X-in-the-Loop Methodology for Proton Exchange Membrane Fuel Cell Systems Design: Review of Advances and Challenges

Abstract

1. Introduction

- FCS efficiency;

- The system’s ability to operate in a degraded mode;

- Optimal energy and power management of the FCS;

- FCS health prognosis and management.

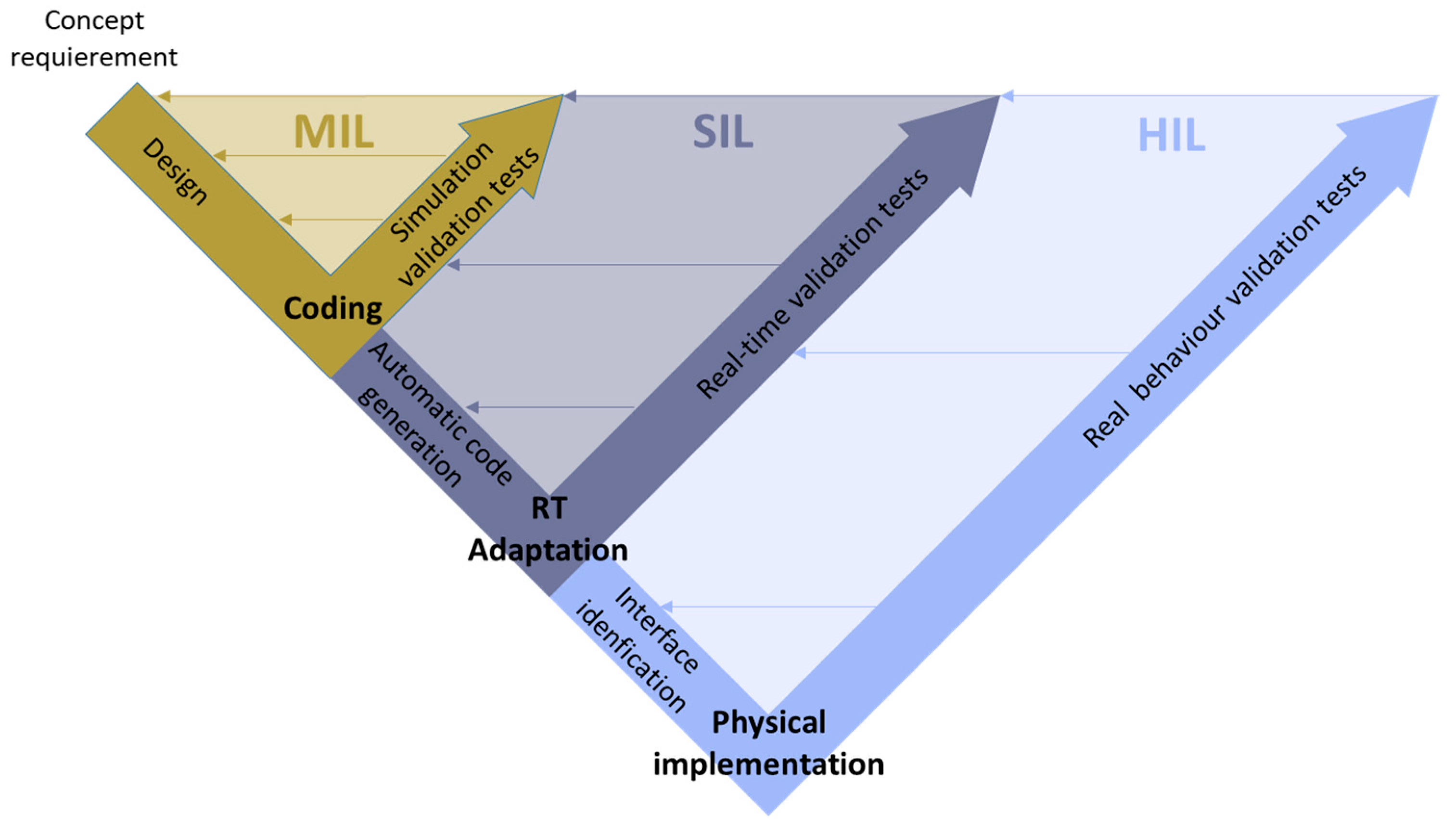

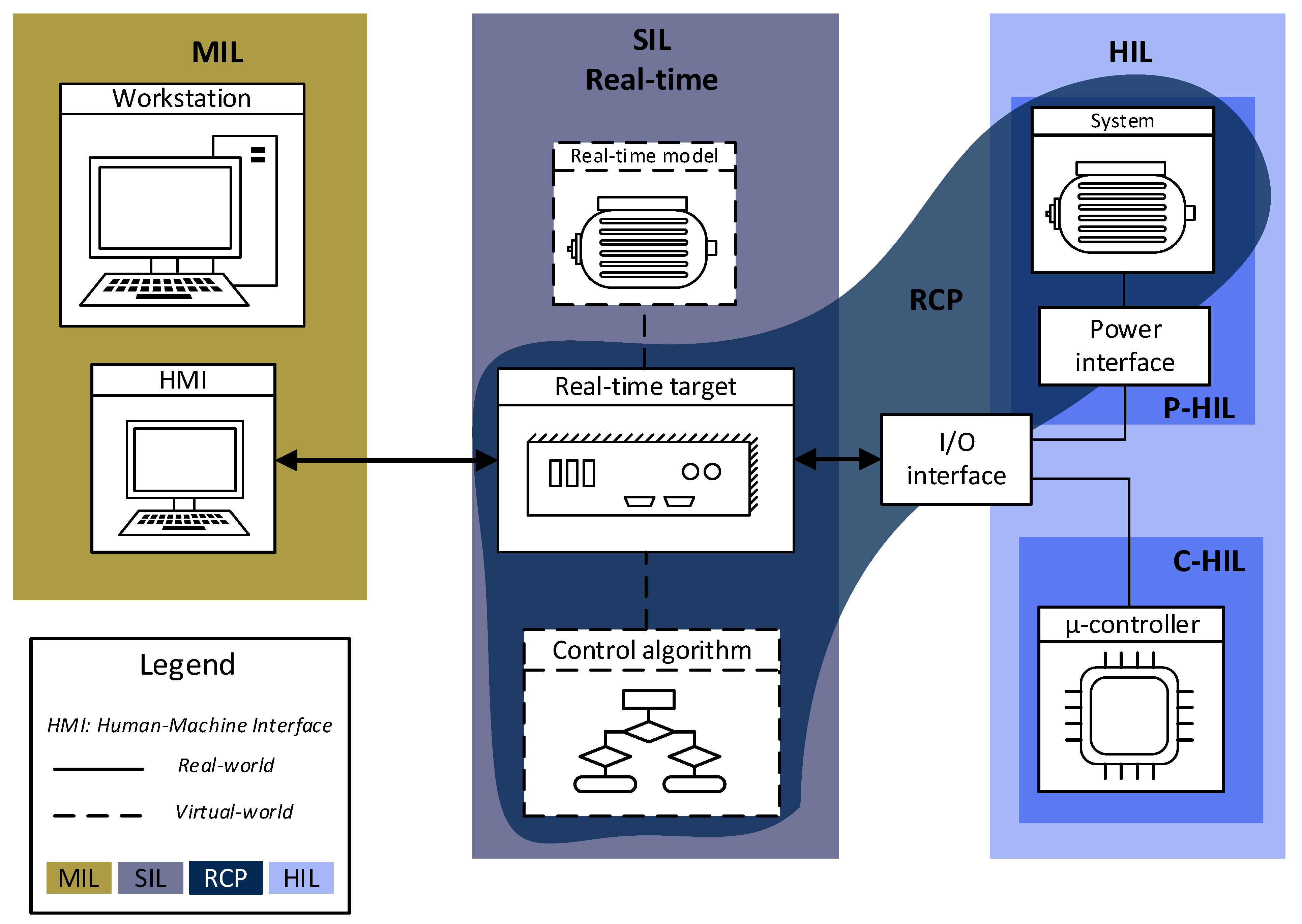

