Abstract

Bifacial photovoltaic panels are preferred over monofacial panels due to the ability of their back surfaces to absorb radiation and generate electricity. However, optimizing the rear-side energy contribution remains a critical area of research. This study systematically investigates how four key parameters (albedo, tilt angle, panel height, and mounting configuration) affect rear-side energy generation and overall panel efficiency. In the first scenario, the impact of surface reflectivity was evaluated. High-reflectivity materials such as aluminum (21.2%) and fresh snow (20.5%) significantly increased rear-side energy yield. The second scenario examined tilt angle, showing that increasing the tilt up to 50° enhanced back-side generation, reaching a gain of 5.5%. The third scenario focused on the effect of panel height, revealing a linear relationship with energy generation. The fourth assessed orientation, comparing horizontal and vertical installations. Horizontal mounting provided a higher rear-side energy yield (4.5%) due to increased exposure to ground-reflected radiation. The findings of this study provide important information for the optimization of bifacial photovoltaic panels and the information will provide guidance for easier and more efficient installation of solar power plants.

1. Introduction

Many factors, such as population growth, advances in technology and industry, and changing lifestyles, have led to the sustained rise in the demand for electrical energy. To address this rising demand in accordance with net zero emission targets, there is a global shift towards renewable energy sources to replace conventional energy sources within developed and developing countries [1,2]. Solar photovoltaic (PV) systems are among the most widely used renewable energy sources in this context. In an effort to meet this increased demand, both developed and developing countries are putting massive efforts and resources into this particular field [3,4,5].

PV panels are developed to convert solar energy into electrical energy. These panels are generally classified as monofacial and bifacial. Of these technologies, bifacial panels are advanced. The bifacial panels have a special feature compared to monofacial panels, as they generate electricity from the front side and the back side. It has also been proven that the replacement of monofacial panels with bifacial panels in solar power plants results in a significant increase in energy efficiency in the use of bifacial panels. This is because electrical energy is generated from the back surface of the PV panel by means of reflection [6]. The first industrial production of BPV panels was initiated in 1984 [7] was an important milestone in solar technology and has increased steadily over the years as their availability in the global market has continued to increase. Predictions show that about 35% of the global market for bifacial panels will be captured by 2027 [8].

A number of research studies have been conducted in the literature on the electrical performance of bifacial photovoltaic (BPV) panels in both experimental and simulated conditions. Ganesan et al. [8] studied the performance of BPV panels at different heights and concluded that the maximum power output achieved was 375 watts at heights above 1 m, with a bifaciality factor of approximately 25%. Ganesan et al. [9] then conducted a study on the reflective properties of five different surfaces (grass, sand, cement, white paint, and aluminum) as substrates in their experimental configuration. They found that aluminum surfaces give the best energy generation, with appreciable albedos between 0.50 and 0.57, having an average bifacial gain of 21.4%. Bifacial gain, a critical metric of BPV performance, is defined as the fraction of additional energy generated by BPV panels compared to monofacial PV panels [9,10]. Pelaez et al. [10] investigated the impact of albedo, slope, row pitch, and spacing on BPV performance in the U.S. and compared five different models, including the radiation tracking model, the visibility factor model, and the experimental model. The study’s findings indicated that a bifacial gain of approximately 20% was attained under specific configurations. Durusoy et al. [11] built a model to estimate the back-surface radiation in an experimental study in Ankara. Marzia et al. [12] examined the performance of BPV on different surfaces (concrete, white tiles, soil, and white pebbles) under UK meteorological conditions. The findings indicated that white pebbles and white tiles yielded the highest energy production, exhibiting a gain exceeding 30%.

Despite the numerous studies conducted on the physical parameters affecting BPV system performance, the majority of these studies have focused on a single variable or have evaluated scenarios within limited ranges. For instance, Ganesan et al. examined the influence of panel height on the albedo effect [8], considering variations in ground materials [9]. Pelaez et al. [10] concentrated on the precision of radiation models, while Durusoy et al. [11] concentrated on back-surface radiation in constrained height ranges. Alam et al. [12] compared bifacial and monofacial systems under varying albedo conditions. Wang et al. [13] considered mounting height and albedo, but only fixed values for tilt angle. Although Yusufoglu et al. [14] considered tilt, albedo, and height together, their analysis was performed in Germany, a region with very different radiation conditions from Türkiye.

The novel aspect of this study is its comprehensive evaluation of the numerous installation parameters that influence the performance of BPV systems. This evaluation is conducted in an integrated manner, encompassing a wide range of intervals, and is performed on a unified platform. Furthermore, it offers a user-friendly analysis infrastructure with an accessible software tool and presents an approach that supports practical decision-making processes based on local climate data without requiring high software knowledge or computational power. In this respect, the study establishes a connection between academic modeling and field realities, thereby making a practical and methodological contribution to extant studies in the literature.

In this study, a parametric analysis was conducted to optimize rear-side energy contribution in BPV systems. The influences of surface albedo, panel tilt angle, mounting height, and installation orientation (horizontal vs. vertical) were analyzed separately. In each analysis, all other parameters were held constant to isolate the specific impact of the parameter under investigation. This methodological approach ensures that the effect of each design parameter on rear-side irradiance can be evaluated independently and in detail, thereby contributing to a better understanding of rear-side optimization in BPV systems.

It is believed that this study will contribute to the determination of the ground and mounting characteristics in the installation of BPV panels. Despite the limited number of studies on BPV panels in Türkiye conditions, no study has been identified in the literature that simultaneously examines the effects of albedo, module height, tilt angle, and mounting configuration on the energy efficiency of BPV panels. This study differentiates itself from the existing literature by offering a comprehensive parametric analysis that simultaneously evaluates the impact of surface albedo, tilt angle, installation height, and mounting configuration on the rear-side energy contribution of BPV panels. A key distinction of this research is the use of experimentally measured Global Horizontal Irradiation (GHI) datasets rather than standard Typical Meteorological Year (TMY) or simulated solar input. This approach allows for more realistic modeling under local climate conditions. Unlike previous studies that often focus on a single parameter or consider generalized assumptions, this work provides a structured comparison across various surface types and geometrical configurations, all simulated under identical environmental input. The developed Python 3.11-based framework enables flexible scenario testing and reproducible analysis. By isolating and quantifying the specific influence of each design factor, the study provides new insights that support more accurate and context-specific decisions for BPV deployment, particularly in mid-latitude regions such as Türkiye.

2. Modeling and Methodology

The bifaciality coefficient/factor () defined in IEC TS 60904-1-2 is used to determine the performance of the back side of a PV panel [6,15]. The bifaciality factor is defined as the ratio of rear-side to front-side output of a PV panel calculated under standard test case (STC) conditions. This calculation provides information on three key characteristics; (i) current, (ii) voltage, (iii) maximum power. The bifaciality factor for short-circuit current (), open circuit voltage (), and maximum power () are expressed in Equations (1)–(3), respectively. Within these equations, signifies the BPV back-surface short-circuit current, whereas denotes the BPV front-surface short-circuit current. It is important to note that the index “” in these equations refers to the back surface, while the index “” refers to the front surface.

The rear-side current () generated by absorbed light from the rear () is calculated as shown in Equation (4). is the front-side current of the BPV module at the maximum power point (MPP) under standard test conditions.

Temperature variations significantly affect the open-circuit voltage of PV cells, while the impact on short-circuit current is comparatively minimal. As temperature increases, a notable drop is observed in voltage, whereas the current remains relatively stable. Each PV cell has defined temperature coefficients that describe the changes in current, voltage, and power with respect to temperature. In this study, the constant voltage temperature coefficient provided by the manufacturer’s datasheet was used for the selected PV panel model. The BPV panel output voltage () is calculated from Equation (5), shown below as a function of temperature, under the assumption of minimal irradiation effect [16].

