Icing Monitoring of Wind Turbine Blade Based on Fiber Bragg Grating Sensors and Strain Ratio Index

Abstract

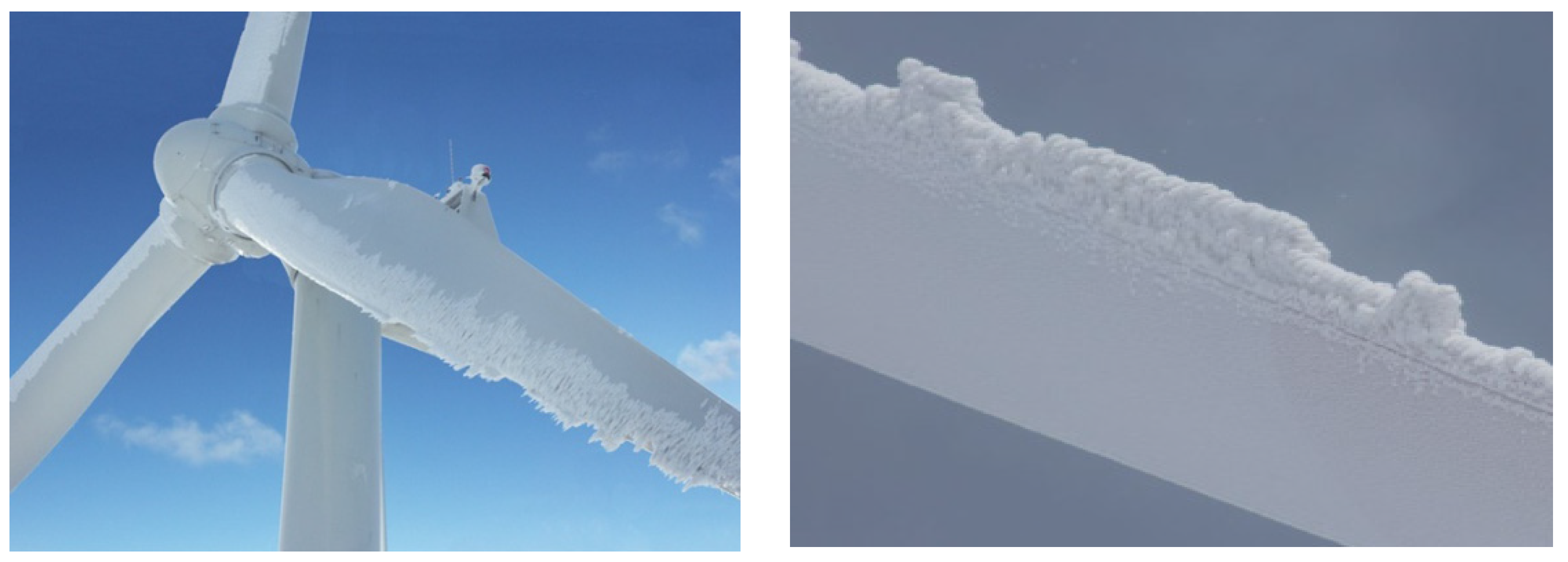

1. Introduction

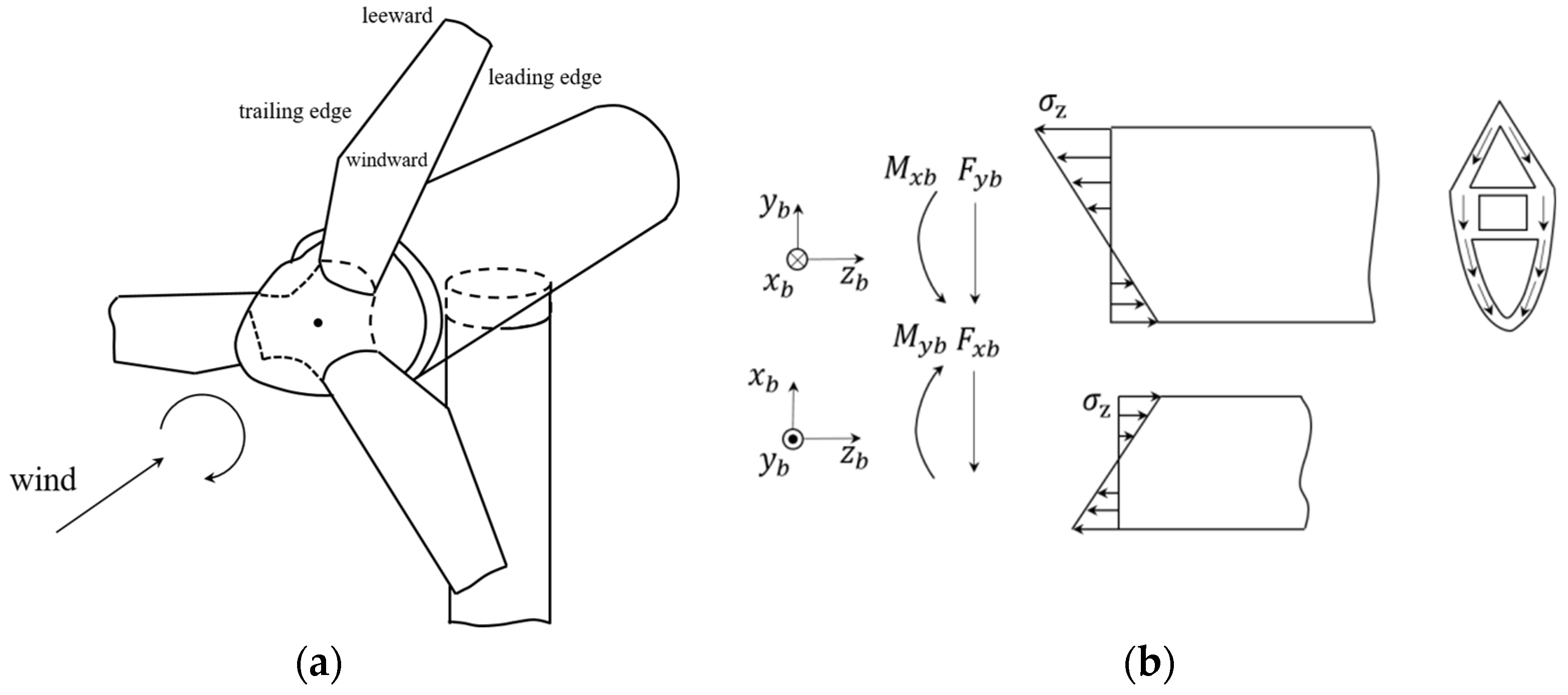

2. Principle of Blade Icing State Based on Strain Values

2.1. Theoretical Analysis of Icing on the Blade

2.2. The Strain Ratio Index for Ice Detection

2.2.1. The Blade in the Normal Condition

2.2.2. The Leading Edge of the Blade Covered with Ice

2.2.3. Damage Occurs on the Blade

