Experimental Testing of New Concrete-Based, Medium-Temperature Thermal Energy Storage Charged by Both a Thermal and Electrical Power Source

Abstract

1. Introduction

- Compactness (high density of accumulated energy, even 3–5 times that of SHTES), thanks to the exploitation of latent heat.

- Temperature stability of the supplied heat (melting temperature of the PCM) [42].

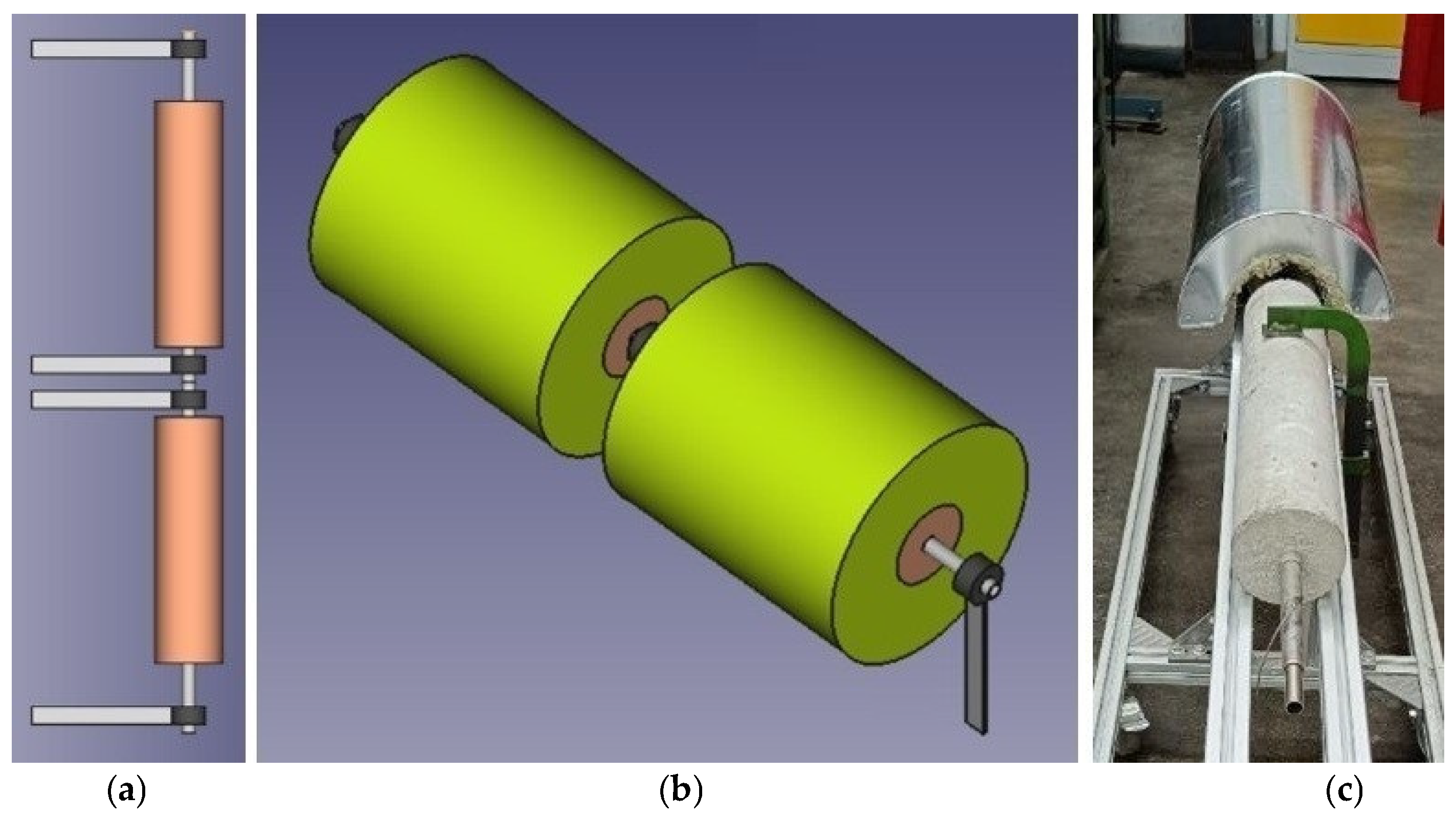

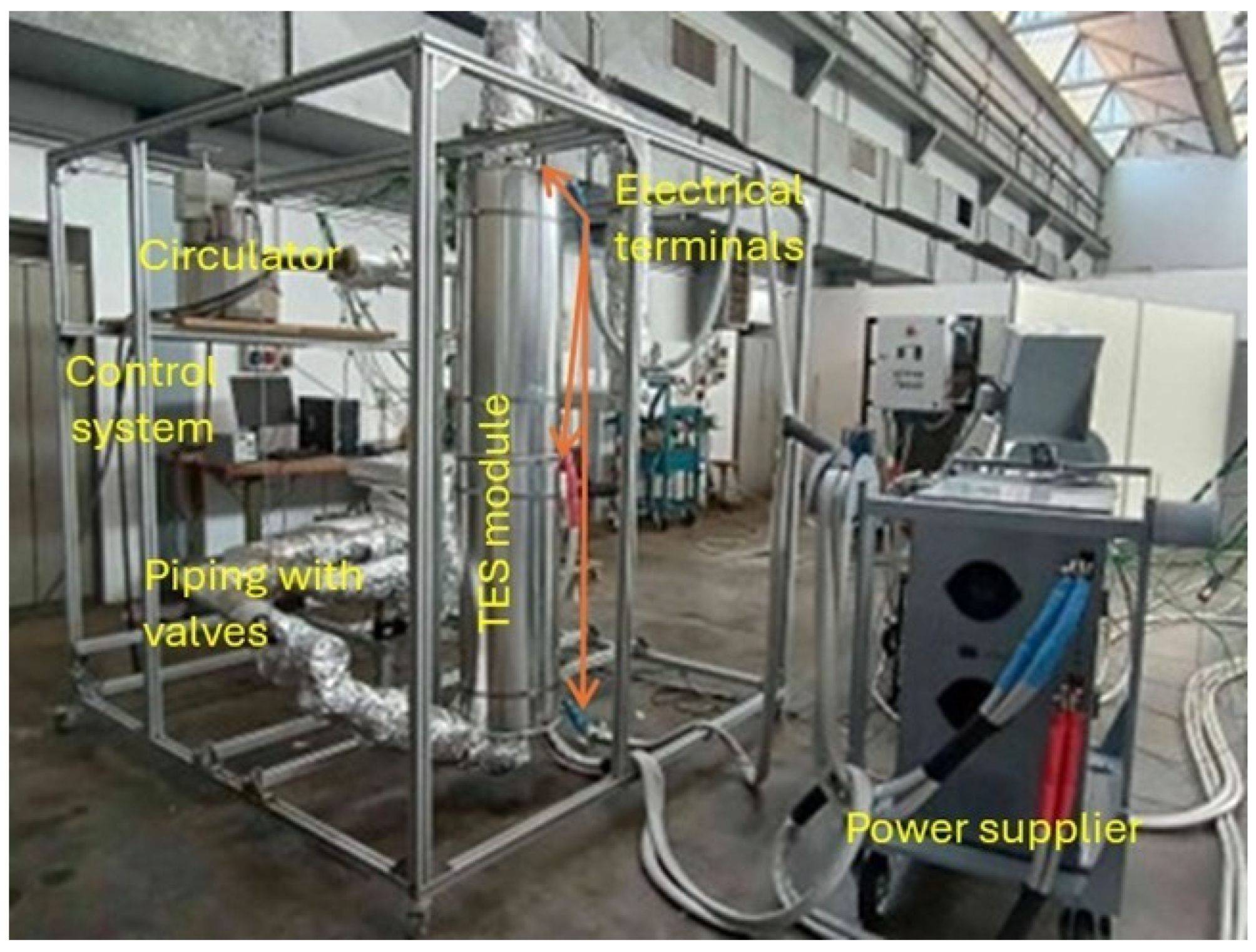

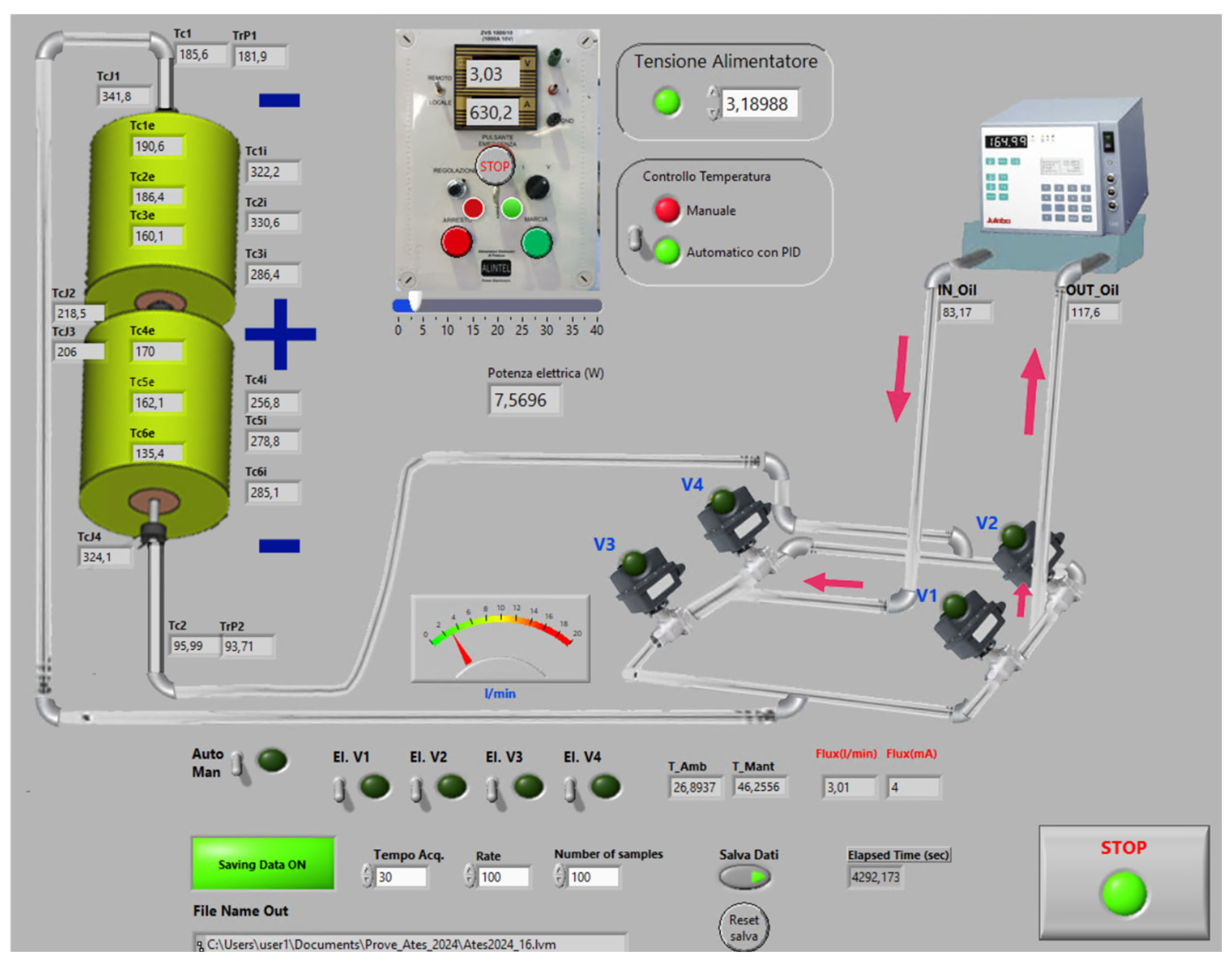

2. Materials and Methods

- Temperature inside the tank(s) volume;

- Temperature of the outer surface of the tube;

- Temperature of the internal and external walls of the tank itself;

- Temperature at the inlet and outlet of the tank and the inlet and outlet of the heater/cooler.