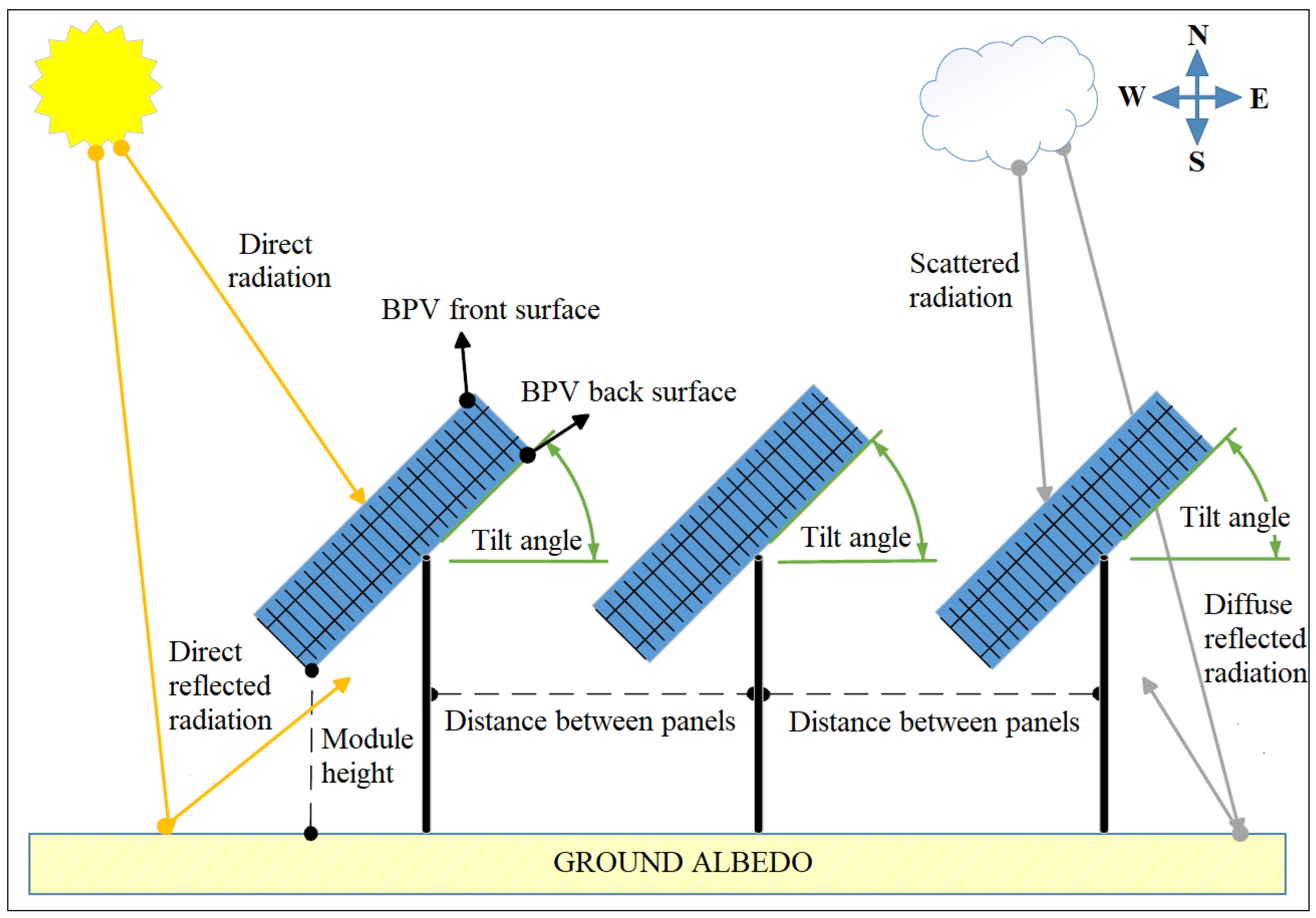

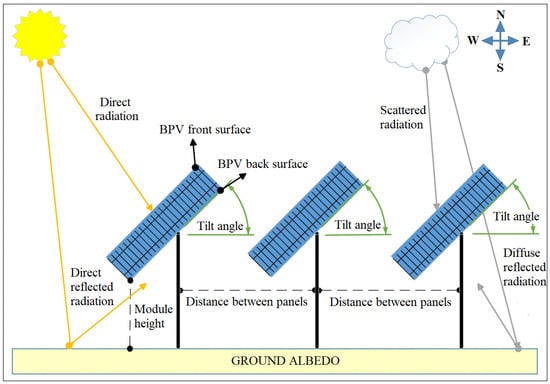

where, is the temperature coefficient of the on voltage and is the voltage below STC. The electrical energy generated by BPV panels depends on many parameters, as shown in Figure 1. These panels utilize both direct solar irradiation and reflected irradiation from clouds and the surrounding environment to generate energy. The panel tilt angle, the height of the panel above the ground, the distance between the panels, and the reflectivity of the ground have been identified as significant factors influencing energy output. Among these factors, the albedo effect, defined as the reflectivity of the ground, emerges as a predominant factor in BPV performance. To this aim, four different scenarios are designed to evaluate the effects of albedo, tilt angle, panel height and mounting configuration on energy generation. A comprehensive analysis is provided for each scenario.

Figure 1.

Key parameters influencing BPV panel performance.

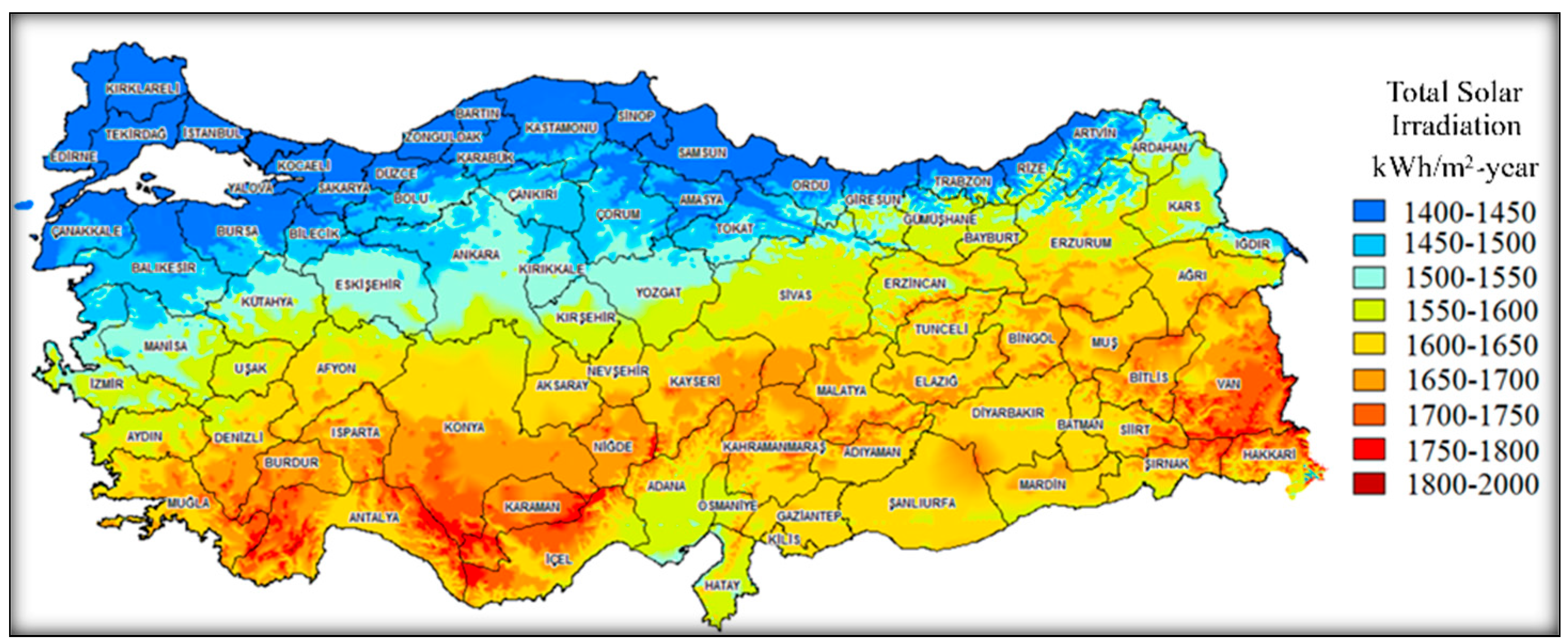

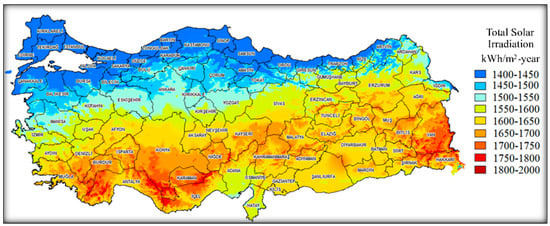

Türkiye is situated between 36° and 42° north latitude and 26° and 45° east longitude. This location puts it within the energy belt of solar energy with significant prospects on the Earth. As shown in Figure 2 of the Atlas of Solar Energy Potential of Türkiye [17], there is a significant increase in total solar radiation as one moves southward, indicating that the southern and southeastern regions have the highest solar energy potential.

Figure 2.

Solar energy potential of Türkiye: yearly distribution of total solar irradiation (kWh/m2-year) [17].

GHI values used in this study were obtained from the Solar Energy Potential Atlas of Türkiye (GEPA), which integrates satellite-based data (e.g., Heliosat, Meteosat), ground-based meteorological observations (e.g., the Turkish State Meteorological Service, MGM, and the Danish Meteorological Institute, DMI), and long-term averaged climate records. In the GEPA framework, solar radiation is decomposed into Direct Normal Irradiance (DNI), diffuse horizontal irradiance (DHI) and GHI components, providing a physically consistent and validated basis for numerical analysis. These data, representative of TMY, inherently reflect both direct and diffuse irradiation contributions, enabling a realistic evaluation of BPV performance across varying configurations.

The atlas provides easy access to solar energy information on total solar irradiation (kWh/m2-day), direct solar irradiation (kWh/m2-day), and hours of sunshine per province and district. Such data are important for determining optimal sites for PV installation and the large-scale feasibility of solar projects. Considering Türkiye’s geographical advantages, the commercial potential value of well-applied investments in PV systems can help greatly to attain the country’s renewable energy targets and sustainability objectives.

GHI is a weather variable that directly affects the performance of PV panels. The magnitude of irradiation that falls on a horizontal surface of the panel directly influences the power output of the PV panel. The GHI data used in this study was obtained from the GEPA [17].

