Artificial Intelligence in Assessing Electricity and Water Demand in Oilseed Processing

Abstract

1. Introduction

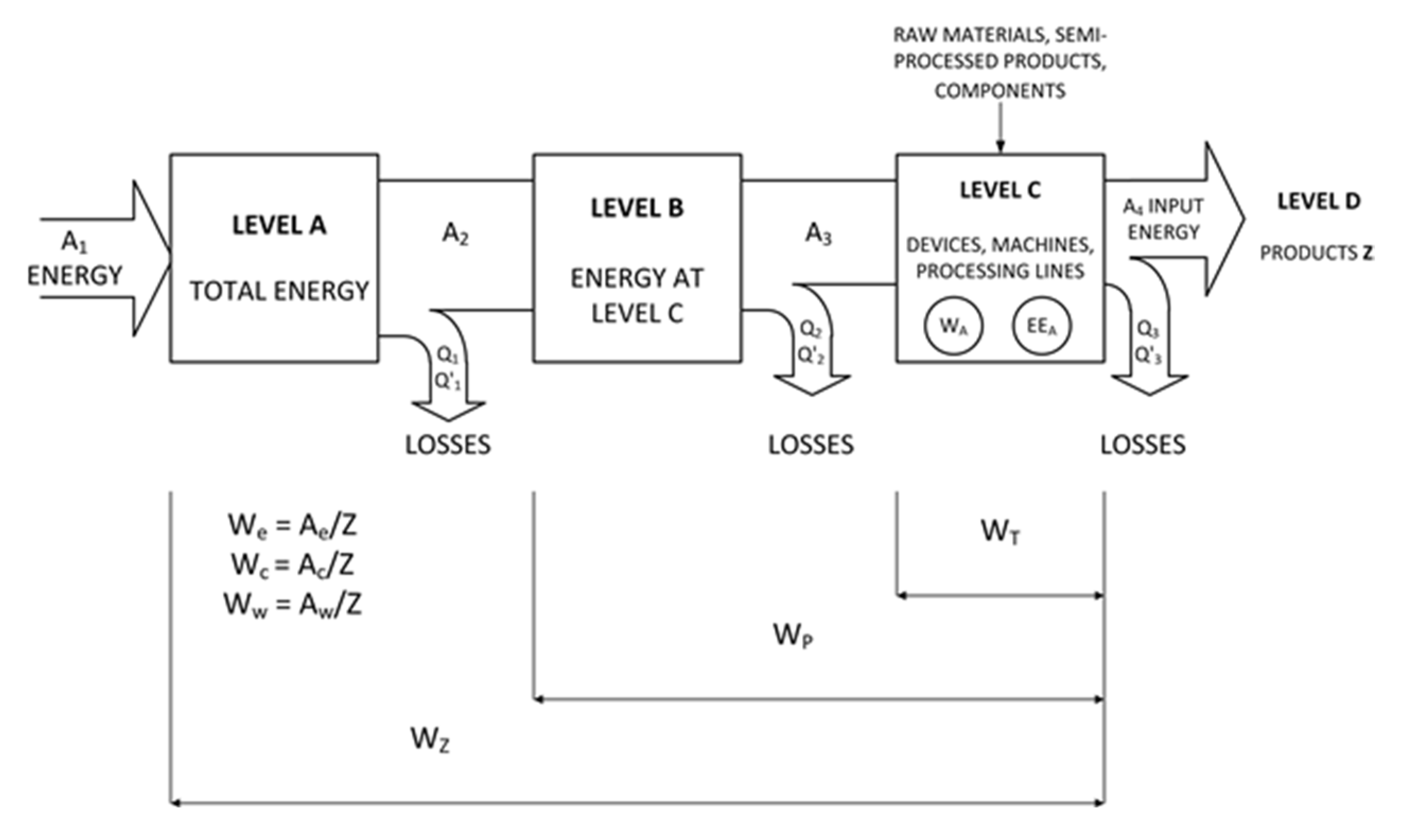

2. Analysis of Oilseed Processing

- At1—total energy consumption (considering the conversion rate 1 kWh = 12 MJ, At1 = 0.012Ae + Ac) [GJ/24 h].

