Thermal Comfort and Energy Consumption in a Residential Building: An Experimental Comparison Between a Heat Pump and Gas Boiler Employing Low-Cost Microcontroller-Driven Sensors

Abstract

1. Introduction

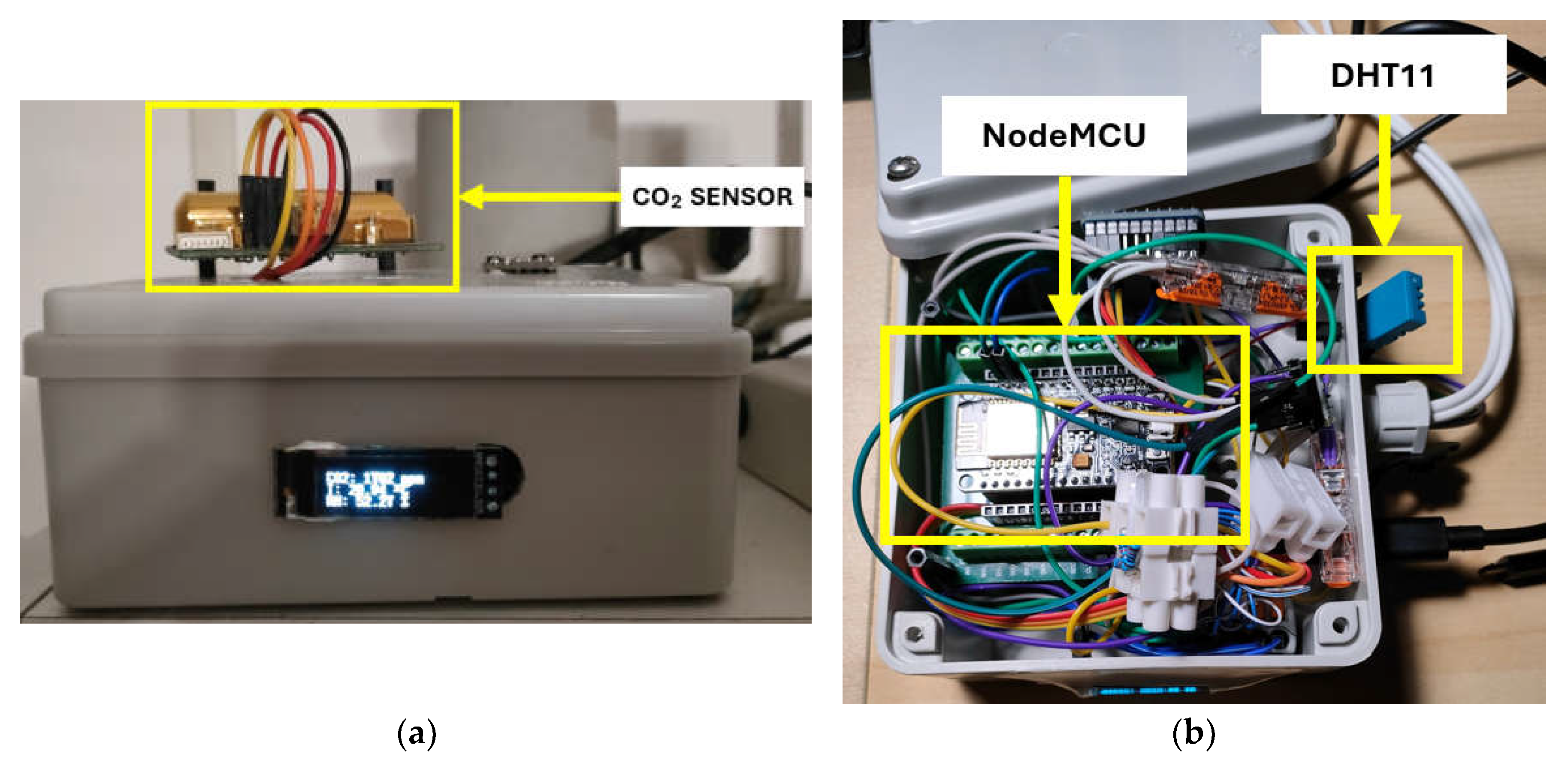

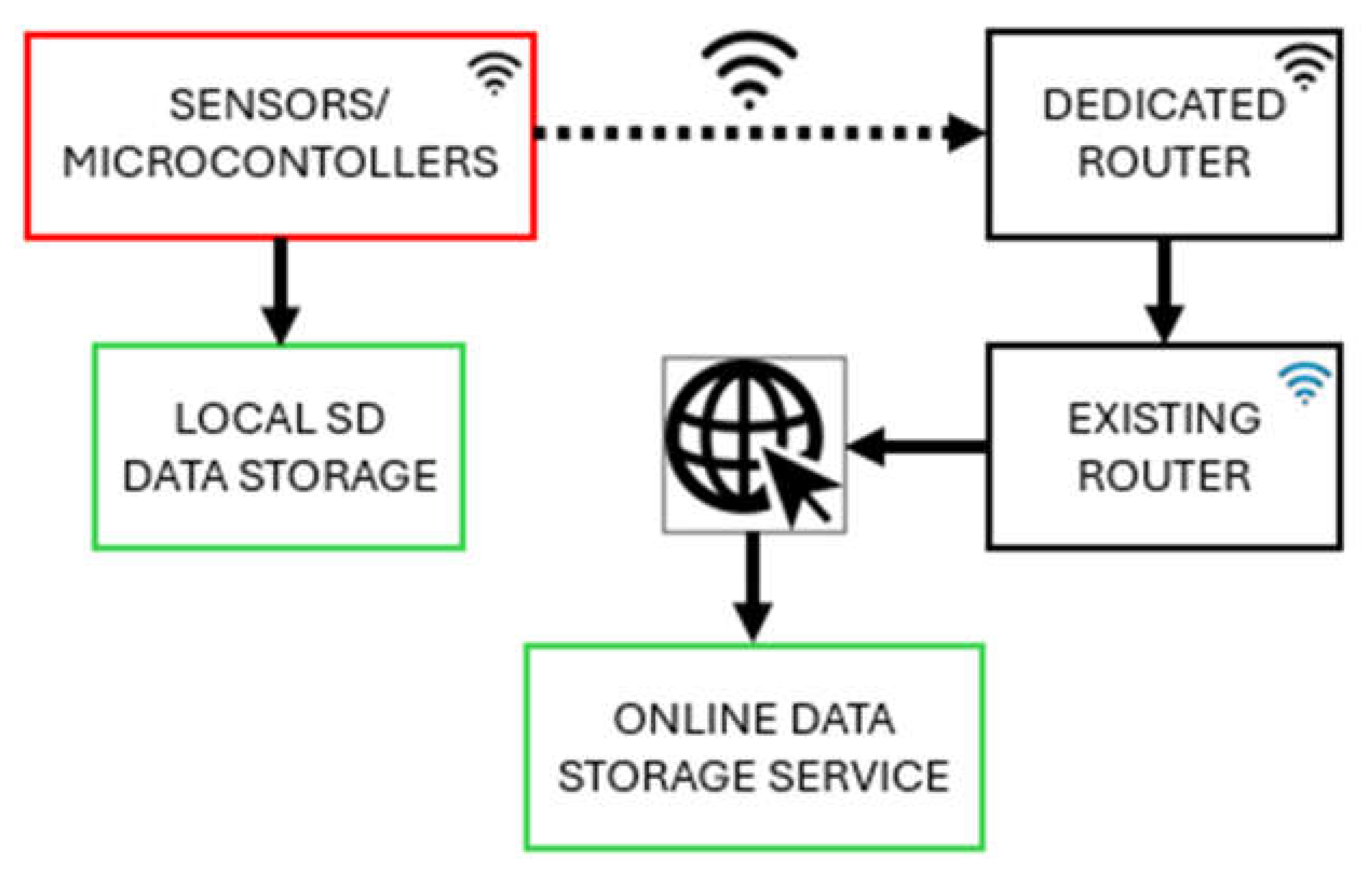

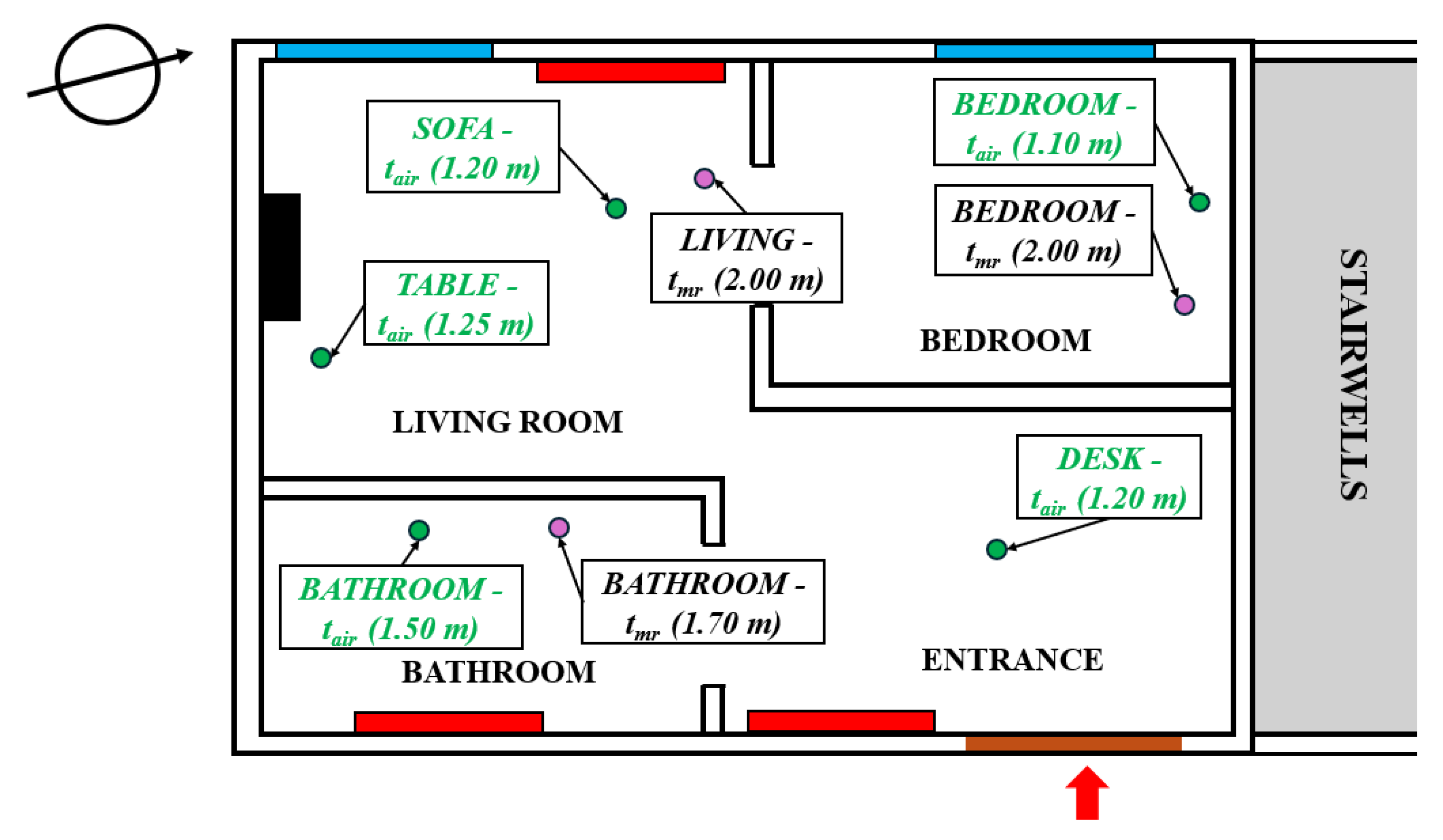

2. Materials and Methods

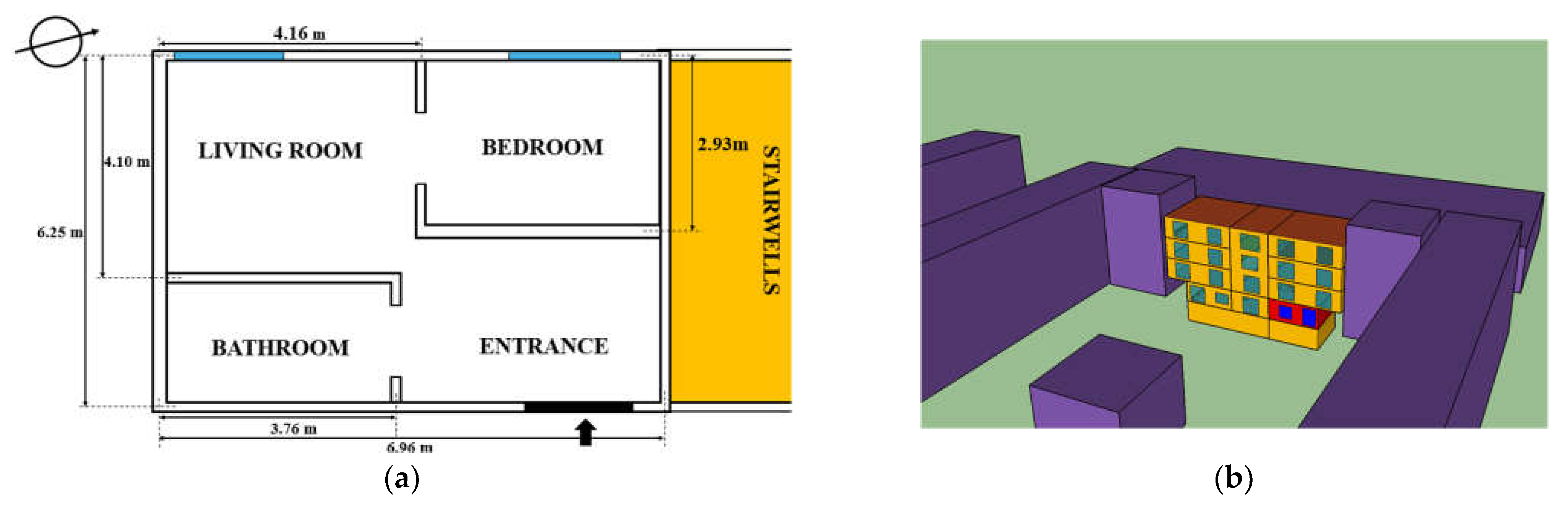

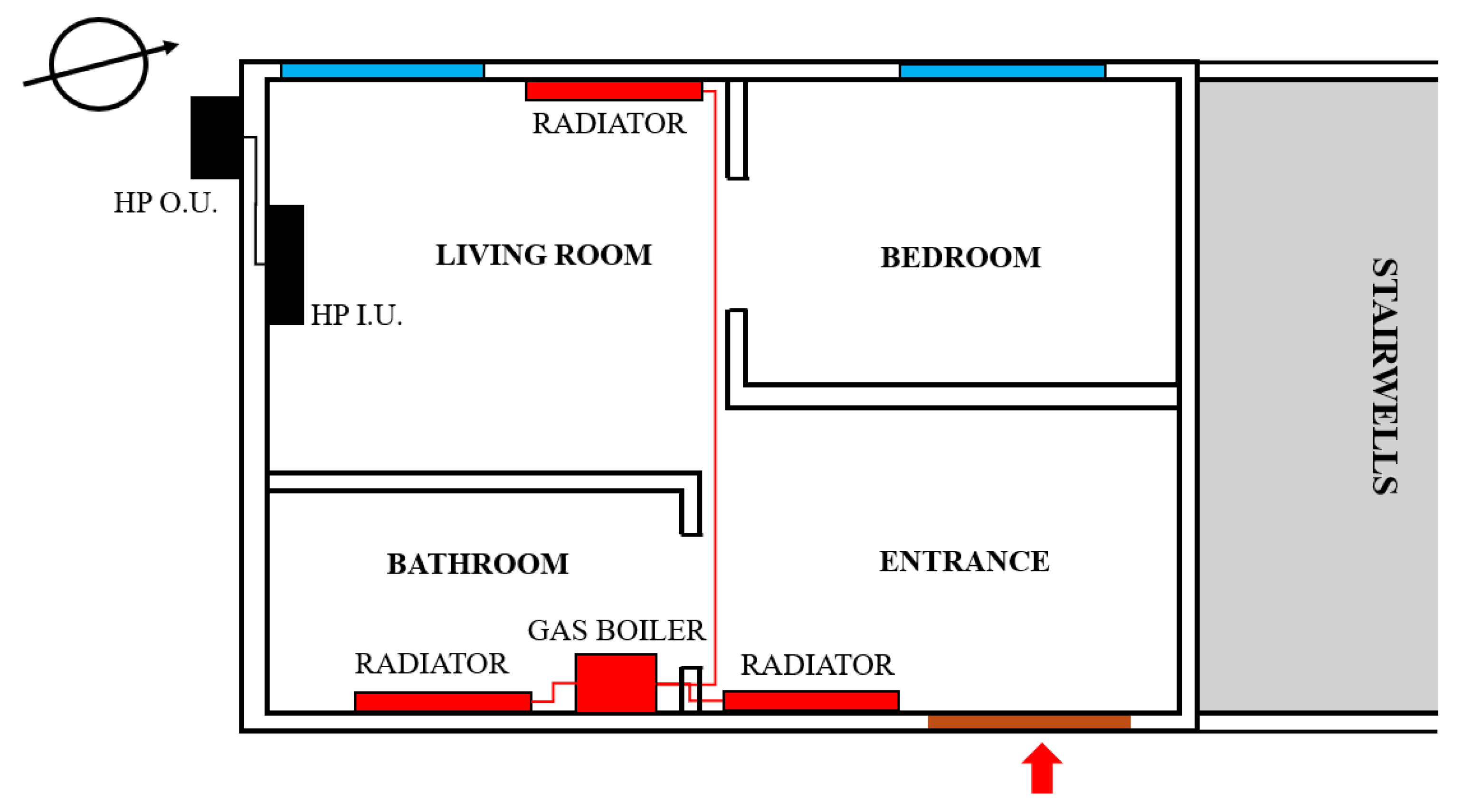

3. Building and Heating System Characteristics

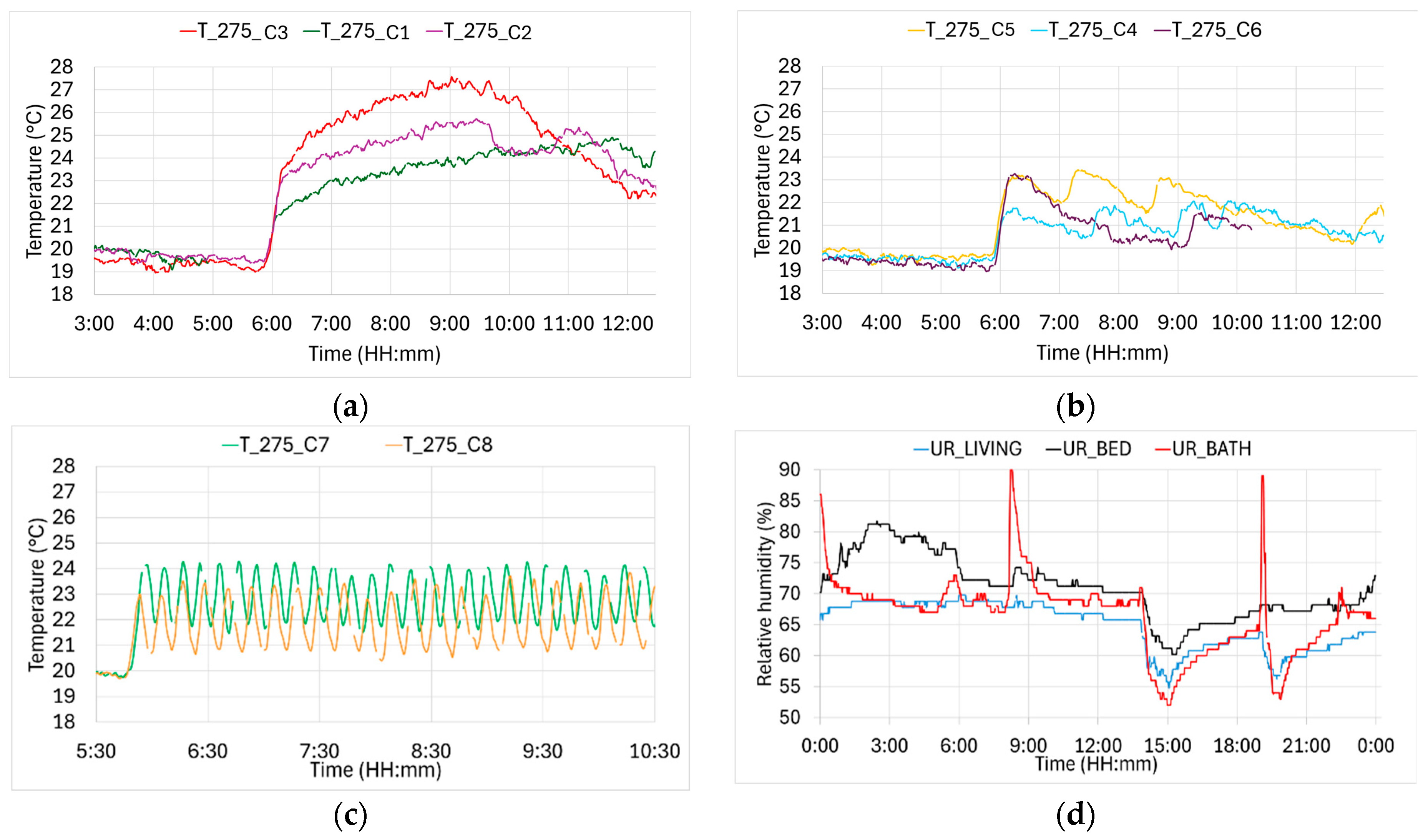