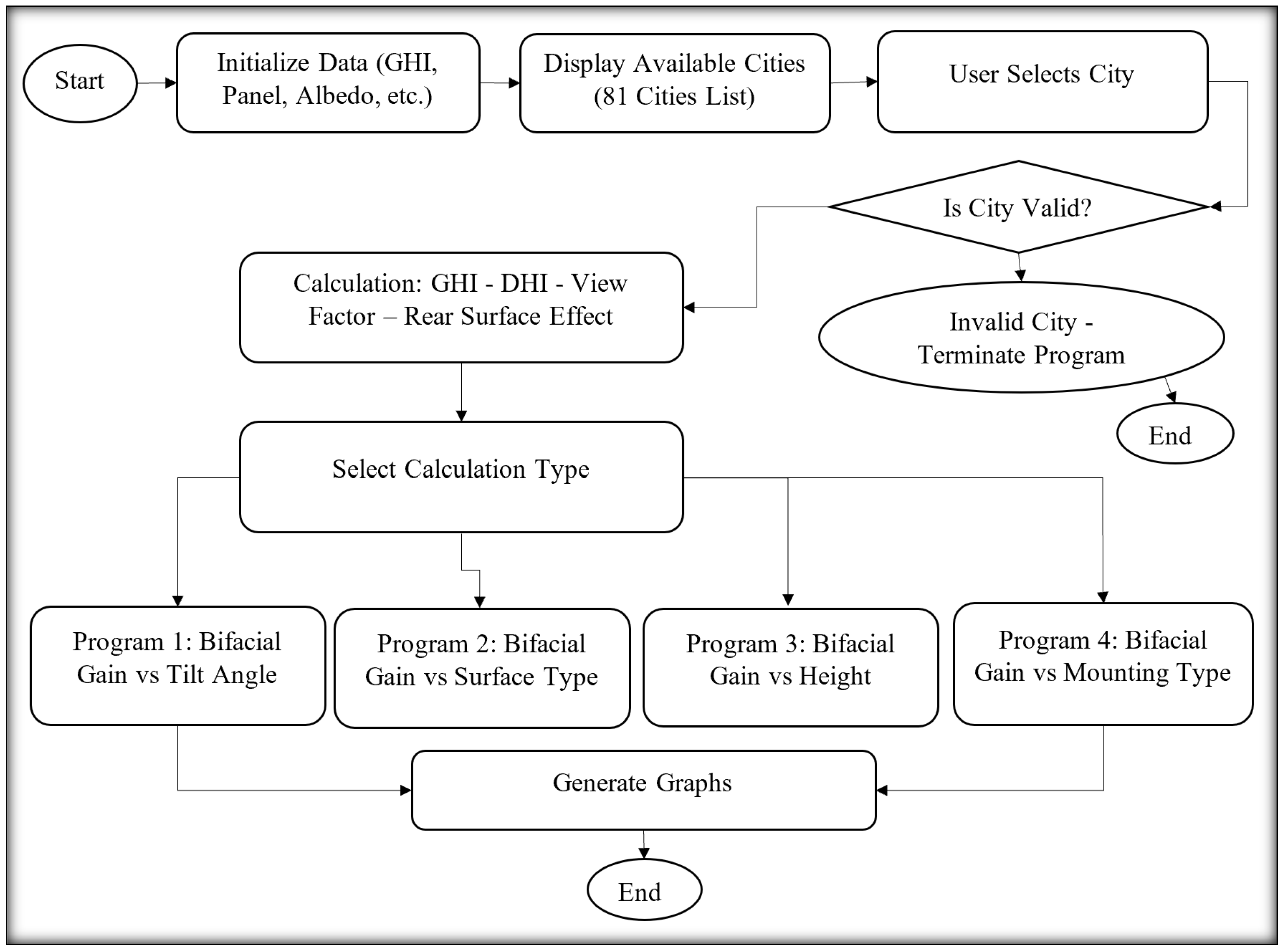

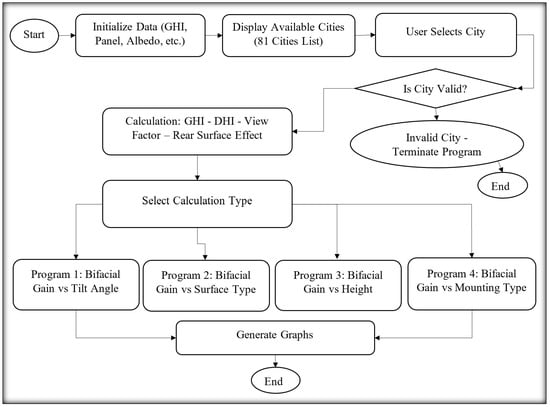

The methodology employed in this study is illustrated in Figure 3. As depicted, solar energy generation parameters are analyzed based on the selected city and the impact of different variables on energy generation is examined. The workflow can be summarized as follows: the user initiates the system by entering GHI, PV panel type and albedo values. Next, a city is selected from a list of 81 provinces in Türkiye and the corresponding GHI value is determined.

Figure 3.

Flowchart of methodology.

In this study, all GHI values were derived from experimentally measured climate datasets obtained from Türkiye’s national solar radiation database. These datasets, which represent typical meteorological conditions over extended periods, provide a reliable basis for analyzing solar performance at the provincial level. Using these realistic and location-specific values, the effects of albedo, panel height, tilt angle, and mounting configuration on rear-side energy generation were analyzed numerically. Although simulations were not performed on an hourly basis, the use of long-term climate data ensures that the temporal variability of solar irradiation is implicitly represented in the results.

Based on the user’s selection, the system evaluates one of the following four relationships; (i) power output vs. tilt angle, (ii) power output vs. surface type, (iii) power output vs. panel height, (iv) power output vs. panel mounting type. The proposed system provides a clear representation of how each parameter affects the energy output of BPV panels.

Experimental GHI data for a total of 81 cities were collected and entered into the program for optimization. To categorize and analyze these data, three separate groups were created as shown in below.

- High GHI (≥5.0): This category includes 19 provinces. Provinces like Antalya, Burdur, Isparta, İzmir, and Muğla have the highest GHI values, making them highly suitable for solar energy investments.

- Medium GHI (4.2 to 4.99): A total of 41 provinces fall under this category. Provinces such as Ankara, Konya, Elaziğ, and Kayseri exhibit moderate solar energy potential.

- Low GHI (<4.2): This group contains 21 provinces, including İstanbul, Zonguldak, Rize, and Trabzon, which have the lowest GHI values and less potential for solar energy utilization.

The provinces with the highest GHI values, measured in kWh/m2-day, exhibit significant solar energy potential. Among the top 10, Antalya, Burdur, and Isparta lead with the highest GHI value of 5.40, followed by Aydin, Denizli, İzmir, Manisa, Muğla, and Usak, all with a GHI value of 5.39. These provinces, located mainly in the Mediterranean and Aegean regions, benefit from their sunny climates and high solar radiation, making them ideal locations for large-scale solar energy investments. Additionally, Adiyaman and Gaziantep achieve a GHI value of 5.03, rounding out the list of the top-performing provinces.

On the other end of the spectrum, the provinces with the lowest GHI values are predominantly located in the northern and eastern parts of Turkey, where climatic conditions limit solar energy potential. Bartin, Bolu, Düzce, İstanbul, Karabük, Kastamonu, Kocaeli, Sakarya, Sinop, and Zonguldak all have a GHI value of 3.80. These provinces, characterized by high precipitation and cloud cover, have limited feasibility for solar energy projects compared to their southern and western counterparts. However, smaller-scale projects or hybrid systems could still be viable solutions in these regions.

All numerical simulations and data visualizations presented in this study were performed using the Python programming language. Custom scripts were developed by the authors, incorporating standard scientific libraries such as NumPy for numerical calculations, Pandas for data handling, and Matplotlib 3.7 for graphical outputs. The computational environment ensured flexibility in parameter variation and reproducibility of the presented results.

In order to perform the analysis in the software, a city must be selected. For examining a specific parameter, other parameters are kept constant to allow for a comparative analysis of the selected parameter. For this reason, Kahramanmaras is chosen as the city for all software analyses. Kahramanmaras stands out with a GHI value of 5.03, placing it among the provinces with high solar energy potential. Located in southeastern Türkiye, the province enjoys a sunny climate and optimal conditions for efficient PV energy generation. Its top ranking shows its suitability for both residential and industrial solar installations. With its high solar potential, Kahramanmaras could advance Türkiye’s renewable energy goals and promote regional energy sustainability [18].

Table 1 presents albedo values for different types of surfaces commonly encountered where PV systems are installed. Depending on the surface type, albedo values play an important role in the performance of BPV systems by affecting the amount of light reflected onto the rear surface of the panels. High-albedo surfaces such as aluminum (0.85) and fresh snow (0.82) provide the highest reflectivity, significantly increasing back-side energy generation. Similarly, high values of wet snow (0.55–0.75) and copper (0.74) also contribute significantly to improving energy efficiency. In contrast, moderate-albedo surfaces like concrete (0.25–0.35), red tiles (0.33), and new galvanized steel (0.35) offer a reasonable level of reflectivity but are less effective than highly reflective materials. These surfaces, commonly found in urban and industrial environments, can still enhance BPV performance to some extent. On the other hand, low-albedo surfaces such as dry asphalt (0.09–0.15), wet asphalt (0.18), and very dirty galvanized materials (0.08) exhibit minimal reflectivity, leading to reduced rear-side energy gains. Similarly, urban environments (0.14–0.22) and grass-covered areas (0.15–0.26) provide only limited reflection. Given these variations, selecting an installation site with high-albedo surfaces or incorporating reflective materials, such as white coatings or bright surfaces, can significantly improve the efficiency of BPV systems. These surfaces were selected based on their common occurrence in PV system environments and their distinct albedo characteristics. The findings from these 13 surface types provide a comprehensive overview of how surface reflectivity influences rear-side energy generation. Also, it can be adopted for additional surface materials such as rooftop coatings, gravel, white membranes, and mixed ground types under varying climatic conditions to refine and broaden the applicability of the results. Additionally, adjusting panel tilt angles and height can further optimize energy yield in environments with lower natural reflectivity.

Table 1.

Albedo values of common surface types for PV applications [19].

