Testing of JTD Engine Fueled with Hemp and Rapeseed Oil Esters

Abstract

1. Introduction

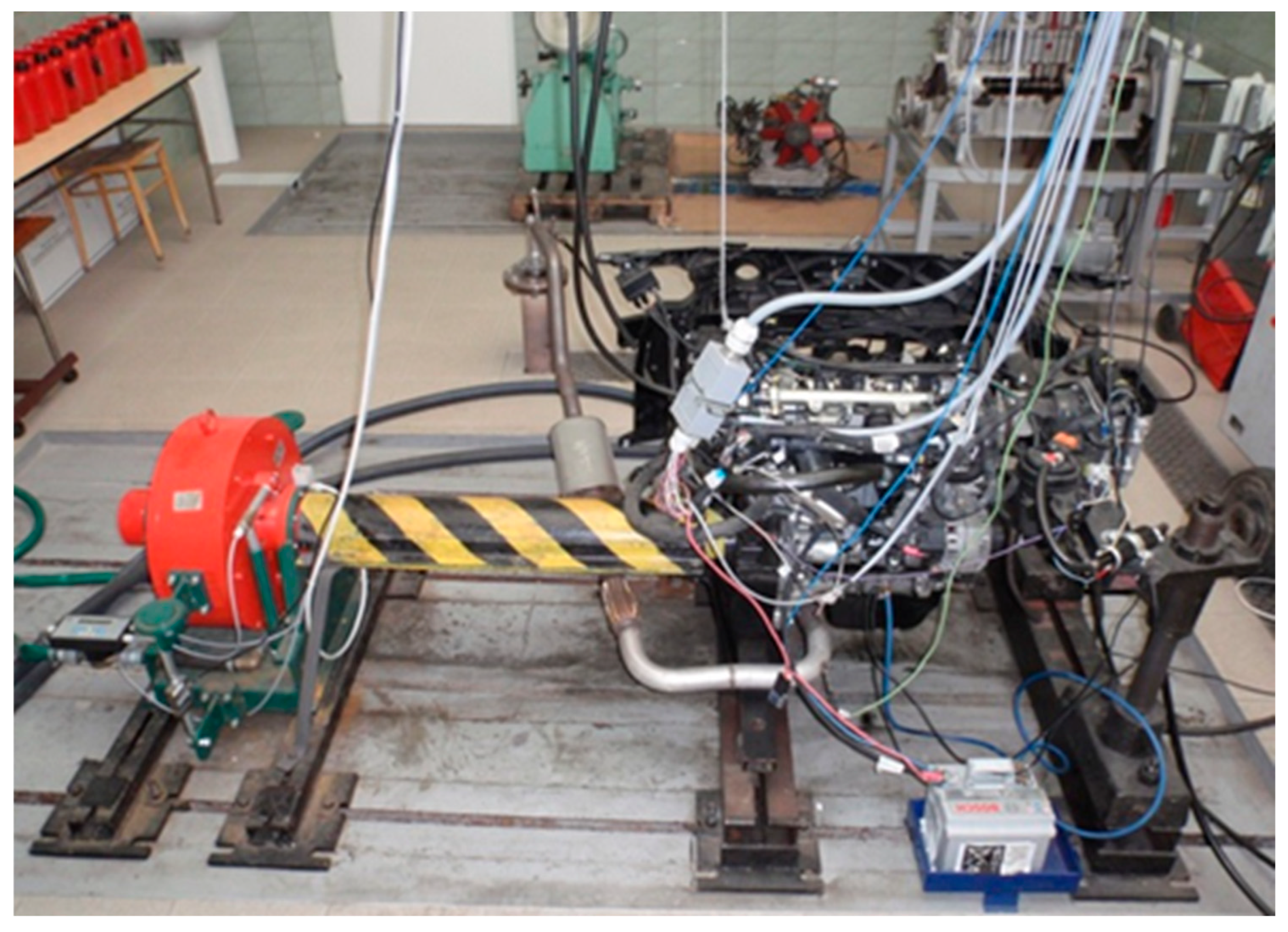

2. Research Methodology

2.1. Scope of Experimental Research

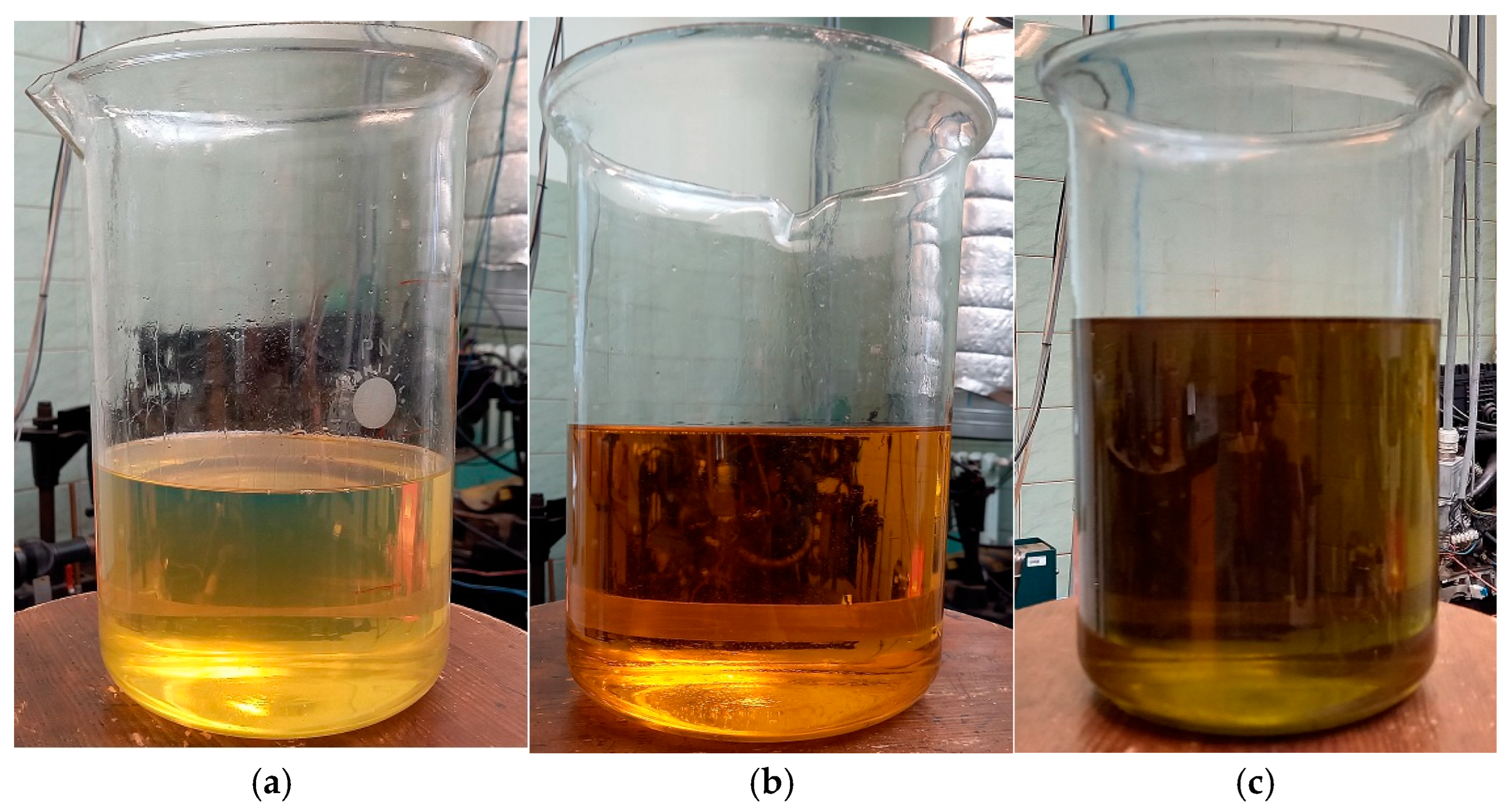

2.2. Fuel Parameters and Production Methodology

2.3. Description of the Test Procedure

3. Experimental Results

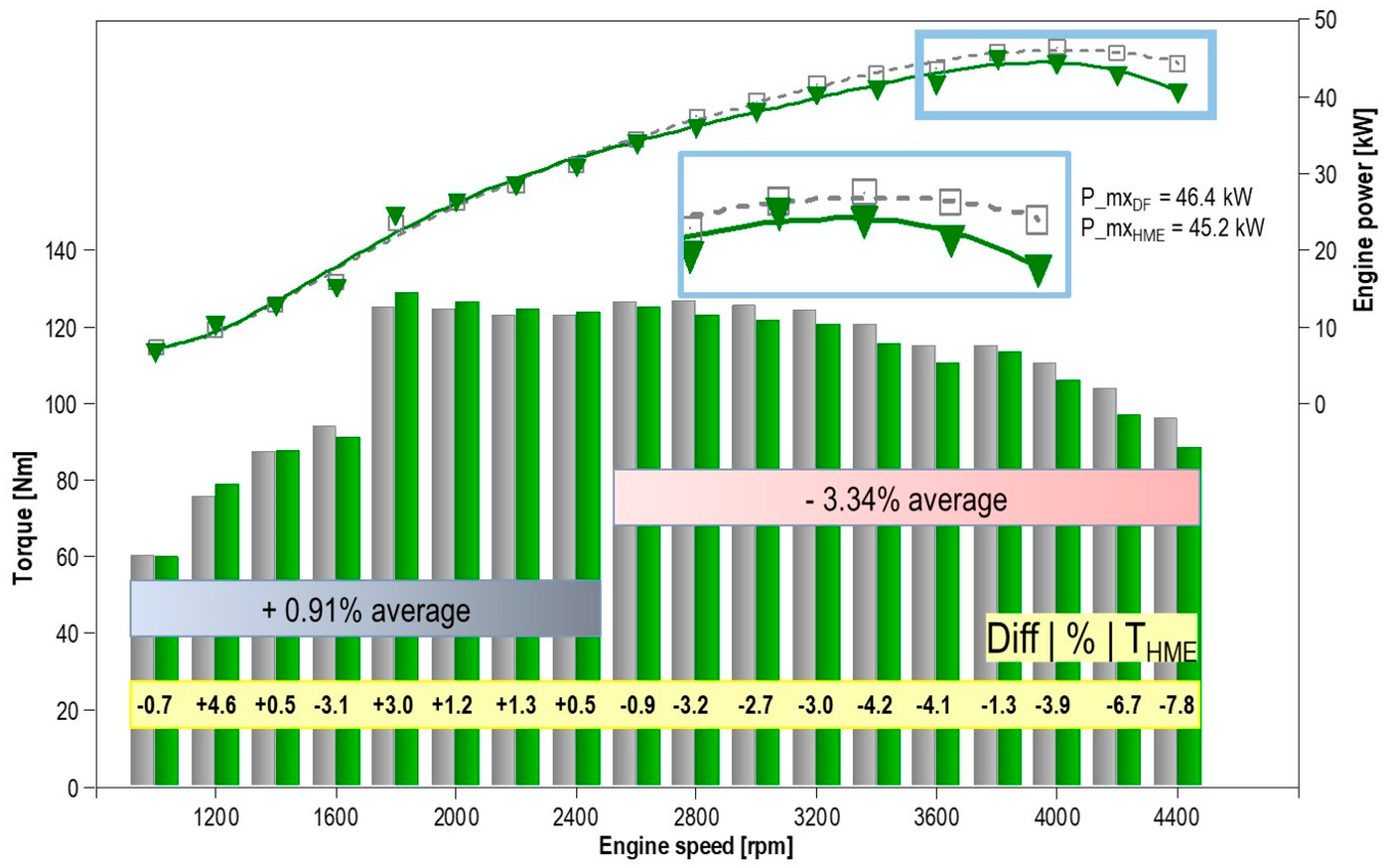

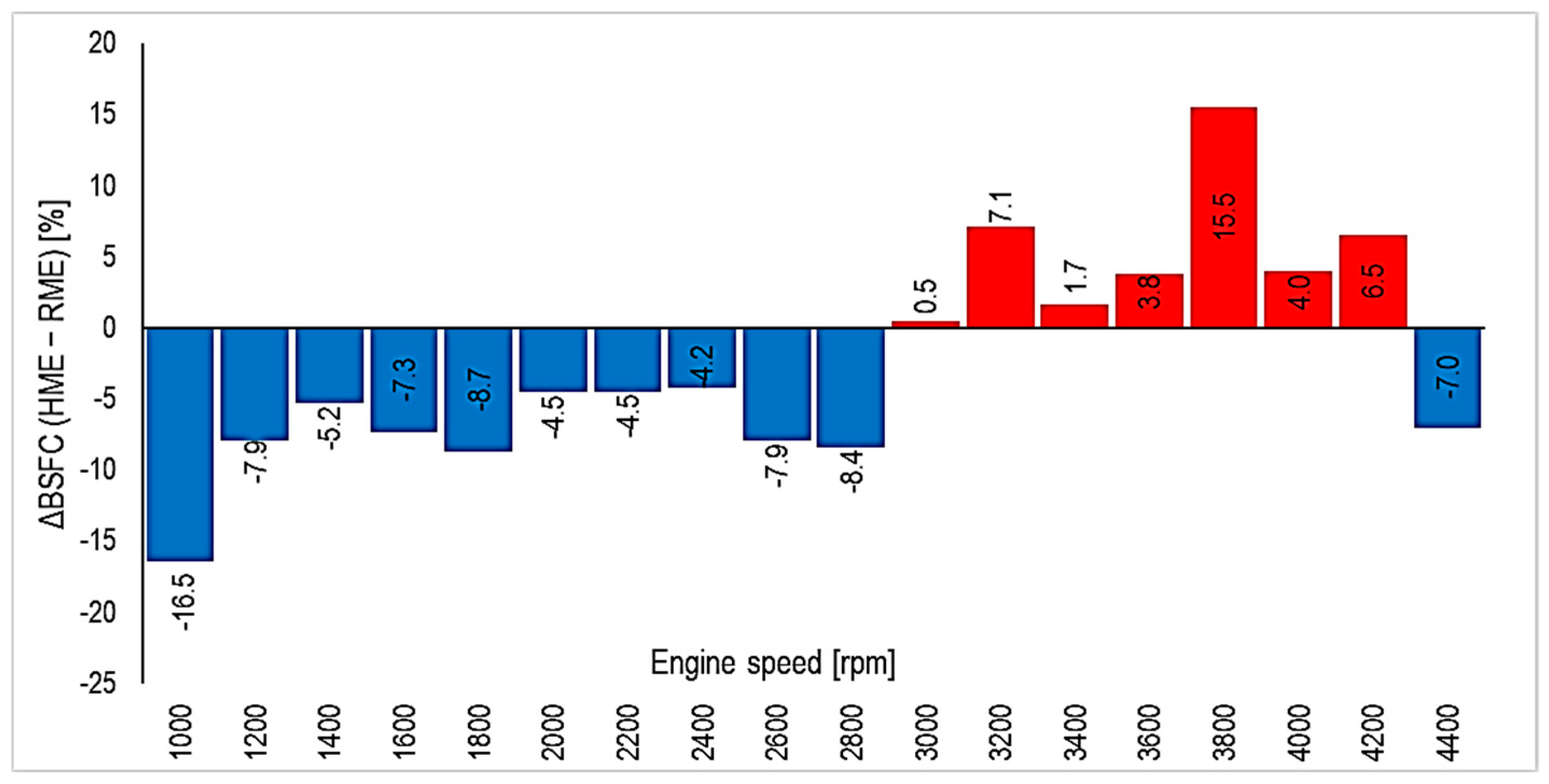

3.1. Performance of the Engine

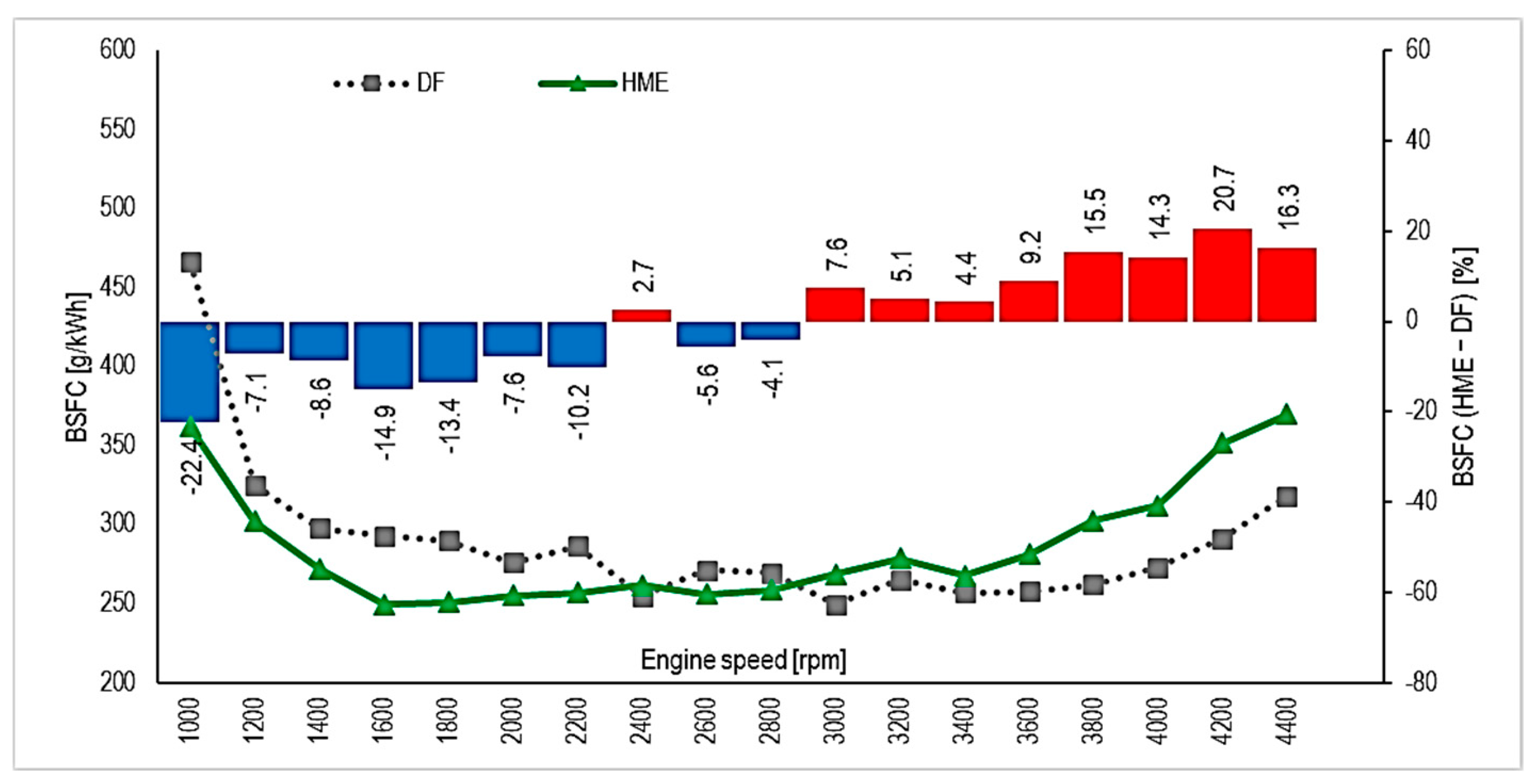

3.2. Fuel Consumption in Terms of Oxygen Content in Biofuels

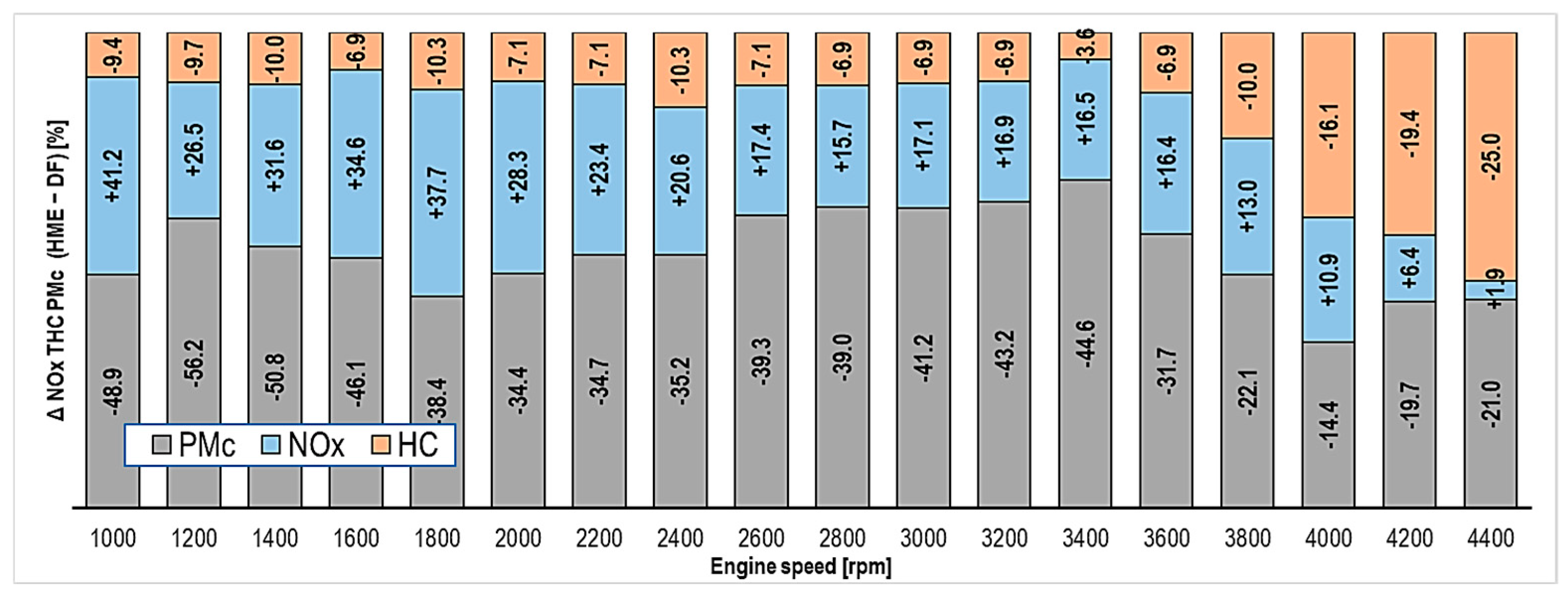

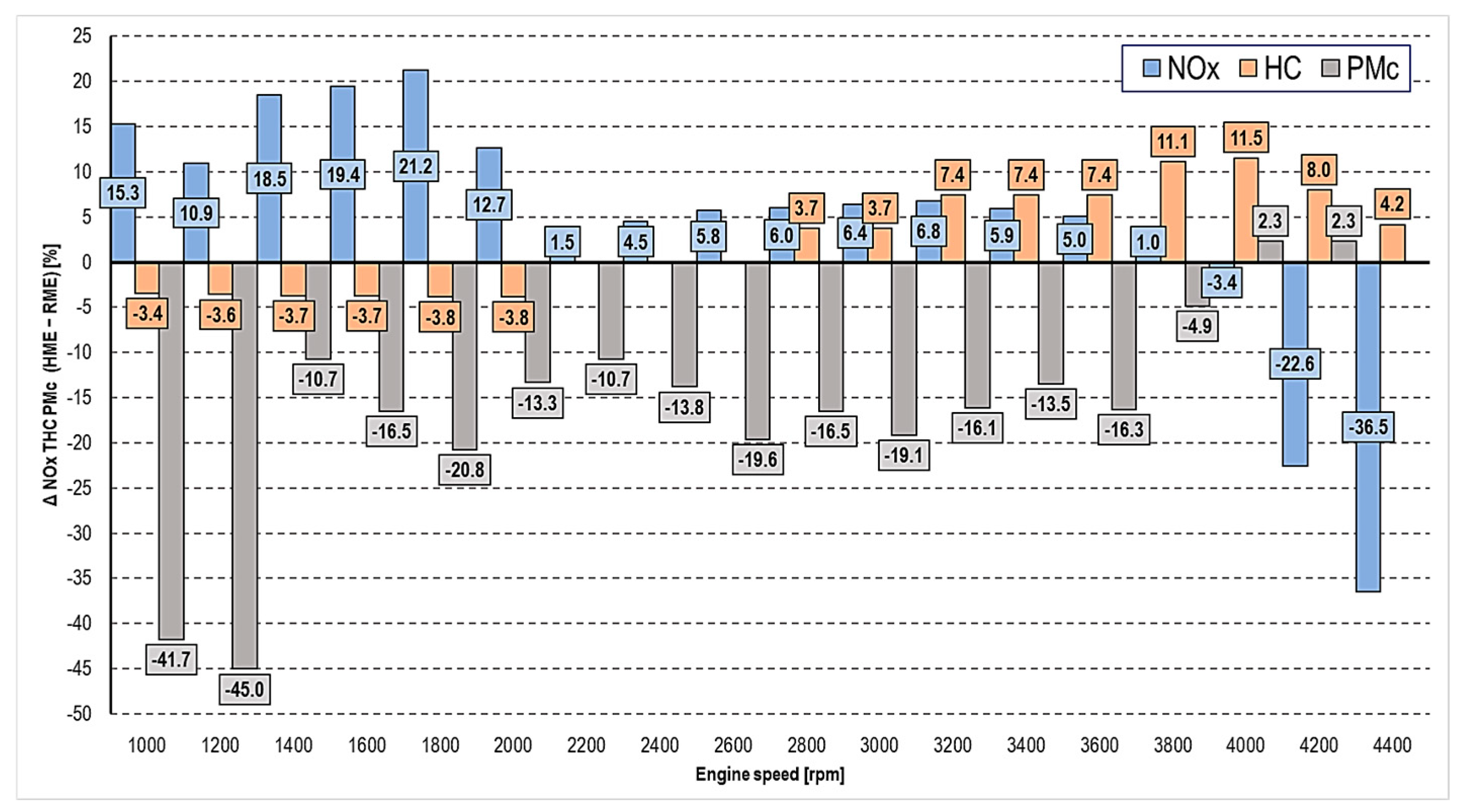

3.3. Exhaust Gas Composition

4. Discussion of Results

5. Summary and Conclusions

- -

- With limited oxygen, the low charge dynamics for HME and RME increased the maximum torque at around 1900 rpm. For HME, the increase in maximum torque relative to DF was 12%. These relationships were