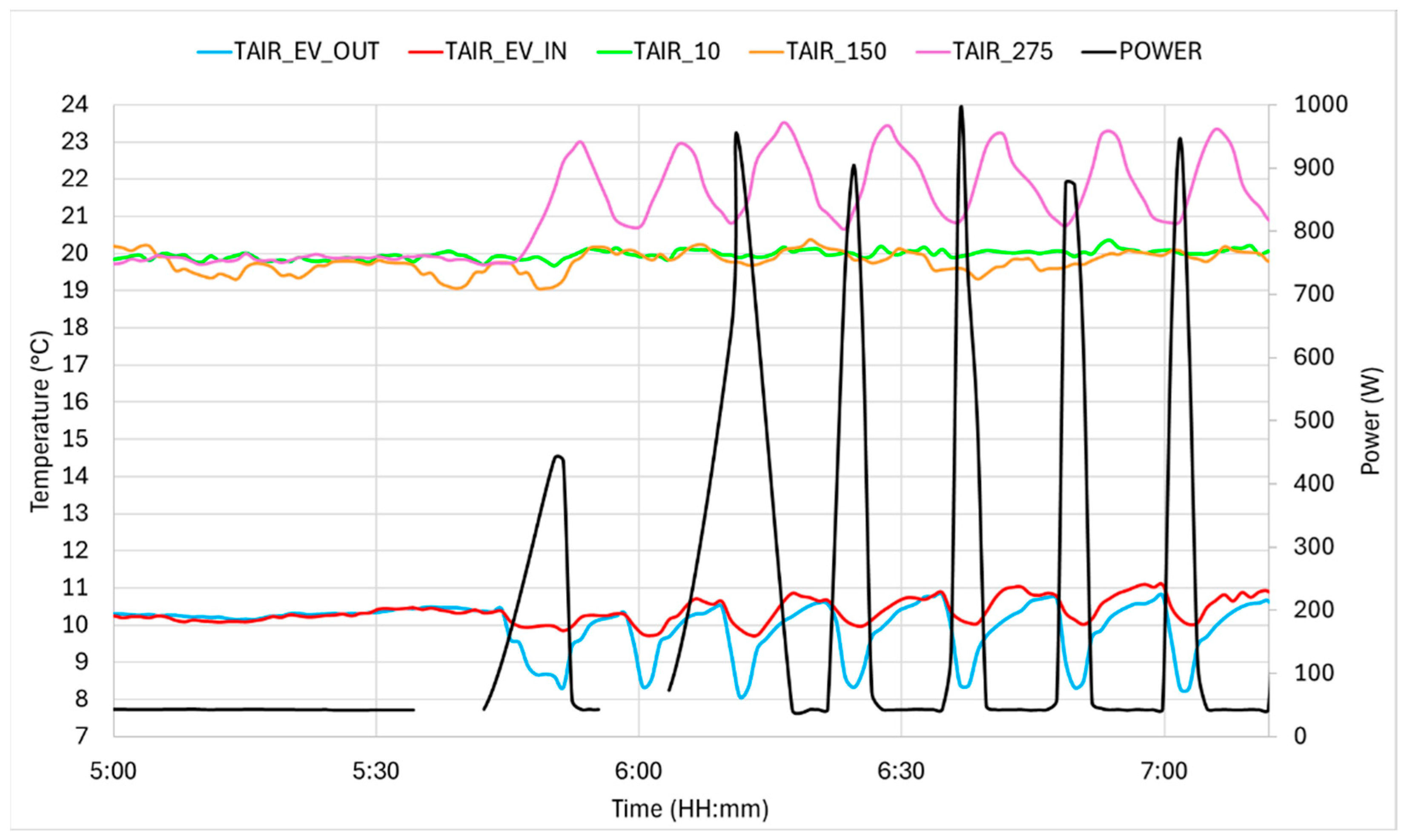

4. Experimental Campaign

5. Results and Discussion

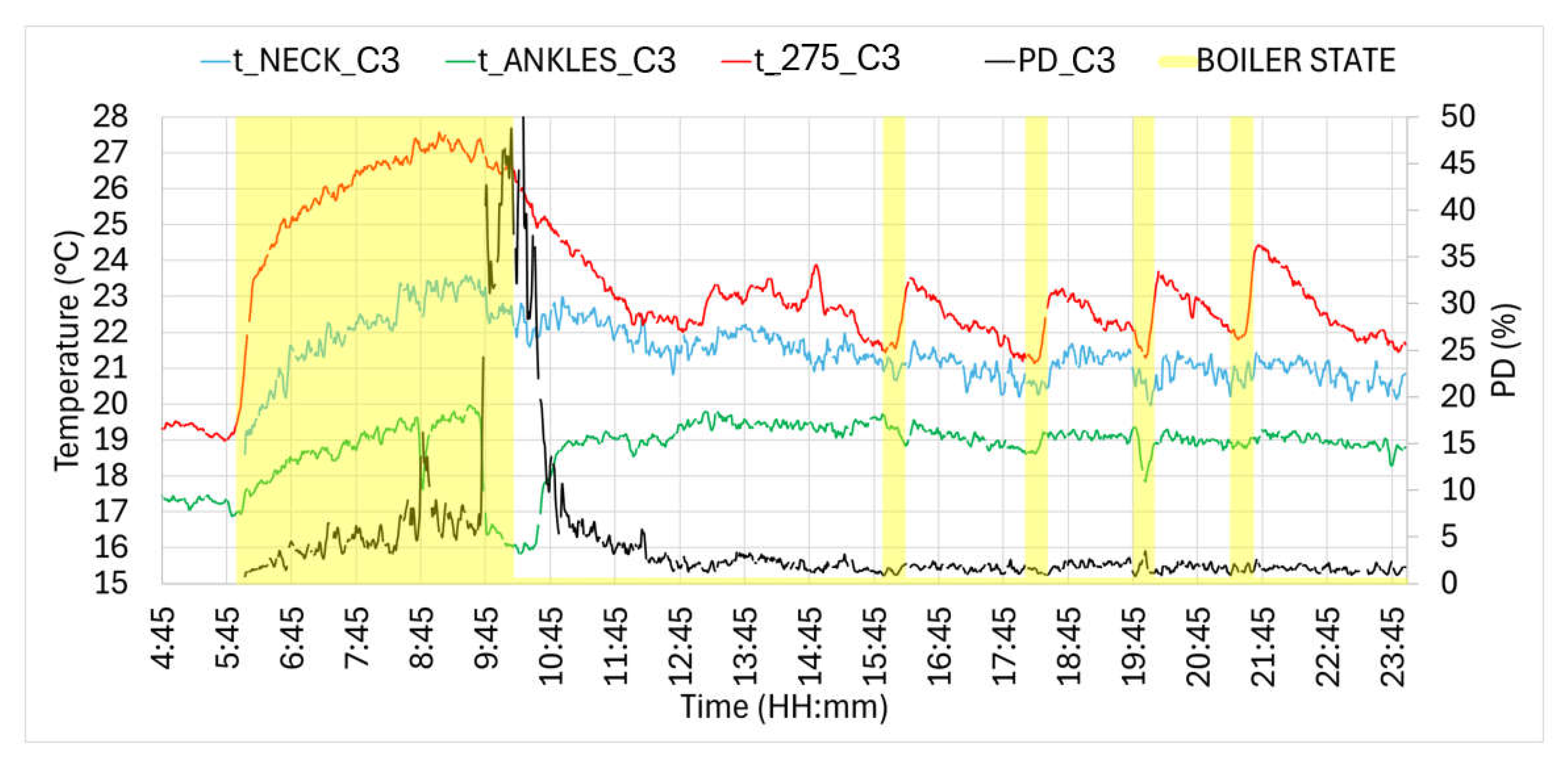

5.1. Comfort Analysis

5.2. Local Discomfort Analysis

5.3. Energy Analysis

5.4. Carbon Dioxide Concentration Analysis

6. Conclusions

- -

- The comfort indices inside the apartment using the heat pump are intermediate between the indices determined when the gas boiler is used with set-points between 20 °C and 21 °C (for example, the heat pump in case C8 with a set-point of 21 °C leads to a PMV of −0.35 