Abstract

As an important component of current power and energy storage systems, lithium-ion batteries have essential scientific significance and application value in terms of accurately and reliably diagnosing their aging to determine system performance, identify potential faults in modules, and prolong their service life. For this purpose, this paper first briefly describes the working principle of lithium-ion batteries and illustrates the possible impacts of various aging mechanisms on the state of battery capacity. Secondly, starting from both implementable and laboratory perspectives, it sorts out and summarizes the diagnostic mechanisms and applicable scenarios of current typical battery aging state assessment and diagnosis methods. Then, targeting the specific aging mechanisms involved in batteries, it elaborates on the targeted diagnosis processes for each aging mechanism. Finally, combined with implementable and laboratory diagnosis methods, it systematically summarizes a highly standardized and universal routine diagnosis process for battery aging. In addition, in combination with the latest development of aging diagnosis and related technologies, this paper reflects on and discusses the possible future development directions of battery diagnosis technologies.

1. Preface

With the implementation of the “dual-carbon” policy (the national strategy to achieve carbon emission peaking by 2030 and carbon neutrality by 2060 [1,2]), the battery industry has entered an unprecedented period of development. As the direct energy supply device for electric vehicles and energy storage systems, its performance directly affects the overall efficiency of the systems it serves [3]. Lithium-ion batteries are widely used due to their advantages, such as high energy density, long lifespan, and lightweight characteristics. However, as the number of charge–discharge cycles increases, their performance in various aspects gradually declines, which is referred to as battery aging [4]. Aging not only affects the battery’s storage capability but may also lead to a reduction in battery safety. Therefore, achieving the effective diagnosis of battery aging holds significant importance for the entire battery industry.

To comprehensively and accurately diagnose battery aging status, it is essential to first understand the aging mechanisms of batteries. Over the past decade, researchers have employed experimental and modeling approaches [5,6]. A deep exploration of the internal mechanisms and corresponding external characteristics of battery aging has been conducted, leading to the development of diagnostic methods that correspond to each aging mechanism. In terms of approach, these methods can be categorized into implementable diagnostic techniques, which primarily observe external battery characteristic curves (such as current, voltage, impedance), and laboratory diagnostic techniques, which mainly involve observing internal materials using precision instruments (such as electron microscopes, energy-dispersive spectrometers).

Among these, implementable diagnosis can preliminarily determine the aging process and degradation direction of batteries, while microdiagnosis can further utilize instruments and image information to verify and refine the results of implementable diagnosis. For each specific aging direction, in-depth research can be conducted through the above combination methods. In practical applications, based on these diagnostic techniques, every aged battery sample can be evaluated for its aging status by following a fixed diagnostic procedure. Nowadays, with the gradual development of computer technology and the increasing production of batteries, modern diagnostic technologies are beginning to align with big data and machine learning. By analyzing historical operation data of batteries, machine learning can achieve online multi-state joint estimation of batteries, transmitting the estimated results to the cloud for analysis and storage to enable data sharing. This cost-effective and efficient diagnostic method is gradually gaining market favor and has significant application value.

To fully and timely summarize the field of battery aging diagnosis, we can also draw on knowledge from many other fields. For example, collagen peptides can be explored for their potential applications in improving material stability or slowing down material aging, which can be analogized to the strategy of slowing down lithium-ion battery aging [7]. For example, the stability and extraction efficiency of antioxidants coincide with the research on aging diagnosis methods for lithium-ion batteries. Just as antioxidants can prevent the oxidation of food ingredients, similar studies on chemical stability may provide new ideas for extending the life of lithium-ion batteries [8]. Precise temperature management is critical for lithium-ion battery operation, as thermal fluctuations accelerate aging mechanisms. Cold chain logistics monitoring technologies—including real-time thermal mapping and adaptive control algorithms—can be adapted to develop predictive battery aging models [9]. The importance of real-time monitoring and early warning systems for microbial growth environments is similar to that of state monitoring and fault prediction technologies in the aging process of lithium-ion batteries. By comparing these two monitoring methods, we may find new ways to improve the accuracy of the aging diagnosis of lithium-ion batteries. This paper first analyzes the aging mechanism in detail during the working process of batteries, then summarizes the existing battery aging diagnosis methods from implementable and micro perspectives, and introduces the diagnostic methods for specific aging mechanisms. Finally, from an overall perspective, a general diagnostic process is proposed, and the future diagnostic trend is predicted.

2. Analysis of the Aging Mechanism of Lithium-Ion Battery

2.1. The Basic Working Principle of Batteries

During the operation of batteries, multiple complex chemical reactions occur internally, which can be compared to the impact of new food packaging materials on the shelf life of food. The research and application of new materials share similar goals with the study of lithium-ion battery materials, namely, to enhance product stability and durability. By studying food packaging materials, we may gain new insights into the diagnosis of lithium-ion battery aging [10]. Taking lithium cobalt oxide/graphite batteries as an example, both the positive- and negative-electrode active materials have a layered structure, consisting of lithium cobalt oxide and graphite, respectively, as shown in Figure 1. During charging, lithium-ions diffuse from the inside of the lithium-containing positive-electrode material to the surface, then enter the electrolyte, pass through the separator, and move toward the negative electrode. Finally, they reach the graphite at the negative electrode, where electrons travel directly from the positive electrode to the negative electrode via the external circuit to combine with the lithium-ions. The discharge process is the reverse of the charging process; during discharge, electrons move from the negative electrode to the positive electrode through the external circuit, generating current for the load.

Figure 1.

Schematic diagram of working principles of lithium-ion battery (lithium cobalt oxide/graphite as example) [5,6].

2.2. Analysis of Battery Aging Mechanism

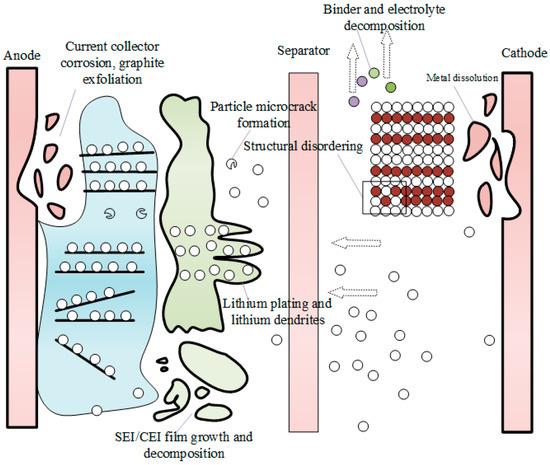

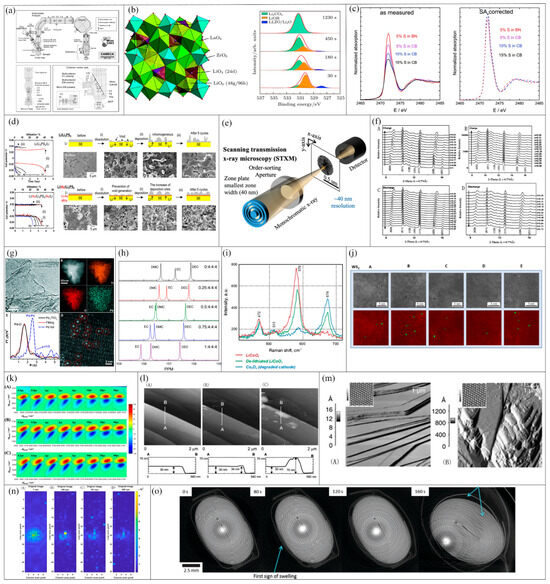

Each time a battery undergoes a charge–discharge cycle, corresponding chemical and physical changes occur inside. These changes can lead to varying degrees of loss in the active lithium or materials within the battery, a process known as battery aging. As the number of charge–discharge cycles increases, the rate of loss also continues to rise. The mechanism of aging can be summarized as shown in Figure 2. From right to left, this shows metal dissolution, electrolyte decomposition, binder degradation, structural disordering, lithium dendrite formation, the microcracking of electrode particles, the growth and decomposition of solid electrolyte interface (SEI)/cathode electrolyte interphase CEI films, graphite spalling, the alteration of electrode composition, and the corrosion of current collectors.

Figure 2.

Diagrammatic sketch of internal battery loss [11].

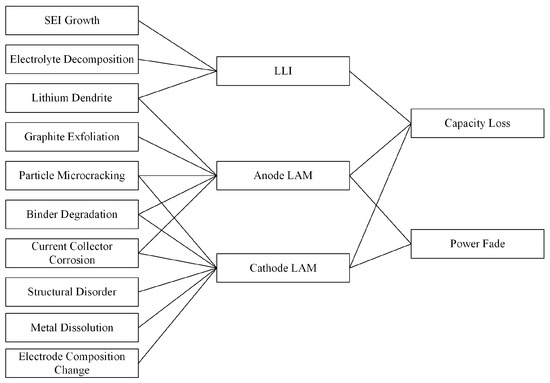

Different loss mechanisms can lead to active lithium loss (LLI) or active material loss (LAM) to some extent, as shown in Figure 3. The losses can be divided into three parts: LLI, negative-electrode LAM, and positive-electrode LAM. Among these, the causes of LLI include the growth and decomposition of SEI/CEI films, electrolyte breakdown, and lithium dendrites. The causes of negative-electrode LAM and positive-electrode LAM include graphite spalling, the microcracking of electrode particles, metal dissolution, structural disordering, changes in electrode composition, binder decomposition, and current collector corrosion. LLI and the LAMs of both electrodes subsequently lead to capacity loss and the power degradation of the battery.