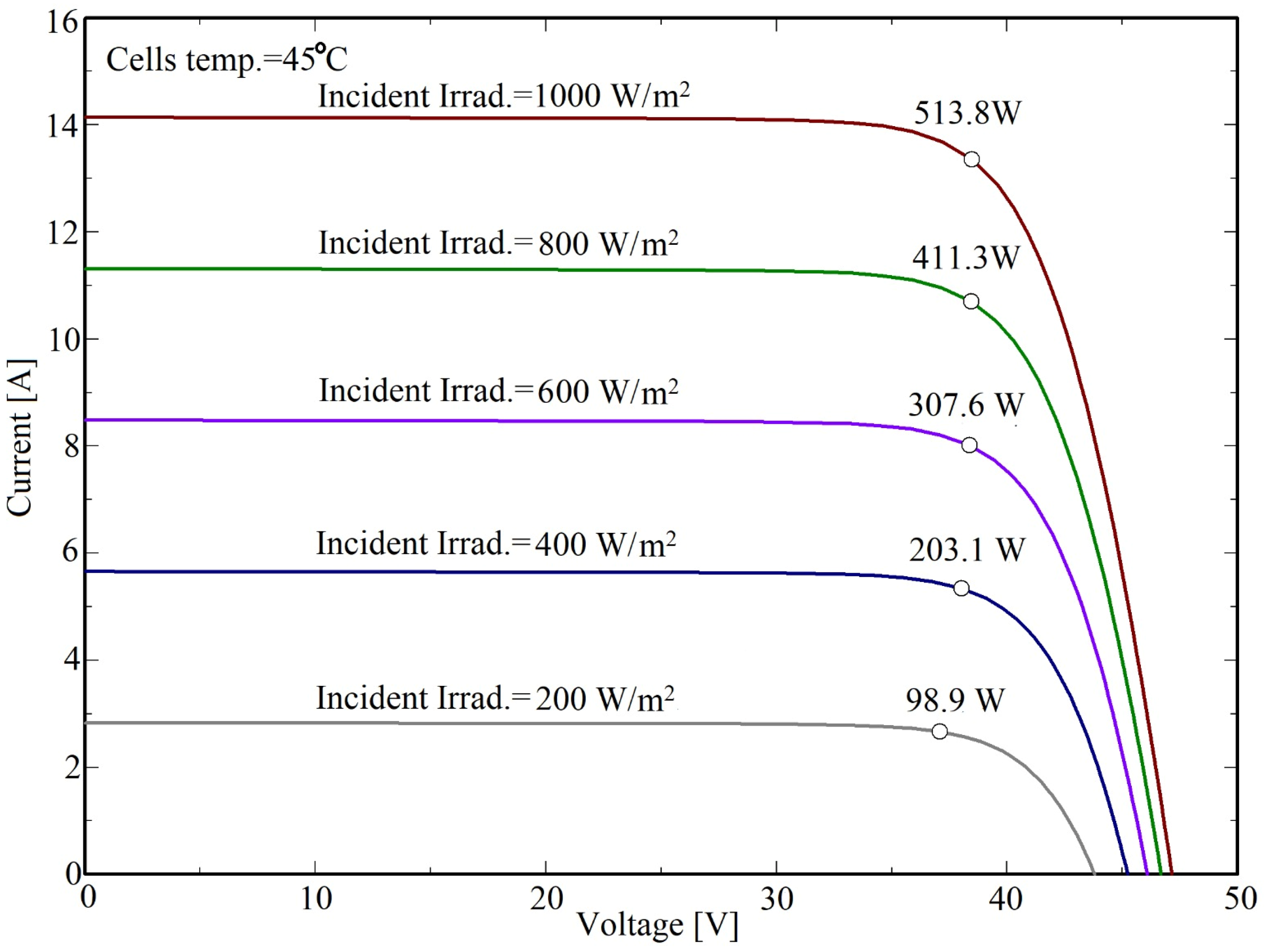

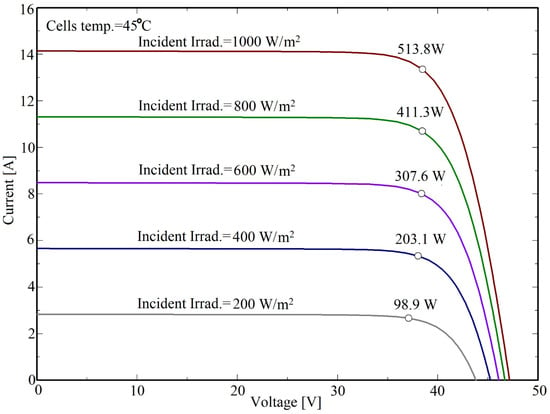

In the study, the BPV panel used is a generic available model based on monocrystalline silicon half-cell technology. The panel has a nominal power of 550 Wp, and the bifaciality factor is assumed to be 80%. It was selected due to its high power rating, up-to-date manufacturing technology, and proven applicability in recent studies [20]. The detailed specifications of the panel are presented in Table 2, and its current–voltage (I–V) characteristics are illustrated in Figure 4. Only a single panel was used in the simulations, and all energy calculations were based on the output of this individual module. This approach allowed for a clear analysis of the effects of various installation conditions—such as albedo, tilt angle, height, and mounting configuration—on panel performance.

Table 2.

Technical specifications of the BPV panels.

Figure 4.

Current–voltage characteristics of the selected BPV panel.

It is acknowledged that the optimal tilt angle for PV panels is not fixed and may vary depending on the geographical location, solar path, and seasonal variations in irradiation. While a steeper tilt angle may increase rear-side exposure to ground-reflected irradiance, it may also reduce front-side production if the panel orientation deviates from the local solar optimum. However, the main objective of this study was not to determine the optimal total energy yield, but rather to analyze the isolated effect of individual design parameters—such as tilt angle—on rear-side performance, assuming all other factors remain constant. In practical applications, several other parameters such as shading, soiling, inter-row spacing, inverter compatibility, and series connection configuration also influence system performance and should be jointly considered in a full optimization framework. These factors are noted as limitations of the current study and will be addressed in future research.

3. Numerical Analysis and Results

This section details the results of the study for each scenario designed to evaluate the rear-side energy contribution in BPV panels. In Section 3.1, the first scenario investigates the impact of surface albedo on rear-side energy generation for different ground materials. Section 3.2 presents the second scenario, which analyzes the effect of tilt angle on rear irradiance levels. The third scenario is discussed in Section 3.3, focusing on how the height of the panel above the ground influences rear-side energy output. Lastly, Section 3.4 provides a comparative assessment of horizontal and vertical mounting configurations as the fourth scenario. In each case, all other variables are held constant to isolate and quantify the effect of the parameter under investigation. The energy contribution from the back surface of the BPV panels is investigated through simplified mathematical models developed under different scenarios. In the initial scenario, the energy generation resulting from solar radiation (albedo contribution) that reaches the rear surface of BPV panels is determined by utilizing Equation (6).

In Equation (6), represents the electrical power (in watts) generated by the back surface of the BPV panels. This power is generated when solar radiation reflected from the ground (due to albedo) reaches the back surface of the panel and the panel converts this radiation into electrical energy. The back-surface energy contribution is determined by several factors, including the daily horizontal global irradiance , the surface albedo coefficient , the panel tilt angle , the height , and the maximum power output of the panel.

This equation has been derived in a simplified approach based on the fundamental physical principles of various models that have been documented in the literature. The parameters in the equation are derived from a variety of sources, including the calculation methods proposed by the National Renewable Energy Laboratory (NREL) [6], experimental and analytical modeling studies published by Sahu et al. [21], and optimization-based approaches by Sun et al. [22]. The effect of tilt on reflected radiation is represented by a cosine component, while the effects on the height factor are expressed by a simple multiplier. This approach provides a practical engineering simplification that facilitates expeditious and precise calculation of the albedo-induced back-surface contribution.

In scenario two, the power generated by the back surface of the solar panel is calculated using Equation (6), with the tilt angle (β) being the variable of interest [6,14,21]. In this equation, the ratio of light from the ground reaching the back surface is found by the expression ((1 − cosβ)/2). The other variables are A, the panel area, and η, the back-surface efficiency of the panel. The effect of height is expressed by the equation (1 + h/1000), where h denotes the height in centimeters. The power contribution of tilt to the back surface was calculated by varying the tilt angle between 10° and 50° in 5° increments and applying Equation (7) for each angle.

In the third scenario, the power generated by the back surface of the solar panel is calculated using Equation (7), with the panel height (h) being the variable of interest [6,14,21]. In order to ascertain the relationship between panel height and energy absorption, the tilt angle was maintained at 20°, while the panel height varied from 40 cm to 100 cm. The energy falling on the back surface was calculated for each height.

In the fourth scenario, Equation (8) [6,14,21] is employed to ascertain the variation in rear-surface energy production with respect to the installation type. The effect of the mounting type is expressed by the coefficient . The coefficient is applied as (horizontal = 1.0, vertical = 0.9).

Additionally, Equation (9) was derived from the model proposed by Yusufoglu et al. [14] to calculate the reflected radiation reaching the rear surface of bifacial solar panels in a more realistic manner. In this model, GHI is divided into direct and diffuse components; the DHI is assumed to be uniformly distributed; the View Factor (), which expresses the geometric access of the panel’s rear surface to the light reflected from the ground, is also included in the equation to analyze the surface effect. is a dimensionless coefficient that defines the extent to which the rear surface of the panel can see the solar radiation reflected from the ground, and it is dynamically determined based on the panel inclination.