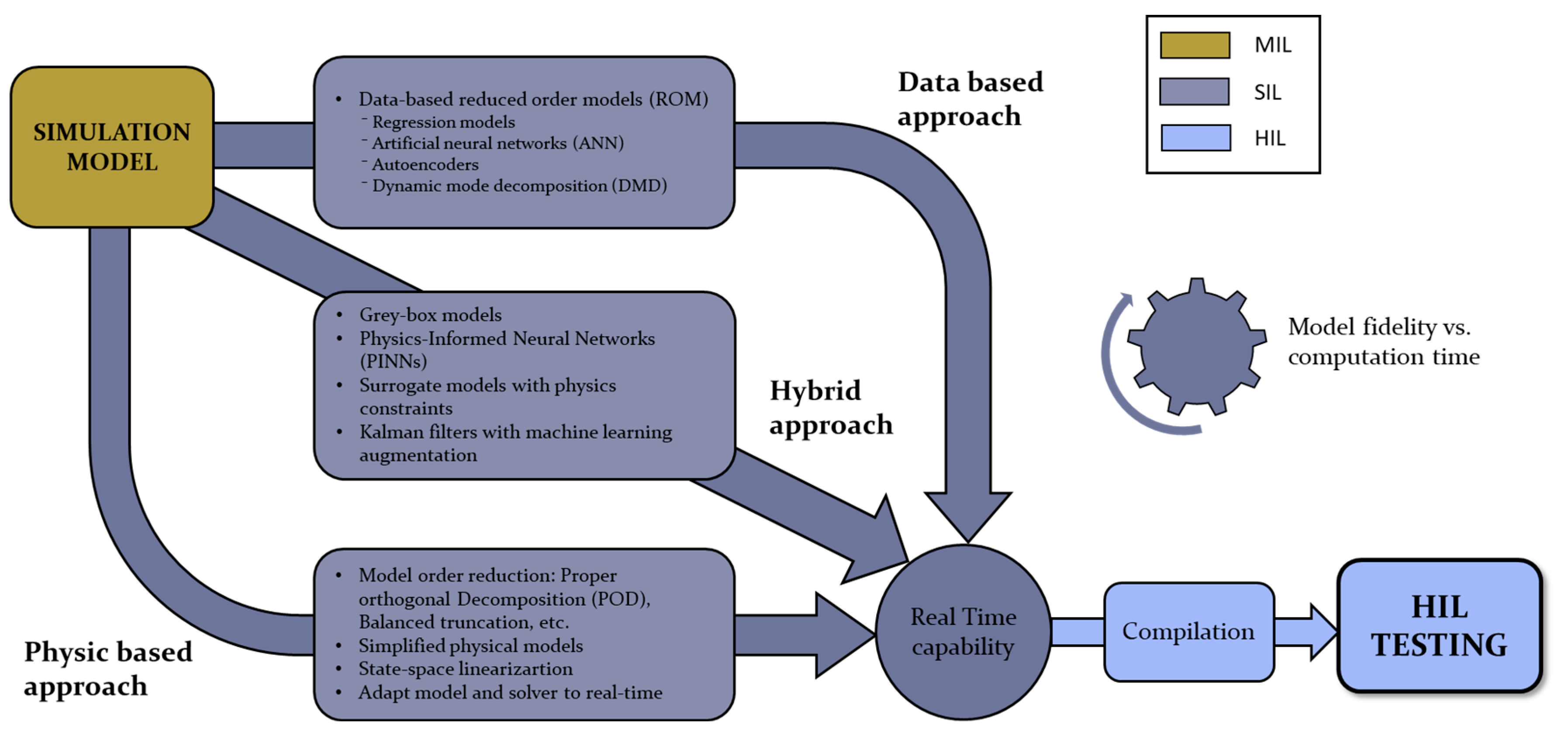

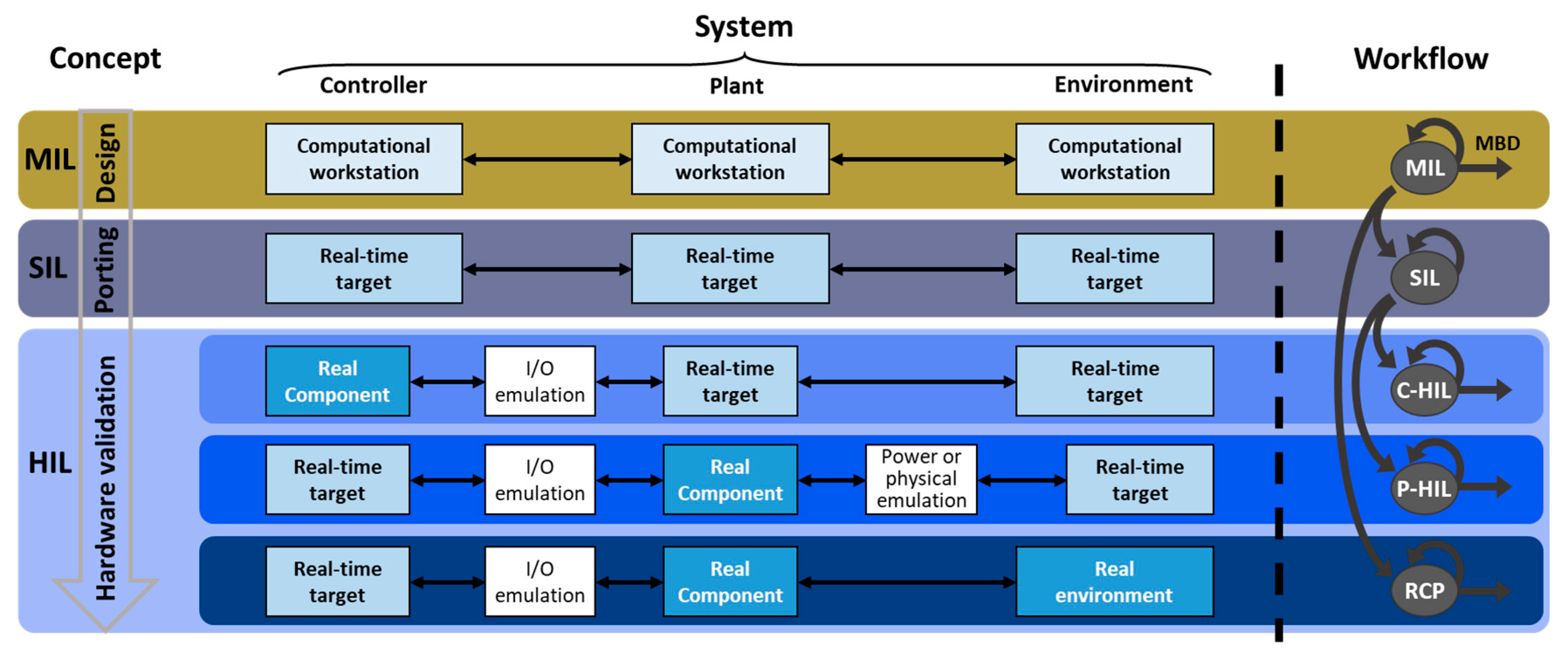

2. XIL Methodology and Definitions

2.1. Historical Review and Terminology

2.2. X-in-the-Loop Stages

2.2.1. Model-in-the-Loop (MIL)

2.2.2. Software-in-the-Loop (SIL)

2.2.3. Hardware-in-the-Loop (HIL)

- Controller-Hardware-In-the-Loop (C-HIL)

- 2.

- Power-Hardware-in-the-Loop (P-HIL)

- 3.

