. "Dry Anaerobic Digestion of Selectively Collected Biowaste: Technological Advances, Process Optimization and Energy Recovery Perspectives" Energies 18, no. 17: 4475. https://doi.org/10.3390/en18174475

APA StyleBień, B., Grobelak, A., Bień, J., Sławczyk, D., Kozłowski, K., Wysokowska, K., & Rak, M. (2025). Dry Anaerobic Digestion of Selectively Collected Biowaste: Technological Advances, Process Optimization and Energy Recovery Perspectives. Energies, 18(17), 4475. https://doi.org/10.3390/en18174475