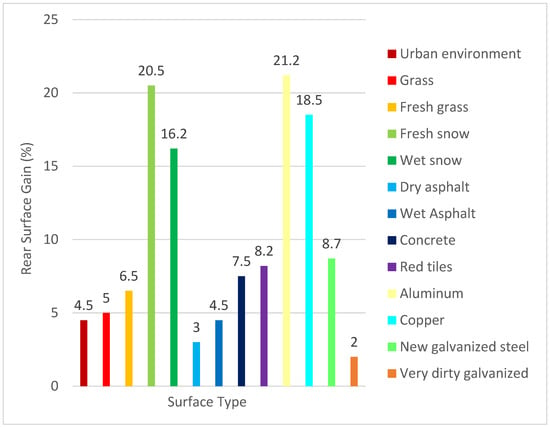

3.1. Impact of Surface Albedo on Rear-Side Energy Generation

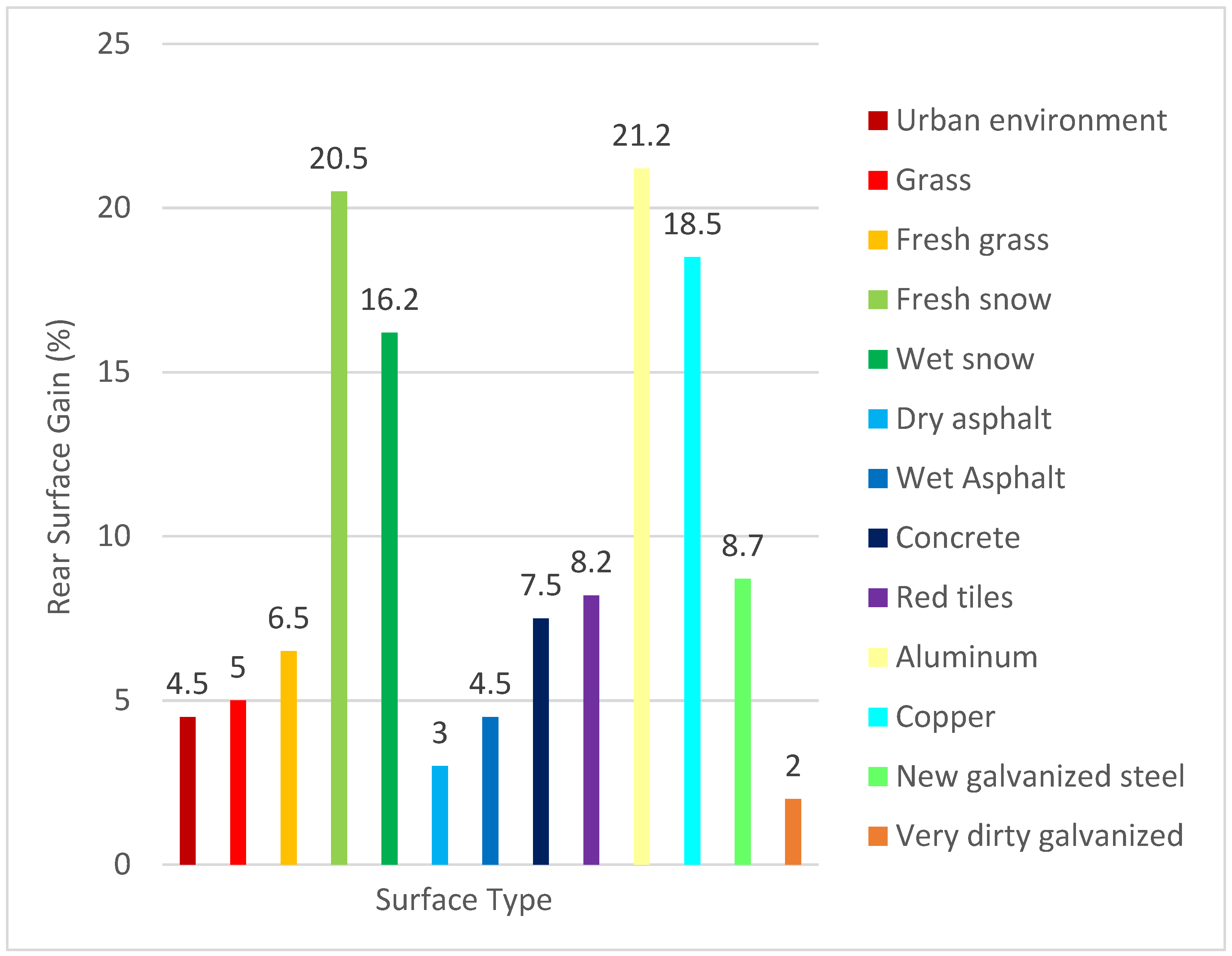

The analysis of rear-surface energy generation based on the albedo effect for various surface types in Kahramanmaras, considering a panel tilted at 20° and elevated 100 cm above the ground, highlights significant differences in energy yield influenced by the underlying surfaces. The aluminum surface demonstrated the highest rear-surface energy generation, reaching 21.2%, due to its excellent reflectivity and high-albedo properties. Similarly, fresh snow (20.5%) and wet snow (16.2%) surfaces also exhibited outstanding performance, reinforcing their high-albedo characteristics. Moderate energy generation was observed on surfaces such as red tiles (8.2%), concrete (7.5%), fresh grass (6.5%), and grass (5%), which, while reflective, are less efficient compared to snow or metallic surfaces. Asphalt surfaces, both dry (3%) and wet (4.5%), recorded significantly lower energy generation due to their absorptive nature, which limits light reflection. The lowest energy generation was observed on very dirty galvanized surfaces (2%), highlighting the critical role of cleanliness in maintaining reflectivity and optimizing energy yield. Copper (18.5%) and new galvanized steel (8.7%) surfaces showed substantial energy generation, though they lagged behind aluminum, indicating that while metallic surfaces generally perform well, material-specific reflectivity matters. These results emphasize the importance of selecting high-albedo surfaces, such as aluminum or snow, to maximize energy yield in BPV systems, while surfaces with poor reflectivity, such as asphalt or dirty materials, significantly limit performance. This analysis underscores the necessity of site-specific surface evaluation for effective BPV system deployment in diverse environmental conditions. The program code used for calculating the rear-side energy contribution is based on the albedo.

The program prompts the user to select a city, and based on the selected city, it calculates the rear-side gain values for different surface types. The calculations are based on a 550 W BPV panel, with its electrical specifications predefined in the program. The panel’s height is fixed at 1 m above the ground and its tilt angle is set at 20 degrees. The following results have been obtained under these conditions as shown in Figure 5.

Figure 5.

Rear-surface energy gain of based on albedo effect for Kahramanmaras; tilt angle: 20°; height from ground: 100 cm.

Figure 5 illustrates the effect of different surface types on the rear-side energy gain of bifacial panels. The highest gain was observed on aluminum surfaces (21.2%), followed by fresh snow (20.5%) and copper (18.5%), highlighting the significant impact of high-reflectivity surfaces on rear-side performance. Surfaces like concrete, red tiles, and new galvanized steel provided moderate gains, while low-albedo surfaces such as dry asphalt (3.0%) and dirty galvanized steel (2.0%) offered minimal contribution. Overall, surface reflectivity is a key factor influencing the efficiency of BPV systems.

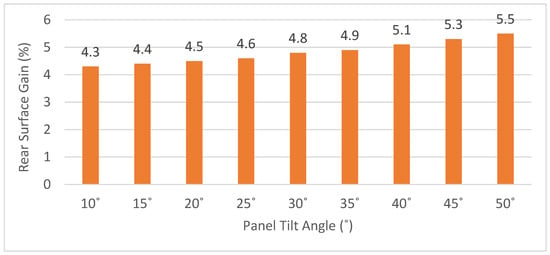

3.2. Effect of Tilt Angle on Rear-Side Energy Contribution

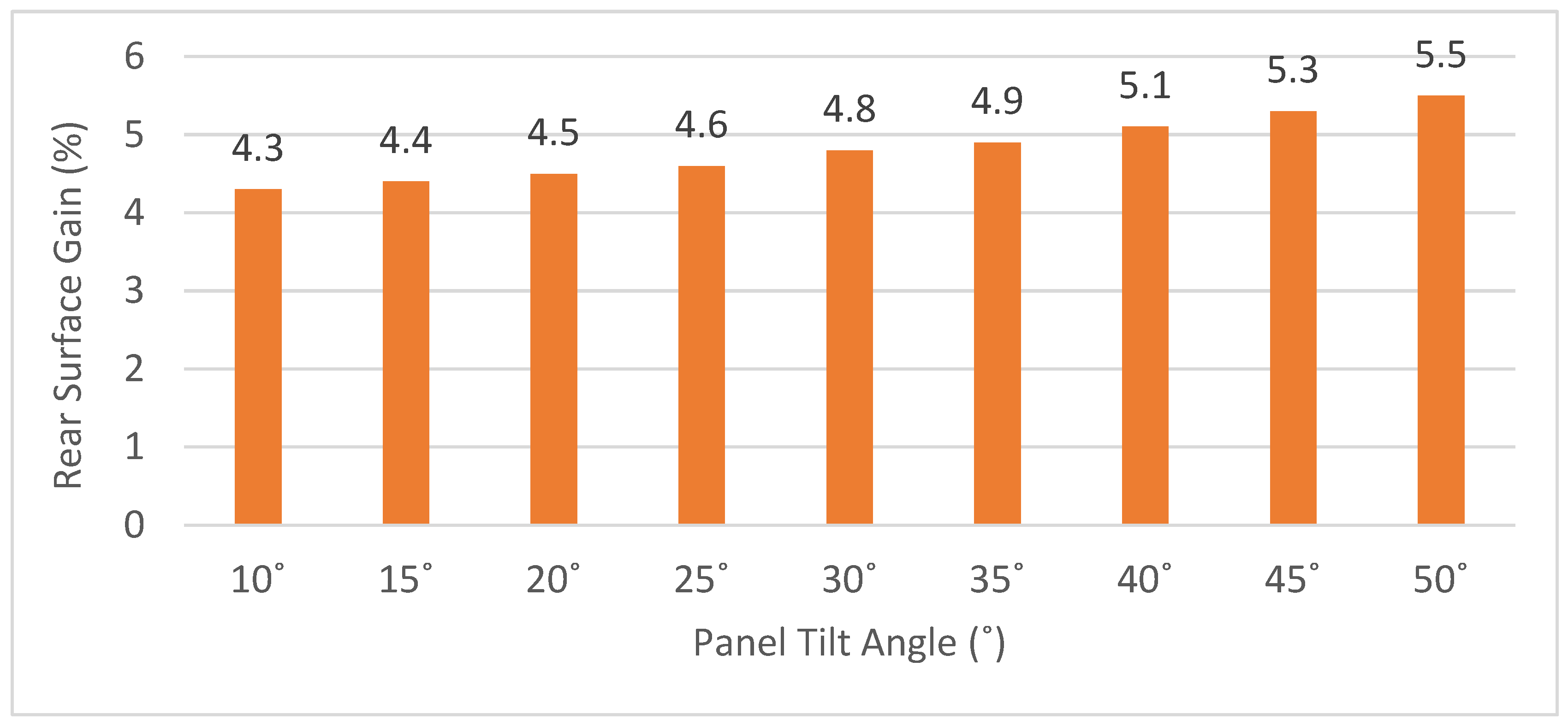

The second analysis illustrates the rear-surface energy generation of a BPV panel based on different tilt angles in Kahramanmaras, with a panel mounted 100 cm above the ground in an urban environment. The results clearly show that as the tilt angle increases, the rear-surface energy generation significantly improves. At a tilt angle of 10°, the energy generation is the lowest, at 4.3%, due to minimal light reflection onto the rear surface caused by the nearly-flat panel orientation. Energy generation gradually increases with tilt angle, reaching 4.5% at 20° and 4.8% at 30°, indicating enhanced light exposure to the rear surface as the tilt angle grows steeper.