Figure 3.

Aging mechanism of batteries and corresponding capacity loss mechanism [12].

3. Battery Aging Diagnosis Means

Existing battery aging diagnostic methods can be divided into implementable and laboratory diagnostic approaches. Implementable diagnosis involves using the external characteristic curves of the battery to make an initial assessment of the entire aging process. Laboratory diagnosis, on the other hand, relies on equipment such as scanning electron laboratory and energy-dispersive spectrometers to observe specific aging conditions inside the battery, including element distribution and material structure changes. We have developed a ratio fluorescence probe based on this paper, providing unique insights for constructing cost-effective and environmentally friendly fluorescence sensors, which are used for high-performance self-absorption (SA) detection. Similar methods are also employed in battery aging diagnosis [13]. Additionally, such techniques are used in the creative reference screening of appropriate microbial fermenters (Livor and Lactobacillus intestinalis) to produce additional fermented fish, the optimization of the appropriate fermentation process, and the use of certain catalysts in battery aging diagnosis to assist in the observation of test results [14]. Pulsed light (PL) irradiation can also be used to degrade harmful substances by removing hydroxyl or carboxyl groups from benzene rings, and new treatment methods can be used for aging diagnosis [15]. At the same time, the traditional testing components are mainly destructive tests, which are time-consuming, inefficient, and cumbersome. Non-destructive testing (NDT), which is fast and simple, has become a new technology, and we can also refer to this testing method for aging diagnosis testing [16].

3.1. Implementable Methods

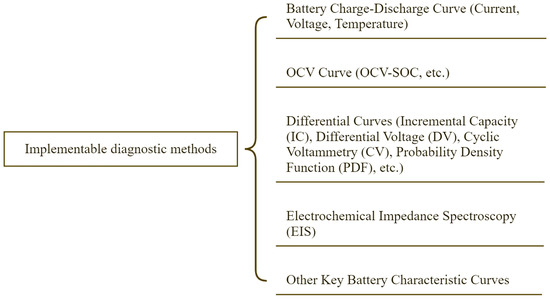

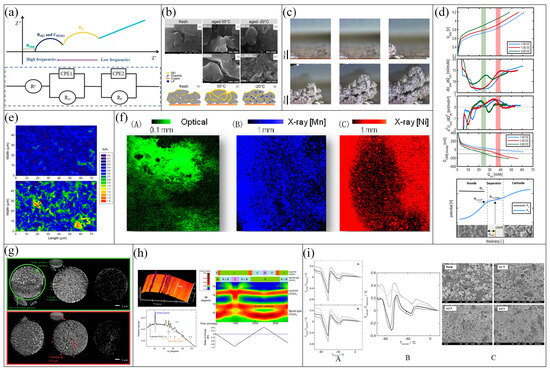

Implementable characteristics are more intuitive than micro characteristics and serve as specific manifestations of the latter. The classification of implementable diagnostic methods is shown in Figure 4 and can be divided into five categories: based on battery charge–discharge curves, based on open-circuit voltage (OCV) curves, electrochemical impedance spectra, and other characteristic curves. Other characteristics include initial Coulombic efficiency (ICE). A critical factor in battery aging is initial Coulombic efficiency, defined as the ratio of discharge capacity to charge capacity during the first cycle. For commercial batteries, ICE directly reflects irreversible capacity loss caused by solid electrolyte interphase (SEI) formation and lithium consumption. Lower ICE values typically correlate with accelerated aging, as they indicate greater initial active lithium loss compared to compound degradation during cycling. However, due to the extensive variety of the fifth category (other characteristic curves), this section primarily details the first four types.

Figure 4.

Classification of implementable diagnostic methods.

3.1.1. Based on Battery Charge and Discharge Curve

The most basic implementable diagnostic method is to determine the aging state of a battery through its charge–discharge curve. The charge–discharge curve describes how current, voltage, and temperature change over time during charging or discharging, as shown in Figure 5a [17]. It is necessary to connect the battery to the charging and discharging equipment, set up the test conditions via a computer, and conduct charge–discharge tests on the battery to obtain the required curve. By comparing the charge–discharge curves at different times, an initial assessment of the battery’s aging state can be made.

Figure 5.

Aging mechanism of batteries and corresponding capacity loss mechanism. (a) Current, voltage and temperature curves of battery CC-CV charging condition from top to bottom [17]. (b) Charging rate test, from top to bottom: terminal voltage, first derivative of voltage, second derivative of voltage [18]. (c) IC curves (top) and DV curves (bottom) of nickel-cobalt-aluminum oxide (NCA) batteries under different cycles [11]. (d) 1/3 C cycle data of LiMn2O4/Li battery (top) PDF curve and (bottom) CV curve [19]. (e) From top to bottom: classical EIS, linear EIS, single-frequency EIS, nonlinear-frequency domain response (NFRA), and odd random response (ORP-EIS) [20].

3.1.2. Based on OCV Curve

OCV stands for open-circuit voltage. This is calculated as the potential difference between the two ends of an electrode when the battery has been left undisturbed for a sufficient period. The OCV curve typically refers to the curve showing how the open-circuit voltage changes with a variable (such as the state of charge or temperature). Commonly used curves include the OCV-SOC curve, where the state of charge (SOC) represents the state of charge of the battery. As the battery transitions from a fully charged state (SOC = 100%) to a completely discharged state (SOC = 0%), the corresponding OCV values will gradually decrease, and the rate of OCV reduction will vary across different SOC ranges, as shown in Figure 5b [18].

When the battery ages, the whole OCV-SOC curve will show a tendency towards inward compression, which is specifically manifested as the change of slope in different SOC intervals, so the property of slope change can help us to preliminarily judge the aging degree of the battery. Furthermore, the temporal evolution of OCV can be quantified by the parameter K, calculated as , where is the time interval between two measurements. The K value serves as an indicator of aging-related phenomena, such as capacity fading or internal self-discharge caused by particle degradation, thereby offering additional diagnostic granularity for the aging process.

3.1.3. Based on Differential Curves

A differential curve refers to a curve where at least one of the coordinates on either the x-axis or the y-axis is derived through differential calculations. Differential curves can clearly show the trend of how one characteristic quantity changes with another, as shown in Figure 5c [11]. Commonly used differential curves for analyzing battery aging include the capacity increment (IC) curve, differential voltage (DV) curve, cyclic voltammetry (CV) curve, and probability density (PDF) curve.

- IC Curve

The IC curve of a battery represents the relationship between the differential of charge (dQ/dV) and voltage (V), describing how capacity changes with voltage during charging or discharging. Typically, the IC curve displays voltage on the x-axis and the differential of capacity with respect to voltage on the y-axis. The IC curve will show “peaks” regardless of whether the battery is charging or discharging, each corresponding to different chemical reactions. However, as the number of cycles increases, these “peaks” tend to become smaller and shift downward to the right. This is because the active material or lithium becomes less active over time due to battery aging, leading to a decrease in internal chemical reaction intensity. By using the characteristic that the position of the “peaks” changes with battery aging and comparing the “peaks” of new and old batteries, one can roughly determine the aging process of the battery.

- 2.

- DV Curve

The “peaks” of the IC curve introduced in (1) are conducive to observing battery aging conditions and mechanisms. The DV curve described here can also clearly distinguish the state of battery aging. The DV curve typically refers to the relationship between dQ/dV and capacity (Ah). Its usage is like that of the IC curve, with corresponding “peaks.” After multiple charge–discharge cycles, the position of these “peaks” will shift to the right. This shifting pattern can also be used to observe the state of battery aging.

- 3.

- CV Curve

By applying a specific voltage signal to the battery electrode and measuring the corresponding current response, the resulting curve is known as a CV curve. The curve displays voltage on the x-axis and current on the y-axis, providing the current response of the battery under different potential conditions, reflecting the electrochemical reaction process within the battery. In cyclic voltammetry tests, the potential is typically scanned back and forth within a certain voltage range to obtain current responses for both forward and reverse scans, allowing the observation of the redox reactions at different potentials.

- 4.

- PDF Curve

Like the IC and DV curves, the PDF curve describes the probability distribution of random variables and can be used to represent the distribution of specific battery parameters. When evaluating the health status of lithium-ion batteries, common parameters include battery capacity, internal resistance, and open-circuit voltage. By collecting a large amount of battery test data, probability density functions for these parameters can be established and used to assess the health status of other battery parameters. The PDF curve also has corresponding “peaks,” as shown in Figure 5d. By combining the position information of these “peaks” for both new and old batteries, the degree of battery aging can be analyzed.

