A Review of Optimization Methods for Pipeline Monitoring Systems: Applications and Challenges for CO2 Transport

Abstract

1. Introduction

- Section 2 describes the scope and methodology for the literature review;

- Section 3 outlines the monitoring objectives and techniques for pipelines transporting various gases and liquids, including CO2;

- Section 4 reviews optimization problems and solution algorithms for sensor placement in such systems;

- Section 6 summarizes the key findings and suggests directions for future work.

2. The Review Scope and Methodology

- CO2 pipeline monitoring objectives:

- “CCS” OR “CCUS” AND “pipeline” AND “monitoring”;

- “CO2 pipeline” AND “monitoring” OR “instrumentation”;

- “CO2 transport” AND “sensor network” or “sensor grid”;

- Optimization of pipeline monitoring:

- “Sensor placement” AND “pipeline monitoring” AND “optimization”;

- “Leak detection” AND “pipeline” AND “optimization”;

- “Pipeline monitoring” AND “machine learning” OR “fault detection”.

- Proposed optimization methods related to pipeline monitoring;

- Addressed sensor placement for various monitoring objectives;

- Offered insights applicable to the pipeline networks.

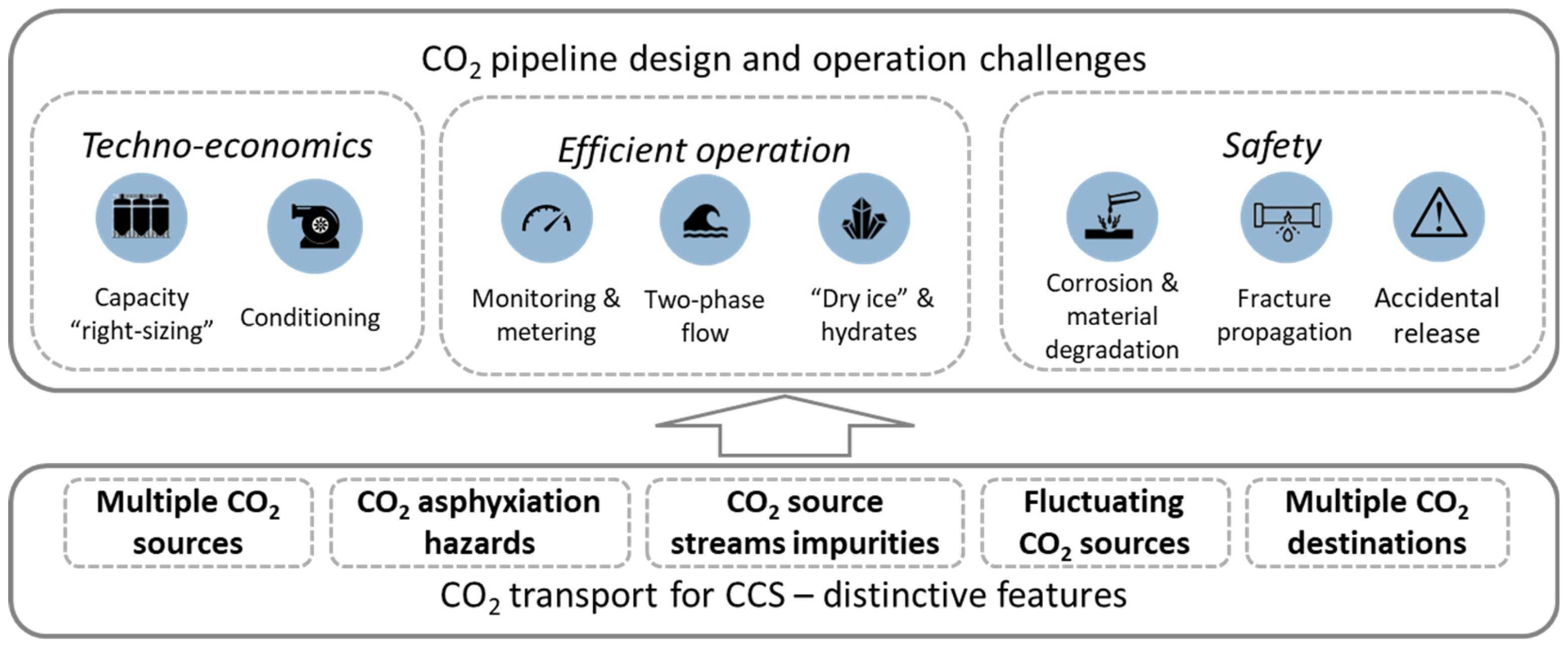

3. CO2 Pipeline Monitoring Objectives

- The pipeline integrity management, which is aimed at detecting damage and failures of the pipeline infrastructure, potentially posing threats to the pipeline operation, the public, or the environment;

- Contamination control to ensure the quality of fluid delivered to a customer;

- Fiscal metering for commercial purposes (custody transfer).

- The free water content and concentration of other impurity components, which may pose a risk of pipeline internal corrosion, hydrate formation (especially for offshore pipelines), transition to two-phase flow upon changes in the pipeline pressure, or additional safety hazards (e.g., when toxic components such as H2S or SO2 are present);

- The pressure variation during start-up, shutdown, depressurization, and normal operation conditions may pose risks of pipeline overpressure and impact the water solubility in dense-phase CO2;

- The temperature variations during start-up, shutdown, and normal operations may alter the CO2 thermodynamic state, the density of CO2 fluid, and the pipeline transportation capacity;

- Measurement of the flow rate and composition of CO2 streams against the product specifications is important for custody transfer to ensure the quantity and quality of the CO2 delivered by the pipeline operator.