reversed at higher speeds of up to 4000 rpm. As a result, the HME-fueled engine had about 4% less maximum power. The authoritative indicator is BSFD. Specific fuel consumption was lower for biofuels at low speeds of up to 2500 rpm, while at higher speeds, the relationship was reversed. This is due to the large difference in fuel density and heating value.

- -

- The level of exhaust emissions differed significantly. For NOx emissions, an average increase of 17% was found for biofuels. Other parameters were reduced: HC was lower relative to DF, while the ratio of HME to RME was variable. For speeds of up to 2500 rpm, significantly lower emissions were observed for HME, though the opposite occurred at higher speeds. The use of biofuels results in an effective reduction in soot in the exhaust gas. The amount of smoke in the exhaust gas decreased by an average of 24% relative to DF and was lowest when using HME.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Czwartkowski, K.; Wierzbic, A.; Golimowski, W. Awareness and Expectations of Polish Consumers Regarding Edible Niche Oils as a Food Product. Sustainability 2022, 14, 14239. [Google Scholar] [CrossRef]

- Fike, J. Industrial Hemp: Renewed Opportunities for an Ancient Crop. CRC Crit. Rev. Plant Sci. 2016, 35, 406–424. [Google Scholar] [CrossRef]

- Lin, Y.; Pangloli, P.; Dia, V.P. Physicochemical, Functional and Bioactive Properties of Hempseed (Cannabis sativa L.) Meal, a Co-Product of Hempseed Oil and Protein Production, as Affected by Drying Process. Food Chem. 2021, 350, 129188. [Google Scholar] [CrossRef]

- Mikulec, A.; Kowalski, S.; Sabat, R.; Skoczylas, Ł.; Tabaszewska, M.; Wywrocka-Gurgul, A. Hemp Flour as a Valuable Component for Enriching Physicochemical and Antioxidant Properties of Wheat Bread. LWT 2019, 102, 164–172. [Google Scholar] [CrossRef]