- At2—total energy consumption (considering the conversion rate 1 kWh = 3.6 MJ, At2 = 0.0036Ae + Ac) [GJ/24 h].

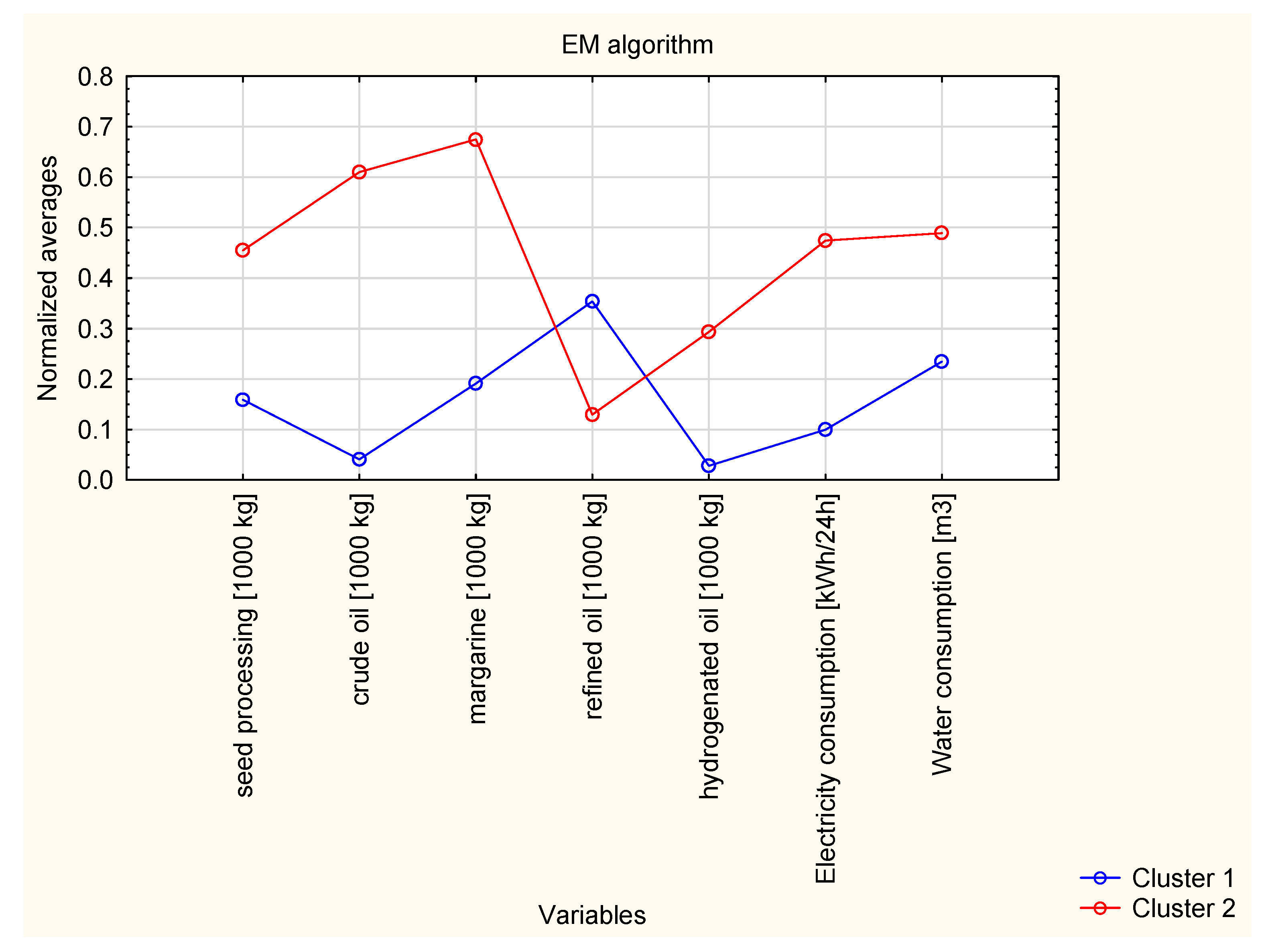

3. Data Analysis

- Below average—from the observed minimum to the overall mean (21,000–66,362.2 [kWh/day]).