- (a)

- Unique physical properties of CO2, e.g., the acoustic attenuation posing a challenge for using ultrasonic flow meters and the presence of impurities that can affect the thermodynamic properties and phase equilibria;

- (b)

- Measurement uncertainties due to pressure or temperature variations in a pipeline system;

- (c)

- Phase transition risks—due to the proximity of CO2 pipeline operation conditions to the CO2 saturation line, two-phase flow can occur during start-up, shutdown, or depressurization;

- Impurities and corrosion hazards—trace components such as H2O, SO2, or H2S may cause corrosion or safety risks, requiring continuous composition monitoring;

- High measurement uncertainty—arising from compressibility effects, temperature sensitivity, and lack of standardized instrumentation;

- Dense-gas safety risks—as released CO2 can accumulate in low-lying areas and pose asphyxiation hazards to humans;

- Transient flow conditions—driven by fluctuating capture and injection rates from industrial sources;

- Lack of standardized monitoring protocols—creating ambiguity in design requirements and performance expectations.

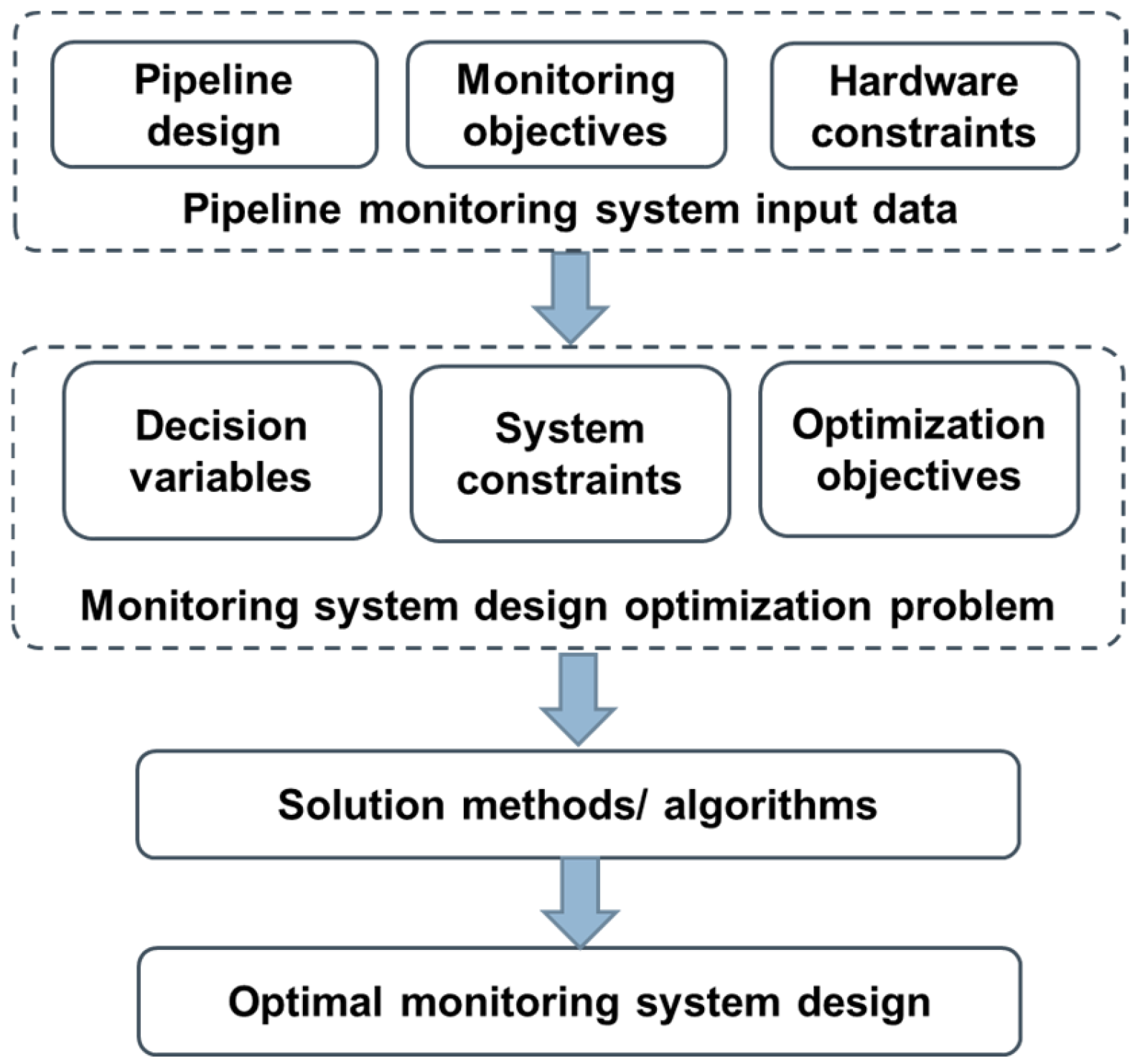

4. Optimization of Pipeline Monitoring

- (1)

- Leak detection and localization;

- (2)

- Flow measurements;

- (3)

- Fluid quality control;

- (4)

- Improving energy efficiency and cost-effectiveness of the monitoring solutions.

4.1. Leak Detection and Localization

4.2. Flow Rate Measurement

4.3. Fluid Quality and Impurities Monitoring

4.4. Energy Efficiency and Cost-Effectiveness of Monitoring System

5. Discussion: Recommendations on Optimizing the CO2 Pipeline Monitoring Systems

5.1. Leak Detection and Localization

5.2. Flow Measurement

5.3. Impurities Monitoring

6. Summary and Directions for Future Studies

- Sensor placement is the most studied pipeline monitoring optimization problem. Other optimization decision variables may include the types and combinations of sensors, as well as the optimal number of sensors or monitoring points;

- Methods of computer-based leak detection and localization, as well as optimal placement of monitoring sensors developed for pipelines transporting liquids (including water distribution systems and pipelines transporting crude oil and petroleum liquids), can be most relevant to liquid and dense-phase CO2 transport;

