Large Temperature Difference Heat Pump System for Long-Distance Heat Transportation: Experimental Study and Feasibility Analysis

Abstract

1. Introduction

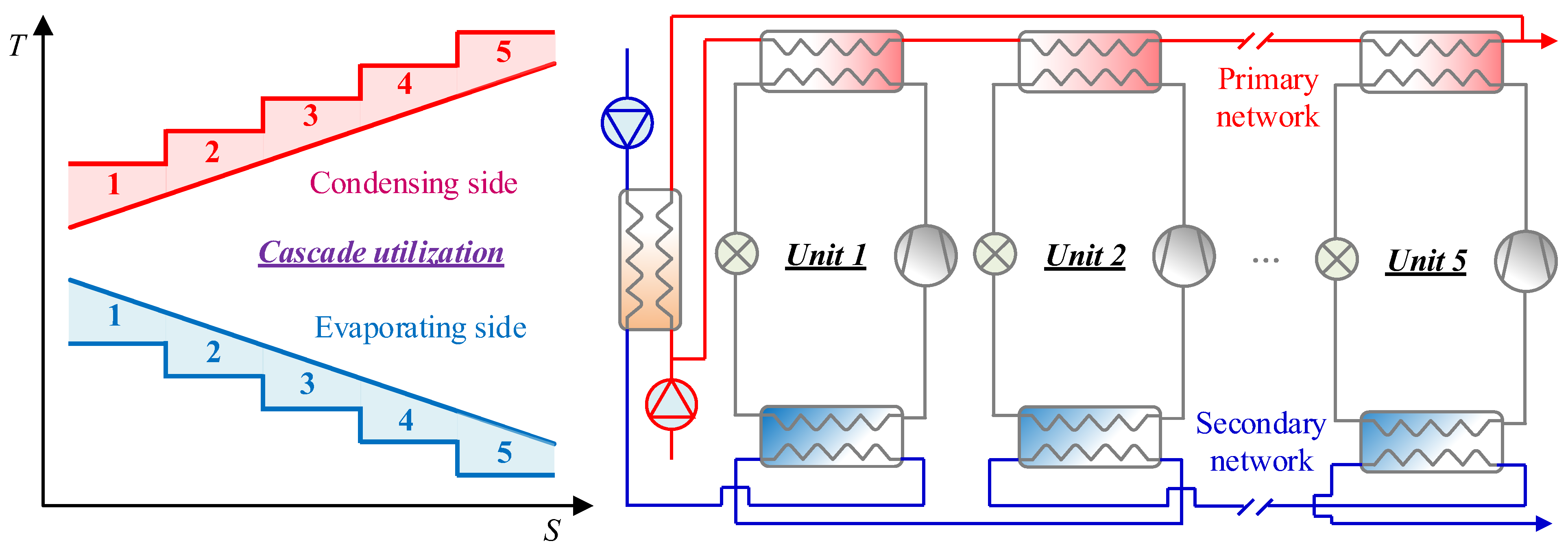

2. Proposal of the Novel System

3. Design of Experiment

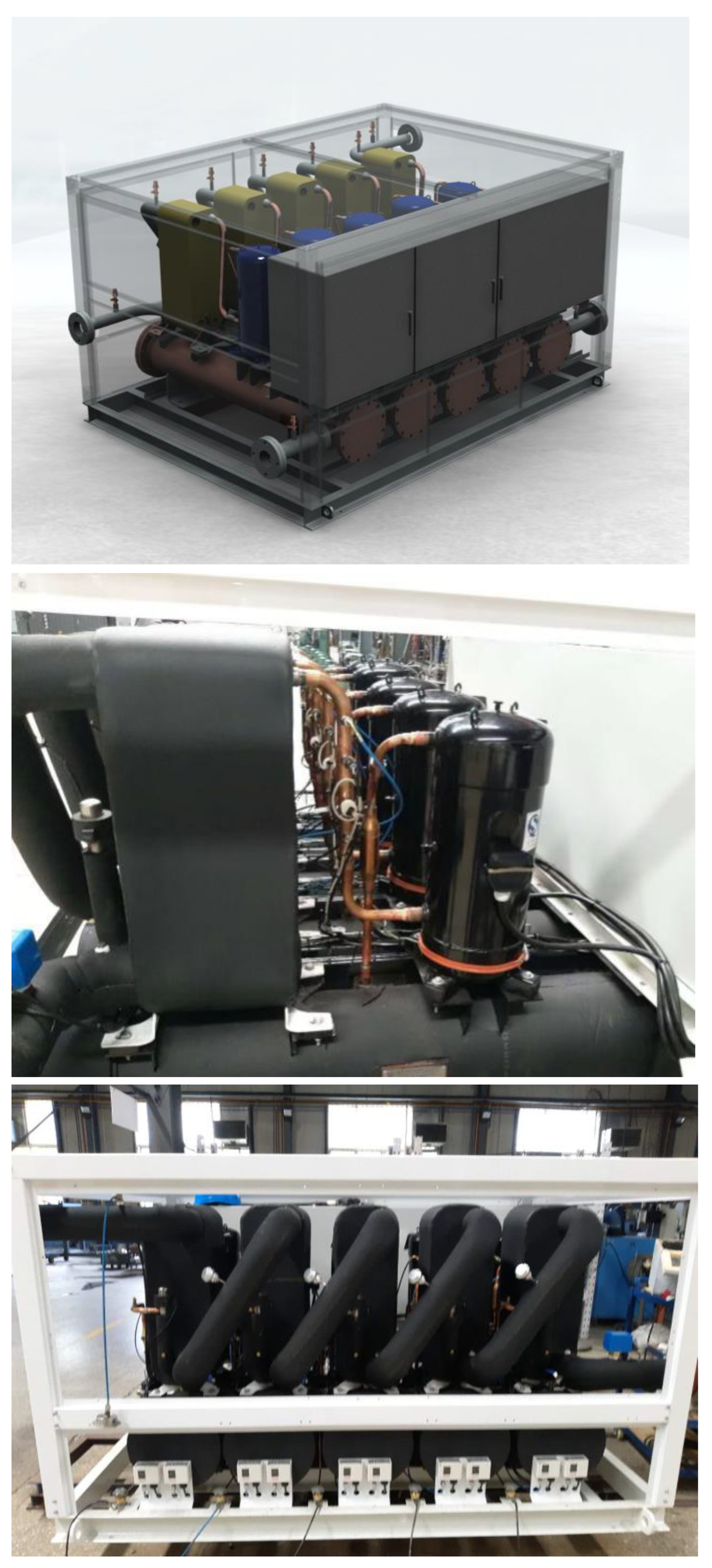

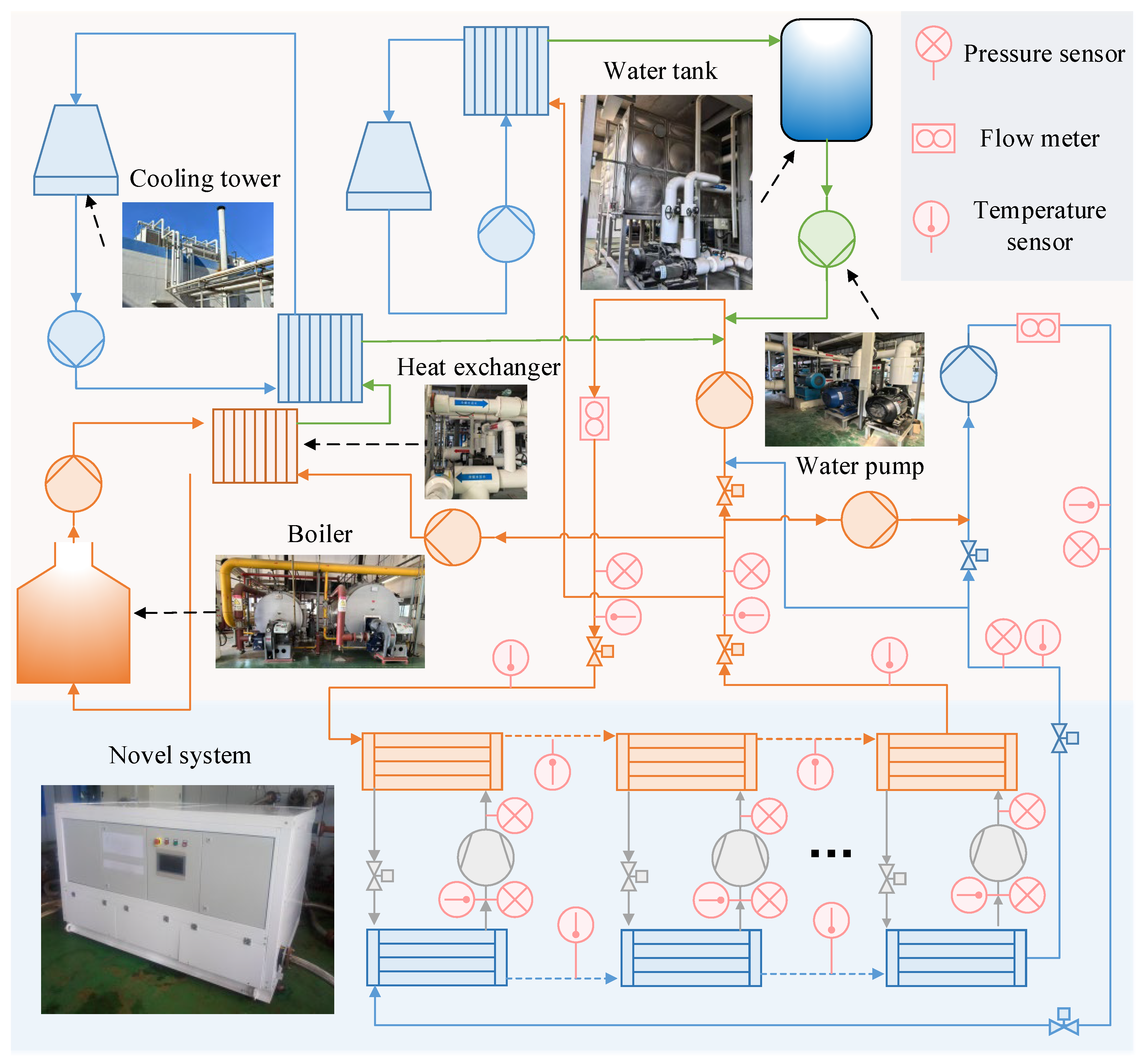

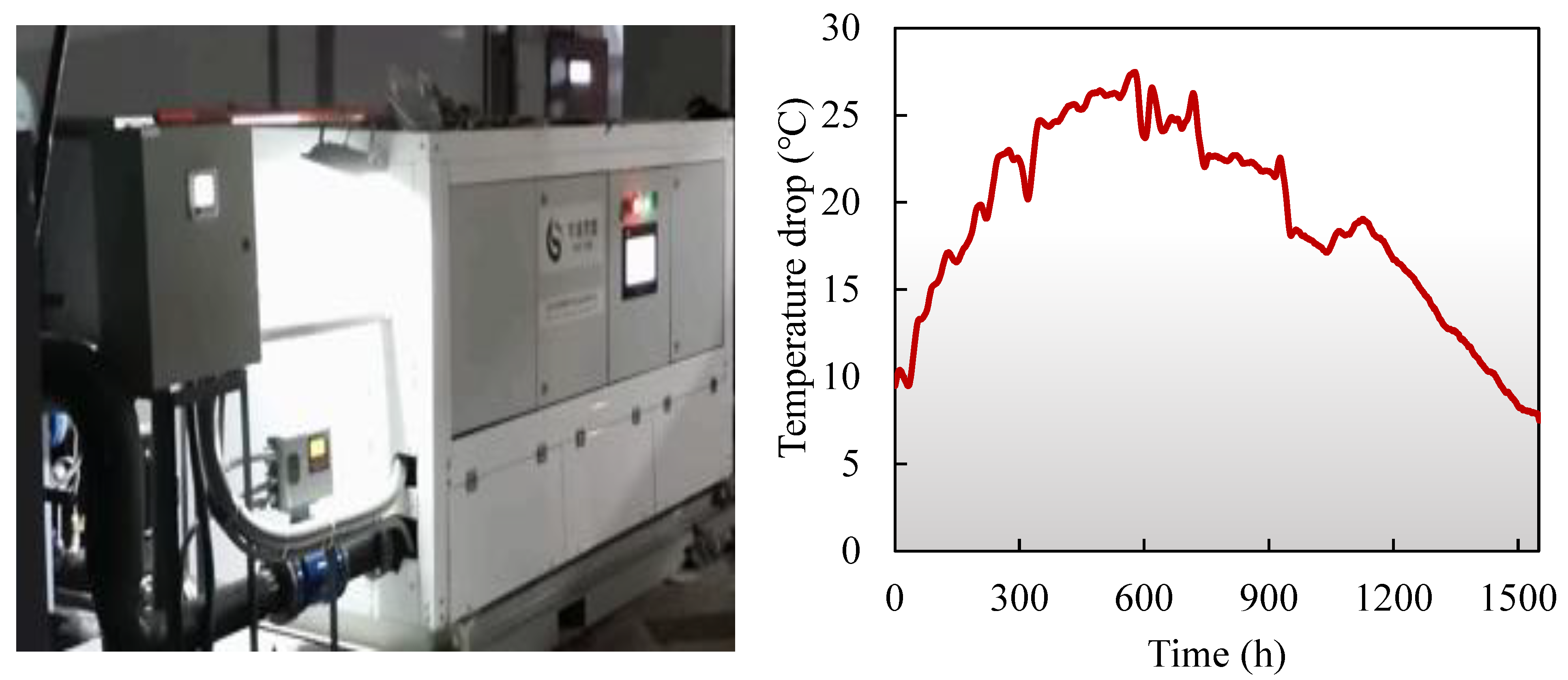

3.1. Design of Experiment Platform

3.2. Design of Experiment Scheme

4. Experimental Results

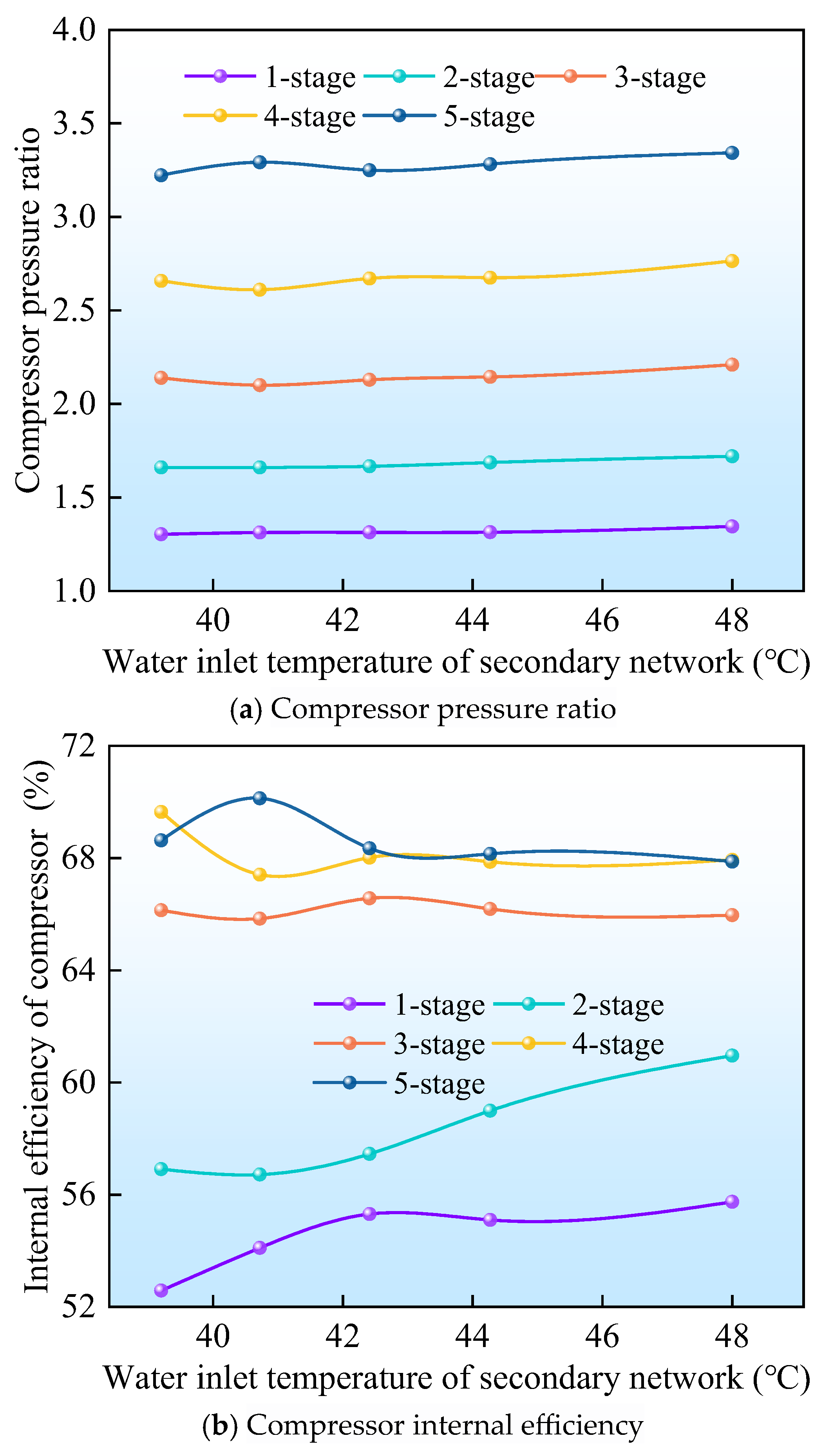

4.1. Influence of Inlet Water Temperature of Secondary Network

4.2. Influence of Water Flow Ratio