- Baeck, S.; Kim, B.; Cho, B.; Kim, E. Analysis of Cannabinoids in Urine Samples of Short-Term and Long-Term Consumers of Hemp Seed Products. Forensic Sci. Int. 2019, 305, 109997. [Google Scholar] [CrossRef]

- Tura, M.; Mandrioli, M.; Valli, E.; Rubino, R.C.; Parentela, D.; Toschi, T.G. Changes in the Composition of a Cold-Pressed Hemp Seed Oil during Three Months of Storage. J. Food Compos. Anal. 2022, 106, 104270. [Google Scholar] [CrossRef]

- Da Porto, C.; Decorti, D.; Tubaro, F. Fatty Acid Composition and Oxidation Stability of Hemp (Cannabis sativa L.) Seed Oil Extracted by Supercritical Carbon Dioxide. Ind. Crops Prod. 2012, 36, 401–404. [Google Scholar] [CrossRef]

- Mnekin, L.; Ripoll, L. Topical Use of Cannabis sativa L. Biochemicals. Cosmetics 2021, 8, 85. [Google Scholar] [CrossRef]

- Teh, S.S.; Bekhit, A.E.D.A.; Carne, A.; Birch, J. Antioxidant and ACE-Inhibitory Activities of Hemp (Cannabis sativa L.) Protein Hydrolysates Produced by the Proteases AFP, HT, Pro-G, Actinidin and Zingibain. Food Chem. 2016, 203, 199–206. [Google Scholar] [CrossRef]

- Lin, Y.; Pangloli, P.; Meng, X.; Dia, V.P. Effect of Heating on the Digestibility of Isolated Hempseed (Cannabis sativa L.) Protein and Bioactivity of Its Pepsin-Pancreatin Digests. Food Chem. 2020, 314, 126198. [Google Scholar] [CrossRef]

- Fayyazbakhsh, A.; Bell, M.L.; Zhu, X.; Mei, X.; Koutný, M.; Hajinajaf, N.; Zhang, Y. Engine Emissions with Air Pollutants and Greenhouse Gases and Their Control Technologies. J. Clean. Prod. 2022, 376, 134260. [Google Scholar] [CrossRef]

- Hemmerlein, N.; Korte, V.; Richter, H.; Schröder, G. Performance, Exhaust Emissions and Durability of Modern Diesel Engines Running on Rapeseed Oil. SAE Trans. 1991, 100, 400–415. [Google Scholar]

- Golimowski, W.; Pasyniuk, P.; Berger, W.A. Common Rail Diesel Tractor Engine Performance Running on Pure Plant Oil. Fuel 2013, 103, 227–231. [Google Scholar] [CrossRef]

