Numerical Simulation of Treatment Capacity and Operating Limits of Alkali/Surfactant/Polymer (ASP) Flooding Produced Water Treatment Process in Oilfields

Abstract

1. Introduction

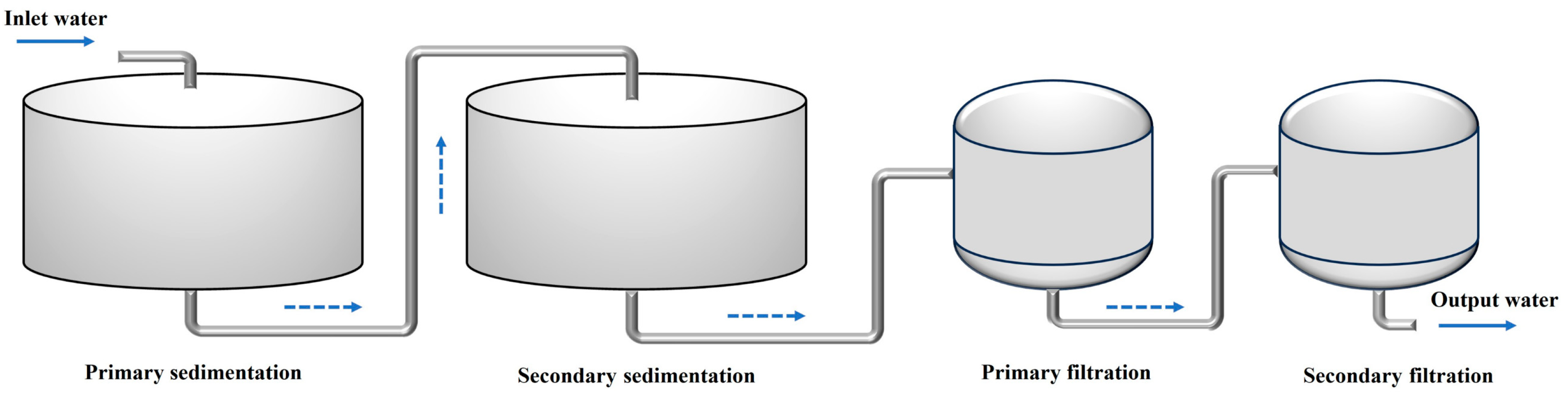

2. Production Description

3. Methodology

3.1. Basic Parameters

3.2. Model Construction

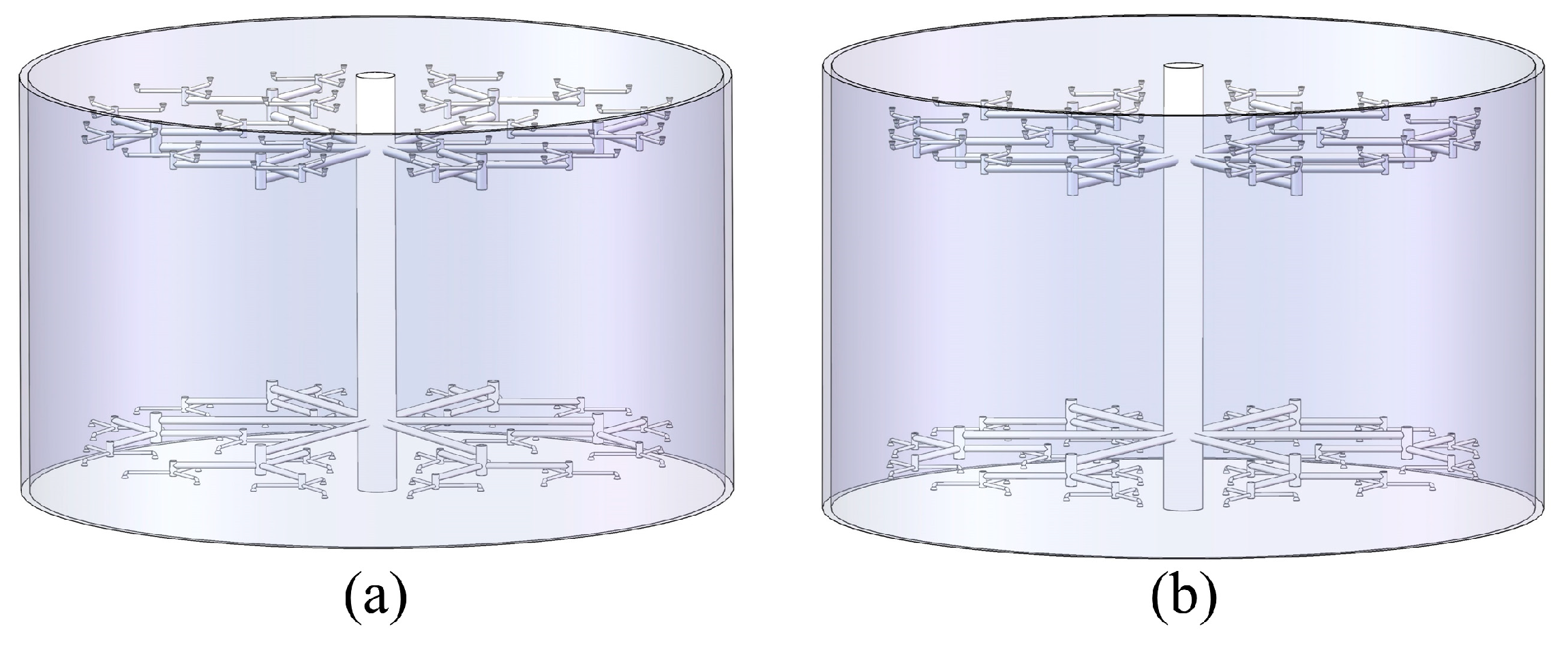

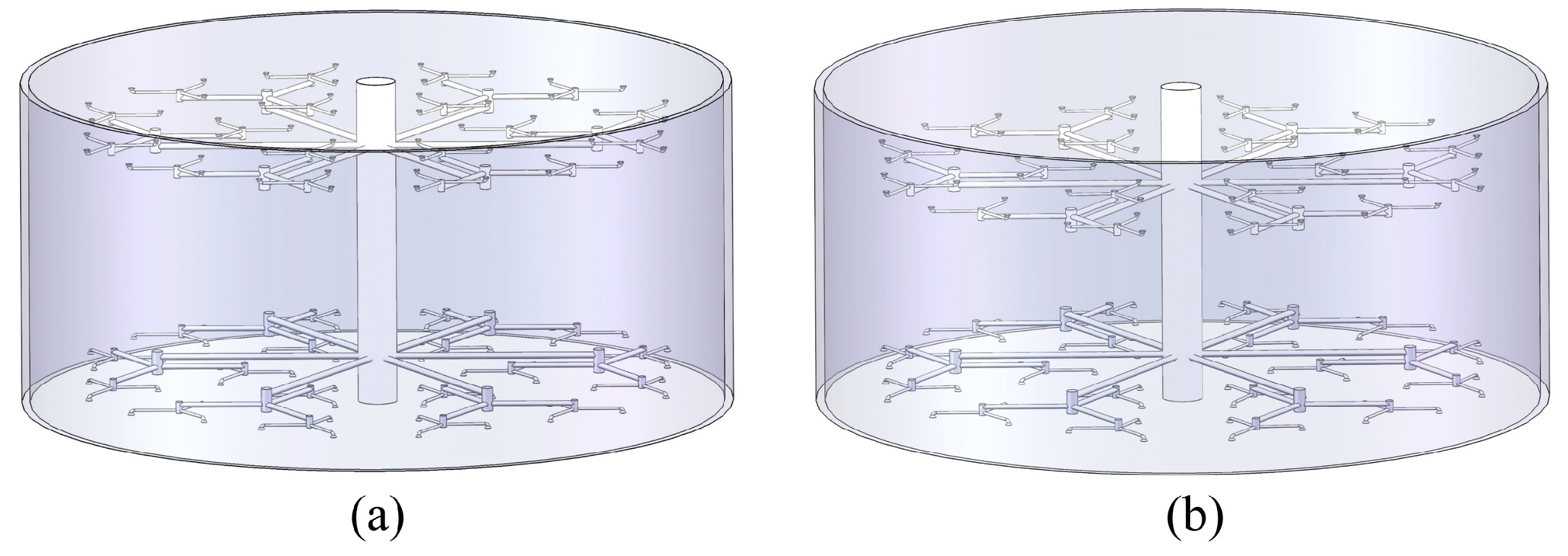

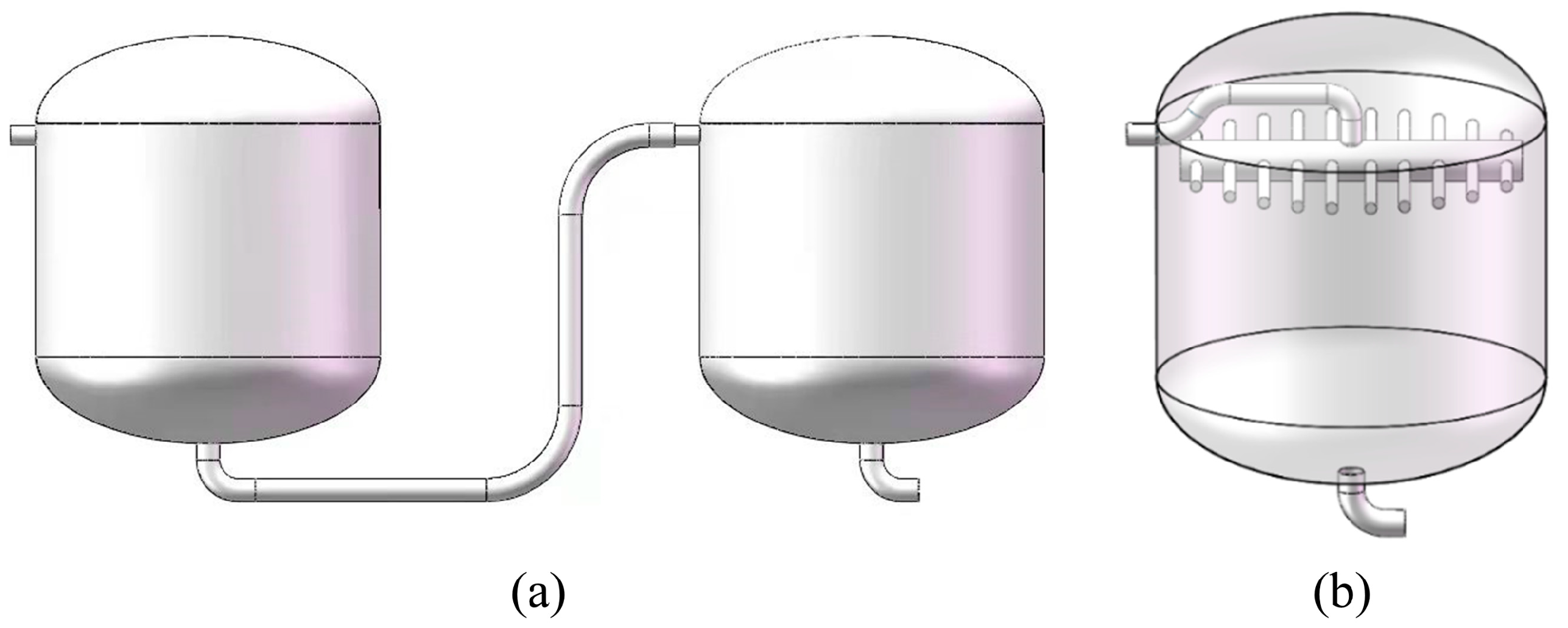