- Artificial Intelligence (AI) and Machine Learning (ML) methods developed for detecting flow anomalies and leak detection in natural gas and oil pipelines can be adapted to improve flow monitoring in CO2 pipelines. In particular, using ML-based anomaly detection and virtual flow metering can enhance flow measurement accuracy in scenarios of transient and two-phase flow to aid the flow assurance in the start-up, shutdown, or emergency operations of CO2 pipelines;

- Adapting the flow models for component tracking, such as those developed for water distribution systems, can be useful for enhancing the composition monitoring in CO2 pipeline networks and potentially optimizing the composition monitoring systems. In addition, finding optimal combinations of measurement techniques, e.g., GC and OFCEAS instruments, as recently recommended for hydrogen transport, may further improve impurity measurement accuracy;

- CO2 pipeline monitoring optimization can be described as a multi-objective optimization problem. While the accuracy of measurements, the number of sensors, and the cost of monitoring are the most commonly employed objective functions, the risks to the nearby population and environmental impacts in the event of accidental CO2 release must also be considered as part of the optimization criteria;

- Various mathematical methods and algorithms for solving the pipeline monitoring optimization problems are available. The specific choice of methods/algorithms depends on the types of the optimization model decision variables and constraints, the number of optimization objectives, the presence of a stochastic component of the objective function, and the multiple potential solutions, amongst other factors;

- Currently, emerging model-based data-driven approaches and non-model-based techniques, such as deep learning, are gaining traction in optimizing the monitoring and control of various pipeline systems. These methods offer significant potential for CO2 transport systems, particularly when integrated with pipeline flow simulators and Digital Twin platforms, to process large datasets covering the various pipeline operation scenarios. For example, graph-based models or physics-informed neural networks (PINN) (see, e.g., [103]) may be promising for capturing both spatial correlations and underlying flow physics in CO2 anomaly detection. This is particularly relevant for CO2 pipelines, where flow dynamics are governed by known physical laws but data are often sparse and unevenly distributed. By embedding governing equations into the learning process, PINNs can leverage limited sensor data while ensuring consistency with the underlying physics.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| ANN | Artificial Neural Network |

| AMGA | Adam-Mutated Genetic Algorithm |

| CCS | Carbon Capture and Storage |

| CPM | Computational Pipeline Monitoring |

| CSO | Combined Sewer Overflows |

| DT | Digital Twin |

| EOR | Enhanced Oil Recovery |

| GA | Genetic Algorithm |

| IPCC | Intergovernmental Panel on Climate Change |

| MILP | Mixed-Integer Linear Programming |

| MINLP | Mixed-Integer Non-Linear Programming |

| ML | Machine Learning |

| MOEA | Multi-Objective Evolutionary Algorithm |

| PINN | Physics-Informed Neural Networks |

| PSO | Particle Swarm Optimization |

| RTC | Real-Time Control |

| SCADA | Supervisory Control and Data Acquisition |

| WDS | Water Distribution System |

| WSN | Wireless Sensor Network |

References

- United Nations Climate Change, The Paris Agreement. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement/the-paris-agreement (accessed on 1 December 2023).

- Intergovernmental Panel on Climate Change: Special Report on Global Warming of 1.5 C (SR15). Available online: https://www.ipcc.ch/sr15/ (accessed on 1 December 2023).

- IEA: CO2 Emissions in 2022. Available online: https://www.iea.org/reports/co2-emissions-in-2022 (accessed on 6 January 2024).

- Bouckaert, S.; Pales, A.F.; McGlade, C.; Remme, U.; Wanner, B.; Varro, L.; D’Ambrosio, D.; Spencer, T. Net Zero by 2050: A Roadmap for the Global Energy Sector; OECD Publishing: Paris, France, 2021; Available online: https://trid.trb.org/View/1856381 (accessed on 6 January 2024).

- Zero Emissions Platform: CCS/CCU Projects. Available online: https://zeroemissionsplatform.eu/knowledge-hub/ (accessed on 5 July 2024).

- Zero Emissions Platform, A Trans-European CO2 Transportation Infrastructure for CCUS: Opportunities & Challenges. Available online: https://zeroemissionsplatform.eu/wp-content/uploads/A-Trans-European-CO2-Transportation-Infrastructure-for-CCUS-Opportunities-Challenges.pdf (accessed on 5 July 2024).

- Global CCS Institute, CCS Explained: Transport. 2022. Available online: https://www.globalccsinstitute.com/wp-content/uploads/2022/07/Factsheet_CCS-Explained_Transport.pdf (accessed on 8 July 2024).

- Metz, B.; Davidson, O.; Coninck, H.d.; Loos, M.; Meyer, L. Carbon Dioxide Capture and Storage; Intergovernmental Panel On Climate Change: Cambridge, UK, 2005; p. 431. Available online: https://www.ipcc.ch/report/carbon-dioxide-capture-and-storage/ (accessed on 30 April 2024).

- Thomas, S. Enhanced oil recovery-an overview. Oil Gas Sci. Technol.-Rev. L’ifp 2008, 63, 9–19. [Google Scholar] [CrossRef]

- C4U (Advanced Carbon Capture for Steel Industries Integrated in CCUS Clusters), The C4U Policy Brief Series D7.4. Available online: https://c4u-project.eu/the-c4u-policy-brief-series/ (accessed on 2 February 2024).

- Wang, H.; Chen, J.; Li, Q. A Review of Pipeline Transportation Technology of Carbon Dioxide. IOP Conf. Ser. Earth Environ. Sci. 2019, 310, 032033. [Google Scholar] [CrossRef]

- Kruse, H.; Tekiela, M. Calculating the consequences of a CO2-pipeline rupture. Energy Convers. Manag. 1996, 37, 1013–1018. [Google Scholar] [CrossRef]

- Cagle, A. A Leaking CO2 Pipeline Can Cause Suffocation Within a Minute. The Government Needs to Regulate Them, Fast. Available online: https://earthjustice.org/article/a-leaking-co2-pipeline-can-cause-suffocation-within-a-minute-the-government-needs-to-regulate-them-fast (accessed on 2 August 2024).

