State of Health Prediction for Lithium-Ion Batteries Based on Gated Temporal Network Assisted by Improved Grasshopper Optimization

Abstract

1. Introduction

- (1)

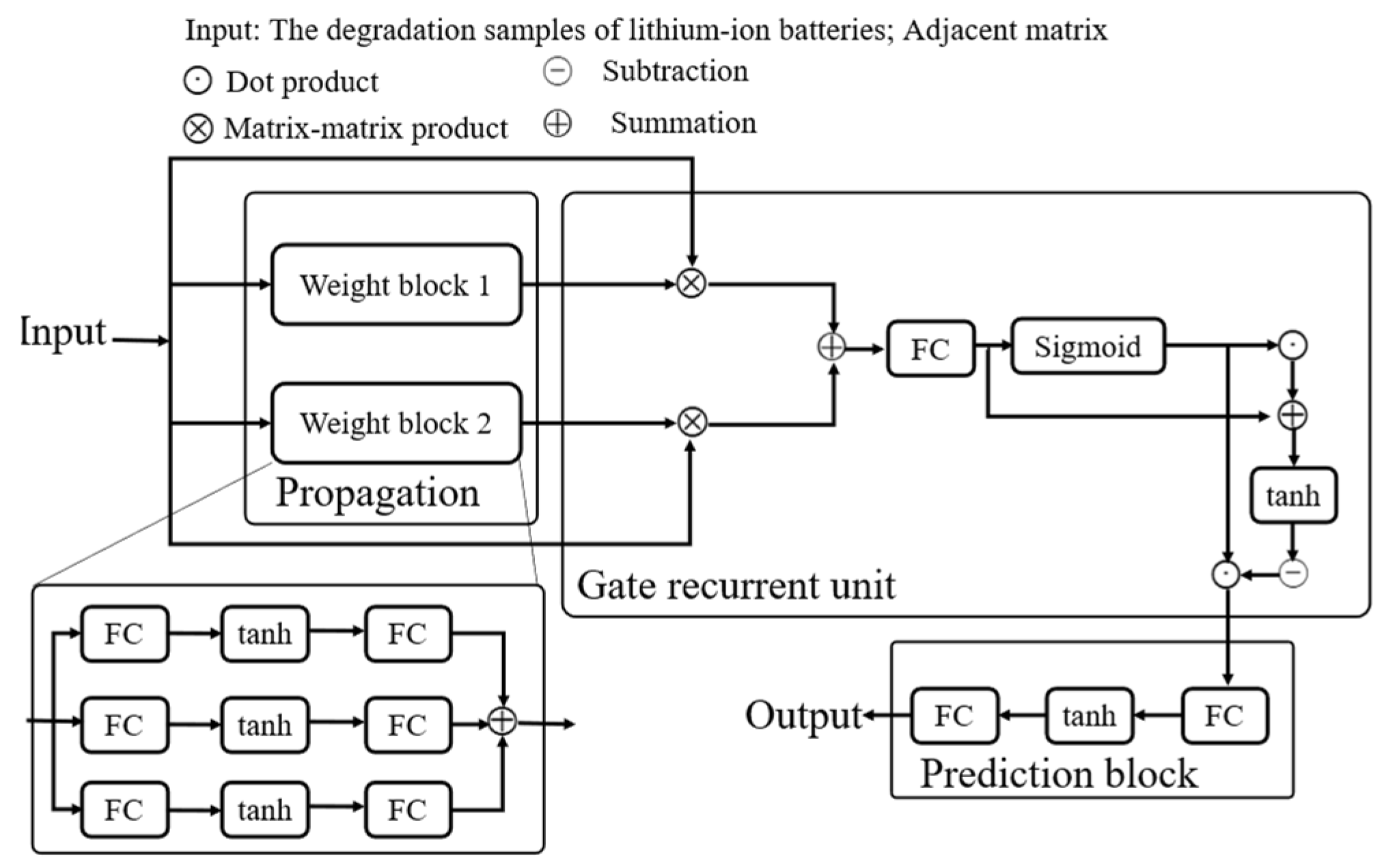

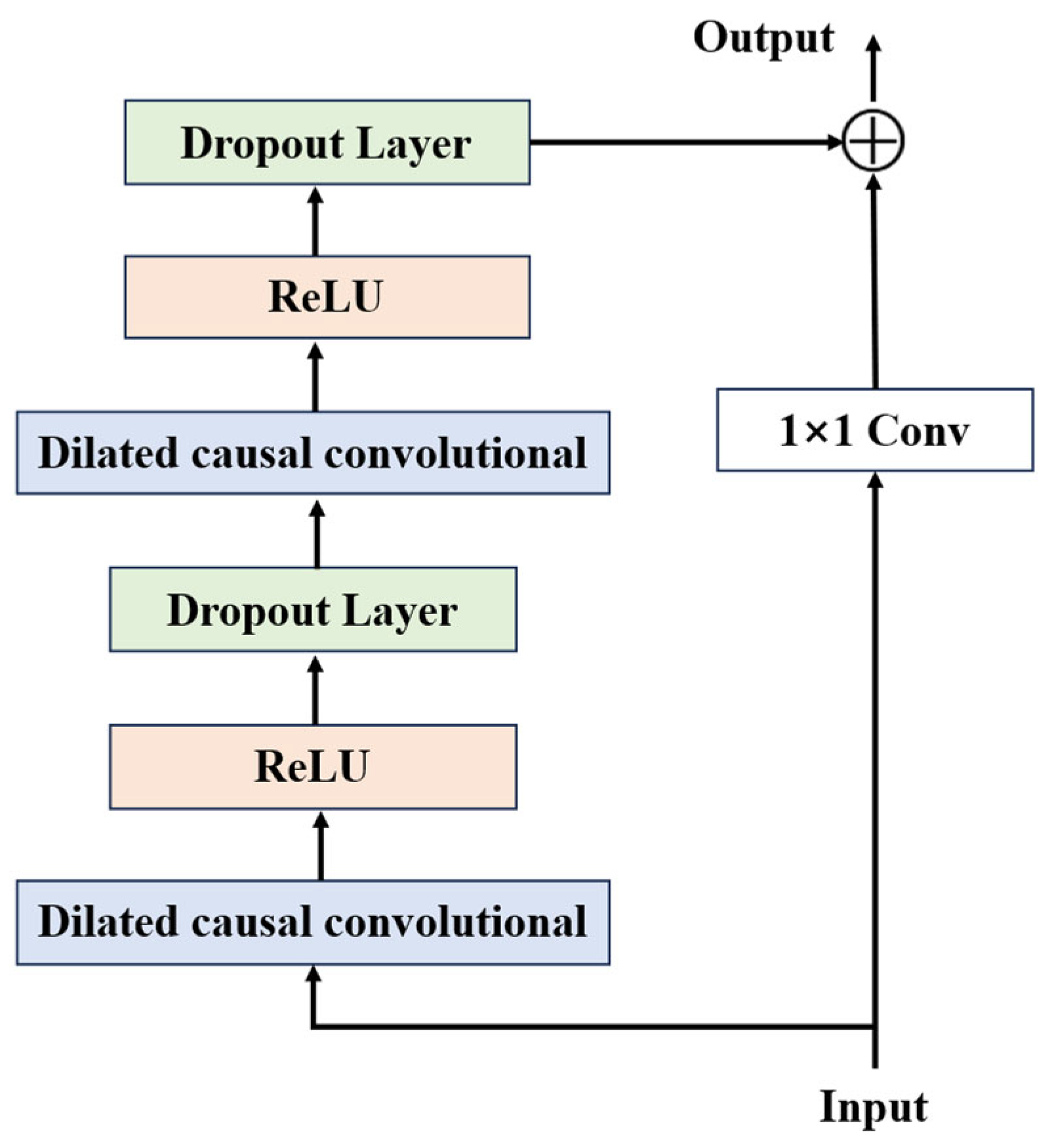

- A graph structure is constructed to represent the degradation information of lithium-ion batteries, enabling extraction of the interdependence among parameters such as voltage and current in non-Euclidean space using a GGNN. Based on this, a TCN is used to obtain the temporal dependence of lithium-ion batteries during the degradation process in the Euclidean space, avoiding the manual feature engineering.

