Research on the Heavy Gas Setting Method of Oil-Immersed Transformer Based on Oil Flow Acceleration Characteristics

Abstract

1. Introduction

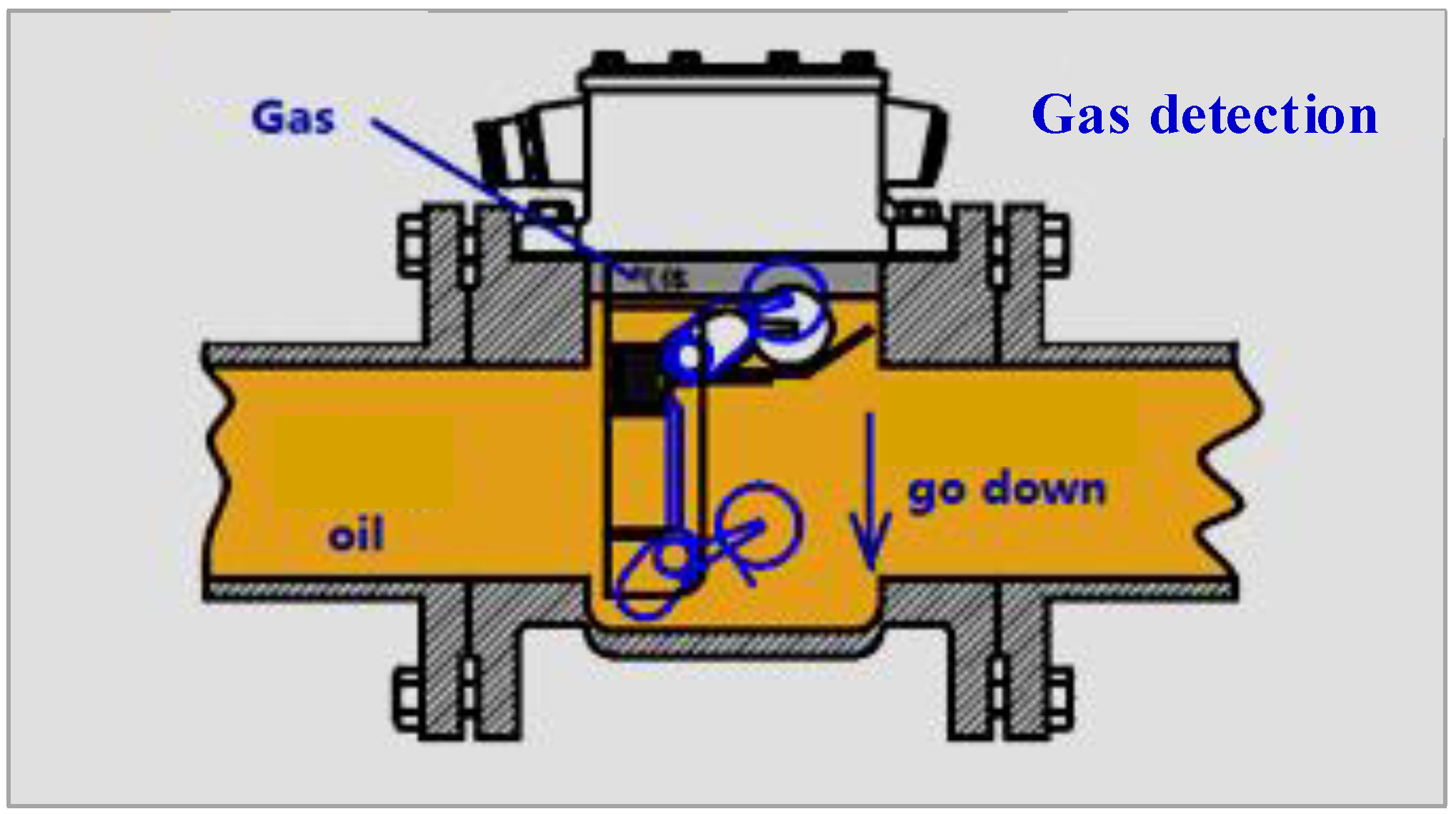

2. Structural and Mechanical Analysis of Gas Relay

2.1. Structural Analysis

2.2. Mechanical Analysis

3. Experimental Analysis of Oil Flow Acceleration Characteristics During Heavy Gas Actuation of the Gas Relay

3.1. Heavy Gas Actuation Test Bench for Gas Relays

3.2. Analysis of Oil Flow Acceleration Test During Heavy Gas Action

4. Simulation Analysis of Oil Flow Acceleration Characteristics During Heavy Gas Alarm Actuation of Gas Relay

4.1. Simulation Model

4.2. Simulation Analysis of Heavy Gas Alarm Actuation Characteristics

- Before the baffle opens, peak flow velocity zones are concentrated in the gaps between the baffle and the frame, as well as near the oil bypass holes, due to the presence of those holes on the baffle. As the baffle opens, the resistance torque of the baffle drops sharply. The baffle and the lower floating ball have a relatively large angular velocity, so the peak flow velocity zone is concentrated near the baffle and the lower floating ball.

- Before the baffle opening, high-pressure regions are concentrated at the front of the baffle and the inlet zone. After the baffle opening, the pressure differential across the baffle is significantly reduced. Pressure peaks relocate below the lower floating ball. This redistribution occurs because the lower floating ball and baffle attain high angular velocity during rotation. The rigid-body motion exerts substantial pressure on the oil flow, amplifying localized pressure effects near the floating ball.

- The oil holes on the baffle serve a dual role: Under normal operating conditions, they provide additional flow paths for the oil. During fault conditions, they reduce pressure distribution on the baffle surface and mitigate the pressure differential across the baffle, and enhance relay stability by balancing transient forces. By redistributing flow and pressure during faults (e.g., sudden oil surges), the oil holes counteract the high angular velocity of the baffle and floating ball, preventing excessive stress concentrations that could trigger false alarms or mechanical failures.

4.3. Result Analysis

5. Conclusions