Substantial increases are observed beyond 30°, with energy generation at 4.9% for 35° and 5.1% for 40°. The sharp rise in energy generation continues, peaking at 5.5% at a tilt angle of 50°, where the panel’s position maximizes light capture and rear-surface reflection. These results highlight the critical role of tilt angle determination in improving the performance of BPV systems. Low tilt angles reduce energy efficiency due to less light reflection, while close-to-vertical angles significantly increase the amount of energy by increasing the amount of light reflected to the back surface and hence the contribution to power generation. Therefore, tilt angle adjustments should be carefully determined to maximize system efficiency under similar environmental conditions. Program code is used for rear-side energy contribution according to tilt angle.

The surface type is fixed as “urban environment,” and the panel height is set 1 m above the ground. The rear-side gain values have been calculated based on varying panel tilt angles. The results obtained under these conditions are presented as shown in Figure 6.

Figure 6.

Rear-surface energy gain of a BPV panel based on different tilt angles for Kahramanmaras; surface type: urban environment; height from ground: 100 cm.

Figure 6 shows the effect of panel tilt angle on rear-side energy gain in BPV systems. As the tilt angle increases from 10° to 50°, the rear-side gain gradually rises from 4.3% to 5.5%. This trend indicates that steeper tilt angles enhance the panel’s exposure to ground-reflected light, improving rear-side performance. Therefore, careful optimization of tilt angles is essential for maximizing overall system efficiency.

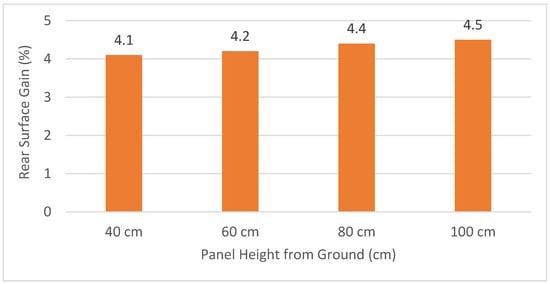

3.3. Influence of Panel Height on Rear Irradiation Performance

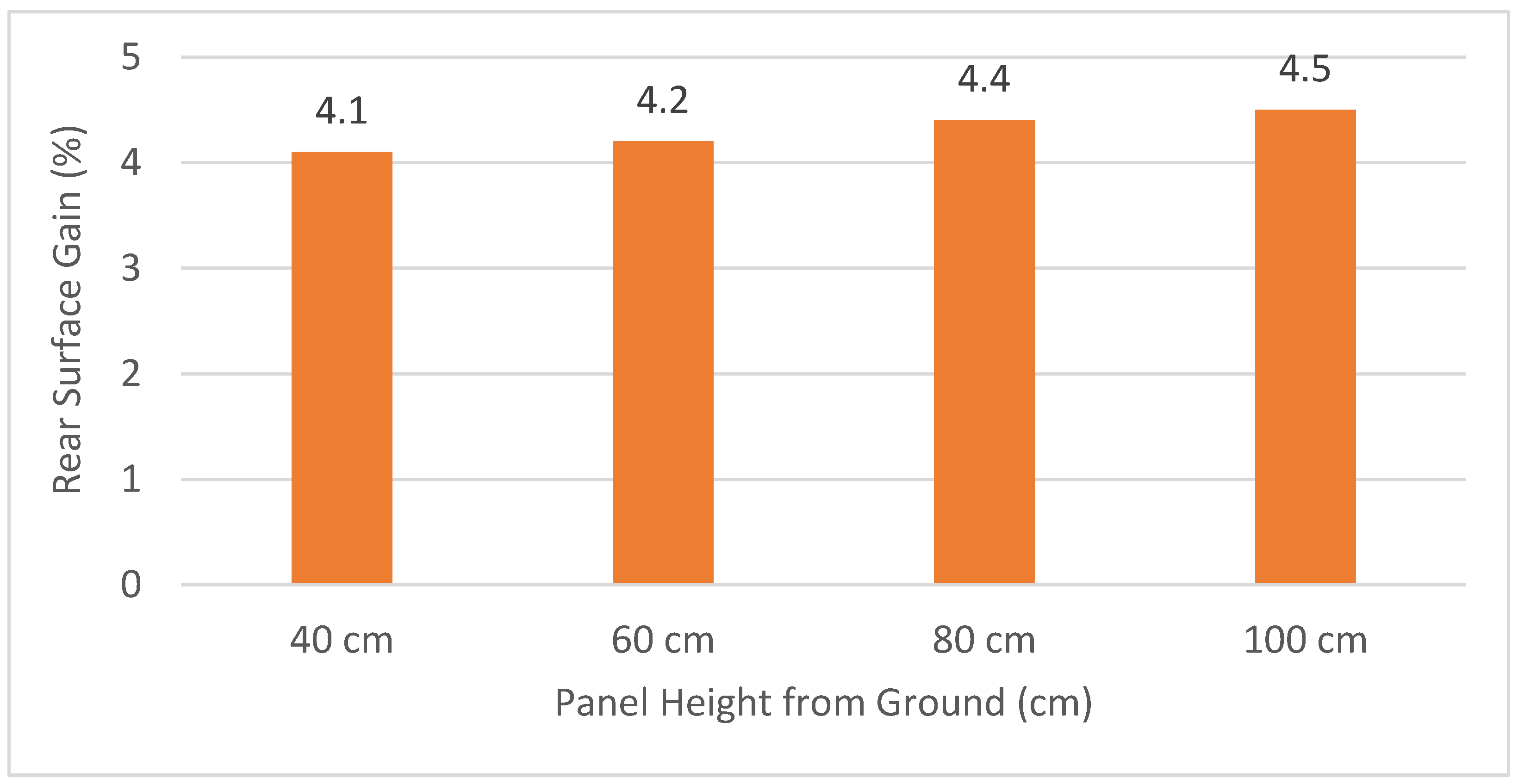

The third analysis illustrates the rear-surface energy generation of a BPV panel based on its height above the ground in an urban environment in Kahramanmaras, with a tilt angle of 20°. The results show a gradual increase in energy production as the panel’s height from the ground increases. At 40 cm above the ground, the energy generation is 4.1%, indicating relatively moderate light reflection onto the rear surface due to limited space for reflected light to reach the panel.

As the height increases to 60 cm, energy generation slightly improves to 4.2%, followed by further gains at 80 cm with 4.4%. The highest energy production, at 4.5%, is observed when the panel is elevated 100 cm above ground. This trend suggests that increasing the panel height allows for better light reflection and less obstruction, leading to more light reaching the rear surface. However, the differences between the heights are relatively small, indicating diminishing returns at higher elevations.

These results emphasize the importance of optimizing the height of BPV panels. While increasing height improves energy generation, the gains beyond a certain elevation are marginal, and practical considerations such as installation costs and structural stability should also be considered in system design. Program code is utilized to observe the effect of panel height. The code has been revised to demonstrate the effect of panel height on rear-side gain. The user selects a city, and the program calculates rear-side energy generation for varying panel heights (40, 60, 80, and 100 cm) under fixed conditions: a panel tilt angle of 20° and a surface type of sand. Figure 7 shows the rear-surface gain depending on the panel height. The gain is at its lowest level at 40 cm above the ground at 4.1%, but gradually increases to 4.5% at 100 cm above the ground.

Figure 7.

Rear-surface energy gain of a BPV panel based on based on its height above the ground in an urban environment for Kahramanmaras; surface type: urban environment; tilt angle: 20°.

Although this study evaluates panel height at four discrete levels (40 cm, 60 cm, 80 cm and 100 cm), which are commonly encountered in field installations, the relationship between height and rear-side energy generation exhibits a nonlinear character that warrants deeper exploration. The observed trend indicates a gradual increase in energy yield with height, yet the relatively small differences between successive values suggest that other factors—such as mutual shading, wind-driven cooling effects, and ground surface uniformity—may influence the overall performance. A denser data range and the inclusion of more complex site conditions could enhance the resolution of this relationship.

This scenario does not aim to maximize total energy output alone but rather to investigate panel height as a design parameter that specifically influences rear-side energy gain in BPV systems. Rear-side performance is highly sensitive to geometric factors, and among these, elevation above ground plays a crucial role in determining the amount of reflected irradiance captured. Since an increase in rear-side energy gain leads to a higher total energy output from the panel, this scenario was specifically developed to analyze the influence of panel height in detail. By isolating the effect of height, this analysis helps to identify the point at which increased elevation yields diminishing energy returns. Such insight is valuable for informing installation designs that must balance energy yield with structural and economic feasibility.