- Rapid-Control-Prototyping (RCP)

2.3. Workflow and Objectives

3. Contributions of XIL Methodology to the FCSs Development

3.1. Fuel Cell System Modelling

3.2. Power Electronics: FPGA Integration

3.3. Air Supply Management System

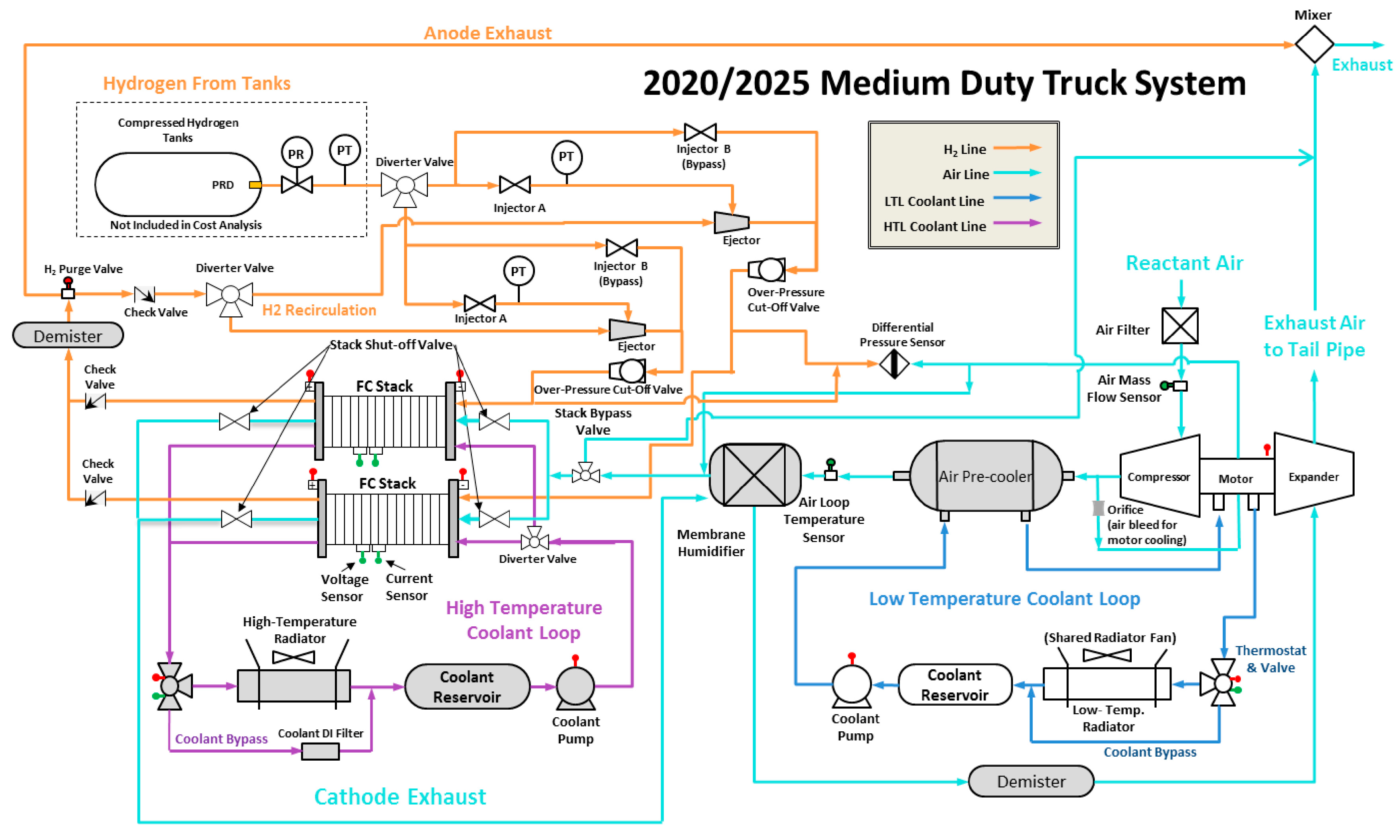

3.4. Hydrogen Supply Management System

3.5. Thermal Management System

3.6. Energy Management Systems

3.7. Multi-Stack FCS

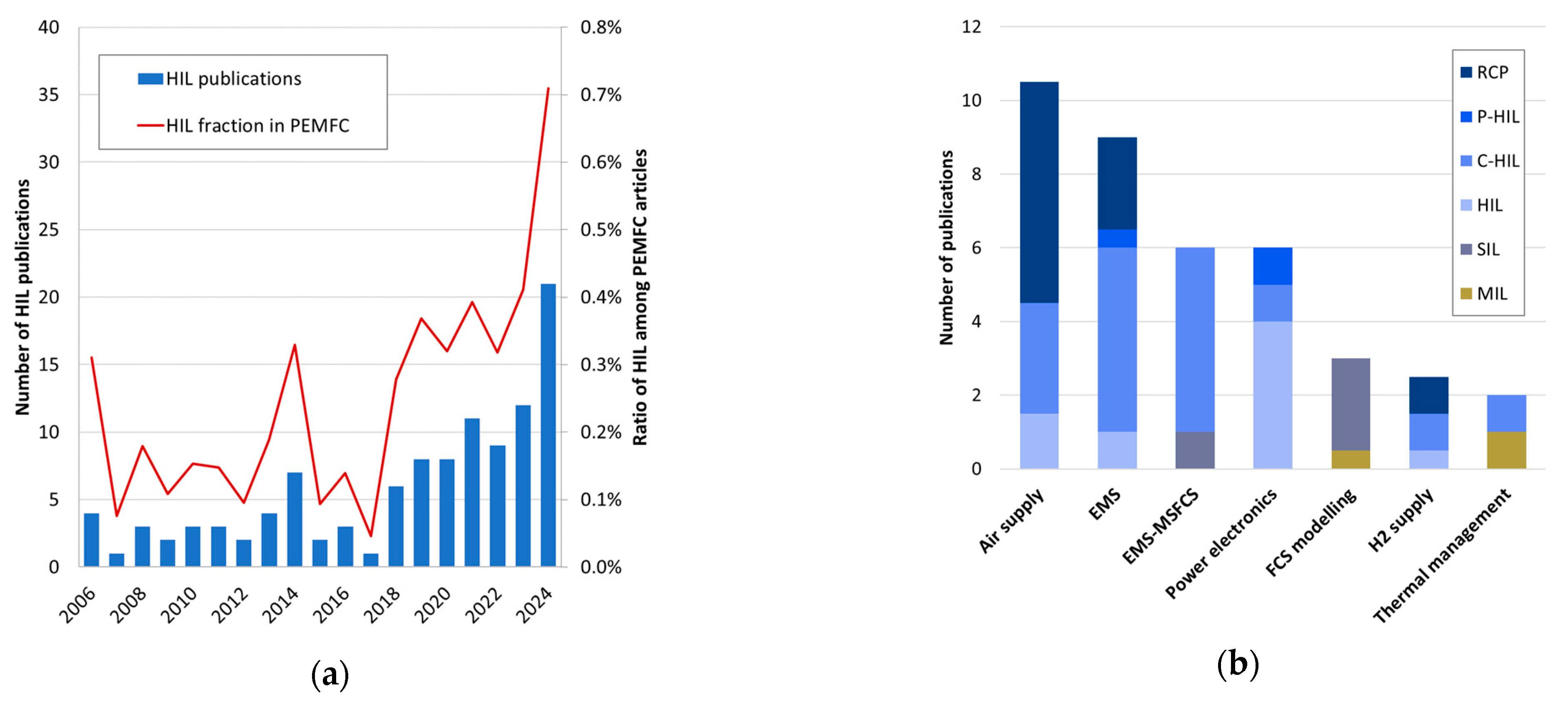

3.8. Synthesis of the Literature in the Field

4. Future Challenges

4.1. Modelling

4.2. Architecture Optimisation

4.3. Energy, Thermal, Power, and Fluid Management Optimisation

4.4. High-Power MSFCSs

5. Conclusions

Funding

Conflicts of Interest

Abbreviations

| ANN | Artificial Neural Network |

| CIL | Controller-in-the-loop |

| C-HIL | Controller Hardware-in-the-loop |

| CPU | Central Processing Unit |

| DMD | Dynamic Mode Decomposition |

| DSP | Digital Signal Processor |

| DUT | Device Under Test |

| ECMS | Equivalent Consumption Minimisation Strategy |

| EMS | Energy Management System |

| EUT | Equipment Under Test |

| FCS | Fuel cell System |

| FIL | FPGA-in-the-loop |

| FPGA | Field Programmable Gate Array |

| HER | Hydrogen Excess Ratio |

| HIL | Hardware-in-the-loop |

| HMI | Human–Machine Interface |

| HUT | Hardware Under Test |

| LCA | Life Cycle Analysis |

| MBD | Model-based Design |

| MIL | Model-in-the-loop |

| MILP | Mixed Integer Linear Programming |

| ML | Machine Learning |

| MPC | Model Predictive Control |

| MSFCSs | Multi-stack fuel cell systems |

| OER | Oxygen Excess Ratio |

| PEMFC | Proton Exchange Membrane Fuel Cell |

| P-HIL | Power Hardware-in-the-loop |

| PID | Proportional Integral Derivative |

| POD | Proper Orthogonal Decomposition |

| PIL | Processor-in-the-loop |

| PINNs | Physics-Informed Neural Networks |

| PLC | Programmable Logic Controller |

| RCP | Rapid Control Prototyping |

| RT | Real-time |

| RIL | Real-physics-in-the-loop |

| ROM | Reduced Order Model |

| SIL | Software-in-the-loop |

| SOC | State Of Charge |

| SUT | System Under Test |

| XIL | X-in-the-loop |

References

- Lohse-Busch, H.; Stutenberg, K.; Duoba, M.; Liu, X.Y.; Elgowainy, A.; Wang, M.; Wallner, T.; Richard, B.; Christenson, M. Automotive fuel cell stack and system efficiency and fuel consumption based on vehicle testing on a chassis dynamometer at minus 18 °C to positive 35 °C temperatures. Int. J. Hydrogen Energy 2020, 45, 861–872. [Google Scholar] [CrossRef]

