1. Introduction

Vacuum circuit breakers possess the advantages of environmental friendliness, flexible installation configurations, simple structure, and ease of maintenance, making them excellent power fault interruption equipment for constructing environmentally friendly power systems [

1,

2,

3]. Currently, vacuum switches are finding wide application in medium-voltage power systems and are rapidly advancing towards high-voltage power systems.

The short-circuit current interruption capability is the core technical indicator of vacuum switches. During the vacuum interruption process, the vacuum arc delivers a large amount of energy to the anode within a short time, causing a rapid temperature rise in the anode material. When the energy is sufficiently large, melting occurs on the anode surface, even resulting in a molten pool. After severe anode erosion occurs, anode metal vapor is continuously released into the arc column region, compromising the dielectric strength of the vacuum medium. Furthermore, after the current zero moment, the anode becomes the cathode and the eroded contact surface becomes prone to electrical discharge phenomena. Consequently, the arc evolution process plays a pivotal role in the vacuum interruption capability [

4,

5,

6].

The study of the arc evolution process has consistently been a focal point in vacuum switch research. Current research on vacuum arcs encompasses both experimental studies and simulation analysis. Experimental work primarily utilizes a high-speed camera to capture images of the vacuum arc [

7,

8,

9,

10]. This approach has yielded insights into the transition rules governing the vacuum arc under different discharge modes and anode activity modes, the evolution process of the vacuum arc under magnetic field, and the interaction between the vacuum arc and the contacts. In recent years, the application of spectroscopic diagnostics to vacuum arcs has advanced significantly [

11,

12,

13]. Using this technology, microscopic parameters such as contact temperature and arc parameters have been acquired.

Due to the special nature of the high-current vacuum discharge, precise diagnosis of vacuum arcs on a large scale has high requirements for experimental equipment. Consequently, simulation studies serve as an effective means for the arc analysis [

14,

15,

16]. Current vacuum arc simulations primarily encompass fluid modeling and hybrid modeling [

17,

18,

19,

20,

21,

22,

23,

24,

25,

26]. For high-current vacuum arcs, fluid simulations could obtain plasma parameters during the arcing process. Particle simulations facilitate the analysis of the vacuum arc from a discrete media perspective, especially under low-current conditions. Meanwhile, the interaction between the arc and the electrode surfaces constitutes a key focus of simulation studies.

Research on vacuum arcs is predominantly conducted under the assumption of uniform burning of the arc within the arc column region. However, asymmetric arcing situations, where the arc root is not positioned at the center of the contacts, frequently occur in vacuum switches [

19,

24,

27]. Potential causes for the occurrence of asymmetric arcing may include, for instance, asymmetries arising during the manufacturing process of the interrupter chamber, the influence of contact surface morphology, and the influence of external mechanical vibrations. The arc parameters undergo significant changes during lateral arcing events. Currently, the influence of such arcs remains inadequately explored.

Therefore, the research objective of this paper is to analyze the parameter variations in a vacuum arc in an asymmetric ignition state. The arc model was established based on magnetohydrodynamics. For a typical medium-voltage vacuum arc firing condition, symmetrical arcing, 33% minor arc offset case, and 67% severe arc offset cases were selected for modeling. The inhomogeneity of the arc offset on the arc parameters was analyzed, and the maximum values of the arc parameters for different arc-firing cases were also compared.

2. Vacuum Arc Model

2.1. Governing Equations

The high current vacuum arc comprises the cathode region, arc column region, and anode region. The computational domain of this model exclusively encompasses the arc column plasma. Within this region, the Debye radius measures approximately 10−7 m, substantially smaller than the interrupter chamber dimensions. Consequently, the arc column plasma qualifies as fully ionized plasma. The contact material in the model is copper; thus, the modeled particles are copper ions and electrons. It is noted that the cathode mixing zone serves as the boundary condition for the arc column model. Therefore, cathode spot phenomena and associated processes—including particle acceleration and ionization—are excluded from this study.

In high-current vacuum arcs, the mean collision time of electrons is approximately 10−11 s, whereas their transit time from cathode to anode is approximately 10−7 s. For ions, the mean collision time is approximately 10−9 s, while their cathode-to-anode transit duration measures approximately 10−6 s. Since the collision times for both species are substantially shorter than their respective transit durations, vacuum arc plasma can be effectively analyzed using fluid dynamics methodologies. In addition, the pressure of the vacuum arc is not very high (on the order of 103~104 Pa), and the temperature is not very low (on the order of 103~104 K); therefore, the ideal gas assumption can be used to describe the vacuum arc.

In high-current vacuum arcs, the relaxation time of arc plasma is extremely short, significantly shorter than the variation rates of both the arc current and the contact gap. Consequently, in 50 Hz power systems, the vacuum arc can be considered to operate in a quasi-steady-state mode.

The ion number density is obtained from Equation (1).

The Debye length in the vacuum arc is significantly smaller than the contact assembly dimensions, permitting the assumption that the arc is a fully ionized plasma. Thus, the electron number density is obtained from Equation (2).

The ion velocity is obtained from Equation (3).

The electron velocity is obtained from Equation (4).