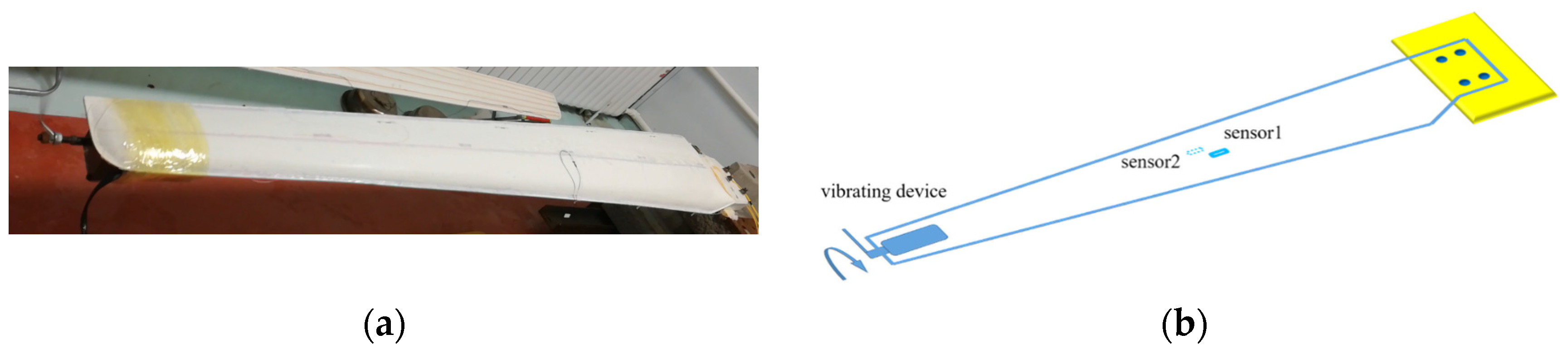

3. Blade Model Experiments

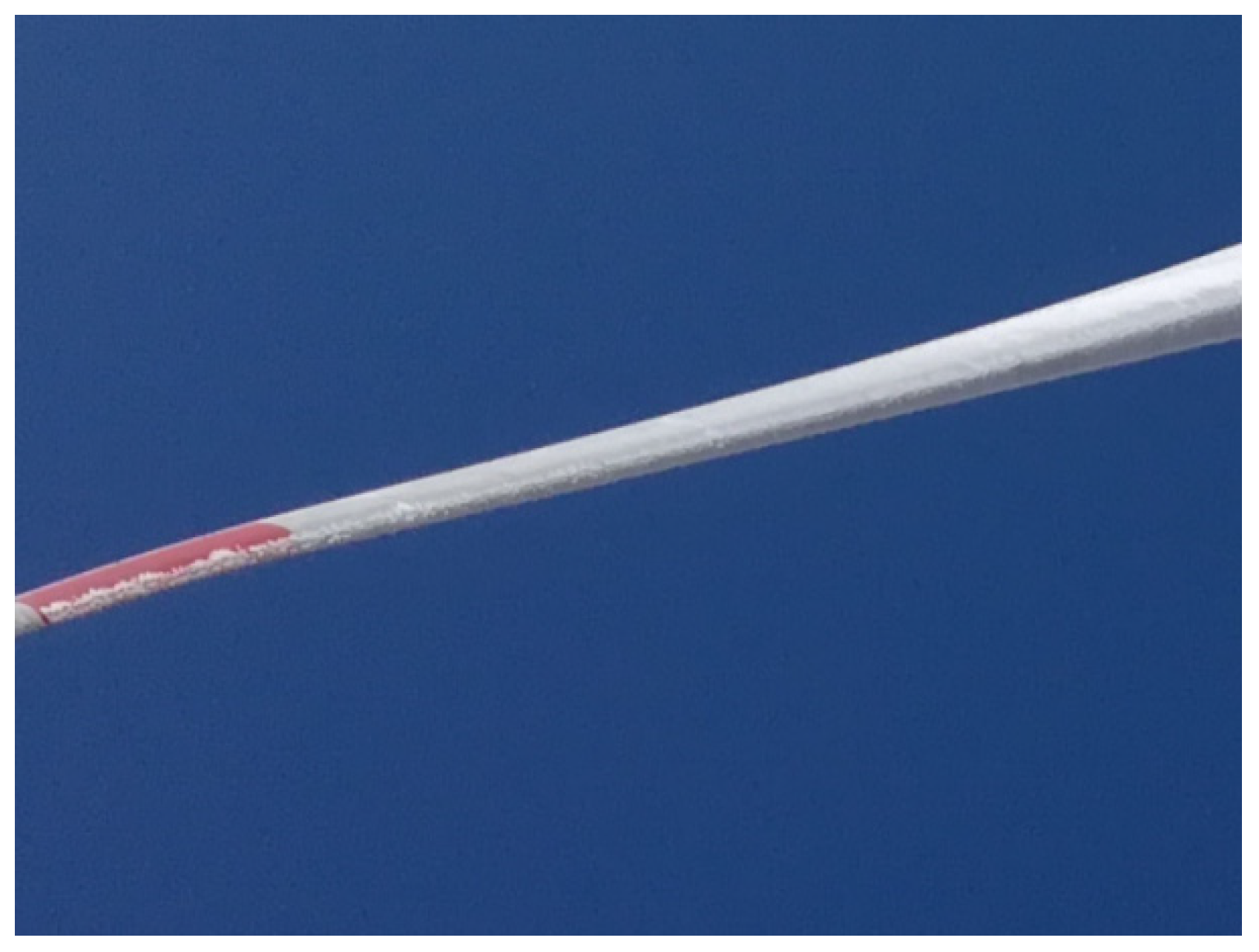

3.1. Experimental Blade Model

3.2. The Experimental Results

4. Field Test of Actual Wind Turbine for Ice Monitoring

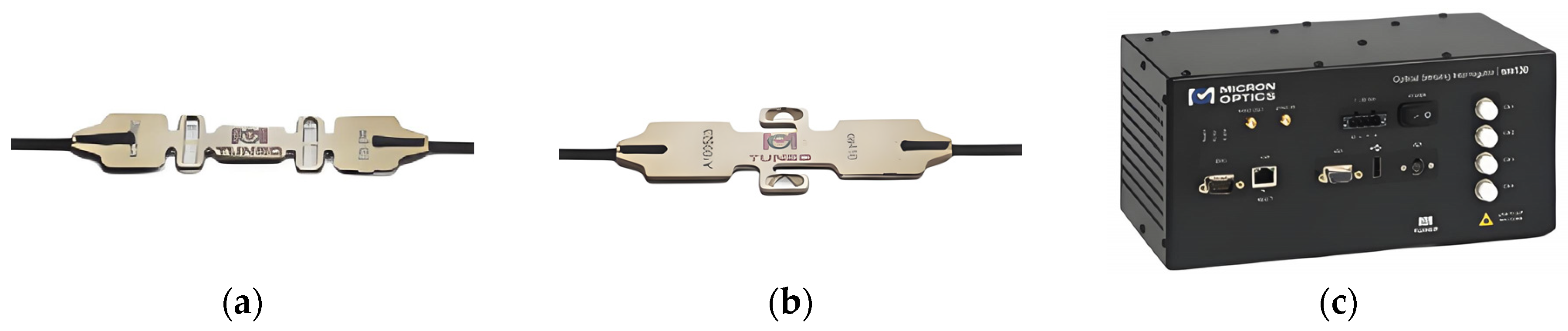

4.1. The Monitoring System

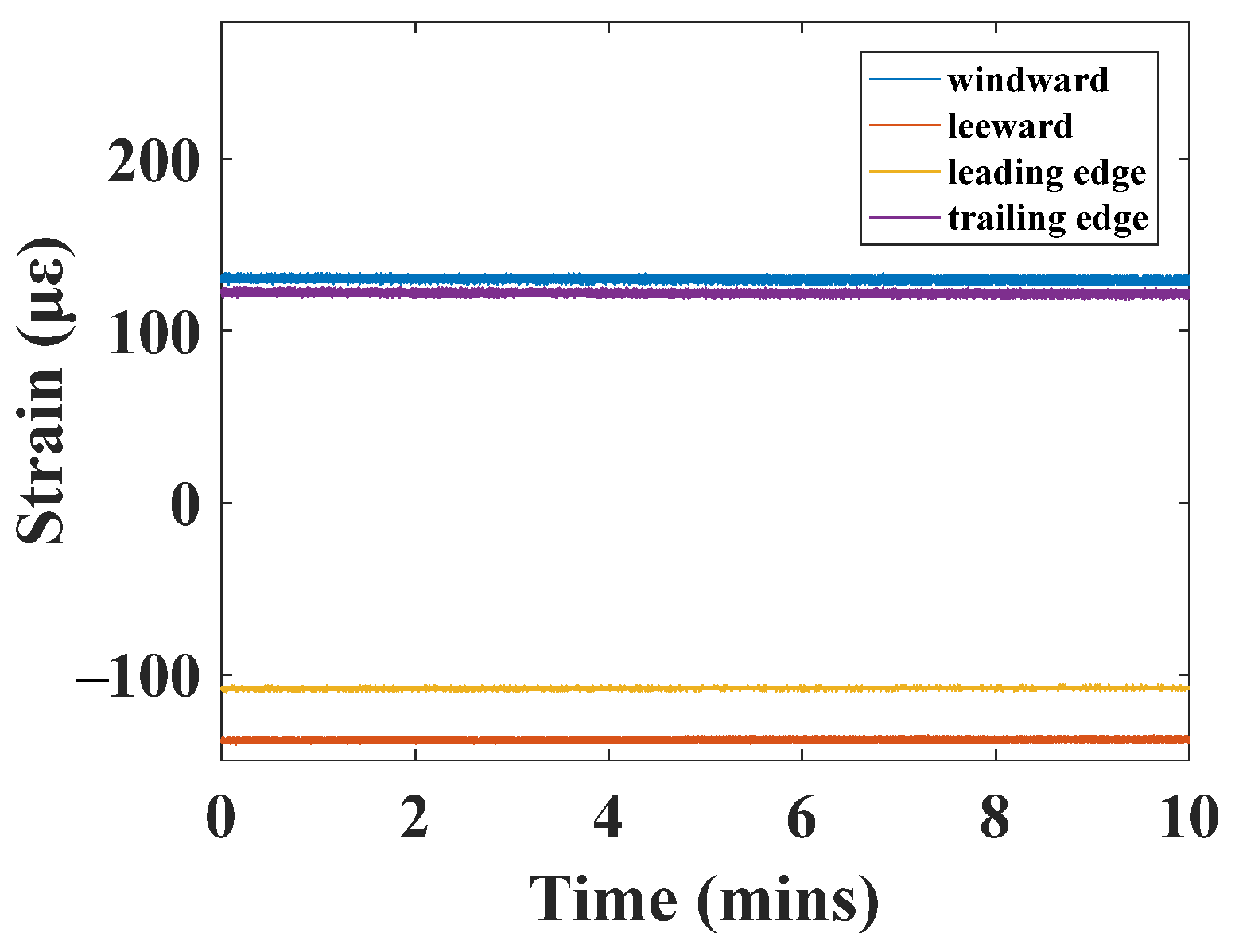

4.2. Strain Value Characteristics of 1.5 MW Wind Turbine Blades

4.3. Ice Coating Detection of the Blade Based on the Measured Strain Values

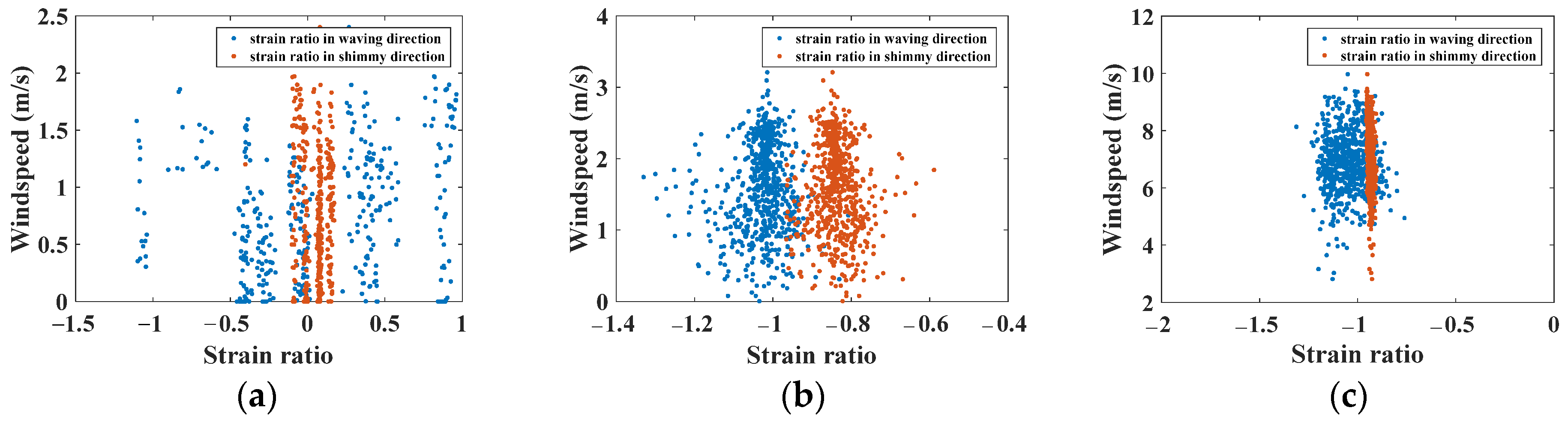

- (1)

- When the wind speed is greater than 8 m/s, the change of strain ratio data in the waving direction is relatively stable, and the value trends to −1. When the wind speed is less than 8 m/s, the data vary widely. The reason is that when the wind speed is low, the wind turbine needs to adjust the blade angle to change the sweep area. Therefore, the strain in the waving direction changes frequently.

- (2)

- The strain ratio in the waving direction has basically no change with the month. Since the strain in the waving direction mainly reflects the change of the blade structure, it can be considered that the blades are not damaged in the testing period.

- (3)

- From September to October 2016, and June 2017, the strain ratio in the shimmy direction is basically maintained at a fixed value of −0.93 and does not vary with the wind speed because the shimmy direction is almost perpendicular to the leading and trailing edges, basically unaffected by wind speed and only affected by impeller rotation and icing.

