Spatiotemporal Variations and Driving Factors of Carbon Emissions Related to Energy Consumption in the Construction Industry of China

Abstract

1. Introduction

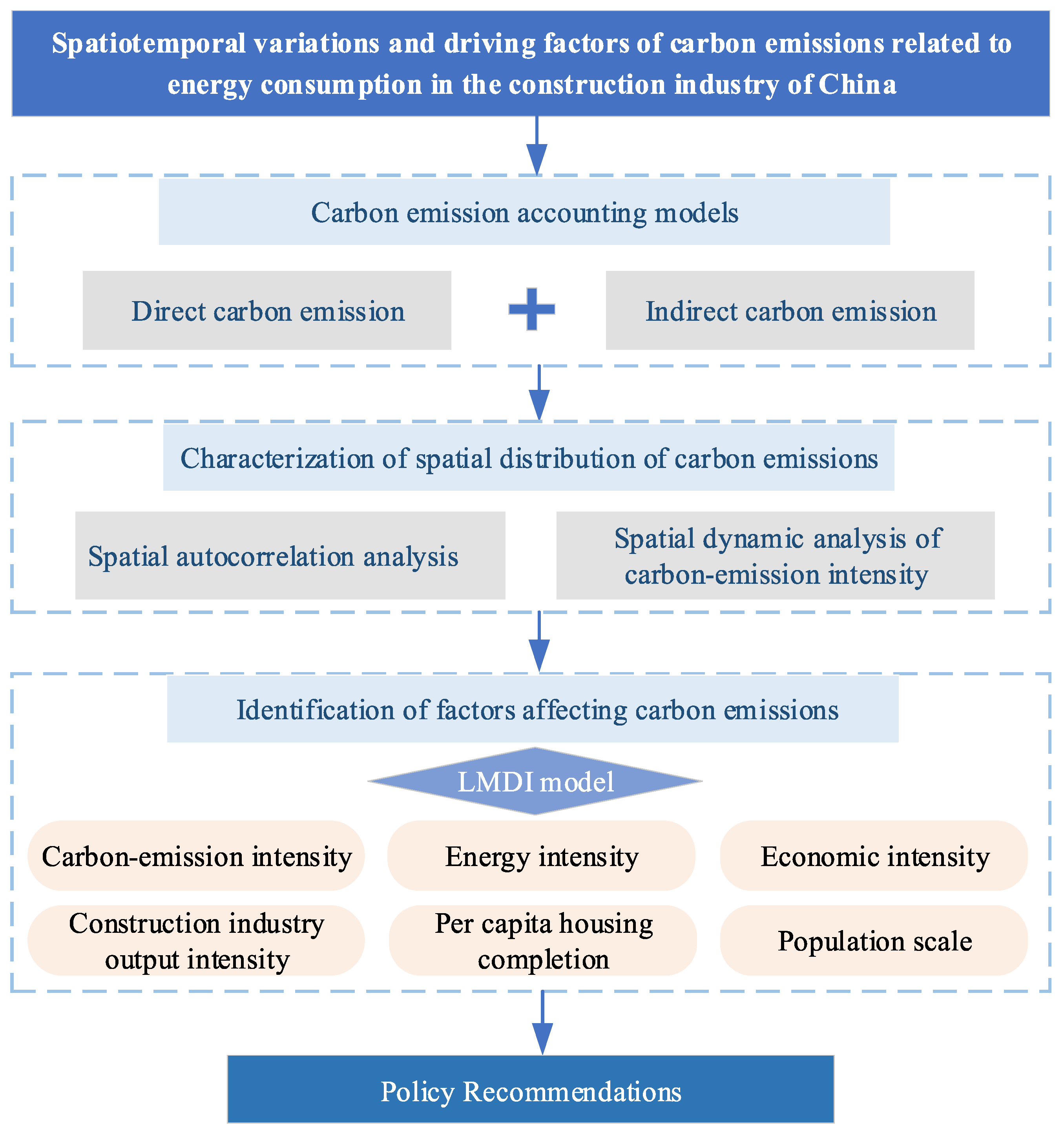

2. Data and Methods

2.1. Data Sources

2.2. Research Methodology

2.2.1. Measurement of Carbon Emissions in Construction Industry

2.2.2. Characterization of Spatial Distribution of Carbon Emissions in Construction Industry

- Spatial autocorrelation analysis

- 2.