- Bilio, M.; Brown, S.; Fairwheather, M.; Mahgerefteh, H. CO2 Pipelines Material and Safety Considerations. In Hazards XXI: Process Safety and Environmental Protection in a Changing World; Institution of Chemical Engineers: Warwickshire, UK, 2009; Volume 155, pp. 423–429. Available online: https://www.icheme.org/media/9558/xxi-paper-061.pdf (accessed on 5 April 2025).

- Jensen, M.; Schlasner, S.; Sorensen, J.; Hamling, J. Subtask 2.19–Operational Flexibility of CO2 Transport and Storage; University of North Dakota: Grand Forks, ND, USA, 2014. Available online: https://www.osti.gov/servlets/purl/1176874 (accessed on 20 May 2024).

- DNV: Design and Operation of CO2 Pipelines: Recommended Practice DNV-RP-F104. Available online: https://www.dnv.com/oilgas/download/dnv-rp-f104-design-and-operation-of-carbon-dioxide-pipelines.html (accessed on 11 November 2023).

- Onyebuchi, V.E.; Kolios, A.; Hanak, D.P.; Biliyok, C.; Manovic, V. A systematic review of key challenges of CO2 transport via pipelines. Renew. Sust. Energ. Rev. 2018, 81, 2563–2583. [Google Scholar] [CrossRef]

- Varela, F.; Yongjun Tan, M.; Forsyth, M. An overview of major methods for inspecting and monitoring external corrosion of on-shore transportation pipelines. Corros. Eng. Sci. Technol. 2015, 50, 226–235. [Google Scholar] [CrossRef]

- Ameh, E.; Ikpeseni, S.; Lawal, L. A review of field corrosion control and monitoring techniques of the upstream oil and gas pipelines. Niger. J. Technol. Dev. 2017, 14, 67–73. [Google Scholar] [CrossRef]

- Utepov, Y.; Kazkeyev, A.; Aniskin, A. A multi-criteria analysis of sewer monitoring methods for locating pipe blockages and manhole overflows. Technobius 2021, 1, 0006. [Google Scholar] [CrossRef]

- Keng, T.S.; Samsudin, M.F.R.; Sufian, S. Evaluation of wastewater treatment performance to a field-scale constructed wetland system at clogged condition: A case study of ammonia manufacturing plant. Sci. Total Environ. 2021, 759, 143489. [Google Scholar] [CrossRef]

- Henrie, M.; Carpenter, P.; Nicholas, R.E. Pipeline Leak Detection Handbook; Gulf Professional Publishing: Amsterdam, The Netherlands, 2016; Available online: https://www.sciencedirect.com/book/9780128022405/pipeline-leak-detection-handbook (accessed on 5 June 2024).

- Adegboye, M.A.; Fung, W.-K.; Karnik, A. Recent Advances in Pipeline Monitoring and Oil Leakage Detection Technologies: Principles and Approaches. Sensors 2019, 19, 2548. [Google Scholar] [CrossRef]

- Mathews, W.; Ruhl, C. Failure Investigation Report—Denbury Gulf Coast Pipelines, LLC—Pipeline Rupture/Natural Force Damage. Available online: https://www.phmsa.dot.gov/sites/phmsa.dot.gov/files/2022-05/Failure%20Investigation%20Report%20-%20Denbury%20Gulf%20Coast%20Pipeline.pdf (accessed on 7 July 2024).

- Blist’an, P.; Pacaiova, H. Modelling Environmental Influence on the Pipelines Integrity; Surveying Geology & Mining Ecology Management (SGEM): Sofia, Bulgaria, 2011; pp. 645–652. Available online: https://www.proquest.com/conference-papers-proceedings/modelling-environmental-influence-on-pipelines/docview/1285485899/se-2?accountid=14511 (accessed on 7 July 2024).

- Ravet, F.; Niklès, M.; Rochat, E. A Decade of Pipeline Geotechnical Monitoring Using Distributed Fiber Optic Monitoring Technology. In Proceedings of the ASME 2017 International Pipeline Geotechnical Conference, Lima, Peru, 25–26 July 2017. [Google Scholar] [CrossRef]

- Matsumura, M. A case study of a pipe line burst in the Mihama Nuclear Power Plant. Mater. Corros. 2006, 57, 872–882. [Google Scholar] [CrossRef]

- Jackson, R.B.; Down, A.; Phillips, N.G.; Ackley, R.C.; Cook, C.W.; Plata, D.L.; Zhao, K. Natural Gas Pipeline Leaks Across Washington, DC. Environ. Sci. Technol. 2014, 48, 2051–2058. [Google Scholar] [CrossRef] [PubMed]

- Qu, Z.; Wang, H.; An, Y.; Yue, H.; Li, J.; Zhang, Y.; Wang, Y.; Yue, T.; Zhou, W. Online monitoring method of hydrate agglomeration in natural gas pipelines based on acoustic active excitation. Measurement 2016, 92, 11–18. [Google Scholar] [CrossRef]

- Vitali, M.; Zuliani, C.; Corvaro, F.; Marchetti, B.; Tallone, F. Statistical analysis of incidents on onshore CO2 pipelines based on PHMSA database. J. Loss Prev. Process Ind. 2022, 77, 104799. [Google Scholar] [CrossRef]

- Duguid, A.; Hawkins, J.; Keister, L. CO2 Pipeline risk assessment and comparison for the midcontinent United States. Int. J. Greenh. Gas Control. 2022, 116, 103636. [Google Scholar] [CrossRef]