- Average—from the median to the overall mean (56,480–66,362.2 [kWh/day]).

- Above average—from the overall mean to the observed maximum (66,362.2–139,300 [kWh]/day).

- Below average—from the observed minimum to the overall mean (275–2838.6 [m3] day−1).

- Average—from the median to the overall mean (1910–2838.6 m3 day−1).

- Above average—from the overall mean to the observed maximum (2838.6–5880 [m3] day−1).

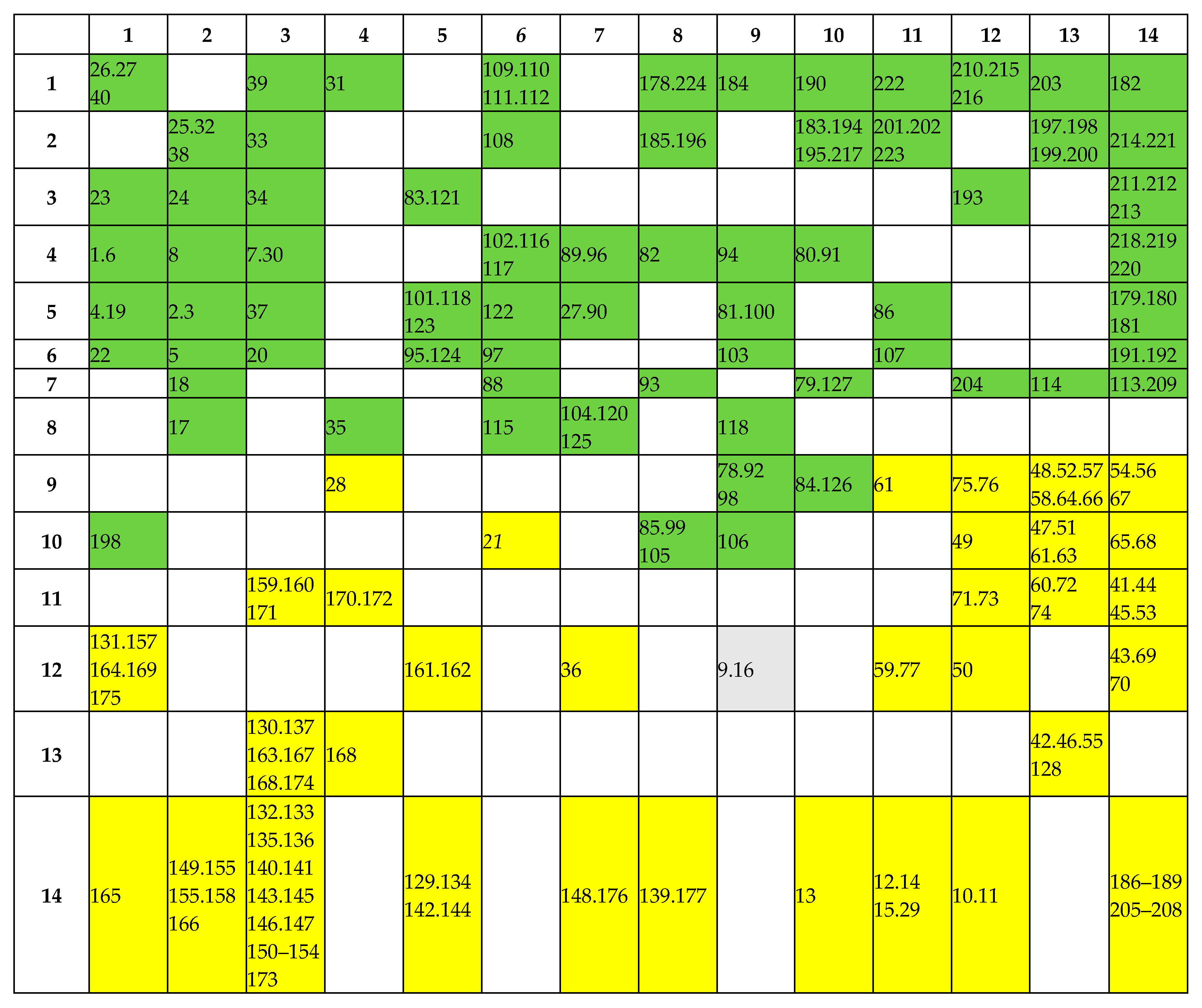

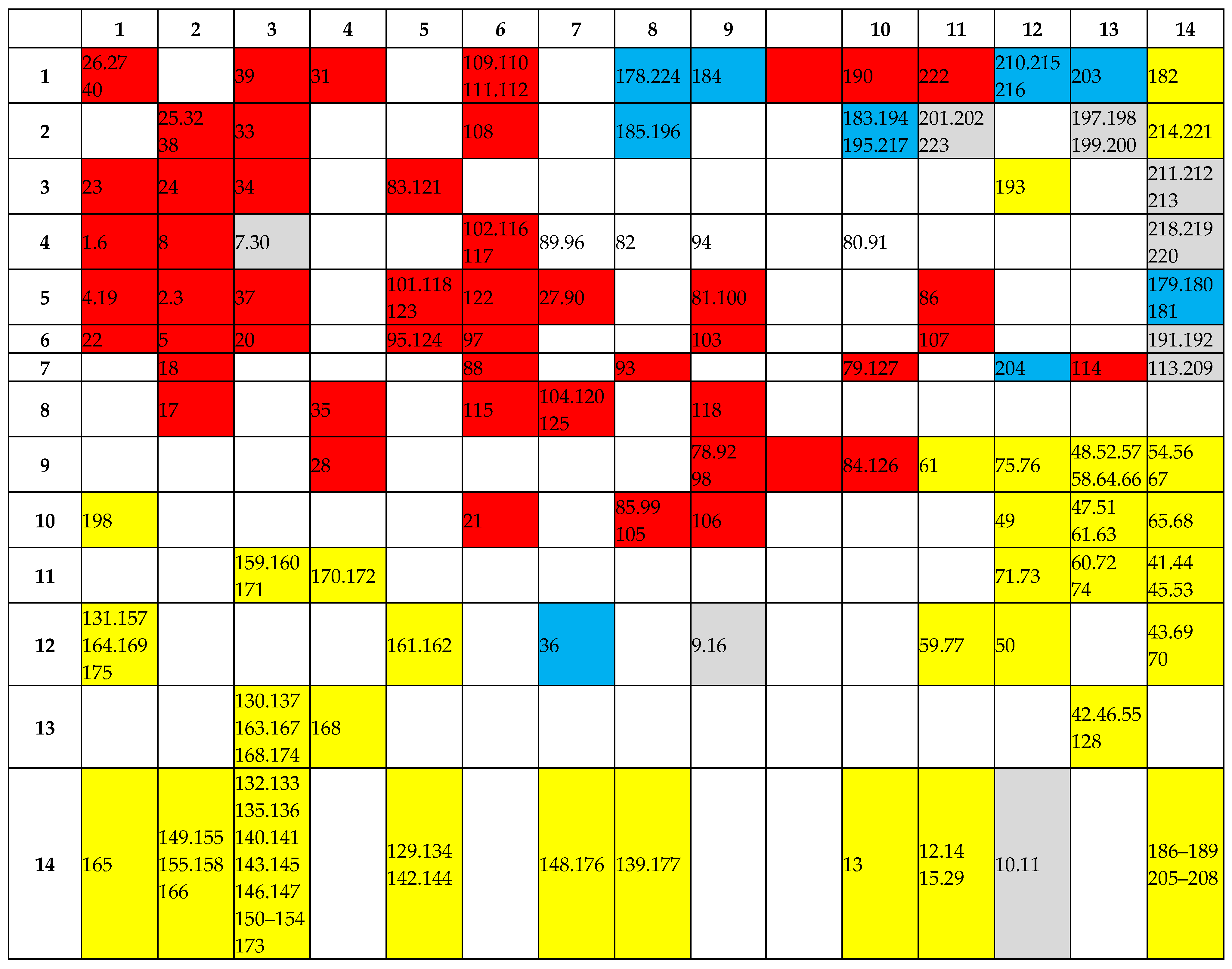

4. Processing Technology Selection System

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Majidi, H.; Hayati, M.M.; Breyer, C.; Mohammadi-ivatloo, B.; Honkapuro, S.; Karjunen, H.; Laaksonen, P.; Sihvonen, V. Overview of energy modeling requirements and tools for future smart energy systems. Renew. Sustain. Energy Rev. 2025, 212, 115367. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Y.; Li, R. Integrating artificial intelligence in energy transition: A comprehensive review. Energy Strategy Rev. 2025, 57, 101600. [Google Scholar] [CrossRef]