- Spatial dynamic analysis of carbon-emission intensity in construction industry

2.2.3. Identification of Factors Affecting Carbon Emissions in Construction Industry

3. Results and Analysis

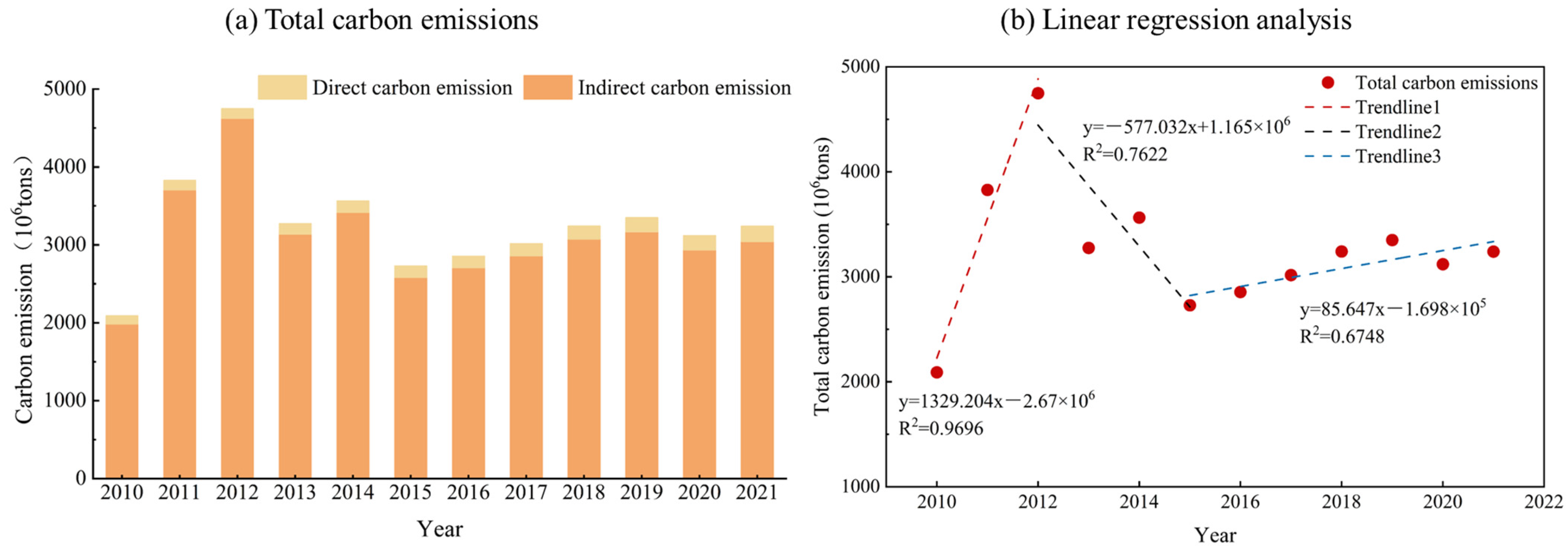

3.1. Temporal Variations in Carbon Emissions from Construction Industry

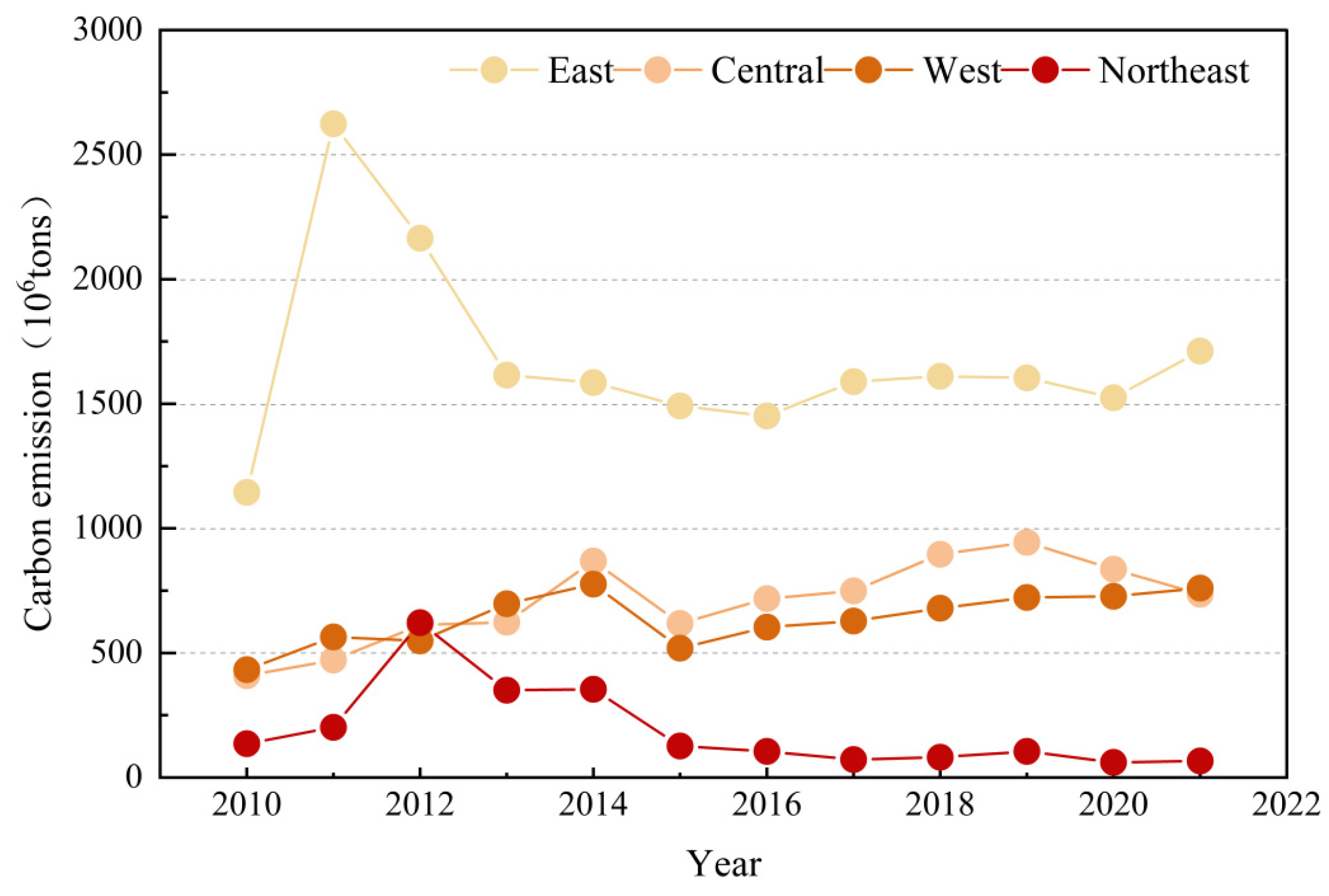

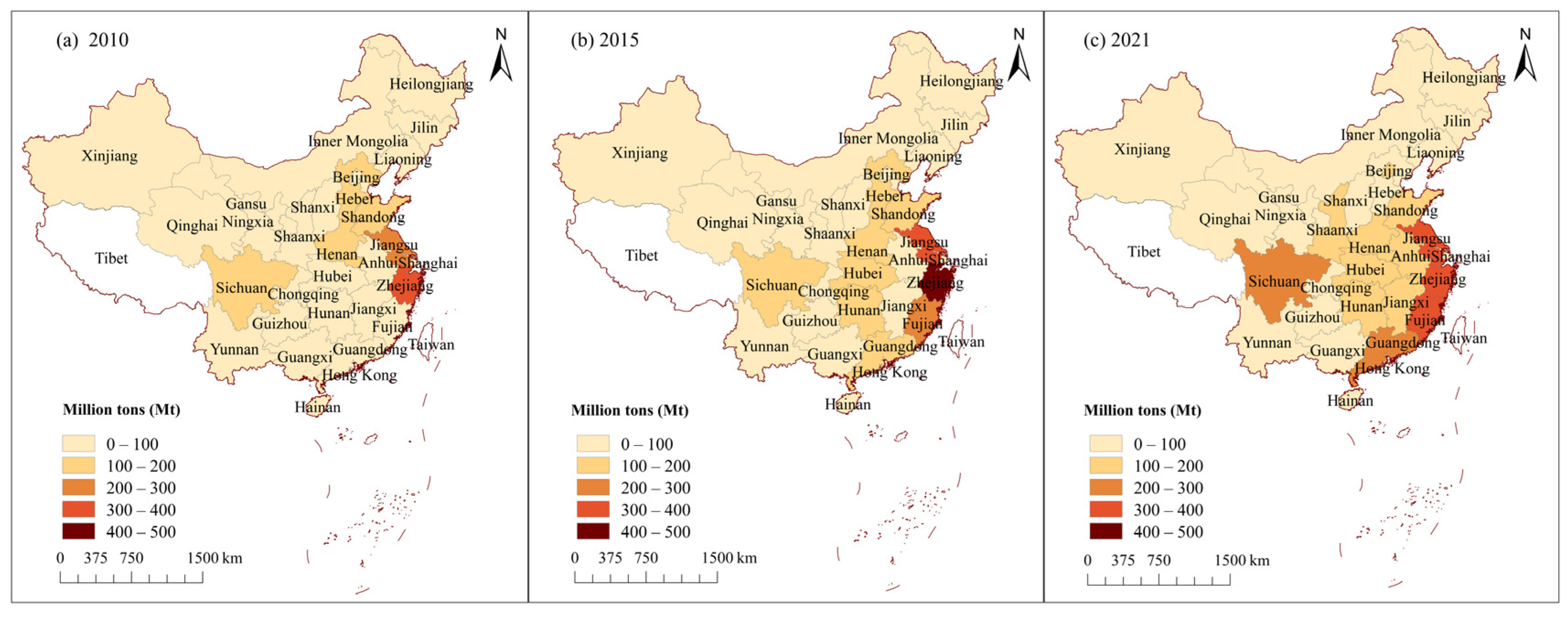

3.2. Spatial Characteristics of Carbon Emissions in Construction Industry

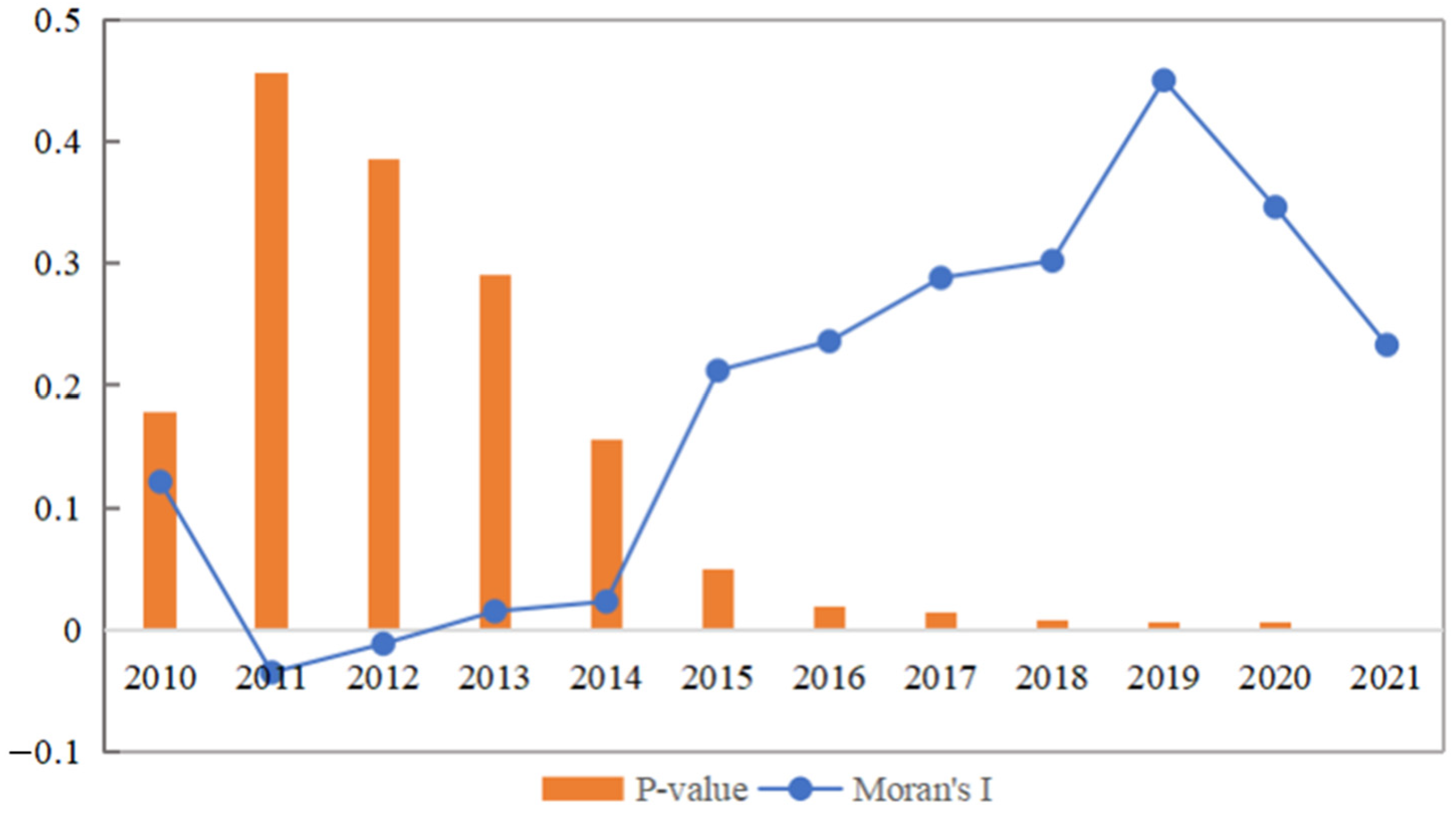

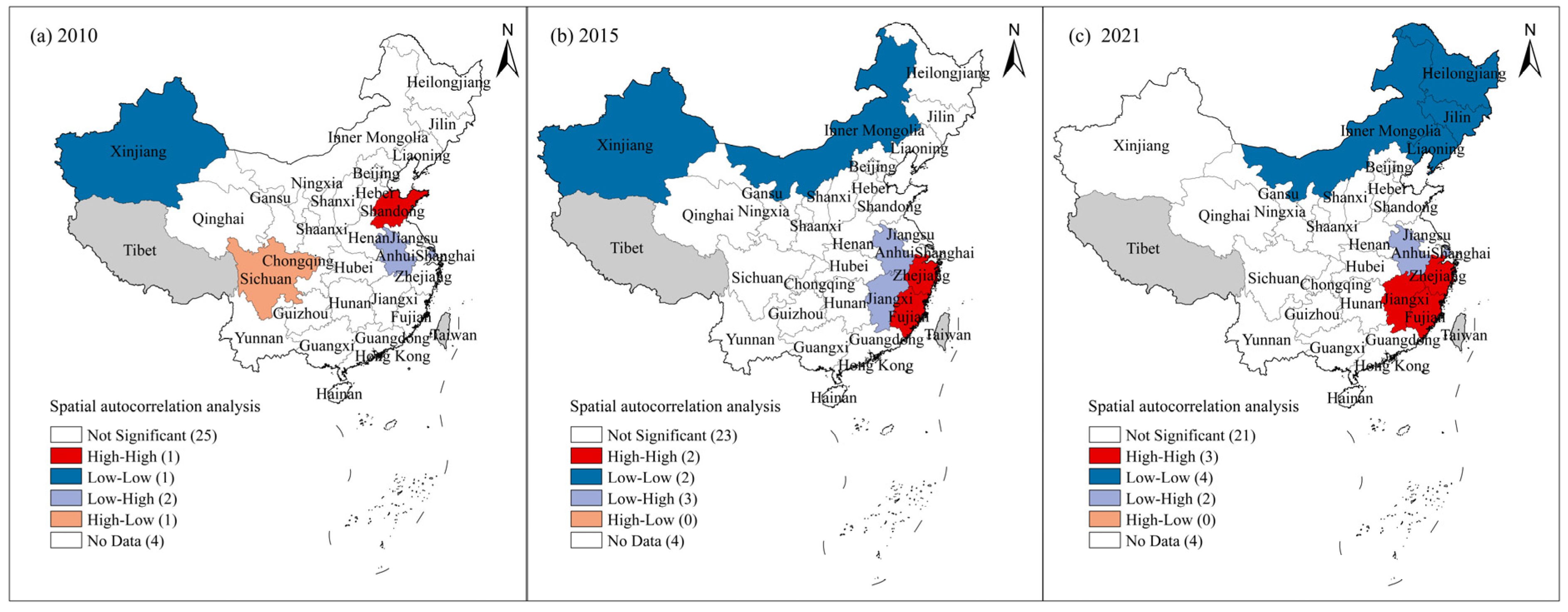

3.2.1. Spatial Distribution and Correlation of Carbon Emissions in the Construction Industry