in the living room, next to the sofa, while when the gas boiler was employed, the PMV value was −0.11 and −0.53, for set-point 21 and 20 °C, respectively).

- -

- The supply water temperature to the radiators has little influence on comfort conditions for a fixed set-point temperature, but has an influence generally on the gas consumption of the gas boiler, as reported in Table 3.

- -

- The results from the experimental analysis were compared with those obtained from CFD and dynamic analyses [31], and the experimental results are partially in agreement with the dynamic ones. Both the experimental and dynamic and CFD analyses clearly show that some rooms (bedroom and bathroom) present situations of discomfort. However, the experimental results highlighted a higher mean radiant temperature, thus better comfort conditions.

- -

- The experimental analysis did not show any particular issues related to local discomfort due to the vertical temperature gradient (for all cases considered, the percentage of dissatisfied PD is in the range of 1.3–4.7%).

- -

- The analysis of air quality leads to the statement that it is poor in the apartment, with an average of over 24 h of CO2 values above 1360 ppm (range 1360–1860 ppm), suggesting a need to improve ventilation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

- // MEAN RADIANT TEMPERATURE DETERMINATION, CONSIDERING THE AIR TEMPERATURE NTC1 AND BLACK GLOBE TEMPERATURE NTC0

- Trad_calc_m = pow(pow(273 + T_m_NTC0, 4) + (T_m_NTC0 - T_m_NTC1) * (0.25 * pow(10, 8)) * (1 / 0.95) * pow(fabs(T_m_NTC0 - T_m_NTC1) / 0.15, 0.25), 0.25) - 273;