- Experimental results indicate that in the gas relay under transient oil flow impacts, the oil flow velocity corresponding to heavy gas alarm actuation initiation varied significantly with increasing excitation pressure, showing fluctuations of up to 16%. The oil flow acceleration exhibited a significant positive correlation with excitation pressure, with stark contrasts between actuated and non-actuated states.

- Simulated velocity and pressure cloud diagrams reveal that the oil bypass holes at the baffle of the gas relay provide additional flow paths for oil under normal (non-fault) conditions. Mitigate pressure buildup on the baffle surface and reduce the pressure differential across the baffle during faults, thereby enhancing gas relay stability.

- When the excitation pressure reaches the critical threshold, the acceleration threshold can accurately trigger the heavy gas alarm, serving as the actuation setting value for the gas relay. Compared to the velocity-based heavy gas alarm actuation method, the acceleration-based method significantly reduces alarm times. For example, at 0.109 MPa excitation pressure, the acceleration-based alarm is 0.314 s. The velocity-based alarm is 0.947 s. This demonstrates a threefold improvement in response efficiency.

- Oil flow acceleration, serving as the characteristic parameter for transient oil flow impacts, offers the advantages of rapid response and high precision, effectively enhancing the actuation reliability of the gas relay.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Serafino, C.; Cavallini, A. Transformer Diagnostics and Maintenance: Practical Indications Derived from A Large Transmission System. IEEE Electr. Insul. Mag. 2024, 41, 15–23. [Google Scholar] [CrossRef]

- Lin, L.; Qiang, C.D.; Zhang, H.; Chen, Q.G.; An, Z.; Xu, W.J. Review of Studies on the Hot Spot Temperature of Oil-Immersed Transformers. Energies 2024, 18, 74. [Google Scholar] [CrossRef]

- Zhou, H.L.; Lu, L.; Wang, G.M.; Su, Z.T. A New Validity Detection Method of Online Status Monitoring Data for Power Transformer. IEEE Access. 2024, 12, 16095–16104. [Google Scholar] [CrossRef]

- Aciu, A.M.; Enache, S.; Nițu, M.C. A Reviewed Turn at of Methods for Determining the Type of Fault in Power Transformers Based on Dissolved Gas Analysis. Energies 2024, 17, 2331. [Google Scholar] [CrossRef]

- An, S.Y. Analysis and Improvement of Malfunction of the Gas Relay. Transformer 2023, 60, 72–75. [Google Scholar]

- Li, Z. Analysis and Prevention of Several Mistakes in Transformer Heavy Gas Protection Measure. Northeast Electr. Power Technol. 2019, 40, 42–44. [Google Scholar]

