Abstract

Wake steering has emerged as a promising strategy to mitigate turbine wake losses, with existing research largely focusing on the aerodynamic optimization of yaw angles. However, many prior approaches rely on static look-up tables (LUTs), offering limited adaptability to real-world wind variability and leading to non-optimal results. More importantly, these energy-focused strategies overlook the mechanical implications of frequent yaw activities in pursuit of the maximum power output, which may lead to premature exhaustion of the yaw system’s design life, thereby accelerating structural degradation. This study proposes a supervisory control framework that balances energy capture with structural reliability through three key innovations: (1) upstream-based inflow sensing for real-time capture of free-stream wind, (2) fatigue-responsive optimization constrained by a dynamic actuation quota system with adaptive yaw activation, and (3) a bidirectional threshold adjustment mechanism that redistributes unused actuation allowances and compensates for transient quota overruns. A case study at an offshore wind farm shows that the framework improves energy yield by 3.94%, which is only 0.29% below conventional optimization, while reducing yaw duration and activation frequency by 48.5% and 74.6%, respectively. These findings demonstrate the framework’s potential as a fatigue-aware control paradigm that balances energy efficiency with system longevity.

1. Introduction

Wake steering in wind farms is a novel control strategy aimed at enhancing overall energy production by deliberately adjusting the yaw angles of upstream turbines, thereby redirecting their aerodynamic wakes away from downstream units to mitigate wake interference. Rooted in fluid dynamics and control theory, the principles of wake steering have undergone extensive theoretical development and field validation in recent years [1]. Empirical studies have demonstrated that wake steering strategies can significantly improve wind farm efficiency and energy yield [2,3,4,5,6]. Consequently, wake steering has garnered considerable attention across both academic and industrial domains, with investigations encompassing yaw-induced wake deviation modeling [7,8,9,10,11,12] and the development of multi-objective control frameworks that jointly optimize energy capture and structural load mitigation for downstream turbines [13,14,15,16]. Furthermore, recent pilot implementations and field validations have demonstrated the industrial feasibility of wake steering control, achieving real-time supervisory integration and closed-loop testing in operational wind farms [1,17].

While the benefits of wake steering strategy are well-documented, its operational trade-offs, particularly those arising from prolonged or repetitive yaw adjustments, are often underappreciated. Continuous yaw maneuvers may impose additional mechanical stresses on turbine components, such as bearings, gears, and actuators, accelerating fatigue accumulation and potentially reducing the operational lifespan of the system. Furthermore, each yaw initiation generates a surge of inrush current that expedites insulation degradation in yaw motors, thereby diminishing the longevity of the electrical drive system and compounding system-level fatigue. This raises concerns about long-term reliability and maintenance costs, particularly in large-scale offshore wind farms where the cumulative effects of frequent yaw cycles across numerous turbines can significantly strain operational resources. Moreover, excessive yaw activity may diminish net energy gains due to increased parasitic power consumption by yaw drives. Most existing optimization frameworks prioritize overall wake loss reduction, often neglecting the critical interplay among net energy yield, yaw actuator duty cycle, and fatigue-induced degradation of both mechanical and electrical components.

Yaw-angle optimization typically relies on gradient-based or nonlinear, non-convex algorithms that perform exhaustive searches across the yaw configuration space. For instance, in a wind farm with one hundred turbines, comprehensive wind rose optimizations spanning all wind directions and speeds can require several hours to days of high-performance computing [18]. The substantial computational burden precludes real-time, online optimization based on live wind measurements. As a result, industry practice typically adopts offline pre-computed strategies, where optimal yaw offsets are calculated for discrete wind condition bins defined by combinations of wind speed, wind direction, and turbulence intensity. These results are then stored in static multidimensional look-up tables (LUTs) [19]. However, these LUTs present significant reliability limitations. Due to their finite resolution, LUTs fail to capture the full spectrum of atmospheric variability; temporal fluctuations, unmeasured turbulence regimes, and site-specific shear profiles frequently fall outside the bounds of predefined bins. This mismatch often results in non-optimal or even counterproductive yaw adjustments when actual conditions deviate from LUT assumptions.

This study proposes a supervisory control framework capable of performing real-time yaw optimization under dynamically evolving wind conditions. Unlike conventional static LUT-based strategies, the proposed framework incorporates adaptive control parameters and fatigue-responsive constraints to iteratively update yaw-angle setpoints for individual turbines based on real-time wind measurements. The inflow identification module continuously monitors leading-edge turbines to infer the prevailing free-stream wind direction and speed, thereby ensuring that all optimization decisions are based on the latest upstream inflow conditions. The fatigue-aware control module periodically assesses cumulative yaw activity across turbines, comparing it with predefined fatigue thresholds to determine whether the optimization process should be initiated or deferred. The optimization module computes yaw setpoints only when both atmospheric variability and fatigue constraints fall within acceptable operational thresholds, thereby avoiding superfluous actuator usage. Operating in a coordinated fashion, these modules enable the supervisory controller to dynamically mediate trade-offs between energy production and long-term component durability. By conditionally engaging yaw optimization only when both flow conditions and fatigue metrics are favorable, the system maintains high reliability without sacrificing responsiveness. The framework’s ability to pursue near-optimal rather than strictly optimal solutions under fatigue constraints enhances both computational efficiency and structural preservation. This coordinated control strategy advances intelligent wind farm operation by extending system lifespan, minimizing actuator wear, and enhancing robustness under variable atmospheric conditions.

2. Supervisory Control Framework Algorithm

The design of a wake steering controller involves determining optimal yaw angles that maximize wind farm power output using engineering wake models. This process depends on accurate wind farm layout data, turbine-specific parameters, and prevailing wind conditions while also accounting for operational constraints such as turbine availability. A supervisory decision-making mechanism is required to orchestrate the sequential optimization process, managing key control elements such as yaw actuation thresholds, inflow update frequency, and fatigue constraints alongside the conditional activation of the yaw optimization solver. The proposed framework dynamically initiates solver execution in response to live wind measurements while continuously monitoring turbine state and environmental variability to guide control decisions.

2.1. Steady-State Wake Model: FLORIS

The FLORIS (flow redirection and induction in steady state) model serves as the core wake modeling engine in the proposed control framework. Developed through a collaboration between the National Renewable Energy Laboratory (NREL) and the Delft University of Technology, the FLORIS software package (version 4.0) [20] integrates parametric wake modeling with time-stepped simulations to capture wind farm dynamics under varying atmospheric conditions. This computational tool supports wind plant optimization by adjusting turbine yaw-angle configurations, thereby improving energy output through iterative operational refinements [21]. Unlike high-fidelity CFD-based solvers, which are computationally prohibitive for real-time applications, FLORIS leverages reduced-order, steady-state formulations to estimate wake deflection, expansion, and velocity deficits with sufficient accuracy for control synthesis. This balance between physical realism and computational tractability makes FLORIS particularly well-suited for integration within real-time optimization and supervisory decision-making loops in large-scale wind farms [6,21].

To improve computational tractability in large-scale wind farm optimization, the FLORIS platform implements a modular solver architecture capable of integrating multiple yaw-angle optimization strategies. Traditional approaches, such as gradient-based methods and nonlinear, non-convex solvers like SciPy’s SLSQP, remain broadly applicable, but their reliance on an exhaustive search across the yaw-angle space incurs high computational costs. This limitation becomes increasingly prohibitive in scenarios involving large turbine arrays and comprehensive wind condition coverage.

To overcome these limitations, the National Renewable Energy Laboratory (NREL) introduced the serial-refine method, which has served as the default yaw optimization solver in FLORIS since Version 3 [18]. The serial-refine method operates in two distinct optimization passes across the wind farm, systematically progressing from the most upstream turbine to the most downstream. In the first pass (“Serial”), each turbine is sequentially optimized over a coarse yaw angle grid, selecting the angle that maximizes total wind farm power while keeping the yaw settings of all other turbines fixed. This search space is defined by the yaw discretization resolution, which specifies how many discrete yaw angles are uniformly sampled across the allowable yaw range. In the second pass (“Refine”), the algorithm applies a refined yaw resolution, conducting a finer local search around the optimal angle identified in the first pass. This involves evaluating additional yaw angles within a narrow symmetric interval centered at the previously selected value, further enhancing sensitivity to localized inflow dynamics. For example, given an allowable yaw range of , a yaw discretization resolution of 5 yields five evenly spaced candidates: . Each turbine is sequentially optimized over the discrete set. Then, with a refined yaw resolution of 4, the refine pass searches an additional offset of and centered on the angle found in the serial pass.