- Yi, J.; Martynov, S.; Mahgerefteh, H. Puncture Failure Size Probability Distribution for CO2 Pipelines. Int. J. Greenh. Gas Control. 2023, 125, 103889. [Google Scholar] [CrossRef]

- Xi, D.; Lu, H.; Fu, Y.; Dong, S.; Jiang, X.; Matthews, J. Carbon dioxide pipelines: A statistical analysis of historical accidents. J. Loss Prev. Process Ind. 2023, 84, 105129. [Google Scholar] [CrossRef]

- Fuchs, H.V.; Riehle, R. Ten years of experience with leak detection by acoustic signal analysis. Appl. Acoust. 1991, 33, 1–19. [Google Scholar] [CrossRef]

- Zhang, J. Designing a cost-effective and reliable pipeline leak-detection system. Pipes Pipelines Int. 1997, 42, 20–26. Available online: https://thewaternetwork.com/_/online-real-time-water-quality-management/storage/TFX%5CDocumentBundle%5CEntity%5CDocument-Uy8r1dAW-8oXjKmN_I_9tQ/vTVmLmtIhnki0rNcq9tn1Q/file/reliability_96_paper.pdf (accessed on 17 March 2025).

- Hamilton, S.; Charalambous, B. Leak Detection: Technology and Implementation; IWA Publishing: London, UK, 2013; Available online: http://library.oapen.org/handle/20.500.12657/33035 (accessed on 1 September 2024).

- Murvay, P.-S.; Silea, I. A survey on gas leak detection and localization techniques. J. Loss Prev. Process Ind. 2012, 25, 966–973. [Google Scholar] [CrossRef]

- Korlapati, N.V.S.; Khan, F.; Noor, Q.; Mirza, S.; Vaddiraju, S. Review and analysis of pipeline leak detection methods. J. Pipeline Sci. Eng. 2022, 2, 100074. [Google Scholar] [CrossRef]

- API Recommended Practice 1130: Computational Pipeline Monitoring for Liquids Pipelines. Available online: https://www.api.org/products-and-services/standards/important-standards-announcements/rp1130 (accessed on 1 August 2024).

- Geiger, G. Pipeline Leak Detection Technologies and Emergency Shutdown Protocols. In Proceedings of the 2014 10th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2014; p. V001T09A015. [Google Scholar] [CrossRef]

- Hainen, A.M.; Harbin, K.B.; Dye, D.; Lindly, J.K. Duration analysis of emergency shutdown incidents regarding hazardous liquid pipelines. J. Perform. Constr. Facil. 2020, 34, 04020040. [Google Scholar] [CrossRef]

- Zhu, P.; Liyanage, J.P.; Panesar, S.S.; Kumar, R. Review of workflows of emergency shutdown systems in the Norwegian oil and gas industry. Saf. Sci. 2020, 121, 594–602. [Google Scholar] [CrossRef]

- Medina, H.; Arnaldos, J.; Casal, J.; Bonvicini, S.; Cozzani, V. Risk-based optimization of the design of on-shore pipeline shutdown systems. J. Loss Prev. Process Ind. 2012, 25, 489–493. [Google Scholar] [CrossRef]

- Chrysostomidis, I.; Geyer, T.A.; Smith, A.; Fedorowick, J.; Bohm, M.; Beynon, E.; Little, C.; Lee, A. CO2 pipeline systems: Assessment of the risks and health and safety regulations. In Institution of Chemical Engineers Symposium Series; Institution of Chemical Engineers: Warwickshire, UK, 2009; pp. 411–415. Available online: https://api.semanticscholar.org/CorpusID:210158823 (accessed on 6 October 2024).

- Sleiti, A.K.; Al-Ammari, W.A. Chapter 10—CO2 transportation: Safety regulations and energy requirement. In Emerging Carbon Capture Technologies; Khalid, M., Dharaskar, S.A., Sillanpää, M., Siddiqui, H., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 279–319. [Google Scholar] [CrossRef]

- Noothout, P.; Wiersma, F.; Hurtado, O.; Macdonald, D.; Kemper, J.; van Alphen, K. CO2 Pipeline Infrastructure—Lessons Learnt. Energy Procedia 2014, 63, 2481–2492. [Google Scholar] [CrossRef]

- WRI Annual Report 2008. Available online: https://www.wri.org/wri-annual-report-2008 (accessed on 3 March 2024).

- Verde, C. Modeling and Monitoring of Pipelines and Networks Advanced Tools for Autiomatic Monotoring and Supervision of Pipelines; Springer: Berlin/Heidelberg, Germany, 2017; Available online: https://link.springer.com/book/10.1007/978-3-319-55944-5 (accessed on 20 November 2023).

- Priyanka, E.; Thangavel, S.; Prabhakaran, P. Rank-based risk target data analysis using digital twin on oil pipeline network based on manifold learning. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022, 236, 1637–1651. [Google Scholar] [CrossRef]

- Liang, J.; Ma, L.; Liang, S.; Zhang, H.; Zuo, Z.; Dai, J. Data-driven digital twin method for leak detection in natural gas pipelines. Comput. Electr. Eng. 2023, 110, 108833. [Google Scholar] [CrossRef]

- Wanasinghe, T.R.; Wroblewski, L.; Petersen, B.K.; Gosine, R.G.; James, L.A.; De Silva, O.; Mann, G.K.; Warrian, P.J. Digital twin for the oil and gas industry: Overview, research trends, opportunities, and challenges. IEEE Access 2020, 8, 104175–104197. [Google Scholar] [CrossRef]

- Arrelano, Y. An overview of the measurement landscape needs for CCS. In TCCS; NCCS: Trondheim, Norway, 2023; Available online: https://www.sintef.no/en/publications/publication/2164190/ (accessed on 1 December 2023).