The current density is obtained from Equations (5) and (6).

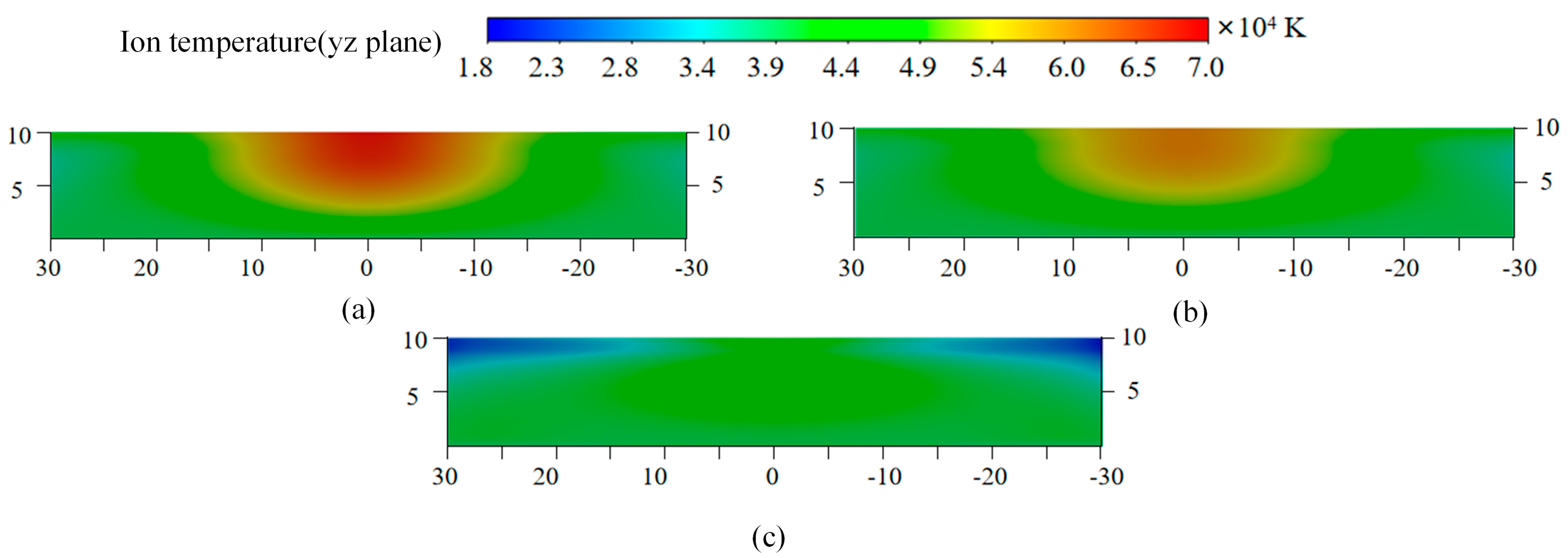

The ion temperature is obtained from Equation (7).

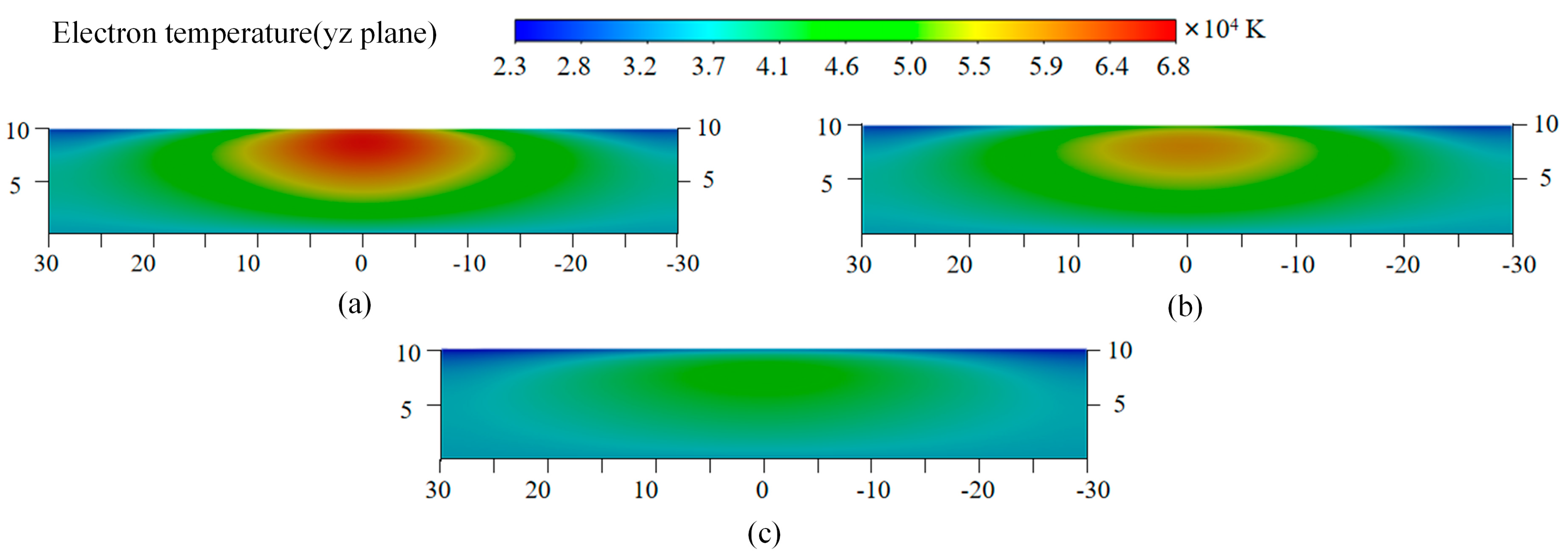

The electron temperature is obtained from Equation (8).