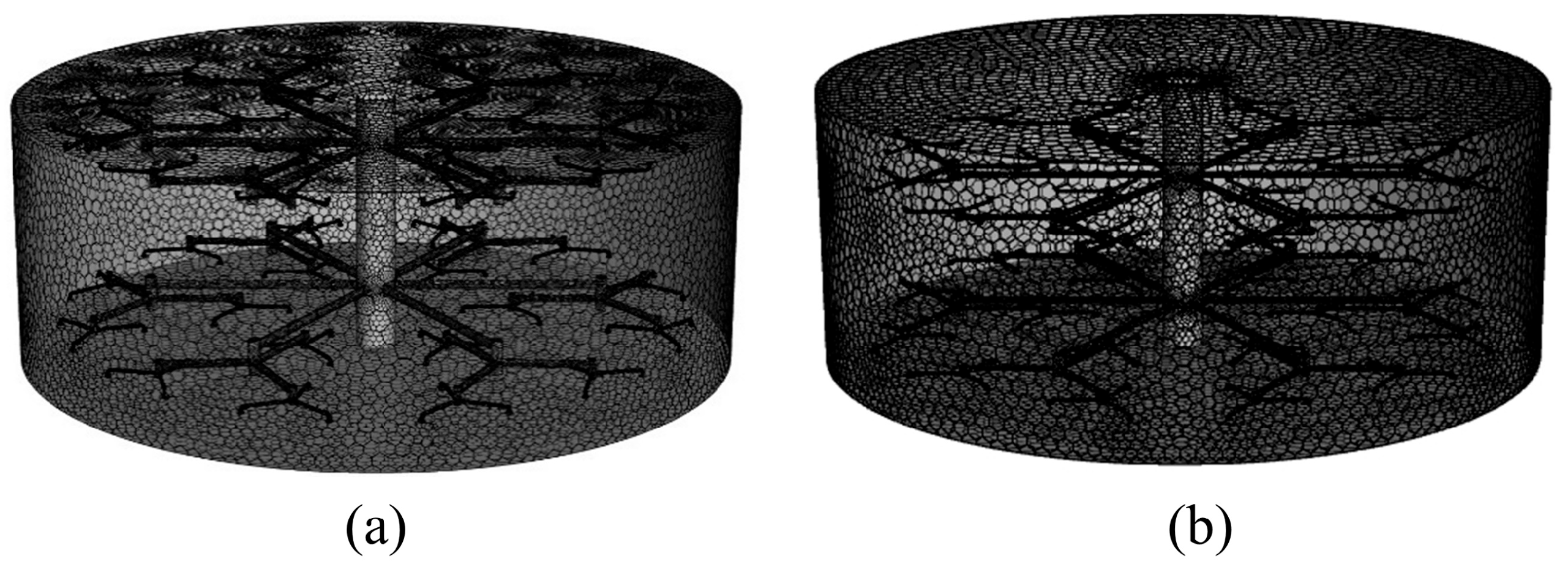

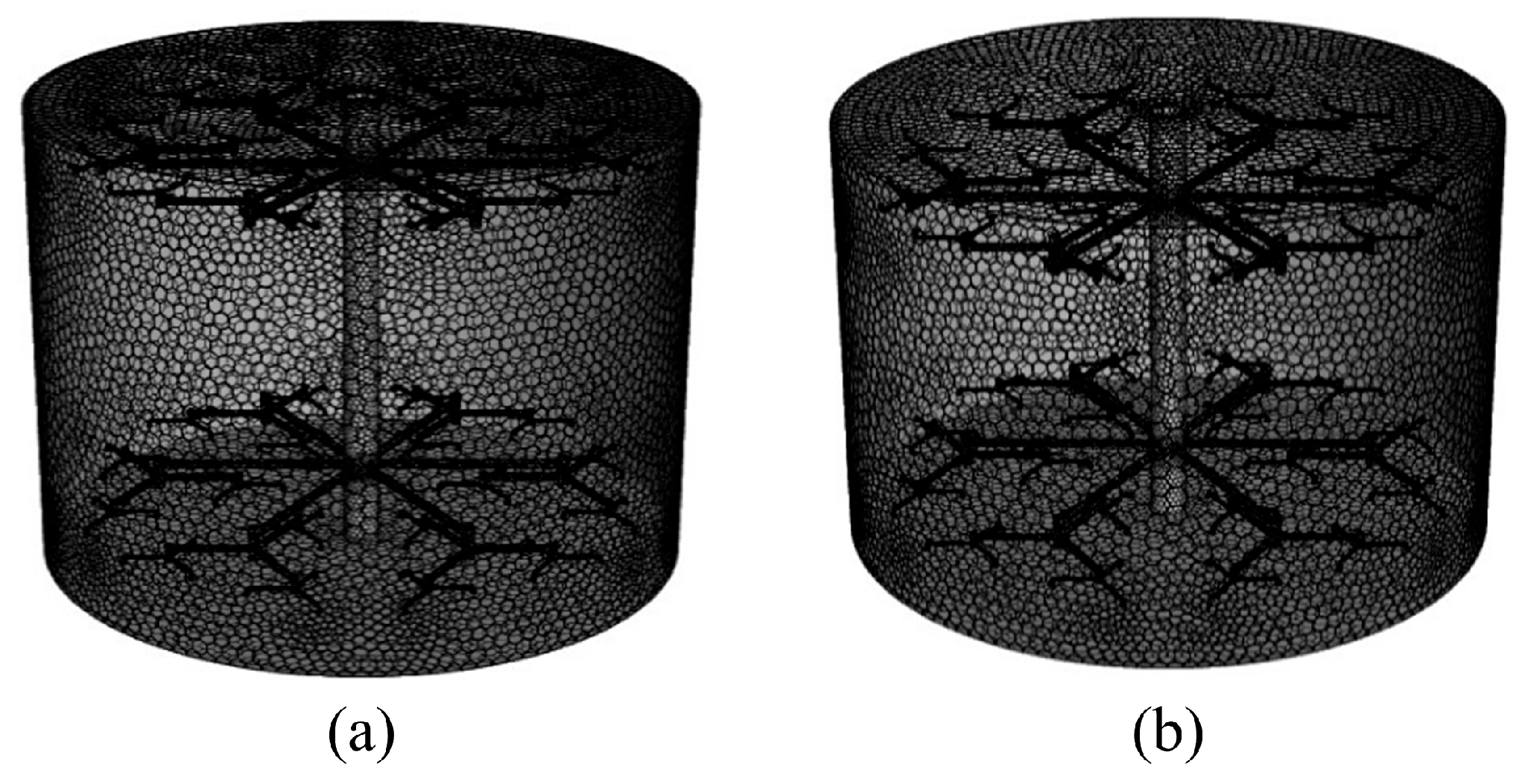

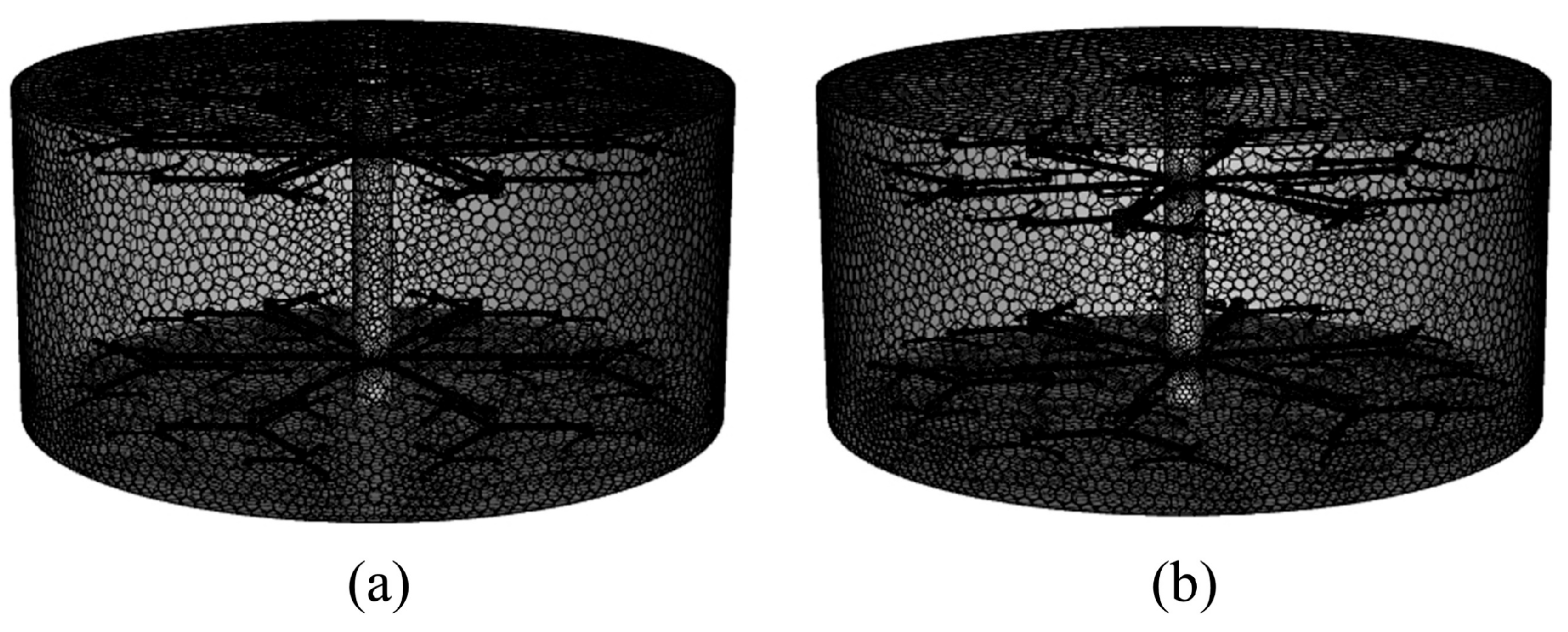

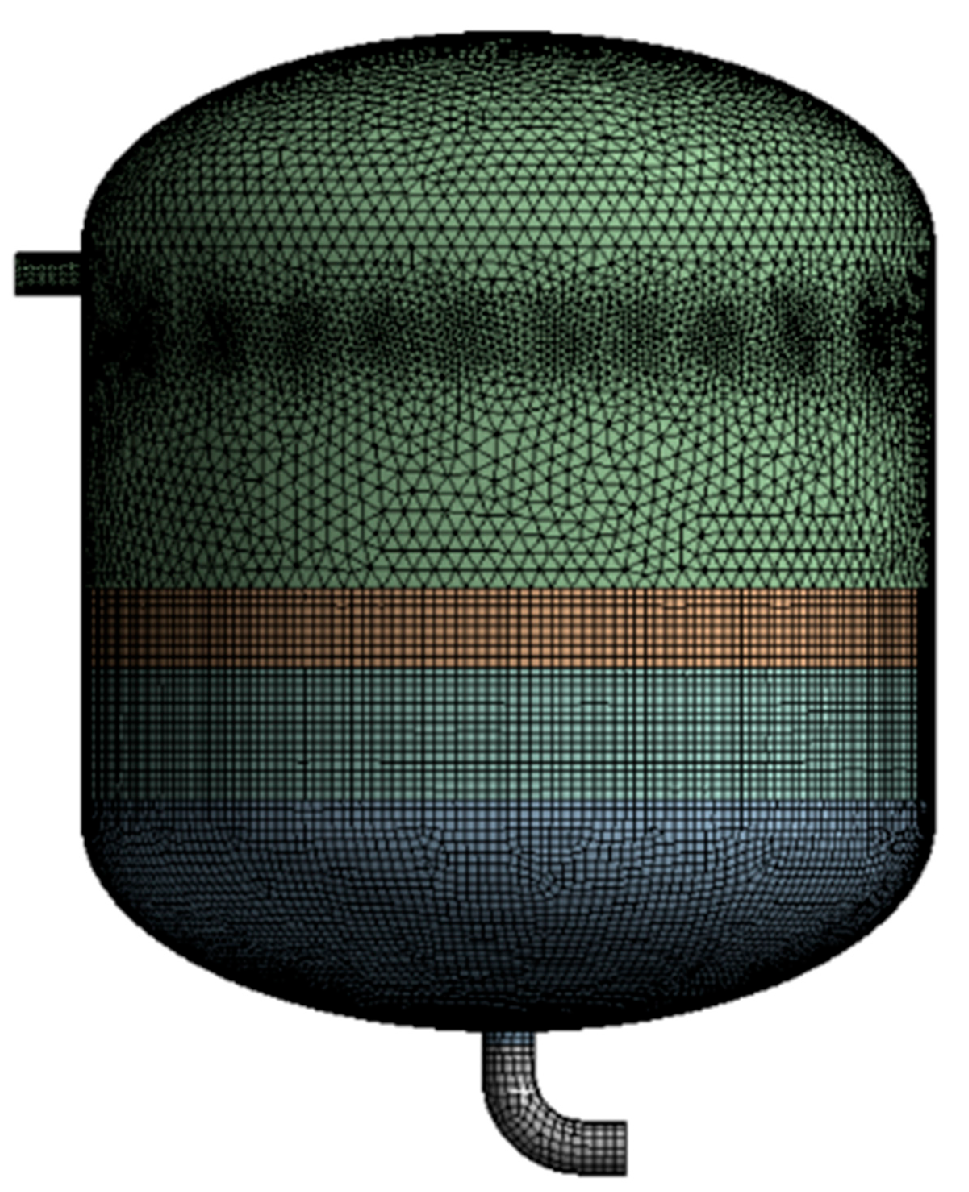

3.2.1. Physical Models

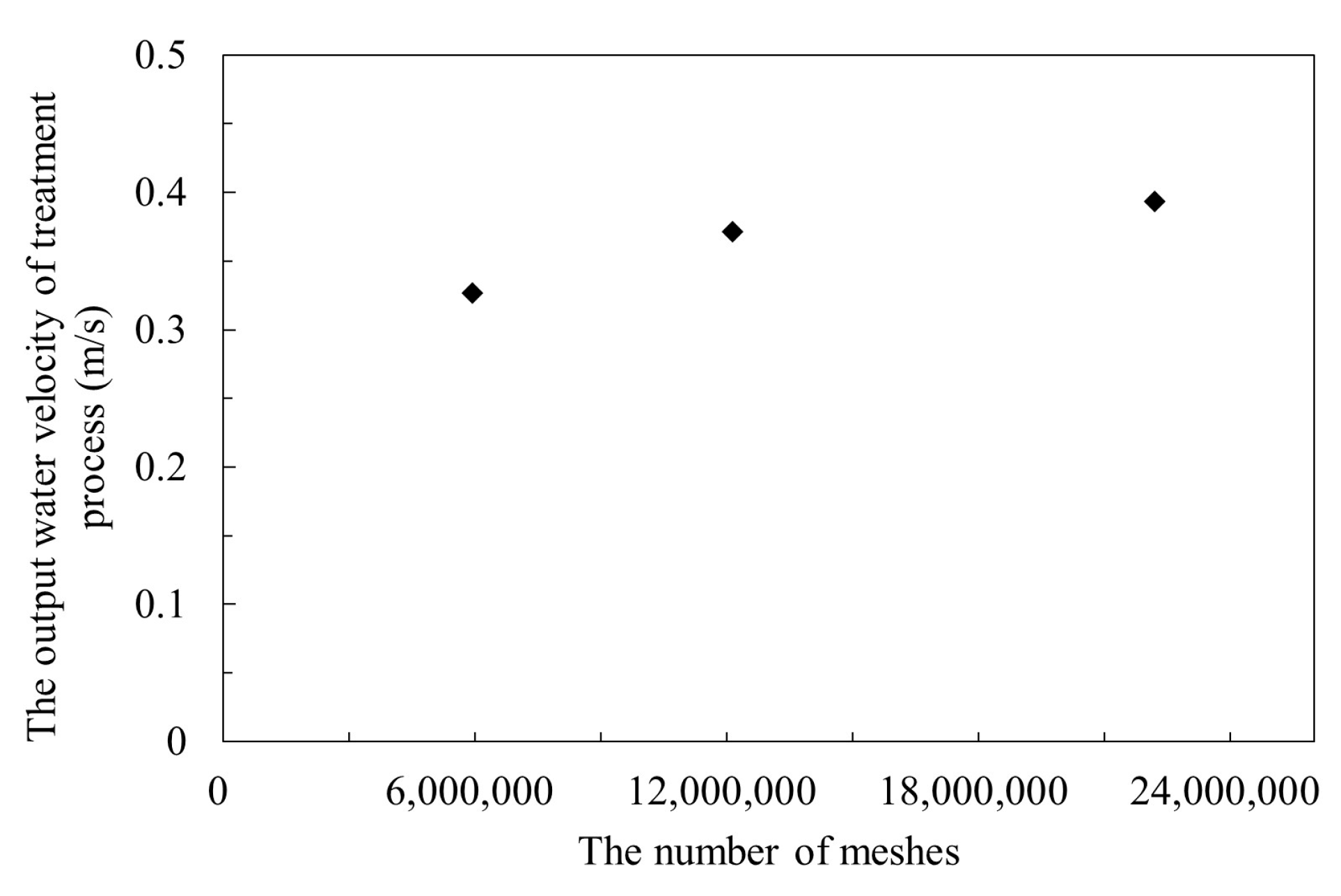

3.2.2. Mesh Generation and Independence Validation

3.2.3. Mathematical Models

3.3. Solution Model

3.3.1. Simulate Conditions and Parameters

3.3.2. Model Assumptions and Limitations

3.3.3. Solution Methods