3.1.4. Electrochemical Impedance Spectrum

Impedance represents the ability of ions to be hindered as they shuttle through the battery, which increases with battery aging [21]. Electrochemical impedance spectroscopy (EIS) quantifies aging mechanisms by probing interfacial resistances, such as SEI film impedance and charge-transfer resistance. For example, EIS Nyquist plots can distinguish between LLI-dominated aging and LAM-dominated aging, providing a diagnostic framework for degradation modes. During the test, a scan is performed over a range of frequencies, from low to high, to obtain impedance values at different frequencies. As the battery ages, changes occur in both the low-frequency and high-frequency regions of the impedance spectrum, allowing for an observation of its general aging state. EIS can be further categorized into classical EIS, linear EIS, single-frequency EIS, nonlinear-frequency domain response (NFRA), and odd random response (ORP-EIS), as shown in Figure 5e.

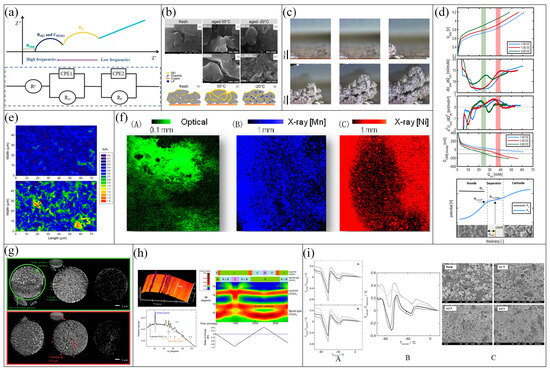

3.2. Laboratory Techniques

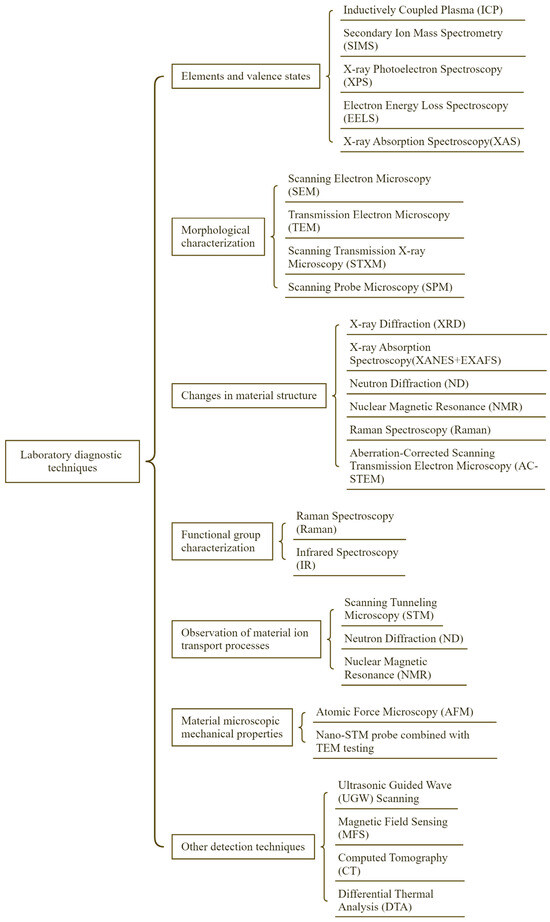

According to the diagnostic content, the existing microdiagnostic means can be divided into seven categories: element composition and valence state analysis, morpho-logical characteristics, material crystal structure characterization, material functional group characterization, material ion transport process observation, material micro-mechanical properties, and other microdiagnostic techniques, as shown in Figure 6.

Figure 6.

Classification of laboratory diagnostic methods.

3.2.1. Analysis of Elemental Composition and Valence State

The determination of elemental composition and valence is mainly based on energy spectrum technology. Different beams are used as excitation sources to irradiate or bombard the surface of the sample. After the action, relevant particles (such as electrons, etc.) will be produced. The elemental composition and valence state can be determined by measuring the binding energy of particles in atoms and analyzing their chemical shift.

- Inductively Coupled Plasma

Inductively coupled plasma (ICP) uses high-frequency electric fields to discharge gases (such as argon) and generate plasma, which passes through the sample, ionizing atoms and molecules within it for elemental analysis. ICP quantitatively analyzes dissolved transition metals in electrolytes or electrodes, correlating their concentration with capacity fade. ICP-MS further detects trace isotopes, while ICP-OES optimizes testing parameters for aging diagnostics. Inductively coupled plasma spectrometers and mass spectrometers are two commonly used analytical instruments. Inductively coupled plasma optical emission spectrometry (ICP-OES) collects and analyzes specific wavelength light signals emitted by the sample using an optical system, with wavelength resolution achieved through gratings or interferometers [22]. It can measure multiple elements simultaneously, offering high sensitivity and a wide linear range; this method is applied to study the impact of drone spray parameters on pesticide droplet deposition and control effectiveness, optimizing parameters through experiments. In the aging diagnosis of lithium-ion batteries, similar experimental methods can be used to optimize various parameters during battery testing, such as optimizing charging and discharging test conditions in implementable diagnostic approaches to improve diagnostic accuracy [23]. Inductively coupled plasma mass spectrometer (ICP-MS) can determine the isotope ratio of multiple elements and detect the limit of detection by the mass analysis of these particles and diagnosis according to the mass-to-charge ratio of ions [24].

- 2.

- Secondary Ion Mass Spectrometry and Hyperspectral Imaging

Secondary ion mass spectrometry (SIMS) bombards the sample surface with high-energy particles to generate secondary particles [25]. These particles are then analyzed using a mass spectrometer to obtain chemical information about the sample surface. Subsequently, hyperspectral imaging technology combined with data reduction algorithms is employed to non-destructively detect the total volatile basic nitrogen (TVB-N) content in chicken meat. This process is like the microdiagnostic techniques used in lithium-ion batteries. For instance, after obtaining extensive internal information about a battery using laboratory inspection equipment, one can apply the data processing methods described in this literature to reduce the complexity of micro-data, extract key information, and assist in assessing the battery’s aging status [26]. The schematic diagram is shown in Figure 7a. In SIMS, high-energy particle beams first bombard the sample surface, causing secondary ions to be emitted from the sample surface with information on elemental composition, compound formation, distribution, and concentration. The emitted secondary ions are then introduced into a mass spectrometer for analysis, which involves a series of ion lenses and a mass analyzer to determine the elemental and compound information on the material’s surface. Specific diagnostic methods can be divided into static SIMS and dynamic SIMS, distinguishing between stable ion bombardment and transient ion bombardment on the sample surface. Static SIMS is primarily used to study elemental and compound information on the sample surface, while dynamic SIMS is suitable for studying the microstructure and interface reactions of materials.

- 3.

- X-ray Photoelectron Spectroscopy

Similar to SIMS is the X-ray photoelectron spectroscopy (XPS), XPS determines chemical states of elements and tracks interfacial reactions, revealing decomposition pathways in aged batteries. XPS uses an X-ray beam with sufficient energy to irradiate samples, interacting with surface atoms and exciting inner electrons to higher energy levels. The excited electrons are then emitted from the sample surface through the photoelectric effect. The emitted photoelectrons carry chemical information about the sample and enter an electron energy analyzer, where their energies are measured to determine their binding energy with atoms [27]. Some researchers have used XPS techniques to determine the valence states of elements in the cubic perovskite material Li7La3Zr2O12 (c-LLZO) after it reacts with H2O and CO2 in air, thereby suggesting the specific substances. The crystal structure diagram and XPS spectrum are shown in Figure 7b.

- 4.

- Electron Energy Loss Spectroscopy

The electron energy loss spectroscopy (EELS) technique uses high-energy electron beams to bombard samples, causing energy loss in the electrons within the sample. This energy loss can be categorized into elastic and inelastic losses (the distinction between elastic and inelastic losses lies in whether the lost energy can be fully recovered; if it can, it is considered an elastic loss; otherwise, it is an inelastic loss). The electrons are then introduced into a spectrometer for analysis, providing information on the electronic structure of the sample. Specifically, EELS probes electronic structures and local bonding environments, enabling the nanoscale analysis of material properties such as electrode degradation and phase transformations in batteries.

EELS diagnostic methods primarily include synchrotron radiation EELS (SR-EELS) and transmission electron microscopy EELS (TEM-EELS). The former uses high-brightness and wide-energy-range electromagnetic radiation as the electron source, while the latter employs a high-spatial-resolution transmission electron microscope to analyze electron energy loss in specific regions of the sample [28]. Additionally, the method can be combined with short-wave and long-wave near-infrared spectroscopy, using color compensation techniques to detect soluble solids content in apples. In battery diagnostics, for some battery information obtained through spectral techniques; the methods described in this literature can be referenced to process and analyze spectral data, enhancing the accuracy and reliability of the diagnosis [29].