The parameters involved in Equations (1)–(8) are

For the definitions of symbols representing physical quantities in the paper, please refer to the Abbreviations Section.

2.2. Boundary Conditions

To analyze the arcing characteristics of asymmetric vacuum arcs, a three-dimensional Cartesian coordinate system is implemented with the cathode center established as the coordinate origin. The positive z-direction is oriented from the cathode toward the anode. The computational model’s boundary conditions consist of cathode boundary conditions, lateral boundary conditions, and anode boundary conditions.

In the vacuum arc, the cathode supplies arc particles and serves as the inlet boundary for the magnetohydrodynamics model of the arc. At lower arc currents, the vacuum arc flow is supersonic. At higher currents, the flow becomes subsonic. The short-circuit current studied in this paper represents a typical case of high-current vacuum arc. According to subsonic computational fluid dynamics principles, a saturation pressure condition must be applied at the cathode inlet boundary. At the same time, the ion temperature and electron temperature on the cathode side are set to 3 eV [

17].

During short-circuit current interruption in a vacuum switch, the arc distribution at the cathode inlet is nonuniform across the contact surface. Arc imaging reveals cathode spots exhibiting maximal size at the center with progressive radial attenuation. To characterize this inhomogeneous current distribution at the cathode boundary, a two-dimensional Gaussian distribution of current density profile is implemented per prior research, with the central density prescribed at twice the area-averaged value. This distribution and saturation pressure together determine the arc density and velocity on the cathode side. At the cathode arc root, the arc current density attains its maximum value, while the ion velocity is set at approximately 1000 m/s.

For arcing conditions where the arc root deviates from the cathode center, the Gaussian distribution center is aligned with the actual arc root position. In the cathode X-Y plane, for symmetric arcing, the center coordinates are (0, 0, 0), and for an arc root offset by 10 mm from cathode center, the center coordinates become (0.01, 0, 0). The current density attenuation rate from center to periphery remains identical to symmetric cases. Consequently, the density at the arc root exhibits a marginal increase compared to symmetric arcing conditions.

Under the applied axial magnetic field of 5 mT/kA specified in this study, radial expansion of the arc column is constrained, resulting in arc morphology parallel to the contact boundaries. Consequently, the arc plasma velocity at side boundaries is prescribed as tangential to the contact surfaces. Adiabatic conditions are imposed at lateral boundaries to eliminate thermal exchange between the arc column and external vacuum environment.

In high-current vacuum arcs, the anode functions as the recipient of the arc. Arc energy elevates the anode temperature. Sufficient energy deposition may induce anode evaporation or particle spluttering. This study focuses exclusively on the arc column region. Anode processes are excluded from the computational model, with the anode configured solely as a passive recipient of the arc.

Consistent with subsonic compressible flow theory, the outlet fluid boundary is specified at Mach number unity. To satisfy the current continuity principle, an anode sheath layer is implemented between the arc column and anode, governed by Equation (15). The anode sheath layer induces a marked reduction in electron temperature at the anode interface.

In this work, the model was implemented within the ANSYS Fluent (version 2020) software framework with secondary development incorporating electromagnetic field equations into the fluid dynamics module. The mesh configuration comprises approximately one million grid cells, with a single simulation requiring approximately 10 h to complete.

4. Discussion

Analysis of the preceding arc plasma parameters reveals that asymmetric arcing forces plasma compression toward the offset side, elevating key parameters, including density, pressure, and temperature, as well as intensifying the constriction state of the arc. Using current density as the representative parameter, this section analyzes asymmetric arcing effects on arc contraction.