3.2.2. Spatial Dynamic Analysis of Carbon-Emission Intensity in Construction Industry

3.3. Factors Affecting Carbon Emissions in Construction Industry

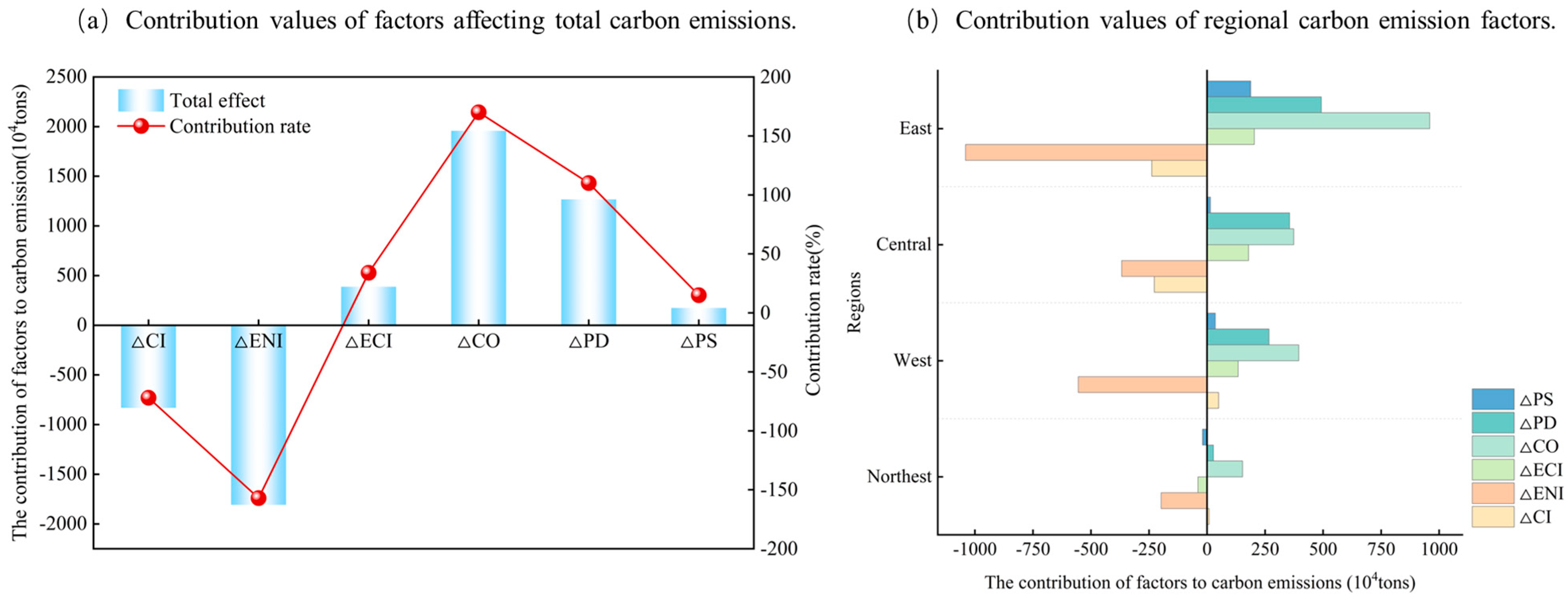

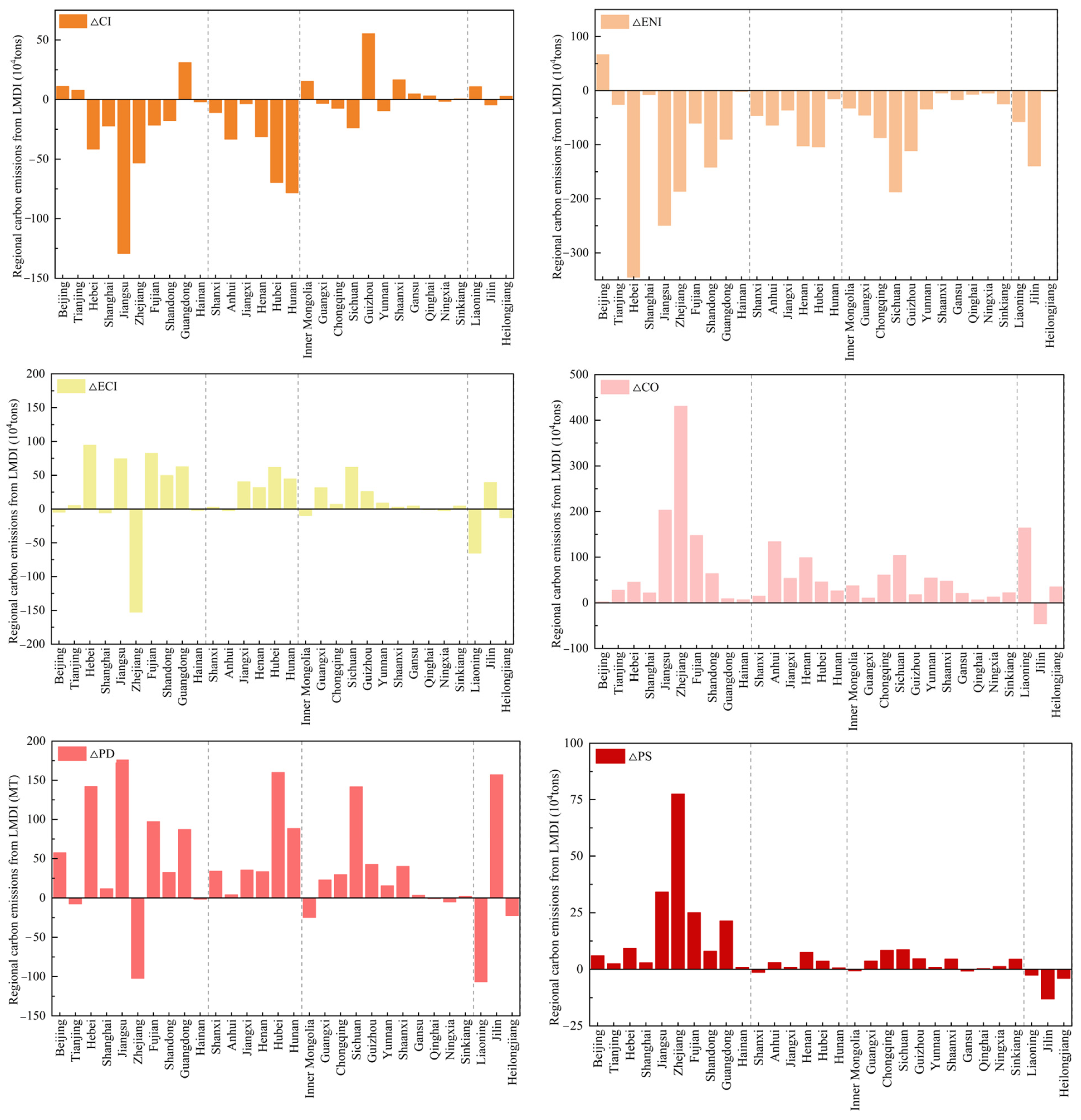

- Carbon-emission intensity: During the study period, this factor had a negative impact on carbon emissions in China’s construction industry, contributing 832.069 million tons, with a contribution rate of 72.34% (Figure 9a). It had both positive and negative effects on the four regions, but overall had a negative impact. It primarily suppressed carbon emissions in the eastern and central regions (Figure 9b), particularly in Jiangsu, Hunan, and Hubei provinces (Figure 10), with contribution amounts of 129.201 million tons, 78.319 million tons, and 69.673 million tons, respectively. Due to the relatively low levels of carbon emissions and energy consumption in the construction industry in the western and northeastern regions, the impact of this factor on carbon emissions in these regions was minimal.

- 2.

- Energy intensity: During the study period, this influencing factor had a negative impact on carbon emissions in China’s construction industry, cumulatively suppressing carbon emissions by 1806.947 million tons, with a contribution rate of 157.09%. Among the four regions, the negative impact on carbon emissions was most significant in the eastern region, primarily concentrated in Hebei Province, Jiangsu Province, and Zhejiang Province, with emission reductions of 344.858 million tons, 249.262 million tons, and 186.317 million tons, respectively. This highlights the critical role of improving energy efficiency in controlling and reducing CECI [37], making it a key factor in carbon emission reduction. Therefore, by scientifically adjusting and managing energy utilization efficiency, the contribution rate to carbon emission reduction in the construction industry can be maximized.

- 3.