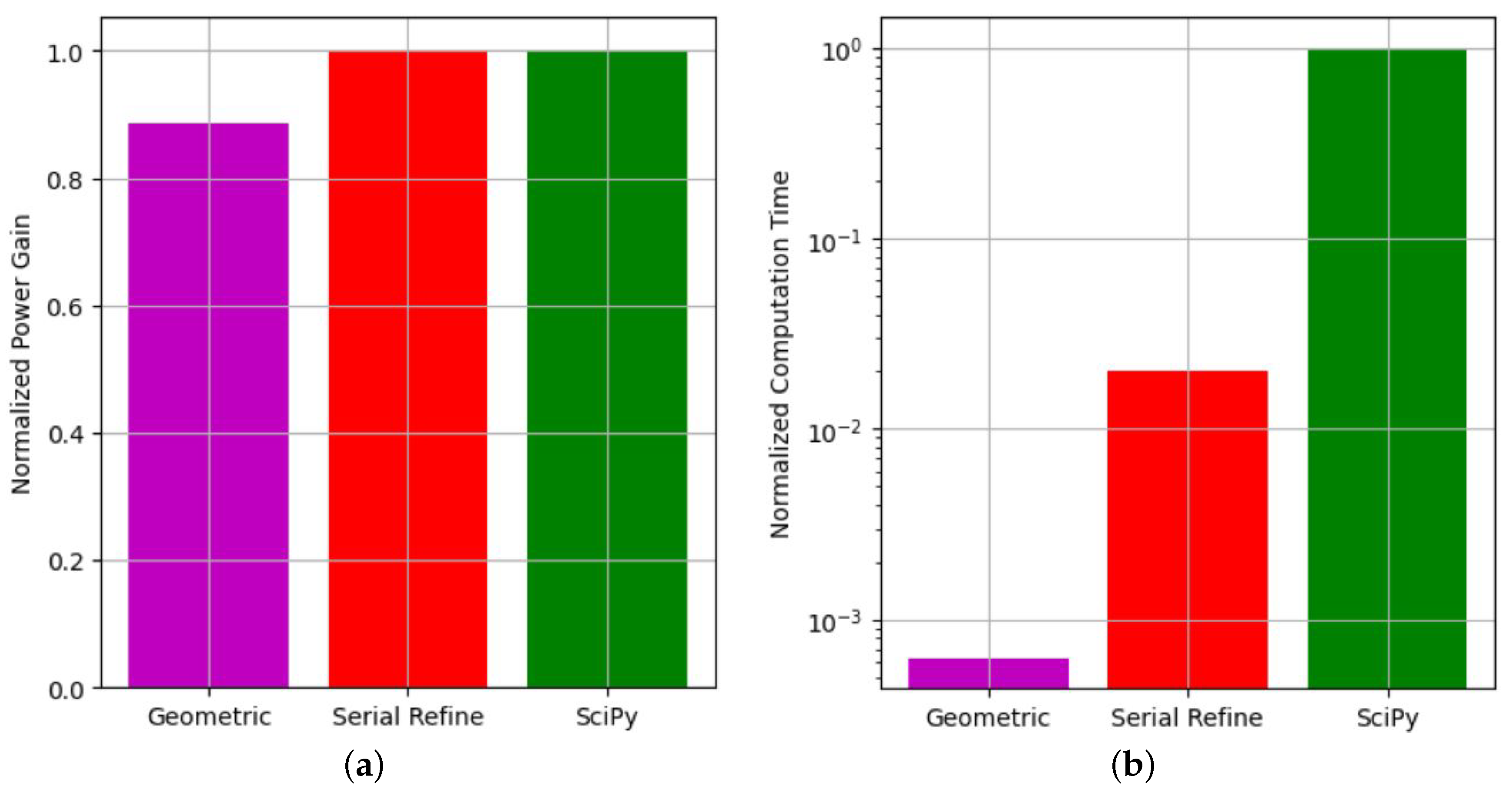

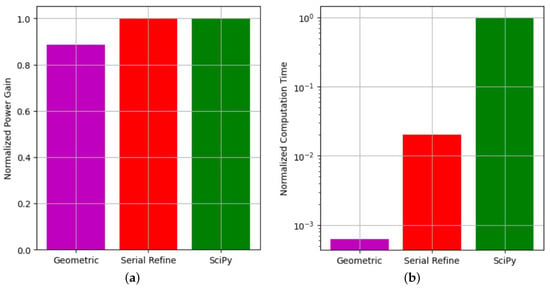

By forgoing global search and relying on localized updates, serial-refine achieves power gains comparable to or exceeding those of more computationally demanding nonlinear solvers. Notably, the method exhibits linear runtime scalability with respect to turbine count, reducing computation time by one to several orders of magnitude [18]. Figure 1 compares the performance of three different yaw optimization algorithms based on a case study involving a three-turbine wind farm with a total installed capacity of 15 MW [22]. The normalized power gains (Figure 1a) are scaled relative to the output of SciPy, which yields the highest total farm power across all tested wind conditions, while computation times (Figure 1b) are normalized against SciPy’s runtime to highlight relative efficiency. The serial-refine method achieves comparable power gains to SciPy but with over 100× faster computation, offering a favorable trade-off between performance and computational cost. In contrast, the geometric method, while computationally cheapest, produces relatively lower power improvements, indicating its limited effectiveness in capturing complex wake interactions. This comparison highlights the serial-refine method as a well-balanced choice for real-time applications, combining near-optimal aerodynamic performance with practical runtime efficiency.

Figure 1.

Comparative performance of three yaw optimization algorithms evaluated on a three-turbine wind farm case study (total capacity: 15 MW). Wind directions were swept from to with a resolution of per step. (a) Power gains normalized to SciPy results; (b) computation time normalized to SciPy runtime. Serial-refine offers similar power performance as SciPy with much lower computational cost, while geometric trades power gain for speed.

The computational efficiency and scalability of the serial-refine method form the algorithmic backbone of the proposed real-time supervisory control framework. Its responsiveness enables seamless integration with the dynamic inflow identification and fatigue-aware supervisory modules discussed in the following sections. From an implementation perspective, the entire control architecture, including the serial-refine method and all supervisory modules, was developed in Python Version 3.12.0 and integrated directly with the FLORIS backend via its modular API. This unified language environment ensures efficient data flow, minimizes interfacing complexity, and facilitates rapid prototyping of coordinated wind farm control strategies.

2.2. Dynamic Inflow Identification

Inflow conditions within a wind farm act as essential boundary inputs for wake steering, capturing the real-time spatial structure of the atmospheric flow over the operational site. These conditions are characterized by a time-resolved matrix encompassing multiple atmospheric variables: wind speed, direction, turbulence intensity, air density, shear, and veer. Among these, wind direction emerges as the dominant variable for optimizing wake steering strategies. It directly determines turbine positional relationships by identifying upstream and downstream units, thereby informing row-wise control prioritization. By continuously tracking the wind direction vector, the control system prioritizes yaw alignment to mitigate wake interference between turbine rows.

Building upon wind condition monitoring as a prerequisite for wake steering optimization, accurate spatial transformation is required to evaluate turbine positions relative to the prevailing wind direction. To address this, a dual-coordinate reference framework is proposed, integrating fixed geographic coordinates with a wind-aligned, rotating reference frame. Specifically, the Cartesian geographic system defines static turbine positions, while a rotating wind-aligned coordinate system continuously reorients its x-axis to align with the instantaneous wind direction (0° representing North, and 90° for East). For any turbine i with geographic coordinates , its position in the rotating system is calculated using the wind direction angle :

This coordinate transformation uncovers essential spatial dependencies relevant to wake steering control. As wind direction varies, the rotating reference frame dynamically reorients turbine positions along its x-axis, directly influencing the upstream–downstream ordering. Turbines closer to the negative x-direction in the rotating system are sorted as upstream, while turbines farther along the positive x-direction are classified as downstream. Downstream turbines inherently suffer from measurement inaccuracies due to wake interference from upstream units, leading to biased wind readings that deviate from true free-stream conditions. To mitigate this, prioritizing “first-order” turbines, i.e., those unobstructed by wakes, becomes essential. By continuously analyzing wind-aligned coordinate transformations, the control algorithm dynamically detects turbines situated at the leading edge of the prevailing inflow. These turbines offer undisturbed flow measurements, which serve as reliable free-stream wind inputs for the wake steering control framework.

The inflow identification module adopts a four-stage procedure to extract undisturbed free-stream wind data under dynamically varying atmospheric conditions. In the first stage, the wind direction domain is discretized into -spaced angular bins to facilitate turbine sorting across the full directional spectrum. For each bin, the system dynamically identifies the turbine that is furthest upstream with respect to the corresponding wind direction and designates it as the first-order reference unit. In the second stage, adjacent angular bins associated with the same first-order turbine are aggregated into unified wind sectors, thereby ensuring consistency in free-stream measurements for real-time wind directions falling within the sector’s angular range. As a result, the full compass is restructured into a set of angular wind sectors, each governed by a distinct first-order turbine. In the third stage, the system periodically acquires wind direction readings from all first-order reference turbines. These discrete readings are averaged to compute the mean wind direction, which is then mapped to its corresponding predefined angular sector. Sector affiliation is confirmed if the computed mean wind direction falls within a given sector’s range, thereby triggering activation of the corresponding first-order turbine’s anemometer as the validated free-stream input source.

2.3. Adaptive Optimization Procedure

The inherently slow dynamic response of yaw actuators hampers real-time wind tracking, while operational durations must remain within fatigue-limited thresholds. Furthermore, the high computational burden of current optimization algorithms precludes real-time online yaw control based on live wind measurements. In light of these constraints, industry-standard practice involves the use of static offline look-up tables (LUTs) as a surrogate approach for approximating yaw-angle optimization. However, this strategy may become increasingly non-optimal as wind conditions evolve rapidly across temporal and spatial dimensions within the wind plant [19].