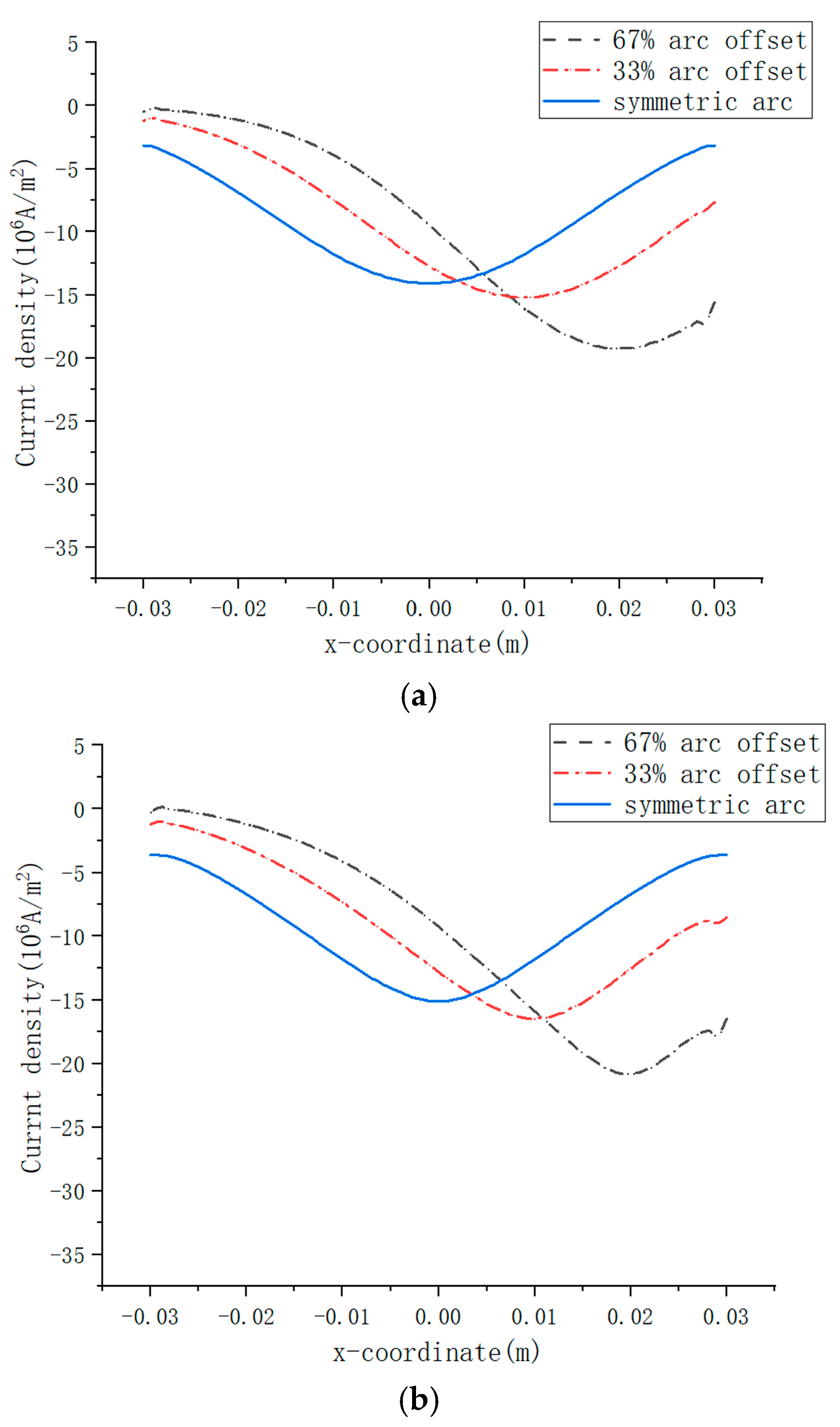

During vacuum arc flow from cathode to anode, axial current density

jz sharply increases as arc constriction progresses. To analyze how arc offset affects this parameter,

Figure 9 presents

jz distributions along the

x-axis at three critical positions: cathode surface, arc column centerline, and anode surface. The negative values of

jz originate from the defined coordinate system where the anode resides at positive z-direction, making the current flow direction negative along the

z-axis.

When arc offset occurs, high-speed imaging reveals that the arc plasma markedly concentrates toward the offset side, resulting in substantially higher current density at this location compared to the symmetrical arcing. In the cathode boundary conditions defined in this study, the current density attenuates toward the arc periphery at an identical decay rate across the cathode surface. Consequently, the more obvious the offset of the arc root, the higher the current density at the arc root. This modeling approach is consistent with the intensified current constriction observed in arc images under offset conditions.

Figure 9a depicts the cathodic axial current density profile, where arc displacement induces lateral shifting of the current density distribution with concurrent peak value enhancement. For symmetric arcing, the current density peaks at the cathode center with 14.1 × 10

6 A/m

2. At 33% arc offset, the peak value reaches 15.2 × 10

6 A/m

2 at the displaced arc root position. Under 67% offset, the current density maximum increases to 19.2 × 10

6 A/m

2 while being laterally offset by 0.02 m from the cathode center.

Figure 9b presents the axial current density profile at the arc column centerplane. The distribution mirrors the cathodic pattern but exhibits elevated peak magnitudes. Compared to the cathode surface, the current density maximum increases to 15.1 × 10

6 A/m

2 for symmetric arcing. Under 33% arc offset, the peak value rises to 16.5 × 10

6 A/m

2. At 67% arc offset, the maximum further escalates to 20.8 × 10

6 A/m

2.