- Economic intensity: During the study period, it had a positive impact on carbon emissions in China’s construction industry, cumulatively promoting carbon emissions of 387.624 million tons, with a contribution rate of 33.70%. Notably, the eastern and central regions demonstrated significant positive impacts, such as Hebei Province, Fujian Province, and Jiangsu Province, with contribution values of 94.650 million tons, 82.510 million tons, and 74.344 million tons, respectively. It was worth noting that this factor had a negative impact on carbon emissions in Zhejiang Province’s construction industry, contributing 152.753 million tons. This indicates that a higher level of economic development has strengthened policy enforcement, enabling low-carbon policies such as carbon emissions trading and green building standards to be more effectively implemented in the construction industry [38]. Therefore, reasonably adjusting the internal economic structure of the industry is particularly important.

- 4.

- Construction industry output intensity: This influencing factor had a significant positive impact on carbon emissions in China’s construction industry and is also a relatively critical influencing factor. Its contribution to carbon emissions is 1958.819 million tons, with a contribution rate of 170.30%. Its contribution to carbon emissions in the eastern region is particularly notable, exhibiting a positive impact, such as in Zhejiang Province and Jiangsu Province, with contribution values of 430.728 million tons and 203.332 million tons, respectively (Figure 9). As the construction industry in the eastern region continues to expand, its energy consumption levels are bound to rise, leading to an increase in carbon emissions. In contrast, the western and northeastern regions, due to limited investment in the construction industry, have a relatively low promotional effect on carbon emissions. The eastern region is transitioning from scale-driven to technology-driven development, and the central and western regions are still in the stage of scale accumulation. This regional disparity underscores the need for differentiated emission reduction pathways in the future.

- 5.

- Per capita housing completion: This factor had a positive impact on carbon emissions in China’s construction industry, with a contribution value of 1267.513 million tons and a contribution rate of 110.2%. Among the four regions, this influencing factor exhibits a gradually decreasing positive impact from east to west, primarily concentrated in Jiangsu Province, Hubei Province, and Sichuan Province, with contribution values of 176.006 million tons, 160.041 million tons, and 141.698 million tons, respectively. The expansion of completed floor area drives carbon emissions across the entire supply chain, including building material production, logistics, transportation, and construction. Example with Jiangsu Province, the “scale effect” generated by the agglomeration of the construction industry and the intensive production mode formed by the concentration of a large number of construction enterprises have increased the spatial concentration of demand for building materials, resulting in a high degree of concentration of carbon emissions in each link of the supply chain, which has further increased the value of the per capita area of housing completed in the region in terms of its contribution to carbon emissions. Therefore, it is important to build a differentiated building area control mechanism to coordinate the synergistic development of regional industrial structure adjustment, energy consumption optimization, and low-carbon technology innovation.

- 6.

- Population scale: This factor had a positive impact on carbon emissions in China’s construction industry. However, the effect of promoting carbon emissions was low, with a contribution of 175.305 million tons and a rate of 15.24%. Owing to the higher level of economic development in the eastern region, the population is also denser, and the changes and migration of the population resulted in the development of the industry [39], causing changes in carbon emissions. The construction industry must attract high-quality talent to achieve the transformation of resource input to industrial efficiency output.

4. Discussion

5. Conclusions

5.1. Findings

5.2. Policy Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| IPCC | Intergovernmental Panel on Climate Change |

| LMDI | Logarithmic mean Divisia index |

| CECI | Carbon emissions in the construction industry |

References

- Fathi, M. Sustainability and energy efficiency in buildings: A review. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2024, 16, 03123002. [Google Scholar] [CrossRef]

- Lu, Y.; Chen, X. Digital economy, new-type urbanization, and carbon emissions: Evidence from China. Environ. Prog. Sustain. Energy 2023, 42, e14045. [Google Scholar] [CrossRef]

- Peter, C.; Fiore, A.; Hagemann, U.; Nendel, C.; Xiloyannis, C. Improving the accounting of field emissions in the carbon footprint of agricultural products: A comparison of default IPCC methods with readily available medium-effort modeling approaches. Int. J. Life Cycle Assess. 2016, 21, 791–805. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Life-cycle carbon emission assessment and permit allocation methods: A multi-region case study of China’s construction sector. Ecol. Indic. 2017, 72, 910–920. [Google Scholar] [CrossRef]

- Jiang, M.; Hao, X. Adjusting the intermediate input sources for global carbon emission reduction: An input–output optimization model. Sci. Total Environ. 2022, 835, 155582. [Google Scholar] [CrossRef]

- Zhao, K.; Cui, X.; Zhou, Z.; Huang, P. Impact of uncertainty on regional carbon peak paths: An analysis based on carbon emissions accounting, modeling, and driving factors. Environ. Sci. Pollut. Res. 2022, 29, 17544–17560. [Google Scholar] [CrossRef]

- Cheng, F.; Yao, J. The effect of the digital economy on carbon emissions in China’s construction industry: Evidence from spatial econometric analysis. Environ. Sci. Pollut. Res. 2024, 31, 63085–63097. [Google Scholar] [CrossRef]

- Chang, D.; Tang, S. Research on Low-Carbon Building Development and Carbon Emission Control Based on Mathematical Models: A Case Study of Jiangsu Province. Energies 2024, 17, 4545. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, C. Characteristics of Spatial-Temporal Evolution of Carbon Emissions from Land Use and Analysis of Influencing Factors in Hubao-Eyu Urban Agglomerations, China. Sustainability 2024, 16, 7565. [Google Scholar] [CrossRef]

- Liu, W.; Ren, D.; Ke, C.; Ying, W. Carbon Emission Influencing Factors and Scenario Prediction for Construction Industry in Beijing-Tianjing-Hebei. Adv. Civ. Eng. 2023, 2023, 2286573. [Google Scholar]

- Liu, Y.; Gan, L.; Cai, W.; Li, R. Decomposition and decoupling analysis of carbon emissions in China’s construction industry using the generalized Divisia index method. Environ. Impact Assess. Rev. 2024, 104, 107321. [Google Scholar] [CrossRef]

- Wu, Y.; Pu, W.; Dong, J.; Dai, W.; Wang, Y. Analysis of land use gravity center change and carbon emission impact in chengdu plain of China from 2006 to 2022. Land 2024, 13, 873. [Google Scholar] [CrossRef]