3. Results and Discussion

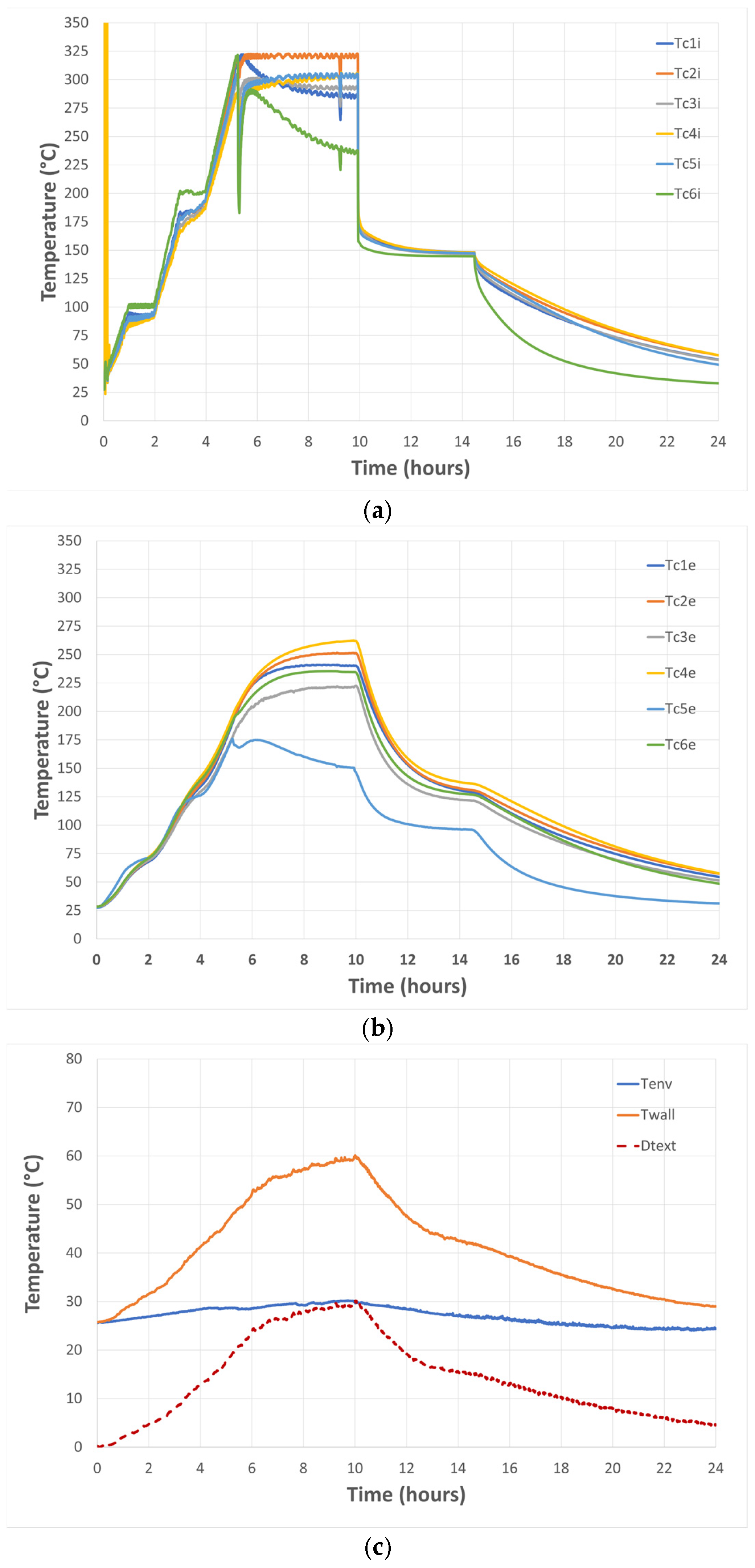

3.1. Charging/Discharging Test

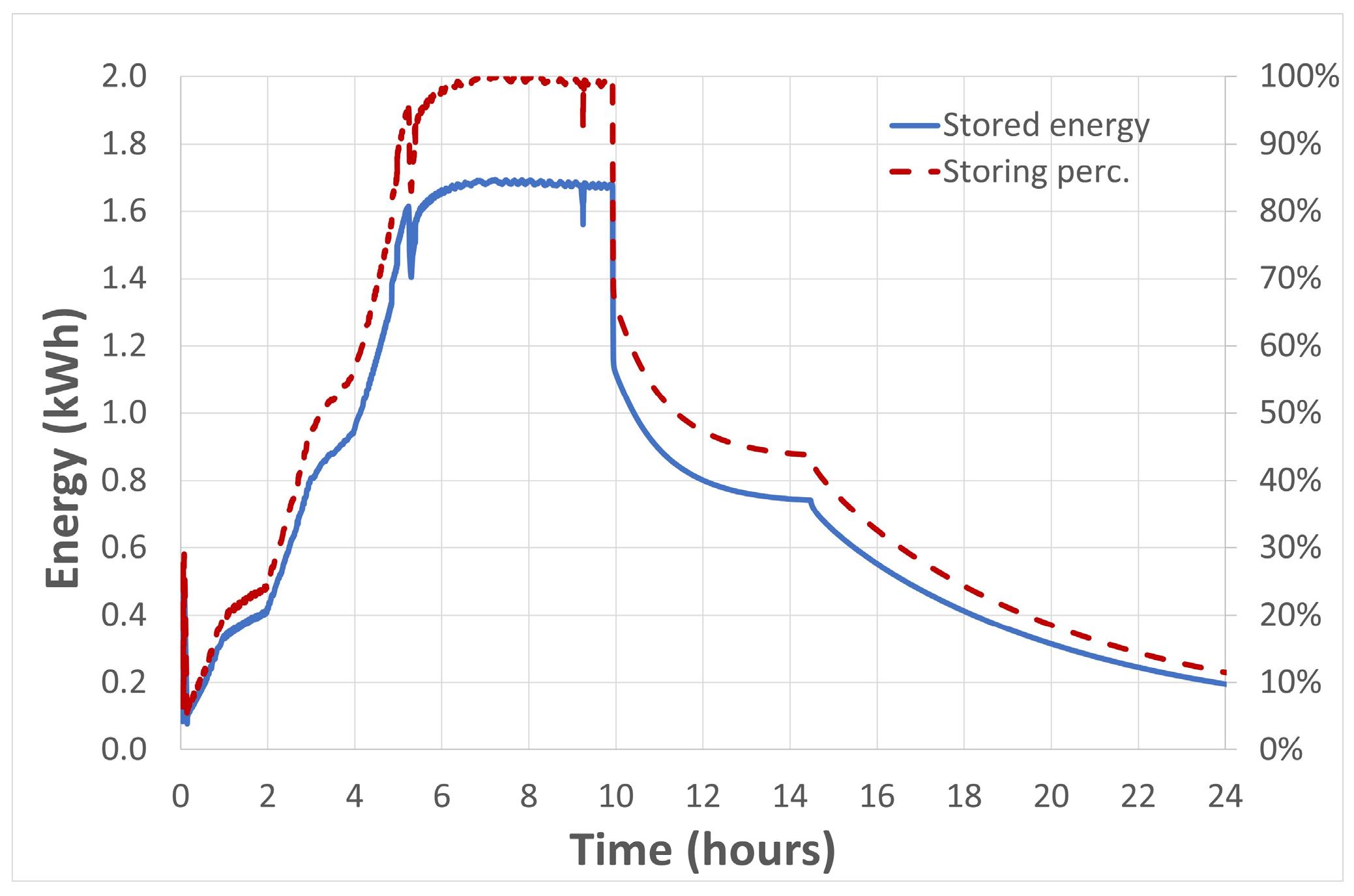

3.1.1. P2H Conversion Method

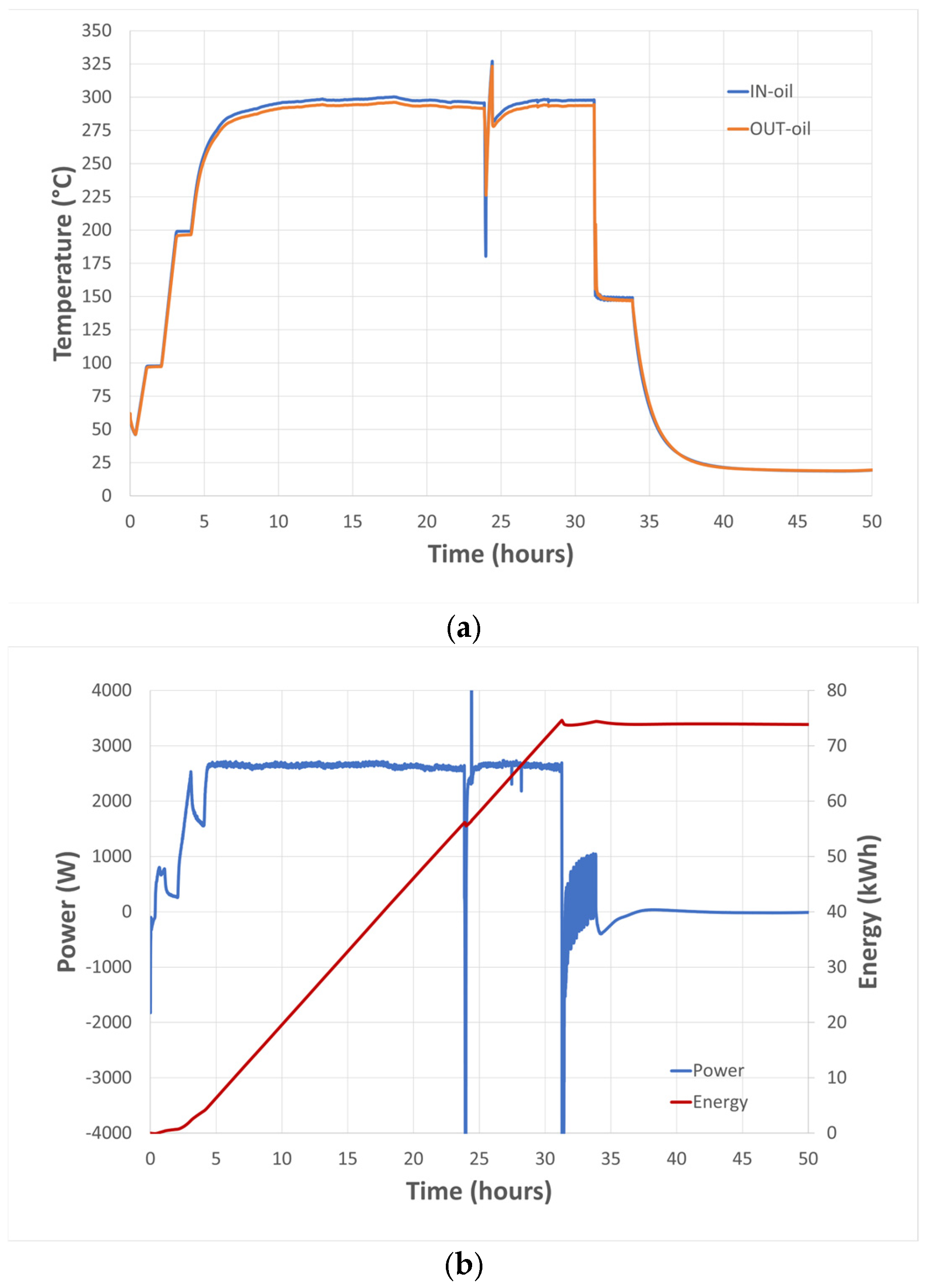

3.1.2. HTF Heating Method

3.1.3. Comparison of Methods

- Joule effect electric heating allows for the generation of heat at the target temperature directly within the heat exchange tube in a very effective manner. In the case of heating via heat transfer fluid, neglecting heat losses along the HTF circuit, heat transfer between the fluid and the heat exchange tube occurs through convection, which appears less effective than the former.

- The heating method significantly impacts charging time: electric heating achieves charging in approximately 3 h from the start of the test, while in the second case the charging time is almost double (6 h). In fact, since the heat transfer within the storage medium is strictly connected to its thermal diffusivity, the possibility of having a high and stable internal temperature on the tube’s wall favors the charging speed.

- In both cases, the concrete accumulated a maximum thermal energy of 1.68 kWh, which is 86% of its theoretical storage capacity (1.96 kWh). This limitation can be attributed to the high level of recorded thermal losses, ranging from 300 W at 150 °C up to approximately 1700 W at 290 °C.