3.3.4. Data Extraction and Processing

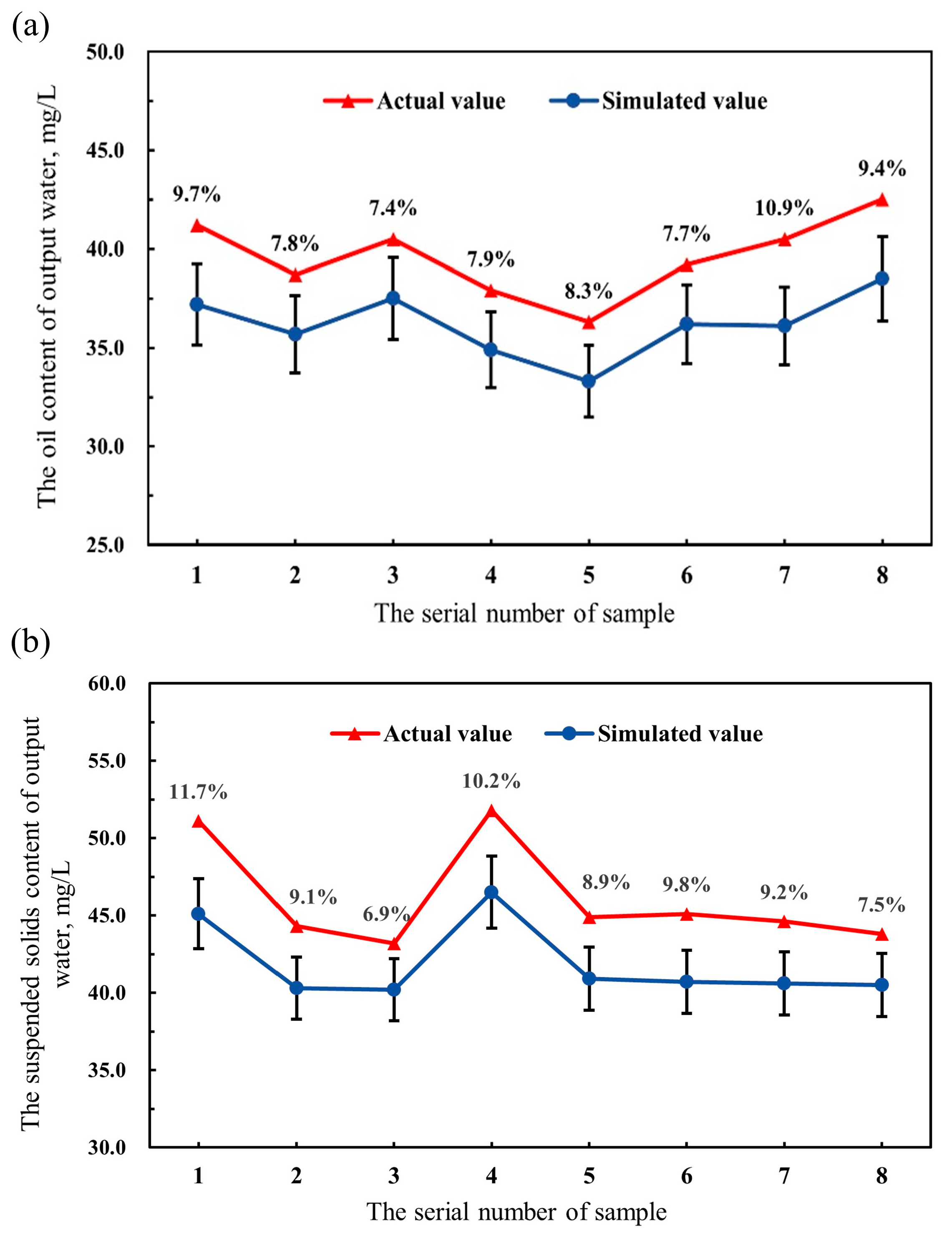

3.4. Model Validation

4. Results and Discussion

4.1. Result of Independence Validation

4.2. Result of Model Validation

4.3. Sedimentation Operation Characteristics

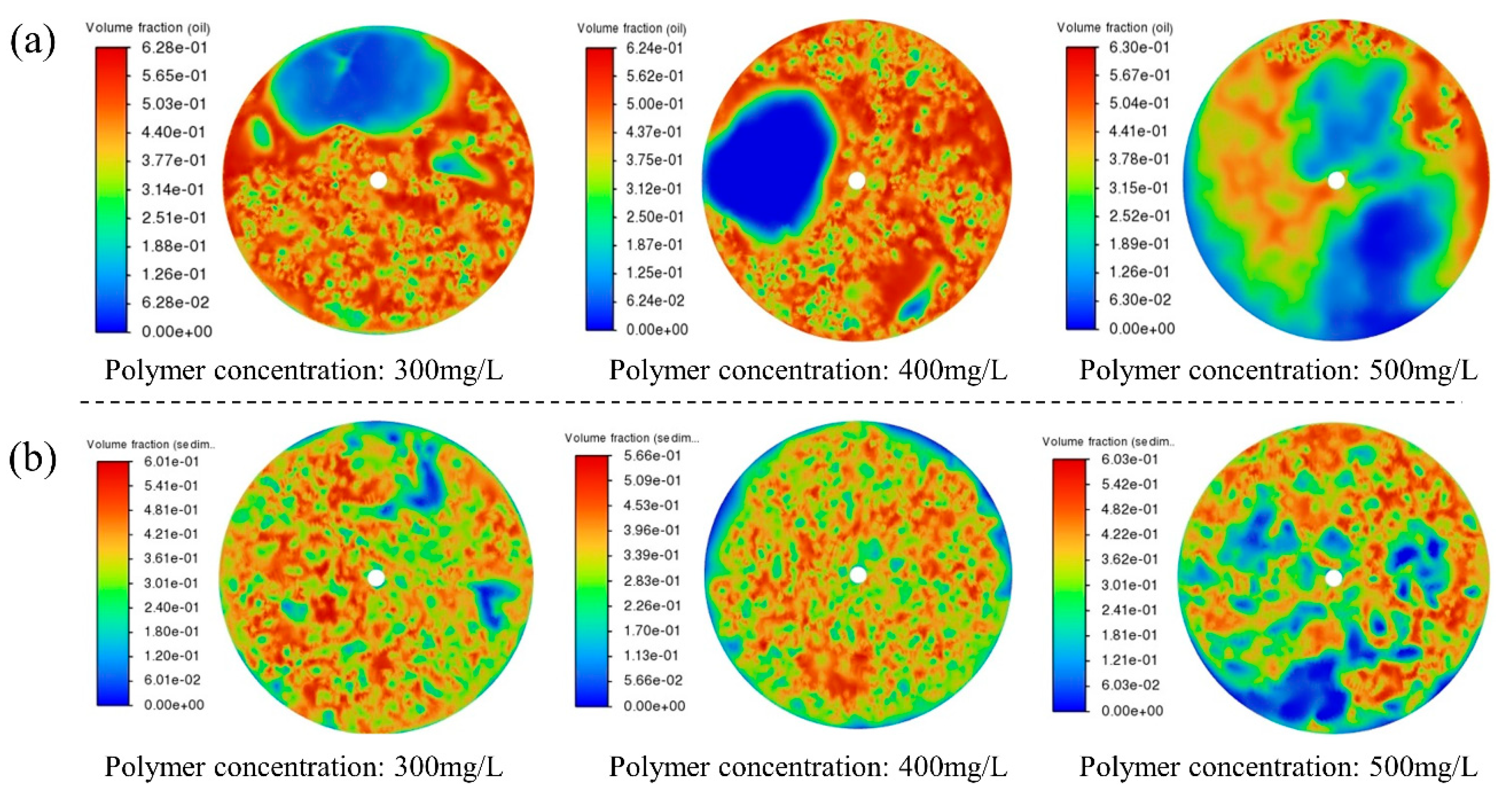

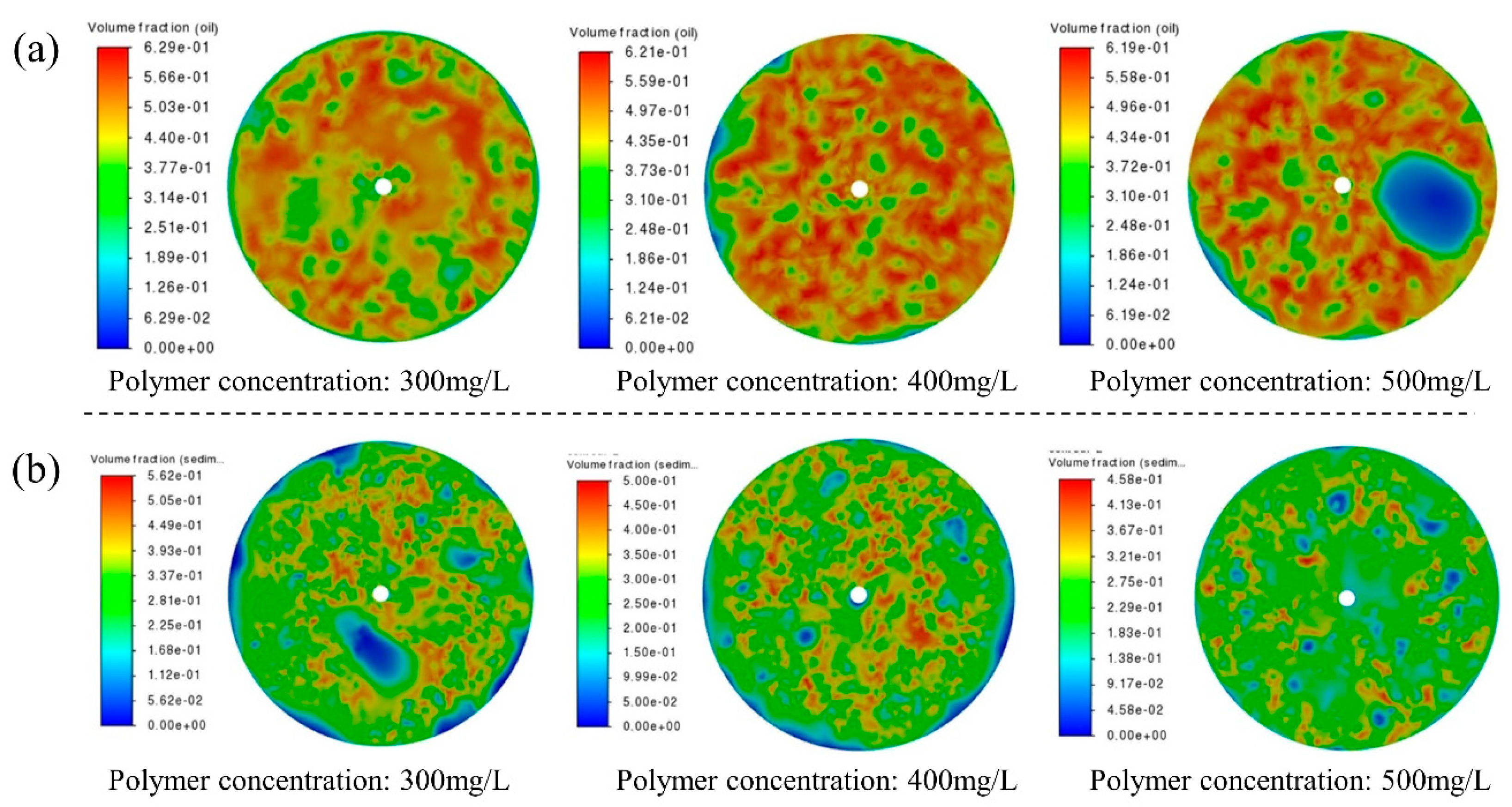

4.3.1. Primary Sedimentation

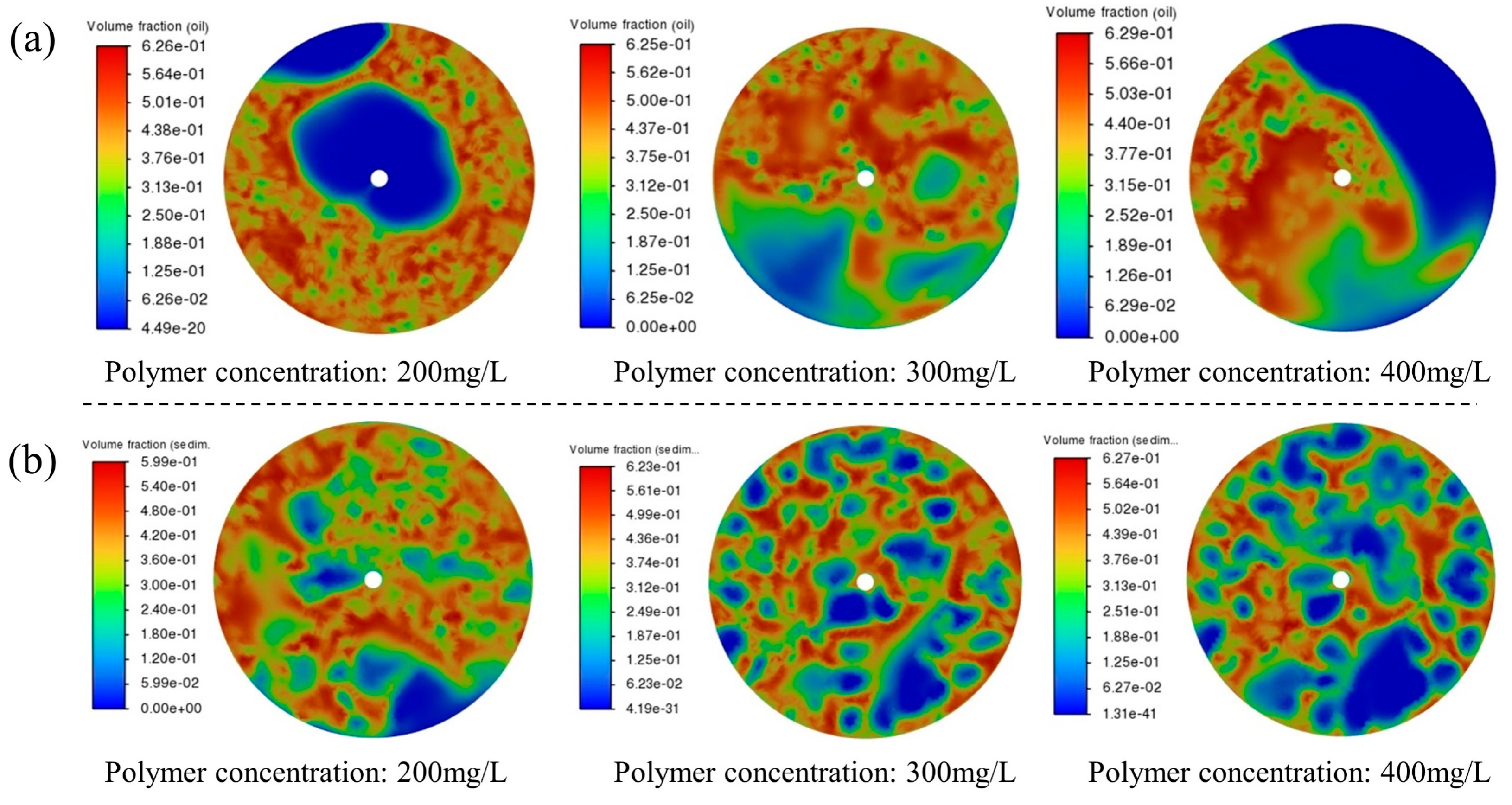

4.3.2. Secondary Sedimentation