- Altarazi, Y.S.M.; Abu Talib, A.R.; Yusaf, T.; Yu, J.; Gires, E.; Ghafir, M.F.A.; Lucas, J. A Review of Engine Performance and Emissions Using Single and Dual Biodiesel Fuels: Research Paths, Challenges, Motivations and Recommendations. Fuel 2022, 326, 125072. [Google Scholar] [CrossRef]

- Go, A.W.; Sutanto, S.; Ong, L.K.; Tran-Nguyen, P.L.; Ismadji, S.; Ju, Y.H. Developments in In-Situ (Trans) Esterification for Biodiesel Production: A Critical Review. Renew. Sustain. Energy Rev. 2016, 60, 284–305. [Google Scholar] [CrossRef]

- Thompson, W.; Meyer, S. Second Generation Biofuels and Food Crops: Co-Products or Competitors? Glob. Food Sec. 2013, 2, 89–96. [Google Scholar] [CrossRef]

- Golimowski, W.; Berger, W.A.; Pasyniuk, P.; Rzeźnik, W.; Czechlowski, M.; Koniuszy, A. Biofuel Parameter Dependence on Waste Fats’ Fatty Acids Profile. Fuel 2017, 197, 482–487. [Google Scholar] [CrossRef]

- Adhikesavan, C.; Ganesh, D.; Augustin, V.C. Effect of Quality of Waste Cooking Oil on the Properties of Biodiesel, Engine Performance and Emissions. Clean. Chem. Eng. 2022, 4, 100070. [Google Scholar] [CrossRef]

- Sakthimurugan, V.; Madhu, S. Novel Scenedesmus Obliquus Algae Biofuel Emission and Performance Characterise in Si-DLC Coated Diesel Engine. Mater. Today Proc. 2023, 77, 490–496. [Google Scholar] [CrossRef]

- Lodi, F.; Zare, A.; Arora, P.; Stevanovic, S.; Ristovski, Z.; Brown, R.J.; Bodisco, T. Engine Performance Characteristics Using Microalgae Derived Dioctyl Phthalate Biofuel during Cold, Preheated and Hot Engine Operation. Fuel 2023, 344, 128162. [Google Scholar] [CrossRef]

- Mehra, K.S.; Singh, S.; Singh, A.K.; Kharkwal, H.; Avikal, S. Performance, Energy, Emission and Cost Analysis of Jatropha (Jatropha curcas) Oil as a Biofuel for Compression Ignition Engine. Mater. Today Proc. 2020, 43, 348–354. [Google Scholar] [CrossRef]

- Venkatesan, S.P.; Rahul, R.; Sabbharishi, V.; Purusothamand, M.; Ganesan, S. Study of Emission Characteristics of a Diesel Engine Run by Fuel Blends of Diesel, Jatropha Biodiesel and Cetane Improver. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Rajpoot, A.S.; Choudhary, T.; Chelladurai, H.; Mishra, S.; Shende, V. Performance Analysis of a CI Engine Powered by Different Generations of Biodiesel; Palm Oil, Jatropha, and Microalgae. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Nagappan, M.; Babu, J.M. In Ternary Blend Fuelled Diesel Engines, Nanoparticles Are Used as an Additive in Biofuel Production and as a Fuel Additive: A Review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Gad, M.S.; Ağbulut, Ü.; Afzal, A.; Panchal, H.; Jayaraj, S.; Qasem, N.A.A.; El-Shafay, A.S. A Comprehensive Review on the Usage of the Nano-Sized Particles along with Diesel/Biofuel Blends and Their Impacts on Engine Behaviors. Fuel 2023, 339, 127364. [Google Scholar] [CrossRef]

- Yildiz, I.; Caliskan, H.; Mori, K. Assessment of Biofuels from Waste Cooking Oils for Diesel Engines in Terms of Waste-to-Energy Perspectives. Sustain. Energy Technol. Assess. 2022, 50, 101839. [Google Scholar] [CrossRef]

- Viswanathan, K.; Taipabu, M.I.; Wu, W. Novel Petit Grain Bitter Orange Waste Peel Oil Biofuel Investigation in Diesel Engine with Modified Fuel Injection Pressure and Bowl Geometry. Fuel 2022, 319, 123660. [Google Scholar] [CrossRef]

- Kabudke, P.D.; Kharde, Y.R.; Parkhe, R.A. Experimental Investigation on Performance of Cotton Seed Biofuel Blended with Diesel on Variable Compression Ratio Diesel Engine. Mater. Today Proc. 2023, 72, 846–852. [Google Scholar] [CrossRef]

- Asokan, M.A.; Prabu, S.S.; Bollu, A.; Reddy, M.A.; Ram, A.; Sukhadia, D.S. Emission and Performance Behavior of Hemp Seed Oil Biodiesel/Diesel Blends in Di Diesel Engine. Mater. Today Proc. 2021, 46, 8127–8132. [Google Scholar] [CrossRef]

- Golimowski, W.; Teleszko, M.; Marcinkowski, D.; Kmiecik, D.; Grygier, A.; Kwaśnica, A. Quality of Oil Pressed from Hemp Seed Varieties: ‘Ealina 8FC’, ‘Secueni Jubileu’ and ‘Finola’. Molecules 2022, 27, 3171. [Google Scholar] [CrossRef]

- Razmaitė, V.; Šiukščius, A.; Leikus, R. Effects of Dietary Rapeseed (Brassica napus), Hemp (Cannabis sativa) and Camelina (Camelina sativa) Seed Cakes Supplementation on Yolk and Albumen Colour and Nutritional Value of Yolk Lipids in Estonian Quail Eggs. Animals 2022, 12, 3110. [Google Scholar] [CrossRef] [PubMed]

- Kurczyński, D.; Wcisło, G. Producing and Testing the Properties of Biodiesel Sourced from Hemp Oil. Energies 2024, 17, 5950. [Google Scholar] [CrossRef]

- Sienkiewicz, A.; Piotrowska-Niczyporuk, A.; Bajguz, A. Fatty Acid Methyl Esters from the Herbal Industry Wastes as a Potential Feedstock for Biodiesel Production. Energies 2020, 13, 3702. [Google Scholar] [CrossRef]

- Addison, G.; Milligan, K.A.; Ohlig, S. Comparative Analysis of ZnO and CeO2 Nanoparticle Additives for the Improvement of Hemp Biofuels as a Sustainable Biodiesel Alternative: A Comprehensive Review. Ind. Crops Prod. 2024, 214, 118480. [Google Scholar] [CrossRef]