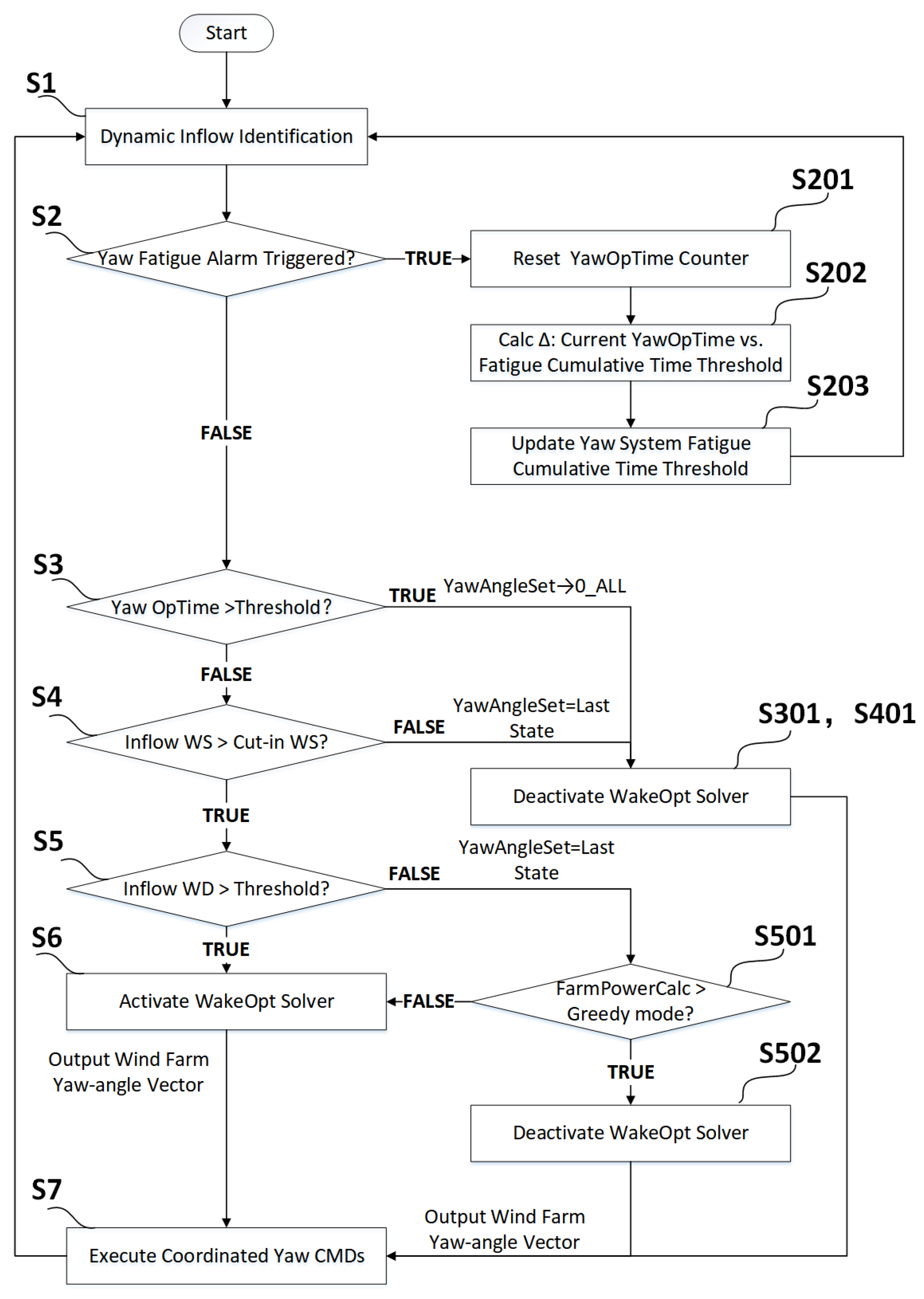

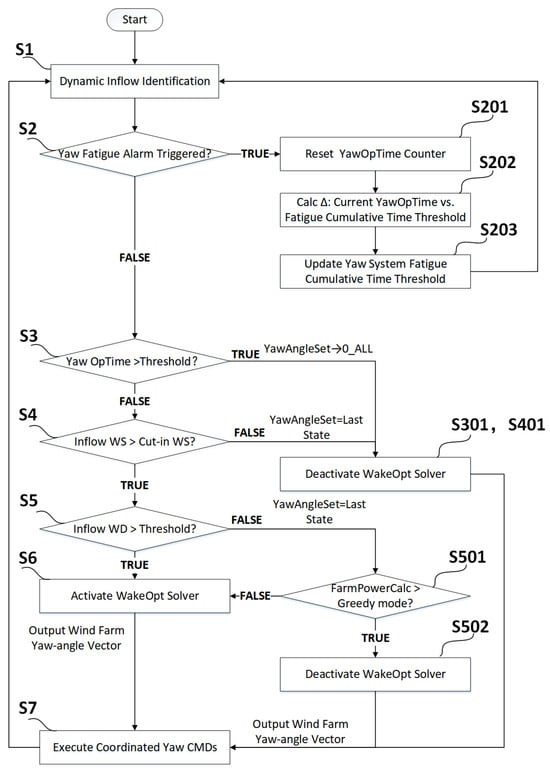

This study concentrates on real-time decision-making processes for adaptive yaw-angle optimization, utilizing live wind condition measurements. The dynamic adaptive control framework functions under a stringent constraint: the fatigue life threshold of the yaw system. The algorithm performs real-time optimization to determine yaw-angle settings that maximize energy capture, adhering to the DNV-ST-0437 standard from Det Norske Veritas (DNV), which stipulates the following: “Operation of the yaw system shall be considered during 10% of the service life” [23]. Upon nearing constraint violations, such as cumulative yaw operations exceeding 10% duty cycle per hour, the algorithm adaptively downgrades to a suboptimal solution. This approach ensures sub-maximal farm-wide power output while complying with system-level fatigue constraints through adjusted yaw-angle settings. Nevertheless, this method is engineered to outperform the greedy control strategy, wherein individual turbines independently aim for maximum power extraction based on localized wind conditions. A flowchart illustrating the adaptive optimization procedure is presented in Figure 2.

Figure 2.

A flow chart of the adaptive optimization procedure.

The procedure begins with dynamic inflow identification (S1), where free-stream wind data are analyzed to extract prevailing wind characteristics such as direction and speed. This foundational step ensures all subsequent control decisions align with current atmospheric conditions. Running in parallel, the fatigue monitoring module (S2) continuously evaluates yaw system usage to flag excessive mechanical stress through a dedicated fatigue alarm. This module acts as a structural safeguard, regulating actuation to protect long-term system health. Upon activation of the fatigue alarm, the controller initiates a three-step mitigation protocol aimed at rebalancing the yaw duty cycle: (S201) resets the yaw operation time (YawOpTime) counter to zero, (S202) computes the deviation between the cumulative yaw time and the allocated fatigue budget for the current procedural cycle, and (S203) updates the next cycle’s fatigue quota by adjusting it with . Here, a positive indicates overuse, triggering a proportional deduction from the next cycle’s quota, while a negative reflects underuse and permits a compensatory increase. Together, these adjustments enable adaptive balancing of the fatigue quota across successive control cycles. Importantly, even in alarm-free states, the fatigue threshold dynamically evolves to reflect changing operational loads, fostering both structural longevity and control responsiveness. At decision node S3, “”, the control logic diverges. If the threshold is breached, the system triggers a global yaw neutralization routine by assigning zero yaw angles to all

turbines , initiating a mechanical cooldown phase. This reset also flags the alarm system, ensuring the event is recorded, and anticipatory adjustments can be made for the subsequent control cycle.

Following structural assessment, the control sequence transitions to evaluating aerodynamic viability through two conditional filters: (S4) confirms whether inflow wind speed exceeds the turbine cut-in threshold, while (S5) verifies that wind direction variability remains within a defined tolerance. Only when both conditions are satisfied does the controller proceed to engage the yaw optimization module (S6). If either condition fails, the system conservatively holds the last known yaw setting , thereby limiting mechanical wear and computational overhead. However, when the inflow wind speed is sufficient , but directional variability does not exceed the threshold , the system inserts a checkpoint to further balance energy capture against actuation cost. The framework introduces an additional checkpoint to evaluate whether the current yaw setting yields more power than a greedy-mode baseline ”. If so, the optimizer is bypassed (S502), avoiding costly computation and actuation but with little expected gain. This ensures that even suboptimal strategies are only retained when they clearly outperform the greedy benchmark; otherwise, farm-level optimization is deemed ineffective. Notably, a pivotal element in this logic is the wind direction variation threshold. It plays a dual stabilizing role: compensating for the yaw system’s inertial lag, which limits futile attempts at real-time wind tracking, and suppressing excessive actuation that could otherwise intensify structural fatigue. Yet, under certain edge conditions, this balance is challenged. For instance, if the wind speed drops below the cut-in threshold but transient wind direction shifts still breach tolerance, the optimizer may be unnecessarily triggered. This results in yaw commands issued during non-generating periods, leading to avoidable actuator fatigue, inefficient use of computational resources, and longer control cycle times due to redundant solver execution, all of which diminish overall control effectiveness. This highlights the rationale behind the S4 filter: ensuring that inflow wind speed exceeds the cut-in threshold before engaging further control logic is essential to avoid energy-neutral yet mechanically costly operations.

Finally, in the execution phase (S7), validated yaw-angle vectors are dispatched as coordinated control commands (CMDs) to individual turbine yaw systems, closing the control loop. The entire procedure repeats continuously with each new wind inflow characterization cycle.

