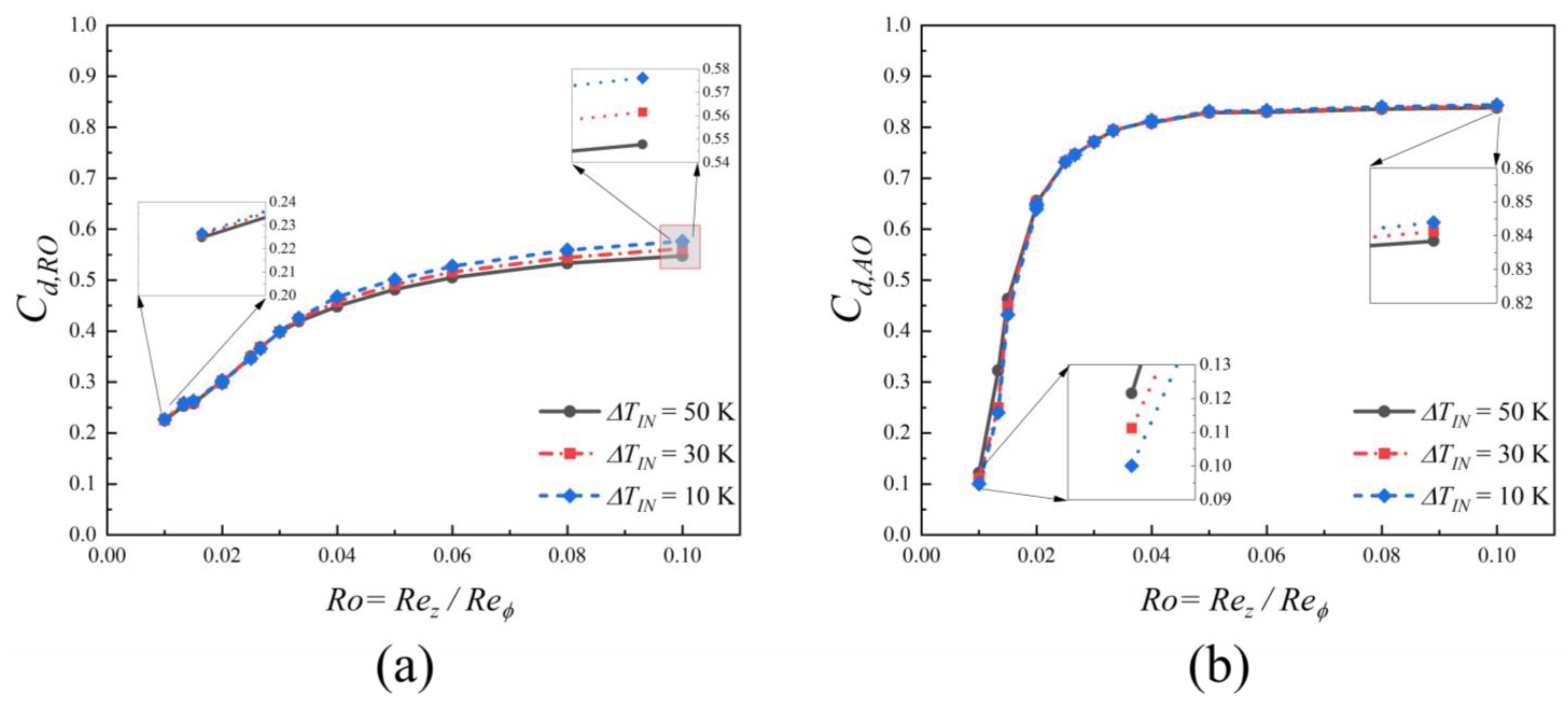

3.1. Effect of Inlet Temperature Differential on Flow Characteristics

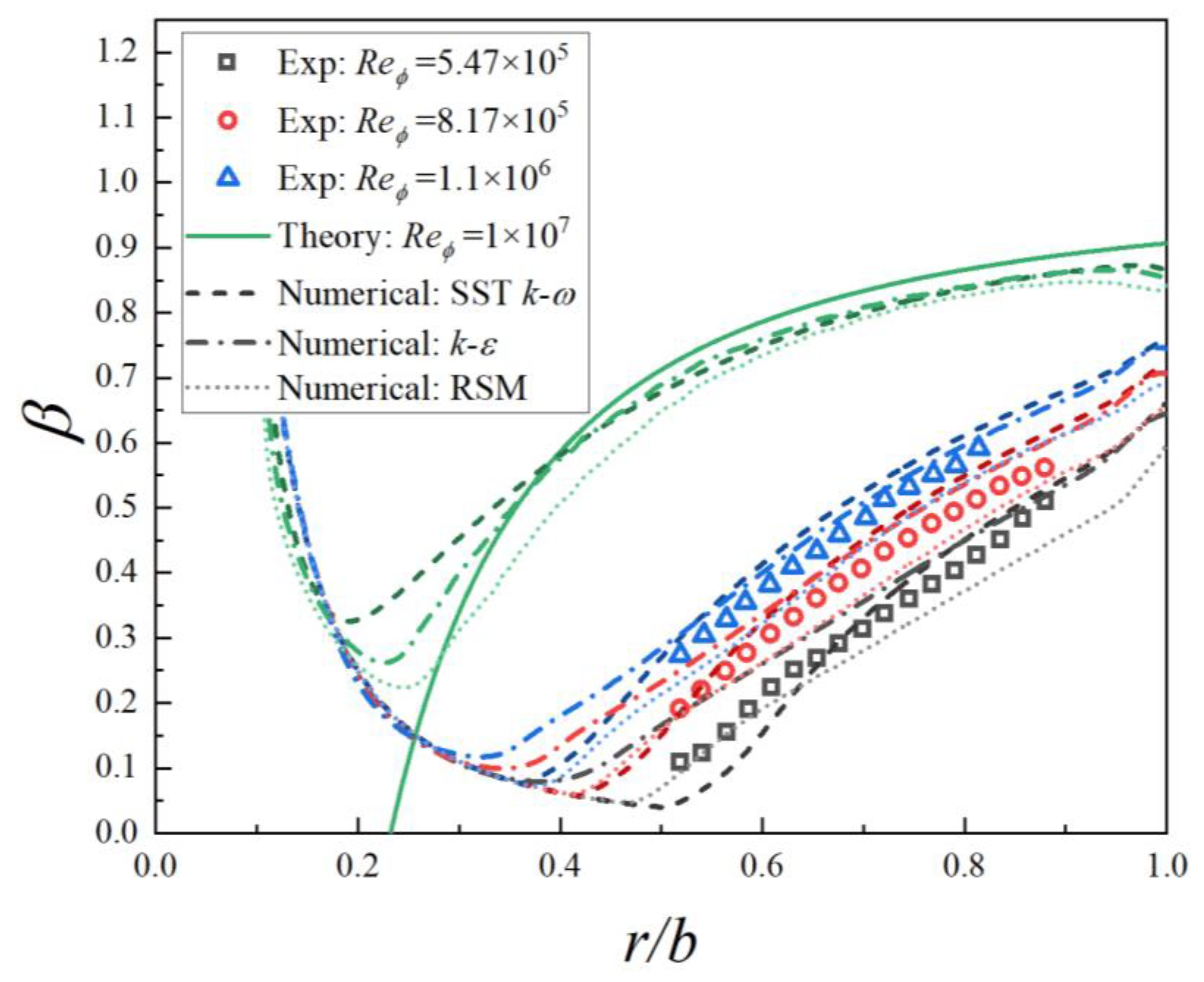

The flow characteristics within rotating cavities are typically governed by the balance between the inertial and rotational forces.