- (4)

- The strain ratio changes greatly in the shimmy direction from November 2016 to May 2017. The strain ratio increases with time from November 2016 to February 2017. By February 2017, the strain ratio reaches a maximum of −0.34 and then gradually decreases. The strain ratio in June 2017 is basically the same as in September 2016.

4.4. Empirical Threshold for Icing Detection Criteria

- (1)

- Ice primarily accumulates at the leading edge, shifting the neutral axis toward the leading edge. This process selectively affects the shimmy direction strain ratio (i.e., leading edge strain/trailing edge strain) with the absolute value reducing from −1.05 to −0.34 (as shown in Figure 25 and Figure 26). In contrast, the waving direction strain ratio (i.e., windward strain/leeward strain) remains stable within [−1.2, −0.8] (as shown in Figure 25 and Figure 26), indicating that icing does not disrupt structural symmetry in the waving direction.

- (2)

- Blade damage (e.g., cracks) disrupts the overall structural integrity, affecting strain distributions in both directions. This process will cause the strain ratios in both waving and shimmy directions to deviate from the baseline ranges with irregular fluctuations, which is the typical difference from the icing induced strain ratio changes.

5. Discussion

5.1. Validation of the Assumption: Ice Accretion-Induced Neutral Axis Shift

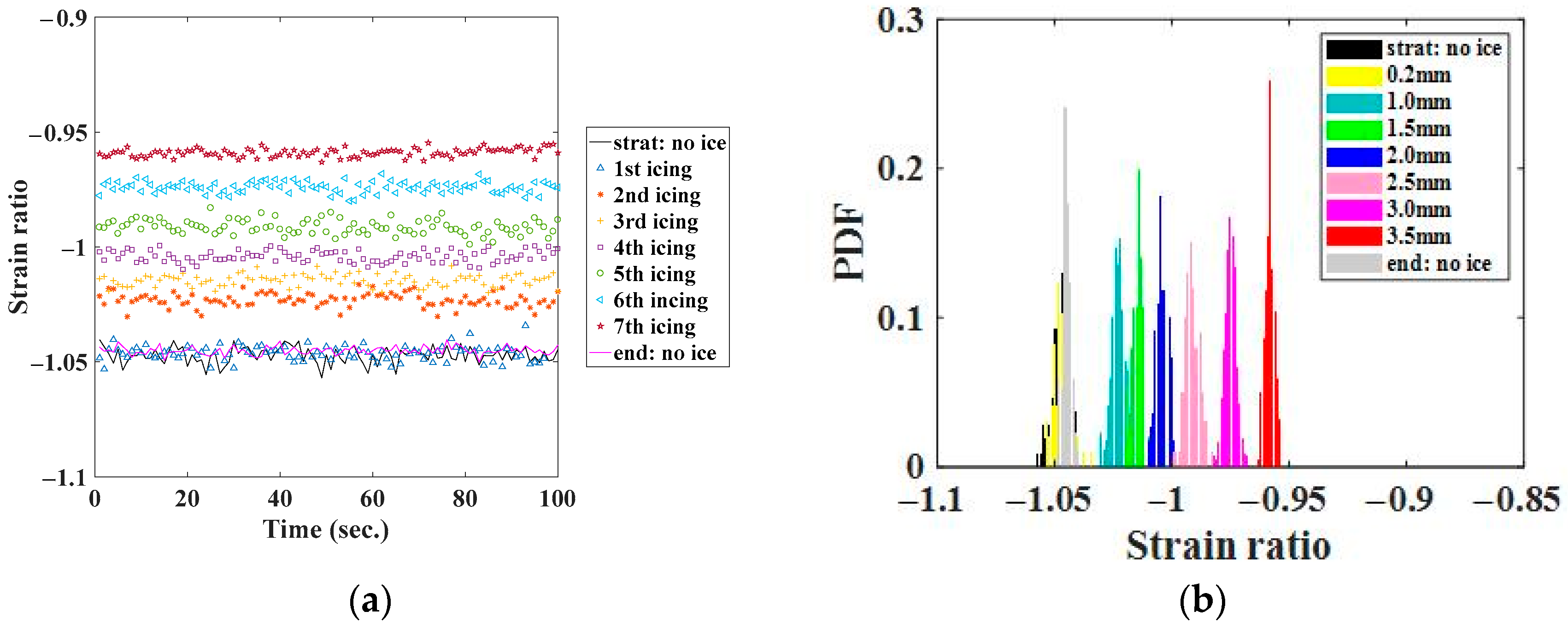

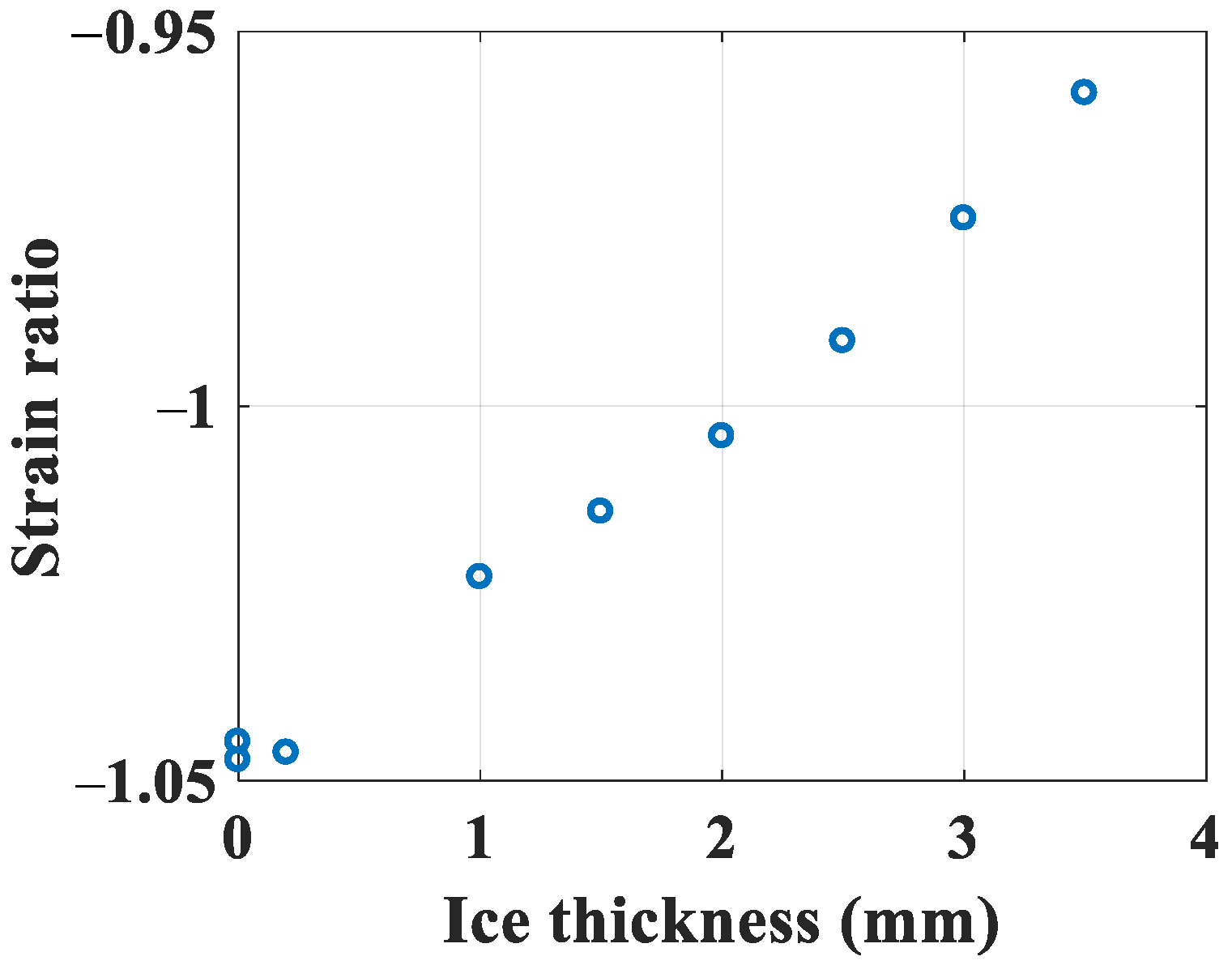

5.2. Validation of the Categorization of Ice Thickness Based on Strain Ratio

5.3. Future Research on Integrating the Kalman Filter and Strain Ratio for Reducing Noise Disturbance

- (1)

- Given that icing-induced neutral axis shifts form the mechanical basis of the strain ratio index, KF could be employed to dynamically track the neutral axis. This will help suppress noise-induced fluctuations in field measurement data and reduce ambiguity from overlapping strain ratio points under different conditions.

- (2)

- Beyond the current static temperature compensation by dedicated sensors, KF will integrate temperature-related state variables into the parameter estimation framework. This will enable more precise correction of dynamic temperature-induced strain changes, improving the stability of utilizing the strain ratio index under varying thermal environments.