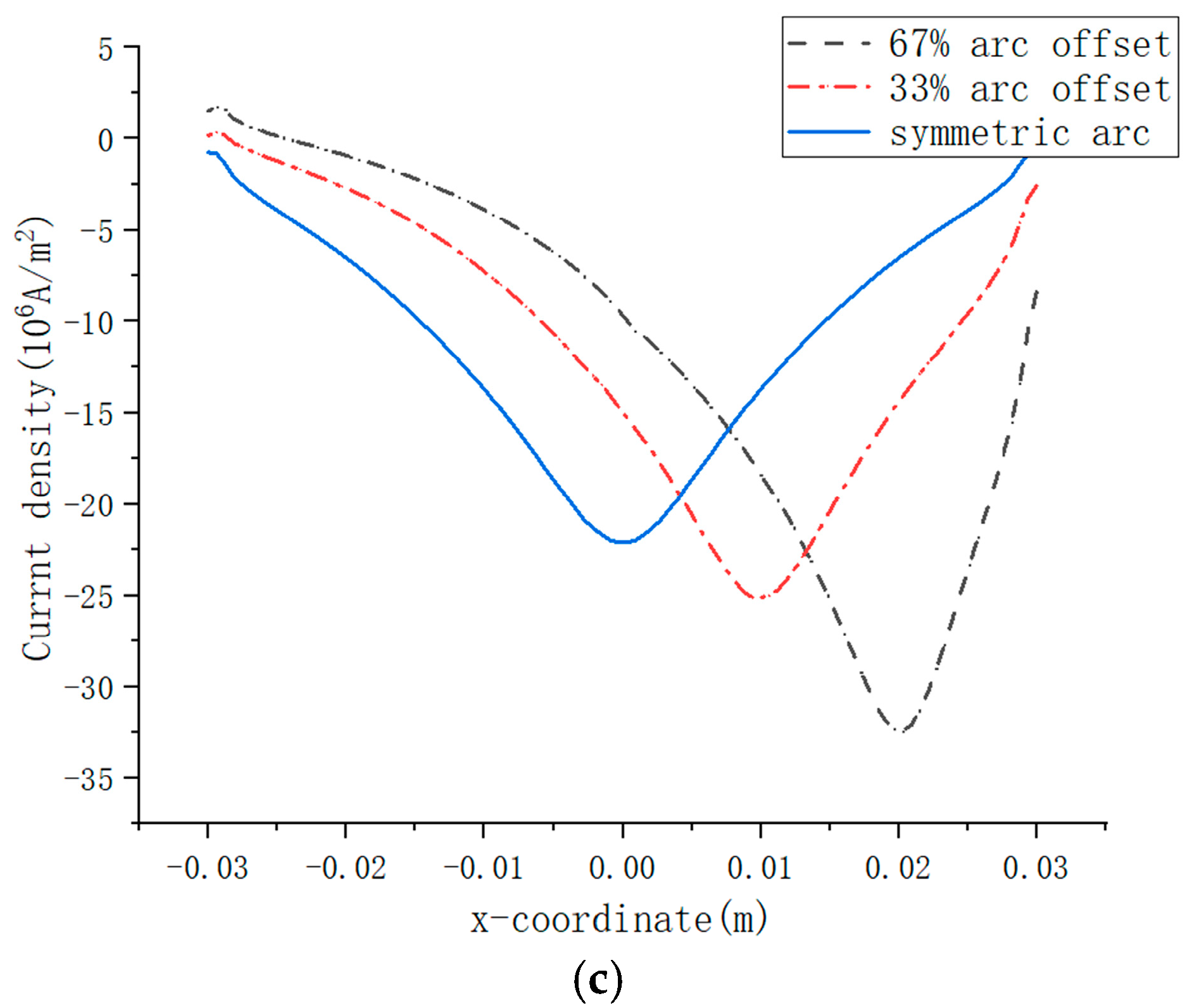

Figure 9c displays the axial current density profile at the anode surface. The distribution exhibits marked constriction compared to the arc column centerplane, indicating intensified arc convergence in the near anode half of the interelectrode gap. For symmetric arcing, the current density maximum escalates to 22.1 × 10

6 A/m

2. Under 33% arc offset, the peak value rises to 25.1 × 10

6 A/m

2. At 67% offset, the maximum surges to 32.4 × 10

6 A/m

2.

The anode current density reflects the thermal loading on the anode induced by arc constriction. In this model, the mean current density is 7.1 × 106 A/m2. During symmetric arcing, the peak anode current density reaches 3.1 times the mean current density. For 33% arc offset, the peak increases to 3.6 times the mean. At 67% offset, the value surges to 4.6 times.