- Sery, J.; Leduc, P. Fuel cell behavior and energy balance on board a Hyundai Nexo. Int. J. Engine Res. 2022, 23, 709–720. [Google Scholar] [CrossRef]

- Weiss, M.; Cloos, K.C.; Helmers, E. Energy efficiency trade-offs in small to large electric vehicles. Environ. Sci. Eur. 2020, 32, 46. [Google Scholar] [CrossRef]

- Padgett, E. On-Road Transit Bus Fuel Cell Stack Durability, DOE Hydrogen and Fuel Cell Technologies Program Record, 20008. 2021. Available online: https://www.hydrogen.energy.gov/docs/hydrogenprogramlibraries/pdfs/20008-fuel-cell-bus-durability.pdf (accessed on 12 December 2024).

- ‘German Hydrogen Trains Experience Problems’, Trains. Available online: https://www.trains.com/trn/news-reviews/news-wire/german-hydrogen-trains-experience-problems/ (accessed on 12 March 2025).

- Szalay, Z. Next Generation X-in-the-Loop Validation Methodology for Automated Vehicle Systems. IEEE Access 2021, 9, 35616–35632. [Google Scholar] [CrossRef]

- Mihalič, F.; Truntič, M.; Hren, A. Hardware-in-the-Loop Simulations: A Historical Overview of Engineering Challenges. Electronics 2022, 11, 2462. [Google Scholar] [CrossRef]

- Ivanov, V.; Augsburg, K.; Bernad, C.; Dhaens, M.; Dutré, M.; Gramstat, S.; Magnin, P.; Schreiber, V.; Skrt, U.; Van Kelecom, N. Connected and Shared X-in-the-Loop Technologies for Electric Vehicle Design. World Electr. Veh. J. 2019, 10, 83. [Google Scholar] [CrossRef]

- Segura, M.; Poggi, T.; Barcena, R. A Generic Interface for x-in-the-Loop Simulations Based on Distributed Co-Simulation Protocol. IEEE Access 2023, 11, 5578–5595. [Google Scholar] [CrossRef]

- Karimi, S.; Gaillard, A.; Poure, P.; Saadate, S. FPGA-Based Real-Time Power Converter Failure Diagnosis for Wind Energy Conversion Systems. IEEE Trans. Ind. Electron. 2008, 55, 4299–4308. [Google Scholar] [CrossRef]

- Sriganesh, R.; Pandikumar, M.; Sundareswaran, R. FPGA based Real Time Simulation of Power Converters. In Proceedings of the 2021 7th International Conference on Electrical Energy Systems (ICEES), Chennai, India, 11–13 February 2021; pp. 370–376. [Google Scholar] [CrossRef]

- Chebabhi, A.; Defdaf, M.; Kessal, A. Design and PIL implementation of a new robust backstepping based low-complexity voltage-oriented control method for four-leg rectifiers. Int. J. Electr. Power Energy Syst. 2024, 155, 109676. [Google Scholar] [CrossRef]

- El Fatimi, A.; Addaim, A.; Guennoun, Z. Design and analysis of a nanosatellite attitude control system using processor-in-the-loop approach. AEU—Int. J. Electron. Commun. 2023, 171, 154880. [Google Scholar] [CrossRef]

- Huang, S.; Wang, W.; Brambley, M.R.; Goyal, S.; Zuo, W. An agent-based hardware-in-the-loop simulation framework for building controls. Energy Build. 2018, 181, 26–37. [Google Scholar] [CrossRef]

- Deng, Y.; Li, H.; Foo, S. Controller Hardware-In-the-Loop simulation for design of power management strategies for fuel cell vehicle with energy storage. In Proceedings of the 2009 IEEE Vehicle Power and Propulsion Conference, Dearborn, MI, USA, 7–10 September 2009; pp. 866–870. [Google Scholar] [CrossRef]

- Mandrioli, C.; Carlsson, M.N.; Maggio, M. Testing Abstractions for Cyber-Physical Control Systems. ACM Trans. Softw. Eng. Methodol. 2023, 33, 1–32. [Google Scholar] [CrossRef]

- Walica, D.; Noskievič, P. Application of the MiL and HiL Simulation Techniques in Stewart Platform Control Development. Appl. Sci. 2022, 12, 2323. [Google Scholar] [CrossRef]

- Coaquira, F.J.T.; Wang, X.S.; Torrez, K.W.V.; Quiroga, M.J.M.; Plata, M.A.S.; Verdueta, G.A.L.; Quispe, S.E.M.; Banegas, G.J.A.; Lopez, F.P.A.; Rojas, A. Model-Based Design and Testbed for CubeSat Attitude Determination and Control System with Magnetic Actuation. Appl. Sci. 2024, 14, 6065. [Google Scholar] [CrossRef]

- Alarcon, J.M.B.; Marmolejo, J.L.S.; Muñoz, L.H.M.; Quesada, E.S.E.; Cordero, A.O.; Carrillo, L.R.G. Performance Evaluation of an H-VTOL Aircraft with Distributed Electric Propulsion and Ducted-Fans Using MIL Simulation. Machines 2023, 11, 852. [Google Scholar] [CrossRef]

- Sandoval, D.A.M.; De La Cruz-Loredo, I.; Saikia, P.; Abeysekera, M.; Ugalde-Loo, C.E. Dynamic verification of an optimisation algorithm for power dispatch of integrated energy systems. Front. Energy Res. 2024, 12, 1385839. [Google Scholar] [CrossRef]

- Cha, M.; Enshaei, H.; Nguyen, H.; Jayasinghe, S.G. Optimal sizing and evaluation of efficient fuel cell utilization for fuel cell battery hybrid electric ferry. Energy Convers. Manag. 2024, 315, 118723. [Google Scholar] [CrossRef]

- Marzi, E.; Morini, M.; Saletti, C.; Gambarotta, A. Coordinating multiple Power-To-Gas plants for optimal management of e-fuel seasonal storage. Smart Energy 2024, 14, 100143. [Google Scholar] [CrossRef]

- Batista, C.L.G.; Weller, A.C.; Martins, E.; Mattiello-Francisco, F. Towards increasing nanosatellite subsystem robustness. Acta Astronaut. 2019, 156, 187–196. [Google Scholar] [CrossRef]

- Li, A.; Ponchant, M.; Sturm, J.; Jossen, A. Reduced-Order Electro-Thermal Battery Model Ready for Software-in-the-Loop and Hardware-in-the-Loop BMS Evaluation for an Electric Vehicle. World Electr. Veh. J. 2020, 11, 75. [Google Scholar] [CrossRef]

- Gao, F.; Blunier, B.; Simões, M.G.; Miraoui, A. PEM Fuel Cell Stack Modeling for Real-Time Emulation in Hardware-in-the-Loop Applications. IEEE Trans. Energy Convers. 2011, 26, 184–194. [Google Scholar] [CrossRef]

- Werner, S.; Masing, L.; Lesniak, F.; Becker, J. Software-in-the-Loop simulation of embedded control applications based on Virtual Platforms. In Proceedings of the 2015 25th International Conference on Field Programmable Logic and Applications (FPL), London, UK, 2–4 September 2015; pp. 1–8. [Google Scholar] [CrossRef]

- Khaled, A.B.; Gaid, M.B.; Simon, D.; Font, G. Multicore simulation of powertrains using weakly synchronized model partitioning. IFAC Proc. Vol. 2012, 45, 448–455. [Google Scholar] [CrossRef]

- Raissi, M.; Perdikaris, P.; Karniadakis, G.E. Physics-informed neural networks: A deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations. J. Comput. Phys. 2019, 378, 686–707. [Google Scholar] [CrossRef]

- Peherstorfer, B.; Willcox, K.; Gunzburger, M. Survey of Multifidelity Methods in Uncertainty Propagation, Inference, and Optimization. SIAM Rev. 2018, 60, 550–591. [Google Scholar] [CrossRef]