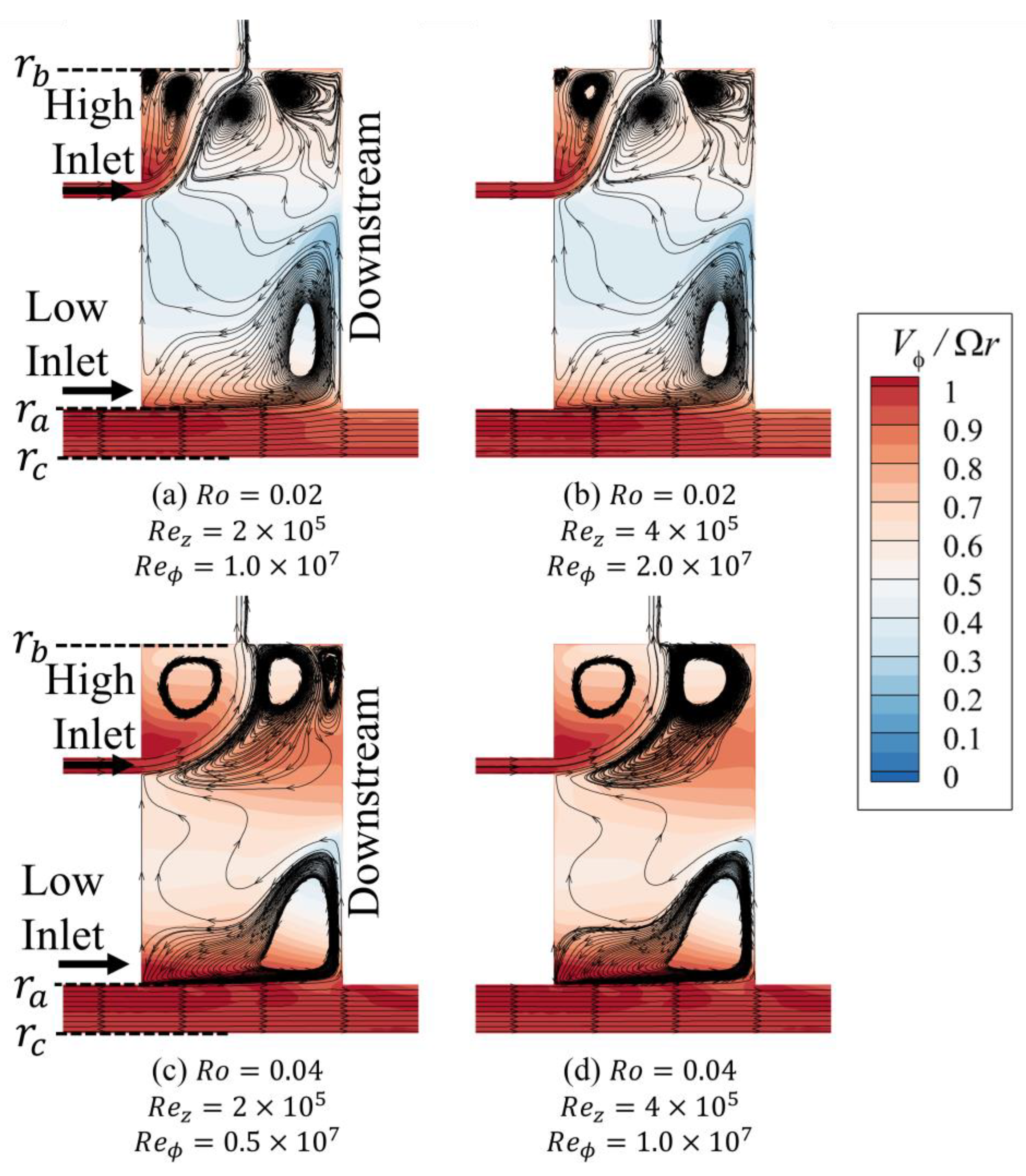

Figure 6 presents two pairs of streamline diagrams overlaid on corresponding swirl ratio

contours for the radial–axial midplane of the cavity, in which the low- and high-inlet jets are subjected to a temperature differential of

K. The figure showcases two pairs of cases where the Rossby number is held constant at

and

, respectively, while the constituent axial and rotational Reynolds numbers (

and

) are varied.

Despite these significant variations in the individual Reynolds numbers, the resulting streamline patterns and swirl ratio contours within each pair are observed to be nearly identical. This striking resemblance confirms that Rossby number flow similarity remains valid even for the complex multi-inlet, multi-outlet configuration investigated in this study and under the influence of inlet temperature differentials. Therefore, the subsequent analysis of the aerothermal characteristics and mass flow distribution in this paper will be framed against an increasing Rossby number to provide a clear and systematic interpretation of the governing flow physics.