- Mills, C.; Chinello, G.; Henry, M. Flow measurement challenges for carbon capture, utilisation and storage. Flow Meas. Instrum. 2022, 88, 102261. [Google Scholar] [CrossRef]

- Sleiti, A.K.; Al-Ammari, W.A.; Vesely, L.; Kapat, J.S. Carbon Dioxide Transport Pipeline Systems: Overview of Technical Characteristics, Safety, Integrity and Cost, and Potential Application of Digital Twin. J. Energy Resour. Technol. 2022, 144, 092106. [Google Scholar] [CrossRef]

- McAllister, E.W. (Ed.) Pipeline Rules of Thumb Handbook—A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering Problems, 8th ed.; Elsevier: Amsterdam, The Netherlands, 2014; Available online: https://app.knovel.com/hotlink/toc/id:kpPRTHE00L/pipeline-rules-thumb/pipeline-rules-thumb (accessed on 11 November 2023).

- Chinello, G.; Arellano, Y.; Span, R.; van Putten, D.; Abdulrahman, A.; Joonaki, E.; Arrhenius, K.; Murugan, A. Toward standardized measurement of CO2 transfer in the CCS chain. Nexus 2024, 1, 100013. [Google Scholar] [CrossRef]

- Collie, G.J.; Nazeri, M.; Jahanbakhsh, A.; Lin, C.-W.; Maroto-Valer, M.M. Review of flowmeters for carbon dioxide transport in CCS applications. Greenh. Gases: Sci. Technol. 2017, 7, 10–28. [Google Scholar] [CrossRef]

- Kanakoudis, V.; Tsitsifli, S. Potable water security assessment—A review on monitoring, modelling and optimization techniques, applied to water distribution networks. Desalination Water Treat. 2017, 99, 18–26. [Google Scholar] [CrossRef]

- Zulkifli, S.N.; Rahim, H.A.; Lau, W.-J. Detection of contaminants in water supply: A review on state-of-the-art monitoring technologies and their applications. Sens. Actuators B Chem. 2018, 255, 2657–2689. [Google Scholar] [CrossRef]

- Stöhr, T.; Reiter, V.; Scheikl, S.; Klopčič, N.; Brandstätter, S.; Trattner, A. Hydrogen quality in used natural gas pipelines: An experimental investigation of contaminants according to ISO 14687:2019 standard. Int. J. Hydrogen Energy 2024, 67, 1136–1147. [Google Scholar] [CrossRef]

- Gambelli, A.M.; Presciutti, A.; Rossi, F. Review on the characteristics and advantages related to the use of flue-gas as CO2/N2 mixture for gas hydrate production. Fluid Phase Equilibria 2021, 541, 113077. [Google Scholar] [CrossRef]

- Kim, J.; Yoon, H.; Hwang, S.; Jeong, D.; Ki, S.; Liang, B.; Jeong, H. Real-time monitoring of CO2 transport pipelines using deep learning. Process Saf. Environ. Prot. 2024, 181, 480–492. [Google Scholar] [CrossRef]

- Casillas, M.V.; Puig, V.; Garza-Castañón, L.E.; Rosich, A. Optimal Sensor Placement for Leak Location in Water Distribution Networks Using Genetic Algorithms. Sensors 2013, 13, 14984–15005. [Google Scholar] [CrossRef]

- Mitchell, M. An Introduction to Genetic Algorithms; MIT Press: Cambridge, MA, USA, 1998; Available online: https://mitpress.mit.edu/9780262631853/an-introduction-to-genetic-algorithms/ (accessed on 6 June 2024).

- Shiddiqi, A.M.; Za’in, C.; Lathifah, A.; Ahmad, T.; Purwitasari, D. GA-Sense: Sensor placement strategy for detecting leaks in water distribution networks based on time series flow and genetic algorithm. MethodsX 2024, 12, 102612. [Google Scholar] [CrossRef]

- Gallagher, K.; Sambridge, M. Genetic algorithms: A powerful tool for large-scale nonlinear optimization problems. Comput. Geosci. 1994, 20, 1229–1236. [Google Scholar] [CrossRef]

- Ribeiro, L.; Sousa, J.; Marques, A.S.; Simões, N.E. Locating Leaks with TrustRank Algorithm Support. Water 2015, 7, 1378–1401. [Google Scholar] [CrossRef]

- Gyongyi, Z.; Garcia-Molina, H.; Pedersen, J. Combating web spam with trustrank. In Proceedings of the 30th International Conference on Very Large Data Bases (VLDB 2004), Toronto, ON, Canada, 29 August–3 September 2004. [Google Scholar] [CrossRef]

- Xing, L.; Raviv, T.; Sela, L. Sensor placement for robust burst identification in water systems: Balancing modeling accuracy, parsimony, and uncertainties. Adv. Eng. Inform. 2022, 51, 101484. [Google Scholar] [CrossRef]

- Hu, Z.; Chen, B.; Chen, W.; Tan, D.; Shen, D. Review of model-based and data-driven approaches for leak detection and location in water distribution systems. Water Supply 2021, 21, 3282–3306. [Google Scholar] [CrossRef]

- Sun, C.; Parellada, B.; Puig, V.; Cembrano, G. Leak localization in water distribution networks using pressure and data-driven classifier approach. Water 2019, 12, 54. [Google Scholar] [CrossRef]

- Madbhavi, R.; Joshi, A.; Munikoti, S.; Das, L.; Mohapatra, P.K.; Srinivasan, B. Sensor Placement for Leak Localization in Water Distribution Networks using Machine Learning. In Proceedings of the 2020 IEEE International Conference on Computing, Power and Communication Technologies (GUCON), Paris, France, 2–4 October 2020; pp. 95–100. [Google Scholar] [CrossRef]

- Cheng, M.; Li, J. Optimal sensor placement for leak location in water distribution networks: A feature selection method combined with graph signal processing. Water Res. 2023, 242, 120313. [Google Scholar] [CrossRef]