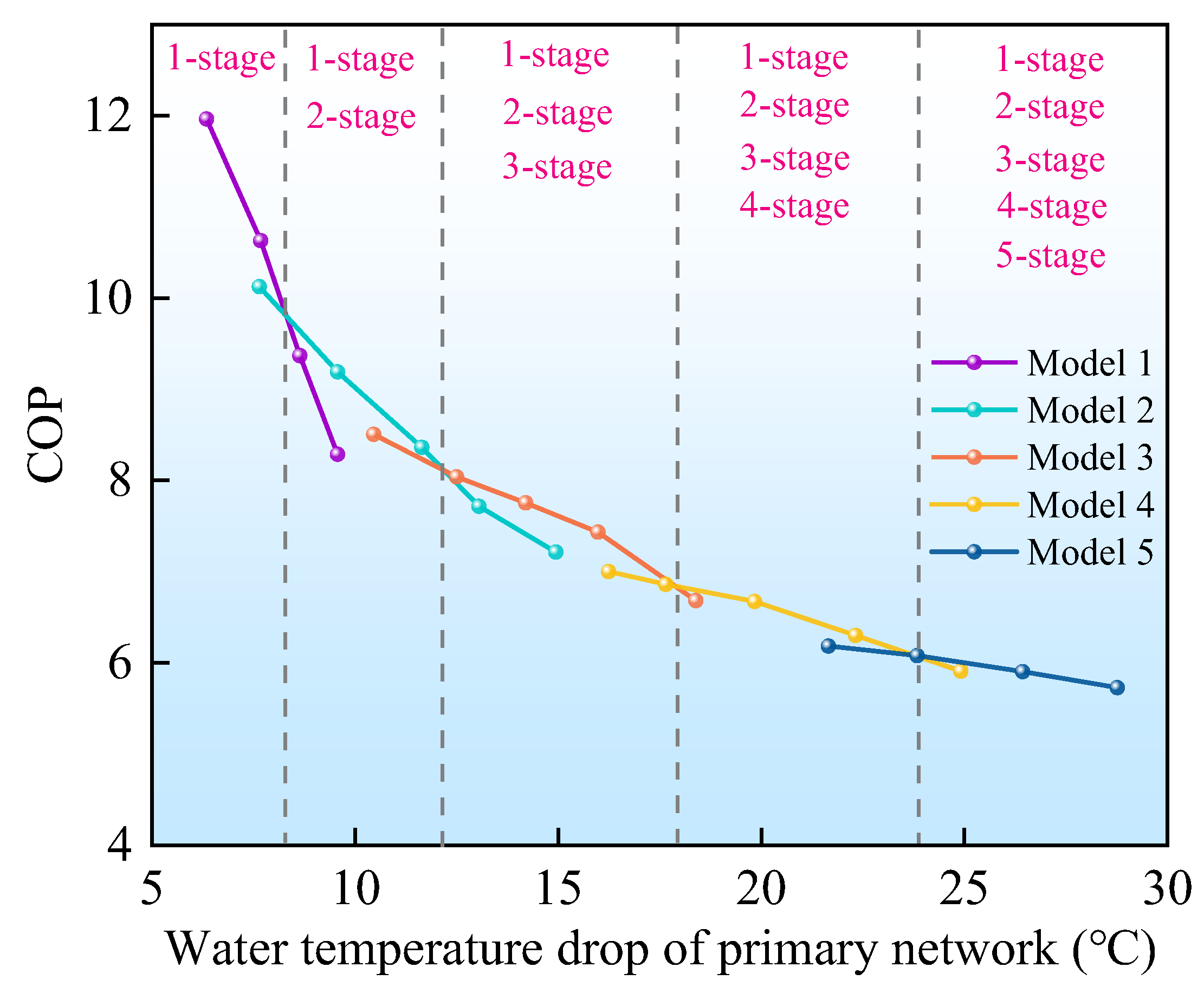

4.3. Influence of Control Strategy

5. Feasibility Analysis

5.1. Application Site and Comparison Object

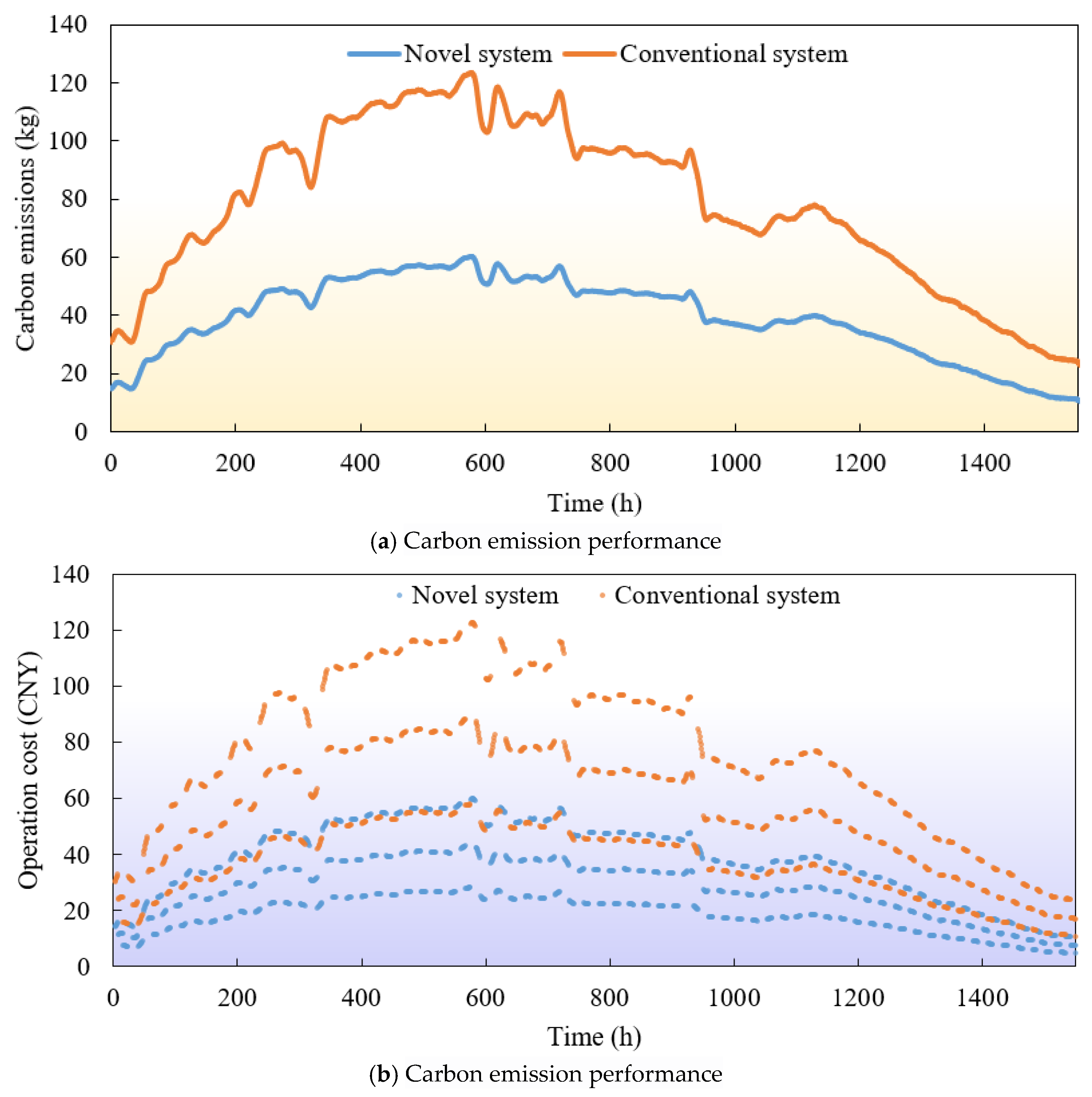

5.2. Environmental and Economic Analysis

6. Conclusions

- (1)

- Primary water temperature drop has the most significant impact on system performance.

- (2)

- Flow rates of both primary/secondary water and secondary water temperature drop have negligible effects.

- (3)

- COP decreases by approximately 1% for every 1 °C reduction in secondary water temperature.

- (4)