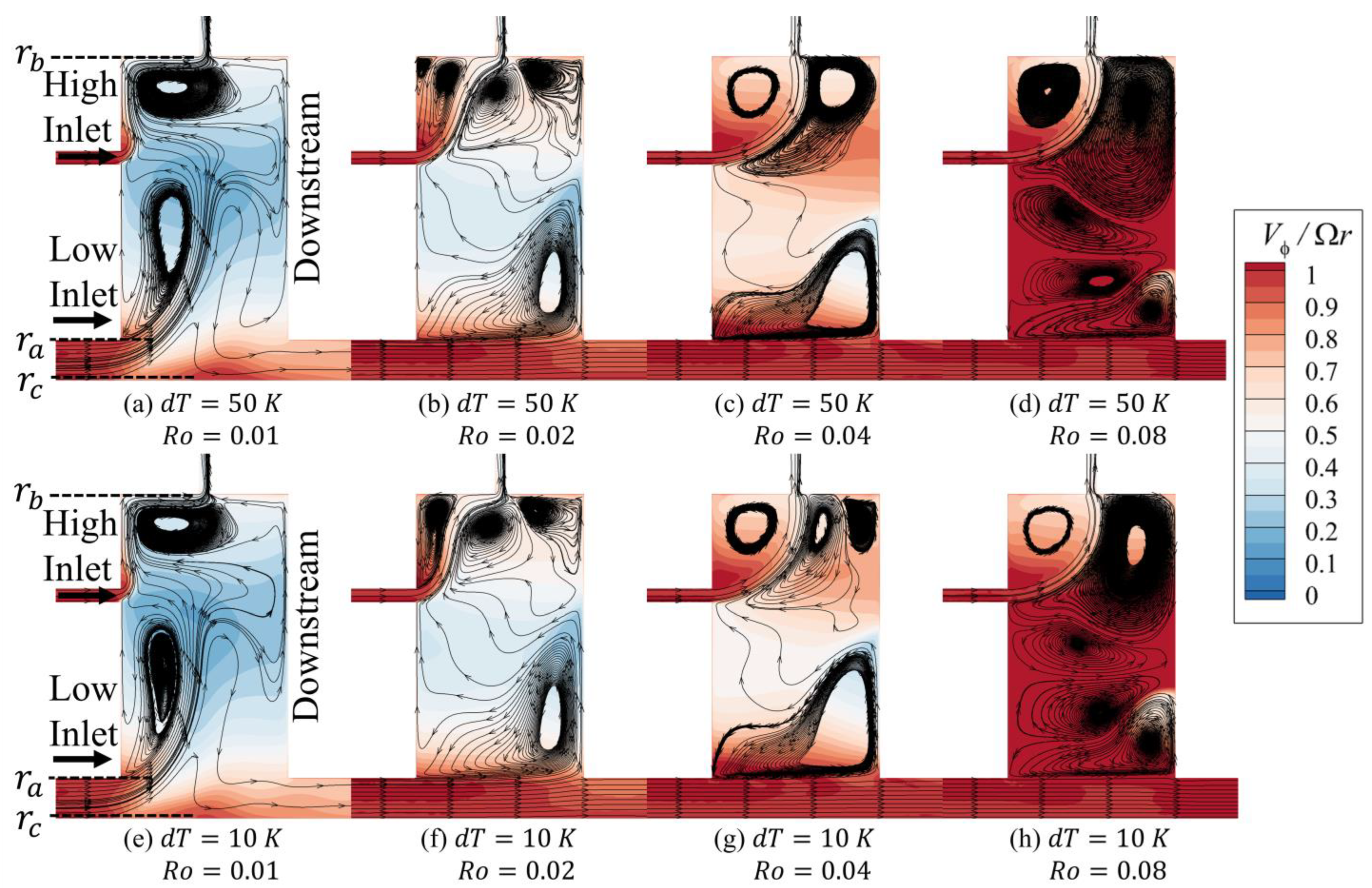

Figure 7 presents the streamline patterns at the cavity’s radial–axial midplane for Rossby numbers ranging from 0.01 to 0.08, under inlet temperature differentials

of 10 K and 50 K. The diagrams reveal a complex flow field dominated by two radially stratified vortical zones that change significantly as the Rossby number increases. Notably, for any given Rossby number, the flow structure is nearly identical for both the 10 K and 50 K temperature differential cases, indicating the secondary role of thermal effects on the overall flow topology.

At the lowest Rossby number of

, the flow within the cavity is heavily dominated by rotational forces, as depicted in

Figure 7a,e. Upon entering the cavity, the low-inlet jet is swept radially outward along the upstream disc. The high-inlet jet is also deflected outward, feeding into a large, axially stretched clockwise vortex that occupies the upper portion of the cavity. While the overall flow structures are very similar, a minor difference can be observed in the low-inlet jet trajectory between the

= 50 K and 10 K cases, where it appears to penetrate slightly further axially into the cavity under the higher temperature differential.

When the Rossby number increases to

= 0.02, as illustrated in

Figure 7b,f, the flow pattern undergoes a significant transformation. The jet from the low inlet now establishes a direct axial path toward the outlet. However, a portion of this flow strikes the downstream disc, which gives rise to a clockwise vortex in the lower-radial area of the cavity. While the overall flow structures remain broadly similar, a subtle difference can be observed in the high-radial region between the high-inlet jet and the upstream disc. In the

= 50 K case of

Figure 7b, small, secondary vortices appear in the cavity’s upstream upper corner. However, at the lower

= 10 K in

Figure 7f, this area is characterized by a single, larger vortex.

Further increasing the Rossby number to 0.04, as illustrated in

Figure 7c,g, results in more changes to the flow structure in the upper recirculation zone. As

rises, the high-inlet jet penetrates further axially before being deflected radially upward in a smooth path. This compresses the downstream vortices against the disc and allows the upstream vortex to expand, filling the upper corner. Differences between the 50 K and 10 K cases become more apparent; the upper downstream vortex is a single entity at 50 K but is split in the 10 K case. Furthermore, the large vortex in the lower recirculation zone is radially shorter when

is 10 K.

As the Rossby number is further increased to 0.08, as seen in

Figure 7d,h, the recirculation zone in the lower-radial area develops into a more complex structure composed of several vortices stacked radially. The primary vortex, which originates from the low-inlet jet impacting the downstream disc, shrinks in its radial dimension. In the upper recirculation zone, the path of the high-inlet jet remains consistent. However, the increased inflow momentum associated with the higher Rossby number leads to a more forceful impact of the deflected jet on the shroud. This causes the clockwise vortex in this upper region to expand and extend downwards, past the radial location of the high inlet. The flow from this enlarged upper vortex then spills into the lower recirculation area, contributing to the formation of the stacked vortex structure and significantly disturbing the local flow field. The higher temperature of the high-inlet (HI) jet at a 50 K differential leads to lower fluid density. At high Rossby numbers, where inertial forces are dominant, this lower-density, high-velocity jet has different momentum and buoyancy characteristics compared to the cooler, denser 10 K jet. This difference in density and momentum upon interacting with the existing cavity flow and the shroud is what can trigger the formation of secondary vortices and enhance the overflow. A key distinction between the temperature differential cases is that the overflow from the downstream high-radial-region vortex is more pronounced at the higher differential of 50 K, which in turn compresses the vortices in the low-radial recirculation zone.

The appearance of these secondary vortices at higher temperature differentials aligns with findings from studies on heated cavities, such as those by Zhao et al. [

11] and Fazeli et al. [

13], which noted that flow becomes more sensitive to thermal effects and gradients, particularly at lower Rossby numbers in their configurations. Our study shows that even with a strong superimposed through-flow, thermal differentials can induce such secondary flow features, especially when inertial forces are significant.