- Zan, T.T.T.; Gupta, P.; Wang, M.; Dauwels, J.; Ukil, A. Multi-Objective Optimal Sensor Placement for Low-Pressure Gas Distribution Networks. IEEE Sens. J. 2018, 18, 6660–6668. [Google Scholar] [CrossRef]

- Kim, C.; Oh, H.; Chang Jung, B.; Moon, S.J. Optimal sensor placement to detect ruptures in pipeline systems subject to uncertainty using an Adam-mutated genetic algorithm. Struct. Health Monit. 2022, 21, 2354–2369. [Google Scholar] [CrossRef]

- Sun, L.; Chen, X.; Zhang, B.; Mu, C.; Zhou, C. Optimization of gas detector placement considering scenario probability and detector reliability in oil refinery installation. J. Loss Prev. Process Ind. 2020, 65, 104131. [Google Scholar] [CrossRef]

- Albaseer, A.; Baroudi, U. Cluster-based node placement approach for linear pipeline monitoring. IEEE Access 2019, 7, 92388–92397. [Google Scholar] [CrossRef]

- Guo, Y.; Kong, F.; Zhu, D.; Tosun, A.Ş.; Deng, Q. Sensor placement for lifetime maximization in monitoring oil pipelines. In Proceedings of the 1st ACM/IEEE International Conference on Cyber-Physical Systems, Stockholm, Sweden, 12–15 April 2010; pp. 61–68. [Google Scholar] [CrossRef]

- Wang, G.T.; Cheng, Q.W.; Zhao, W.; Liao, Q.; Zhang, H.R. Review on the transport capacity management of oil and gas pipeline network: Challenges and opportunities of future pipeline transport. Energy Strateg. Rev. 2022, 43, 100933. [Google Scholar] [CrossRef]

- Nasirian, A.; Maghrebi, M.F.; Yazdani, S. Leakage detection in water distribution network based on a new heuristic genetic algorithm model. J. Water Resour. Prot. 2013, 05, 294–303. [Google Scholar] [CrossRef]

- Yu, J.; Zavala, V.M.; Anitescu, M. A scalable design of experiments framework for optimal sensor placement. J. Process Contr 2018, 67, 44–55. [Google Scholar] [CrossRef]

- Elnaggar, O.E.; Ramadan, R.A.; Fayek, M.B. WSN in monitoring oil pipelines using ACO and GA. Procedia Comput. Sci. 2015, 52, 1198–1205. [Google Scholar] [CrossRef]

- Tromp, R.R.; Cerioni, L.M.C. Multiphase Flow Regime Characterization and Liquid Flow Measurement Using Low-Field Magnetic Resonance Imaging. Molecules 2021, 26, 3349. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, A.; Pizzo, P. Optimization of an Algorithm for the Measurement of Unsteady Flow-Rates in High-Pressure Pipelines and Application of a Newly Designed Flowmeter to Volumetric Pump Analysis. J. Eng. Gas Turbines Power 2015, 138, 031604. [Google Scholar] [CrossRef]

- van Westering, W.; Hellendoorn, H. Optimal sensor placement using gas distribution network models: A case study. In Proceedings of the 2015 IEEE 12th International Conference on Networking, Sensing and Control, Taipei, Taiwan, 9–11 April 2015. [Google Scholar] [CrossRef]

- Preis, A.; Whittle, A.; Ostfeld, A. Multi-objective optimization for conjunctive placement of hydraulic and water quality sensors in water distribution systems. Water Supply 2011, 11, 166–171. [Google Scholar] [CrossRef]

- He, G.; Zhang, T.; Zheng, F.; Zhang, Q. An efficient multi-objective optimization method for water quality sensor placement within water distribution systems considering contamination probability variations. Water Res. 2018, 143, 165–175. [Google Scholar] [CrossRef]

- Cardoso, S.M.; Barros, D.B.; Oliveira, E.; Brentan, B.; Ribeiro, L. Optimal sensor placement for contamination detection: A multi-objective and probabilistic approach. Environ. Model. Softw. 2021, 135, 104896. [Google Scholar] [CrossRef]

- Naserizade, S.S.; Nikoo, M.R.; Montaseri, H. A risk-based multi-objective model for optimal placement of sensors in water distribution system. J. Hydrol. 2018, 557, 147–159. [Google Scholar] [CrossRef]

- Naeem, S.; Ali, A.; Anam, S.; Ahmed, M.M. An unsupervised machine learning algorithms: Comprehensive review. Int. J. Comput. Digit. Syst. 2023, 13, 911–921. [Google Scholar] [CrossRef]

- Arrhenius, K.; Büker, O.; Fischer, A.; Persijn, S.; Moore, N.D. Development and evaluation of a novel analyser for ISO14687 hydrogen purity analysis. Meas. Sci. Technol. 2020, 31, 075010. [Google Scholar] [CrossRef]

- Bermúdez, A.; Shabani, M. Numerical simulation of gas composition tracking in a gas transportation network. Energy 2022, 247, 123459. [Google Scholar] [CrossRef]

- Fan, D.; Gong, J.; Zhang, S.; Shi, G.; Kang, Q.; Xiao, Y.; Wu, C. A transient composition tracking method for natural gas pipe networks. Energy 2021, 215, 119131. [Google Scholar] [CrossRef]

- Bleschke, T.; Chaczykowski, M. Composition tracking of natural gas–hydrogen mixtures in pipeline flow using high-resolution schemes. Int. J. Hydrogen Energy 2024, 79, 756–770. [Google Scholar] [CrossRef]

- Varshney, S.; Kumar, C.; Swaroop, A.; Khanna, A.; Gupta, D.; Rodrigues, J.J.P.C.; Pinheiro, P.R.; De Albuquerque, V.H.C. Energy Efficient Management of Pipelines in Buildings Using Linear Wireless Sensor Networks. Sensors 2018, 18, 2618. [Google Scholar] [CrossRef]