- The system has an optimal control strategy. As the temperature difference of the primary network increases, the system should open each heat pump module step by step.

- (5)

- Compared with the scheme using the single-stage heat pump system, the carbon emissions and operation costs of the scheme using the novel system can be reduced by more than 50%.

- (6)

- The increasing use of renewable energy sources has led to greater uncertainty in electricity pricing and carbon emission factors, raising concerns about the feasibility of the system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| cwc | Water-specific heat capacity in the condenser, kJ/(kg·K) |

| cwe | Water-specific heat capacity in the evaporator, kJ/(kg·K) |

| Cpower | Hourly power cost, CYN/h |

| COP | Coefficient of performance of refrigeration system |

| COPh | Coefficient of performance of heat pump system |

| Epower | Hourly electricity carbon emissions, kg/h |

| Fpower | Carbon emissions from electricity, kg/kWh |

| mwc | Mass flow rate of water in the condenser, kg/s |

| mwe | Mass flow rate of water in the evaporator, kg/s |

| Twic | Inlet water temperature in the condenser, °C |

| Twoc | Outlet water temperature in the condenser, °C |

| Twie | Inlet water temperature in the evaporator, °C |

| Twoe | Outlet water temperature in the evaporator, °C |

| ΔTwp | Water temperature drop of primary network, °C |

| Wcom | Energy consumption of the compressor, kW |

| Zpower | Power price, CNY/kWh |

References

- Ermel, C.; Bianchi, M.V.A.; Cardoso, A.P.; Schneider, P.S. Thermal Storage Integrated into Air-Source Heat Pumps to Leverage Building Electrification: A Systematic Literature Review. Appl. Therm. Eng. 2022, 215, 118975. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, W.; Fang, H.; Xia, J. Clean Heating in Northern China: Regional Investigations and Roadmap Studies for Urban Area Towards 2050. J. Clean. Prod. 2022, 334, 130233. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhou, J.; Xu, F.; Deng, G. Solar Assisted Air Source Heat Pump Systems for Campus Water Heating in China: Economic Optimization of Solar Fraction Design. Appl. Therm. Eng. 2022, 213, 118767. [Google Scholar] [CrossRef]

- Lu, Y.; Yu, M.; Yu, J. Performance Analysis of Dual Ejector-Expansion Air Source Heat Pump Cycle with Three-Stage Evaporation for Cold Region Application. Appl. Therm. Eng. 2023, 226, 120259. [Google Scholar] [CrossRef]