| // INPUTA DATA |

| ta = T_m_NTC1; //AIR TEMPERATURE (READINGS FROM NTC1) |

| tr = Trad_calc_m; // MEAN RADIANT TEMPERATURE |

| rh = RH_m_DHT11; // RELATIVE HUMIDITY (READING FROM DHT11 HUMIDITY SENSOR) |

| met = 1.0; // METABOLIC RATE |

| wme = 0.0; // EXTERNAL WORK |

| vel = 0.05; // AIR VELOCITY |

| clo = 1.0; // CLOTHING |

| // PARTIAL VAPOR PRESSURE APPROXIMATION |

| float pa = rh * 10 * exp(16.6536 - 4030.183 / (ta + 235)); |

| // CLOTHING RESISTANCE DETERMINATION IN m2K/W |

| float icl = 0.155 * clo; |

| // METABOLIC RATE IN W/m2 |

| float m = met * 58.15; |

| // EXTERNAL WORK IN W/m2 |

| float w = wme * 58.15; |

| // MW BALANCE |

| float mw = m - w; |

| // CLOTHING FACTOR DETERMINATION |

| float fcl; |

| if (icl <= 0.078) { |

| fcl = 1 + 1.29 * icl; |

| } else { |

| fcl = 1.05 + 0.645 * icl; |

| } |

| // hc COEFFICIENT DETERMINATION |

| float hcf = 12.1 * sqrt(vel); |

| float hc = -2000; // STARTING |

| float taa = ta + 273; |

| float tra = tr + 273; |

| float tcla = taa + (35.5 - ta) / (3.5 * icl + 0.1); |

| float p1 = icl * fcl; |

| float p2 = p1 * 3.96; |

| float p3 = p1 * 100; |

| float p4 = p1 * taa; |

| float p5 = 308.7 - 0.028 * mw + p2 * pow((tra / 100), 4); |

| float hcn = 0; |

| float xn = tcla / 100; |

| float xf = xn + 0.1; |

| float eps = 0.0015; // TOLERANCE |

| int n = 0; |

| while (fabs(xn - xf) > eps) { |

| xf = (xf + xn) / 2; |

| hcn = 2.38 * pow(fabs(100 * xf - taa), 0.25); |

| hc = (hcf > hcn) ? hcf : hcn; |

| xn = (p5 + p4 * hc - p2 * pow(xf, 4)) / (100 + p3 * hc); |

| n++; |

| } |

| float tcl = 100 * xn - 273; |

| // FINAL DETERMINATION OF PMV AND PPD |

| ts = 0.303 * exp(-0.036 * m) + 0.028; |

| pmv = ts * (mw - (3.05 * 0.001 * (5733 - 6.99 * mw - pa)) - max(0.0, 0.42 * (mw - 58.15)) - (1.7 * 0.00001 * m * (5867 - pa)) - (0.0014 * m * (34 - ta)) - (3.96 * fcl * (pow(xn, 4) - pow(tra / 100, 4))) - (fcl * hc * (tcl - ta))); |

| ppd = 100 - 95 * exp(-0.03353 * pow(pmv, 4) - 0.2179 * pow(pmv, 2)); |

| // END OF PMV AND PPD CALCULATION. |

References

- European Heat Pump Association. Available online: https://www.ehpa.org (accessed on 23 June 2025).

- European Heat Pump Association. European Heat Pump Market and Statistics Report 2023. Available online: https://www.ehpa.org/news-and-resources/publications/european-heat-pump-market-and-statistics-report-2023 (accessed on 23 June 2025).

- Péan, T.Q.; Salom, J.; Costa-Castelló, R. Review of control strategies for improving the energy flexibility provided by heat pump systems in buildings. J. Process Control 2019, 74, 35–49. [Google Scholar] [CrossRef]

- Gholamzadehmir, M.; Del Pero, C.; Buffa, S.; Fedrizzi, R. Adaptive-predictive control strategy for HVAC systems in smart buildings–A review. Sustain. Cities Soc. 2020, 63, 102480. [Google Scholar] [CrossRef]

- Mathews, E.H.; Botha, C.P.; Arndt, D.C.; Malan, A. HVAC control strategies to enhance comfort and minimise energy usage. Energy Build. 2001, 33, 853–863. [Google Scholar] [CrossRef]

- Kong, M.; Dong, B.; Zhang, R.; O’Neill, Z. HVAC energy savings, thermal comfort and air quality for occupant-centric control through a side-by-side experimental study. Appl. Energy 2022, 306, 117987. [Google Scholar] [CrossRef]

- Goyal, S.; Barooah, P.; Middelkoop, T. Experimental study of occupancy-based control of HVAC zones. Appl. Energy 2015, 140, 75–84. [Google Scholar] [CrossRef]

- Ballerini, V.; Valdiserri, P.; Krawczyk, D.A.; Sadowska, B.; Lubowicka, B.; di Schio, E.R. Design, comparison and application of artificial intelligence predictive models based on experimental data for estimating carbon dioxide concentration inside a building. Appl. Therm. Eng. 2025, 261, 125122. [Google Scholar] [CrossRef]

- Pandey, B.; Bohara, B.; Pungaliya, R.; Patwardhan, S.C.; Banerjee, R. A thermal comfort-driven model predictive controller for residential split air conditioner. J. Build. Eng. 2021, 42, 102513. [Google Scholar] [CrossRef]

- Karami, M.; McMorrow, G.V.; Wang, L. Continuous monitoring of indoor environmental quality using an Arduino-based data acquisition system. J. Build. Eng. 2018, 19, 412–419. [Google Scholar] [CrossRef]

- Willem, H.; Lin, Y.; Lekov, A. Review of energy efficiency and system performance of residential heat pump water heaters. Energy Build. 2017, 143, 191–201. [Google Scholar] [CrossRef]

- Brenn, J.; Soltic, P.; Bach, C. Comparison of natural gas-driven heat pumps and electrically driven heat pumps with conventional systems for building heating purposes. Energy Build. 2010, 42, 904–908. [Google Scholar]

- Lin, H.; Clavreul, J.; Jeandaux, C.; Crawley, J.; Butnar, I. Environmental life cycle assessment of heating systems in the UK: Comparative assessment of hybrid heat pumps vs. condensing gas boilers. Energy Build. 2021, 240, 110865. [Google Scholar] [CrossRef]

- Nielsen, M.G.; Morales, J.M.; Zugno, M.; Pedersen, T.E.; Madsen, H. Economic valuation of heat pumps and electric boilers in the Danish energy system. Appl. Energy 2016, 167, 189–200. [Google Scholar] [CrossRef]

- Lu, Z.; Ziviani, D. Operating cost comparison of state-of-the-art heat pumps in residential buildings across the United States. Energy Build. 2022, 277, 112553. [Google Scholar]

- Gradziuk, B.; Gradziuk, P. Heat pumps versus biomass boilers: A comparative analysis of heating costs for public buildings. Ann. Pol. Assoc. Agric. Agrobusiness Econ. 2020, 22, 77–85. [Google Scholar] [CrossRef]

- Ballerini, V.; Rossi di Schio, E.; Valdiserri, P. How the energy price variability in Italy affects the cost of building heating: A Trnsys-guided comparison between air-source heat pumps and gas boilers. Buildings 2022, 12, 1936. [Google Scholar] [CrossRef]

- Mansi, S.A.; Barone, G.; Forzano, C.; Pigliautile, I.; Ferrara, M.; Pisello, A.L.; Arnesano, M. Measuring Human Physiological Indices for Thermal Comfort Assessment through Wearable Devices: A Review. Measurement 2021, 183, 109872. [Google Scholar] [CrossRef]

- Solano, J.C.; Caamaño-Martín, E.; Olivieri, L.; Almeida-Galárraga, D. HVAC systems and thermal comfort in buildings climate control: An experimental case study. Energy Rep. 2021, 7, 269–277. [Google Scholar] [CrossRef]

- Fanger, P.O. Thermal Comfort: Analysis and Applications in Environmental Engineering; Danish Technical Press: Copenhagen, Denmark, 1970; ISBN 978-87-571-0341-0. [Google Scholar]

- Ma, Z.; Zhao, D.; She, C.; Yang, Y.; Yang, R. Personal thermal management techniques for thermal comfort and building energy saving. Mater. Today Phys. 2021, 20, 100465. [Google Scholar] [CrossRef]