3.2.2. Morphological Representation

The morphological characteristics of the internal materials of batteries are usually observed by instruments with precision down to nanometers, mainly using high-resolution electron microscopes such as scanning electron microscopes, transmission electron microscopes, scanning transmission X-ray microscopes, and scanning probe microscopes.

- Scanning Electron Microscopy

Scanning electron microscopy (SEM) is indispensable in characterizing battery degradation, as it visualizes morphological changes such as electrode cracking, SEI film growth, and lithium dendrite formation. For instance, the SEM imaging of aged graphite anodes reveals particle fractures and SEI layer thickening, which correlate with active lithium loss (LLI). SEM uses an electron beam emitted by an electron gun to scan the sample surface, measuring the reflection, scattering, and absorption characteristics of electrons to obtain relevant information about the sample surface. The schematic diagram of the lithium metal surface image observed by SEM is shown in Figure 7d.

- 2.

- Transmission Electron Microscopy

Transmission electron microscopy (TEM) enables the atomic-scale analysis of battery materials, revealing crystallographic defects and phase transformations. For instance, TEM has identified Mn dissolution from cathodes and its deposition on anodes, a key contributor to capacity loss. The main principle is that the electron beam penetrates the sample and forms an image after focusing. Due to this characteristic, TEM can observe the internal structure of samples with higher resolution than SEM.

- 3.

- Scanning Transmission X-ray Microscopy

The core components of the scanning transmission X-ray microscope (STXM) technology include the X-ray source and detector. The X-ray source generates rays that pass through the sample, and the detector measures the electron signals from X-ray transmission and characteristic X-ray absorption signals to visualize the fine morphology of the sample. This technique, known as scanning transmission X-ray microscopy (STXM), combines X-ray spectroscopy with high spatial resolution, making it particularly useful for mapping chemical composition changes in aged electrodes and studying heterogeneous degradation patterns or localized failure sites. The schematic diagram is shown in Figure 7e.

- 4.

- Scanning Probe Microscopy

The scanning probe microscopes (SPMs) used include the scanning tunneling microscope (STM) and the atomic force microscope (AFM). These instruments combine the advantages of optical and electron microscopes. The two most critical components of SPM are the probe and the scanning tube. The probe makes direct contact with the sample to sense its surface properties, while the scanning tube precisely controls the relative position between the probe and the surface. By quantifying surface topography changes and electronic state variations at electrode interfaces, SPM techniques (AFM/STM) provide critical insights into SEI growth dynamics and lithium deposition behavior during battery aging. By using suitable probes to scan the sample surface (AFM can detect the topography of the sample surface and STM can provide images of the electronic states on the sample surface), these instruments can characterize the morphology of the material being studied. Detailed discussions on AFM and STM are provided in Section 3.2.5, “Observation of Material Ion Transport Processes,” and Section 3.2.6, “Microscopic Mechanical Properties of Materials.”

3.2.3. Material Crystal Structure Change

If you want to further observe the crystal structure of materials, most electron microscopes cannot meet the requirements of accuracy, and more accurate spectroscopic techniques or optical microscopes are needed. Representative technologies include X-ray diffraction, extended X-ray fine spectrum, neutron diffraction, nuclear magnetic resonance, Raman spectrum, etc., and representative electron microscopes include the spherical aberration-corrected scanning transmission electron microscope.

These techniques collectively establish structure–degradation correlations across multiple scales: from bulk phase transitions (XRD/ND) to local atomic environments (XAS/NMR) and atomic-scale defects (AC-STEM). Their complementary applications enable comprehensive diagnosis of the crystallographic origins of battery aging.

- X-ray Diffraction

X-ray diffraction (XRD) is a critical tool for studying battery materials, as it can monitor real-time structural evolution during cycling or analyze crystalline changes after aging. By analyzing the diffraction pattern, information about the structure and composition of the material can be obtained [30]. This method can also be used to study the inactivation effects of temperature-controlled short-wave infrared radiation on lipase and lipoxygenase in wheat germ, as well as their impact on the storage stability and quality of wheat germ oil [31]. In battery research, this approach to studying the effects of temperature and other factors on battery material performance and aging processes can be analogously applied [32]. The energy spectrum of LixMn0.25Fe0.75PO4 energy spectrum is shown in Figure 7f.

- 2.

- X-ray Absorption Spectroscopy

X-ray Absorption Spectroscopy (XAS) encompasses two complementary techniques for analyzing materials: X-ray absorption near-edge structure (XANES) and extended X-ray absorption fine-structure (EXAFS) analysis. These methods provide detailed information about the electronic structure and local atomic environments in battery materials.

The method for determining the elemental composition and valence state of elements also includes X-ray absorption near-edge structure (XANES). This technique uses X-rays to irradiate samples, causing their atoms to absorb energy. Inner electrons are excited to higher energy levels and then emitted from the sample through the photoelectric effect. Information about the electron structure information of atoms and molecules in the sample is obtained via measurement with an energy analyzer. A schematic diagram of XANES is shown in Figure 7c, where the left image shows the sulfur K-edge XANES spectra of samples containing different concentrations of sulfur added to carbon black (CB) and boron nitride (BN); the right image shows the same spectrum after SA correction.

Extended X-ray absorption fine-structure (EXAFS) techniques are used to analyze the local structure and chemical environment of atoms in materials. This technique utilizes synchrotron radiation X-rays to irradiate samples, causing inner-shell electrons to be ionized after absorbing photons and releasing them as spherical light electrons. If other particles are present around the absorbing atom, the light electrons will be scattered; if no other particles are present, the light electrons will disappear. By measuring the absorption spectrum of X-rays, information about the local structure and chemical environment of sample atoms can be obtained. For samples with long-range disorder but short-range order in their crystal structures (such as catalysts, solutions, or samples containing trace elements), EXAFS is a relatively effective analytical method. The schematic diagram is shown in Figure 7g, where (A) is a representative TEM image of Pd1/TiO2, showing the cross-section of an ultra-thin TiO2 after aberration correction in scanning transmission electron microscopy (STEM) mode; (B) is a scanning transmission electron microscopy-energy-dispersive X-ray spectroscopy (STEM-EDS) elemental map of a single-Pd1/TiO2 nanosheet; (C) is the Fourier-transform extended X-ray absorption fine-structure (FT-EXAFS) spectrum of Pd1/TiO2 displaying atoms adjacent to Pd atoms; (D) is a high-resolution high-angle annular dark-field (HAADF) STEM image of Pd1/TiO2.

- 3.

- Neutron Diffraction

Neutron diffraction (ND) technology leverages the principle of neutron interaction with matter. Neutrons, one of the fundamental particles that make up atoms, can be produced through nuclear fission or other methods. In experiments, neutron sources are commonly used to generate neutrons. When neutrons pass through matter, they interact with atomic nuclei and electrons within the material, producing diffraction phenomena. Unlike X-ray diffraction, neutron diffraction is related to the interaction between atomic nuclei in crystals.

While both neutron diffraction (ND) and X-ray diffraction (XRD) probe material structures, ND offers unique advantages for battery research through its exceptional sensitivity to light elements. In lithium-ion battery studies, ND can directly determine lithium atomic positions and detect hydrogen-containing species, capabilities that are severely limited in conventional XRD analysis. These characteristics make ND an indispensable tool for investigating lithium migration pathways and electrolyte decomposition mechanisms.

The wavelength of neutrons is typically in the order of the lattice spacing of materials, making neutron diffraction more sensitive to crystal lattices. This phenomenon can be used to observe the crystal structure of materials.

- 4.

- Nuclear Magnetic Resonance

The fundamental principle of nuclear magnetic resonance (NMR) technology is that when atomic nuclei are subjected to an external magnetic field, they undergo energy-level splitting. When the frequency of the applied radiofrequency field numerically equals the distance between the energy levels, the atomic nuclei absorb the radiofrequency energy, resulting in resonance absorption. By measuring the resonance absorption signal, information such as the number of atomic nuclei in the sample, chemical shift, coupling constants, and relaxation time can be obtained. In the study of battery aging, NMR technology can be used to determine the NMR spectrum of active substances, thereby obtaining their structural information. As shown in Figure 7h, this figure illustrates the NMR spectra of LiPF6 carbonyl region 13C with different molar ratios.

- 5.

- Raman Spectroscopy

The principle of Raman spectroscopy is based on Raman scattering. When high-intensity incident light interacts with a substance, a small portion of the scattered light has a different wavelength from the incident light. This change in wavelength is determined by the chemical structure of the sample being measured, and this scattered light is called Raman scattering. The frequency changes in this scattered light are related to the vibration modes of the molecules in the material. This makes Raman spectroscopy particularly valuable for identifying bond vibration changes in electrode materials and SEI composition through characteristic fingerprint spectra, enabling the non-destructive monitoring of chemical degradation processes. As shown in Figure 7i, which illustrates the Raman spectra of three substances on the cathode, this can be used to further observe the battery structure by referencing the analysis of sugar diffusion and optimization in Gaido Seak based on finite element analysis, as well as hyperspectral imaging techniques [33].