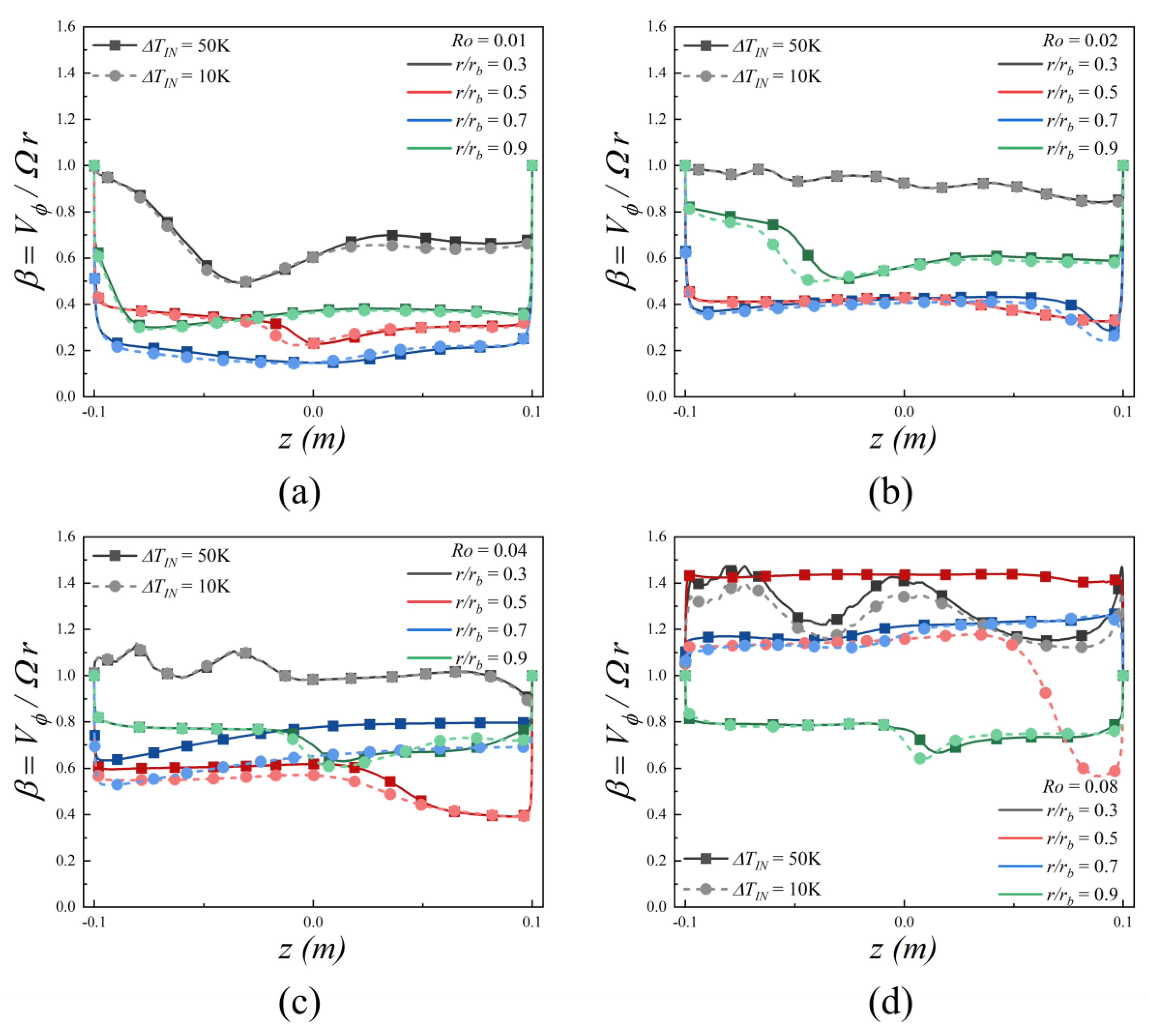

To analyze the cavity swirl ratio

in greater detail, the axial distributions are examined at various radial locations (

). As shown in

Figure 8, these distributions are mapped from the upstream rotor surface (

0.1 m) to the downstream rotor surface (

0.1 m). Subfigures (a) through (d) illustrate the axial distributions of the swirl ratio for Rossby numbers of 0.01, 0.02, 0.04, and 0.08, respectively. In each graph, the darker lines with square symbols represent the 50 K inlet temperature differential, while the lighter lines with circular symbols correspond to the 10 K differential.

Based on the data presented in

Figure 8, several overarching characteristics of the axial swirl ratio distributions can be identified. A consistent trend is

approaching unity near both the upstream and downstream rotor surfaces, which aligns with the expected behaviour of the near-wall fluid achieving corotation with the discs. In the region between these surfaces, the profiles are marked by steep gradients close to the walls and a comparatively flat profile within the central core. This pattern is typical of rotating cavity flows, signifying the presence of thin Ekman boundary layers where disc-induced viscous effects are significant, and a central, largely inviscid core. Furthermore, an increase in

leads to a noticeable elevation in the magnitude of the

across all monitored radial locations.

Under the most rotationally dominant condition of

, the profile in

Figure 8a reveals a zone of high swirl near the upstream disc, which is most pronounced in the low-radial region at

. This corresponds to the upward deflection of the low-inlet jet that was previously observed in the streamline patterns of

Figure 7a,e. The limited axial penetration of this inflow jet is captured in the swirl profile at

, which shows a distinct minimum value at approximately

m. While the overall profiles for the 50 K and 10 K cases are very similar, the most discernible, albeit minor, difference between the two inlet temperature differentials also occurs in this low-radial region. When the

increases to 0.02, the swirl ratio at a relative radius of

initially oscillates around

near the upstream disc before settling to approximately

closer to the downstream disc, as shown in

Figure 8b. The primary distinctions in the swirl ratio profiles between the two temperature differentials are observed in the higher-radial locations of

0.7 and

0.9. At these locations, the larger 50 K temperature differential results in elevated axial swirl ratios at specific points. Meanwhile, the axial swirl ratios at lower-radial locations of

0.3 and

0.5. In contrast, at the lower-radial locations of

0.3 and

0.5, the axial swirl ratio profiles exhibit negligible differences between the two temperature cases, resulting in nearly overlapping plots.

As the Rossby number increases to 0.04 shown in

Figure 8c, fluctuations in the low-radial region of

0.3 are further amplified. The primary differences between the inlet temperature differentials are confined to the mid-radial locations of

0.5 and 0.7, where a higher

results in an increased swirl ratio across nearly the entire axial length. This location corresponds to the position of the vortex in the lower recirculation zone, as shown previously in the streamline patterns of

Figure 7c,g. Upon further increasing the Rossby number to 0.08, as illustrated in

Figure 8d, the differences in the swirl ratio profiles for the two inlet temperature differentials become evident at all monitored radial locations within the cavity. A larger temperature differential

generally results in an elevated and more stable swirl ratio compared to the lower differential

.