3. Results and Discussion

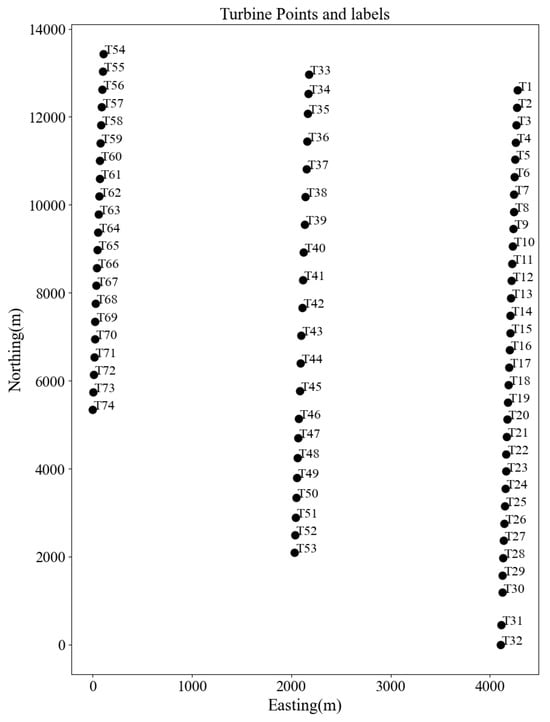

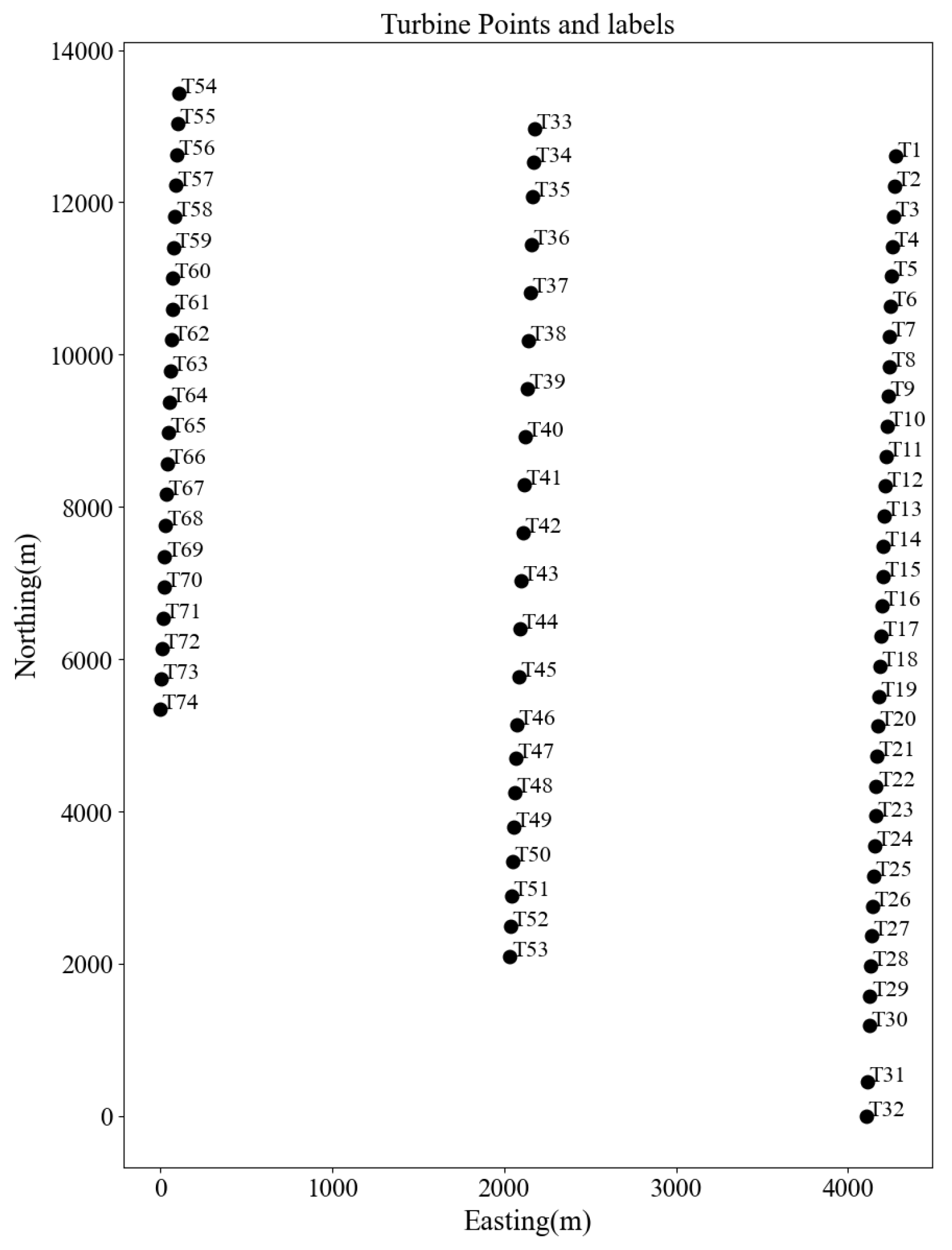

To evaluate the real-world effectiveness of the proposed control algorithm, a case study was conducted on an offshore wind farm located in the Eastern China Sea, as illustrated in Figure A1. The data were obtained through collaboration with the wind farm operator and included turbine SCADA records and layout information. Due to proprietary constraints, the raw dataset is not publicly available. The site comprises 74 turbines (T1–T74) uniformly distributed across a East–North grid, representative of utility-scale offshore deployments. By integrating the algorithm with the farm’s layout and its operational data, this study quantifies improvements in both energy yield and yaw system fatigue management. Notably, it addresses a critical gap in existing wake steering research by explicitly integrating yaw duty constraints, offering practical implications for similar offshore systems.

The wind farm comprises 72 commercial 4.0 MW turbines and two prototypes (T31: 7.0 MW and T32: 6.2 MW) now operating as standard production units. Notably, T31 remained offline during the measurement campaign due to scheduled maintenance and is, therefore, excluded from all subsequent analyses. Comprehensive specifications for all turbines, including rotor diameter, cut-in wind speed, and yaw rate, are detailed in Table 1. As shown, the 4.0 MW turbines are categorized as Type A or Type B, while the 6.2 MW unit is labeled Type C, each with distinct aerodynamic and control characteristics.

Table 1.

Specifications of turbines installed on the offshore wind farm.