As evidenced by plasma parameters in

Figure 1,

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7 and

Figure 8 and current density profiles in

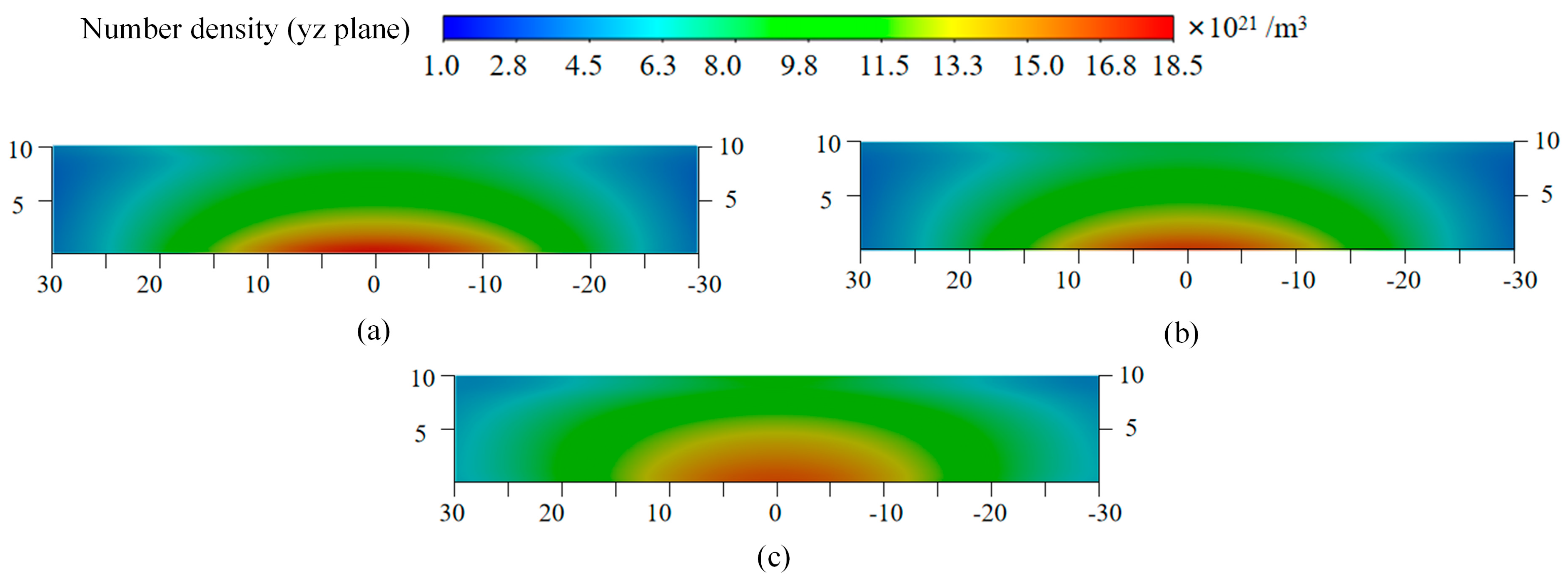

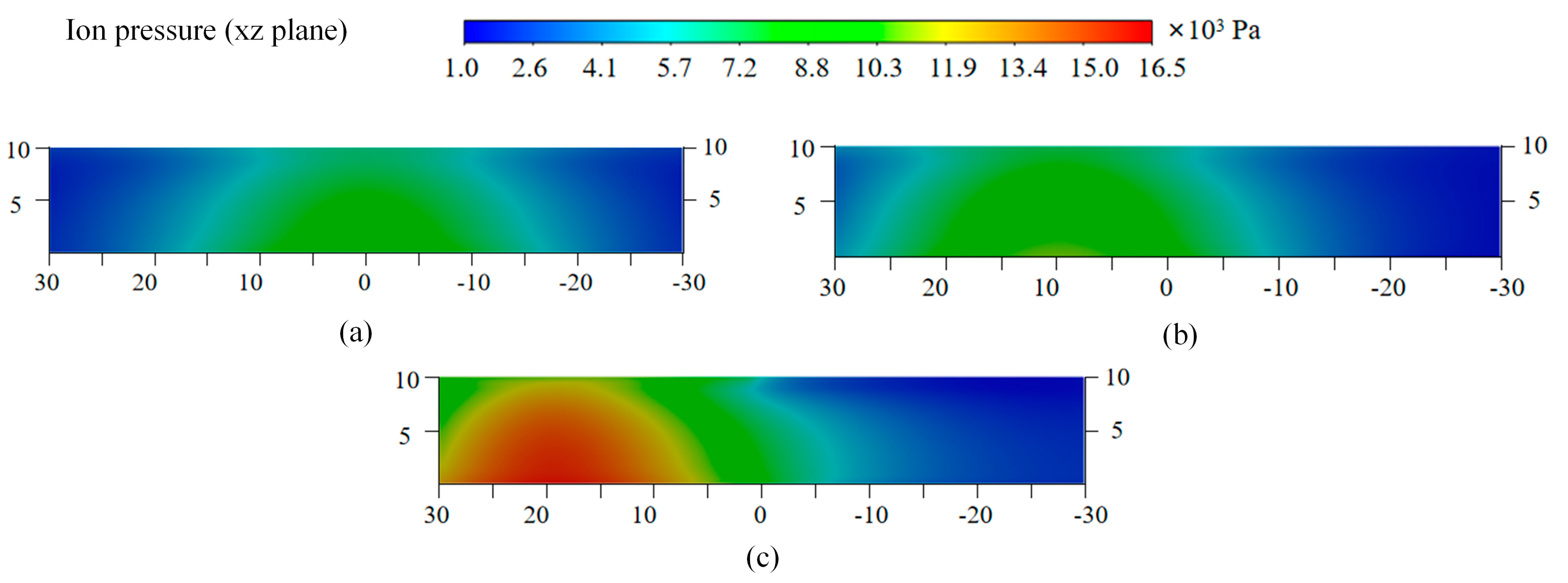

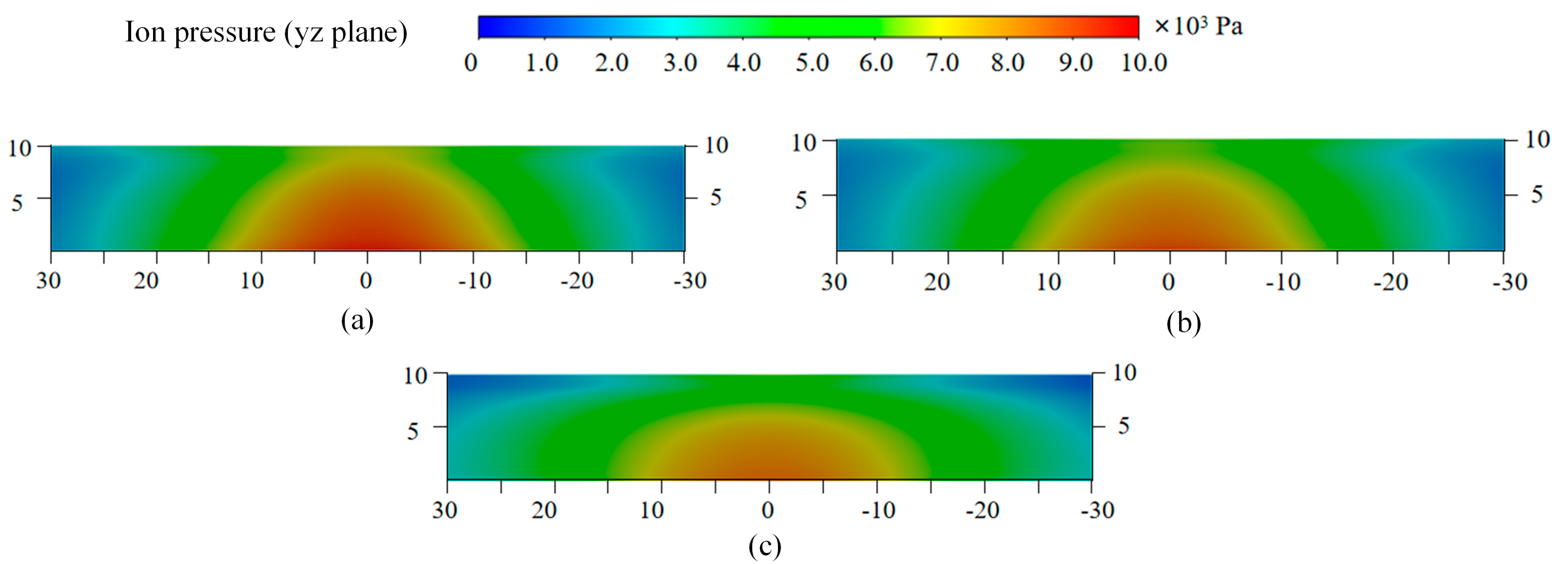

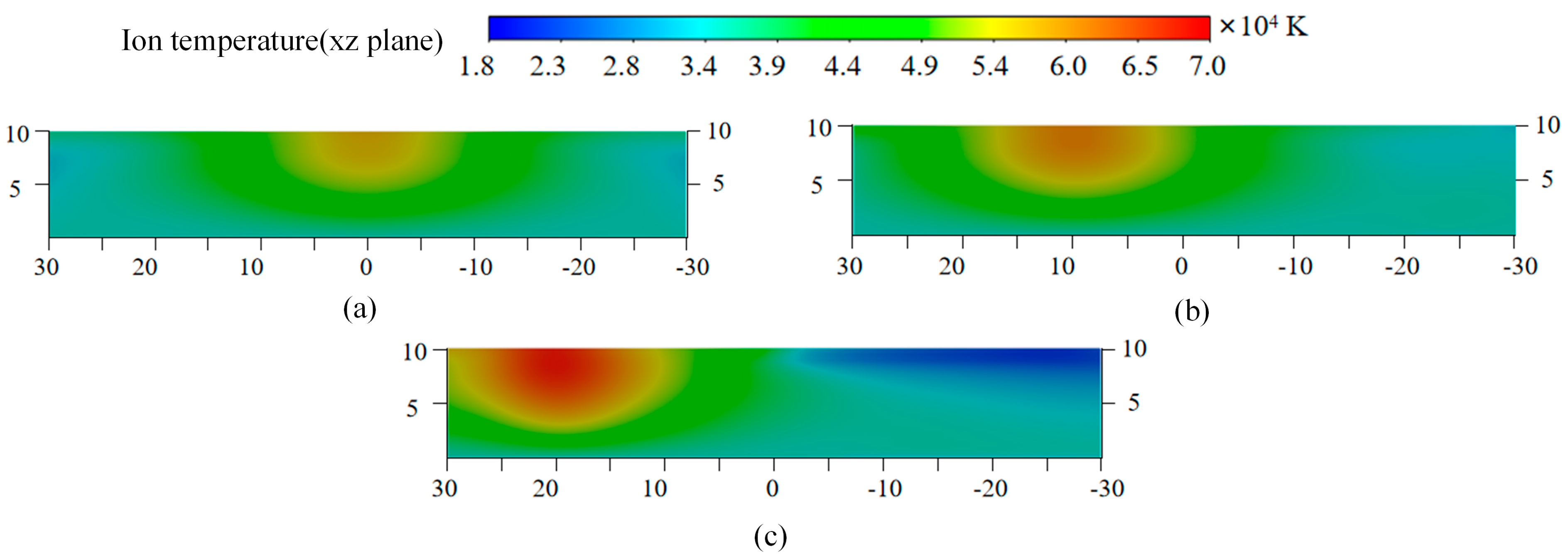

Figure 9, arc root displacement induces asymmetric plasma distributions. To quantify this effect, plasma parameters on the arc root along the positive semi-axis and corresponding mirrored locations along the negative semi-axis are statistically analyzed.

Table 1 shows the comparison of arc parameters at the corresponding coordinates. For the comparison between ion pressure and ion number density, we chose the cathode side. For 33% arc offset, the ion pressure and density at the arc root reach 10,900 Pa and 20.4 × 10

21 m

−3, respectively, while at the mirrored coordinate, these values decrease to 5200 Pa and 9.7 × 10

21 m

−3, representing approximately 50% of the arc root values. For 67% offset, the arc root registers 16,300 Pa and 29.4 × 10

21 m

−3, whereas the mirrored point exhibits a sharp decline to 2700 Pa and 5.5 × 10

21 m

−3, corresponding to less than 20% of the arc root parameters.

For ion temperature and electron temperature on the anode side, comparative analysis reveals significant thermal asymmetry at mirrored coordinates. Under 33% arc offset, Ti reaches 60,800 K and Te reaches 72,500 K at the arc root, while the corresponding negative semi-axis point exhibits reductions of exactly 32% in Ti and 55% in Te. At 67% arc offset, Ti reaches 69,000 K and Te reaches 80,100 K at the arc root, with more pronounced reductions of 67% in Ti and 71% in Te at the mirrored point.

Arc offset induces not only spatial heterogeneity in vacuum arc but also significant parameter amplification. As quantified in