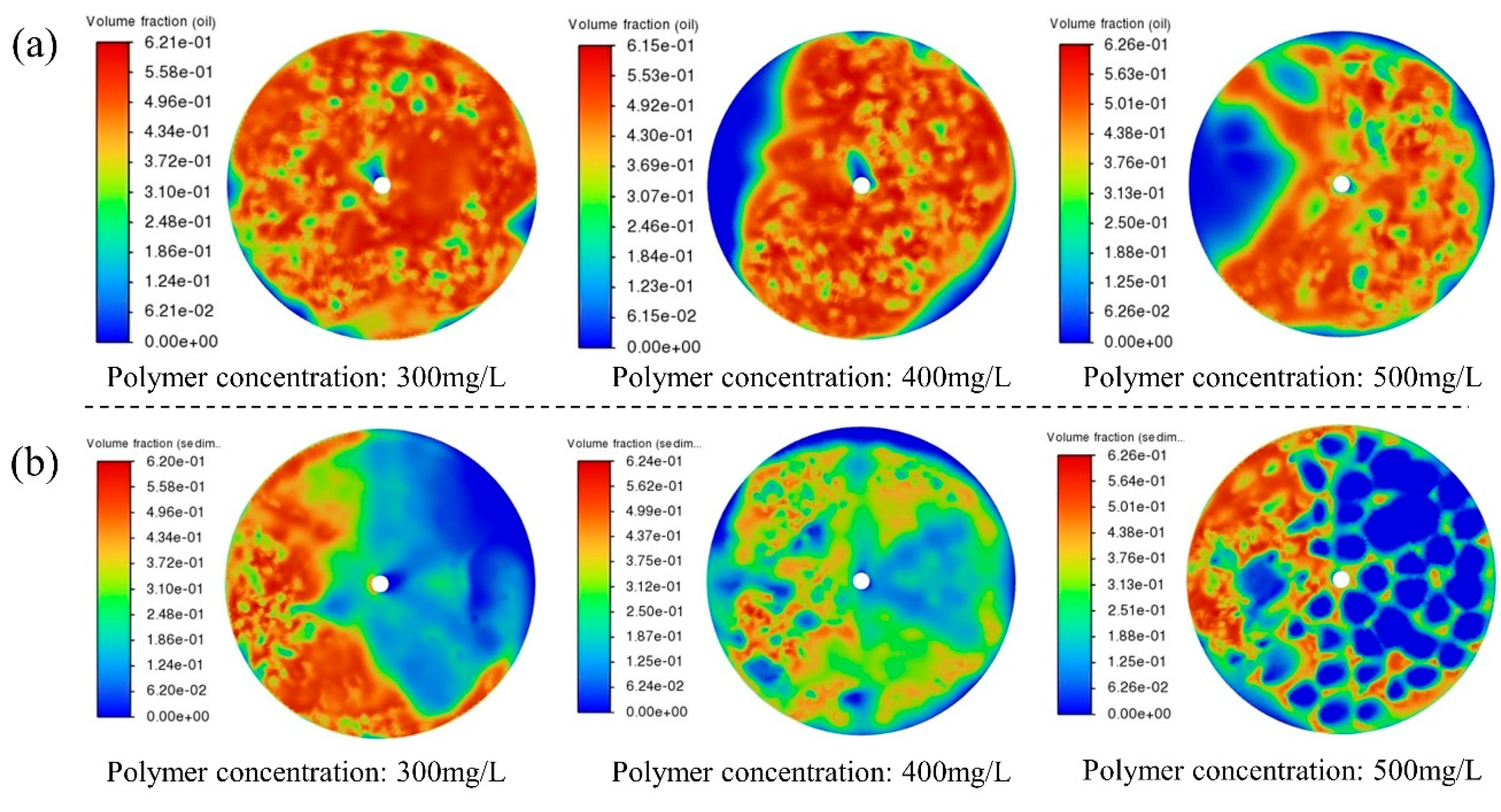

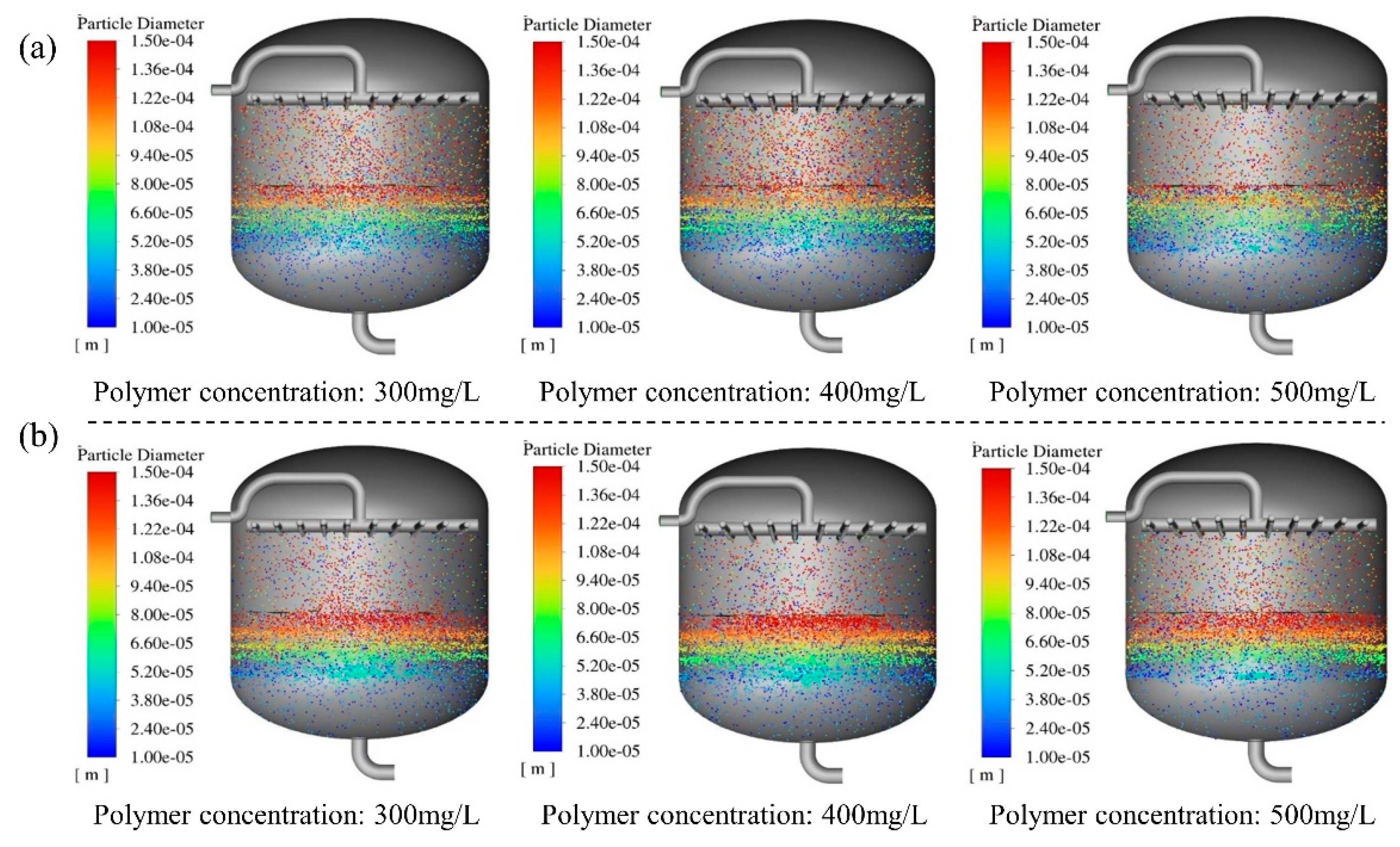

4.4. Filtration Operation Characteristics

4.4.1. Primary Filtration

4.4.2. Secondary Filtration

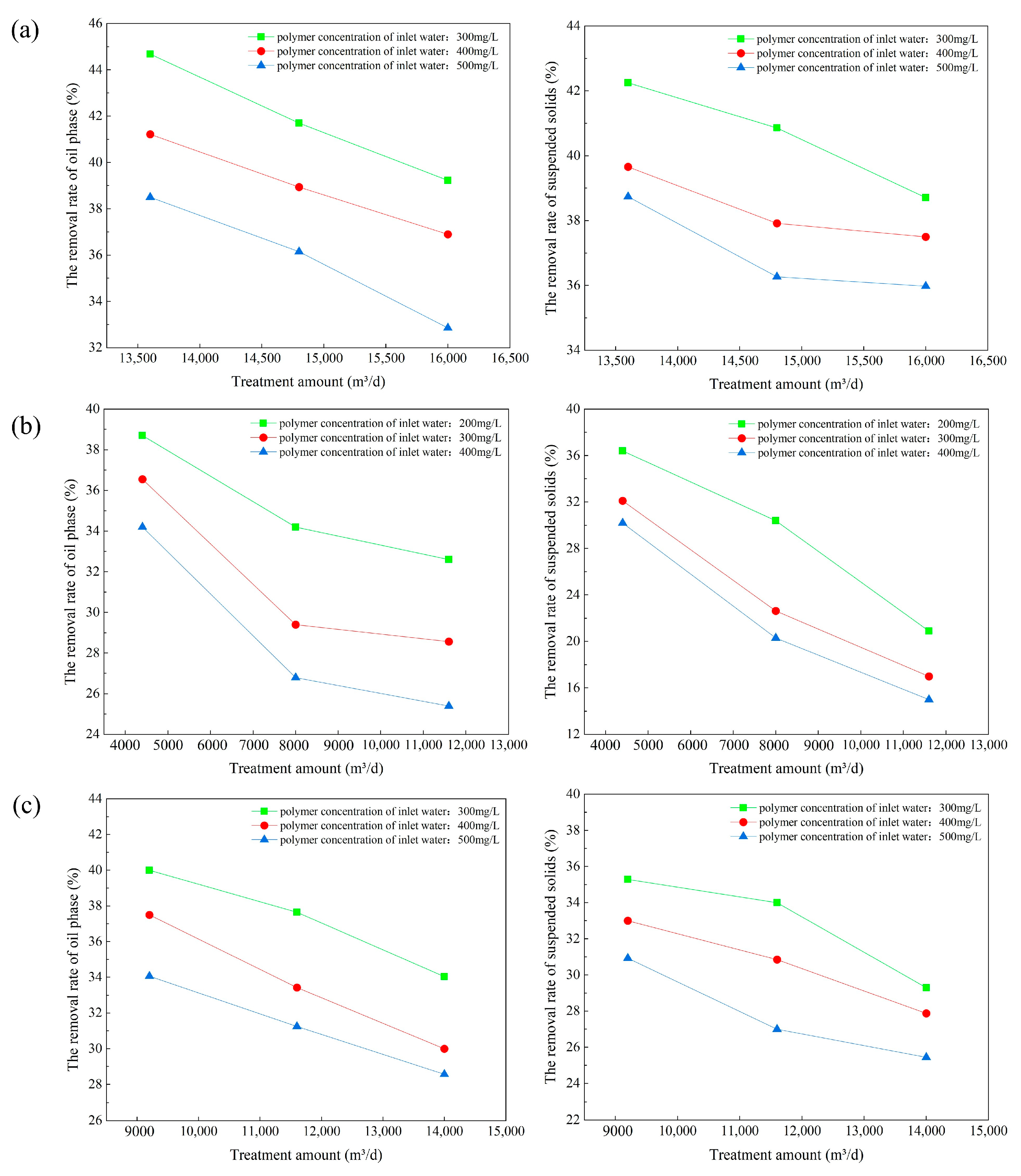

4.5. Treatment Capacity of Treatment Process

4.6. Operating Limits of Treatment Process

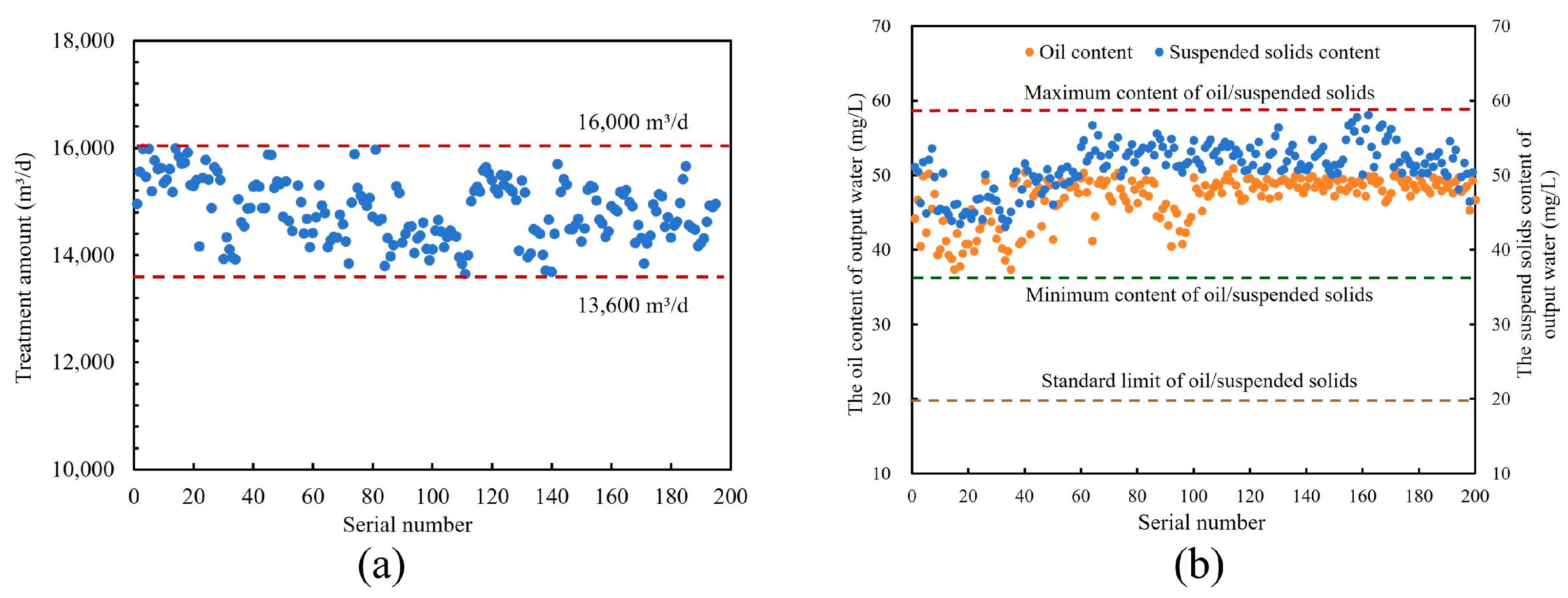

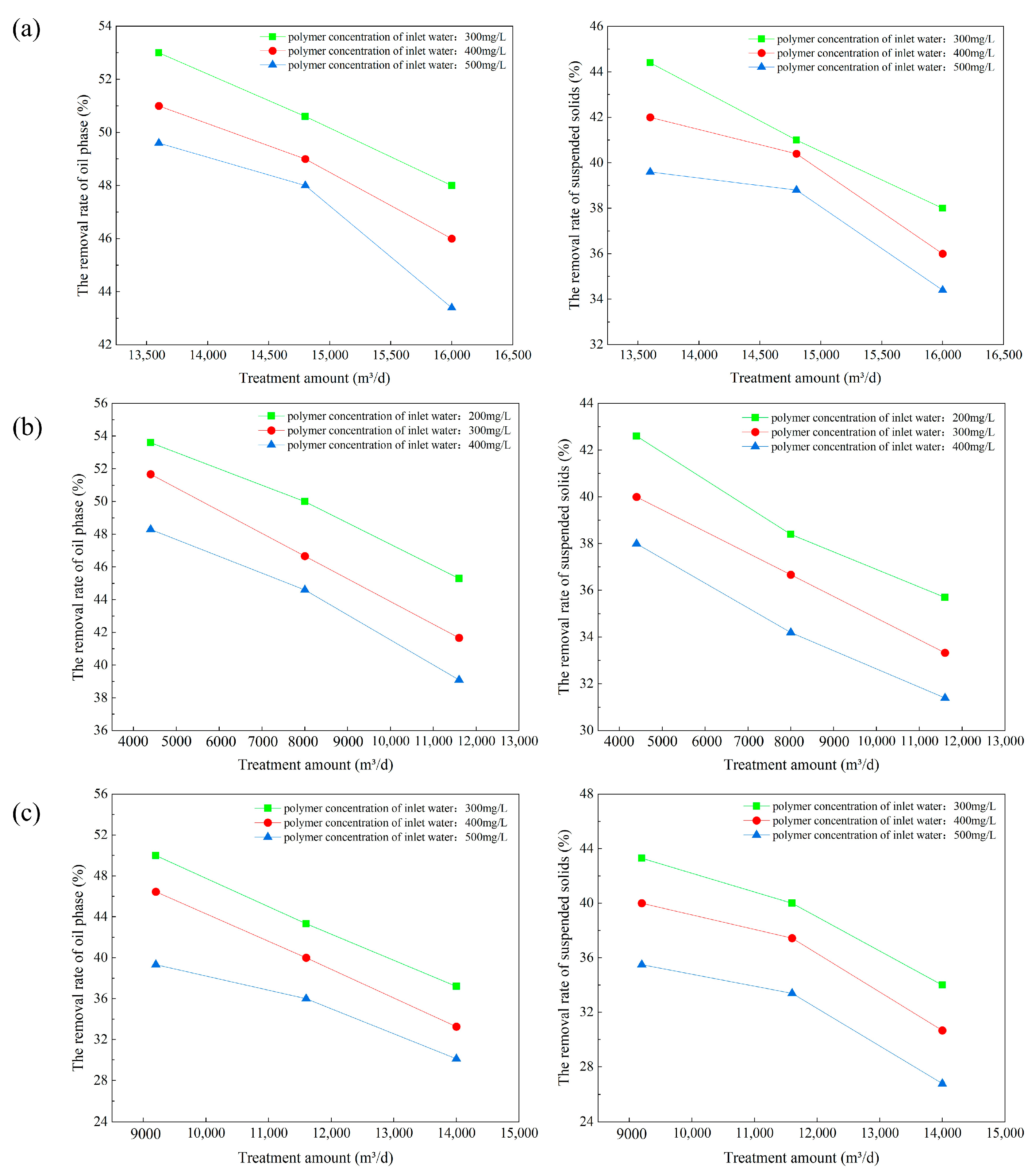

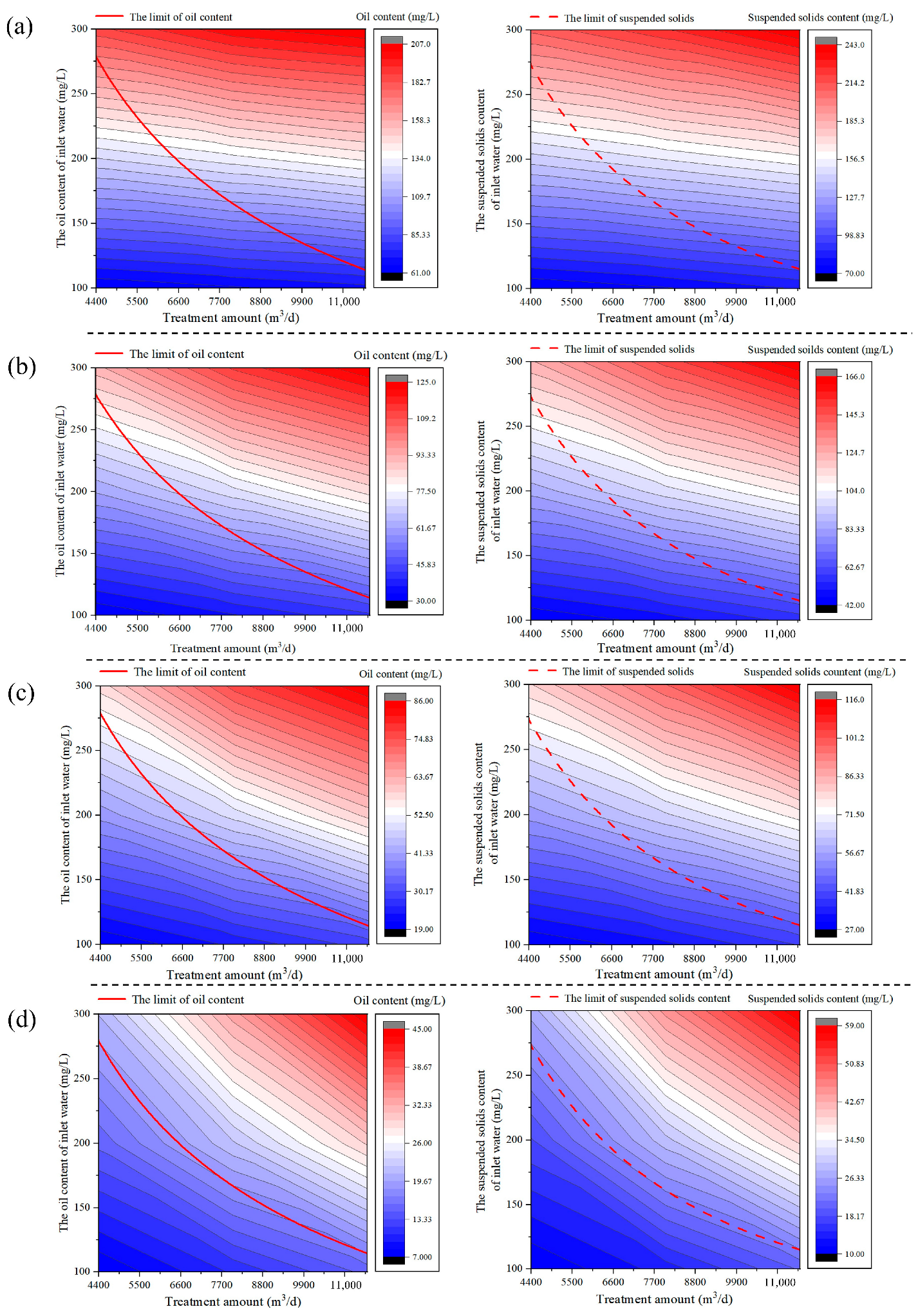