- Wang, J.; Jin, C.; Wang, P. A Uniform Control Strategy for the Interlinking Converter in Hierarchical Controlled Hybrid AC/DC Microgrids. IEEE Trans. Ind. Electron. 2018, 65, 6188–6197. [Google Scholar] [CrossRef]

- Vygoder, M.; Banihashemi, F.; Gudex, J.; Eggebeen, A.; Oriti, G.; Cuzner, R.M. A Novel Protection Design Process to Increase Microgrid Resilience. IEEE Trans. Ind. Appl. 2024, 60, 5372–5387. [Google Scholar] [CrossRef]

- Nazir, M.; Burkes, K.; Enslin, J.H. Converter-Based Solutions: Opening New Avenues of Power System Protection Against Solar and HEMP MHD-E3 GIC. IEEE Trans. Power Deliv. 2021, 36, 2542–2549. [Google Scholar] [CrossRef]

- Mather, B.A.; Kromer, M.A.; Casey, L. Advanced photovoltaic inverter functionality verification using 500kw power hardware-in-loop (PHIL) complete system laboratory testing. In Proceedings of the 2013 IEEE PES Innovative Smart Grid Technologies Conference (ISGT), Washington, WA, USA, 24–27 February 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Tran, Q.T.; Besanger, Y.; Jung, M.; Nguyen, T.L. Digital twin integrated power-hardware-in-the-loop for the assessment of distributed renewable energy resources. Electr. Eng. 2022, 104, 377–388. [Google Scholar] [CrossRef]

- Molitor, C.; Benigni, A.; Helmedag, A.; Chen, K.; Cali, D.; Jahangiri, P.; Muller, D.; Monti, A. Multiphysics Test Bed for Renewable Energy Systems in Smart Homes. IEEE Trans. Ind. Electron. 2013, 60, 1235–1248. [Google Scholar] [CrossRef]

- Sharma, N.; Mademlis, G.; Liu, Y.; Tang, J. Evaluation of Operating Range of a Machine Emulator for a Back-to-Back Power-Hardware-in-the-Loop Test Bench. IEEE Trans. Ind. Electron. 2022, 69, 9783–9792. [Google Scholar] [CrossRef]

- Liu, W.; Kim, J.-M.; Wang, C.; Im, W.-S.; Liu, L.; Xu, H. Power Converters Based Advanced Experimental Platform for Integrated Study of Power and Controls. IEEE Trans. Ind. Inform. 2018, 14, 4940–4952. [Google Scholar] [CrossRef]

- Hans, F.; Borowski, P.; Wendt, J.; Quistorf, G.; Jersch, T. Opportunities and Challenges of Advanced Testing Approaches for Multi-Megawatt Wind Turbines. IEEE Open J. Power Electron. 2024, 5, 323–335. [Google Scholar] [CrossRef]

- Edrington, C.S.; Steurer, M.; Langston, J.; El-Mezyani, T.; Schoder, K. Role of Power Hardware in the Loop in Modeling and Simulation for Experimentation in Power and Energy Systems. Proc. IEEE 2015, 103, 2401–2409. [Google Scholar] [CrossRef]

- Viehweider, A.; Lauss, G.; Lehfuss, F. Interface and stability issues for SISO and MIMO power hardware in the loop simulation of distribution networks with photovoltaic generation. Int. J. Renew. Energy Res. 2012, 2, 631–639. [Google Scholar]

- Badar, J.; Akhter, F.; Munir, H.M.; Bukhari, S.S.H.; Ro, J.-S. Efficient Real-Time Controller Design Test Bench for Power Converter Applications. IEEE Access 2021, 9, 118880–118892. [Google Scholar] [CrossRef]

- Xia, Z.; Gao, F.; Togai, K.; Yamaura, H. Accelerated and Integrated Real Time Testing Process Based on Two Universal Controllers on Rapid Controller Prototyping. SAE Int. J. Passeng. Cars—Mech. Syst. 2008, 1, 258–267. [Google Scholar] [CrossRef]

- Tarnapowicz, D.; Zaleski, T.; Matuszak, Z.; Jaskiewicz, M. Energy Optimization of Marine Drive Systems with Permanent Magnet Synchronous Motors. Energies 2024, 17, 31. [Google Scholar] [CrossRef]

- Caldognetto, T.; Petucco, A.; Lauri, A.; Mattavelli, P. A flexible power electronic converter system with rapid control prototyping for research and teaching. HardwareX 2023, 14, e00411. [Google Scholar] [CrossRef] [PubMed]

- Gao, F.; Blunier, B.; Chrenko, D.; Bouquain, D.; Miraoui, A. Multirate fuel cell emulation with spatial reduced real-time fuel cell modeling. IEEE Trans. Ind. Appl. 2012, 48, 1127–1135. [Google Scholar] [CrossRef]

- Gerard, M.; Poirot-Crouvezier, J.-P.; Hissel, D.; Pera, M.-C. Oxygen starvation analysis during air feeding faults in PEMFC. Int. J. Hydrogen Energy 2010, 35, 12295–12307. [Google Scholar] [CrossRef]

- Tardy, E.; Poirot-Crouvezier, J.-P.; Schott, P.; Morel, C.; Serre, G.; Bultel, Y. Investigation of liquid water heterogeneities in large area proton exchange membrane fuel cells using a Darcy two-phase flow model in a multiphysics code. Int. J. Hydrogen Energy 2022, 47, 38721–38735. [Google Scholar] [CrossRef]

- Pei, P.; Chen, H. Main factors affecting the lifetime of Proton Exchange Membrane fuel cells in vehicle applications: A review. Appl. Energy 2014, 125, 60–75. [Google Scholar] [CrossRef]

- Katrašnik, T.; Kravos, A. Advanced State-of-X diagnostics of proton exchange membrane fuel cells enabled by the multi-scale modeling framework. Int. J. Hydrogen Energy 2025, 141, 1359–1371. [Google Scholar] [CrossRef]

- He, W.; Tian, Z.; Wang, Q.; Hou, X.; Zhou, J.; Zhou, D.; Yang, Y. A novel high-dimensional and multi-physics modeling approach of proton exchange membrane fuel cell for real-time simulation. Energy Convers. Manag. 2023, 286, 116988. [Google Scholar] [CrossRef]

- Hu, H.; Ou, K.; Yuan, W.-W. Fused multi-model predictive control with adaptive compensation for proton exchange membrane fuel cell air supply system. Energy 2023, 284, 128459. [Google Scholar] [CrossRef]

- Kravos, A.; Kregar, A.; Penga, Ž.; Barbir, F.; Katrašnik, T. Real-time capable transient model of liquid water dynamics in proton exchange membrane Fuel Cells. J. Power Sources 2022, 541, 231598. [Google Scholar] [CrossRef]

- Ma, R.; Liu, C.; Zheng, Z.; Gechter, F.; Briois, P.; Gao, F. CPU-FPGA based real-time simulation of fuel cell electric vehicle. Energy Convers. Manag. 2018, 174, 983–997. [Google Scholar] [CrossRef]

- Wang, H.; Xu, J.; Sun, Y.; Du, P.; Lei, Y. Theoretical Comparison, Real-Time Emulation, and Experiment Validation of DC/DC Converter for Fuel Cell Electric Vehicle. IEEE Access 2024, 12, 56824–56835. [Google Scholar] [CrossRef]

- Hao, X.; Salhi, I.; Laghrouche, S.; Ait-Amirat, Y.; Djerdir, A. Robust control of four-phase interleaved boost converter by considering the performance of PEM fuel cell current. Int. J. Hydrogen Energy 2021, 46, 38827–38840. [Google Scholar] [CrossRef]

- Li, X.; Li, Q.; Wang, T.; Chen, W.; Zhang, S. Adaptive Power Transient Smoothing Control Considering Performance Degradation for Multi-Stack Fuel Cell Hybrid Power Systems. IEEE Trans. Transp. Electrif. 2023, 10, 7501–7512. [Google Scholar] [CrossRef]

- Zhou, Y.; Obeid, H.; Laghrouche, S.; Hilairet, M.; Djerdir, A. A novel second-order sliding mode control of hybrid fuel cell/super capacitors power system considering the degradation of the fuel cell. Energy Convers. Manag. 2021, 229, 113766. [Google Scholar] [CrossRef]