- O’Hegarty, R.; Kinnane, O.; Lennon, D.; Colclough, S. Air-to-Water Heat Pumps: Review and Analysis of the Performance Gap Between In-Use and Product Rated Performance. Renew. Sustain. Energy Rev. 2022, 155, 111887. [Google Scholar] [CrossRef]

- Guo, F.; Zhu, X.; Li, P.; Yang, X. Low-Grade Industrial Waste Heat Utilization in Urban District Heating: Simulation-Based Performance Assessment of a Seasonal Thermal Energy Storage System. Energy 2022, 239, 122345. [Google Scholar] [CrossRef]

- Fang, H.; Xia, J.; Zhu, K.; Su, Y.; Jiang, Y. Industrial Waste Heat Utilization for Low Temperature District Heating. Energy Policy 2013, 62, 236–246. [Google Scholar] [CrossRef]

- Fu, L.; Li, Y.; Wu, Y.; Wang, X.; Jiang, Y. Low Carbon District Heating in China in 2025—A District Heating Mode with Low Grade Waste Heat as Heat Source. Energy 2021, 230, 120765. [Google Scholar] [CrossRef]

- Li, Y.; Pan, W.; Xia, J.; Jiang, Y. Combined Heat and Water System for Long-Distance Heat Transportation. Energy 2019, 172, 401–408. [Google Scholar] [CrossRef]

- Xie, X.; Jiang, Y. Absorption Heat Exchangers for Long-Distance Heat Transportation. Energy 2017, 141, 2242–2250. [Google Scholar] [CrossRef]

- Li, T.; Chen, W.; Li, X.; Wang, B.; Shi, W. Investigation of Control Strategies for Dual-Temperature District Heating Substations with Two Absorption Heat Pumps and Two Heat Exchangers. Energy Convers. Manag. 2024, 309, 118431. [Google Scholar] [CrossRef]

- Yi, Y.; Xie, X.; Jiang, Y.; Sun, M.; Yang, E. Process Design, Performance Comparison and Operating Test of the Multi-Stage Vertical Absorption Heat Exchanger Realizing Independent Heating in Three Zones. Appl. Therm. Eng. 2024, 255, 123907. [Google Scholar] [CrossRef]

- Demir, H.; Mobedi, M.; Ülkü, S. A Review on Adsorption Heat Pump: Problems and Solutions. Renew. Sustain. Energy Rev. 2008, 12, 2381–2403. [Google Scholar] [CrossRef]

- Goyal, A.; Staedter, M.A.; Garimella, S. A Review of Control Methodologies for Vapor Compression and Absorption Heat Pumps. Int. J. Refrig. 2019, 97, 1–20. [Google Scholar] [CrossRef]

- Bamigbetan, O.; Eikevik, T.M.; Nekså, P.; Bantle, M. Review of Vapour Compression Heat Pumps for High Temperature Heating Using Natural Working Fluids. Int. J. Refrig. 2017, 80, 197–211. [Google Scholar] [CrossRef]

- Wang, J.; Gullo, P.; Ramezani, H. Review on the Trend of Ultra-Low-GWP Working Fluids for Small-Capacity Vapour-Compression Systems. Sustain. Energy Technol. Assess. 2024, 66, 103803. [Google Scholar] [CrossRef]

- Zhou, F.; Zhang, T.; Wei, D.; Liu, J.; Zhang, X. Optimal Refrigerant Selection and Parameter Analysis of a Wastewater Heat Pump Using CO2 Zeotropic Mixtures. Appl. Therm. Eng. 2024, 253, 123789. [Google Scholar] [CrossRef]

- Zhang, C.; Han, Z.; Dong, J.; Li, M.; Zhang, Y.; Li, X.; Wen, Z.; Wang, Q. A Novel Data Center Air Conditioner and Its Application Scheme Balancing High-Efficiency Cooling and Waste Heat Recovery: Environmental and Economic Analysis. Energy 2024, 291, 130294. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, F.; Lyu, N.; Fan, H.; Zhang, X. Analysis of Low GWP Ternary Zeotropic Mixtures Applied in High-Temperature Heat Pump for Waste Heat Recovery. Energy Convers. Manag. 2023, 292, 117381. [Google Scholar] [CrossRef]

- Obika, E.; Heberle, F.; Brüggemann, D. Thermodynamic analysis of novel mixtures including siloxanes and cyclic hydrocarbons for high-temperature heat pumps. Energy 2024, 294, 130858. [Google Scholar] [CrossRef]

- Feng, C.; Guo, C.; Chen, J.; Tan, S.; Jiang, Y. Thermodynamic analysis of hybrid working fluids in industrial waste heat recovery heat pumps. Energy Convers. Manag. 2024. [Google Scholar]