- 6.

- Scanning Transmission Electron Microscopy with Aberration Correction

Aberration correction scanning transmission electron microscopy (AC-STEM) refers to an optical defect in transmission electron microscopy that causes blurring and distortion in imaging. By introducing specific electric or magnetic fields in the electron transmission microscope, the effect of aberration can be corrected, thereby improving the resolution and quality of the image. AC-STEM uses an electron beam to scan through a sample; it then reconstructs the three-dimensional structure of the sample from the transmitted electron images collected from the sample. These images can be processed using computer algorithms and image processing techniques to obtain high-resolution three-dimensional information.

This aberration-corrected technique provides atomic-resolution imaging capabilities that are particularly valuable for observing defect formation and interface reconstruction, crucial for understanding nanoscale degradation initiation mechanisms in battery materials.

Compared to traditional X-ray crystallography and nuclear magnetic resonance techniques, aberration-corrected scanning transmission electron microscopy offers higher resolution and broader applicability. As shown in Figure 7j, the top row displays an AC-STEM image of a two-dimensional WS2 sheet containing nanoholes irradiated by ions (the dark area in the image), while the bottom row shows an artificially identified image of the nanoholes (bright green).

3.2.4. Characterization of Material Functional Groups

Compared with the elemental composition and crystal structure mentioned above, the chemical properties of material functional groups are more active. Although the specific components of functional groups can be intuitively observed by acid–base neutralization, oxidation–reduction, precipitation formation, etc., it will change the battery material and may even cause safety problems. Raman spectroscopy and infrared spectroscopy are commonly used in laboratories to diagnose the required functional groups.

- Raman Spectroscopy

This technology has been described in detail in the previous article, so it will not be repeated here.

- 2.

- Infrared Spectroscopy

Infrared (IR) spectroscopy is an absorption spectrum that uses infrared radiation at specific wavelengths (typically divided into three regions: near-infrared 0.75–2.5 μm, mid-infrared 2.5–25 μm, and far-infrared 25–1000 μm) to interact with samples. The infrared radiation within these wavelength ranges is associated with the vibration modes of chemical bonds and the rotational motions of molecules, causing substances to absorb specific infrared spectra. The form of motion corresponding to infrared light is molecular vibration, which alters the dipole moment and thus produces infrared absorption. The frequency of vibration is related to the strength of chemical bonds and atomic mass, so infrared spectroscopy determines functional groups by measuring the vibration frequencies of chemical bonds in molecules. This makes IR spectroscopy particularly powerful for battery diagnostics, where it can identify organic functional groups in degraded electrolytes and binder degradation products. The technique also probes inorganic components in SEI layers through lattice vibrations, while resolving dynamic interactions like Li+ solvation structure changes, as demonstrated in Figure 7k for LiTFSI systems. These capabilities are critical for understanding electrolyte aging mechanisms.

3.2.5. Observation of Ion Transport Process in Materials

- Scanning Tunneling Microscopy

Scanning tunneling microscopy (STM) uses the tunneling effect to observe the surface of materials. STM can closely examine and locate individual atoms; it is a scanning microscopy tool where the tip consists of just one atom. When the tip scans the sample at a height of less than one nanometer, the electron cloud overlaps and produces a tunneling effect under an applied voltage, causing electrons to escape. As the distance between the probe and the sample surface continuously changes, the current fluctuates, revealing the topography of the sample at the atomic scale and allowing for detailed contouring. These unique capabilities make STM particularly valuable for battery research, enabling the atomic-scale visualization of electrode surface evolution during cycling. The technique directly images SEI layer formation, lithium deposition patterns, and graphite anode morphological changes (as demonstrated in Figure 7l). With its ultra-high resolution, STM reveals localized degradation hotspots and quantifies surface roughness changes that critically impact ion transport processes.

Neutron diffraction and nuclear magnetic resonance are described in detail in Section 3.2.3 (3) and Section 3.2.3 (4), and so they will not be repeated here.

3.2.6. Microscopic Mechanical Properties of Materials

The characterization of microscopic mechanical properties provides crucial insights into structural degradation and interface evolution in aged lithium-ion batteries. These techniques enable the quantitative assessment of mechanical property changes that contribute to performance degradation.

- Atomic Force Microscopy

Atomic force microscopy (AFM) acquires the surface morphology and mechanical properties of samples by scanning their surfaces. It can measure surface height differences at the nanoscale and obtain atomic-level information about the surface through the interaction between the probe and the sample. Beyond topography, AFM precisely characterizes nanoscale mechanical property changes in electrode materials and interfaces, including SEI layer stiffness evolution, particle fracture toughness reduction, and binder degradation. When the sample’s morphology changes, the interaction forces between the tip and the sample also change (for example, from attraction to repulsion), causing the slight displacement of the AFM’s microcantilever. The photodetector on the AFM precisely amplifies the displacement changes of the microcantilever via a light spot. Finally, data processing yields images and related data of the sample’s surface structure. The schematic diagram observed by AFM is shown in Figure 7m, which includes (a) highly oriented pyrolytic graphite (HOPG) and (b) composite electrode AFM images.

- 2.

- Nanometer, Scanning Tunneling Microscopy Probe Combined with Transmission Electron Microscopy Test

In traditional transmission electron microscopy (TEM), nanoprobes or scanning tunneling microscopy (STM) probes are usually used in combination to achieve more detailed sample analysis. Two test method are listed as follows:

- Nanoprobe combined with TEM test method: Nanoprobe can be introduced into TEM to achieve mechanical operation of samples at the nanoscale, and to achieve accurate analysis of samples. Common nanoprobe includes ion beam etching probe, atomic force microscope probe, etc. Nanoprobe-TEM enables the in situ mechanical testing of electrode materials at nanoscale resolution, revealing crack propagation mechanisms and phase-dependent mechanical property changes during cycling.

- STM probe combined with TEM test method: The STM probe can realize the in situ electrical property analysis of samples in TEM. The electrical property information of samples can be obtained by scanning the surface of the samples and detecting the electronic structure of the samples. STM-TEM combines atomic-scale imaging with simultaneous electrical characterization, allowing the direct correlation of structural defects with local conductivity changes in aged electrodes.

3.2.7. Other Microscopic Diagnostic Techniques

- Ultrasonic Guided Wave Scanning

Ultrasound-guided wave (UGW) scanning is a non-destructive testing technique that uses the principle of ultrasonic waves propagating and reflecting within structures to diagnose and evaluate internal defects in materials. It can determine the location, size, and type of defects in structures through changes in the signal along the propagation path. By applying ultrasonic excitation to the surface of a structure, sound waves are introduced into the interior, where they propagate as guided waves, reflecting and scattering at interfaces between the surface and the interior. When ultrasonic waves encounter structural defects caused by battery aging, such as cracks, protrusions, or material changes, they undergo reflection, scattering, and energy loss. By analyzing the signal characteristics of ultrasonic waves propagating within the structure, such as amplitude, time delay, and spectrum, the position and size of defects can be determined. This is then compared with reference signals from defect-free structures for analysis and interpretation. The schematic diagram is shown in Figure 7n, which illustrates the UGW spectra of lithium-ion batteries at different aging cycles.

- 2.

- Magnetic Sensing

Magnetic field sensing (MFS) detects batteries based on the principles of battery electrochemical reactions and electromagnetic theory. When a battery is charging or discharging, an induced magnetic field is generated both inside and around the battery. By placing a magnetometer around the battery to measure the magnetic field strength, changes in the battery’s performance and state can affect the surrounding magnetic field [34]. Analyzing and comparing the changes in magnetic field strength recorded by the magnetometer with those of a reference battery allows for the evaluation of differences between the two.

- 3.

- Computerized Tomography

Computed tomography (CT) is a non-destructive diagnostic technique that reconstructs the three-dimensional image of an object by scanning it from multiple angles with X-rays and then reconstructing it by computer. It can provide detailed information about the internal structure and composition of an object, as shown in Figure 7o, which is a CT image of a lithium cobalt oxide battery during charging.

- 4.

- Differential Thermal Analysis

Differential thermal analysis (DTA) techniques study the thermal properties and phase transition behaviors of materials by measuring the temperature differences between samples and reference materials. During the experiment, the differential thermal analyzer measures the temperature difference between the sample and the reference sample to calculate the heat difference. By analyzing the measured data, one can observe the thermal effects of the sample at different temperature ranges, such as exothermic peaks and endothermic peaks. By comparing the position, shape, and intensity of these thermal effect peaks, it is possible to infer potential phase transitions, chemical reactions, or pyrolysis phenomena in the sample. For lithium-ion battery cathode materials, these thermal effect peaks may be related to lithium-ion insertion and extraction, lattice structure phase changes, and material pyrolysis.

Figure 7.