- Fantozzi, F.; Ferico, S.D.; Desideri, U. Study of a cogeneration plant for agro-food industry. Appl. Therm. Eng. 2000, 20, 993–1017. [Google Scholar] [CrossRef]

- Kaur, M.; Sharma, H.K.; Kumar, N. Processing of Oilseeds. In Agro-Processing and Food Engineering: Operational and Application Aspects; Springer: Singapore, 2022; pp. 483–533. [Google Scholar]

- Sandouqa, A.; Al-Hamamre, Z. Energy analysis of biodiesel production from jojoba seed oil. Renew. Energy 2019, 130, 831–842. [Google Scholar] [CrossRef]

- WS Atkins Int. Environmental Protection in the Agri-Food Industry; Environmental Standards; Ochrona Środowiska w Przemyśle Rolno-Spożywczym. Standardy Środowiskowe; FAPA: Warszawa, Poland, 1998; pp. 37–41, 78, 82, 85, 87, 105. [Google Scholar]

- Zaki, M.A.M.; Ooi, J.; Ng, W.P.Q.; How, B.S.; Lam, H.L.; Foo, D.C.; Lim, C.H. Impact of industry 4.0 technologies on the oil palm industry: A literature review. Smart Agric. Technol. 2025, 10, 100685. [Google Scholar] [CrossRef]

- Batchelor, S.E.; Booth, E.J.; Walker, K.C. Energy analysis of rape methyl ester (RME) production from winter oilseed rape. Ind. Crops Prod. 1995, 4, 193–202. [Google Scholar] [CrossRef]

- Jóźwiak, D.; Szlęk, A. Ocena oleju rzepakowego jako paliwa kotłowego. Energetyka I Ekol. 2006, 6, 449–451. [Google Scholar]

- Wojdalski, J.; Dróżdż, B. Podstawy Analizy Energochłonności Produkcji Zakładów Przemysłu Rolno-Spożywczego; MOTROL, Motoryzacja i Energetyka Rolnictwa: Lublin, Poland, 2006; pp. 294–304, Tom 8A. [Google Scholar]

- Bystram, K. Assessment of Energy Intensity of Production in the Food Industry; Oil Industry; Ocena Energochłonności Produkcji w Przemyśle Spożywczym. Branża Olejarska; IBMER: Warszawa, Poland, 1986. [Google Scholar]

- Dróżdż, B.; Wojdalski, J. Effect of Selected Technical and Technological Factors on Energy Consumption in the Oil Seed Processing Plants. Ann. Wars. Agric. Univ. 2001, 40, 59–66. [Google Scholar]

- Dróżdż, B.; Wojdalski, J. Conditions of energy management in oilseed processing plants [Uwarunkowania gospodarki energetycznej zakładów przetwórstwa nasion oleistych]. Inżynieria Rol. 2003, 8, 117–124. [Google Scholar]

- Teixeira, M.A. Heat and power demands in babassu palm oil extraction industry in Brazil. Energy Convers. Manag. 2005, 46, 2068–2074. [Google Scholar] [CrossRef]

- Husain, Z.; Zainal, Z.A.; Abdullah, M.Z. Analysis of biomass-residue-based cogeneration system in palm oil mills. Biomass Bioenergy 2003, 24, 117–124. [Google Scholar] [CrossRef]

- Svanes, E.; Waalen, W.; Uhlen, A.K. Environmental impacts of rapeseed and turnip rapeseed grown in Norway, rape oil and press cake. Sustainability 2020, 12, 10407. [Google Scholar] [CrossRef]

- Witten, I.H.; Frank, E. Data Mining: Practical Machine Learning Tools and Techniques; Morgan Kaufmann: New York, NY, USA, 2000. [Google Scholar]

- Data Analysis Software System, version 13; TIBCO Software Inc.: Santa Clara, CA, USA, 2017.