Table 2, during 33% slight arc offset, the peak values of ion pressure, ion density, ion temperature, electron temperature, and current density increase by 12%, 11%, 6%, 6%, and 14%, respectively, relative to symmetric arc condition. Under 67% severe offset, the maximum increase in these five parameters is significantly higher, reaching 67%, 61%, 12%, 18%, and 47%.

Asymmetric arc ablation induces significant plasma morphology changes, intensifying energy deposition into the anode and accelerating contact erosion due to elevated plasma parameters. Under 33% minor offset, peak parameter increases remain moderate with 6–14% versus symmetric arcing, with erosion effects within controllable bounds. During 67% severe offset, critical parameter escalation occurs with 12–67% amplification compounded by extreme spatial heterogeneity, which significantly impedes interruption capability through uncontrolled anode erosion and material expulsion.

In high-current vacuum arcs, the arc delivers a large amount of energy to the anode. When the energy is high enough, the anode material is eroded, and the anode surface is damaged, which can easily lead to discharge after zero crossing. At the same time, the metal vapor released by the high-temperature anode damages the insulation strength of the vacuum gap, thereby reducing the success rate of disconnection.

The heat flux density transferred to the anode increases with elevated arc density and temperature.

Table 1 and

Table 2 demonstrate that under asymmetric arcing conditions, the arc undergoes intensified constriction, thereby augmenting localized heat flux density toward the anode. This phenomenon exacerbates severely at 66% severe offset condition. Furthermore, when the anode arc root deviates from the contact center, radial heat dissipation efficiency decreases substantially. Consequently, asymmetric arcing induces significantly enhanced anode erosion compared to symmetric counterparts.