Example of laboratory diagnosis. (a) IMS-1280 schematic diagram [35]. (b) Li7La3Zr2O12(c-LLZO) schematic diagram of crystal structure (left) and energy spectrum variation in LLZO micro powder surface at different exposure times in air (right) [36]. (c) Sulfur k-edge XANES spectra (left) and same spectra after self-absorption (SA) correction (right) were measured on samples with different concentrations of sulfur added to carbon black (CB) and boron nitride (BN [37]. (d) SEM image and schematic diagram of morphology change on lithium metal surface in constant current cycling test. (e) STXM diagrammatic sketch [38]. (f) The variation laws in XRD spectra of LixMn0.25Fe0.75PO4 with lithium content x during the first cycle (0.05C charge–discharge (A,B)) and the second cycle (0.5 C charge–discharge (C,D)). (g): (A) representative TEM image of Pd1/TiO2 (B) STEM-EDS elemental mapping of a single-Pd1/TiO2 nanosheet (C) FT-EXAFS spectra of Pd1/TiO2 and its adjacent atoms; (D) high-resolution HAADF-STEM image of Pd1/TiO2 [39]. (h) NMR spectrum is shown with different molar ratios LiPF6’s carbonyl zone 13C. (i) Raman spectra of the three cathode materials. (j) Top row: AC-STEM images of ion irradiated two-dimensional WS2 thin sheets containing nanopores (dark areas in the image) (A–E); bottom row: artificially identified nanopores are bright green [40]. (k) Two-dimensional infrared spectra of the C≡N stretching of SCN-anion probes in LiTFSI aqueous solutions with concentrations (A) 1, (B) 10, and (C) 18 mol/kg. (l) STM images of the anode graphite before and after CV (2 × 2 μm) and its height distribution in 1 m LiClO4/TFPC (A) before cycling, (B) after one cycle between 2.8 to 0 V, and (C) after three cycles in 1 m LiClO4/TFP [41]. (m) 10 × 10 µm2 AFMFigure: (A) HOPG and (B) composite electrode [42]. (n) UGW diagrams of lithium batteries at different ages [43]: (A) the first cycle, (B) the 100th cycle, (C) the 151st cycle, and (D) the 200th cycle. (o) CT images of LiCoO2 battery during charging at 0 s,80 s,120 s, and 160 s.

4. Specific Diagnostic Protocols for Each Aging Mechanism

The aging mechanisms of batteries vary significantly at different stages of aging. In the early stage, the dominant mechanism is LLI caused by the growth and thickening of SEI/CEI films. This is partly due to the formation of SEI/CEI films during the battery’s pre-manufacturing process and partly because particles in the electrolyte react with the SEI/CEI film during subsequent use, leading to further thickening. As the battery continues to be used, the primary aging mechanism shifts from LLI to LAM, with LAM being predominant in the negative electrode. The main factors contributing to LAM include electrode metal dissolution, disordered electrode particle structure, and changes in electrode composition.

At the electrode interfaces, aging induces distinct yet interrelated degradation processes. The anode SEI progressively thickens due to continuous reduction reactions and mechanical stress, primarily consuming active lithium-ions and increasing interfacial impedance. Conversely, the cathode CEI thickens through oxidation reactions and transition metal dissolution, which predominantly compromise cathode structural integrity and charge transport kinetics. These parallel but interconnected mechanisms synergistically accelerate overall battery degradation.

Although these factors, which account for a significant portion of the aging mechanism, have been identified and are subject to relatively comprehensive implementable diagnostic methods, mechanisms such as electrolyte decomposition, lithium dendrite formation, graphite spalling, and particle microcracking, which account for a smaller proportion, have a minimal impact on the external characteristic curves diagnosed practically. Moreover, the trends reflected in these curves are often the result of multiple mechanisms working together, so they can only be observed using laboratory diagnostic techniques.

4.1. Diagnostic Methods Dominated by LLI

4.1.1. Electrolyte Decomposition

The electrolyte plays an important role in ion transport and charge balance in batteries. It is usually a mixture of organic solvent and LiPF6. Although this ratio has been optimized for safety, it is still not stable enough. For example, when HF is present, the contaminated LiPF6 will attack the electrode material as a corrosive medium, leading to material dissolution [44]. In recent decades, due to the relatively minor role of electrolyte decomposition in aging mechanisms, most research has focused on the decomposition mechanisms and stability of electrolytes [45,46]. For instance, a thermosensitive smart polymer aqueous two-phase flotation system, combined with HPLC, can be used to simultaneously separate, enrich, and detect trace amounts of ciprofloxacin and lomefloxacin in food samples. In battery analysis, for the detection and analysis of trace substances in batteries, reference can be made to their separation and detection techniques to examine impurities or degradation products within the battery, thereby understanding its aging condition [47]. At the beginning of the 21st century, Gnanaraj and Zinigrad et al. used an accelerated calorimeter to verify that when the temperature rises to around 70 °C, the SEI/CEI film will decompose, and pyruvic acid (C3H4O3) from the solvent in the electrolyte will directly contact lithium, producing gas. Gas production leads to direct contact between the negative electrode and air, reacting with oxygen, which also causes secondary damage to the battery [48]. Wang et al. used a C80 calorimeter to study the decomposition of LiPF6 when the temperature reached 170 °C [49]. In the following decade, research on electrolyte decomposition products and electrolyte materials sprang up like mushrooms after rain. The focus was primarily on new types of electrolyte materials, electrolyte leakage and stability, and the chemical recycling of these materials [50,51,52,53]. Similar to how external factors influence physical processes in such studies, this research also examines how different environmental conditions or treatment methods affect the charging and discharging processes or the aging of batteries. Due to the limitations of the “one-too-many” mechanism of macro-characteristic curves, to accurately determine whether the electrolyte decomposes during aging, it is usually necessary to combine other analytical methods, such as energy spectrum analysis, to determine the chemical composition and structure of the decomposition products and assess whether the electrolyte has decomposed and the degree of decomposition.

4.1.2. SEI/CEI Film Thickens

The formation of the SEI/CEI film is due to the reaction between the anode material and lithium-ions in the electrolyte during the initial use of the battery, resulting in the creation of a stable film. This film primarily consists of dissolved substances from the electrolyte, decomposition products of the electrolyte, and reduction products of the anode material. The SEI/CEI film protects the anode from reacting with the electrolyte, promotes the conduction of lithium-ions within the battery, and prevents particles from moving freely inside the battery. However, as the battery cycles, the film continuously reacts with active lithium, increasing its thickness and consuming active lithium, which reduces the battery’s capacity. This is a significant cause of battery aging [54].

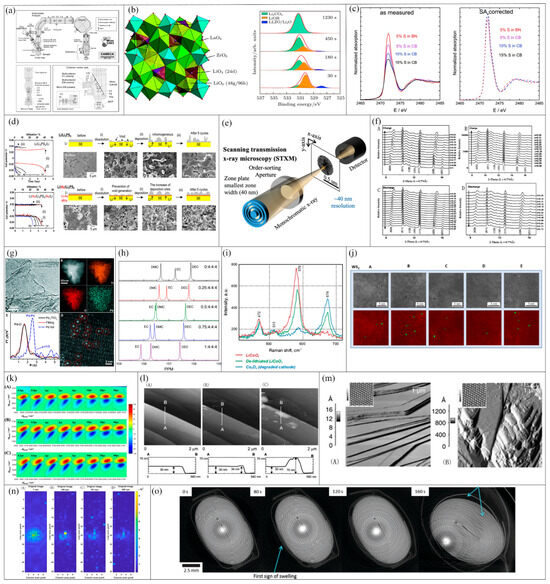

Li et al. used EIS to preliminarily estimate the impedance of the SEI/CEI film [11]. The EIS diagnostic results are described using a Nyquist diagram, which intuitively illustrates the impedance characteristics of the battery’s SEI/CEI film. For example, the resistance (RSEI/CEI) of the film can indicate the quality and stability of the SEI/CEI film. If the SEI/CEI film is in good condition, RSEI/CEI should be low, as shown in Figure 8a. After an initial assessment using EIS, further verification can be conducted by observing the SEI/CEI film of aged batteries with SEM. There will be certain differences between the SEI/CEI films of new and aged batteries: the SEI/CEI film of a new battery typically has a relatively uniform and smooth surface, presenting a more regular structure. In contrast, the SEI/CEI film of an aged battery may exhibit an uneven, rough, or granular surface, possibly with cracks or pores, as shown in Figure 8b.

4.1.3. Lithium Dendrite Phenomenon

During the battery charging process, some lithium-ions are not fully embedded into the anode material but gradually accumulate on its surface. This leads to an increasing number of lithium-ions on the anode material until capacity is exceeded, resulting in free lithium metal deposits on the anode surface. This phenomenon is known as lithium plating, and the deposited lithium is referred to as lithium dendrites, as shown in Figure 8c [55,56,57]. Overcharging can exacerbate this deposition. Here, we can refer to the development of a recyclable non-ligand biphase extraction method for determining the presence of lead in food samples. In terms of detecting heavy metal impurities in batteries, their detection methods can be referenced to measure the heavy metal content in batteries, thereby assessing the quality and safety of the battery [58]. Regarding the specific reasons for lithium plating, there are currently two perspectives. The first perspective is from the potential angle, which holds that when the overpotential of the anode relative to metallic lithium/lithium-ions is less than 0 V, lithium plating will occur. The second perspective focuses on concentration, suggesting that due to the lower solid-phase diffusion coefficient of the anode, lithium plating will happen when the concentration of diffused lithium-ions reaches the level of saturation [59,60,61,62,63].