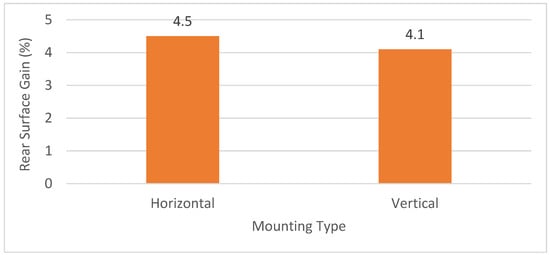

3.4. Comparison of Horizontal and Vertical Mounting Configurations

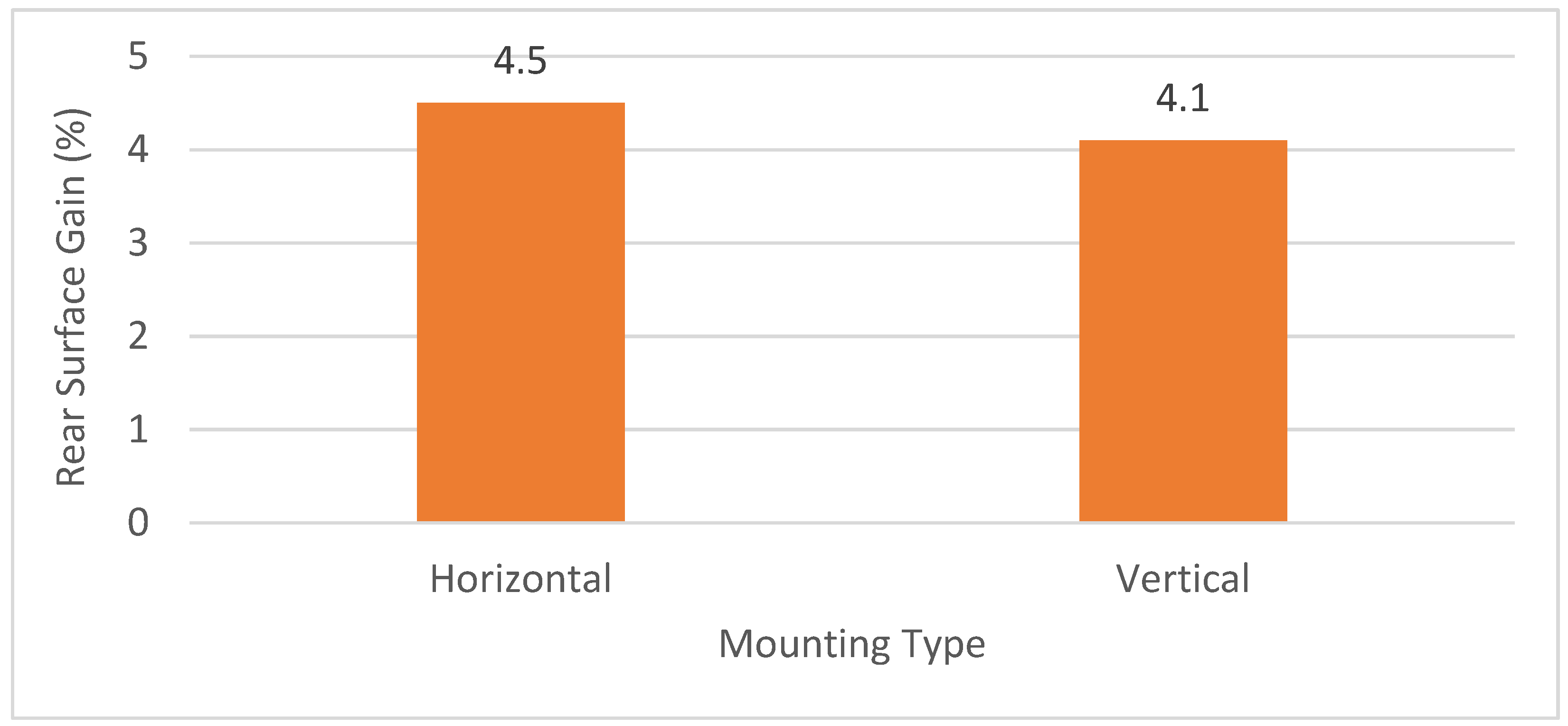

The fourth analysis compares rear-surface energy generation for two mounting types—horizontal and vertical—in an urban environment in Kahramanmaras, with the panel tilted at 20° and elevated 100 cm above the ground. The results indicate that horizontal mounting provides higher rear-surface energy generation (4.5%) compared to vertical mounting (4.1%).

The superior performance of horizontal mounting can be attributed to its larger surface area exposed to reflected light from the ground. This mounting enables light to be received by the back surface of the panel, thereby enhancing energy production. Vertical mounting, however, has a narrower exposure, limiting reflected light to the back surface and lowering energy generation slightly.

Although the variation is not significant between the two mounting orientations, when tested at a large scale, it is seen that horizontal mounting is more effective in back-surface energy generation under the same conditions. It suggests the importance of paying attention to the orientation of mounting during the design and installation of BPV systems, keeping in mind the installation area, to ensure energy efficiency at the highest level.

The code was utilized in order to contrast horizontal and vertical mounting types with steady conditions. In the implementation of the code, the value of albedo for the type of surface used was 0.18 (urban environment), the tilt angle of the panel was 20°, and the panel height from the ground level was 100 cm. The obtained gains are shown in Figure 8. Figure 8 compares the impact of mounting type on rear-side energy gain. Horizontal mounting provides a slightly higher gain (4.5%) compared to vertical mounting (4.1%).

Figure 8.

Rear-surface energy gain based on mounting type for Kahramanmaras; surface type: urban environment; tilt angle: 20°; height from ground: 100 cm.

In the horizontal and vertical mounting configuration analysis, the same BPV panel was used in both scenarios to ensure a fair and accurate comparison. The horizontal configuration was modeled by rotating the panel physically by 90°, without altering its dimensions, such that its longer edge remained parallel to the ground. Conversely, in the vertical configuration, the longer edge was oriented perpendicular to the ground.

In order to isolate the influence of orientation on rear-side energy gain, all other parameters such as panel height, tilt angle, surface albedo, and GHI were kept constant throughout the analysis. The effect of shading from adjacent panels was intentionally excluded, as it depends on many variable site-specific factors such as inter-row spacing, tilt variation, ground slope, and terrain profile. Excluding shading allows for a clear assessment of how orientation alone affects BPV panel performance.

This difference in rear-side energy gain is primarily attributed to the greater exposure of the horizontally mounted panel’s rear surface to ground-reflected irradiation. In a horizontal orientation, the panel spans a wider area parallel to the ground, increasing the angular view factor toward the reflective surface beneath. This configuration enhances the panel’s ability to receive and utilize reflected radiation, especially in environments with moderately reflective surfaces such as concrete or dry soil.

3.5. Verification of Model Accuracy Using Published Data

Although direct experimental measurements were not conducted within the scope of this study due to limited financial resources, the mathematical model and simulation framework developed here were rigorously validated through comparison with existing experimental and semi-empirical studies in the literature. The theoretical formulation of the model is built upon widely accepted methodologies, including the irradiance modeling approaches introduced by NREL [6], the experimental and analytical work of Sahu et al. [21], and optimization-based frameworks proposed by Sun et al. [22].

Simulation results obtained from this model exhibit strong alignment with the performance trends and value ranges reported in experimentally validated studies such as those by Ganesan et al. [8,9], Pelaez et al. [10], Durusoy et al. [11], Alam et al. [12], and Wang et al. [13]. This consistency underscores the credibility and reliability of the model and confirms its relevance to real-world BPV system performance analysis. Future work will focus on validating the model through field measurements, further enhancing its accuracy and practical applicability.

In order to verify the accuracy and validity of the model developed in this study, the rear-side energy gain rates obtained were compared with experimental and numerical findings reported in the literature.

Ganesan et al. [9] investigated the role of the albedo effect on energy gains from the rear surface in BPV systems. In the experimental analyses conducted within this scope, aluminum surfaces provided an average of 21.4% contribution from the rear surface; additionally, light-colored and highly reflective surfaces, such as white-painted surfaces, contributed an average of 18.9%. In the present study, the highest contributions were obtained from aluminum (21.2%), fresh snow (20.5%), and copper (18.5%) surfaces, respectively. These results largely coincide with the field study conducted by Ganesan and colleagues.

A parallel can be drawn between the two studies in terms of surfaces with low albedo. For instance, in this study, the contribution of grass surfaces to the rear-surface gain of BPV panels was determined to be approximately 5%. Similarly, in the study by Ganesan and colleagues, an average of 5% bifacial gain was reported from grass surfaces. In both studies, grass was classified among surfaces with low reflectivity, and its contribution was observed to be limited.

The findings obtained in the study conducted by Baloch et al. [23] are consistent with the results of the present study. White cement, a surface with a high albedo, exhibited the greatest bifacial energy gain at 28.5%. In the context of a medium-albedo-value desert sand surface, the aforementioned ratio was documented to be 18.59%, while the gain obtained on the low-albedo grass surface was found to be constrained to 8.4%. The findings suggest a predominant linear relationship between ground reflectivity and the rear-surface contribution of BPV systems.

Furthermore, the present study comparatively analyzed BPV panels installed both vertically (east–west oriented) and horizontally (north–south oriented) and presented the resulting daily specific energy generation values depending on the installation orientation. Consequently, the daily energy generation of panels in the vertical configuration was measured at 4.63 kWh/kWp, while that of panels in the horizontal configuration was measured at 6.18 kWh/kWp. In this study, the rear-surface gain was determined to be 4.1% in the vertical configuration and 4.5% in the horizontal configuration. As the bifacial gain (rear-surface contribution) was not directly provided in the study by Baloch et al. [23], it is not possible to clearly distinguish how much of the total generation difference is due to rear-surface reflections. Nevertheless, a comparison of the orientations of the panels is noteworthy in terms of demonstrating the effect of orientation on energy yield. Although the values are not directly comparable, the horizontal configuration showing higher performance is a common trend in both studies.

A comparison of the findings of this study with those of Ghenai et al. [24] clearly demonstrates the effect of albedo values on the performance of BPV systems. In Ghenai et al.’s study [24], under conditions of a 25° panel tilt and a 100 cm mounting height, increasing the albedo value from 10% to 90% resulted in a rise in bifacial gain from 2.10% to 16.70%. In a similar vein, the present study demonstrated a 21.2% gain through the utilization of aluminum, a surface with high reflectivity, at a 20° tilt and a height of 100 cm. Conversely, on a surface with a “very dirty galvanized” condition and a low albedo value (albedo: 0.08), the rear-surface gain was measured at 2%. Upon examination of the discrepancies in slope and albedo parameters, it can be concluded that the results of the two studies are relatively similar.

In Ghenai’s study [24], the panel tilt parameter was evaluated, and it was determined that while albedo was kept constant at 0.1 and panel height at 100 cm, increasing the tilt angle from 15° to 35° resulted in a rise in bifacial gain from 1.18% to 3.24%. In this study, under conditions of similar albedo (0.14–0.22) in an urban environment and once more with a panel height of 100 cm, increasing the tilt angle from 10° to 50° resulted in an increase in rear-surface gain from 5.1% to 5.8%. While both studies demonstrate that increasing the tilt has a positive effect on bifacial gain, the increase observed in this study is more limited.

Furthermore, similar comparisons can be made in terms of panel height parameters. In the study by Ghenai et al. [24], an increase in panel height from 0.5 m to 1.5 m under a 25° panel tilt and 10% albedo value resulted in an enhancement of bifacial gain from 1.73% to 2.20%. In this study, however, at a 20° tilt and 100 cm height, under low-albedo “very dirty galvanized” surface conditions, the gain increased from 4.1% to 4.5%. The findings suggest that increasing the panel height has a beneficial impact on bifacial performance in both studies.