- Li, K.; Liu, Y.; Chen, L.; Xue, X. Data efficient indoor thermal comfort prediction using instance based transfer learning method. Energy Build. 2024, 306, 113920. [Google Scholar] [CrossRef]

- Boutahri, Y.; Tilioua, A. Machine learning-based predictive model for thermal comfort and energy optimization in smart buildings. Results Eng. 2024, 22, 102148. [Google Scholar] [CrossRef]

- Yussuf, R.O.; Asfour, O.S. Applications of artificial intelligence for energy efficiency throughout the building lifecycle: An overview. Energy Build. 2024, 305, 113903. [Google Scholar] [CrossRef]

- Boicu, M.G.; Stamatescu, G.; Făgărăşan, I.; Vasluianu, M.; Neculoiu, G.; Dobrea, M.A. Optimizing Occupant Comfort in a Room Using the Predictive Control Model as a Thermal Control Strategy. Sensors 2024, 24, 3857. [Google Scholar] [CrossRef] [PubMed]

- Myroniuk, K.; Furdas, Y.; Zhelykh, V.; Adamski, M.; Gumen, O.; Savin, V.; Mitoulis, S.-A. Passive Ventilation of Residential Buildings Using the Trombe Wall. Buildings 2024, 14, 3154. [Google Scholar] [CrossRef]

- Ballerini, V.; Coccagna, M.; Bisi, M.; Volta, A.; Droghetti, L.; Rossi di Schio, E.; Valdiserri, P.; Mazzacane, S. The Role of Mechanical Ventilation in Indoor Air Quality in Schools: An Experimental Comprehensive Analysis. Buildings 2025, 15, 869. [Google Scholar] [CrossRef]

- Dong, Z.; Boyi, Q.; Pengfei, L.; Zhoujian, A. Comprehensive evaluation and optimization of rural space heating modes in cold areas based on PMV-PPD. Energy Build. 2021, 246, 111120. [Google Scholar] [CrossRef]

- Pereira, P.F.D.C.; Broday, E.E.; Xavier, A.A.D.P. Thermal comfort applied in hospital environments: A literature review. Appl. Sci. 2020, 10, 7030. [Google Scholar] [CrossRef]

- Valdiserri, P.; Cesari, S.; Coccagna, M.; Romio, P.; Mazzacane, S. Experimental Data and Simulations of Performance and Thermal Comfort in a Patient Room Equipped with Radiant Ceiling Panels. Buildings 2020, 10, 235. [Google Scholar] [CrossRef]

- ISO 7730 2005-11-15; Ergonomics of the Thermal Environment: Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. International Organization for Standardization: Geneva, Switzerland, 2005.

- Ballerini, V.; Volo, E.P.B.d.; Pulvirenti, B.; di Schio, E.R.; Valdiserri, P.; Guidorzi, P. Influence of Different Heating Systems on Thermal Comfort Perception: A Dynamic and CFD Analysis. J. Phys. Conf. Ser. 2024, 2685, 012021. [Google Scholar] [CrossRef]

- Conrad Electronic, TRU COMPONENTS 10kΩ NTC. Datasheet. Available online: https://asset.conrad.com/media10/add/160267/c1/-/en/001570951DS00/datasheet-1570951-tru-components-mjsts-103-3950-1-600-3d-temperature-sensor-30-up-to-105-c-10-k-3950-k.pdf (accessed on 16 August 2025).

- Mouser Electronics. DHT11 Humidity and Temperature Sensor. Available online: https://www.mouser.com/datasheet/2/758/DHT11-Technical-Data-Sheet-Translated-Version-1143054.pdf (accessed on 23 June 2025).

- ASAIR AHT10 Technical Manual. Available online: https://server4.eca.ir/eshop/AHT10/Aosong_AHT10_en_draft_0c.pdf (accessed on 23 June 2025).

- Winsen. Intelligent Infrared Carbon Dioxide Module (Model: MH-Z14A). Available online: https://www.winsen-sensor.com/d/files/MH-Z14A.pdf (accessed on 23 June 2025).

- Qingxian Zeming Langxi Electronic. ZMPT101BCurrent-Type Voltage Transformer. Available online: https://futuranet.it/futurashop/image/catalog/data/Download/1606-HR1232.pdf (accessed on 23 June 2025).

- Qingxian Zeming Langxi Electronic. ZMCT103C Current Transformer. Available online: https://5nrorwxhmqqijik.leadongcdn.com/ZMCT103C+specification-aidirBqoKomRilSjpimnokp.pdf (accessed on 23 June 2025).

- AZ-Delivery C1 Mini NodeMcu, Based on ESP8266. Available online: https://cdn.shopify.com/s/files/1/1509/1638/files/Betriebsanleitung-AZ-D1miniV1.2_2.pdf?v=1590603445 (accessed on 23 June 2025).

- Argolab CH250 Climatic Chamber, 250LT. Available online: https://www.argo-lab.com/Media/FileDocumenti/ENG/manuali/CLIMATEST.pdf (accessed on 23 June 2025).

- Sensirion. Datasheet Sensirion SCC30 Sensor Module CO2, Humidity, and Temperature Sensor. Available online: https://sensirion.com/media/documents/4EAF6AF8/61652C3C/Sensirion_CO2_Sensors_SCD30_Datasheet.pdf (accessed on 23 June 2025).

- Google docs Google, LLC. Available online: https://docs.google.com (accessed on 23 June 2025).

- UNI EN 14511-3; Air Conditioners, Liquid Chilling Packages and Heat Pumps for Space Heating and Cooling and Process Chillers, with Electrically Driven Compressors—Part 3: Test Methods. Ente Nazionale Italiano di Unificazione: Milano, Italy, 2018.

- UNI UNI 10349-1:2016; Heating and Cooling of Buildings—Climatic Data—Part 1: Monthly Averages for Italian Locations. Ente Nazionale Italiano di Unificazione: Milano, Italy, 2016.