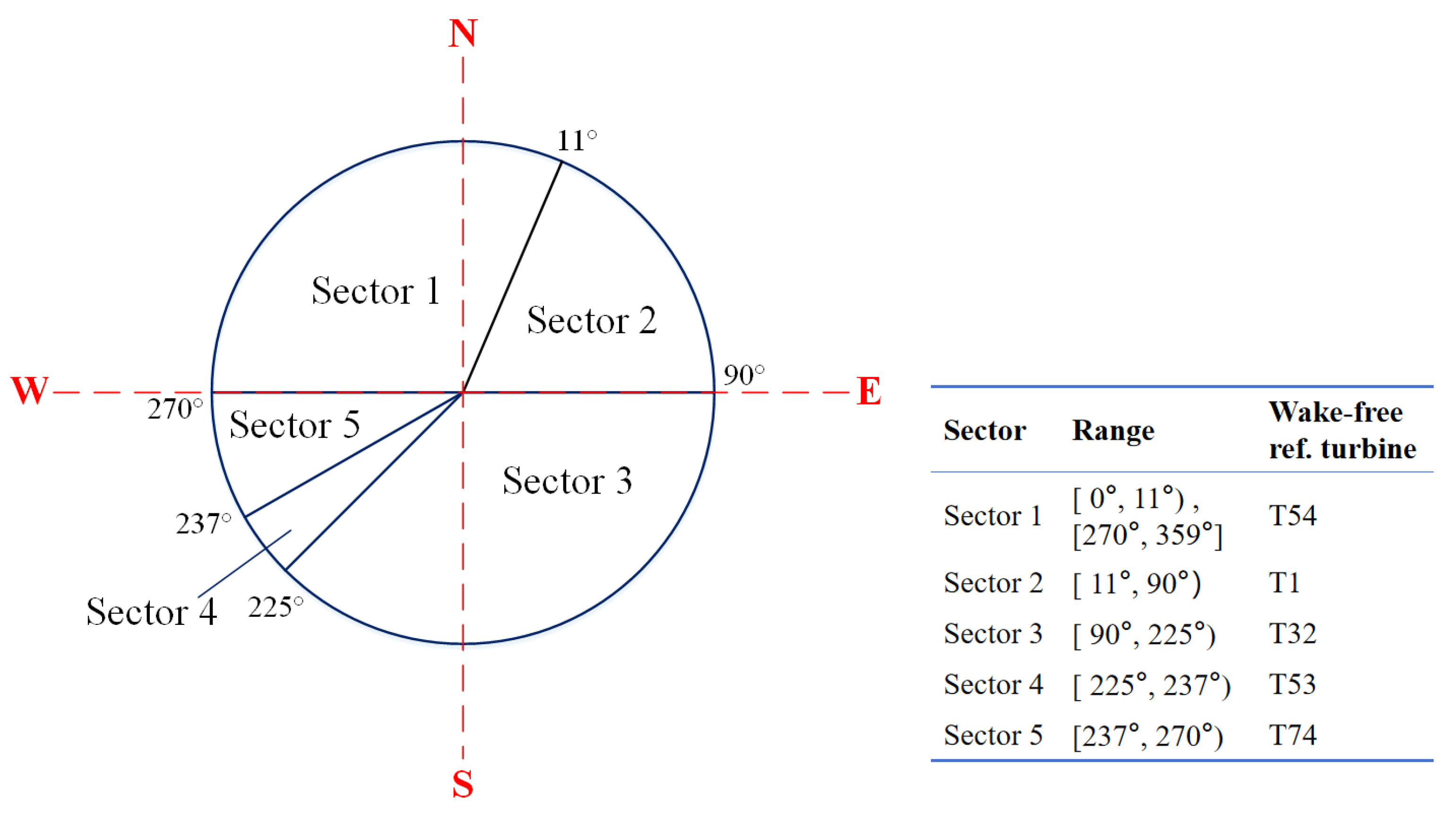

3.1. Inflow Data Processing

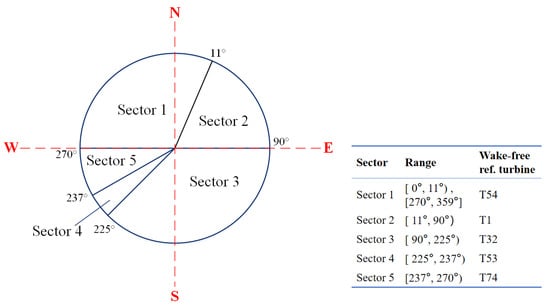

Through rotating coordinate alignment, turbines positioned furthest upstream under specific wind directions are prioritized as first-order reference units, which are free of wake influence. This wind farm’s spatial configuration and 360° directional analysis systematically define first-order turbines for distinct wind sectors(see Figure 3). Each sector is assigned a specific angular range to ensure full directional coverage. For instance, Sector 1 covers the intervals from 0° to 11° and from 270° to 359°. A tabular list systematically maps sectors to wake-free reference turbines (T54, T1, T32, T53, and T74), prioritizing upstream units under corresponding wind directions. During real-time operation, when the measured wind direction falls within a given sector, the free-stream wind speed is sourced exclusively from the anemometer of the sector’s assigned reference turbine. This turbine provides validated inflow conditions for downstream wake steering control.

Figure 3.

Wake-free reference turbine assignment based on wind farm spatial configuration and 360° directional sectors.

The analysis is based on SCADA data collected on 2 July 2023, with a 10-minute sampling resolution. The 2 July 2023 was selected as a representative case study day based on its inclusion of three critical operating conditions for wake steering validation: (i) dominant southeasterly inflow (135°–180°), aligning with the prevailing wind sector of the farm; (ii) wind speeds occasionally falling below the turbine cut-in threshold, resulting in curtailed power output; (iii) transient wind direction shifts exceeding the ±8° yaw control threshold. These characteristics allowed efficient assessment of the control framework across multiple boundary scenarios within a single 24-h period, making the dataset well-suited for validation purposes.

To support this analysis, SCADA data from all turbines were preprocessed to ensure temporal alignment and continuity. Due to asynchronous timing systems across turbine types A, B, and C, comprehensive preprocessing was conducted. First, all datasets were temporally resampled and synchronized to a common timeline (00:00:00 to 23:50:00 UTC+8) with uniform 10-min intervals. Second, although missing values in wind speed and direction were rare, a linear interpolation strategy was implemented as a precautionary step to ensure temporal continuity across the full dataset. Data harmonization is essential to enable real-time coordination of control decisions and yaw command dispatch within the centralized wake steering system.

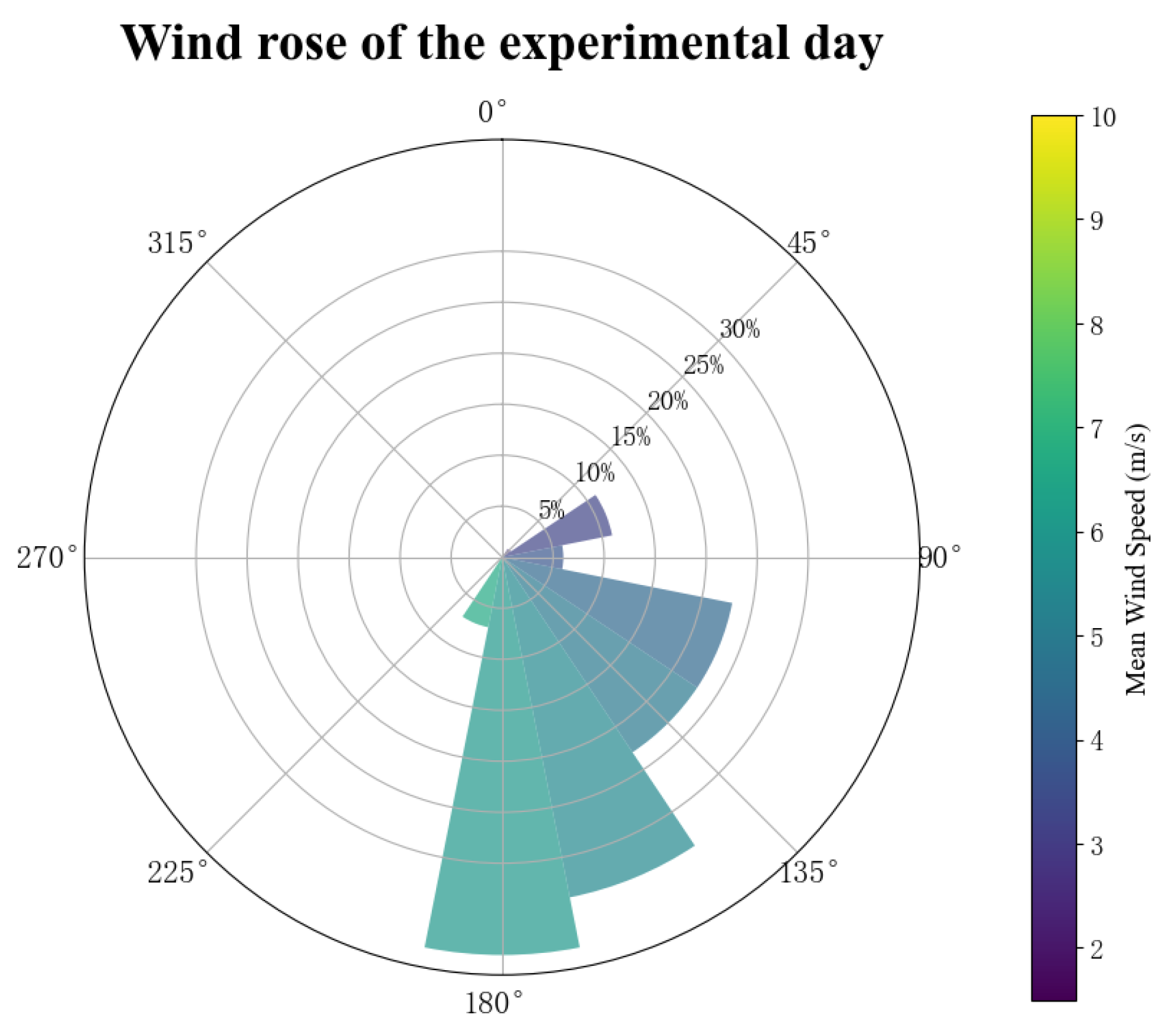

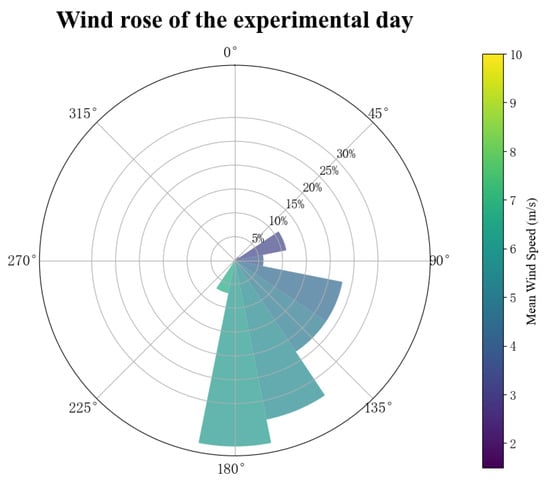

The processed dataset corresponds to a prevailing southeasterly wind regime, ranging from 135° to 180°, with average wind speeds predominantly between 0.4 and 9.6 m/s. Notably, wind direction frequencies peak between 158° and 180°, accounting for 25%–30% of all observations, as illustrated by the light teal sectors in the wind rose diagram (Figure 4). This directional consistency both validates the interpolation approach and offers a representative operating envelope for calibrating the wake steering controller under typical inflow conditions.

Figure 4.

Wind rose of the experimental day (2 July 2023).

3.2. Supervisory Wake Steering Control

In compliance with DNV’s operational guidelines [23], which recommend that yaw system operations should not exceed 10% of its service life, a time-based supervisory monitoring framework is employed. This system employs a rolling time window, for example, one hour, to track yaw actuator fatigue accumulation across the wind farm. A fatigue alarm is triggered whenever the cumulative yaw operation time for any individual turbine surpasses 360 s within this window. Once the alarm is activated, the supervisory controller enforces a protective response: the wake steering optimization module is immediately suspended, and all turbine yaw angles are set to zero. This control strategy remains in effect until the start of the next monitoring cycle, thereby preventing accelerated mechanical degradation while maintaining operational safety margins.