4.6.1. Operating Limits of Class I Treatment Process

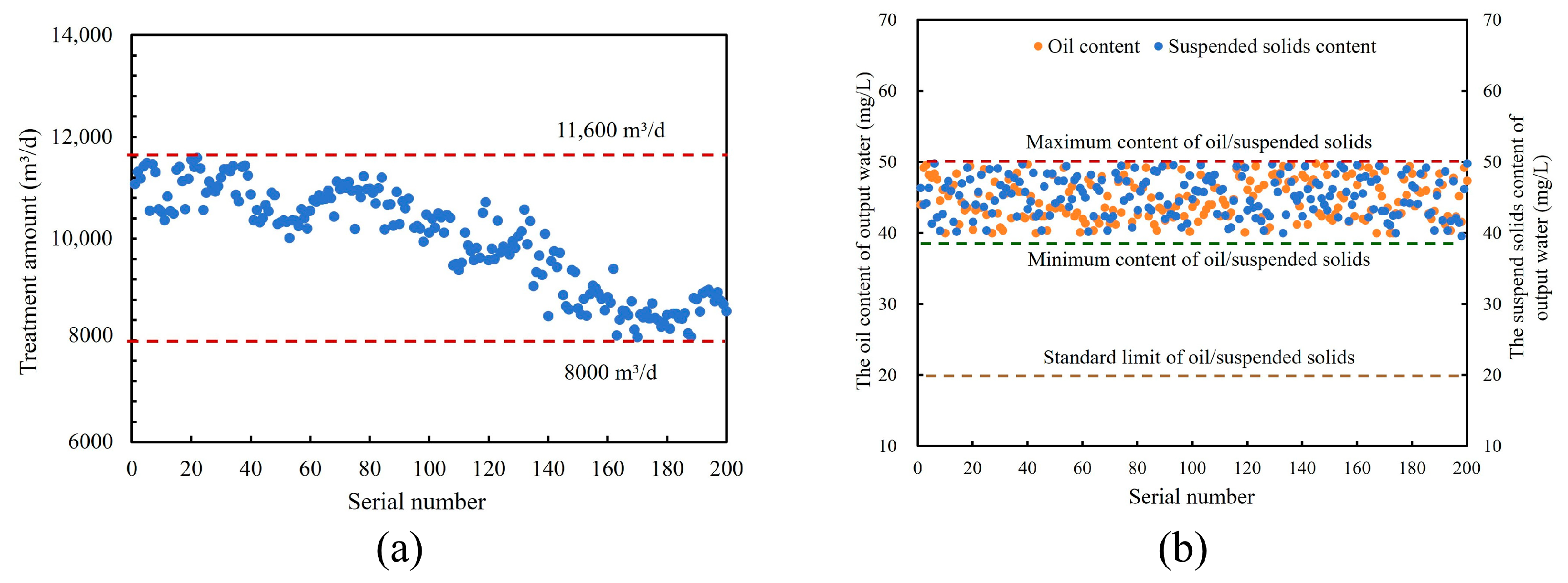

4.6.2. Operating Limits of Class II Treatment Process

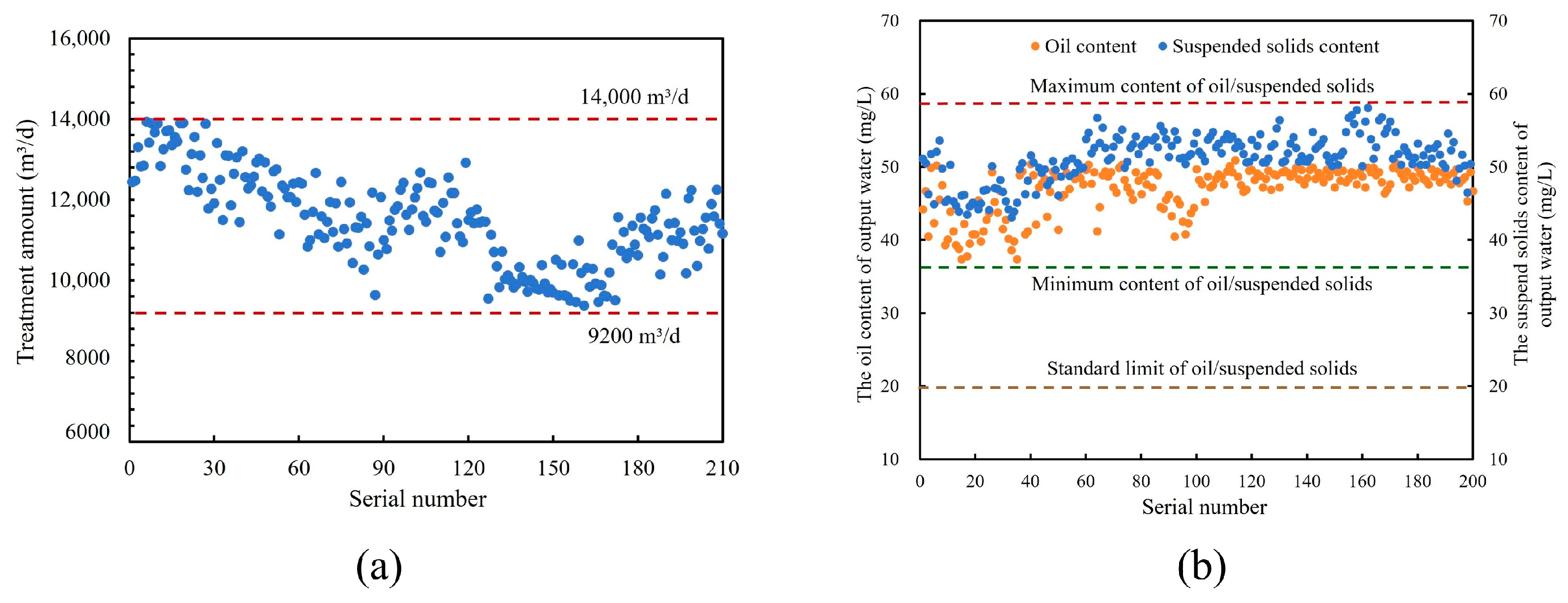

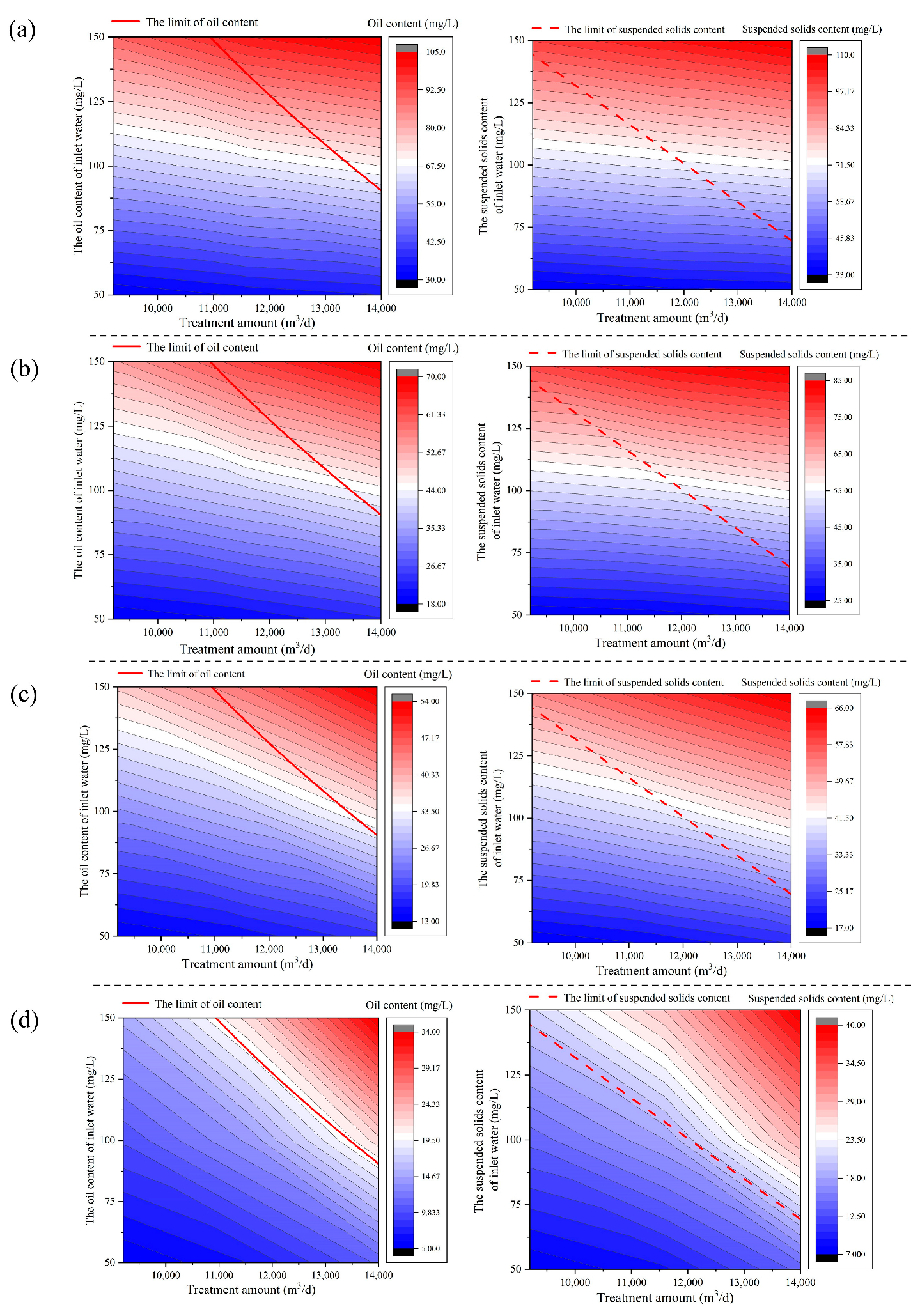

4.6.3. Operating Limits of Class III Treatment Process

5. Conclusions

- (1)

- For produced water treatment, elevated treatment volumes and increased polymer concentrations in the influent water adversely affect both sedimentation separation efficiency and filter media adsorption capacity. More specifically, the concentrations of both oil and suspended solids in the sedimentation tank exhibit significant reductions, accompanied by a corresponding diminishment of high-concentration zones within the respective oil and suspended solids layers. Concurrently, the filtration process shows an increase in the number of escaping particles under the filter material.

- (2)