Therefore, in practical vacuum interrupters, enhanced manufacturing precision and improved operating mechanism performance are required to minimize severe asymmetric arcing condition.

5. Conclusions

Asymmetric arcing in vacuum arcs significantly alters plasma distributions. This article establishes a magnetohydrodynamic model to quantitatively analyze it. The investigated contacts feature a 60 mm diameter, with cases analyzed for symmetric arcing, 33% minor arc offset (arc root displacement: 10 mm), and 67% severe arc offset (arc root displacement: 20 mm). Key findings are summarized below:

1. Arc offset induces plasma distribution heterogeneity. Parameters at the arc root on the positive semi-axis were compared with mirrored coordinates on the negative semi-axis. For 33% offset, ion pressure and density at the negative coordinate approximate 50% of root values. Under 67% offset, these parameters fall below 20%. Simultaneously, for the 33% arc offset situation, the ion temperature and electrons at the corresponding coordinate points decreased by 30–50%, while for the 67% arc offset situation, they decreased by 70%.

2. Severe arc offset produces pronounced escalation of peak plasma parameters. Under 33% offset, maximum values of ion pressure, ion density, ion temperature, electron temperature, and current density increase by 12%, 11%, 6%, 6%, and 14%, respectively, relative to symmetric arcing. At 67% severe arc deviation, the maximum increases in these five parameters demonstrate stronger amplification, reaching 67%, 61%, 12%, 18%, and 47%.