- Jia, Y.; Li, S.; Liu, Z. Numerical investigation on optimization of ejector primary nozzle geometries with fixed/varied nozzle exit position. Appl. Therm. Eng. 2020, 175, 115426. [Google Scholar] [CrossRef]

- Dou, P.; Jia, T.; Chu, P.; Dai, Y.; Shou, C. Performance Analysis of No-Insulation Long Distance Thermal Transportation System Based on Single-Stage Absorption-Resorption Cycle. Energy 2022, 243, 123125. [Google Scholar] [CrossRef]

- Hou, G.; Taherian, H. Performance analysis of a hybrid ground source heat pump system integrated with liquid dry cooler. Appl. Therm. Eng. 2019, 159, 113830. [Google Scholar] [CrossRef]

- Tan, Y.; Hou, Z.; Wang, L.; Li, X.; Wang, Z.; Yuan, J. Performance assessment of a two-stage evaporation grade compression heat pump system for double temperature level drinking water production. Appl. Therm. Eng. 2023, 228, 120488. [Google Scholar] [CrossRef]

- Ma, Q.; Luo, L.; Wang, R.Z.; Sauce, G. A review on transportation of heat energy over long distance: Exploratory development. Renew. Sustain. Energy Rev. 2009, 13, 1532–1540. [Google Scholar] [CrossRef]

- Zhang, Q.; Di, H.F. Research on Optimization of Heating Parameters of Secondary Network in Central Heating System. J. Heat. Vent. Air Cond. 2012, 42, 33–37. [Google Scholar]

- GB/T 10870-2014; National Technical Committee for Standardization of Refrigeration and Air Conditioning Equipment (SAC/TC 238). Test Method for Performance of Vapor Compression Cycle Chiller (Heat Pump) Units. China Standards Press: Beijing, China, 2014.

| Device | Parameter | Value |

|---|---|---|

| Compressor | Type | Scroll Compressor |

| Rated refrigerating capacity | 19.0 kW/23.8 kW/25.7 kW/30.6 kW/36.1 kW | |

| Rated power | 5.8 kW/7.2 kW/7.8 kW/9.1 kW/10.9 kW | |

| Evaporator | Type | Plate heat exchanger |

| Heat exchange area | 7.4 m2/7.4 m2/7.4 m2/7.4 m2/7.4 m2 | |

| Condenser | Type | Shell and Tube Condenser |

| Heat exchange area | 2.5 m2/2.5 m2/2.5 m2/2.5 m2/2.5 m2 | |

| Expansion Valve | Type | Electronic Expansion Valve |

| Rated refrigerating capacity | 105 kW/70 kW/70 kW/70 kW/70 kW | |

| Flow Diameter | 6.5 mm/5.5 mm/5.5 mm/5.5 mm/5.5 mm |

| Device | Parameter | Value |

|---|---|---|

| Temperature sensor | Type | Platinum Resistance PT100 |

| Accuracy | ±0.3 °C | |

| Measurement Range | −50 °C to +200 °C | |

| Temperature sensor | Type | Piezoresistive pressure sensor |

| Accuracy | ±0.03 bar | |

| Measurement Range | 0~40 bar | |

| Flow meter | Type | Vortex flowmeter |

| Accuracy | ±0.075 T/h | |

| Measurement Range | 0~30 T/h | |

| Power meter | Accuracy | ±0.04 kw |

| Measurement Range | 0~20 kW |

| Time | Price (CNY/kWh) |

|---|---|

| 08:00–11:00, 17:00–23:00 | 0.8368 |

| 07:00–08:00, 13:00–17:00, 23:00–24:00 | 0.6072 |

| 00:00–07:00, 11:00–13:00 | 0.3966 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, Q.; Li, M.; Dang, C.; Hou, B.; Zhang, S. Large Temperature Difference Heat Pump System for Long-Distance Heat Transportation: Experimental Study and Feasibility Analysis. Energies 2025, 18, 4449. https://doi.org/10.3390/en18164449

Miao Q, Li M, Dang C, Hou B, Zhang S. Large Temperature Difference Heat Pump System for Long-Distance Heat Transportation: Experimental Study and Feasibility Analysis. Energies. 2025; 18(16):4449. https://doi.org/10.3390/en18164449

Chicago/Turabian StyleMiao, Qing, Minxia Li, Chaobin Dang, Beiran Hou, and Shigang Zhang. 2025. "Large Temperature Difference Heat Pump System for Long-Distance Heat Transportation: Experimental Study and Feasibility Analysis" Energies 18, no. 16: 4449. https://doi.org/10.3390/en18164449

APA StyleMiao, Q., Li, M., Dang, C., Hou, B., & Zhang, S. (2025). Large Temperature Difference Heat Pump System for Long-Distance Heat Transportation: Experimental Study and Feasibility Analysis. Energies, 18(16), 4449. https://doi.org/10.3390/en18164449