- Cai, W.; Dong, J.B. Analysis of Causes of Misoperation of Transformer Gas Protection. Electr. Eng. 2021, 5, 86–88+91. [Google Scholar]

- Wang, Y.L.; Shen, L.; Li, H.; Ma, X.L.; Gong, Z.W.Y.; Cao, Z.G. Cause Analysis and Diagnosis Method Discussion of Transformer Heavy Gas Protection Action. Electrotech. Electric. 2021, 5, 27–31. [Google Scholar]

- Yan, C.; Xu, C.; Liu, H.; Guo, J.; Zhang, P.; Xu, Y.; Zhou, X.; Zhang, B. Research on Oil Pressure Rise and Fluctuation Due to Arcing Faults Inside Transformers. IEEE Trans. Power Deliv. 2023, 38, 1483–1492. [Google Scholar] [CrossRef]

- Tadokoro, T.; Kotari, M.; Ohtaka, T.; Iwata, M.; Amakawa, T. Pressure Rises due to Arc under Insulating Oil in Closed Vessel—Pressure Fluctuation of Depth Direction in Oil. Electr. Eng. Japan. 2018, 202, 43–53. [Google Scholar] [CrossRef]

- He, W.H.; Zhang, Z.L.; Yang, Y.; Gao, J.T.; Pei, X.C.; Deng, J.; Pan, Z.C.; Lv, J.Z.; Yao, H.L. Risk Assessment Study of Oil Flow Under Inrush Current on the Misoperation of Converter Transformer Gas Relay. Appl. Sci. 2025, 15, 2235. [Google Scholar] [CrossRef]

- Li, B.; Hao, Z.; Li, S.; Pan, S.; Xiong, J.; Zhang, B. Response Characteristics of The Buchholz Relay and Novel Non-electric-parameter Protection Methods. IEEE Trans. Power Deliv. 2023, 38, 4103–4113. [Google Scholar] [CrossRef]

- Pan, Z.C.; Liu, X.Z.; Ou, S.S.; Zhang, L.; Deng, J.; Huang, Z.K. Cause Analysis and Anti-vibration Performance Study of Gas Relay in Process of No-load Closing of Converter Transformer. Transformer 2023, 60, 55–60. [Google Scholar] [CrossRef]

- Zhou, D.; Li, Z.Y.; Sun, W.X.; Lin, C.Y.; Yang, X.; Hao, Z.G. Research on the Gas Protection Performance under External Short-circuit Faults. High Volt. Appar. 2019, 55, 120–127+134. [Google Scholar]

- Lins, I.X.; Lima Filho, H.J.; dos Santos, V.A.; Pereira, J.C.; Mak, J.; Vieira, C.W. Hydrodynamic Study of the Oil Flow in A Protective Relay Coupled to A Power Transformer: CFD Simulation and Experimental Validation. Eng. Fail. Anal. 2021, 128, 105599. [Google Scholar] [CrossRef]

- Li, S.N.; Han, D.D.; Zhou, X.; Zhang, S.Q.; Lan, H. Research on the Reverse Oil Flow Action of Buchholz Relay by CFD. Energy Res. Inf. 2020, 36, 222–227. [Google Scholar]

- Yan, C.G.; Xu, C.; Cao, P.; Gao, K.; Zhu, S.Y.; Wei, Y.Z.; Wu, J.Z.; Li, L.N. Research on Transient Characteristics of Power Transformer Gas Relay. Adv. Technol. Electr. Eng. Energy 2022, 41, 1–7. [Google Scholar]

- Ding, G.C.; Yang, H.T.; Li, B.Y.; Wu, X.; Hu, X.; Wu, J. Study on Operation Characteristics Test of Gas Relay with On-load Tap Changer. High Volt. Appar. 2023, 59, 156–161. [Google Scholar]

- Yan, D.; Ma, R.; Yang, H.; Liang, Y. Analysis Correlation Modeling of the Oil Flow of Transformer and Temperature. In Proceedings of the 5th International Conference on Electric Utility Deregulation and Restructuring and Power Technologies, Changsha, China, 26–29 November 2015. [Google Scholar]

- Jiang, D.Y.; Lü, P.R.; Wei, J.L.; Wan, S.T.; Ma, Z.Q. Study on Action Characteristics of Gas Relay under Transient Oil Flow Shock. Transformer 2021, 58, 57–61. [Google Scholar]