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X. Carbon emission of global construction sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- Zhou, Y.; Hu, D.; Wang, T.; Tian, H.; Gan, L. Decoupling effect and spatial-temporal characteristics of carbon emissions from construction industry in China. J. Clean. Prod. 2023, 419, 138243. [Google Scholar] [CrossRef]

- Xiao, Y.; Huang, H.; Qian, X.M.; Zhang, L.Y. Can new-type urbanization reduce urban building carbon emissions? New evidence from China. Sustain. Cities Soc. 2023, 90, 104410. [Google Scholar] [CrossRef]

- Zhou, Y.; Miao, H.; Li, C.; Ding, L. Spatio-temporal patterns and impact mechanisms of CO2 emissions from China’s construction industry under urbanization. Sustain. Cities Soc. 2024, 106, 105353. [Google Scholar] [CrossRef]

- Li, C.; Zhang, L.; Gu, Q.; Guo, J.; Huang, Y. Spatio-temporal differentiation characteristics and urbanization factors of urban household carbon emissions in China. Int. J. Environ. Res. Public Health 2022, 19, 4451. [Google Scholar] [CrossRef]

- Min, J.; Yan, G.; Abed, A.M.; Elattar, S.; Khadimallah, M.A.; Jan, A.; Ali, H.E. The effect of carbon dioxide emissions on the building energy efficiency. Fuel 2022, 326, 124842. [Google Scholar] [CrossRef]

- Yin, X.; Lin, K. Spatial-temporal characteristics and driving factors of carbon emissions from the construction industry in the Belt and Road region of China. Front. Environ. Sci. 2024, 12, 1398328. [Google Scholar] [CrossRef]

- Li, H.; Calder, C.A.; Cressie, N. Beyond Moran’s I: Testing for spatial dependence based on the spatial autoregressive model. Geogr. Anal. 2007, 39, 357–375. [Google Scholar] [CrossRef]

- Wu, H.; Zheng, X.; Zhou, L.; Meng, Y. Spatial autocorrelation and driving factors of carbon emission density of crop production in China. Environ. Sci. Pollut. Res. 2024, 31, 27172–27191. [Google Scholar] [CrossRef]

- Xu, Z.; Chen, H.; Song, W. Spatial-Temporal Pattern of Urban Land Green Use Efficiency and Its Influencing Factors in Guizhou Province, China, Based on County Units. Land 2024, 13, 2140. [Google Scholar] [CrossRef]

- Raczyński, L.; Wiślicki, W.; Krzemień, W.; Kowalski, P.; Alfs, D.; Bednarski, T.; Białas, P.; Curceanu, C.; Czerwiński, E.; Dulski, K.; et al. Calculation of the time resolution of the J-PET tomograph using kernel density estimation. Phys. Med. Biol. 2017, 62, 5076. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Y.; Meng, H.; Lim, J.B.; Yang, W. A novel global modelling strategy integrated dynamic kernel canonical variate analysis for the air handling unit fault detection via considering the two-directional dynamics. J. Build. Eng. 2024, 96, 110402. [Google Scholar] [CrossRef]

- Wang, D.; Pan, W.Q.; Liu, Q.; Gao, X.D. Factors decomposition of CO2 emission in China’s industries: Based on LMDI model. Syst Eng Theory Pr. 2012, 32, 1193–1203. [Google Scholar]

- Sun, Q.; Chen, H.; Long, R.; Zhang, J.; Yang, M.; Huang, H.; Ma, W.; Wang, Y. Can Chinese cities reach their carbon peaks on time? Scenario analysis based on machine learning and LMDI decomposition. Appl. Energy 2023, 347, 121427. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, X. Tracking China’s CO2 emissions using Kaya-LMDI for the period 1991–2022. Gondwana Res. 2024, 133, 60–71. [Google Scholar] [CrossRef]

- Song, M.; Wang, Y.; Wang, C.; Musakwa, W.; Ji, Y. Spatial and Temporal Characteristics of Carbon Emissions from Construction Industry in China from 2010 to 2019. Sustainability (2071-1050) 2024, 16, 5927. [Google Scholar] [CrossRef]

- Lu, Y.; Cui, P.; Li, D. Carbon emissions and policies in China’s building and construction industry: Evidence from 1994 to 2012. Build. Environ. 2016, 95, 94–103. [Google Scholar] [CrossRef]

- Liu, G.; Li, X.; Tan, Y.; Zhang, G. Building green retrofit in China: Policies, barriers and recommendations. Energy Policy 2020, 139, 111356. [Google Scholar] [CrossRef]

- Zhao, C.Z.; Liu, Y.; Ren, S.W.; Quan, J. Testing and green assessment technology for ready-mixed concrete. Key Eng. Mater. 2018, 768, 306–313. [Google Scholar] [CrossRef]

- Wang, Q.; Appolloni, A.; Liu, J. Does “low-carbon pilot policy” affect the carbon intensity of construction industry? Exploring the implementation mechanism and effectiveness in China. Eng. Constr. Archit. Manag. 2024, 31, 3222–3248. [Google Scholar] [CrossRef]

- Wang, W.; Hao, S.; Zhong, H.; Sun, Z. How to promote carbon emission reduction in buildings? Evolutionary analysis of government regulation and financial investment. J. Build. Eng. 2024, 89, 109279. [Google Scholar] [CrossRef]

- Li, Q.Y.; Zhang, Y.; Hu, M.Q.; Yu, J. Provincial Practice of Achieving the” Dual Carbon” Target: Taking Zhejiang Province as an Example. J. Ecol. Rural Environ. 2024, 40, 191–204. [Google Scholar]

- Liu, Y.B.; Deng, W.F.; Luo, K.; Tang, M.Y. Impact of environmental taxation on financial performance of energy-intensive firms: The role of digital transformation. Emerg. Mark. Financ. Trade 2024, 60, 598–616. [Google Scholar] [CrossRef]