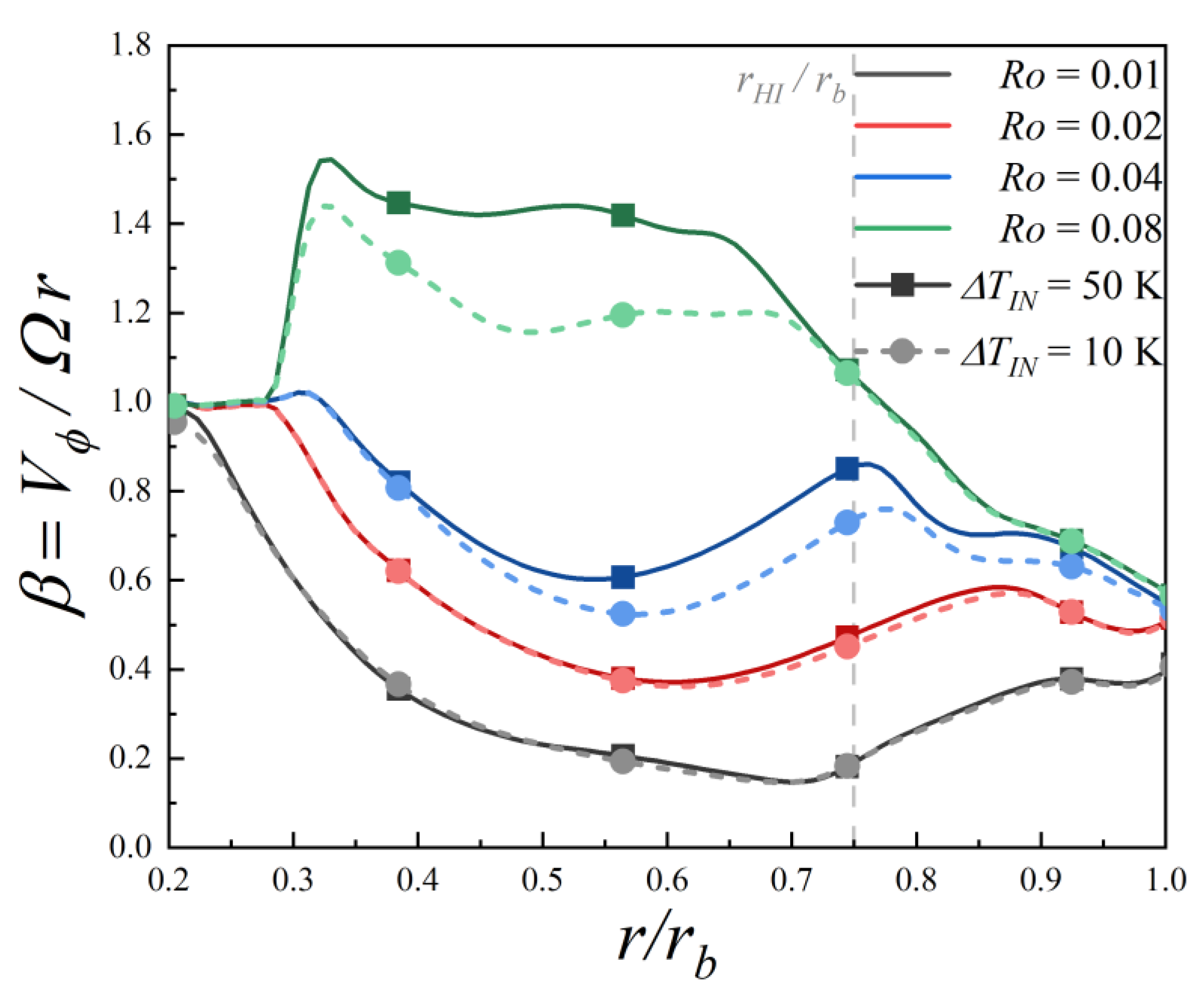

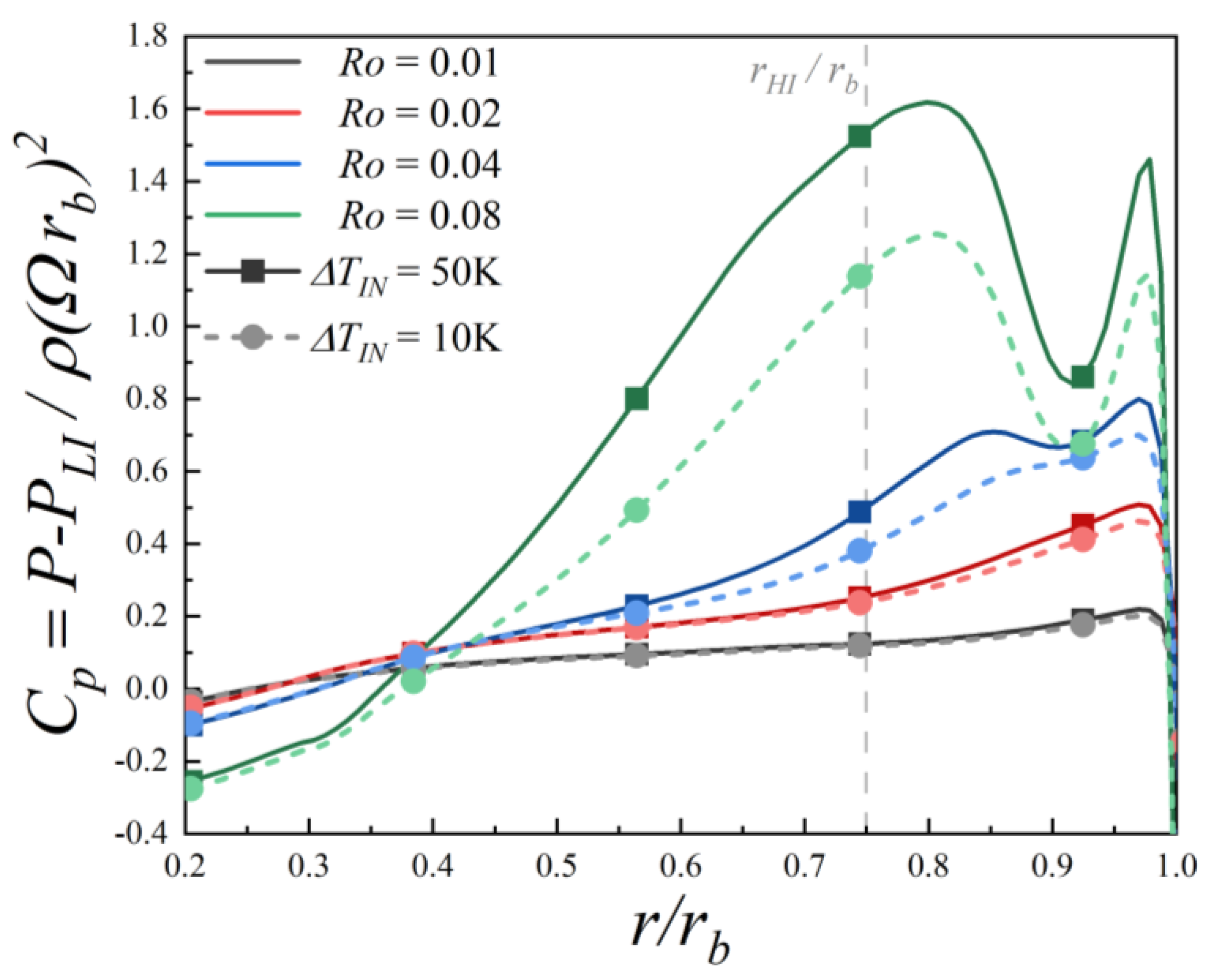

To supplement the analysis of axial profiles, the circumferentially averaged swirl ratio at the cavity’s midplane (

m) is presented in

Figure 9, illustrating the radial distributions of swirl ratio under various Rossby numbers. In the figure, a vertical dotted line indicates the radial location of the high inlet

, serving as a reference point for flow interactions in the outer part of the cavity. Similar to

Figure 8, the results for the 50 K inlet temperature differential are shown using darker lines with square markers, whereas the 10 K differential is represented by lighter lines with circular markers.