- Bondarenko, A.V.; Islamov, S.R.; Ignatyev, K.V.; Mardashov, D.V. Laboratory studies of polymer compositions for well-kill under increased fracturing. Perm J. Pet. Min. Eng. 2020, 20, 37–48. [Google Scholar] [CrossRef] [PubMed]

- Belousov, A.; Lushpeev, V.; Sokolov, A.; Sultanbekov, R.; Tyan, Y.; Ovchinnikov, E.; Shvets, A.; Bushuev, V.; Islamov, S. Experimental Research of the Possibility of Applying the Hartmann–Sprenger Effect to Regulate the Presure of Natural Gas in Non-Stationary Conditions. Processes 2025, 13, 1189. [Google Scholar] [CrossRef]

| Factory | Daily Processing Capacity [103 kg] (Product) | Total Installed Power of Electrical Devices P [kW] | Km Indicator for the Daily Period (Average Value) [kW/103 kg] | Daily Energy and Water Consumption (Average Value) | ||||

|---|---|---|---|---|---|---|---|---|

| Ae [kWh] | Ac [GJ] | At1 [GJ] | At2 [GJ] | Aw [m3] | ||||

| 1 | 165 (margarine) | 1700 | 7.97 | 23,303 | 1022.0 | 1301.6 | 1105.9 | 2006.3 |

| 2 | 180 (refined oil, margarine) | 6000 | 46.19 | 44,078 | 999.4 | 1528.3 | 1158.1 | 343.1 |

| 3 | 1228 (refined oil, margarine) | 12,640 | 20.41 | 11,333 | 317.9 | 453.9 | 358.7 | 2958.1 |

| 4 | 160 (refined oil, crude oil) | 2374 | 14.91 | 96,740 | 1823.1 | 2984.0 | 2171.4 | 4919.5 |

| 5 | 337 (refined oil, margarine) | 8100 | 23.24 | 10,952 | 594.0 | 725.4 | 633.4 | 520.8 |

| 6 | 240 (refined oil, hydrogenated oil) | 2550 | 10.42 | 32,204 | 1093.0 | 1479.4 | 1208.9 | 497.6 |

| Factory | Specific Energy Consumption Indicators in Relation to 103 [kg] of Raw Material for a Daily Period (Average Values) | |||||

|---|---|---|---|---|---|---|

| We [kWh/103 kg] | Wc [GJ/103 kg] | Wt1 [GJ/103 kg] | Wt2 [GJ/103 kg] | Ww [m3/103 kg] | EEe [kg/kWh] | |

| 1 | 108.6 | 4.77 | 6.08 | 5.16 | 7.39 | 9.21 |

| 2 | 135.6 | 2.87 | 4.49 | 3.35 | 2.11 | 7.37 |

| 3 | 48.3 | 1.36 | 1.94 | 1.53 | 14.31 | 20.70 |

| 4 | 145.5 | 2.72 | 4.46 | 3.24 | 7.82 | 6.87 |

| 5 | 67.9 | 3.68 | 4.49 | 3.92 | 2.49 | 14.73 |

| 6 | 212.4 | 8.36 | 10.90 | 9.12 | 1.56 | 4.71 |

| Multiple Regression Equations | R2 | Independent Variables | |

|---|---|---|---|

| Markings/Dimension | Number Range | ||

| Aw = 562.19 + 3.13 S1 | 0.66 | S1 [104 m2] | 58.6–1377.3 |

| Aw = −1296.5 + 4.712 P1 + 444.809 logP2 | 0.94 | P4 [kW] P11 [kW] | 192.2–1087.0 100.0–3875.0 |

| Aw = 51.69 + 4.775 Z2 − 1900/Z2 + 2400/Z3 | 0.71 | Z2 [103 kg] Z3 [103 kg] | 10.0–338.0 1.0–97.0 |

| Network Type | Quality (Learn.) | Quality (Test) | Quality (Valid.) | Error (Learn.) | Error (Test) | Error (Valid.) | Learning Algorithm | Error Function | Activation (Hidden) | Activation (Output) |