- (2)

- An improved grasshopper optimization algorithm (IGOA) is developed to achieve the hyperparameter optimization of the GGNN-TCN, in which an adaptive attenuation function is proposed to alleviate problems such as poor convergence and stagnation during the searching process.

- (3)

- A SOH prediction method is proposed based on the GGNN-TCN and the IGOA for complex degradation data of lithium-ion batteries. The experiments on the show that it has better predictive ability compared to traditional methods.

2. Preliminaries

2.1. Gated Graph Convolution Network

2.2. Temporal Convolutional Network

2.3. Grasshopper Optimization Algorithm

3. Proposed Method

3.1. Adjacency Matrix for GGNN

3.2. Improved Grasshopper Optimization Algorithm

3.3. SOH Estimation Method for Lithium-Ion Batteries Based on IGOA-GGNN-TCN

4. Results and Discussion

4.1. Dataset Description

4.2. Evaluation Metrics

4.3. Comparison Experiments Using Different Optimization Algorithms

4.4. Comparative Experiments of Different Deep Learning Methods

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feng, X.; Zhang, Y.; Xiong, R.; Wang, C. Comprehensive performance comparison among different types of features in data-driven battery state of health estimation. Appl. Energy 2024, 369, 123555. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, Y.; He, Y.; Lyu, Z.; Cai, Y.; Zhang, S. SOC Estimation of Lithium-Ion Battery Pack Based on Discharge Stage Division and Fusion Modeling. IEEE Trans. Instrum. Meas. 2025, 74, 2515914. [Google Scholar] [CrossRef]

- Li, C.; Yang, L.; Li, Q.; Zhang, Q.; Zhou, Z.; Meng, Y.; Zhao, X.; Wang, L.; Zhang, S.; Li, Y.; et al. SOH estimation method for lithium-ion batteries based on an improved equivalent circuit model via electrochemical impedance spectroscopy. J. Energy Storage 2024, 86, 111167. [Google Scholar] [CrossRef]

- Long, Z.; Yuan, L.; Yin, A.; Zhou, J.; Song, L. A neural-driven stochastic degradation model for state-of-health estimation of lithium-ion battery. J. Energy Storage 2024, 79, 110248. [Google Scholar] [CrossRef]

- Li, X.; Yuan, C.; Wang, Z.; He, J.; Yu, S. Lithium battery state-of-health estimation and remaining useful lifetime prediction based on non-parametric aging model and particle filter algorithm. Etransportation 2022, 11, 100156. [Google Scholar] [CrossRef]

- Bracale, A.; De Falco, P.; Di Noia, L.P. Probabilistic state of health and remaining useful life prediction for Li-ion batteries. IEEE Trans. Ind. Appl. 2022, 59, 578–590. [Google Scholar] [CrossRef]

- Zhou, J.; Qin, Y.; Luo, J.; Zhu, T. Remaining useful life prediction by distribution contact ratio health indicator and consolidated memory GRU. IEEE Trans. Ind. Inform. 2022, 19, 8472–8483. [Google Scholar] [CrossRef]

- Wu, T.; Huang, Y.; Xu, Y.; Jiang, J.; Liu, S.; Li, Z. SOH prediction for lithium-ion battery based on improved support vector regression. Int. J. Green Energy 2023, 20, 227–236. [Google Scholar] [CrossRef]

- Yang, N.; Song, Z.; Hofmann, H.; Sun, J. Robust State of Health estimation of lithium-ion batteries using convolutional neural network and random forest. J. Energy Storage 2022, 48, 103857. [Google Scholar] [CrossRef]