- Wan, S.T.; Wei, J.L.; Lü, P.R.; Jiang, D.Y.; Dou, L.J.; Ma, Z.Q. A method for Monitoring Operation Status of Oil-immersed Transformer Based on the Baffle Angle Characteristic of Gas Relay. Power Syst. Technol. 2021, 45, 417–423. [Google Scholar]

- Wan, S.T.; Zhang, Z.H.; Lü, P.R. Recognition Method for Transformer Heavy Gas Fault Degree Based on Gas Relay Baffle Operating Time Characteristic. Power Syst. Technol. 2022, 46, 1965–1972. [Google Scholar]

- Wan, S.T.; Zhang, Z.H.; Li, S.P. A New Method for Heavy Gas Alarm Based on the Rotational Angular Velocity of A New Type of Gas Relay Baffle. Electr. Power Syst. Prot. Control 2022, 50, 152–159. [Google Scholar]

- Wan, S.T.; Wei, J.L.; Lü, P.R.; Jiang, D.Y.; Dou, L.J.; Ma, Z.Q. Non-electric protection method for oil-immersed transformer based on Initial Angular Acceleration of Baffle Rotation of Gas Relay. High Volt. Eng. 2021, 45, 1003–6520. [Google Scholar]

- Xue, B.; Yi, W.S.; Li, Y.B.; Liu, C.X.; Tian, S.Y.; Ma, J.Y.; Zhang, T.B.; Wan, S.T. A Novel Anti-maloperation Gas Relay for Internal Fault Protection of Oil-immersed Transformers. Adv. Electr. Comput. Eng. 2025, 25, 21–28. [Google Scholar] [CrossRef]

- Liu, C.X.; Zhang, T.B.; Zhang, C.H.; Xu, B.; He, S.X.; Wan, S.T. Research on the Heavy Gas Action Characteristics of BF Type Double Float Ball Gas Relay Under Transient Oil Flow Impact. Energies 2025, 18, 945. [Google Scholar] [CrossRef]

| Excitation Pressure (MPa) | The Pressure Corresponding to Heavy Gas Action (kPa) | Oil Flow Velocity at Heavy Gas Alarm Actuation Initiation (m/s) | The Pressure Corresponding to the End of Heavy Gas Action (kPa) | Maximum Oil Flow Acceleration (m/s2) |

|---|---|---|---|---|

| 0.108 | - | - | - | 0.727 |

| 0.109 | 1.380 | 0.807 | −1.432 | 1.226 |

| 0.110 | 2.746 | 0.859 | −1.552 | 1.374 |

| 0.115 | 3.345 | 0.890 | −1.723 | 1.571 |

| 0.120 | 6.600 | 0.959 | −1.621 | 2.829 |

| 0.125 | 8.271 | 0.977 | −1.627 | 2.986 |

| 0.130 | 10.630 | 0.908 | 0.848 | 5.092 |

| 0.135 | 11.387 | 0.930 | −0.13 | 5.379 |

| 0.140 | 14.443 | 0.820 | 2.153 | 8.286 |

| Number of Grids | Heavy Gas Action Oil Flow Velocity (m/s) | Maximum Oil Flow Acceleration (m/s2) |

|---|---|---|

| 1,156,754 | 0.782 | 0.985 |

| 1,527,271 | 0.852 | 1.231 |

| 1,836,948 | 0.848 | 1.256 |

| 2,103,695 | 0.849 | 1.257 |

| 2,313,939 | 0.850 | 1.259 |

| Mesh Metric | Minimum Value | Maximum Value | Mean Value | Standard Deviation |