- Szulczyk, K.R.; Badeeb, R.A. Nontraditional Sources for Biodiesel Production in Malaysia: The Economic Evaluation of Hemp, Jatropha, and Kenaf Biodiesel. Renew Energy 2022, 192, 759–768. [Google Scholar] [CrossRef]

- Verma, T.N.; Shrivastava, P.; Rajak, U.; Dwivedi, G.; Jain, S.; Zare, A.; Shukla, A.K.; Verma, P. A Comprehensive Review of the Influence of Physicochemical Properties of Biodiesel on Combustion Characteristics, Engine Performance and Emissions. J. Traffic Transp. Eng. 2021, 8, 510–533. [Google Scholar] [CrossRef]

- Uslu, S.; Simsek, S.; Simsek, H. RSM Modeling of Different Amounts of Nano-TiO2 Supplementation to a Diesel Engine Running with Hemp Seed Oil Biodiesel/Diesel Fuel Blends. Energy 2023, 266, 126439. [Google Scholar] [CrossRef]

- Gaur, A.; Dwivedi, G.; Baredar, P.; Jain, S. Influence of Blending Additives in Biodiesel on Physiochemical Properties, Engine Performance, and Emission Characteristics. Fuel 2022, 321, 124072. [Google Scholar] [CrossRef]

- Nagwan, H.; Bangari, R.S.; Singh, K.; Kumar, P. Study the Performance Characteristics of CI Engine with Hemp Oil Methyl Ester, Ethanol and Diesel Blends. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Sultanbekov, R.; Denisov, K.; Zhurkevich, A.; Islamov, S. Reduction of Sulphur in Marine Residual Fuels by Deasphalting to Produce VLSFO. J. Mar. Sci. Eng. 2022, 10, 1765. [Google Scholar] [CrossRef]

- Sultanbekov, R.; Beloglazov, I.; Islamov, S.; Ong, M.C. Exploring of the Incompatibility of Marine Residual Fuel: A Case Study Using Machine Learning Methods. Energies 2021, 14, 8422. [Google Scholar] [CrossRef]

- Sultanbekov, R.; Islamov, S.; Mardashov, D.; Beloglazov, I.; Hemmingsen, T. Research of the Influence of Marine Residual Fuel Composition on Sedimentation Due to Incompatibility. J. Mar. Sci. Eng. 2021, 9, 1067. [Google Scholar] [CrossRef]

- ISO 8178-1; Reciprocating Internal Combustion Engines—Exhaust Emission Measurement. International Organization for Standardization: Geneve, Switzerland, 2020.

- Wołoszyn, J.; Haraf, G.; Okruszek, A.; Wereńska, M.; Goluch, Z.; Teleszko, M. Fatty Acid Profiles and Health Lipid Indices in the Breast Muscles of Local Polish Goose Varieties. Poult. Sci. 2020, 99, 1216–1224. [Google Scholar] [CrossRef]

- Ramírez-Verduzco, L.F.; Rodríguez-Rodríguez, J.E.; Jaramillo-Jacob, A.D.R. Predicting Cetane Number, Kinematic Viscosity, Density and Higher Heating Value of Biodiesel from Its Fatty Acid Methyl Ester Composition. Fuel 2012, 91, 102–111. [Google Scholar] [CrossRef]

- Islam, M.A.; Magnusson, M.; Brown, R.J.; Ayoko, G.A.; Nabi, M.N.; Heimann, K. Microalgal Species Selection for Biodiesel Production Based on Fuel Properties Derived from Fatty Acid Profiles. Energies 2013, 6, 5676–5702. [Google Scholar] [CrossRef]

- Hawrot-Paw, M.; Ratomski, P.; Koniuszy, A.; Golimowski, W.; Teleszko, M.; Grygier, A. Fatty Acid Profile of Microalgal Oils as a Criterion for Selection of the Best Feedstock for Biodiesel Production. Energies 2021, 14, 7334. [Google Scholar] [CrossRef]

- Deshmukh, S.; Bala, K.; Kumar, R. Selection of Microalgae Species Based on Their Lipid Content, Fatty Acid Profile and Apparent Fuel Properties for Biodiesel Production. Environ. Sci. Pollut. Res. 2019, 26, 24462–24473. [Google Scholar] [CrossRef] [PubMed]

- Gongping, M.; Zhong, W.; Peng, H.; Peiyong, N.; Xiaozhe, W.; Shi-Qiang, G. Experimental Research on the Flame Temperature of Biodiesel Fuel Combustion in Open-air Conditions. In Proceedings of the 2011 International Conference on Electric Information and Control Engineering (ICEICE 2011), Wuhan, China, 15–17 April 2011. [Google Scholar]

- OIML R99-1 & 2:2008 (reconfirmed 2024); Instruments for Measuring Vehicle Exhaust Emissions—Part 1: Metrological and Technical Requirements; Part 2: Metrological Control and Performance Tests. International Organization of Legal Metrology: Paris, France, 2008.

- ISO 3930/PAS 3930:2009; Instruments for Measuring Vehicle Exhaust Emissions—Metrological and Technical Requirements. International Organization for Standardization: Geneva, Switzerland, 2009.

- BAR-97; Emissions Inspection System Specifications. California Bureau of Automotive Repair: Sacramento, CA, USA, 2017.

- Directive 2014/32/EU; The Harmonisation of the Laws of the Member States Relating to the Making Available on the Market of Measuring Instruments (Measuring Instruments Directive, MID). European Parliament and Council: Brussels, Belgium, 2014.

- ISO 1585:2020; Road Vehicles—Engine Test Code—Net Power. International Organization for Standardization: Geneva, Switzerland, 2020.