- Jia, J.; Liang, J.; Shi, Y.; Wen, J.; Pang, X.; Zeng, J. SOH and RUL prediction of lithium-ion batteries based on Gaussian process regression with indirect health indicators. Energies 2020, 13, 375. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, Z.; Gao, J.; Chen, H. A novel method for remaining useful life of solid-state lithium-ion battery based on improved CNN and health indicators derivation. Mech. Syst. Signal Process. 2024, 220, 111646. [Google Scholar] [CrossRef]

- Lee, G.; Kwon, D.; Lee, C. A convolutional neural network model for SOH estimation of Li-ion batteries with physical interpretability. Mech. Syst. Signal Process. 2023, 188, 110004. [Google Scholar] [CrossRef]

- Zhang, C.; Luo, L.; Yang, Z.; Zhao, S.; He, Y.; Wang, X.; Wang, H. Battery SOH estimation method based on gradual decreasing current, double correlation analysis and GRU. Green Energy Intell. Transp. 2023, 2, 100108. [Google Scholar] [CrossRef]

- Chen, Y.; Duan, W.; Huang, X.; Wang, S. Multi-output fusion SOC and SOE estimation algorithm based on deep network migration. Energy 2024, 308, 133032. [Google Scholar] [CrossRef]

- Sun, Y.; Xiong, R.; Wang, C.; Tian, J.; Li, H. Deep neural network based battery impedance spectrum prediction using only impedance at characteristic frequencies. J. Power Sources 2023, 580, 233414. [Google Scholar] [CrossRef]

- Liu, H.; Deng, Z.; Che, Y.; Xu, L.; Wang, B.; Wang, Z.; Xie, Y.; Hu, X. Big field data-driven battery pack health estimation for electric vehicles: A deep-fusion transfer learning approach. Mech. Syst. Signal Process. 2024, 218, 111585. [Google Scholar] [CrossRef]

- Ma, Y.; Shan, C.; Gao, J.; Chen, H. A novel method for state of health estimation of lithium-ion batteries based on improved LSTM and health indicators extraction. Energy 2022, 251, 123973. [Google Scholar] [CrossRef]

- Liu, S.; Chen, Z.; Yuan, L.; Xu, Z.; Jin, L.; Zhang, C. State of health estimation of lithium-ion batteries based on multi-feature extraction and temporal convolutional network. J. Energy Storage 2024, 75, 109658. [Google Scholar] [CrossRef]

- Cheng, K.; Zhang, K.; Wang, Y.; Yang, C.; Li, J.; Wang, Y. Research on gas turbine health assessment method based on physical prior knowledge and spatial-temporal graph neural network. Appl. Energy 2024, 367, 123419. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, F.; Xu, Q.; Wang, Y.; Yan, H.; Xie, M. Capacity estimation of lithium-ion batteries based on data aggregation and feature fusion via graph neural network. Appl. Energy 2023, 336, 120808. [Google Scholar] [CrossRef]

- Yeh, W.C.; Lin, Y.P.; Liang, Y.C.; Lai, C.; Huang, C. Simplified swarm optimization for hyperparameters of convolutional neural networks. Comput. Ind. Eng. 2023, 177, 109076. [Google Scholar] [CrossRef]

- Ren, J.; Wang, Z.; Pang, Y.; Yuan, Y. Genetic algorithm-assisted an improved AdaBoost double-layer for oil temperature prediction of TBM. Adv. Eng. Inform. 2022, 52, 101563. [Google Scholar] [CrossRef]

- Yuan, Y.; Yang, Q.; Ren, J.; Fan, J.; Shen, Q.; Wang, X.; Zhao, Y. Learning-imitation strategy-assisted alpine skiing optimization for the boom of offshore drilling platform. Ocean. Eng. 2023, 278, 114317. [Google Scholar] [CrossRef]

- Yuan, Y.; Yang, Q.; Ren, J.; Mu, X.; Wang, Z.; Shen, Q.; Zhao, W. Attack-defense strategy assisted osprey optimization algorithm for PEMFC parameters identification. Renew. Energy 2024, 225, 120211. [Google Scholar] [CrossRef]