- (1)

- The strain ratio index is derived directly from the mechanical behavior of the blade (neutral axis shift due to icing), with clear physical meaning, simplicity, and interpretability. It avoids complex model assumptions of linear system dynamics, making it more reasonable to implement and interpret in complex engineering applications.

- (2)

- As validated in both laboratory experiments (Figure 10 and Figure 11) and field tests (Figure 25 and Figure 26), the strain ratio index consistently captures icing-induced changes (e.g., reducing absolute values in the shimmy direction) despite noise, enabling possible indications of thin/intermediate/thick ice with high efficiency.

5.4. Future Research on Industrial Implementation

- (1)

- For algorithm optimization, a more robust data processing framework should be developed, incorporating adaptive filtering and machine learning algorithms to suppress noise and eliminate interference from non-icing factors. This will improve the anti-disturbance capability of the strain ratio index and enhance the generalization ability under different application scenes.

- (2)

- For methodology validation, more field tests to more types of wind turbines (e.g., 6.7 MW, 16.2 MW models) and diverse cold-region environments (e.g., high-altitude areas, coastal cold zones) would be considered to verify the universality of the method.

- (3)

- For industrial application, a complete workflow including automated icing state classification (thin/intermediate/thick ice) and action linkage with deicing systems should be established to form an autonomous icing monitoring, early warning, and decision-making system.

6. Conclusions

- A quasi-distributed FBG monitoring technology can be used to realize real-time and dynamic monitoring for large wind turbines. The packaged FBG strain and temperature sensors are placed inside the blade, enabling in-line quasi-distributed measurements, and the FBG demodulator can be mounted on the blade and rotated simultaneously with the blade.