In previous studies, researchers have tried methods such as Coulomb efficiency, electrochemical calorimetry, and three electrodes to determine dendrite precipitation [64,65,66]. However, these methods not only require expensive equipment but also yield inaccurate results. This section primarily introduces the differential voltage analysis (DVA) method, which has a simple operation process and can preliminarily diagnose lithium plating on batteries through non-destructive means. It is sufficient to obtain the relationship curve between battery voltage and charge capacity. Subsequently, the data obtained should be processed with first and second derivatives, as shown in Figure 8d. It is evident that when constant current charging is performed at 2 C and 1.5 C, there are distinct characteristic peaks in the first derivative at approximately 22 mAh and 40 mAh, respectively. In the second derivative plot, there are noticeable decreases at these two points, indicating lithium plating. To further observe whether dendrite formation has occurred, in situ optical microscopy or other electron microscopy techniques can be used for observation.

4.2. A Diagnostic Method Dominated by LAM

4.2.1. Graphite Flaking

Graphite, due to its excellent electrical conductivity and chemical stability, is often used as an additive in negative-electrode materials to enhance the conductivity of batteries and the reaction rate for intercalation/deintercalation. A decade ago, to increase energy density, researchers began exploring and using silicon materials as battery anodes. Silicon has a higher theoretical capacity, but it tends to expand and contract in volume during charging and discharging, leading to structural damage. Therefore, researchers have addressed the issue of volume expansion in silicon anode materials to some extent by synthesizing nanostructures and coating protective layers, thereby achieving higher energy density [67].

Although researchers have made considerable achievements in the research of graphite anodes [68]; however, with the continuous disembedding of particles during use, thry still suffer varying degrees of damage (volume change is usually about 12%) and even fall off [69]. Sethuraman et al. provide a good summary of the causes of graphite structural disorder and even fracture [70]; based on the Daumas–Hérold model, relevant diagrams have been poduced for lithium intercalation and deintercalation within a certain voltage platform region, as shown in Figure 8e. This demonstrates the state of the anode graphite under normal conditions and during different stages of charging (Stage 1–Stage 4—where gray stripes represent anode graphite and blue spherical particles represent Li+), and the phenomenon of graphite exfoliation under a certain number of charge–discharge cycles has been observed using Raman spectroscopy (ID/IG is the peak ratio of D to G peaks, with a higher value indicating more defects in that area).

4.2.2. Electrode Particle Microcrack

The phrase microcracks in electrode particles refers to the phenomenon of microcracks being in the particles in the electrode during the use of the battery. They can be divided into intergranular cracks and intragranular cracks, which will hurt the performance and life of the battery. Thomas et al. conducted thorough research on the microstructure of cracks in the positive-electrode particles of nickel-rich NMC811 lithium-ion batteries [71]. High-resolution CT technology was used to observe the particles before and after cycling, as shown in Figure 8g. The green box contains the observation results of the battery in its factory condition, while the red box shows the results after multiple cycles of charging to 4.5 V and discharging to 3 V. This figure shows that the particles already had multiple cracks before cycling, with lengths reaching 8 μm, and many cracks even penetrated to the surface of the particle. This is due to defects in the preparation process, such as coating and imprinting techniques. Comparing these with the images from after cycling, it was found that the phenomena were more severe and the cracks were more pronounced.

4.2.3. Metal Dissolves

The ions such as manganese (Mn2+), nickel (Ni+), and cobalt (Co2+) in cathode materials are known as transition metal ions. During charging, these transition metals are oxidized to higher oxidation states, releasing lithium-ions. In the discharge process, they are reduced back to lower oxidation states and reabsorbed. Theoretically, only Li+ should move back and forth between the positive and negative electrodes. However, with increasing cycle counts, the presence of these metal components can often be detected in the electrolyte, SEI/CEI film, or even the carbon anode [72]. Similar sensors can be used for diagnosis, drawing on models that detect the height of a pole using ultrasonic sensors throughout the entire growth cycle of wheat. Due to the chemical reactions during charging and discharging [73], the HF produced can corrode the electrodes, exposing transition metals on the electrode surface and leading to the loss of active materials. At this point, we can draw on research on the inhibitory effect of lemongrass oil encapsulated in liposomes on the growth of Listeria monocytogenes in cheese [74]. In battery research, methods similar to those used for studying antimicrobial effects can be applied to investigate the inhibitory effects of additives or protective materials on internal chemical reactions within the battery, thereby delaying battery aging [75,76]. Chen et al. [77] studied the relationship between Mn content in the anode and battery capacity loss using an ICP atomic spectrophotometer. The results showed that when 100 ppm Mn2+ was added, the battery capacity loss was about 63.3%, while the loss was only 10.6% without the addition of Mn2+. In addition, Mn2+ would dissolve into the SEI/CEI film and capture Li+ during the deintercalation process [78]. James et al. [79] carried out a series of experiments to study the phenomenon of capacity loss caused by transition metal dissolution, and the relationship between Mn2+ dissolution and capacity loss was quantified. Combined with ICP-MS, the following conclusions were obtained: each deposition of Mn2+ on SEI/CEI film captured an additional 0~102 Li+, which was consistent with the analysis results of previous scholars.

Although it has been confirmed that the dissolution of Mn2+ is the primary mechanism leading to Li+ loss due to transition metal dissolution, relatively few studies have been conducted using implementable diagnostics. Therefore, more specific experimental methods are needed to accurately determine the extent of transition metal dissolution. The dissolution of Mn2+ was observed using fluorescence spectroscopy to measure the Mn content in the SEI/CEI film and on the anode, as shown in Figure 8f [80,81,82].

4.2.4. The Structure Is Disordered

Different cathode materials have different structural and performance characteristics. At present, the three main cathode materials have a layered structure [83,84], Olivine structure [85], and Spinel structure [86]. Researchers are also constantly looking for more cathode materials, such as LiCo2/3Ni1/6Mn1/6O2 [87], to improve the performance of the battery.

Previous studies were performed on the diagnosis of structural disorder [88,89,90,91,92]. One very effective method is to use neutron diffraction to observe the structural changes of battery cathode materials during charging and discharging processes. As shown in Figure 8h, the left image shows the diffraction pattern of the battery at the 5th minute during cycling, while the right image displays the diffraction patterns corresponding to different phase transitions. If the crystal structure changes, the intensity will vary, even if the diffraction angle 2θ remains unchanged. By comparing these with the diffraction patterns of newly charged and discharged batteries, one can diagnose whether the structure has become disordered.

4.2.5. Electrode Composition Changed

Electrode composition change refers to the phenomenon that the active material in the electrode changes during the use of the battery [93]. This change primarily occurs in the cathode material. During charging and discharging, lithium-ions intercalate and deintercalate between the cathode material and the electrolyte, altering the composition or structure of the cathode material. The self-assembly technology of nanomaterials can be utilized to create highly ordered electrode structures, which may help to improve battery performance and extend its lifespan [94]. Additionally, nanomaterials can be used to develop highly sensitive sensors to monitor chemical and physical changes associated with battery aging [95]. These changes are more pronounced at high temperatures [96]. As the battery continues to be recycled, the active material in the cathode material will decay [97]. This is due to the fragmentation of active material particles, structural damage, and surface deactivation. Additionally, lithium-ions in the cathode material may be dissolved by transition metals and undergo other chemical reactions. In such cases, studies used color sensor arrays, sensory analysis, and gas chromatography techniques to identify honey [98]. In battery aging diagnosis, when it is necessary to classify and differentiate multiple battery samples, this multi-technology approach can be referenced, combining the advantages of various detection methods to more accurately determine the aging state and type of batteries [99,100]. The differential thermal analyzer can be used to observe whether the electrode composition changes. The differential thermal analysis (DTA) spectrum and the schematic diagram of the electrode image under SEM observation are shown in Figure 8i.