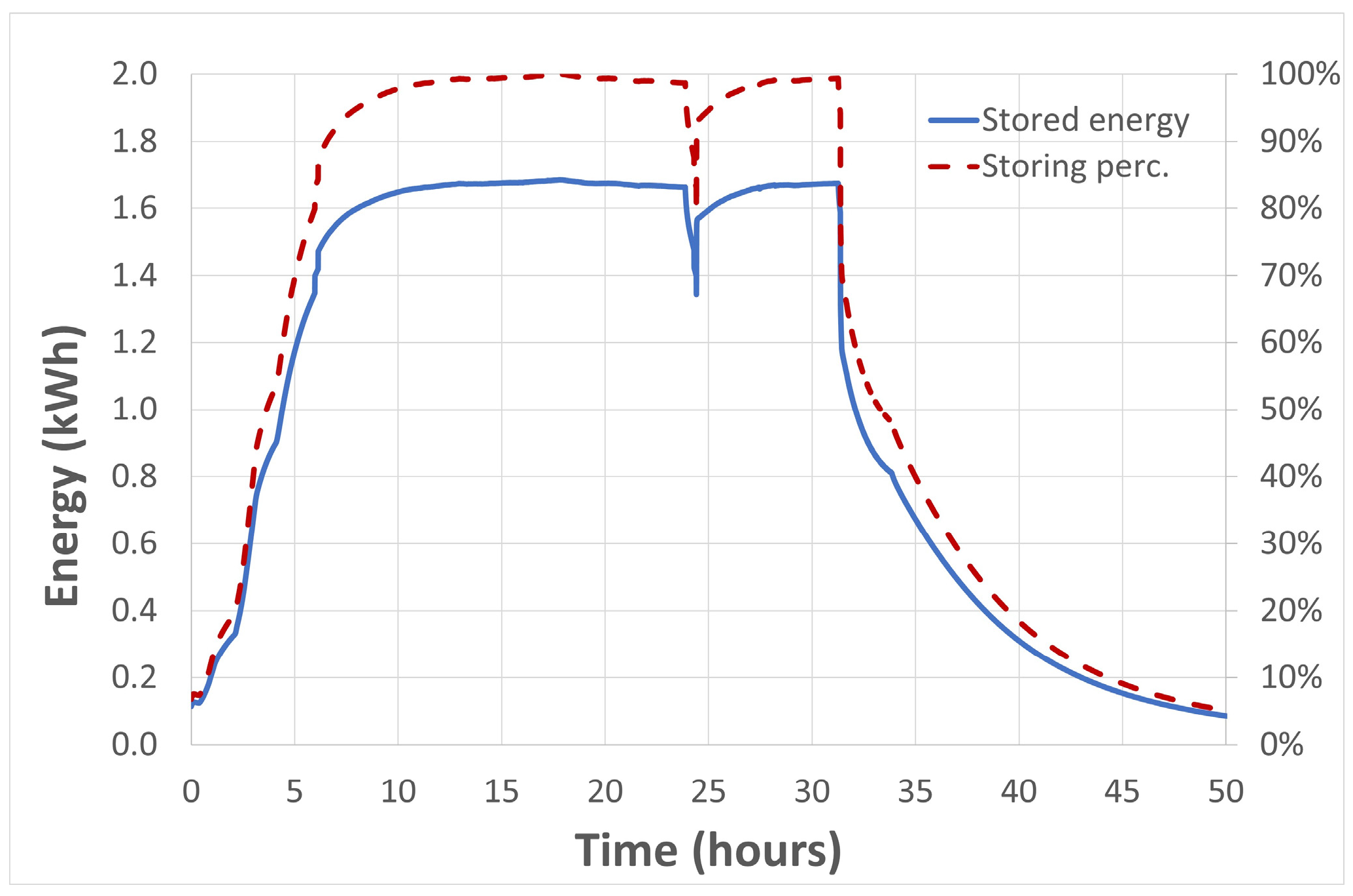

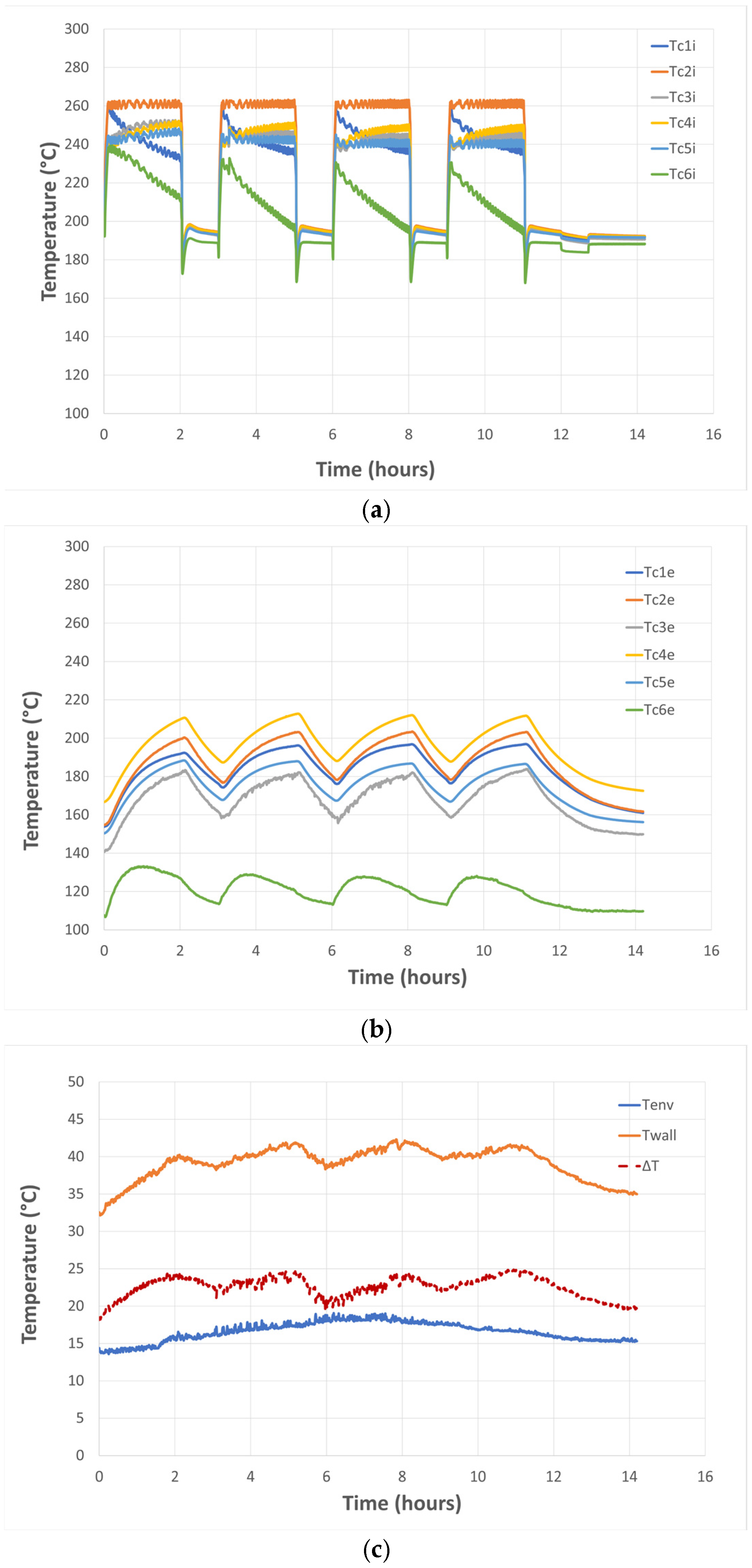

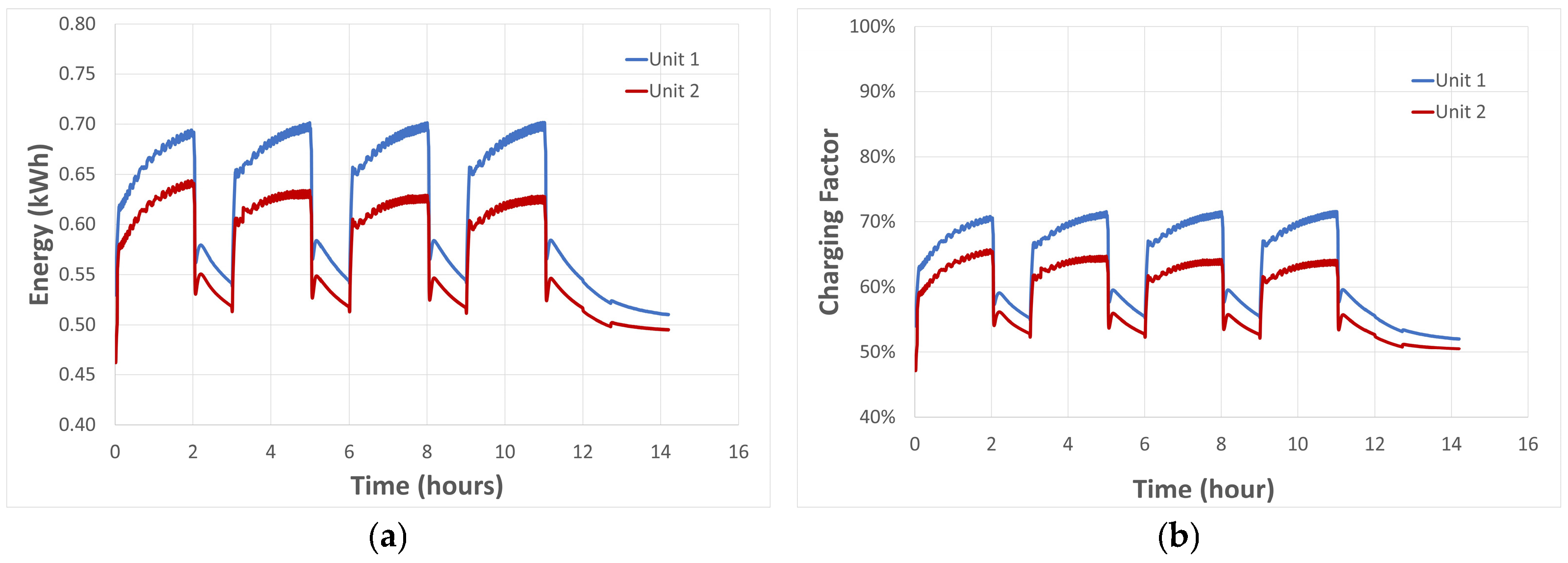

3.2. Cyclical Test

4. Conclusions

4.1. Key Findings

- Reliable and Efficient Electrical Charging: The TEES concept operates reliably and efficiently during its electrical charging phase. The measured electrical resistance of the exchange tube aligns with theoretical values, indicating minimal current leakage or additional electrical resistance.

- Effective Internal Electro-Thermal Conversion: The internal electro-thermal conversion, based on the Joule effect, ensures stable heat generation within the tube at the target temperature. This heat is then effectively transferred to the concrete storage medium via conduction, differentiating it from heat transfer fluid convection.

- Limiting Factors Identified: Despite the effective heat generation and transfer, the thermal diffusivity of the storage medium (concrete) remains a limiting factor in quickly and fully utilizing the storage capacity. Additionally, significant thermal losses were observed (300 W at 120–140 °C and 1700 W at 280–290 °C), which hinder system charging and reduce recovered thermal energy.

- Crucial for Future Devices: Reducing these thermal losses is paramount for future laboratory-scale devices to allow for a more accurate assessment of the concept’s performance.

- Cyclic Operation Stability: In cyclic operation, the system’s thermal behavior stabilizes after the second cycle. The duration of both charging and discharging phases is crucial for effective utilization of the storage medium’s capacity.

4.2. Future Research Directions