A clear trend is that the swirl ratio generally increases across the radius as the Rossby number increases. At the lowest Rossby number of , the profile is the lowest, and the impact of the inlet temperature differential is negligible. However, as increases, a higher temperature differential of consistently results in a higher swirl ratio, an effect that becomes more significant at higher values. For instance, the maximum percentage difference between the swirl ratios for the two temperature differentials is 24.06% at , compared to 20.59% at and only 4.79% at . Moreover, for Rossby numbers of 0.02 and 0.04, a pronounced peak in the swirl ratio develops at a high-radial position (). In contrast, the case exhibits a broad surge in swirl ratio across the cavity’s mid-section, where it remains above unity, unlike the dip seen at lower Rossby numbers.

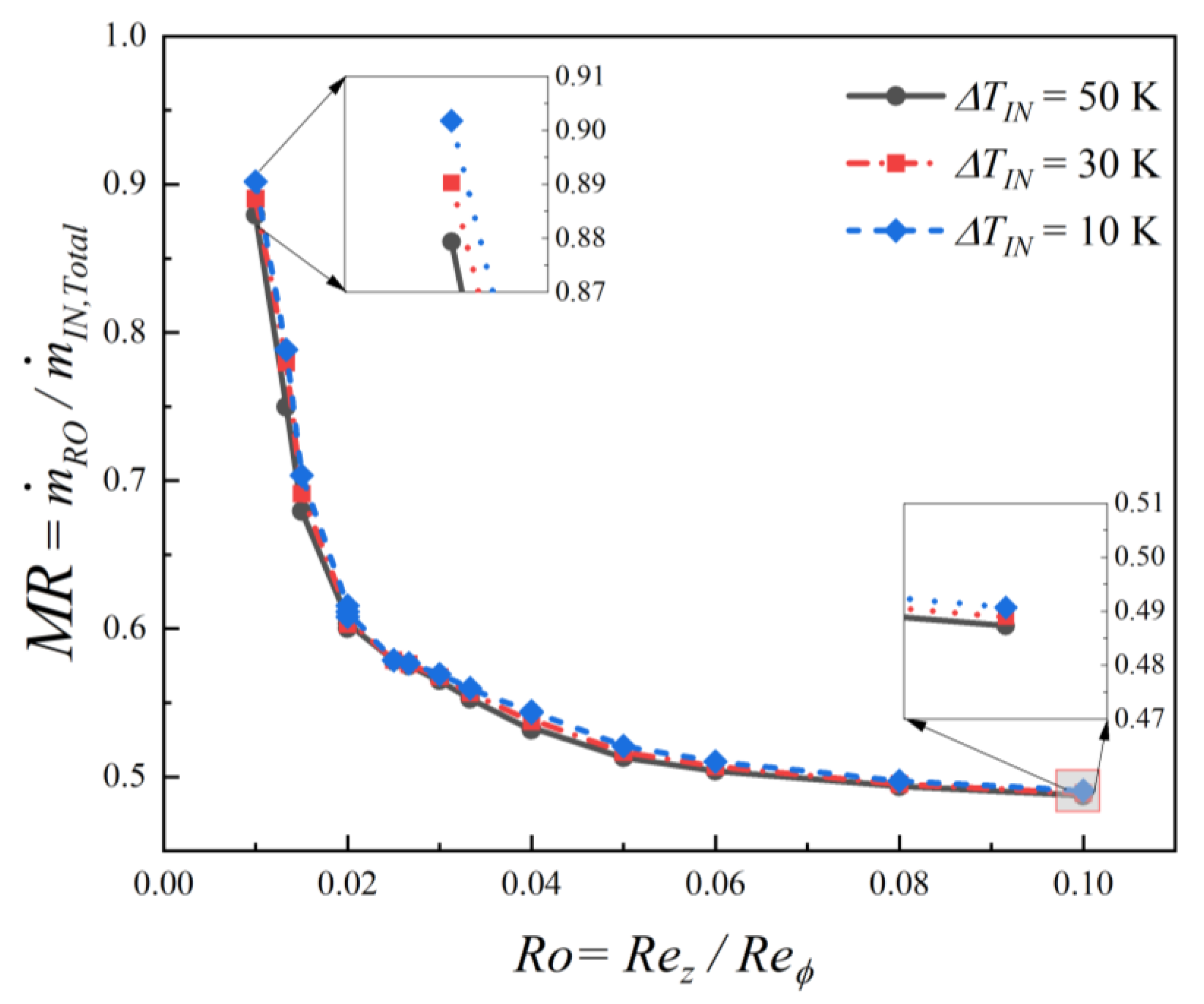

Figure 10 illustrates the relationship between the mass flow distribution that leaves the cavity via radial outlet as denoted by the mass flow ratio

, the Rossby number

, and the inlet temperature differential

. A dominant trend is observed where the

decreases sharply as the Rossby number increases, falling from approximately 0.9 at

to approximately 0.5 at

. This signifies a fundamental shift in the flow distribution, where rotationally dominated conditions of low

favour the radial outlet, while inertia-dominated conditions of high

result in a more balanced split between the radial and axial outlets. which plateaus to approximately 0.5. In comparison, the inlet temperature differential plays a secondary role. A higher

consistently results in a slightly lower

through the radial outlet across the entire range of Rossby numbers tested. However, as highlighted by the magnified insets, this thermal effect is minor; the difference in

between the different temperature cases is only 2.5% at

and diminishes to 0.7% at

.

In this section, it is revealed that Rossby number is the primary driver of flow characteristics within the multi-inlet, multi-outlet corotating-disc cavity and that the inlet temperature differential plays a secondary role. The overall flow topology, defined by radially stratified vortical zones, is largely dictated by the Rossby number. However, increasing the inlet temperature differential induces subtle changes, such as the formation of secondary vortices and more pronounced vortex overflow at higher Rossby numbers. This thermal influence is also evident in the swirl ratio, where a higher temperature differential consistently results in an elevated and more stable swirl, an effect that becomes more significant as the Rossby number increases. Consequently, these changes to the internal flow field affect the mass flow distribution. A higher inlet temperature differential consistently leads to a slight reduction in the mass flow ratio through the radial outlet across the entire range of Rossby numbers tested. However, this thermal effect on the mass flow split is minor.