To effectively manage the fatigue quota allocated to yaw system operations, which is capped at 10% of service time within each rolling monitoring window, wind direction variability emerges as a key constraint. Frequent directional fluctuations inherently accelerate the depletion of this finite yaw actuation quota. To mitigate this, the farm-level controller applies a supervisory wind direction variation threshold of , which aligns with industry-standard yaw misalignment tolerances commonly used in greedy-mode operations. Under greedy control, individual turbines only initiate yaw corrections when the wind direction deviates beyond from the nacelle’s current orientation. By adopting the equivalent threshold at the farm supervisory level, the control framework prevents additional yaw actuations induced by the wake steering strategy. Specifically, when wind direction changes remain within , neither the turbine-level controllers nor the farm-level optimization module trigger yaw adjustments. This parity minimizes redundant actuation and ensures that wake steering does not impose an additional fatigue burden under nominal wind fluctuation conditions.

In configuring the serial-refine yaw control strategy, yaw actuation was constrained within a positive-only allowable range of . This decision is grounded in both practical and aerodynamic considerations. From a control standpoint, switching frequently between large positive and negative yaw angles in response to small wind direction shifts can introduce unnecessary mechanical complexity and increased wear. Aerodynamically, positive yaw misalignments have demonstrated consistent benefits over negative counterparts in multiple studies. For instance, it was observed that positive yawing reduces blade root bending moment fatigue, whereas negative yawing amplifies it [24].

To explore yaw configurations efficiently within this constrained space, we adopted a two-pass discretization strategy denoted as . The first pass (“Serial”) samples five uniformly spaced yaw angles across the full allowable range (i.e., yaw discretization resolution = 5), establishing a coarse control surface. The second pass (“Refine”) then applies a refined yaw resolution of 4, generating tighter local candidate angles around the initial optimum to further enhance wake steering alignment. The first pass yields a yaw-angle range such as ; the refine pass then locally tunes the chosen value by one of range , enabling finer adaptation while maintaining actuation feasibility.

3.3. Comparative Evaluation of Control Strategies

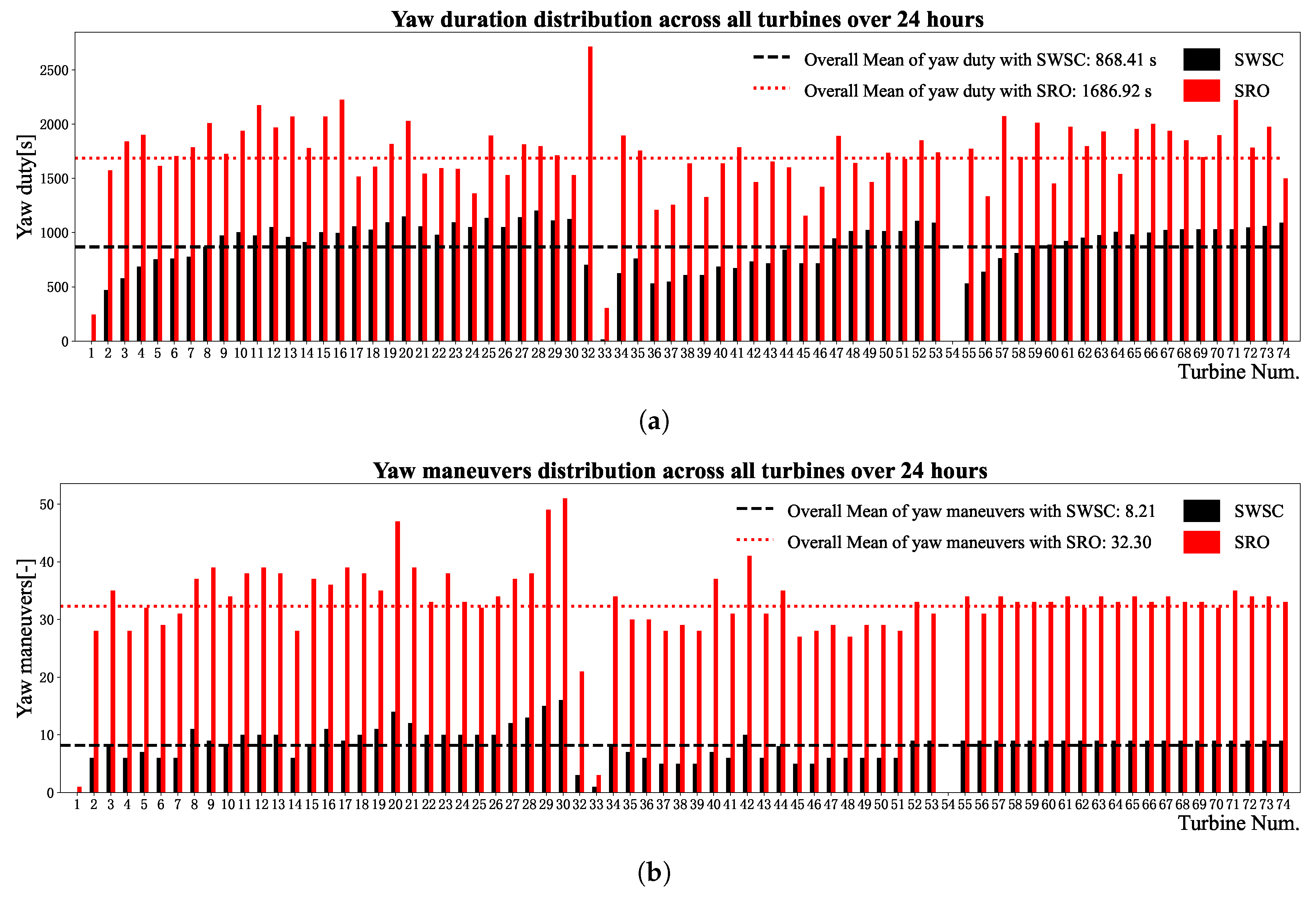

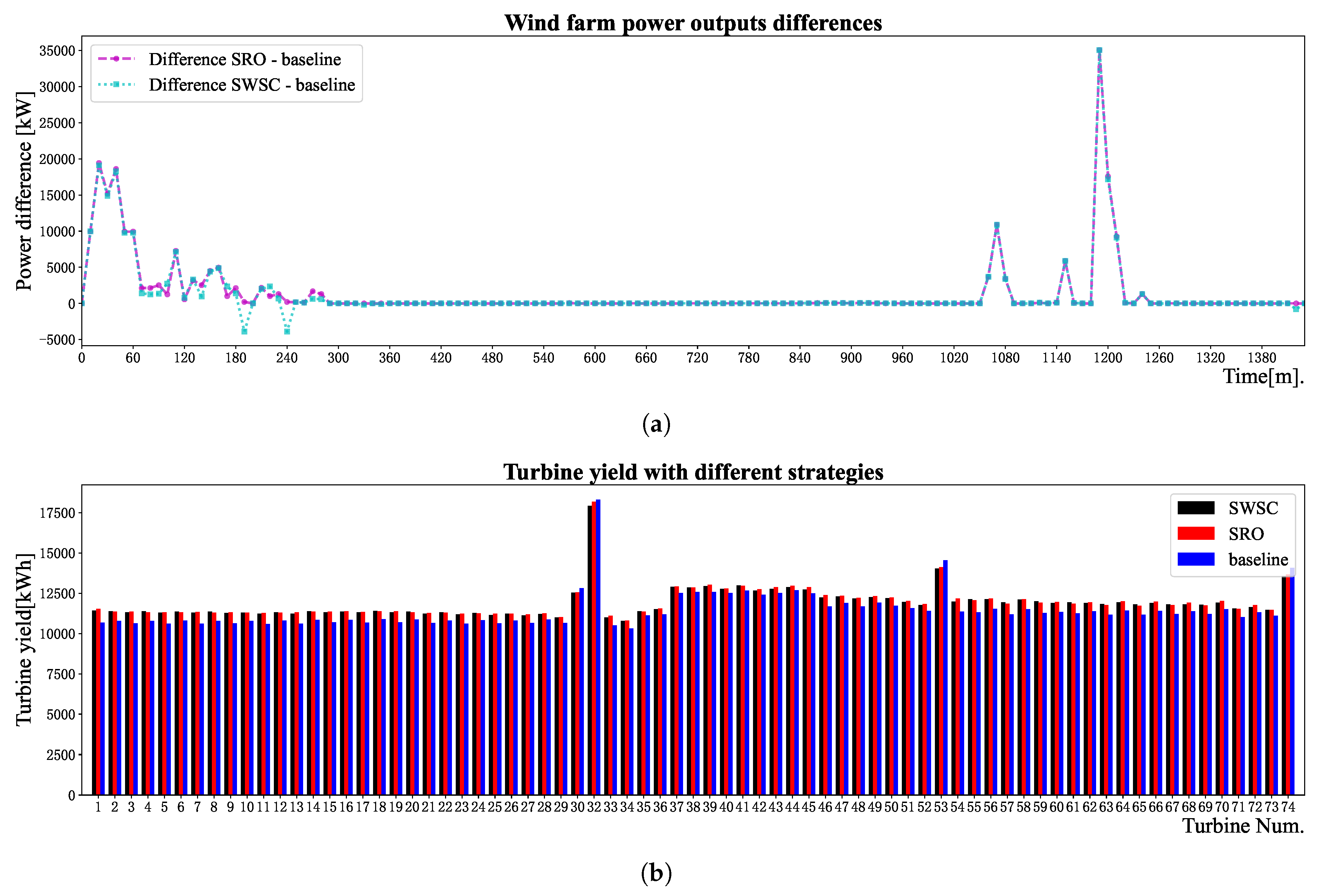

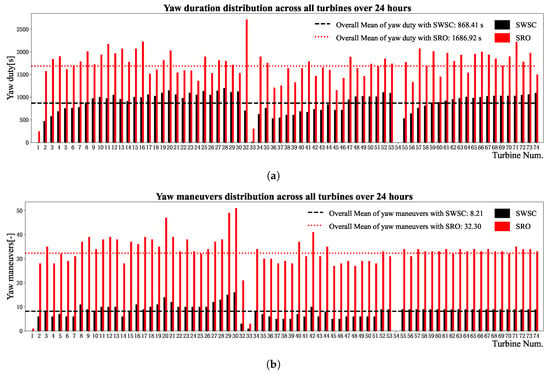

A systematic comparative analysis was conducted between the proposed supervisory wake steering controller (SWSC), which incorporates the serial-refine optimization (SRO) within a supervisory control framework, and the benchmark SRO method operating without supervisory coordination. The SWSC adopts a hierarchical farm-level flow control architecture, whereas the SRO approach relies on iterative yaw angle refinements based on localized flow field predictions. Both strategies were assessed under identical 24 h of continuous simulation scenarios to ensure fair benchmarking. The performance outcomes, including energy yield and yaw actuation metrics, are visually summarized in Figure 5 and Figure 6, providing a comprehensive overview of each controller’s operational behavior and effectiveness.