- Duan, W.; Song, S.; Xiao, F.; Chen, Y.; Peng, S.; Song, C. Battery SOH estimation and RUL prediction framework based on variable forgetting factor online sequential extreme learning machine and particle filter. J. Energy Storage 2023, 65, 107322. [Google Scholar] [CrossRef]

- Yuan, Y.; Shen, Q.; Xi, W.; Wang, S.; Ren, J.; Yu, J.; Yang, Q. Multidisciplinary design optimization of dynamic positioning system for semi-submersible platform. Ocean. Eng. 2023, 285, 115426. [Google Scholar] [CrossRef]

- Meraihi, Y.; Gabis, A.B.; Mirjalili, S.; Ramdane-Cherif, A. Grasshopper optimization algorithm: Theory, variants, and applications. IEEE Access 2021, 9, 50001–50024. [Google Scholar] [CrossRef]

- Hichem, H.; Elkamel, M.; Rafik, M.; Mesaaoud, M.T.; Ouahiba, C. A new binary grasshopper optimization algorithm for feature selection problem. J. King Saud Univ.-Comput. Inf. Sci. 2022, 34, 316–328. [Google Scholar] [CrossRef]

- Tian, Z.; Li, X.; Chen, Z.; Zheng, Y.; Fan, H.; Li, Z.; Li, C.; Du, S. Interactive prostate MR image segmentation based on ConvLSTMs and GGNN. Neurocomputing 2021, 438, 84–93. [Google Scholar] [CrossRef]

- Qin, P.; Hu, H.; Yang, Z. The improved grasshopper optimization algorithm and its applications. Sci. Rep. 2021, 11, 23733. [Google Scholar] [CrossRef] [PubMed]

- Liang, P.; Li, Y.; Wang, B.; Yuan, X.; Zhang, L. Remaining useful life prediction via a deep adaptive transformer framework enhanced by graph attention network. Int. J. Fatigue 2023, 174, 107722. [Google Scholar] [CrossRef]

- Birkl, C.R. Diagnosis and Prognosis of Degradation in Lithium-Ion Batteries. Ph.D. Thesis, University of Oxford, Oxford, UK, 2017. [Google Scholar]

- Tian, J.; Xiong, R.; Shen, W. State-of-health estimation based on differential temperature for lithium ion batteries. IEEE Trans. Power Electron. 2020, 35, 10363–10373. [Google Scholar] [CrossRef]

- Trojovský, P.; Dehghani, M. Subtraction-average-based optimizer: A new swarm-inspired metaheuristic algorithm for solving optimization problems. Biomimetics 2023, 8, 149. [Google Scholar] [CrossRef] [PubMed]

- Cheng, M.Y.; Prayogo, D. Symbiotic organisms search: A new metaheuristic optimization algorithm. Comput. Struct. 2014, 139, 98–112. [Google Scholar] [CrossRef]

- Ayyarao, T.S.L.V.; Ramakrishna, N.S.S.; Elavarasan, R.M.; Polumahanthi, N.; Rambabu, M.; Saini, G. War strategy optimization algorithm: A new effective metaheuristic algorithm for global optimization. IEEE Access 2022, 10, 25073–25105. [Google Scholar] [CrossRef]

- Meng, X.; Sun, C.; Mei, J.; Tang, X.; Hasanien, H.M.; Jiang, J.; Fan, F.; Song, K. Fuel cell life prediction considering the recovery phenomenon of reversible voltage loss. J. Power Sources 2025, 625, 235634. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, Y.; Gao, J.; Chen, H. Remaining useful life prediction for solid-state lithium batteries based on spatial–temporal relations and neuronal ODE-assisted KAN. Reliab. Eng. Syst. Saf. 2025, 260, 111003. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, Y.; Gao, J.; Chen, H. Cured memory RUL prediction of solid-state batteries combined progressive-topologia fusion health indicators. IEEE Trans. Ind. Inform. 2025, 21, 4051–4060. [Google Scholar] [CrossRef]