- Hao, X.; Salhi, I.; Laghrouche, S.; Ait-Amirat, Y.; Djerdir, A. Backstepping Supertwisting Control of Four-Phase Interleaved Boost Converter for PEM Fuel Cell. IEEE Trans. Power Electron. 2022, 37, 7858–7870. [Google Scholar] [CrossRef]

- Abbaspour, A.; Yen, K.K.; Forouzannezhad, P.; Sargolzaei, A. An Adaptive Resilient Control Approach for Pressure Control in Proton Exchange Membrane Fuel Cells. IEEE Trans. Ind. Appl. 2019, 55, 6344–6354. [Google Scholar] [CrossRef]

- Matraji, I.; Laghrouche, S.; Jemei, S.; Wack, M. Robust control of the PEM fuel cell air-feed system via sub-optimal second order sliding mode. Appl. Energy 2013, 104, 945–957. [Google Scholar] [CrossRef]

- Laghrouche, S.; Matraji, I.; Ahmed, F.S.; Jemei, S.; Wack, M. Load governor based on constrained extremum seeking for PEM fuel cell oxygen starvation and compressor surge protection. Int. J. Hydrogen Energy 2013, 38, 14314–14322. [Google Scholar] [CrossRef]

- Phan, V.D.; Trinh, H.-A.; Ahn, K.K. Finite-Time Command Filtered Control for Oxygen-Excess Ratio of Proton Exchange Membrane Fuel Cell Systems with Prescribed Performance. Mathematics 2023, 11, 914. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y. Pressure and oxygen excess ratio control of PEMFC air management system based on neural network and prescribed performance. Eng. Appl. Artif. Intell. 2023, 121, 105850. [Google Scholar] [CrossRef]

- Zhang, H.K.; Wang, Y.F.; Wang, D.H.; Wang, Y.L. Adaptive robust control of oxygen excess ratio for PEMFC system based on type-2 fuzzy logic system. Inf. Sci. 2020, 511, 1–17. [Google Scholar] [CrossRef]

- Liu, J.; Laghrouche, S.; Ahmed, F.-S.; Wack, M. PEM fuel cell air-feed system observer design for automotive applications: An adaptive numerical differentiation approach. Int. J. Hydrogen Energy 2014, 39, 17210–17221. [Google Scholar] [CrossRef]

- Ma, L.; Zhao, H.; Qu, Y.; Zhao, S.; Yu, Y.; Wei, W. Reduced-order active disturbance rejection control method for PEMFC air intake system based on the estimation of oxygen excess ratio. IET Renew. Power Gener. 2023, 17, 951–963. [Google Scholar] [CrossRef]

- Olteanu, S.C.; Aitouche, A.; Belkoura, L.; Jouni, A.; Embedded, P.E.M. fuel cell stack nonlinear observer by means of a Takagi-Sugeno approach. Stud. Inform. Control. 2015, 24, 61–70. [Google Scholar] [CrossRef]

- Ramos-Paja, C.A.; Spagnuolo, G.; Petrone, G.; Mamarelis, E. A perturbation strategy for fuel consumption minimization in polymer electrolyte membrane fuel cells: Analysis, Design and FPGA implementation. Appl. Energy 2014, 119, 21–32. [Google Scholar] [CrossRef]

- Guo, X.; Fan, N.; Dong, Z.; Wang, C. Adaptive Prescribed Performance Control for PEM Fuel Cell Air Supply Systems With Unknown Air Compressor Faults. IEEE Trans. Ind. Electron. 2024, 71, 7664–7672. [Google Scholar] [CrossRef]

- Quan, S.; Wang, Y.-X.; Xiao, X.; He, H.; Sun, F. Feedback linearization-based MIMO model predictive control with defined pseudo-reference for hydrogen regulation of automotive fuel cells. Appl. Energy 2021, 293, 116919. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, G.; Wang, Y. Modeling and control for PEMFC hydrogen management subsystem based on neural network compensation and prescribed tracking accuracy. Fuel 2023, 352, 129019. [Google Scholar] [CrossRef]

- He, H.; Quan, S.; Sun, F.; Wang, Y.-X. Model predictive control with lifetime constraints based energy management strategy for proton exchange membrane fuel cell hybrid power systems. IEEE Trans. Ind. Electron. 2020, 67, 9012–9023. [Google Scholar] [CrossRef]

- Su, Z.; Yuhang, B.; Zhirong, P.; Jianhua, G. Research on the fault-tolerant control in thermal management subsystem of multi-stack fuel cells. In Proceedings of the 2023 CAA Symposium on Fault Detection, Supervision and Safety for Technical Processes, SAFEPROCESS 2023, Yibin, China, 22–24 September 2023. [Google Scholar] [CrossRef]

- Pouget, J.; Riffonneau, Y. Signal Hardware-In-the-Loop simulator of hybrid railway traction for the evaluation of energy management. In Proceedings of the 2012 IEEE Vehicle Power and Propulsion Conference, Seoul, Republic of Korea, 9–12 October 2012; pp. 914–919. [Google Scholar] [CrossRef]

- Löffler, C.; Geertsma, R.; Polinder, H.; Coraddu, A. Optimizing Fuel Consumption of a Dual-Fuel Full-Electric Vessel Using Model Predictive Control. In Proceedings of the 2024 IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Naples, Italy, 26–29 November 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Jiang, D.; Long, Y.; Fu, P.; Guo, C.; Tang, Y.; Huang, H. A novel multi-stack fuel cell hybrid system energy management strategy for improving the fuel cell durability of the hydrogen electric Multiple Units. Int. J. Green Energy 2023, 21, 1766–1775. [Google Scholar] [CrossRef]

- Lu, D.; Hu, D.; Yi, F.; Li, J.; Yang, Q. Optimal selection range of FCV power battery capacity considering the synergistic decay of dual power source lifespan. Int. J. Hydrogen Energy 2023, 48, 13578–13590. [Google Scholar] [CrossRef]

- Nazir, M.S.; Ahmad, I.; Khan, M.J.; Ayaz, Y.; Armghan, H. Adaptive control of fuel cell and supercapacitor based hybrid electric vehicles. Energies 2020, 13, 5587. [Google Scholar] [CrossRef]

- Lambert, H.; Hernandez-Torres, D. Development and optimization of energy management strategies for hybrid heavy duty vehicle: From model to hardware in the loop validation. In Proceedings of the 2025 IEEE Transportation Electrification Conference and Expo (ITEC), Anaheim, CA, USA, 18–20 June 2025. [Google Scholar]

- Li, Q.; Su, B.; Pu, Y.; Han, Y.; Wang, T.; Yin, L.; Chen, W. A State Machine Control Based on Equivalent Consumption Minimization for Fuel Cell/Supercapacitor Hybrid Tramway. IEEE Trans. Transp. Electrif. 2019, 5, 552–564. [Google Scholar] [CrossRef]

- Li, H.; Ravey, A.; N’Diaye, A.; Djerdir, A. A novel equivalent consumption minimization strategy for hybrid electric vehicle powered by fuel cell, battery and supercapacitor. J. Power Sources 2018, 395, 262–270. [Google Scholar] [CrossRef]

- Yan, Y.; Li, Q.; Chen, W.; Su, B.; Liu, J.; Ma, L. Optimal Energy Management and Control in Multimode Equivalent Energy Consumption of Fuel Cell/Supercapacitor of Hybrid Electric Tram. IEEE Trans. Ind. Electron. 2019, 66, 6065–6076. [Google Scholar] [CrossRef]

- Lin, X.; Zeng, S.; Li, X. Online correction predictive energy management strategy using the Q-learning based swarm optimization with fuzzy neural network. Energy 2021, 223, 120071. [Google Scholar] [CrossRef]

- Kandidayeni, M.; Fernandez, A.O.M.; Khalatbarisoltani, A.; Boulon, L.; Kelouwani, S.; Chaoui, H. An Online Energy Management Strategy for a Fuel Cell/Battery Vehicle Considering the Driving Pattern and Performance Drift Impacts. IEEE Trans. Veh. Technol. 2019, 68, 11427–11438. [Google Scholar] [CrossRef]

- Shi, W.; Huangfu, Y.; Xu, L.; Pang, S. Online energy management strategy considering fuel cell fault for multi-stack fuel cell hybrid vehicle based on multi-agent reinforcement learning. Appl. Energy 2022, 328, 120234. [Google Scholar] [CrossRef]