- Larger Modules and Optimization: Future efforts will focus on developing and testing larger-sized modules to optimize their thermal performance by minimizing thermal losses. This will simultaneously accelerate the progress of the technology readiness level (TRL) of this compact and reliable TEES system concept, and will also allow its costs and performance to be evaluated.

- Multi-Arrayed Configurations: As a next step, a series of modules will be created and integrated into multi-arrayed configurations (combining series and parallel layouts). This will facilitate the testing of operational strategies to optimize the simultaneous charging of these modules with both electricity and heat. The use of larger modules is desirable to minimize thermal losses and increase the TRL of this innovative TEES system concept.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CAES | Compressed-Air Energy Storage |

| CB | Carnot Battery |

| HSM | Heat Storage Medium |

| HTF | Heat Transfer Fluid |

| LHTES | Latent Heat Thermal Energy Storage |

| mEPCM | micro-Encapsuled Phase Change Material |

| NEPCM | Nano Enhanced Phase Change Material |

| ORC | Organic Rankine Cycle |

| P2H | Power to Heat |

| PCM | Phase Change Material |

| PHES | Pumped Hydro Energy Storage |

| PTES | Pumped Thermal Electricity Storage |

| SHTES | Sensible Heat Thermal Energy Storage |

| TEES | Thermal Electrical Energy Storage |

| TES | Thermal Energy Storage |

| TRL | Technology Readiness Level |

References

- Dumonta, O.; Frate, G.F.; Pillai, A.; Lecompte, S.; De paepe, M.; Lemort, V. Carnot Battery Technology: A State-of-the-Art Review. J. Energy Storage 2020, 32, 101756. [Google Scholar] [CrossRef]