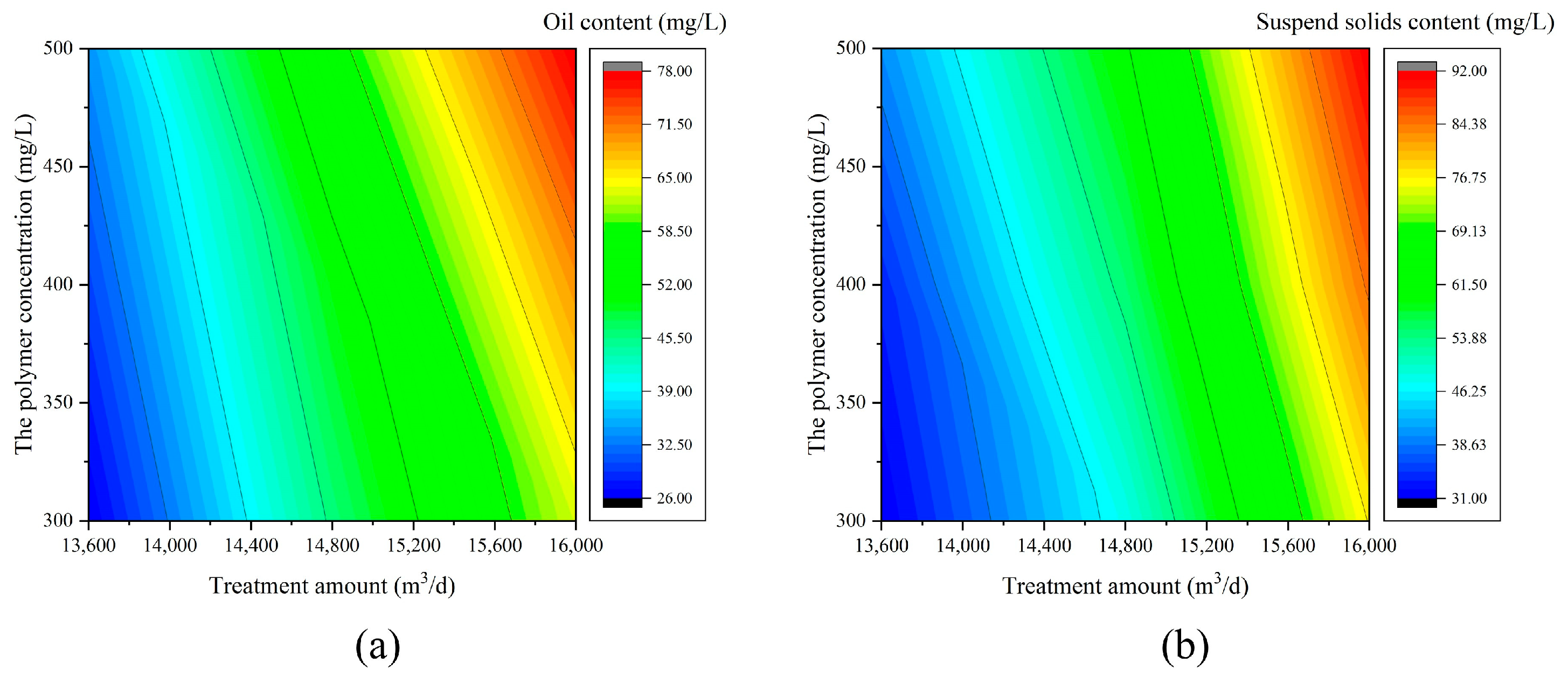

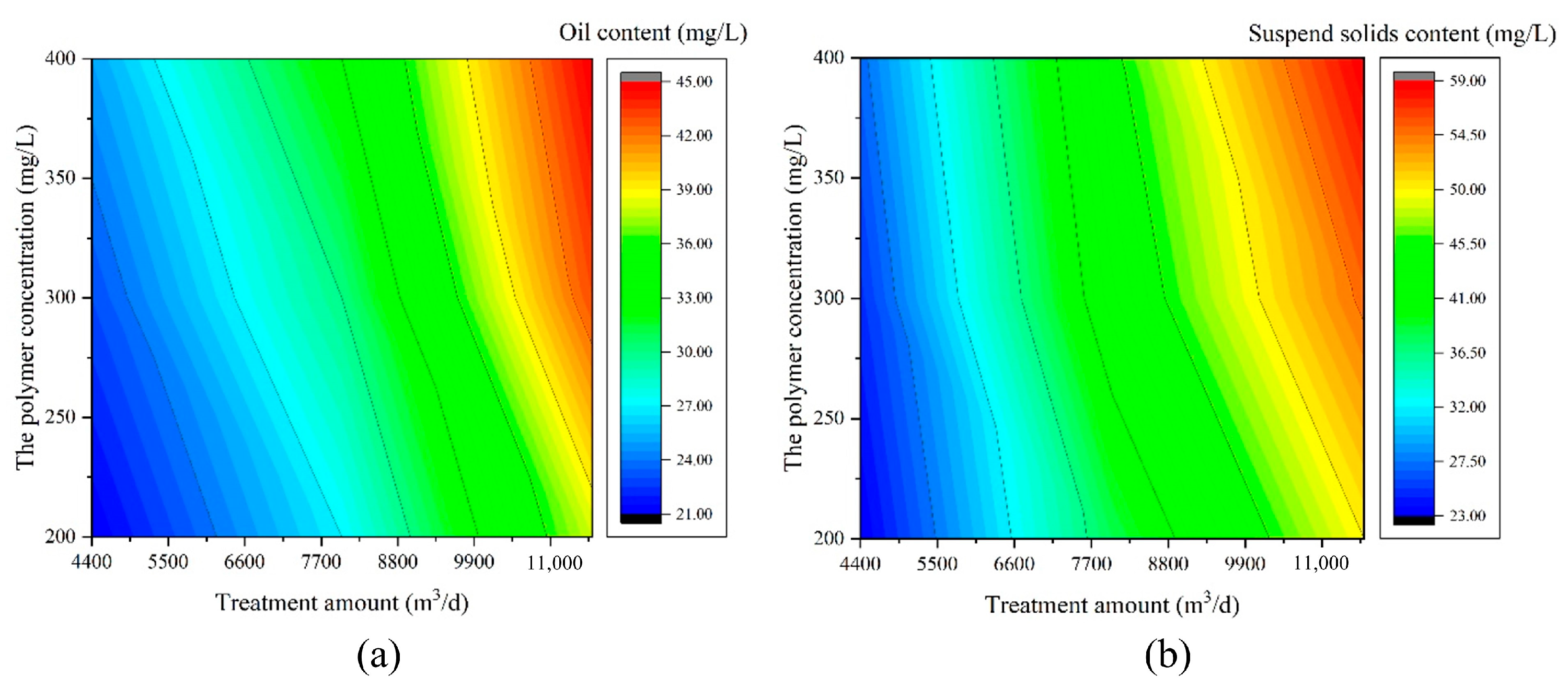

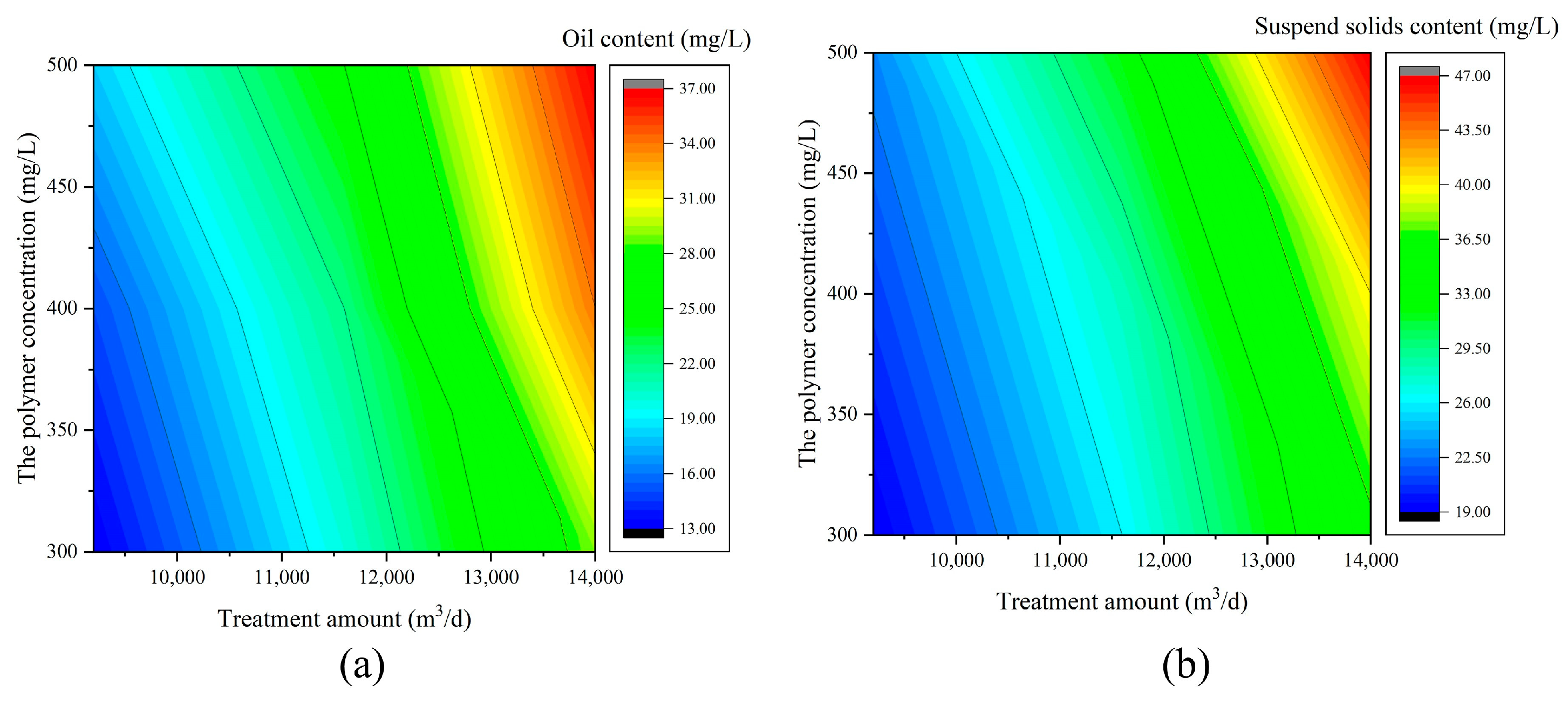

- The simulation results show that the oil content range of treated water from the class I treatment process is 26–78 mg/L, and the suspended solid content is 31–92 mg/L. The output water oil content of the class II treatment process is 21–45 mg/L, and the suspended solid content is 23–59 mg/L. The oil content of the output water from class III treatment process is 13–37 mg/L, and the suspended solid is 19–47 mg/L. Under certain operating conditions, the treated water meets the standards with both oil and suspended solids content below 20 mg/L.

- (3)

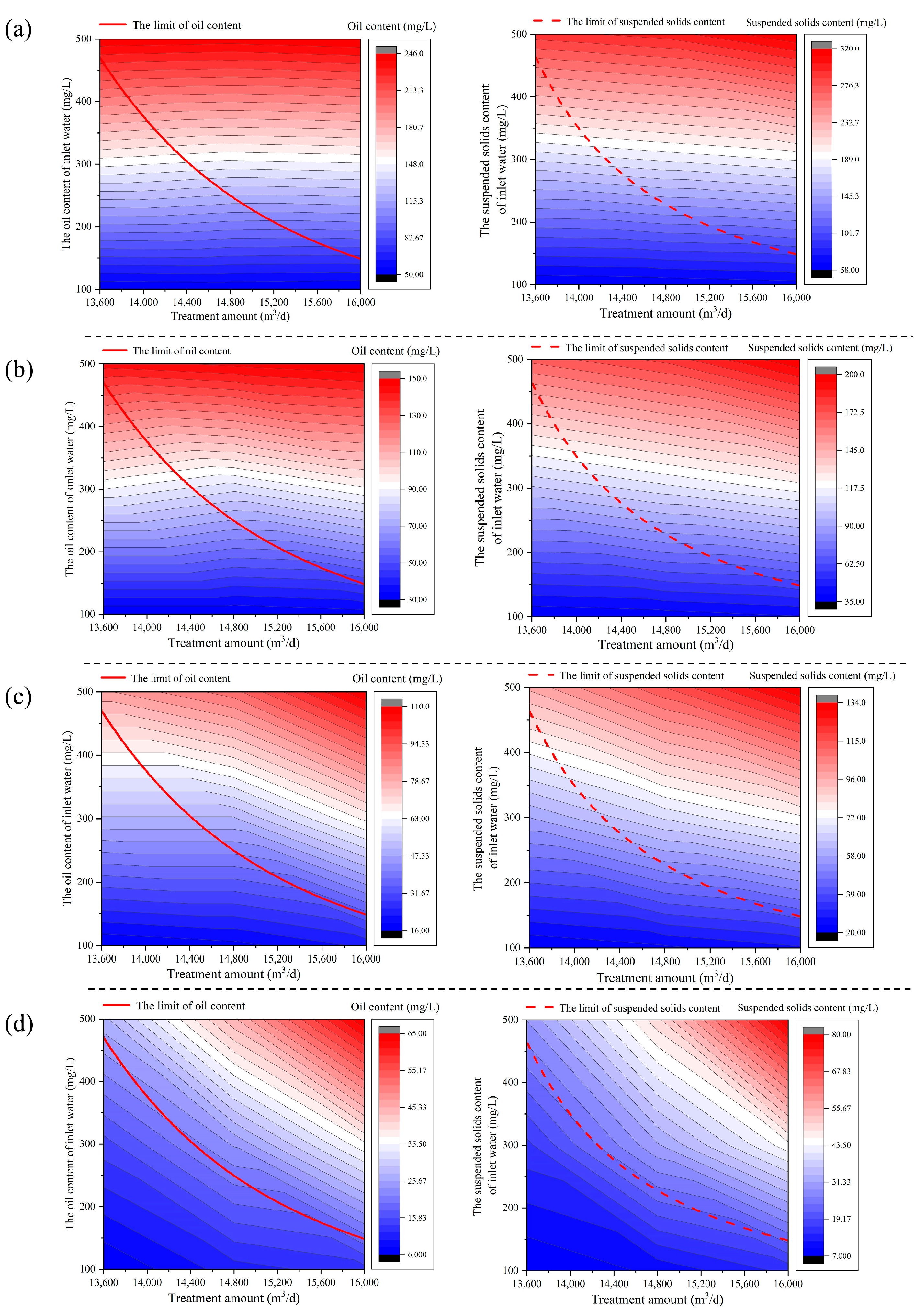

- Based on the numerical simulation results, the polynomial interpolation method was employed to determine the water quality parameters for each treatment node, ensuring that the treated produced water meets the standard with oil and suspended solids content below 20 mg/L. The operating limits of the ASP flooding produced water treatment process are established. Take the class II treatment process as an example. Within the treatment amount range of 4400–11,600 m3/d, the treated water meets quality standards when the oil and suspended solids content of the produced water is between 100 and 275 mg/L, and operating conditions stay below the limit curves.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ji, B.; Xu, T.; Gao, X.; Yu, H.; Liu, H. Production evolution patterns and development stage division of waterflooding oilfields. Pet. Explor. Dev. 2023, 50, 433–441. [Google Scholar] [CrossRef]