- Pereira, D.F.; Lopes, F.D.C.; Watanabe, E.H. Nonlinear Model Predictive Control for the Energy Management of Fuel Cell Hybrid Electric Vehicles in Real Time. IEEE Trans. Ind. Electron. 2021, 68, 3213–3223. [Google Scholar] [CrossRef]

- Zhou, D.; Al-Durra, A.; Matraji, I.; Ravey, A.; Gao, F. Online Energy Management Strategy of Fuel Cell Hybrid Electric Vehicles: A Fractional-Order Extremum Seeking Method. IEEE Trans. Ind. Electron. 2018, 65, 6787–6799. [Google Scholar] [CrossRef]

- Bankati, W.R.; Boulon, L.; Jemei, S. Remaining useful life prognostic-based energy management strategy for multi-fuel cell stack systems in automotive applications. Int. J. Hydrogen Energy 2024, 82, 374–383. [Google Scholar] [CrossRef]

- Kopka, T.; Coraddu, A.; Polinder, H. Optimal Energy Management of FC- Battery Shipboard Power System using Dynamic Programming. In Proceedings of the 2024 IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Naples, Italy, 26–29 November 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Marx, N.; Boulon, L.; Gustin, F.; Hissel, D.; Agbossou, K. A review of multi-stack and modular fuel cell systems: Interests, application areas and on-going research activities. Int. J. Hydrogen Energy 2014, 39, 12101–12111. [Google Scholar] [CrossRef]

- Zhou, S.; Fan, L.; Zhang, G.; Gao, J.H.; Lu, Y.D.; Zhao, P.; Wen, C.K.; Shi, L.; Hu, Z. A review on proton exchange membrane multi-stack fuel cell systems: Architecture, performance, and power management. Appl. Energy 2022, 310, 118555. [Google Scholar] [CrossRef]

- Igourzal, A.; Auger, F.; Olivier, J.-C.; Retière, C. Improving the operation of multi-stack PEM fuel cell systems to increase efficiency, durability and lifespan while reducing ageing. Energy Convers. Manag. 2024, 314, 118630. [Google Scholar] [CrossRef]

- James, B.; Huya-Kouadio, J.; Houchins, C.; De Santis, D. Mass Production Cost Estimation of Direct H2 PEM Fuel Cell Systems for Transportation Applications: 2018 Update. 2018. Available online: https://sainc.com/what-we-do/energy-consulting/ (accessed on 5 February 2024).

- Meng, X.; Li, Q.; Huang, T.; Wang, X.; Zhang, G.; Chen, W. A Distributed Performance Consensus Control Strategy of Multistack PEMFC Generation System for Hydrogen EMU Trains. IEEE Trans. Ind. Electron. 2021, 68, 8207–8218. [Google Scholar] [CrossRef]

- Wang, T.; Li, Q.; Wang, X.; Chen, W.; Breaz, E.; Gao, F. A Power Allocation Method for Multistack PEMFC System Considering Fuel Cell Performance Consistency. IEEE Trans. Ind. Appl. 2020, 56, 5340–5351. [Google Scholar] [CrossRef]

- Peng, F.; Xie, X.; Wu, K.; Zhao, Y.; Ren, L. Online hierarchical energy management strategy for fuel cell based heavy-duty hybrid power systems aiming at collaborative performance enhancement. Energy Convers. Manag. 2023, 276, 116501. [Google Scholar] [CrossRef]

- Jian, B.; Wang, H. Hardware-in-the-loop real-time validation of fuel cell electric vehicle power system based on multi-stack fuel cell construction. J. Clean. Prod. 2022, 331, 129807. [Google Scholar] [CrossRef]

- Jung, J.-H.; Ahmed, S. Dynamic model of PEM fuel cell using real-time simulation techniques. J. Power Electron. 2010, 10, 739–748. [Google Scholar] [CrossRef]

- Jung, J.-H.; Ahmed, S.; Enjeti, P. PEM fuel cell stack model development for real-time simulation applications. IEEE Trans. Ind. Electron. 2011, 58, 4217–4231. [Google Scholar] [CrossRef]

- Jung, J.-H. Real-time and power hardware-in-the-loop simulation of PEM fuel cell stack system. J. Power Electron. 2011, 11, 202–210. [Google Scholar] [CrossRef][Green Version]

- Mayyas, A.R.; Ramani, D.; Kannan, A.M.; Hsu, K.; Mayyas, A.; Schwenn, T. Cooling strategy for effective automotive power trains: 3D thermal modeling and multi-faceted approach for integrating thermoelectric modules into proton exchange membrane fuel cell stack. Int. J. Hydrogen Energy 2014, 39, 17327–17335. [Google Scholar] [CrossRef]

- Xie, Z.; Zhou, S.; Gao, J.; Zhang, G.; Shen, W.; Design, S. Matching, and Analysis of Air Supply Devices for Multi-Stack Fuel Cell Systems. Energy Technol. 2023, 11, 2201331. [Google Scholar] [CrossRef]

- Silva, R.E.; Harel, F.; Jemei, S.; Gouriveau, R.; Hissel, D.; Boulon, L.; Agbossou, K. Proton Exchange Membrane Fuel Cell Operation and Degradation in Short-Circuit. Fuel Cells 2014, 14, 894–905. [Google Scholar] [CrossRef]

- Siad, I.; Battiston, A.; Leroy, T.; Martin, J.-P.; Pierfederici, S. Exploration of Partial Power Converter Topology for Fuel Cell Multi-Stack Systems in Heavy-Duty Applications. In Proceedings of the 2024 IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Naples, Italy, 26–29 November 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Wang, H.; Gaillard, A.; Hissel, D. Online electrochemical impedance spectroscopy detection integrated with step-up converter for fuel cell electric vehicle. Int. J. Hydrogen Energy 2019, 44, 1110–1121. [Google Scholar] [CrossRef]

- Depernet, D.; Narjiss, A.; Gustin, F.; Hissel, D.; Pera, M.-C. Integration of electrochemical impedance spectroscopy functionality in proton exchange membrane fuel cell power converter. Int. J. Hydrogen Energy 2016, 41, 5378–5388. [Google Scholar] [CrossRef]

| XIL | Automotive World Point of View | Proposed Academic Point of View | Difference |

|---|---|---|---|

| MIL | Development of control laws in a simulated environment, more or less faithfully, without real-time constraints | Simultaneous code development for the control laws and for the model of the system without real-time constraints | The automotive world uses pre-existing models of the system |

| SIL | Real-time PC-based testing of control functions using an environment simulator (vehicle) | Adaptation of the code of the control laws and of the model of the system to meet real-time constraints: model reduction, fixed time steps, code compilation | The automotive world uses a PC platform with pre-existing compiled models of the system called simulators |

| HIL | Testing of the actual microcontroller interfaced with a real-time simulated environment | All tests involving a hardware or emulated element interfaced with a real-time simulated system | The automotive world restricts this approach to microcontroller validation |

| P-HIL | Testing of the actual microcontroller interfaced with physical parts and real-time emulated parts of the system under test (SUT) with power exchanges | Emulation of one or possibly multiple physical devices controlled by a real-time model through a test-bench involving power exchanges. It can be connected to a real physical system (actuator, engine, or battery). Only a part of the system may be emulated, while the other is simulated. This is referred to as semi-virtual simulation | The automotive world restricts this approach to microcontroller validation |

| C-HIL | - | Testing of the actual microcontroller interfaced with a real-time simulated environment | The academic “C-HIL” corresponds to the automotive “HIL” |

| RCP | Development of control laws interfacing with a real physical system | Development of control laws interfacing with a real physical system | Similar definitions |

| Objectives | XIL Academic Approach |

|---|---|

| Developing a prototype for the control of an existing system | MIL ➜ RCP |

| Improving/tuning the control of an existing system | [MIL➜] RCP |

| Developing a system from design to implementation | MIL ➜ SIL ➜ C-HIL [➜P-HIL] |

| Integrating and testing an existing algorithm in a controlled environment | C-HIL |

| Optimising the sizing of an energy chain | MIL |

| Designing a system and its control using Model-Based Design (MBD) | MIL |

| Verifying the applicability of an algorithm in real-time | SIL |

| Performing component tests | P-HIL |

| Evaluating the performance of a system and its control | MIL [➜RCP] |

| Evaluating the behaviour outside of operating conditions | MIL [➜C-HIL] |

| Verifying the physical behaviour of a system before its final integration | C-HIL + P-HIL |