- Rehman, S.; Al-Hadhrami, L.M.; Alam, M.M. Pumped Hydro Energy Storage System: A Technological Review. Renew. Sustain. Energy Rev. 2015, 44, 586–598. [Google Scholar] [CrossRef]

- Benato, A.; Stoppato, A. Pumped Thermal Electricity Storage: A Technology Overview. Therm. Sci. Eng. Progress. 2018, 6, 301–315. [Google Scholar] [CrossRef]

- Geyer, M.; Prieto, C. Storing Energy Using Molten Salts. In Storing Energy; Elsevier: Amsterdam, The Netherlands, 2022; pp. 445–486. [Google Scholar]

- Liang, T.; Vecchi, A.; Knobloch, K.; Sciacovelli, A.; Engelbrecht, K.; Li, Y.; Ding, Y. Key Components for Carnot Battery: Technology Review, Technical Barriers and Selection Criteria. Renew. Sustain. Energy Rev. 2022, 163, 112478. [Google Scholar] [CrossRef]

- Tassenoy, R.; Couvreur, K.; Beyne, W.; De Paepe, M.; Lecompte, S. Techno-Economic Assessment of Carnot Batteries for Load-Shifting of Solar PV Production of an Office Building. Renew. Energy 2022, 199, 1133–1144. [Google Scholar] [CrossRef]

- Vecchi, A.; Knobloch, K.; Liang, T.; Kildahl, H.; Sciacovelli, A.; Engelbrecht, K.; Li, Y.; Ding, Y. Carnot Battery Development: A Review on System Performance, Applications and Commercial State-of-the-Art. J. Energy Storage 2022, 55, 105782. [Google Scholar] [CrossRef]

- Dreißigacker, V.; Lucht, G. Electrically Heated High-Temperature Thermal Energy Storage with Dual Operating Modes: From Concept to Validation. Energies 2023, 16, 7344. [Google Scholar] [CrossRef]

- Nitsch, F.; Wetzel, M.; Gils, H.C.; Nienhaus, K. The Future Role of Carnot Batteries in Central Europe: Combining Energy System and Market Perspective. J. Energy Storage 2024, 85, 110959. [Google Scholar] [CrossRef]

- Zhao, Y.; Huang, J.; Song, J.; Ding, Y. Thermodynamic Investigation of a Carnot Battery Based Multi-Energy System with Cascaded Latent Thermal (Heat and Cold) Energy Stores. Energy 2024, 296, 131148. [Google Scholar] [CrossRef]

- Theologou, K.; Johnson, M.; Tombrink, J.; Corrales Ciganda, J.L.; Trebilcock, F.T.; Couvreur, K.; Tassenoy, R.; Lecompte, S. CHESTER: Experimental Prototype of a Compressed Heat Energy Storage and Management System for Energy from Renewable Sources. Energy Convers. Manag. 2024, 311, 118519. [Google Scholar] [CrossRef]

- Huang, J.; Zhao, Y.; Song, J.; Wang, K.; Zhu, P.; Liu, B.; Sun, P. Thermodynamic Investigation of a Joule-Brayton Cycle Carnot Battery Multi-Energy System Integrated with External Thermal (Heat and Cold) Sources. Appl. Energy 2025, 377, 124652. [Google Scholar] [CrossRef]

- Laterre, A.; Frate, G.F.; Lemort, V.; Contino, F. Carnot Batteries for Integrated Heat and Power Management in Residential Applications: A Techno-Economic Analysis. Energy Convers. Manag. 2025, 325, 119207. [Google Scholar] [CrossRef]

- Albay, A.; Zhu, Z.; Mercangöz, M. Optimization-Based State-of-Charge Management Strategies for Supercritical CO2 Brayton Cycle Pumped Thermal Energy Storage Systems. J. Energy Storage 2025, 111, 115387. [Google Scholar] [CrossRef]

- Li, W.; Wang, S.; Xu, S.; Wang, Q.; Markides, C.N. An Intensive Review of ORC-Based Pumped Thermal Energy Storage. Energy 2025, 330, 136792. [Google Scholar] [CrossRef]

- Novotny, V.; Basta, V.; Smola, P.; Spale, J. Review of Carnot Battery Technology Commercial Development. Energies 2022, 15, 647. [Google Scholar] [CrossRef]

- Prieto, C.; Pino, F.J.; Cabeza, L.F. Techno-Economic Analysis of a Concrete Storage Concept for Parabolic Trough Solar Power Plants. J. Energy Storage 2023, 58, 106372. [Google Scholar] [CrossRef]

- Yan, T.; Wang, R.Z.; Li, T.X.; Wang, L.W.; Fred, I.T. A Review of Promising Candidate Reactions for Chemical Heat Storage. Renew. Sustain. Energy Rev. 2015, 43, 13–31. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Vérez, D.; Zsembinszki, G.; Borri, E.; Prieto, C. Key Challenges for High Temperature Thermal Energy Storage in Concrete—First Steps towards a Novel Storage Design. Energies 2022, 15, 4544. [Google Scholar] [CrossRef]

- Rahjoo, M.; Goracci, G.; Gaitero, J.J.; Martauz, P.; Rojas, E.; Dolado, J.S. Thermal Energy Storage (TES) Prototype Based on Geopolymer Concrete for High-Temperature Applications. Materials 2022, 15, 7086. [Google Scholar] [CrossRef]

- Boquera, L.; Castro, J.R.; Fernandez, A.G.; Navarro, A.; Pisello, A.L.; Cabeza, L.F. Thermo-Mechanical Stability of Concrete Containing Steel Slag as Aggregate after High Temperature Thermal Cycles. Sol. Energy 2022, 239, 59–73. [Google Scholar] [CrossRef]

- Rahjoo, M.; Goracci, G.; Martauz, P.; Rojas, E.; Dolado, J.S. Geopolymer Concrete Performance Study for High-Temperature Thermal Energy Storage (TES) Applications. Sustainability 2022, 14, 1937. [Google Scholar] [CrossRef]

- Boquera, L.; Castro, J.R.; Pisello, A.L.; Fabiani, C.; D’Alessandro, A.; Ubertini, F.; Cabeza, L.F. Thermo-Mechanical Stability of Supplementary Cementitious Materials in Cement Paste to Be Incorporated in Concrete as Thermal Energy Storage Material at High Temperatures. J. Energy Storage 2022, 54, 105370. [Google Scholar] [CrossRef]

- Hoivik, N.; Greiner, C.; Barragan, J.; Iniesta, A.C.; Skeie, G.; Bergan, P.; Blanco-Rodriguez, P.; Calvet, N. Long-Term Performance Results of Concrete-Based Modular Thermal Energy Storage System. J. Energy Storage 2019, 24, 100735. [Google Scholar] [CrossRef]

- Buscemi, A.; Panno, D.; Ciulla, G.; Beccali, M.; Lo Brano, V. Concrete Thermal Energy Storage for Linear Fresnel Collectors: Exploiting the South Mediterranean’s Solar Potential for Agri-Food Processes. Energy Convers. Manag. 2018, 166, 719–734. [Google Scholar] [CrossRef]

- Ndiaye, K.; Ginestet, S.; Cyr, M. Thermal Energy Storage Based on Cementitious Materials: A Review. AIMS Energy 2018, 6, 97–120. [Google Scholar] [CrossRef]

- Hoivik, N.; Greiner, C.; Tirado, E.B.; Barragan, J.; Bergan, P.; Skeie, G.; Blanco, P.; Calvet, N. Demonstration of EnergyNest Thermal Energy Storage (TES) Technology. AIP Conf. Proc. 2017, 1850, 080011. [Google Scholar]