4.2.6. The Adhesive Decomposed

A binder is a material used to fix and connect various components inside a battery. It serves functions such as securing electrode materials, providing electronic conductive pathways, offering ion transport channels, protecting electrode materials, and enhancing battery performance. In addition to these capabilities, binders must also resist electrolyte corrosion and withstand electrochemical corrosion caused by charging, discharging, and side reactions. Currently, for lithium cobalt oxide, ternary, and iron phosphate batteries, the main binder used is PVDF (Poly (vinylidene fluoride)), with NMP (N-Methyl-2-pyrrolidone) as the solvent. For graphite anodes, the primary binder is CMC + SBR (carboxymethyl cellulose + styrene-butadiene rubber), with water as the solvent. Of course, different types of batteries and battery systems require different types and performance levels of binders. Furthermore, with the development of battery technology, new binders and synthesis techniques continue to emerge, such as PDADMAC (Poly (diallyl dimethylammonium chloride)), styrene, and mixed solvents comprising methyl acrylate [101,102,103,104]. Research has also explored the synergistic antibacterial effects of cold nitrogen plasma and clove oil on E. coli O157:H7 biofilms on lettuce. In battery aging studies, similar approaches can be applied to explore synergistic effects between different diagnostic techniques or treatment methods, thereby improving the accuracy and comprehensiveness of battery aging diagnostics [105].

Using SEM, it is relatively simple to observe whether the binder decomposes. It is necessary to adjust the parameters of the SEM instrument, such as acceleration voltage, magnification, and probe current, to obtain clear images [106,107]. Due to the different materials, the decomposition mechanisms of various binders also vary. For example, PVDF undergoes chemical reactions with O2 in the air during preparation, forming K(HF2), among other products. By observing and analyzing the characteristic peaks in the XRD diffraction patterns, one can determine whether the binder has decomposed. If the binder decomposes or degrades, it results in a weakening or disappearance of peak shapes and intensities, or the appearance of new peaks. Comparing the experimental XRD diffraction patterns with known standard samples can help to assess the degree of binder decomposition [108].

4.2.7. Collective Fluid Corrosion

The current collector needs to carry the active materials of both positive- and negative-electrodes and can gather and output the current generated by these materials. However, in practical applications, different materials have different defects; for example, aluminum foil is prone to corrosion, making it commonly used as the material for positive-electrode current collectors. Copper, on the other hand, is resistant to corrosion but can oxidize at higher potentials, making it suitable as the material for negative-electrode current collectors. Corrosion generally occurs at the interface between the positive- and negative-electrode current collectors and the electrolyte, as lithium battery electrolytes typically contain corrosive substances such as fluorides and acidic materials [109,110]. Research has utilized a polyoxymethylene lauryl ether–salt biphasic system combined with high-performance liquid chromatography to separate, concentrate, and determine trace amounts of chloramphenicol in shrimp from different waters. In battery diagnostics, to detect impurities or harmful substances in batteries, reference can be made to their separation and detection techniques, allowing the analysis of pollutants or additives in the battery [111].

Observing whether the positive- and negative-electrode collectors have corroded or the degree of corrosion is relatively simple. If the corrosion is severe, it is easy to detect from macroscopic images that the collector has changed color or appears uneven on the surface. Specifically, SEM can be used to observe the corrosion of aluminum foil collectors; corroded collectors will show pits or holes, as well as oxides or corrosion products [112]. These voids or products will present different shapes and colors. At present, advanced collector materials, anti-corrosion coatings, and optimized battery design processes are the main approaches to deal with this situation [113].

Figure 8.

Example diagram of specific aging mechanism diagnosis. (a) Typical electrochemical impedance spectroscopy principle diagram (top) and equivalent circuit model for lithium-ion batteries (bottom). (b) SEM images of anode aging: (A) is a new battery, (C) is at 50% depth of discharge (DOD), (D) is using AP2 at 100% DOD at 55 °C (F) is at 50% DOD, (G) is using AP2 100% DOD at −20 °C, and (B,E,H) show anode conditions of new and old batteries at 55 °C and −20 °C, respectively. (c) In situ optical snapshot of lithium dendrite growth during plating. (d) Principle of differential voltage analysis, from top to bottom: terminal voltage during charge rate testing, first derivative of charging voltage, second derivative of charging voltage, individual anode potentials, schematic diagrams of solid and electrolyte potentials. (e) Raman spectra of original graphite electrode (top) and electrode cycling between 1 and 0.18 vs. Li/Li+ (bottom) [114]; (f) A is optical fluorescence image, and B and C are X-ray fluorescence (XRF) spectra of Mn and Ni element distribution [115]; (g) Study of microstructure of primary and secondary particles in NMC811 under waveguide X-ray imaging technology; uncharged original secondary particles (top) and aged secondary particles that were charged five times to 4.5 V before disassembly imaging and n discharged to 3 V (bottom); (h) Neutron diffraction patterns during charge–discharge cycles; (i) Differential thermal analysis spectra of the electrolyte for cycling and storage batteries at 40 °C from March to December (A), (B) the storage batteries at 55 °C from March to December, SEM images of new batteries and those under different charge cut-off voltages (C) [116].

5. Diagnostic Process and Development Trend

When receiving samples of aged batteries, inspectors do not know in advance the proportion of aging mechanisms. They usually first determine whether the current aging state is early or midway/late through basic charge–discharge curves, then diagnose the specific mechanism that needs to be diagnosed. In this section, we summarize a routine process for diagnosing the dominant aging mechanisms in batteries and offer insights into future diagnostic trends.

5.1. Routine Diagnostic Process

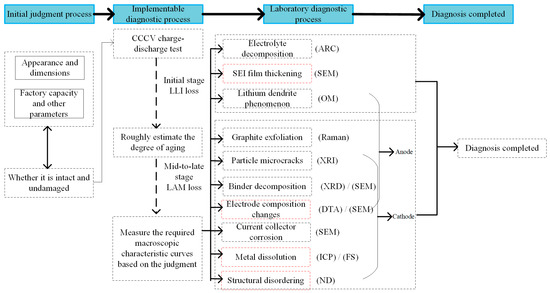

The specific diagnostic methods for various aging mechanisms of batteries have been detailed in the previous section. For specific aging battery samples, in-depth research can be conducted by combining implementable and microdiagnostic techniques. This section will provide a detailed explanation of how to conduct an aging diagnosis on a complete battery aging sample, as shown in Figure 9.

Figure 9.

Specific aging mechanism diagnostic flow chart.

First, by reviewing the factory parameters of the battery, information such as voltage, internal resistance, mass, and size can be obtained. Comparing these with the original dimensions can help to determine if deformation has occurred and the extent of this deformation, which can provide an initial assessment of aging. If the battery deforms, the likelihood of safety issues is higher, often due to improper usage conditions like overcharging or deep cycling. According to the basic working principles of batteries discussed in Section 1, overcharging can cause lithium-ions to penetrate through the separator into the graphite anode in large quantities or even entirely, leading to a collapse of the grid structure in the positive-electrode material. This not only damages the original structure but also increases the risk of lithium plating on the anode, which accelerates the growth of lithium dendrites. In severe cases, this can puncture the separator, cause internal short circuits, and lead to electrolyte decomposition and gas production, resulting in battery swelling. Deep cycling has similar effects, causing changes in the volume of the SEI/CEI film covering the surface of the anode material and creating cracks that allow reactions between the inner layer and the electrolyte, ultimately leading to SEI/CEI film failure and safety issues with the battery. If no deformation occurs, this indicates normal aging.

Next, it is necessary to conduct routine charge–discharge tests on aged samples, properly connect the battery’s charge–discharge equipment, and select appropriate charge–discharge values and rates based on previously queried factory parameters. The test will record parameters such as current, voltage, and temperature throughout the complete charging process of the battery. These parameters are typically collected over time. After obtaining these parameters, data processing is performed to derive information about the capacity state. In experiments, the discharge process is generally used to calculate the battery’s capacity state. The calculated capacity state is then compared with the factory parameters to roughly determine whether the current sample is in the early or mid–late stages of aging. The aging mechanisms differ significantly between different aging periods. In the early stage, capacity loss is mainly caused by LLI, while in the mid–late stages, it is due to LAM.

After determining the aging process, it is necessary to select appropriate testing methods based on requirements to obtain the required macroscopic characteristic curves, such as using impedance spectra to determine if the SEI/CEI film has thickened, or differential voltage to detect lithium dendrite formation. Since the trend of the curves and various characteristics are influenced by multiple mechanisms, it is necessary to combine laboratory diagnostic techniques to determine the proportion of aging caused by specific mechanisms. For example, it is necessary to use an accelerated calorimeter to study whether the electrolyte has undergone compositional changes or decomposition and use a scanning electron microscope to observe the thickness of the SEI/CEI coating on the outer layer of the anode graphite. It is necessary choose the appropriate equipment based on the mechanism to be observed, disassemble the sample before observation, and polish it according to the requirements of the observation equipment to prepare it for observation. It is necessary place the processed sample on the sample holder for observation to obtain results, which requires operators to have sufficient safety awareness. If conditions permit, new battery samples can be tested using the same procedure to compare the observed results and determine whether the aging mechanism measured is the primary cause of aging.

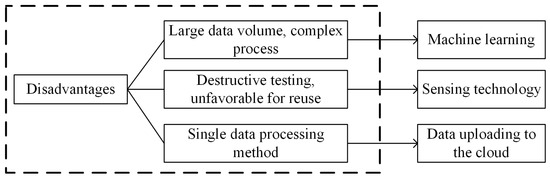

5.2. Trend in Development