- Zheng, L.; Zhang, S.; Li, Y.; Liu, Y.; Ge, Q.; Gu, L.; Xie, Y.; Wang, X.; Ma, Y.; Liu, J.; et al. MTGNN: A drug–target–disease triplet association prediction model based on multimodal heterogeneous graph neural networks and direction-aware metapaths. J. Chem. Inf. Model. 2025, 65, 5921–5933. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Hu, Y.; Liu, S.; Yin, J.; Fan, K.; Yi, L. An AGCRN Algorithm for pressure prediction in an Ultra-long mining face in a medium–thick coal Seam in the Northern Shaanxi Area, China. Appl. Sci. 2023, 13, 11369. [Google Scholar] [CrossRef]

- Han, H.; Zhu, R.; Liu, J.X.; Dai, L.Y. Predicting miRNA-disease associations via layer attention graph convolutional network model. BMC Med. Inform. Decis. Mak. 2022, 22, 69. [Google Scholar] [CrossRef] [PubMed]

| Methods | R2 | RMSE | MAPE | Time (h) |

|---|---|---|---|---|

| IGOA-GGNN-TCN | 0.9965 | 0.0027 | 0.0037 | 5.86 h |

| GOA-GGNN-TCN | 0.9840 | 0.0059 | 0.0069 | 6.74 h |

| SABO-GGNN-TCN | 0.9852 | 0.0057 | 0.0079 | 7.51 h |

| SOS-GGNN-TCN | 0.9667 | 0.0086 | 0.0103 | 7.89 h |

| Methods | R2 | RMSE | MAPE |

|---|---|---|---|

| IGOA-GGNN-TCN | 0.9965 | 0.0027 | 0.0037 |

| TCN | 0.9875 | 0.0052 | 0.0069 |

| GGNN | 0.9787 | 0.0069 | 0.0087 |

| Methods | R2 | RMSE | MAPE |

|---|---|---|---|

| IGOA-GGNN-TCN | 0.9965 | 0.0027 | 0.0037 |

| sCNN | 0.9635 | 0.0091 | 0.0106 |

| GRU | 0.9792 | 0.0068 | 0.0075 |

| LSTM | 0.9807 | 0.0066 | 0.0085 |

| lightLA | 0.9791 | 0.0068 | 0.0091 |

| MTGNN | 0.9815 | 0.0064 | 0.0068 |

| AGCRN | 0.9738 | 0.0076 | 0.0093 |

| LAGCN | 0.9835 | 0.0061 | 0.0051 |

| CMGRU | 0.9889 | 0.0049 | 0.0074 |

| Methods | IGOA-GGNN-TCN | sCNN | GRU | LSTM | lightLA | MTGNN | AGCRN | LAGCN | CMGRU |

|---|---|---|---|---|---|---|---|---|---|

| Training time (s) | 132.3445 | 104.0792 | 146.3712 | 153.2817 | 317.9561 | 141.5486 | 124.6817 | 135.8773 | 170.4817 |

| Testing time (s) | 0.02676 | 0.02201 | 0.02357 | 0.02618 | 0.04923 | 0.02596 | 0.02131 | 0.02816 | 0.02983 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, X.; Peng, S.; Mo, M. State of Health Prediction for Lithium-Ion Batteries Based on Gated Temporal Network Assisted by Improved Grasshopper Optimization. Energies 2025, 18, 3856. https://doi.org/10.3390/en18143856

Wei X, Peng S, Mo M. State of Health Prediction for Lithium-Ion Batteries Based on Gated Temporal Network Assisted by Improved Grasshopper Optimization. Energies. 2025; 18(14):3856. https://doi.org/10.3390/en18143856

Chicago/Turabian StyleWei, Xiankun, Silun Peng, and Mingli Mo. 2025. "State of Health Prediction for Lithium-Ion Batteries Based on Gated Temporal Network Assisted by Improved Grasshopper Optimization" Energies 18, no. 14: 3856. https://doi.org/10.3390/en18143856

APA StyleWei, X., Peng, S., & Mo, M. (2025). State of Health Prediction for Lithium-Ion Batteries Based on Gated Temporal Network Assisted by Improved Grasshopper Optimization. Energies, 18(14), 3856. https://doi.org/10.3390/en18143856