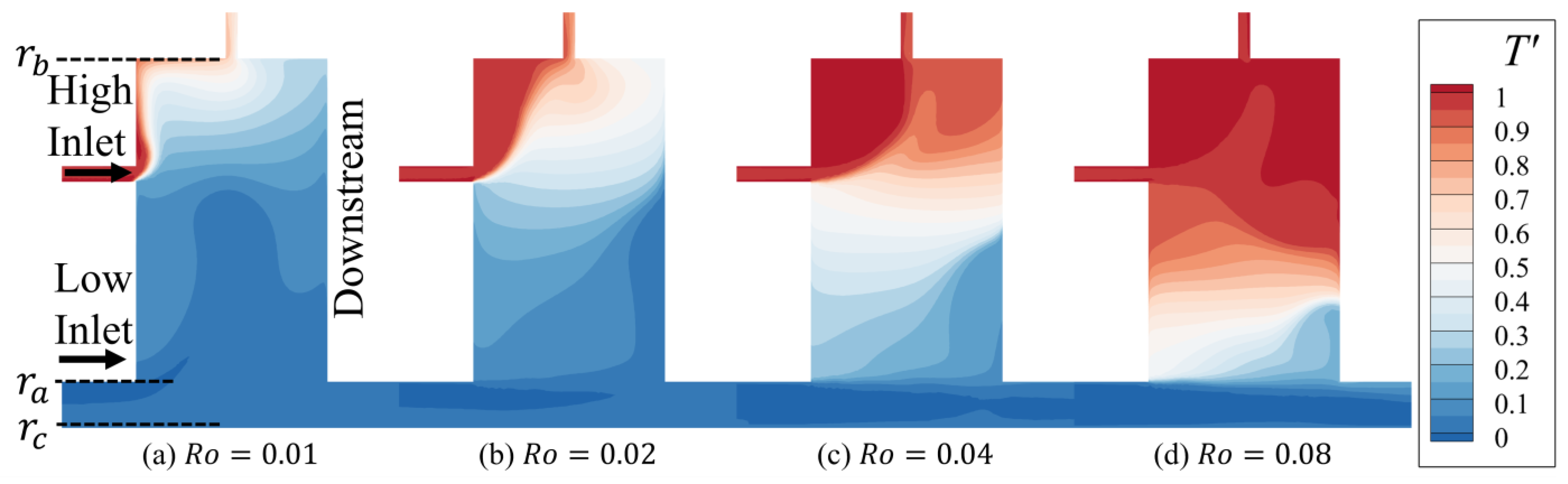

3.3. Cavity Thermal Field and Outlet Thermal Characteristics

To analyze the thermal field within the cavity, the temperature is normalized into a dimensionless form T′, defined as

. This allows for a clear comparison of the thermal distribution across different operating conditions.

Figure 14 presents the contours of this dimensionless temperature on the radial–axial midplane for Rossby numbers ranging from 0.01 to 0.08, all under a constant inlet temperature differential of

K. A consistent feature across all cases is the clear thermal stratification, with the cooler fluid from the low inlet generally occupying the lower and inner regions of the cavity, while the hotter fluid from the high inlet dominates the upper and outer regions.

As

increases, a significant change in the thermal distribution is observed. At the lowest Rossby number of

, the hot fluid from the high inlet is largely contained in the upper-radial region near the upstream disc, with minimal mixing into the lower cavity, as shown in

Figure 14a. As Ro increases to 0.02 and 0.04, the increased inertial influence causes the hot jet to penetrate deeper into the cavity, pushing the thermal interface further down and leading to more significant mixing between the hot and cold streams. Additionally, the primary vortex denoted by dark blue, which originates from the cold low-inlet jet impacting the downstream disc, shrinks in its radial dimension, when comparing between

Figure 14b and

Figure 14c. At the highest Rossby number of

,

Figure 14d shows that the hot fluid extends across almost the entire upper half of the cavity and begins to migrate towards the lower region, indicating substantial thermal mixing driven by the strong inflow momentum of the high-inlet jet.

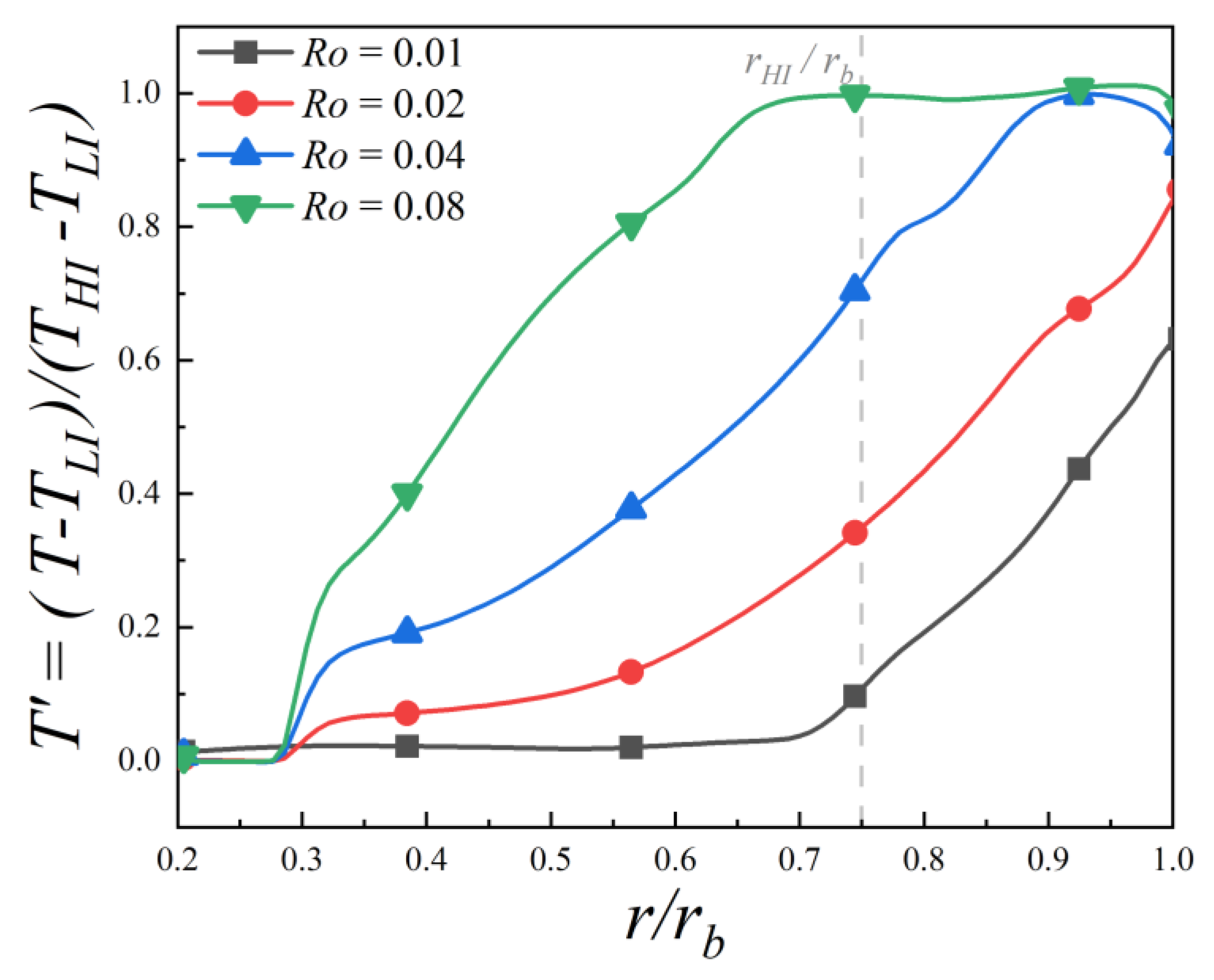

To further quantify the thermal distribution shown in the preceding contour plots,

Figure 15 presents the circumferentially averaged radial profiles of the dimensionless temperature

at the cavity’s axial midplane. In general, the data illustrates that as the Rossby number increases, the dimensionless temperature rises across the entire radial span of the cavity, indicating that the hot fluid from the high inlet penetrates more effectively into the lower-radial region.