|---|---|---|---|---|---|---|---|---|---|---|

| MLP 5-5-1 | 0.9452 | 0.9665 | 0.9398 | 0.0558 | 0.0315 | 0.0507 | BFGS 13 | SOS | Exponent. | Tanh |

| Network Type | Seed Processing 103 [kg] | Hydrogenated Oil 103 [kg] | Raw Oil 103 [kg] | Margarine 103 [kg] | Refined Oil 103 [kg] |

|---|---|---|---|---|---|

| MLP 5-5-1 | 3.1234 | 3.5778 | 1.7104 | 1.0284 | 1.0071 |

| Network Type | Quality (Learn.) | Quality (Test) | Quality (Valid.) | Error (Learn.) | Error (Test) | Error (Valid.) | Learning Algorithm | Error Function | Activation (Hidden) | Activation (Output) |

|---|---|---|---|---|---|---|---|---|---|---|

| MLP 5-5-1 | 0.9878 | 0.9689 | 0.9924 | 0.0116 | 0.0334 | 0.0100 | BFGS 51 | SOS | Tanh | Logistic |

| Network Type | Hydrogenated Oil [kg] | Refined Oil 103 [kg] | Seed Processing 103 [kg] | Margarine 103 [kg] | Raw Oil 103 [kg] |

|---|---|---|---|---|---|

| MLP 5-5-1 | 25.7730 | 5.3706 | 2.3179 | 1.1688 | 1.1328 |

| Network Type | Quality (Learn.) | Quality (Test) | Quality (Valid.) | Error (Learn.) | Error (Test) | Error (Valid.) | Learning Algorithm | Error Function | Activation (Hidden) | Activation (Output) |

|---|---|---|---|---|---|---|---|---|---|---|

| MLP 4-5-1 | 0.8298 | 0.9592 | 0.9603 | 0.1604 | 0.0748 | 0.0492 | BFGS 6 | SOS | Tanh | Logistic |

| Network Type | Hydrogenated Oil 103 [kg] | Refined Oil 103 [kg] | Margarine 103 [kg] | Raw Oil 103 [kg] |

|---|---|---|---|---|

| MLP 4-5-1 | 25.7730 | 5.3706 | 1.1688 | 1.1328 |

| Processing of Seeds | Crude Oil 103 [kg] | Margarine 103 [kg] | Refined Oil 103 [kg] | Hydrogenated Oil 103 [kg] | Electricity Consumption [kWh/day] | Water Consumption [m3] |

|---|---|---|---|---|---|---|

| 377.83 | 267.00 | 222.90 | 14.30 | 0.69 | 73,055.35 | 1223.15 |

| 329.63 | 162.00 | 338.00 | 14.30 | 0.69 | 55,351.34 | 1566.94 |

| 271.44 | 162.00 | 222.90 | 70.00 | 0.69 | 53,217.13 | 643.41 |

| 125.78 | 162.00 | 222.90 | 14.30 | 2.33 | 28,979.75 | 5853.86 |

| 361.40 | 162.00 | 222.90 | 14.30 | 0.69 | 55,204.67 | 1001.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trajer, J.; Dróżdż, B.; Sałat, R.; Wojdalski, J. Artificial Intelligence in Assessing Electricity and Water Demand in Oilseed Processing. Energies 2025, 18, 4300. https://doi.org/10.3390/en18164300

Trajer J, Dróżdż B, Sałat R, Wojdalski J. Artificial Intelligence in Assessing Electricity and Water Demand in Oilseed Processing. Energies. 2025; 18(16):4300. https://doi.org/10.3390/en18164300

Chicago/Turabian StyleTrajer, Jędrzej, Bogdan Dróżdż, Robert Sałat, and Janusz Wojdalski. 2025. "Artificial Intelligence in Assessing Electricity and Water Demand in Oilseed Processing" Energies 18, no. 16: 4300. https://doi.org/10.3390/en18164300

APA StyleTrajer, J., Dróżdż, B., Sałat, R., & Wojdalski, J. (2025). Artificial Intelligence in Assessing Electricity and Water Demand in Oilseed Processing. Energies, 18(16), 4300. https://doi.org/10.3390/en18164300