- Girardi, F.; Giannuzzi, G.M.; Mazzei, D.; Salomoni, V.; Majorana, C.; Di Maggio, R. Recycled Additions for Improving the Thermal Conductivity of Concrete in Preparing Energy Storage Systems. Constr. Build. Mater. 2017, 135, 565–579. [Google Scholar] [CrossRef]

- Martins, M.; Villalobos, U.; Delclos, T.; Armstrong, P.; Bergan, P.G.; Calvet, N. New Concentrating Solar Power Facility for Testing High Temperature Concrete Thermal Energy Storage. Energy Procedia 2015, 75, 2144–2149. [Google Scholar] [CrossRef]

- Skinner, J.E.; Brown, B.M.; Selvam, R.P. Testing of High Performance Concrete as a Thermal Energy Storage Medium at High Temperatures. In Proceedings of the ASME 2011 5th International Conference on Energy Sustainability, Parts A, B, and C, Washington, DC, USA, 7–10 August 2011; pp. 723–728. [Google Scholar]

- Ozger, O.B.; Girardi, F.; Giannuzzi, G.M.; Salomoni, V.A.; Majorana, C.E.; Fambri, L.; Baldassino, N.; Di Maggio, R. Effect of Nylon Fibres on Mechanical and Thermal Properties of Hardened Concrete for Energy Storage Systems. Mater. Des. 2013, 51, 989–997. [Google Scholar] [CrossRef]

- Emerson, J.; Micah, H.; Panneer, S. Concrete as a Thermal Energy Storage Medium for Thermocline Solar Energy Storage Systems. Sol. Energy 2013, 96, 194–204. [Google Scholar]

- Laing, D.; Bauer, T.; Lehmann, D.; Bahl, C. Development of a Thermal Energy Storage System for Parabolic Trough Power Plants with Direct Steam Generation. In Proceedings of the ASME 3rd International Conference on Energy Sustainability 2009, ES2009, San Francisco, CA, USA, 19–23 July 2009; Volume 2, pp. 551–559. [Google Scholar]

- Laing, D.; Lehmann, D.; Fiß, M.; Bahl, C. Test Results of Concrete Thermal Energy Storage for Parabolic Trough Power Plants. J. Sol. Energy Eng. 2009, 131, 041007. [Google Scholar] [CrossRef]

- Miliozzi, A.; Giannuzzi, G.M.; Mazzei, D.; Liberatore, R.; Crescenzi, T.; Mele, D. Concrete Based Thermal Energy Storage. Devise. Patent 102017000129902, 14 November 2017. [Google Scholar]

- Ding, Z.; Wu, W.; Leung, M. Advanced/Hybrid Thermal Energy Storage Technology: Material, Cycle, System and Perspective. Renew. Sustain. Energy Rev. 2021, 145, 111088. [Google Scholar] [CrossRef]

- Laing, D.; Bahl, C.; Bauer, T.; Fiss, M.; Breidenbach, N.; Hempel, M. High-Temperature Solid-Media Thermal Energy Storage for Solar Thermal Power Plants. Proc. IEEE 2012, 100, 516–524. [Google Scholar] [CrossRef]

- Stückle, A.; Laing, D.; Müller-Steinhagen, H. Numerical Simulation and Experimental Analysis of a Modular Storage System for Direct Steam Generation. Heat. Transf. Eng. 2014, 35, 812–821. [Google Scholar] [CrossRef]

- Laing-Nepustil, D.; Zunft, S. Using Concrete and Other Solid Storage Media in Thermal Energy Storage Systems. In Advances in Thermal Energy Storage Systems; Elsevier: Amsterdam, The Netherlands, 2021; pp. 83–110. [Google Scholar]

- Sattler, J.C.; Caminos, R.A.C.; Ürlings, N.; Dutta, S.; Ruiz, V.; Kalogirou, S.; Ktistis, P.; Agathokleous, R.; Jung, C.; Alexopoulos, S.; et al. Operational Experience and Behaviour of a Parabolic Trough Collector System with Concrete Thermal Energy Storage for Process Steam Generation in Cyprus. AIP Conf. Proc. 2020, 2303, 140004. [Google Scholar]

- Skinner, J.E.; Strasser, M.N.; Brown, B.M.; Panneer Selvam, R. Testing of High-Performance Concrete as a Thermal Energy Storage Medium at High Temperatures. J. Sol. Energy Eng. 2014, 136, 021004. [Google Scholar] [CrossRef]

- Miliozzi, A.; Liberatore, R.; Crescenzi, T.; Veca, E. Experimental Analysis of Heat Transfer in Passive Latent Heat Thermal Energy Storage Systems for CSP Plants. Energy Procedia 2015, 82, 730–736. [Google Scholar] [CrossRef]

- Hassan, A.K.; Abdulateef, J.; Mahdi, M.S.; Hasan, A.F. Experimental Evaluation of Thermal Performance of Two Different Finned Latent Heat Storage Systems. Case Stud. Therm. Eng. 2020, 21, 100675. [Google Scholar] [CrossRef]

- Fornarelli, F.; Valenzano, M.; Fortunato, B.; Camporeale, S.M.; Torresi, M.; Oresta, P. Heat Transfer Enhancement Induced by the Geometry of a LHTES Device. Energy Procedia 2018, 148, 471–478. [Google Scholar] [CrossRef]

- Ma, Y.; Meng, Y.; Li, J.; Chen, W.; Yang, X.; Li, S.; Chong, D.; Yan, J. Numerical Simulation and Structural Optimization of Spiral Finned Tube Thermal Energy Storage. Int. J. Adv. Nucl. React. Des. Technol. 2023, 5, 123–136. [Google Scholar] [CrossRef]

- Elmaazouzi, Z.; El Alami, M.; Agalit, H.; Bennouna, E.G. Performance Evaluation of Latent Heat TES System-Case Study: Dimensions Improvements of Annular Fins Exchanger. Energy Rep. 2020, 6, 294–301. [Google Scholar] [CrossRef]

- Chieruzzi, M.; Miliozzi, A.; Torre, L.; Kenny, J.M. Nanofluids with Enhanced Heat Transfer Properties for Thermal Energy Storage. In Intelligent Nanomaterials; Wiley: Hoboken, NJ, USA, 2016; pp. 295–359. [Google Scholar]

- Miliozzi, A.; Liberatore, R.; Nicolini, D.; Chieruzzi, M.; Veca, E.; Crescenzi, T.; Torre, L. Heat Exchange Analysis on Latent Heat Thermal Energy Storage Systems Using Molten Salts and Nanoparticles as Phase Change Materials. In Advancements in Energy Storage Technologies; Intech: London, UK, 2018; p. 13. [Google Scholar]

- Miliozzi, A.; Dominici, F.; Candelori, M.; Veca, E.; Liberatore, R.; Nicolini, D.; Torre, L. Development and Characterization of Concrete/PCM/Diatomite Composites for Thermal Energy Storage in CSP/CST Applications. Energies 2021, 14, 4410. [Google Scholar] [CrossRef]

- Miliozzi, A.; Nicolini, D.; Liberatore, R.; Veca, E.M.; Giorgi, G.; Napoli, G. Analisi e Progettazione Di Accumuli Energetici Ibridi a Media Temperatura Comprendenti Lo Stoccaggio Di Tipo Termo-Elettrico (TEES) e Sensibile/Latente (SH/LH TES) a Media Temperatura; ENEA: Rome, Italy, 2023; Available online: https://www.ricercasistemaelettrico.enea.it/archivio-documenti.html?task=download.send&id=5186:analisi-e-progettazione-di-accumuli-energetici-ibridi-a-media-temperatura-comprendenti-lo-stoccaggio-di-tipo-tees-e-sh-lh-tes-media-temperatura&catid=587 (accessed on 23 June 2025).