- There are six different states of large-scale wind turbines during long-term operation: wind turbines are off and blades do not rotate, wind turbines are off but blades rotate, wind turbines generate electricity normally, wind turbines change from off to power-on state, wind turbines change from power-on to off state, and wind turbines shut down quickly due to excessive wind speed. Based on the characteristics of strain data, the above six wind turbine operating states can be effectively identified.

- The mechanically derived strain ratio is interpretability and the change of strain ratios in different directions can be used for icing detection, since the absolute value of strain ratio in the shimmy direction will decrease with the increase in the ice thickness on the blade, while the strain ratio in the waving direction remains unchanged.

- Laboratory experiment and in-field wind turbine test validate the effectiveness and robustness of the proposed method under complex operation scenarios.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| FBG | Fiber Bragg grating |

| Probability distribution function |

References

- Wei, K.; Yang, Y.; Zuo, H.; Zhong, D. A review on ice detection technology and ice elimination technology for wind turbine. Wind Energy 2020, 23, 433–457. [Google Scholar] [CrossRef]

- Lehtomäki, V. Wind Energy in Cold Climates Available Technologies-Report; Task 19, Technical Report; IEA: Paris, France, 2018; Available online: https://www.researchgate.net/publication/305881044_IEA_Wind_Task_19_-_Available_Technologies_report_of_Wind_Energy_in_Cold_Climates (accessed on 1 July 2016).

- Hämäläinen, K.; Niemelä, S. Production of a numerical icing atlas for Finland. Wind Energy 2017, 20, 171–189. [Google Scholar] [CrossRef]

- Fang, H.; Wang, L. Fast ice detection for wind turbine blades via the langevin equation. Proc. J. Phys. Conf. Ser. 2016, 753, 072016. [Google Scholar] [CrossRef]

- Muñoz, C.Q.G.; Márquez, F.P.G.; Tomás, J.M.S. Ice detection using thermal infrared radiometry on wind turbine blades. Measurement 2016, 93, 157–163. [Google Scholar] [CrossRef]

- Douvi, E.; Douvi, D. Aerodynamic Characteristics of Wind Turbines Operating under Hazard Environmental Conditions: A Review. Energies 2023, 16, 7681. [Google Scholar] [CrossRef]

- Dalili, N.; Edrisy, A.; Carriveau, R. A review of surface engineering issues critical to wind turbine performance. Renew. Sustain. Energy Rev. 2009, 13, 428–438. [Google Scholar] [CrossRef]

- Blasco, P.; Palacios, J.; Schmitz, S. Effect of icing roughness on wind turbine power production. Wind Energy 2017, 20, 601–617. [Google Scholar] [CrossRef]

- Gao, L.Y.; Tao, T.; Liu, Y.Q.; Hu, H. A field study of ice accretion and its effects on the power production of utility-scale wind turbines. Renew. Energy 2021, 167, 917–928. [Google Scholar] [CrossRef]

- Contreras Montoya, L.T.; Lain, S.; Ilinca, A. A review on the estimation of power loss due to icing in wind turbines. Energies 2022, 15, 1083. [Google Scholar] [CrossRef]

- Chuang, Z.J.; Yi, H.; Chang, X.; Liu, H.X.; Zhang, H.D.; Xia, L.L. Comprehensive Analysis of the Impact of the Icing of Wind Turbine Blades on Power Loss in Cold Regions. J. Mar. Sci. Eng. 2023, 11, 1125. [Google Scholar] [CrossRef]

- Høyland, K.V.; Nord, T.; Turner, J.; Hornnes, V.; Gedikli, E.D.; Bjerkås, M.; Hendrikse, H.; Hammer, T.; Ziemer, G.; Stange, T. Fatigue damage from dynamic ice action–The FATICE project. In Proceedings of the 26th International Conference on Port and Ocean Engineering Under Arctic Conditions, Moscow, Russia, 14–18 June 2021. [Google Scholar]

- Rocchi, E. Modeling of the Trajectory of Ice Thrown from a Wind Turbine. Master’s Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2023. [Google Scholar]

- Nodeland, A.M.; Bredesen, R.E.; Byrkjedal, Ø. Risk of ice throw from wind turbines validated with data from field measurements using drones. In Proceedings of the IWAIS 2022–19th International Workshop on Atmospheric Icing of Structures, Montréal, QC, Canada, 19–23 June 2022. [Google Scholar]

- Kabardin, I.; Dvoynishnikov, S.; Gordienko, M.; Kakaulin, S.; Ledovsky, V.; Gusev, G.; Zuev, V.; Okulov, V. Optical Methods for Measuring Icing of Wind Turbine Blades. Energies 2021, 14, 6485. [Google Scholar] [CrossRef]

- Wang, P.; Zhou, W.; Bao, Y.; Li, H. Ice monitoring of a full-scale wind turbine blade using ultrasonic guided waves under varying temperature conditions. Struct. Control Health Monit. 2018, 25, e2138. [Google Scholar] [CrossRef]