The rear-side gain values obtained in this study were compared with similar findings reported in the literature, and a comparative summary is presented in Table 3.

Table 3.

Technical specifications of the bifacial PV modules.

4. Conclusions

This study explores the factors that significantly impact the performance of BPV panels, with a particular focus on albedo, tilt angle, panel height, and mounting configuration. The results reveal that highly reflective materials, such as aluminum and fresh snow, significantly increase back-side energy generation, so surface reflectivity is critically important. Additionally, the findings indicate that increasing the panel tilt angle enhances energy efficiency. But, an optimal tilt angle must be determined to balance front- and back-side energy generation. The effect of panel height on rear-side energy generation was evaluated within the range of 40 cm to 100 cm. The results indicate that rear-side energy generation increases as the panel height increases. For instance, the rear-side energy gain was measured as 4.1%at a height of 40 cm and reached 4.5% at 100 cm. Moreover, horizontal placement of panels is better than vertical placement due to the greater surface area presented to reflected light. Overall, the study proves that one can significantly enhance the efficiency of BPV panels by optimizing such parameters. For obtaining maximum energy output, the parameters should be optimized based on the findings of the study taking into account the selection of installation location and material. According to this, the present study can serve as a reference guide for the design and installation of BPV systems.

In contrast to prior studies that often evaluate one or two design factors in isolation, this work provides a more comprehensive assessment of the rear-side energy response of BPV panels by jointly analyzing the effects of surface albedo, tilt angle, installation height, and orientation. The results show not only the anticipated trends but also quantify the magnitude of impact under standardized climatic inputs. By employing experimental GHI data from a mid-latitude region, the findings offer localized relevance and practical insight for deployment strategies. The structured methodology used also allows designers to isolate key parameters affecting rear-side yield, which contributes to the optimization of BPV systems beyond general theoretical expectations.

It should be noted that in real-world conditions, the reflectivity of ground surfaces may degrade over time due to factors such as dust accumulation, vegetation growth, or surface soiling. These effects can significantly reduce rear-side irradiation in BPV panels. Although this study was conducted under idealized surface conditions to isolate the albedo effect, future work should incorporate dynamic surface changes to more accurately model bifacial performance.

The proposed parametric relationships regarding rear-side energy contribution were validated through numerical analysis and simulation-based modeling under various scenarios. The simulations were performed using experimental input parameters such as GHI, surface albedo values, and geometrical configurations, providing consistent and interpretable results across different conditions.

5. Future Study

In future studies, a real-time monitoring system will be developed to further validate the simulation results presented in this study. This setup will include sensor-based measurements of rear-side irradiation and power output under different surface types and environmental conditions. By comparing field data with modeled outputs, the accuracy of the proposed parametric relationships can be further verified, thereby enhancing the practical relevance and applicability of the findings. Also, a machine-learning-powered prediction model can provide optimized panel location and tilt angles based on environmental and meteorological inputs. Furthermore, Python-based simulation models can be integrated with geographic information systems to improve site selection for BPV installations by providing site-specific energy yield predictions. These analyses will facilitate more accurate performance prediction and more knowledgeable pre-installation decision-making for large-scale BPV deployments.

Author Contributions

The two authors have worked together on the study. E.O. was involved in the organization of data, research, methodology, software, validation, visualization, and writing. F.D. provided conceptualization and supervision. Both F.D. and E.O. authors contributed to the final version of the manuscript. F.D. supervised the project. As a result, the article reflects the equal contribution of both authors. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by a grant from the Kahramanmaras Sutcu İmam University Scientific Research Projects Unit, Project Number: 2024/6-5 D.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| BPV | Bifacial Photovoltaic |

| GEPA | Türkiye Solar Energy Potential Atlas |

| GHI | Global Horizontal Irradiation |

| GIS | Geographic Information Systems |

| PV | Photovoltaic |

| STC | Standard Test Conditions |

References

- Alami, A.H.; Rabaia, M.K.H.; Sayed, E.T.; Ramadan, M.; Abdelkareem, M.A.; Alasad, S.; Olabi, A.-G. Management of potential challenges of PV technology proliferation. Sustain. Energy Technol. Assess. 2022, 51, 101942. [Google Scholar] [CrossRef]

- Dominguez, R.; Carrión, M.; Oggioni, G. Planning and operating a renewable-dominated European power system under uncertainty. Appl. Energy 2020, 258, 113989. [Google Scholar] [CrossRef]

- Chikte, R.; Subramaniam, P.; Baloch, A.A.; Anzil, M.M.; Susantyoko, R.A.; Albadwawi, O.; Qasem, H.; John, J.J. Spatial albedo mapping using an autonomous rover for site assessment of bifacial PV power plant. Sol. Energy 2024, 276, 112644. [Google Scholar] [CrossRef]

- Dinçer, F. Overview of the photovoltaic technology status and perspective in Turkey. Renew. Sustain. Energy Rev. 2011, 15, 3768–3779. [Google Scholar] [CrossRef]

- Dincer, F.; Ozer, E. Assessing the potential of a rooftop grid-connected photovoltaic system for Gaziantep Islamic Science and Technology University/Turkey. Jordan J. Electr. Eng. 2023, 9, 149–165. [Google Scholar] [CrossRef]

- Stein, J.; Reise, C.; Castro, J.B.; Friesen, G.; Maugeri, G.; Urrejola, E.; Ranta, S. Bifacial Photovoltaic Modules and Systems: Experience and Results from International Research and Pilot Applications; Sandia National Lab. (SNL-NM): Albuquerque, NM, USA, 2021. [CrossRef]

- Lorenzo, E. On the historical origins of bifacial PV modelling. Sol. Energy 2021, 218, 587–595. [Google Scholar] [CrossRef]

- Ganesan, K.; Winston, D.P.; Sugumar, S.; Prasath, T.H. Performance investigation of n-type PERT bifacial solar photovoltaic module installed at different elevations. Renew. Energy 2024, 227, 120526. [Google Scholar] [CrossRef]

- Ganesan, K.; Winston, D.P.; Sugumar, S.; Jegan, S. Performance analysis of n-type PERT bifacial solar PV module under diverse albedo conditions. Sol. Energy 2023, 252, 81–90. [Google Scholar] [CrossRef]

- Pelaez, S.A.; Deline, C.; MacAlpine, S.M.; Marion, B.; Stein, J.S.; Kostuk, R.K. Comparison of bifacial solar irradiance model predictions with field validation. IEEE J. Photovolt. 2018, 9, 82–88. [Google Scholar] [CrossRef]

- Durusoy, B.; Ozden, T.; Akinoglu, B.G. Solar irradiation on the rear surface of bifacial solar modules: A modeling approach. Sci. Rep. 2020, 10, 13300. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.; Gul, M.S.; Muneer, T. Performance analysis and comparison between bifacial and monofacial solar photovoltaic at various ground albedo conditions. Renew. Energy Focus 2023, 44, 295–316. [Google Scholar] [CrossRef]

- Wang, S.; Wilkie, O.; Lam, J.; Steeman, R.; Zhang, W.; Khoo, K.S.; Siong, S.C.; Rostan, H. Bifacial photovoltaic systems energy yield modelling. Energy Procedia 2015, 77, 428–433. [Google Scholar] [CrossRef]

- Yusufoglu, U.A.; Lee, T.H.; Pletzer, T.M.; Halm, A.; Koduvelikulathu, L.J.; Comparotto, C.; Kopecek, R.; Kurz, H. Simulation of energy production by bifacial modules with revision of ground reflection. Energy Procedia 2014, 55, 389–395. [Google Scholar] [CrossRef]

- Wang, L.; Liu, F.; Yu, S.; Quan, P.; Zhang, Z. The study on micromismatch losses of the bifacial PV modules due to the irradiance nonuniformity on its backside surface. IEEE J. Photovolt. 2019, 10, 135–143. [Google Scholar] [CrossRef]

- Bhang, B.G.; Lee, W.; Kim, G.G.; Choi, J.H.; Park, S.Y.; Ahn, H.-K. Power performance of bifacial c-Si PV modules with different shading ratios. IEEE J. Photovolt. 2019, 9, 1413–1420. [Google Scholar] [CrossRef]

- Solar Energy Potential Atlas (GEPA). Available online: https://gepa.enerji.gov.tr/ (accessed on 5 February 2025).

- Dinçer, F.; Özer, E. Design of a hybrid renewable energy system and green hydrogen production for smart cities: A carbon emission reduction approach. Int. J. Energy Stud. 2025, 10, 1125–1158. [Google Scholar] [CrossRef]

- PVsyst Albedo Coefficient. Available online: https://www.pvsyst.com/help-pvsyst7/albedo.htm (accessed on 5 February 2025).

- Dincer, F.; Ozer, E. Performance analysis of bifacial photovoltaic panels under different albedo effects: A case study in Abu Dhabi, UAE. In Proceedings of the 2024 6th International Conference on Smart Power & Internet Energy Systems (SPIES), Abu Dhabi, United Arab Emirates, 4–6 December 2024; pp. 147–150. [Google Scholar] [CrossRef]

- Sahu, P.K.; Roy, J.N.; Chakraborty, C. Performance assessment of a bifacial pv system using a new energy estimation model. Sol. Energy 2023, 262, 111818. [Google Scholar] [CrossRef]

- Sun, X.; Khan, M.R.; Deline, C.; Alam, M.A. Optimization and performance of bifacial solar modules: A global perspective. Appl. Energy 2018, 212, 1601–1610. [Google Scholar] [CrossRef]

- Baloch, A.A.; Hammat, S.; Figgis, B.; Alharbi, F.H.; Tabet, N. In-field characterization of key performance parameters for bifacial photovoltaic installation in a desert climate. Renew. Energy 2020, 159, 50–63. [Google Scholar] [CrossRef]

- Ghenai, C.; Ahmad, F.F.; Rejeb, O.; Hamid, A.K. Sensitivity analysis of design parameters and power gain correlations of bi-facial solar PV system using response surface methodology. Sol. Energy 2021, 223, 44–53. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).