| Sensor | Type–Model | Measured Quantity | Uncertainty |

|---|---|---|---|

| Temperature | NTC 10 kOhm at 25 °C | Temperature (°C) | ±0.4 K |

| Humidity | DHT11 | Relative humidity (%) | ±5% |

| Humidity | AHT10 | Relative humidity (%) | ±3% |

| CO2 sensor | MHZ14A | CO2 concentration (ppm) | ±(50 ppm + 5% reading value) |

| Current sensor | ZMCT103C | Current (A) | ±1% |

| Voltage | ZMPT101B | Voltage (V) | ±1% |

| Component | U-Value (W/(m2K)) | Thickness (m) |

|---|---|---|

| Dividing walls | 2.074 | 0.10 |

| External walls | 0.667 | 0.30 |

| Inter-floor | 0.595 | 0.42 |

| Case | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 |

|---|---|---|---|---|---|---|---|---|

| Heating system | BOILER | BOILER | BOILER | BOILER | BOILER | BOILER | HP | HP |

| Air set-point, tset (°C) | 21 | 21 | 21 | 20 | 20 | 20 | 21 | 20 |

| Water temperature, tw (°C) | 45 | 55 | 65 | 45 | 55 | 65 | - | - |

| Gas volume (Sm3) | 2.61 | 2.71 | 3.49 | 1.94 | 2.49 | 1.87 | - | - |

| HP electricity demand (kWh) | - | - | - | - | - | - | 4.07 | 2.34 |

| Case | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 |

|---|---|---|---|---|---|---|---|---|

| Heating system | BOILER | BOILER | BOILER | BOILER | BOILER | BOILER | HP | HP |

| tset (°C) | 21 | 21 | 21 | 20 | 20 | 20 | 21 | 20 |

| tw (°C) | 45 | 55 | 65 | 45 | 55 | 65 | - | - |

| HS-ON factor (-) | 0.39 | 0.35 | 0.28 | 0.07 | 0.11 | 0.05 | 0.38 | 0.15 |

| text (°C) (24 h) | 10.7 | 10.8 | 12.2 | 14.1 | 9.9 | 5.9 | 14.7 | 14.8 |

| text (°C) (HS-ON) | 12 | 12 | 12.6 | 14.8 | 10.4 | 6.3 | 14.9 | 15.2 |

| URext (%) (24 h) | 85 | 87 | 74 | 78 | 89 | 83 | 92 | 91 |

| PMV BATH (-) | −0.32 | −0.28 | −0.33 | −0.77 | −0.57 | −0.75 | −0.85 | −0.79 |

| PMV BED (-) | −0.73 | −0.76 | −0.73 | −1.06 | −1.00 | −0.92 | −0.90 | −0.93 |

| PMV SOFA (-) | −0.11 | −0.15 | −0.04 | −0.53 | −0.42 | −0.44 | −0.35 | −0.37 |

| PMV DESK (-) | −0.17 | −0.17 | −0.07 | −0.51 | −0.46 | −0.54 | −0.36 | −0.38 |

| PMV TABLE (-) | −0.11 | −0.15 | −0.04 | −0.53 | −0.42 | −0.44 | −0.35 | −0.37 |

| PPD BATH (%) | 7.1 | 6.6 | 7.3 | 17.5 | 11.8 | 16.8 | 20.2 | 18.2 |

| PPD BED (%) | 16.2 | 17.2 | 16.2 | 28.7 | 26.1 | 22.9 | 22.1 | 23.3 |

| PPD SOFA (%) | 5.3 | 5.5 | 5.0 | 10.9 | 8.7 | 9.0 | 7.5 | 7.8 |

| PPD DESK (%) | 5.6 | 5.6 | 5.1 | 10.4 | 9.4 | 11.1 | 7.7 | 8.0 |

| PPD TABLE (%) | 5.3 | 5.5 | 5.0 | 10.9 | 8.7 | 9.0 | 7.5 | 7.8 |

| Case | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 |

|---|---|---|---|---|---|---|---|---|

| tair bathroom | 21.2 | 21.4 | 21.2 | 19.5 | 20.4 | 19.6 | 19.2 | 19.3 |

| tair bedroom | 19.3 | 19.3 | 19.4 | 18.4 | 18.5 | 17.9 | 18.7 | 18.8 |

| tair sofa | 21.8 | 21.6 | 20.0 | 20.2 | 20.6 | 20.4 | 20.3 | 20.7 |

| tair desk | 21.5 | 21.4 | 21.8 | 20.4 | 20.4 | 19.9 | 20.3 | 20.6 |

| tair table | 21.7 | 21.7 | 22.1 | 20.0 | 20.6 | 20.1 | 19.9 | 20.2 |

| tmr living | 23.1 | 23.2 | 23.7 | 21.4 | 22.1 | 22.0 | 22.8 | 22.2 |

| tmr bathroom | 22.0 | 22.3 | 22.3 | 20.0 | 21.2 | 20.3 | 19.6 | 19.9 |

| tmr bedroom | 21.1 | 21.1 | 21.4 | 19.3 | 20.0 | 21.4 | 20.2 | 19.8 |

| RH living | 64 | 62 | 59 | 71 | 64 | 69 | 70 | 70 |

| RH bathroom | 69 | 62 | 60 | 79 | 65 | 75 | 82 | 82 |

| RH bedroom | 69 | 65 | 62 | 76 | 69 | 74 | 75 | 76 |

| Case | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 |

|---|---|---|---|---|---|---|---|---|

| temp. ankles (°C) | 19.4 | 18.9 | 18.9 | 18.2 | 18.2 | 18.4 | 18.1 | 18.4 |

| temp. neck (°C) | 21.2 | 21.1 | 21.5 | 20 | 20.3 | 19.9 | 20.2 | 20.3 |

| PD (%) | 1.7 | 3.4 | 4.7 | 1.8 | 2.5 | 1.3 | 2.2 | 1.7 |

| Case | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 |

|---|---|---|---|---|---|---|---|---|

| CO2 concentration (ppm) | 1775 | 1551 | 1460 | 1804 | 1396 | 1360 | 1460 | 1860 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ballerini, V.; Rossi di Schio, E.; Chekifi, T.; Valdiserri, P. Thermal Comfort and Energy Consumption in a Residential Building: An Experimental Comparison Between a Heat Pump and Gas Boiler Employing Low-Cost Microcontroller-Driven Sensors. Energies 2025, 18, 4398. https://doi.org/10.3390/en18164398

Ballerini V, Rossi di Schio E, Chekifi T, Valdiserri P. Thermal Comfort and Energy Consumption in a Residential Building: An Experimental Comparison Between a Heat Pump and Gas Boiler Employing Low-Cost Microcontroller-Driven Sensors. Energies. 2025; 18(16):4398. https://doi.org/10.3390/en18164398

Chicago/Turabian StyleBallerini, Vincenzo, Eugenia Rossi di Schio, Tawfiq Chekifi, and Paolo Valdiserri. 2025. "Thermal Comfort and Energy Consumption in a Residential Building: An Experimental Comparison Between a Heat Pump and Gas Boiler Employing Low-Cost Microcontroller-Driven Sensors" Energies 18, no. 16: 4398. https://doi.org/10.3390/en18164398

APA StyleBallerini, V., Rossi di Schio, E., Chekifi, T., & Valdiserri, P. (2025). Thermal Comfort and Energy Consumption in a Residential Building: An Experimental Comparison Between a Heat Pump and Gas Boiler Employing Low-Cost Microcontroller-Driven Sensors. Energies, 18(16), 4398. https://doi.org/10.3390/en18164398