- Yilbaşi, Z.; Yesilyurt, M.K.; Yaman, H.; Arslan, M. The Industrial-Grade Hemp (Cannabis sativa L.) Seed Oil Biodiesel Application in a Diesel Engine: Combustion, Harmful Pollutants, and Performance Characteristics. Sci. Technol. Energy Transit. (STET) 2022, 77, 15. [Google Scholar] [CrossRef]

- Gracz, W.; Marcinkowski, D.; Golimowski, W.; Szwajca, F.; Strzelczyk, M.; Wasilewski, J.; Krzaczek, P. Multifaceted Comparison Efficiency and Emission Characteristics of Multi-Fuel Power Generator Fueled by Different Fuels and Biofuels. Energies 2021, 14, 3388. [Google Scholar] [CrossRef]

- Nwafor, O.M.I.; Rice, G. Performance of Rapeseed Methyl Ester in Diesel Engine. Renew. Energy 1995, 6, 335–342. [Google Scholar] [CrossRef]

- Kawano, D.; Ishii, H.; Goto, Y. Effect of Biodiesel Blending on Emission Characteristics of Modern Diesel Engine. SAE Tech. Pap. 2008, 1, 2384–2392. [Google Scholar]

- Tsolakis, A.; Megaritis, A.; Wyszynski, M.L.; Theinnoi, K. Engine Performance and Emissions of a Diesel Engine Operating on Diesel-RME (Rapeseed Methyl Ester) Blends with EGR (Exhaust Gas Recirculation). Energy 2007, 32, 2072–2080. [Google Scholar] [CrossRef]

- Mamat, R.; Abdullah, N.R.; Xu, H.; Wyszynski, M.; Tsolakis, A. Effect of Fuel Temperature on Performance and Emissions of a Common Rail Engine Operating with Rapeseed Methyl Ester (RME); SAE Technical Paper 2009-01-1896; SAE International: Warrendale, PA, USA, 2009. [Google Scholar]

- Merkisz, J.; Kozak, M.; Pielecha, J.; Andrzejewski, M. The Influence of Application of Different Diesel Fuel-RME Blends on PM Emissions from a Diesel Engine. Combust. Engines 2012, 1, 35. [Google Scholar] [CrossRef]

- Chen, H.; Xie, B.; Ma, J.; Chen, Y. NOx Emission of Biodiesel Compared to Diesel: Higher or Lower? Appl. Therm. Eng. 2018, 137, 584–593. [Google Scholar] [CrossRef]

- Beatrice, C.; Guido, C.; Di Iorio, S.; Napolitano, P.; Del Giacomo, N. Impact of RME and GTL Fuel on Combustion and Emissions of a “Torque-Controlled” Diesel Automotive Engines. SAE Int. J. Fuels Lubr. 2010, 3, 118–134. [Google Scholar] [CrossRef]

- Magno, A.; Mancaruso, E.; Vaglieco, B.M. Endoscopic Investigation of Combustion Process in a Small Compression Ignition Engine Fuelled with Rapeseed Methyl Ester; SAE Technical Paper 2014-01-2649; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Magno, A.; Mancaruso, E.; Vaglieco, B.M. Analysis of Combustion Phenomena and Pollutant Formation in a Small Compression Ignition Engine Fuelled with Blended and Pure Rapeseed Methyl Ester. Energy 2016, 106, 618–630. [Google Scholar] [CrossRef]

| Parameters | Unit | RME | HME | DF EN590 [49] |

|---|---|---|---|---|

| Saturated fatty acid | (SFA) | 7.26 | 11.81 | - |

| Monosaturated fatty acid | (MUFA) | 69.93 | 86.98 | - |

| Polyunsaturated fatty acids | (PUFA) | 22.61 | 0.00 | - |

| Degree of unsaturation | (DU) | 115.15 | 86.98 | - |

| Saponification value | (SV) | 198.78 | 196.56 | - |

| Iodine value | (IV) | 109.21 | 78.18 | - |

| Cetan number | (CN) | 49.19 | 56.48 | 51 |

| Long-chain saturated factor | (LCSF) | 2.39 | 4.85 | - |

| Cold filter plugging point | (CFPP; °C) | −9.00 | −1.00 | −10 |

| Cloud point | (CP; °C) | −3.00 | −1.00 | - |

| Allylic position equivalents | (APE) | 113.69 | 86.37 | - |

| Bis-allylic position equivalents | (BAPE) | 29.83 | 2.52 | - |

| Oxidation stability | (OS; h) | 7.81 | 4.09 | - |

| Higher heating value | (HHV; MJ·kg−1) | 39.48 | 39.15 | 42.00 |

| Kinematic viscosity 40 °C | (mm2·s−1) | 1.35 | 1.40 | 2.00 |

| Density 15 °C | (g·cm−3) | 0.87 | 0.85 | 0.82 |

| Component of Exhaust Gases | Measurement Range | Resolution |

|---|---|---|

| CO | 0–15% | 0.001% |

| CO2 | 0–20% | 0.1% |

| HC | 0–20,000 ppm | 1 ppm |

| O2 | 0–21.7% | 0.01% |

| Lamda | 0.8–1.2 | 0.001 |

| NOx | 0–5000 ppm | 1 ppm |

| Parameters | Unit | Value |

|---|---|---|

| Piston diameter | [mm] | 69.6 |

| Stroke | [mm] | 82 |

| Displacement | [cm3] | 1248 |

| Power | [kW] | 51 |

| Revolution in max. power | [rpm] | 4000 |

| Max. torque | [Nm] | 145 |

| Revolution in max. torque | [rpm] | 1750 |

| Compression ratio | [-] | 18.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koniuszy, A.; Hawrot-Paw, M.; Golimowski, W.; Osipowicz, T.; Prajwowski, K.; Szwajca, F.; Marcinkowski, D.; Berger, W.A. Testing of JTD Engine Fueled with Hemp and Rapeseed Oil Esters. Energies 2025, 18, 3526. https://doi.org/10.3390/en18133526

Koniuszy A, Hawrot-Paw M, Golimowski W, Osipowicz T, Prajwowski K, Szwajca F, Marcinkowski D, Berger WA. Testing of JTD Engine Fueled with Hemp and Rapeseed Oil Esters. Energies. 2025; 18(13):3526. https://doi.org/10.3390/en18133526

Chicago/Turabian StyleKoniuszy, Adam, Małgorzata Hawrot-Paw, Wojciech Golimowski, Tomasz Osipowicz, Konrad Prajwowski, Filip Szwajca, Damian Marcinkowski, and Wojciech Andrew Berger. 2025. "Testing of JTD Engine Fueled with Hemp and Rapeseed Oil Esters" Energies 18, no. 13: 3526. https://doi.org/10.3390/en18133526

APA StyleKoniuszy, A., Hawrot-Paw, M., Golimowski, W., Osipowicz, T., Prajwowski, K., Szwajca, F., Marcinkowski, D., & Berger, W. A. (2025). Testing of JTD Engine Fueled with Hemp and Rapeseed Oil Esters. Energies, 18(13), 3526. https://doi.org/10.3390/en18133526