|---|---|---|---|---|

| Grid cell quality | 0.13536 | 0.99999 | 0.83489 | 0.00963 |

| Excitation Pressure (MPa) | Velocity Excitation Function |

|---|---|

| 0.108 | 0.01634 + 0.43069 t + 0.58513 t2 − 0.13706 t3 − 0.37002 t4 |

| 0.109 | 0.04993 + 0.44627 t + 2.77415 t2 − 3.83364 t3 + 1.42266 t4 |

| 0.110 | 0.03877 + 0.30228 t + 3.89745 t2 − 5.5609 t3 + 2.30505 t4 |

| 0.115 | 0.03738 + 0.43533 t + 4.02812 t2 − 5.69261 t3 + 2.29437 t4 |

| 0.120 | 0.0415 + 0.65216 t + 8.21292 t2 − 12.18082 t3 + 5.35491 t4 |

| 0.125 | 0.02616 + 0.45503 t + 11.86521 t2 − 21.41371 t3 + 11.04012 t4 |

| 0.130 | 0.04049 + 0.00423 t + 21.16775 t2 − 36.16894 t3 + 19.05476 t4 |

| 0.135 | 0.02057 + 0.33261 t + 20.90007 t2 − 34.11282 t3 + 16.01169 t4 |

| 0.140 | 0.04082 + 0.79846 t + 30.76397 t2 − 50.22432 t3 + 26.56221 t4 |

| Excitation Pressure (MPa) | Experimental Oil Flow Velocity at Heavy Gas Alarm Actuation (m/s) | Simulated Oil Flow Velocity at Heavy Gas Alarm Actuation (m/s) | Relative Error of Oil Flow Velocity at Heavy Gas Alarm Actuation | Maximum Oil Flow Acceleration in Experiments (m/s2) | Simulated Maximum Oil Flow Acceleration (m/s2) | Relative Error of Maximum Oil Flow Acceleration |

|---|---|---|---|---|---|---|

| 0.109 | 0.807 | 0.852 | 2.758% | 1.226 | 1.231 | 1.439% |

| 0.110 | 0.859 | 0.894 | 1.374 | 1.391 | ||

| 0.115 | 0.89 | 0.883 | 1.571 | 1.565 | ||

| 0.120 | 0.959 | 0.974 | 2.829 | 2.871 | ||

| 0.125 | 0.977 | 0.988 | 2.986 | 3.063 | ||

| 0.130 | 0.908 | 0.894 | 5.092 | 5.026 | ||

| 0.135 | 0.93 | 0.950 | 5.379 | 5.420 | ||

| 0.140 | 0.820 | 0.863 | 8.286 | 8.565 |

| Excitation Pressure (MPa) | Time Required from Excitation Pressure Application to Baffle Rotation Initiation (s) | Oil Flow Velocity at Baffle Rotation Initiation (m/s) | Maximum Oil Flow Acceleration (m/s2) | Oil Flow Velocity Alarm Time t1 (s) | Oil Flow Acceleration Alarm Time t2 (s) |

|---|---|---|---|---|---|

| 0.108 | - | - | 0.740 | - | - |

| 0.109 | 0.947 | 0.849 | 1.231 | 0.947 | 0.314 |

| 0.110 | 0.827 | 0.887 | 1.391 | 0.763 | 0.185 |

| 0.115 | 0.652 | 0.870 | 1.565 | 0.631 | 0.135 |

| 0.120 | 0.388 | 0.941 | 2.871 | 0.356 | 0.039 |

| 0.125 | 0.376 | 0.957 | 3.063 | 0.337 | 0.037 |

| 0.130 | 0.242 | 0.834 | 5.026 | 0.246 | 0.032 |

| 0.135 | 0.240 | 0.897 | 5.420 | 0.234 | 0.023 |

| 0.140 | 0.161 | 0.775 | 8.565 | 0.172 | 0.008 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Tong, Z.; Mao, J.; Wang, J.; He, S.; Zhang, T.; Wan, S. Research on the Heavy Gas Setting Method of Oil-Immersed Transformer Based on Oil Flow Acceleration Characteristics. Energies 2025, 18, 3859. https://doi.org/10.3390/en18143859

Sun Y, Tong Z, Mao J, Wang J, He S, Zhang T, Wan S. Research on the Heavy Gas Setting Method of Oil-Immersed Transformer Based on Oil Flow Acceleration Characteristics. Energies. 2025; 18(14):3859. https://doi.org/10.3390/en18143859

Chicago/Turabian StyleSun, Yuangang, Zhixiang Tong, Jian Mao, Junchao Wang, Shixian He, Tengbo Zhang, and Shuting Wan. 2025. "Research on the Heavy Gas Setting Method of Oil-Immersed Transformer Based on Oil Flow Acceleration Characteristics" Energies 18, no. 14: 3859. https://doi.org/10.3390/en18143859

APA StyleSun, Y., Tong, Z., Mao, J., Wang, J., He, S., Zhang, T., & Wan, S. (2025). Research on the Heavy Gas Setting Method of Oil-Immersed Transformer Based on Oil Flow Acceleration Characteristics. Energies, 18(14), 3859. https://doi.org/10.3390/en18143859