- Zheng, D.S.; Li, Z.Y.; Du, Z.Y.; Ma, Y.; Zhang, L.; Du, C.; Li, Z.J.; Cui, L.Q.; Zhang, L.; Xuan, X.G.; et al. Design of Capacitance and Impedance Dual-Parameters Planar Electrode Sensor for Thin Ice Detection of Aircraft Wings. IEEE Sens. J. 2022, 22, 11006–11015. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, C.H.; Li, S.R.; Guo, X.W.; Wang, Q.; He, Y.Z.; Lv, H.Y.; Yan, H.K.; Liu, D.G. A Novel Fiber-Optic Ice Sensor to Identify Ice Types Based on Total Reflection. Sensors 2023, 23, 3996. [Google Scholar] [CrossRef]

- Rizk, P.; Younes, R.; Ilinca, A.; Khoder, J. Wind turbine ice detection using hyperspectral imaging. Remote Sens. Appl. 2022, 26, 100711. [Google Scholar] [CrossRef]

- Yousuf, A.; Jin, J.Y.; Sokolov, P.; Virk, M.S. Study of ice accretion on wind turbine blade profiles using thermal infrared imaging. Wind Eng. 2021, 45, 872–883. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Zhou, W.S.; Li, H. Icing estimation on wind turbine blade by the interface temperature using distributed fiber optic sensors. Struct. Control Health Monit. 2020, 27, e2534. [Google Scholar] [CrossRef]

- Davis, N.N.; Byrkjedal, O.; Hahmann, A.N.; Clausen, N.E.; Zagar, M. Ice detection on wind turbines using the observed power curve. Wind Energy 2016, 19, 999–1010. [Google Scholar] [CrossRef]

- Weijtjens, W.; de Oliveira Junior, A.F.; Cloet, B.; Yilmaz, Ö.C.; Devriendt, C. Large scale test of vibration based icing detection for wind turbines. Proc. J. Phys. Conf. Ser. 2024, 2647, 192008. [Google Scholar] [CrossRef]

- Szasz, R.Z.; Ronnfors, M.; Revstedt, J. Influence of ice accretion on the noise generated by an airfoil section. Int. J. Heat Fluid Flow 2016, 62, 83–92. [Google Scholar] [CrossRef]

- Ye, F.; Ezzat, A.A. Icing detection and prediction for wind turbines using multivariate sensor data and machine learning. Renew. Energy 2024, 231, 120879. [Google Scholar] [CrossRef]

- Jin, X.; Zhang, X.; Cheng, X.; Jiang, G.; Masisi, L.; Huang, W. A physics-based and data-driven feature extraction model for blades icing detection of wind turbines. IEEE Sens. J. 2023, 23, 3944–3954. [Google Scholar] [CrossRef]

- Cheng, X.; Shi, F.; Liu, Y.; Liu, X.; Huang, L. Wind turbine blade icing detection: A federated learning approach. Energy 2022, 254, 124441. [Google Scholar] [CrossRef]

- Tian, W.; Cheng, X.; Li, G.; Shi, F.; Chen, S.; Zhang, H. A multilevel convolutional recurrent neural network for blade icing detection of wind turbine. IEEE Sens. J. 2021, 21, 20311–20323. [Google Scholar] [CrossRef]

- Burton, T.; Jenkins, N.; Sharpe, D.; Bossanyi, E. Wind Energy Handbook; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Gonzalez, M.; Frövel, M. Fiber Bragg Grating Sensors ice detection: Methodologies and performance. Sens. Actuators A-Phys. 2022, 346, 113778. [Google Scholar] [CrossRef]

- Soman, R.; Majewska, K.; Mieloszyk, M.; Malinowski, P.; Ostachowicz, W. Application of Kalman Filter based Neutral Axis tracking for damage detection in composites structures. Compos. Struct. 2018, 184, 66–77. [Google Scholar] [CrossRef]

- Soman, R.; Malinowski, P.; Majewska, K.; Mieloszyk, M.; Ostachowicz, W. Kalman filter based neutral axis tracking in composites under varying temperature conditions. Mech. Syst. Signal Process. 2018, 110, 485–498. [Google Scholar] [CrossRef]

| State | Threshold-Based Differentiation Criterion (with a Fluctuation Range of ±20%) |

|---|---|

| Normal state | Strain ratio in both waving and shimmy directions stabilize within [−1.2, −0.8] |

| Icing state (No damage) |

|

| Damage | Strain ratio in both waving and shimmy directions exhibit either <−1.2 or >−0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Y.; Zhang, Z.; Wang, X.; Li, W.; Xu, Y. Icing Monitoring of Wind Turbine Blade Based on Fiber Bragg Grating Sensors and Strain Ratio Index. Energies 2025, 18, 4295. https://doi.org/10.3390/en18164295

Tian Y, Zhang Z, Wang X, Li W, Xu Y. Icing Monitoring of Wind Turbine Blade Based on Fiber Bragg Grating Sensors and Strain Ratio Index. Energies. 2025; 18(16):4295. https://doi.org/10.3390/en18164295

Chicago/Turabian StyleTian, Yadi, Zhaohui Zhang, Xiaojing Wang, Wanheng Li, and Yang Xu. 2025. "Icing Monitoring of Wind Turbine Blade Based on Fiber Bragg Grating Sensors and Strain Ratio Index" Energies 18, no. 16: 4295. https://doi.org/10.3390/en18164295

APA StyleTian, Y., Zhang, Z., Wang, X., Li, W., & Xu, Y. (2025). Icing Monitoring of Wind Turbine Blade Based on Fiber Bragg Grating Sensors and Strain Ratio Index. Energies, 18(16), 4295. https://doi.org/10.3390/en18164295