| Topics | Stage | Remarks | System Under Test | Reference |

|---|---|---|---|---|

| Fuel cell system modelling for real-time capability | SIL | Model reduction in complete FCS. | None | He, 2023 [50] |

| SIL | Development of a linear model for air loop control. | None | Hu, 2023 [51] | |

| MIL/SIL | Water management modelling. 1 kHz capability. | None | Kravos, 2022 [52] | |

| Power electronics | HIL | Coupling FPGA for power electronics modelling and CPU for fuel cell modelling. | None | Ma, 2018 [53] |

| HIL | Converter modelled in FPGA board of a MicroLabBox, controller, and fuel cell model running on the real-time processor of the MicroLabBox. | Power converter | Wang, 2024 [54] | |

| C-HIL | Power converter control development for an MSFCS. Control is running on a DSP. | DSP controller | Li, 2023 [56] | |

| HIL | Power converter control. Two dSPACE are used for modelling and control. | None | Zhou, 2021 [57] | |

| P-HIL | Power converter control and integration of a 1 kW fuel cell. Controller deported on dSPACE and a FPGA board. | FC + Controller | Hao, 2021 [55] and [58] | |

| HIL | Propose and test different methods for computation time reduction in an RT-LAB HIL test-bench. | None | Jung, 2010 [98,99,100] | |

| Gases supply | HIL | Fault tolerant control for air and H2. Everything is tested on an OPAL-RT target. | None | Abbaspour, 2019 [59] |

| Air supply | RCP | Control of the OER for improving the net power efficiency. | Compressor | Matraji, 2013 [60] |

| RCP | Control of the OER and pressure under dynamic load. | Compressor | Laghrouche, 2013 [61] | |

| HIL | State observer for oxygen flow and pressure running on an ARDUINO communicating with real-time fuel cell model. | ARDUINO state observer | Olteanu, 2015 [67] | |

| RCP | Control of OER under dynamic load. Use a 100 W fuel cell for validation of the control algorithm. | FC + compressor | Phan, 2023 [62] | |

| C-HIL | Control of the compressor voltage running on an FPGA. Real-time model running on a computer. | FPGA controller | Ramos-Paja, 2014 [68] | |

| RCP | Control of OER based on an artificial neural network. Models and controller run on dSPACE. A real compressor is tested. | Compressor | Wang, 2023 [63] | |

| RCP | Control of OER based on fuzzy logic. Models and controller run on dSPACE. A real compressor is tested. | Compressor | Zhang, 2020 [64] | |

| C-HIL | Adaptive fault tolerant controller for the OER. The model is running on a Speedgoat while the controller is compiled on a DSP. | DSP controller | Guo, 2024 [69] | |

| RCP | Adaptive control of the OER based on a state observer. FC model is running on an FPGA. A real compressor is included. A CompactRIO controls in real-time the compressor. | Compressor | Liu, 2014 [65] | |

| C-HIL | Control of the OER based on a state observer. FC model is running on OPAL-RT. The controller runs on a DSP. | DSP controller | Ma, 2023 [66] | |

| H2 supply | C-HIL | Model predictive control of the H2 excess ratio. Two DSP used for modelling and control. | DSP controller | Quan, 2021 [70] |

| RCP | Controller based on artificial neural networks for the anode pressure and HER control. Test-bench include real sensors, a motor, and a pump. | Motor, pump and sensors | Wang, 2023 [71] | |

| Thermal management | MIL | 3-D finite element modelling of the thermal component on a fuel cell system. MIL used for designing the thermal system. | None | Mayyas, 2014 [101] |

| C-HIL | Model predictive controller including stack temperature estimation developed and included in HIL testing. | Controller | He, 2020 [72] | |

| EMS | C-HIL | Rule-based EMS using low pass filter and ageing modelling. Controller running on a vehicle control unit communicating with a real-time vehicle model. | Controller | Lu, 2023 [77] |

| HIL | Lookup table-based EMS optimised off-line by a MILP and Bayesian optimisation. The control in embedded on a dSPACE target and real-time models are running on a Speedgoat target. | Controller | Lambert, 2025 [79] | |

| C-HIL | Controller based on state machine and ECMS for a tramway application. Models are running on an OPAL-RT target while the controller runs on a DSP. | Controller | Li, 2019 [80] | |

| HIL | Minimisation of the equivalent energy consumption based on the tramway state. Model and controller are running on two separate CPU of the OPAL-RT target. | None | Yan, 2019 [82] | |

| RCP | Online H2 consumption optimisation by an ECMS technique. Validation of the proposed algorithm on an RCP test-bench with a 1.2 kW fuel cell and the controller running on a dSPACE MicroAutoBox. | Controller + FC | Li, 2018 [81] | |

| P-HIL/ C-HIL | EMS based on reinforcement leaning with online prediction tested on an HIL setup. Real components controlled by a vehicle control unit. | Power train + controller | Lin, 2021 [83] | |

| RCP | EMS based on a fuzzy logic controller and an online driving cycle recognition. A LabVIEW model considering electric motor, battery, and converters and the EMS gives online current set point for the real 500 W fuel cell system. | FC | Kandidayeni, 2019 [84] | |

| C-HIL | EMS strategy for hybrid fuel cell and super-capacitor vehicle. Rule-based power splitting and a close control for power converter with the integration of the time-varying parameters such as inductance and capacitance. The controller is tested on a C-HIL setup with models running on a desktop computer. | Controller | Nazir, 2020 [78] | |

| C-HIL | Non-linear predictive control of the fuel cell current in order to find the maximum efficiency point. Test-bench include a 3 kW fuel cell. Controller is running on a BeagleBone Black processor. | Controller | Pereira, 2021 [86] | |

| C-HIL/RCP | Online optimisation based on fractional order extremum seeking. Online results compared with offline optimisation by dynamic programming. RCP include a 1.2 kW fuel cell. | Controller + FC | Zhou, 2018 [87] | |

| EMS for MSFCS | C-HIL | Consensual power splitting of MSFCS for extending the system lifetime. Load following even in the case of electrical failure. Controller validated on a DSP communicating with models on an OPAL-RT target | Controller | Meng, 2021 [94] |

| C-HIL | Virtual droop control of the MSFCS in a tramway application. Power splitting and load following even in case of electrical failure. Validation on a C-HIL test-bench. | Controller | Wang, 2020 [95] | |

| C-HIL | Adaptive virtual droop control depending on each stack degradation. The controller is running on a DSP while models are running on an OPAL-RT target. | Controller | Li, 2023 [56] | |

| C-HIL | EMS based on machine learning in order to reduce online the hydrogen consumption of a commercial hydrogen fuel cell vehicle model. They tested and validated the ability of reconfiguration in case of loss of stack. | Controller | Shi, 2022 [85] | |

| SIL | Impact of the coordination between top-level and low-level management systems on fuel consumption. | None | Peng, 2023 [96] | |

| C-HIL | Validation of the EMS with a 4 stacks MSFCS with bus voltage stability as goal. Validation of the controller in a CHIL setup. | Controller | Jian et al. [97] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lambert, H.; Hernàndez-Torres, D.; Retière, C.; Garnier, L.; Poirot-Crouvezier, J.-P. X-in-the-Loop Methodology for Proton Exchange Membrane Fuel Cell Systems Design: Review of Advances and Challenges. Energies 2025, 18, 3774. https://doi.org/10.3390/en18143774

Lambert H, Hernàndez-Torres D, Retière C, Garnier L, Poirot-Crouvezier J-P. X-in-the-Loop Methodology for Proton Exchange Membrane Fuel Cell Systems Design: Review of Advances and Challenges. Energies. 2025; 18(14):3774. https://doi.org/10.3390/en18143774

Chicago/Turabian StyleLambert, Hugo, David Hernàndez-Torres, Clément Retière, Laurent Garnier, and Jean-Philippe Poirot-Crouvezier. 2025. "X-in-the-Loop Methodology for Proton Exchange Membrane Fuel Cell Systems Design: Review of Advances and Challenges" Energies 18, no. 14: 3774. https://doi.org/10.3390/en18143774

APA StyleLambert, H., Hernàndez-Torres, D., Retière, C., Garnier, L., & Poirot-Crouvezier, J.-P. (2025). X-in-the-Loop Methodology for Proton Exchange Membrane Fuel Cell Systems Design: Review of Advances and Challenges. Energies, 18(14), 3774. https://doi.org/10.3390/en18143774