- Kaelbling, L.P.; Littman, M.L.; Moore, A.W. Reinforcement learning: A survey. J. Artif. Intell. Res. 1996, 4, 237–285. [Google Scholar] [CrossRef]

- Jang, B.; Kim, M.; Harerimana, G.; Kim, J.W. Q-learning algorithms: A comprehensive classification and applications. IEEE Access 2019, 7, 133653–133667. [Google Scholar] [CrossRef]

- Rahmani, A.M.; Ali, S.; Malik, M.H.; Yousefpoor, E.; Yousefpoor, M.S.; Mousavi, A.; Khan, F.; Hosseinzadeh, M. An energy-aware and Q-learning-based area coverage for oil pipeline monitoring systems using sensors and Internet of Things. Sci. Rep. 2022, 12, 9638. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Sage, P. Water Loss Detection via Genetic Algorithm Optimization-based Model Calibration. In Water Distribution Systems Analysis Symposium; ASCE: Reston, VA, USA, 2012; pp. 1–11. [Google Scholar] [CrossRef]

- Boatwright, S. Integrated Optimal Pressure Sensor Placement and Localisation of Leak/Burst Events Using Interpolation and a Genetic Algorithm. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2020. Available online: https://etheses.whiterose.ac.uk/29227/ (accessed on 20 November 2023).

- Simone, A.; Cesaro, A.; Cristo, C.D.; Fecarotta, O.; Morani, M.C. Monitoring planning for urban drainage networks. IOP Conf. Ser. Earth Environ. Sci. 2023, 1136, 012008. [Google Scholar] [CrossRef]

- Osiadacz, A.J.; Chaczykowski, M.; Kotyński, Ł.; Bleschke, T.; Uilhoorn, F.; Kwestarz, M. Composition tracking of CO2-rich streams in large-scale pipeline networks under steady-state conditions. J. Phys. Conf. Ser. 2024, 2899, 012016. [Google Scholar] [CrossRef]

- Cai, S.; Mao, Z.; Wang, Z.; Yin, M.; Karniadakis, G.E. Physics-informed neural networks (PINNs) for fluid mechanics: A review. Acta Mech. Sin. 2021, 37, 1727–1738. [Google Scholar] [CrossRef]

| Transported Fluid and Network Type | Monitoring Objective(s) | Decision Variable(s) | Optimization Objective(s) | Type of Optimization Problem | Single/Multi-Objective | Method(s)/Algorithm(s) | Refs. |

|---|---|---|---|---|---|---|---|

| Water distribution networks | Loss quantification; leak localization | Hydraulic model parameters | Maximum accuracy of water loss detection and localization | Non-linear optimization problem | Single objective | GA | Wu and Sage [99] |

| Leak localization | Sensor positions, leak/burst localization parameters | Maximum accuracy of leak localization | Non-linear optimization problem | Multi-objective | Data-driven, Multi-Objective Evolutionary Algorithm | Boatwright [100] | |

| Positions of sensors | Minimum number of sensors; maximum accuracy of leak localization | Non-linear optimization problem | Single objective | ML classification and feature selection | Madbhavi et al. [72] | ||

| Water quality and contamination detection and localization | Sensors positions | Minimum number of sensors, detection time, and population affected; maximum probability of detection | Non-linear optimization problem | Multi-objective | NSGA | He et al. [87], Cardoso et al. [88] | |

| Urban drainage collection networks | Water quality and the presence of pathogens | Sensors positions | Minimum number of sensors; maximum network reliability and sensor node centrality | MILP or MINLP (depending on the problem formulation) | Single objective | SCIP algorithm (spatial branch-and-bound algorithm); Complex Network Theory | Simone et al. [101] |

| Oil transmission pipelines | Temperature and pressure monitoring | Sensor positions | Minimum power consumption by sensors | MILP | Single objective | Greedy algorithm | Guo et al. [78] |

| Leak localization | Activity time of sensors | Minimum sensor’s power consumption; maximum pipeline coverage | Non-linear optimization problem | Single objective | Reinforcement Learning Algorithm (AI Machine Learning) | Rahmani et al. [98] | |

| Natural gas transmission lines | Leak detection and fault diagnostics | Sensor positions | Maximize the detected number of contaminant points | MILP | Single objective | Deep learning | Liang et al. [50] |

| Natural gas distribution network | Estimating flow under uncertain demand | Sensors positions | Maximum accuracy of the measurement across entire network | Constrained MINLP | Single objective | Greedy algorithm (GA) | van Westering and Hellendoorn [85] |

| Low-pressure gas distribution networks | Detecting flow anomalies | Sensors positions | Minimum time to detection, maximum sensitivity, and impact propagation | MINLP | Multi-objective | Greedy, GRASP, NSGA II, FrameSense, and PSO algorithms | Zan et al. [74] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, T.; Martynov, S.; Mahgerefteh, H. A Review of Optimization Methods for Pipeline Monitoring Systems: Applications and Challenges for CO2 Transport. Energies 2025, 18, 3591. https://doi.org/10.3390/en18143591

Xu T, Martynov S, Mahgerefteh H. A Review of Optimization Methods for Pipeline Monitoring Systems: Applications and Challenges for CO2 Transport. Energies. 2025; 18(14):3591. https://doi.org/10.3390/en18143591

Chicago/Turabian StyleXu, Teke, Sergey Martynov, and Haroun Mahgerefteh. 2025. "A Review of Optimization Methods for Pipeline Monitoring Systems: Applications and Challenges for CO2 Transport" Energies 18, no. 14: 3591. https://doi.org/10.3390/en18143591

APA StyleXu, T., Martynov, S., & Mahgerefteh, H. (2025). A Review of Optimization Methods for Pipeline Monitoring Systems: Applications and Challenges for CO2 Transport. Energies, 18(14), 3591. https://doi.org/10.3390/en18143591