Figure 5.

Comparative yaw system performance between SWSC and SRO controllers. (a) Daily yaw actuation duration per turbine (upper: SWSC mean = 868.41 s vs. SRO mean = 1686.92 s). (b) Yaw maneuver frequency distribution (lower: SWSC mean = 8.21 vs. SRO mean = 32.30 operations/day).

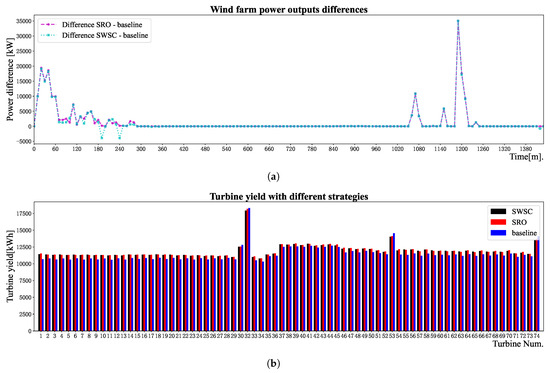

Figure 6.

Comparative analysis of wind farm power outputs and turbine-level yields under different control strategies. (a) Power differences between SRO (purple), SWSC (cyan), and baseline (greedy mode). (b) Turbine-specific yields under SWSC (black), SRO (red), and baseline (blue).

The comparative performance of SWSC and SRO control strategies is quantitatively demonstrated in Figure 5. The upper subplot Figure 5a highlights a significant reduction in yaw system workload under SWSC management: the mean daily yaw actuation time per turbine is reduced from 1686.92 s (SRO) to 868.41 s, representing a 48.5% decrease. Notably, SWSC maintains yaw adjustments below 1210 s for all turbines (black bars), while temporal accumulation exceeding 2000s is observed in 11 SRO units (red bars). The lower subplot Figure 5b further supports this finding by comparing the yaw maneuver frequency. SWSC averages 8.21 yaw operations per turbine per day, dramatically lower than the 32.30 operations/day recorded under SRO, a 74.6% reduction. This benefit is particularly pronounced among upstream turbines (T3–T30), where SWSC restricts daily maneuver counts to fewer than 15, compared to SRO peaks reaching 30–50 operations/day. Both metrics collectively verify SWSC’s capacity to alleviate yaw system fatigue through its fatigue-aware supervisory scheduling logic.

Figure 6a illustrates the 24-h temporal profile of net power output differentials between the SRO (purple) and SWSC (cyan) strategies, with both evaluated relative to the baseline greedy-mode operation. Both strategies demonstrate significant power gains (0–35,000 kW range) during active wake steering phases. Remarkably, SWSC matches SRO’s performance for the majority of the time, indicating comparable control efficacy under normal operating conditions. Notably, SWSC strategically reduces optimization activity under specific boundary conditions:

- During the 60–90 min interval, it retains the prior yaw configuration to mitigate unnecessary actuation in response to minor wind direction shifts (within ), leading to only a slight power deficit compared to SRO;

- Between 190–240 min, wake steering is suspended altogether as wind speeds fall below the 3.5 m/s cut-in threshold of Turbine Type C, thereby avoiding potential mechanical resonance risks associated with low-RPM operation;

- From 290–1050 min, both strategies yield power outputs indistinguishable from the baseline greedy-mode operation due to negligible wake interactions under southeast wind directions, where inter-turbine spacing exceeds seven rotor diameters.

Interestingly, SWSC not only reduces actuation effort but can, in some cases, outperform the SRO. For instance, at 220 min, SWSC’s retained yaw setting yields a net power output of 8231.31 kW, surpassing the SRO’s yield of 6904.56 kW. Over the 24-h period, SWSC exhibits superior performance during a total of 100 min, accounting for 6.94% of the operational time. This apparent paradox arises from the discretized nature of the SRO search algorithm: since the serial-refine method evaluates turbine yaw settings over a fixed discrete grid, the retained yaw angle in SWSC occasionally lies between two discrete grid points, incidentally aligning with a configuration that, while not explicitly evaluated by SRO, results in superior overall performance. This highlights a subtle but important strength of SWSC: it can occasionally outperform grid-based optimization by capturing performance peaks that fall between predefined discrete yaw settings.

Figure 6b quantifies turbine-specific daily energy yields across all turbines under SWSC (black), SRO (red), and baseline (blue) strategies. The SRO and SWSC strategies achieved collective energy yield improvements of 4.23% and 3.94%, respectively, over 24 h compared to the baseline greedy operation, demonstrating effective wake steering implementation. Notably, while SWSC’s gain slightly trails SRO by 0.29%, this marginal difference confirms its ability to maintain wake control performance while reducing yaw system actuations by 48.5% (as quantified in Figure 5).

These findings not only validate the supervisory control framework’s dual benefit in energy yield and fatigue management but also underscore its scalability for real-world offshore wind farm deployment. Importantly, the algorithm’s structure is modular and data-agnostic, relying solely on standard SCADA inputs such as wind speed, direction, and yaw duration without requiring site-specific tuning. Key operational thresholds, including the ±8° directional tolerance and the 10% fatigue actuation quota, follow established international standards (e.g., DNV-ST-0437), supporting the framework’s compatibility with diverse wind farm configurations. To further demonstrate reproducibility, we also analyzed July 23, with results presented in the Supplementary Material (Figures S1–S3), confirming consistent control behavior and performance outcomes. As a result, the control logic remains reproducible and generalizable under similar operating conditions.

3.4. Future Work

While the proposed framework demonstrates strong performance in fatigue-aware energy optimization, several extensions are envisioned to enhance its broader applicability. Future developments will address more complex operational environments by incorporating spatially heterogeneous flow modeling. This will improve the representation of terrain-induced wake interactions and atmospheric boundary layer dynamics. In parallel, probabilistic uncertainty quantification will be embedded into the FLORIS-based optimization engine, enabling the controller to handle sensor noise and environmental variability with greater resilience.

To support real-world implementation, integration with existing turbine control infrastructure is a key focus. The framework’s modular design is compatible with standard SCADA inputs and enables real-time actuation via supervisory overlays on OEM controller platforms. In deployment, edge controllers will be installed on each turbine to manage local execution, while a centralized controller at the farm level will dispatch optimized yaw commands through the edge layer. This structure ensures scalable integration across diverse wind farm configurations.

Future validation will explore digital twin environments or industrial control sandboxes to evaluate system performance under practical constraints. These efforts aim to accelerate the framework’s transition to industrial-grade applications, supporting its incorporation into grid-responsive dispatch strategies and long-term asset management planning.

4. Conclusions

This study proposes a novel wake steering control framework incorporating three core innovations. First, the inflow identification module demonstrates superior global accuracy by dynamically selecting the furthest upstream turbines under arbitrary wind directions to characterize free-stream conditions. This real-time capability ensures optimization adapts to transient meteorological conditions, overcoming traditional methods’ latency in non-stationary flows. Second, the framework introduces a fatigue-aware optimization strategy that deliberately integrates suboptimal control actions and constraint-based regulation, shifting the objective from short-term power maximization to long-term mechanical reliability. This self-regulating approach balances energy yield with structural preservation. Third, the control logic includes a bidirectional yaw threshold adjustment mechanism, which allows temporary exceedance of yaw duration limits to be compensated in subsequent cycles. Simultaneously, unused fatigue margins are reallocated to expand future actuation tolerances. This adaptive mechanism mitigates transient load spikes and strengthens fatigue resilience over the turbine’s operational life while maintaining safety compliance.

The efficacy of the proposed framework is assessed through a case study involving a real offshore wind farm, using high-resolution SCADA data for simulation-based validation under representative operating scenarios. The SWSC strategy achieves 3.94% aggregate energy yield improvement over 24 h, marginally 0.29% below SRO’s 4.23% gain, while almost halving the yaw system duty time (868.41 vs. 1686.92 s/day duration). More significantly, the SWSC strategy reduces yaw activation frequency by 74.6%, far exceeding its 48.5% reduction in cumulative yaw duration. Since each yaw initiation induces a surge of high inrush current that accelerates motor insulation degradation, this sharp decline in activation frequency contributes directly to enhanced electrical component longevity. Additionally, SWSC demonstrates an unexpected performance benefit: it can occasionally outperform SRO by incidentally retaining yaw settings that lie between the discrete grid points used in SRO. Collectively, these results underscore SWSC’s unique ability to balance simplicity, robustness, and opportunistic performance gains.