- D’Aguanno, B.; Karthik, M.; Grace, A.N.; Floris, A. Thermostatic Properties of Nitrate Molten Salts and Their Solar and Eutectic Mixtures. Sci. Rep. 2018, 8, 10485. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.-G.; Hu, C.-X.; Liu, S.-J.; Guo, H.; Wu, Y.-T. The Thermal Conductivity of Molten NaNO3, KNO3, and Their Mixtures. Energy Procedia 2017, 143, 774–779. [Google Scholar] [CrossRef]

- Umair, M.M.; Zhang, Y.; Iqbal, K.; Zhang, S.; Tang, B. Novel Strategies and Supporting Materials Applied to Shape-Stabilize Organic Phase Change Materials for Thermal Energy Storage—A Review. Appl. Energy 2019, 235, 846–873. [Google Scholar] [CrossRef]

- Miliozzi, A.; Chieruzzi, M.; Torre, L. Experimental Investigation of a Cementitious Heat Storage Medium Incorporating a Solar Salt/Diatomite Composite Phase Change Material. Appl. Energy 2019, 250, 1023–1035. [Google Scholar] [CrossRef]

- Leng, G.; Qiao, G.; Jiang, Z.; Xu, G.; Qin, Y.; Chang, C.; Ding, Y. Micro Encapsulated & Form-Stable Phase Change Materials for High Temperature Thermal Energy Storage. Appl. Energy 2018, 217, 212–220. [Google Scholar] [CrossRef]

- Deng, Y.; Li, J.; Qian, T.; Guan, W.; Wang, X. Preparation and Characterization of KNO3/Diatomite Shape-Stabilized Composite Phase Change Material for High Temperature Thermal Energy Storage. J. Mater. Sci. Technol. 2017, 33, 198–203. [Google Scholar] [CrossRef]

- Eddhahak-Ouni, A.; Drissi, S.; Colin, J.; Neji, J.; Care, S. Experimental and Multi-Scale Analysis of the Thermal Properties of Portland Cement Concretes Embedded with Microencapsulated Phase Change Materials (PCMs). Appl. Therm. Eng. 2014, 64, 32–39. [Google Scholar] [CrossRef]

- Jeong, S.-G.; Jeon, J.; Lee, J.-H.; Kim, S. Optimal Preparation of PCM/Diatomite Composites for Enhancing Thermal Properties. Int. J. Heat. Mass. Transf. 2013, 62, 711–717. [Google Scholar] [CrossRef]

- Gao, H.; Wang, J.; Chen, X.; Wang, G.; Huang, X.; Li, A.; Dong, W. Nanoconfinement Effects on Thermal Properties of Nanoporous Shape-Stabilized Composite PCMs: A Review. Nano Energy 2018, 53, 769–797. [Google Scholar] [CrossRef]

- Qian, T.; Li, J.; Min, X.; Deng, Y.; Guan, W.; Ning, L. Diatomite: A Promising Natural Candidate as Carrier Material for Low, Middle and High Temperature Phase Change Material. Energy Convers. Manag. 2015, 98, 34–45. [Google Scholar] [CrossRef]

- Joule, J.P. On the Production of Heat by Voltaic Electricity. Proc. R. Soc. Lond. 1840, 4, 259–260. [Google Scholar]

- Lee, S.; Cho, W.-M.; Son, H.; Woo, H.-S.; Ju, B.-S.; Chang, Y.-S. Effect of Elevated Temperature and Internal Pressure Due to Severe Accidents on the Internal Pressure Capacity of Prestressed Concrete Containment Vessel. Int. J. Energy Res. 2024, 2024, 9717587. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Thermal Conductivity (W/(m⋅°C)) | Specific Heat (kJ/(kg⋅°C)) | Thermal Capacity (kWh/(m3⋅°C)) |

|---|---|---|---|---|

| Aluminum | 2700 | 220 | 0.93 | 0.70 |

| Copper | 8500 | 380 | 0.4 | 0.94 |

| Cast Iron | 7900 | 44.3 | 0.67 | 1.47 |

| Lead | 11,340 | 35.3 | 0.13 | 0.41 |

| Brick | 1700 | 0.6 | 0.84 | 0.40 |

| Concrete | 2400 | 1.5 | 1.0 | 0.67 |

| Granite | 2700 | 2.75 | 0.8 | 0.60 |

| Graphite | 2250 | 137 | 0.5 | 0.31 |

| Limestone | 2500 | 2.5 | 0.8 | 0.56 |

| Sandstone | 2400 | 2.2 | 0.82 | 0.55 |

| Sodium chloride | 2300 | 6.7 | 0.98 | 0.63 |

| Molten salts | 2000 | 1 | 1.5 | 0.83 |

| Mineral oil | 800 | 0.1 | 2.6 | 0.58 |

| Synthetic oil | 900 | 0.1 | 2.2 | 0.55 |

| Liquid sodium | 870 | 71 | 1.3 | 0.31 |

| Water | 1000 | 0.6 | 4.2 | 1.17 |

| Component | Mix |

|---|---|

| Water | 7.12%wt |

| Cement (CEM II 42.5R-B/(P-LL)) | 18.02%wt |

| Sand (0–4) | 34.19%wt |

| Small gravel (5–15) | 12.57%wt |

| Gravel (15–30) | 17.97%wt |

| Nylon fiber (Meraflex) | 0.05%wt |

| Carbon fiber | 0.24%wt |

| Fibermix | 0.68%wt |

| Super-plasticizing additive | 0.20%wt |

| mEPCM | 8.96%wt |

| Water/Cement rate | 0.4 |

| Volumic mass (kg/m3) | 2220 |

| Step | Method: Conversion P2H | Method: Heating by HTF |

|---|---|---|

| charging | Duration: 10 h Target temperature: 320 °C | Duration: 30 h Thermal oil flow: 18 L/min Thermal oil inlet temperature: 320 °C |

| discharging | Duration: 4.5 h Thermal oil flow: 18 L/min Thermal oil inlet temperature: 150 °C | Duration: 3 h Thermal oil flow: 13.5 L/min Thermal oil inlet temperature: 150 °C |

| Step | |

|---|---|

| charging | Duration: 2 h Target temperature: 260 °C |

| discharging | Duration: 1 h Thermal oil flow: 14 L/min Inlet thermal oil temperature: 180 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liberatore, R.; Nicolini, D.; Lanchi, M.; Miliozzi, A. Experimental Testing of New Concrete-Based, Medium-Temperature Thermal Energy Storage Charged by Both a Thermal and Electrical Power Source. Energies 2025, 18, 3511. https://doi.org/10.3390/en18133511

Liberatore R, Nicolini D, Lanchi M, Miliozzi A. Experimental Testing of New Concrete-Based, Medium-Temperature Thermal Energy Storage Charged by Both a Thermal and Electrical Power Source. Energies. 2025; 18(13):3511. https://doi.org/10.3390/en18133511

Chicago/Turabian StyleLiberatore, Raffaele, Daniele Nicolini, Michela Lanchi, and Adio Miliozzi. 2025. "Experimental Testing of New Concrete-Based, Medium-Temperature Thermal Energy Storage Charged by Both a Thermal and Electrical Power Source" Energies 18, no. 13: 3511. https://doi.org/10.3390/en18133511

APA StyleLiberatore, R., Nicolini, D., Lanchi, M., & Miliozzi, A. (2025). Experimental Testing of New Concrete-Based, Medium-Temperature Thermal Energy Storage Charged by Both a Thermal and Electrical Power Source. Energies, 18(13), 3511. https://doi.org/10.3390/en18133511