- Wang, D.; Chen, C.; Findlay, C.; Huang, J.; Lin, J.Y.; Abedullah; Alam, M.J.; Hussain, A.; Nuryartono, N.; Sudaryanto, T.; et al. Stage Segmentation of Rural Transformation and Comparisons Among Bangladesh, China, Indonesia, and Pakistan: Combining Machine Learning and New Structural Economics to Facilitate International Agricultural Development and Policy Design. Asia Pac. Policy Stud. 2025, 12, e70016. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, S.; Zhu, Y.; Xu, X.W. The measurement of carbon emission effect of construction land changes in Anhui Province based on the extended LMDI model. J. Resour. Ecol. 2013, 4, 186–192. [Google Scholar]

- Xie, A.; Liu, L.; Qin, L. Fuzzy comprehensive evaluation of happiness index of nine cities in pearl river delta based on AHP. J. Math. 2021, 2021, 7732095. [Google Scholar] [CrossRef]

- Qiao, X.N.; Peng, L.Z. Carbon Peaking, Carbon Neutrality and Green and Low-Carbon Development of China’s Economy. Economics 2022, 17, 290–324. [Google Scholar]

- Ni, G.; Fang, Y.; Niu, M.; Lv, L.; Song, C.; Wang, W. Spatial differences, dynamic evolution and influencing factors of China’s construction industry carbon emission efficiency. J. Clean. Prod. 2024, 448, 141593. [Google Scholar] [CrossRef]

- Zhang, P.; Hu, J.; Zhao, K.; Chen, H.; Zhao, S.; Li, W. Dynamics and decoupling analysis of carbon emissions from construction industry in China. Buildings 2022, 12, 257. [Google Scholar] [CrossRef]

- Seyedabadi, M.R.; Karrabi, M.; Shariati, M.; Karimi, S.; Maghrebi, M.; Eicker, U. Global building life cycle assessment: Comparative study of steel and concrete frames across European Union, USA, Canada, and Australia building codes. Energy Build. 2024, 304, 113875. [Google Scholar] [CrossRef]

- Jiang, T.; Li, S.; Yu, Y.; Peng, Y. Energy-related carbon emissions and structural emissions reduction of China’s construction industry: The perspective of input–output analysis. Environ. Sci. Pollut. Res. 2022, 29, 39515–39527. [Google Scholar] [CrossRef] [PubMed]

- Sun, K.; Han, J.; Sun, W.; Yan, T.; Liu, C.; Yang, Z.; He, W.; Xie, W.S. The efficiency evaluation and the spatiotemporal differences of CO2 emissions in China’s construction industry. J. Clean. Prod. 2023, 426, 139205. [Google Scholar] [CrossRef]

- Li, Z.; Wang, F.; Kang, T.; Wang, C.; Chen, X.; Miao, Z.; Zhang, L.; Ye, Y.; Zhang, H. Exploring differentiated impacts of socioeconomic factors and urban forms on city-level CO2 emissions in China: Spatial heterogeneity and varying importance levels. Sustain. Cities Soc. 2022, 84, 104028. [Google Scholar] [CrossRef]

- Sun, R.; Yand, M. A Study on the Influencing Factors of Carbon Emissions in Provincial Construction Industry Based on LMDI Model–Taking Shandong Province as an Example. In Proceedings of the Tenth International Forum of Decision Sciences, Harbin, China, 2–3 July 2022; Springer: Singapore, 2022; pp. 249–263. [Google Scholar]

- Liang, H.; Bian, X.; Dong, L. Towards net zero carbon buildings: Accounting the building embodied carbon and life cycle-based policy design for Greater Bay Area, China. Geosci. Front. 2024, 15, 101760. [Google Scholar] [CrossRef]

| Eastern | Central | Western | Northeastern |

|---|---|---|---|

| Beijing | Shanxi | Inner Mongolia | Liaoning |

| Tianjing | Anhui | Guangxi | Jilin |

| Hebei | Jiangxi | Chongqing | Heilongjiang |

| Shanghai | Henan | Sichuan | |

| Jiangsu | Hubei | Guizhou | |

| Zhejiang | Hunan | Yunnan | |

| Fujian | Shaanxi | ||

| Shandong | Gansu | ||

| Guangdong | Qinghai | ||

| Hainan | Ningxia | ||

| Xinjiang |

| Energy Source | Conversion Factor for Standard Coal (kgce/kg) | Carbon-Emission Factor (kgCO2/kgce) |

|---|---|---|

| Raw coal | 0.7143 | 0.7559 |

| Petrol | 1.4714 | 0.5538 |

| Paraffin | 1.4714 | 0.5714 |

| Diesel oil | 1.4571 | 0.5921 |

| Fuel oil | 1.4286 | 0.6185 |

| Liquefied petroleum gas | 1.7143 | 0.5042 |

| Natural gas | 1.3300 | 0.4483 |

| Electricity | 0.1229 | 0.2900 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Li, M.; Sun, J.; Liu, J.; Wang, Y.; Li, L.; Xiong, X. Spatiotemporal Variations and Driving Factors of Carbon Emissions Related to Energy Consumption in the Construction Industry of China. Energies 2025, 18, 3700. https://doi.org/10.3390/en18143700

Zhang Y, Li M, Sun J, Liu J, Wang Y, Li L, Xiong X. Spatiotemporal Variations and Driving Factors of Carbon Emissions Related to Energy Consumption in the Construction Industry of China. Energies. 2025; 18(14):3700. https://doi.org/10.3390/en18143700

Chicago/Turabian StyleZhang, Yue, Min Li, Jiazhen Sun, Jie Liu, Yinsheng Wang, Li Li, and Xin Xiong. 2025. "Spatiotemporal Variations and Driving Factors of Carbon Emissions Related to Energy Consumption in the Construction Industry of China" Energies 18, no. 14: 3700. https://doi.org/10.3390/en18143700

APA StyleZhang, Y., Li, M., Sun, J., Liu, J., Wang, Y., Li, L., & Xiong, X. (2025). Spatiotemporal Variations and Driving Factors of Carbon Emissions Related to Energy Consumption in the Construction Industry of China. Energies, 18(14), 3700. https://doi.org/10.3390/en18143700