Future research will focus on expanding the framework’s applicability in more complex operational scenarios. Key directions include incorporating spatially heterogeneous flow models to better capture terrain-induced wake effects and boundary layer dynamics, as well as embedding probabilistic uncertainty quantification into the FLORIS-based optimization core to improve robustness against sensor noise and environmental variability. From an implementation perspective, the framework will be further integrated into existing turbine control systems through modular supervisory overlays compatible with OEM platforms. Validation efforts using digital twin environments and industrial control sandboxes are also planned to demonstrate real-time operability under field conditions, paving the way for industrial-scale deployment.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/en18133452/s1, Figure S1: Wind Rose for 23 July 2023; Figure S2: Comparative yaw system performance between SWSC and SRO controllers; Figure S3: Comparative analysis of wind farm power outputs and turbine-level yields under different control strategies.

Author Contributions

Conceptualization, Y.S. and J.Z.; methodology, Y.S.; software, C.L. and E.W.; validation, S.Z. and X.W.; formal analysis, Y.S., J.Z. and G.H.; investigation, Y.W.; resources, G.H. and P.H.; data curation, C.L. and E.W.; writing—original draft preparation, Y.S.; writing—review and editing, J.Z. and S.Z.; visualization, Y.W.; supervision, P.H.; project administration, Y.S.; funding acquisition, Y.S. and X.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by SKL-OWPE and WEHEU under Grants HFQZS2024-11.

Data Availability Statement

The datasets presented in this article are not readily available because the SCADA data and farm-specific parameters constitute commercially confidential information limited by proprietary privacy. Requests to access the datasets should be directed to the corresponding author.

Acknowledgments

The authors gratefully acknowledge the financial support provided by the State Key Laboratory of Offshore Wind Power Equipment and Wind Energy High-Efficient Utilization in China.

Conflicts of Interest

Authors Yang Shen, Jinkui Zhu, Peng Hou, Guodong He, Chao Lu, Enyu Wang and Yiwen Wu were employed by the Zhejiang Baima Lake Laboratory Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CMDs | Commands |

| DNV | Det Norske Veritas |

| FLORIS | Flow Redirection and Induction in Steady State |

| NREL | National Renewable Energy Laboratory |

| SCADA | Supervisory Control And Data Acquisition |

| SRO | Serial-refine Optimization |

| SWSC | Supervisory Wake Steering Controller |

Appendix A. Wind Farm Layout

Figure A1.

Layout of 74 offshore wind turbines (T1-T74) on an East–North coordinate system. Turbine positions are labeled by black dots and are uniformly distributed across the plotted area.

Figure A1.

Layout of 74 offshore wind turbines (T1-T74) on an East–North coordinate system. Turbine positions are labeled by black dots and are uniformly distributed across the plotted area.

References

- Meyers, J.; Bottasso, C.; Dykes, K.; Fleming, P.; Gebraad, P.; Giebel, G.; Göçmen, T.; Van Wingerden, J.-W. Wind farm flow control: Prospects and challenges. Wind Energy Sci. 2022, 7, 2271–2306. [Google Scholar] [CrossRef]

- Fleming, P.; King, J.; Dykes, K.; Simley, E.; Roadman, J.; Scholbrock, A.; Murphy, P.; Lundquist, J.K.; Moriarty, P.; Fleming, K.; et al. Initial results from a field campaign of wake steering applied at a commercial wind farm—Part 1. Wind Energy Sci. 2019, 4, 273–285. [Google Scholar] [CrossRef]

- Fleming, P.; King, J.; Simley, E.; Roadman, J.; Scholbrock, A.; Murphy, P.; Lundquist, J.K.; Moriarty, P.; Fleming, K.; van Dam, J.; et al. Continued results from a field campaign of wake steering applied at a commercial wind farm: Part 2. Wind Energy Sci. 2020, 5, 945–958. [Google Scholar] [CrossRef]

- Bensason, D.; Simley, E.; Roberts, O.; Fleming, P.; Debnath, M.; King, J.; Bay, C.; Mudafort, R. Evaluation of the potential for wake steering for US land-based wind power plants. J. Renew. Sustain. Energy 2021, 13, 033303. [Google Scholar] [CrossRef]

- Doekemeijer, B.M.; Kern, S.; Maturu, S.; Kanev, S.; Salbert, B.; Schreiber, J.; Campagnolo, F.; Bottasso, C.L.; Schuler, S.; Wilts, F.; et al. Field experiment for open-loop yaw-based wake steering at a commercial onshore wind farm in Italy. Wind Energy Sci. 2021, 6, 159–176. [Google Scholar] [CrossRef]

- Simley, E.; Fleming, P.; Girard, N.; Alloin, L.; Godefroy, E.; Duc, T. Results from a wake-steering experiment at a commercial wind plant: Investigating the wind speed dependence of wake-steering performance. Wind Energy Sci. 2021, 6, 1427–1453. [Google Scholar] [CrossRef]

- Ti, Z.; Deng, X.W.; Zhang, M. Artificial Neural Networks based wake model for power prediction of wind farm. Renew. Energy 2021, 172, 618–631. [Google Scholar] [CrossRef]

- Lin, J.W.; Zhu, W.J.; Shen, W.Z. New engineering wake model for wind farm applications. Renew. Energy 2022, 198, 1354–1363. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, X. A novel dynamic wind farm wake model based on deep learning. Appl. Energy 2020, 277, 115552. [Google Scholar] [CrossRef]

- Ling, Z.; Zhao, Z.; Liu, Y.; Liu, H.; Liu, Y.; Ma, Y.; Wang, T.; Wang, D. A three-dimensional wake model for wind turbines based on a polynomial distribution of wake velocity. Ocean Eng. 2023, 282, 115064. [Google Scholar] [CrossRef]

- Ti, Z.; Deng, X.W.; Yang, H. Wake modeling of wind turbines using machine learning. Appl. Energy 2020, 257, 114025. [Google Scholar] [CrossRef]

- Qian, G.W.; Ishihara, T. Wind farm power maximization through wake steering with a new multiple wake model for prediction of turbulence intensity. Energy 2021, 220, 119680. [Google Scholar] [CrossRef]

- Shaler, K.; Jonkman, J.; Barter, G.E.; Kreeft, J.J.; Muller, J.P. Loads assessment of a fixed-bottom offshore wind farm with wake steering. Wind Energy 2022, 25, 1530–1554. [Google Scholar] [CrossRef]

- He, R.; Yang, H.; Lu, L. Optimal yaw strategy and fatigue analysis of wind turbines under the combined effects of wake and yaw control. Appl. Energy 2023, 337, 120878. [Google Scholar] [CrossRef]

- Lin, M.; Porté-Agel, F. Power maximization and fatigue-load mitigation in a wind-turbine array by active yaw control: An LES study. In Proceedings of the Science of Making Torque from Wind (TORQUE 2020), The Netherlands (online), 28 September 2020. [Google Scholar]

- He, R.; Yang, H.; Lu, L.; Gao, X. Site-specific wake steering strategy for combined power enhancement and fatigue mitigation within wind farms. Renew. Energy 2024, 225, 120324. [Google Scholar] [CrossRef]

- Bachant, P.; Ireland, P.; Burrows, B.; Qiao, C.; Duncan, J.; Zheng, D.; Dua, M. Development and validation of a hybrid data-driven model-based wake steering controller and its application at a utility-scale wind plant. Wind Energy Sci. 2024, 9, 2235–2259. [Google Scholar] [CrossRef]

- Fleming, P.A.; Stanley, A.P.J.; Bay, C.J.; King, J.; Simley, E.; Doekemeijer, B.M.; Mudafort, R. Serial-refine method for fast wake-steering yaw optimization. In Proceedings of the Science of Making Torque from Wind (TORQUE 2022), Delft, The Netherlands, 1 June 2022. [Google Scholar]

- Kanev, S. Dynamic wake steering and its impact on wind farm power production and yaw actuator duty. Renew. Energy 2020, 146, 9–15. [Google Scholar] [CrossRef]

- FLORIS: FLOw Redirection and Induction in Steady State. Available online: https://www2.nrel.gov/wind/floris (accessed on 4 March 2025).

- Gebraad, P.M.O.; Teeuwisse, F.W.; Van Wingerden, J.W.; Fleming, P.A.; Ruben, S.D.; Marden, J.R.; Pao, L.Y. Wind plant power optimization through yaw control using a parametric model for wake effects—A CFD simulation study. Wind Energy 2016, 19, 95–114. [Google Scholar] [CrossRef]

- Compare Yaw Optimizers Within FLORIS. Available online: https://nrel.github.io/floris/examples/examples_control_optimization/006_compare_yaw_optimizers.html (accessed on 11 March 2025).

- DNV-ST-0437 Loads and Site Conditions for Wind Turbines. Available online: https://www.dnv.com/energy/standards-guidelines/dnv-st-0437-loads-and-site-conditions-for-wind-turbines/ (accessed on 19 May 2025).

- Damiani, R.; Dana, S.; Annoni, J.; Fleming, P.; Roadman, J.; van Dam, J.; Dykes, K. Assessment of wind turbine component loads under yaw-offset conditions. Wind Energy Sci. 2018, 3, 173–189. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).