The radial temperature profiles at the cavity midplane reveal that thermal mixing is strongly dictated by the Rossby number. In the rotation-dominated regime at , the hot fluid from the high inlet is confined to the outer radii (), leaving the majority of the cavity core unheated (). As inertial forces become more significant at , the hot jet penetrates further inward, initiating a temperature rise from a much smaller radius of . This trend intensifies at , which exhibits a steeper temperature gradient and higher overall temperatures across the profile. Finally, at the inertia-dominated condition of , the hot fluid fully saturates the upper regions of the cavity, with plateauing near unity for . This indicates a substantial overflow of hot air into the lower cavity.

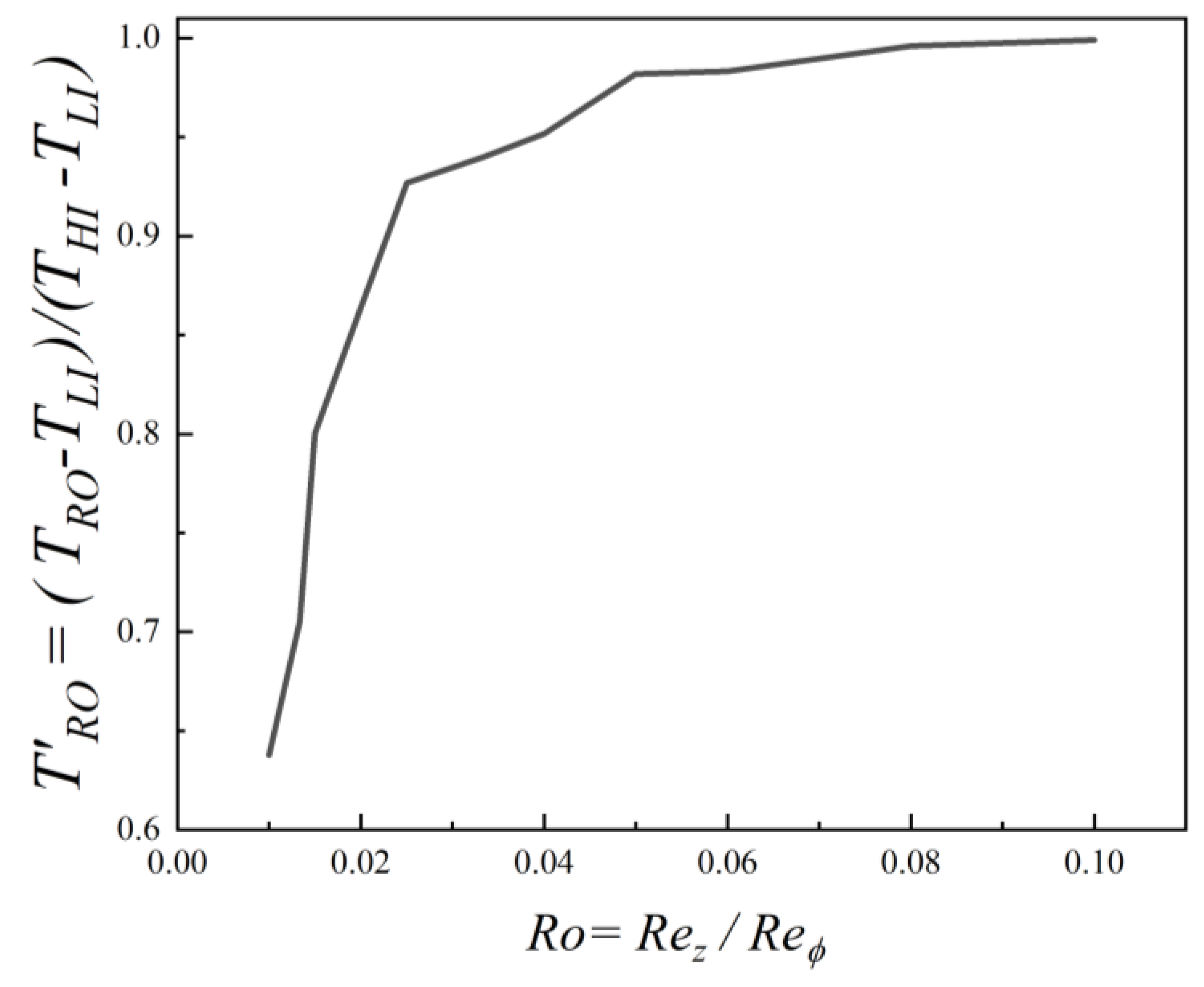

To quantify the impact of these internal thermal field changes on the outlet flow,

Figure 16 plots the dimensionless temperature of the radial outlet

, as a function of the Rossby number. The corresponding dimensionless temperature for the axial outlet

is not shown, as it remains at approximately zero across the entire range of Rossby numbers investigated. This indicates that the outflow through the axial path is composed almost entirely of the unheated fluid from the low inlet.

The behaviour of the radial outlet temperature

is directly linked to the thermal mixing patterns observed in

Figure 14 and

Figure 15. The temperature at the radial outlet undergoes a sharp increase as the Rossby number rises from 0.01 to approximately 0.05, after which it begins to plateau. At low Rossby numbers of

, the rotation-dominated flow confines the hot fluid from the high inlet to the upper-radial region, which results in incomplete mixing. The fluid exiting the radial outlet is therefore a combination of hot and cooler cavity fluid, leading to a dimensionless temperature significantly below 1. As the Rossby number increases to the range of

, the greater inertial influence causes the hot jet from the high-inlet to penetrate deeper into the cavity and enhance thermal mixing. This progressively raises the temperature of the fluid in the upper cavity, causing the sharp rise in

seen in

Figure 16. At high Rossby numbers of

, the hot fluid from the high-inlet jet extends across almost the entire upper half of the cavity, saturating the outer regions with high-temperature fluid where

. Consequently, the fluid exiting the radial outlet consists almost entirely of unmixed, hot fluid from the high inlet, causing the

to plateau at a value approaching unity.

In summary, the thermal characteristics of the cavity are highly dependent on the Rossby number, which governs the extent of thermal mixing between the hot and cold inlet streams. At low Rossby numbers, the flow is rotationally dominated, leading to clear thermal stratification where the cooler fluid occupies the lower and inner regions, and the hotter fluid is contained in the upper and outer areas. As the Rossby number increases, enhanced inertial forces drive deeper penetration of the hot jet, leading to significant thermal mixing and a more uniform temperature distribution in the cavity’s upper half. Consequently, the temperature of the fluid exiting the radial outlet rises sharply with the Rossby number, eventually plateauing as it becomes saturated with unmixed hot fluid from the high inlet. In contrast, the axial outlet temperature remains consistently cool, indicating it is fed almost entirely by the unheated low-inlet stream across all tested conditions.