- Chang, S.; Wang, M.; Wang, M. The identification of the development stages of the karstic fracture-cavity carbonate reservoirs: A case study on the lungu oilfield, Tarim basin. Front. Earth Sci. 2023, 11, 1238759. [Google Scholar] [CrossRef]

- Hu, G.; Tian, X.H.; Liu, Q.W.; Yi, L.Z.; Liu, D.W.; Li, P.C. Quick assessment to ascertain technical rational well spacing density in artificial water flooding oilfield. J. Pet. Sci. Eng. 2021, 196, 108087. [Google Scholar] [CrossRef]

- Wang, Y.W.; Liu, H.Q.; Zhang, Q.C.; Chen, Z.X.; Wang, J.; Dong, X.H.; Chen, F.X. Pore-scale experimental study on EOR mechanisms of combining thermal and chemical flooding in heavy oil reservoirs. J. Pet. Sci. Eng. 2020, 185, 106649. [Google Scholar] [CrossRef]

- Lu, J.Y.; Pu, W.F.; Wei, H.; Zou, B.Y.; Li, B.W.; Liu, R. Progress in research of sulfobetaine surfactants used in tertiary oil recovery. J. Surfactants Deterg. 2023, 26, 459–475. [Google Scholar] [CrossRef]

- Sun, Z.; Kang, X.D.; Lu, X.G.; Li, Q.; Jiang, W.D. Effects of crude oil composition on the ASP flooding: A case from Saertu, Xingshugang and Lamadian Oilfield in Daqing. Colloids Surf. A Physicochem. Eng. Asp. 2018, 555, 586–594. [Google Scholar] [CrossRef]

- Guo, H.; Li, Y.Q.; Wang, F.Y.; Gu, Y.Y. Comparison of Strong-Alkali and Weak-Alkali ASP-Flooding Field Tests in Daqing Oil Field. SPE Prod. Oper. 2018, 33, 353–362. [Google Scholar] [CrossRef]

- Zhong, H.; Shi, B.; Bi, Y.; Cao, X.; Zhang, H.; Yu, C.; Tang, H. Interaction of elasticity and wettability on enhanced oil recovery in viscoelastic polymer flooding: A case study on oil droplet. Geoenergy Sci. Eng. 2025, 250, 213827. [Google Scholar] [CrossRef]

- Wang, Z.H.; Liu, X.Y.; Luo, H.; Peng, B.L.; Sun, X.T.; Liu, Y.; Rui, Z. Foaming Properties and Foam Structure of Produced Liquid in Alkali/Surfactant/Polymer Flooding Production. J. Energy Resour. Technol. 2021, 143, 103005. [Google Scholar] [CrossRef]

- Hong, J.; Wang, Z.H.; Li, J.L.; Xu, Y.F.; Xin, H. Effect of Interface Structure and Behavior on the Fluid Flow Characteristics and Phase Interaction in the Petroleum Industry: State of the Art Review and Outlook. Energy Fuels 2023, 37, 9914–9937. [Google Scholar] [CrossRef]

- Wang, Z.H.; Xu, Y.F.; Khan, N.; Zhu, C.L.; Gao, Y.H. Effects of the Surfactant, Polymer, and Crude Oil Properties on the Formation and Stabilization of Oil-Based Foam Liquid Films: Insights from the Microscale. J. Mol. Liq. 2023, 373, 121194. [Google Scholar] [CrossRef]

- Kirkebæk, B.; Simoni, G.; Lankveld, I.; Poulsen, M.; Christensen, M.; Quist-Jensen, C.; Yu, D.H.; Ali, A. Oleic acid-coated magnetic particles for removal of oil from produced water. J. Pet. Sci. Eng. 2022, 211, 110088. [Google Scholar] [CrossRef]

- Weschenfelder, S.E.; Fonseca, M.J.; Borges, C.P. Treatment of produced water from polymer flooding in oil production by ceramic membranes. J. Pet. Sci. Eng. 2021, 196, 108021. [Google Scholar] [CrossRef]

- Shah, M.; Parmar, H.; Rhyne, L.; Kalli, C.; Utikar, R. A novel settling tank for produced water treatment: CFD simulations and PIV experiments. J. Pet. Sci. Eng. 2019, 182, 106352. [Google Scholar] [CrossRef]

- Li, J.B.; Niu, L.W.; Lu, X.G. Performance of ASP compound systems and effects on flooding efficiency. J. Pet. Sci. Eng. 2019, 178, 1178–1193. [Google Scholar] [CrossRef]

- Wu, D.; Xia, F.J.; Lin, S.; Cai, X.; Zhang, H.P.; Liu, W.J.; Li, Y.H.; Zhang, R. Effects of secondary emulsification of ASP flooding produced fluid during surface processes on its oil/water separation performances. J. Pet. Sci. Eng. 2021, 202, 108426. [Google Scholar] [CrossRef]

- Yu, Z.C.; Li, K.; Wang, S. Filtration model and its application progress in oilfield produced water treatment. Desalination Water Treat. 2022, 261, 94–106. [Google Scholar] [CrossRef]

- Wang, Z.H.; Zhu, J.W.; Zhao, X.F.; Qi, X.D.; Hong, J. Numerical optimization of duration time for the gravitational sedimentation process of produced water in oilfield. Desalination Water Treat. 2024, 319, 100467. [Google Scholar] [CrossRef]

- He, G.X.; Nie, S.M.; Sun, L.Y.; Cao, D.L.; Liao, K.X.; Liang, Y.T. Numerical simulation for the separation process of suspended fine sand from oil and water emulsion in a large-size sedimentation tank. Desalination Water Treat. 2018, 115, 153–171. [Google Scholar] [CrossRef]

- Wang, Z.H.; Wang, C.; Meng, L.; Qi, X.D.; Hong, J. Prediction of sump oil growth rate towards gravitational settling of produced water in oilfield based on machine learning. Desalination Water Treat. 2024, 317, 100189. [Google Scholar] [CrossRef]

- Liu, J.; Liu, H.Y.; Guo, J.; Li, M.J.; Li, L.; Sun, T.F. Experimental Research on a Cyclone Air Flotation Separator for Polymer-Containing Wastewater. Chem. Technol. Fuels Oils 2021, 57, 705–712. [Google Scholar] [CrossRef]

- Wang, C.; Lu, Y.L.; Song, C.; Zhang, D.C.; Rong, F.; He, L.M. Separation of emulsified crude oil from produced water by gas flotation: A review. Sci. Total Environ. 2022, 845, 157304. [Google Scholar] [CrossRef] [PubMed]

- Alammar, A.; Park, S.H.; Williams, C.J.; Derby, B.; Szekely, G. Oil-in-water separation with graphene-based nanocomposite membranes for produced water treatment. J. Membr. Sci. 2020, 603, 118007. [Google Scholar] [CrossRef]

- Guan, C.D.; Yang, L.J.; Zhu, L.J.; Xia, D.H. One-step removal of all pollutants to produce clean water: Construct a novel dual-functional aramid nanofibre membrane for simultaneous oil-in-water separation and single-ring aromatic compound removal. J. Clean. Prod. 2022, 361, 132259. [Google Scholar] [CrossRef]

- Huang, B.; Wang, J.; Zhang, W.; Fu, C.; Wang, Y.; Liu, X.B. Screening and Optimization of Demulsifiers and Flocculants Based on ASP Flooding-Produced Water. Processes 2019, 7, 239. [Google Scholar] [CrossRef]

- Miang, K.C.; Wang, J.W.; Li, M.H.; Oettel, B.A.; Kaner, R.B.; Jassby, D.H.; Eric, M. Performance, energy and cost of produced water treatment by chemical and electrochemical coagulation. Water 2020, 12, 3426. [Google Scholar] [CrossRef]

- Liu, Y.L.; Zheng, Y.; Zhang, P.; Wei, W.L. A CFD Methodology for Solid and Liquid Flow Fields of Sedimentation Tanks. Sustain. Environ. Transp. 2012, 178, 371–375. [Google Scholar] [CrossRef]

- Tarpagkou, R.; Pantokratoras, A. CFD methodology for sedimentation tanks: The effect of secondary phase on fluid phase using DPM coupled calculations. Appl. Math. Model. 2013, 37, 3478–3494. [Google Scholar] [CrossRef]

- Vinicius, G.P.; Victor, S.L.B.; Fernando, C.D.L.; Alex, T.A.; Andre, L.M. CFD-DEM modeling and simulation of dynamic filtration over heterogeneous porous medium. Powder Technol. 2024, 445, 120057. [Google Scholar]

- Zhu, Y.Z.; Sun, H.L.; Xu, S.L.; Hu, L.K.; Cao, H.T.; Cai, Y.Q.; Liu, J.W. Mechanics of the penetration and filtration of cement-based grout in porous media: New insights from CFD–DEM simulations. Tunneling Undergr. Space Technol. 2023, 133, 104928. [Google Scholar] [CrossRef]

- Anna, M.K.; Johannes, L.; Stephan, M.; Matthias, W. On the balance of hydrophilicity and electrostatic interactions during particle filtration and backwash at microfiltration pores. J. Membr. Sci. 2023, 680, 121640. [Google Scholar]

- Zhang, B.; Yu, S.L.; Zhu, Y.B.; Shi, W.X.; Zhang, R.J.; Li, L. Application of a polytetrafluoroethylene (PTFE) flat membrane for the treatment of pre-treated ASP flooding produced water in a Daqing oilfield. RSC Adv. 2016, 6, 62411–62419. [Google Scholar] [CrossRef]

- Wang, Z.H.; Li, J.X.; Yu, X.Y.; Wang, M.X.; Le, X.P.; Yu, T.Y. Scaling Deposition Behavior in Sieve Tubes of Produced Water Filter in Polymer Flooding. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 26–28 September 2016. [Google Scholar]

- Qi, H.B.; Shang, X.; Zhang, X.X.; Wang, Q.S.; Meng, F.B.; Liang, Z.L.; Liang, S.J. Numerical simulation of oil-water separation in sedimentation tank based on CFD-PBM model. Energy Sources Part A Recovery Util. Environ. Eff. 2024, 46, 3902–3917. [Google Scholar] [CrossRef]

- Liu, X.Y.; Chen, J.X.; Wang, R.; Su, Y.F.; Zhou, Z.H.; Hou, Z.Z.; Li, Z.R.; Zhao, J.H.; Shi, W.C.; Yu, X.Q.; et al. Long-Lasting Filtration of Oily Water by Anti-Fouling Underwater Oleophobic Sand Particles. J. Bionic Eng. 2024, 21, 913–923. [Google Scholar] [CrossRef]

- Dai, C.L.; Zhao, G.; You, Q.; Zhao, M.W. The investigation of a new moderate water shutoff agent: Cationic polymer and anionic polymer. J. Appl. Polym. Sci. 2014, 131, 39462. [Google Scholar] [CrossRef]

- Sharma, S.K.; Duvedi, R.K.; Bedi, S.; Mann, S. Numerical implementation of drop spin and tilt method for five-axis tool positioning for tensor product surfaces. Int. J. Adv. Manuf. Technol. 2021, 115, 2001–2016. [Google Scholar] [CrossRef]

- Wan, Y.Y.; Mu, H.M.; Luo, N.; Yang, J.P.; Tian, Y.; Hong, N.; Dong, H.L. Rapid accuracy determining DNA purity and concentration in heavy oils by spectrophotometry methods. Pet. Sci. 2023, 20, 3394–3399. [Google Scholar] [CrossRef]

- Vivek, R.; Jie, W.; Suresh, B.; Rajarathinam, P. Studying particle attrition in a solid-liquid agitated vessel using focused beam reflectance measurement (FBRM). Chem. Eng. Process. 2023, 183, 109256. [Google Scholar]

- Taherinejad, M.; Gorman, J.; Sparrow, E.; Derakhshan, S. Porous medium model of a hollow-fiber water filtration system. J. Membr. Sci. 2018, 563, 210–220. [Google Scholar] [CrossRef]

- Khuzhayorov, B.; Fayziev, B.; Begmatov, T. Model of suspension filtration in a porous medium taking into account diffusion and dynamical factors. AIP Conf. Proc. 2022, 2637, 040014. [Google Scholar]

| Classification | Oil Droplets Average Size, μm | Suspended Solids Average Size, μm | Polymer Concentration, mg/L | Oil Content, mg/L | Suspended Solids Content, mg/L | Interfacial Tension, mN/m |

|---|---|---|---|---|---|---|

| class I | 0.742 | 16.53 | 358.7 | 538.0 | 532.0 | 0.154 |

| class II | 0.767 | 17.04 | 276.0 | 303.0 | 297.0 | |

| class III | 0.689 | 15.09 | 415.2 | 138.0 | 145.0 |

| Classification of Treatment Process | Structural Dimensions of Primary Sedimentation Tank | Structural Dimensions of Secondary Sedimentation Tank |

|---|---|---|

| class I | Φ32,500 mm × 12,000 mm | Φ32,500 mm × 12,000 mm |

| class II | Φ16,300 mm × 12,700 mm | Φ16,300 mm × 12,700 mm |

| class III | Φ27,200 mm × 12,800 mm | Φ27,200 mm × 12,800 mm |

| Classification of Treatment Process | Treatment Amount, m3/d | Inlet Water Polymer Concentration, mg/L |

|---|---|---|

| class I | 13,600/14,800/16,000 | 300/400/500 |

| class II | 4400/8000/11,600 | 200/300/400 |

| class III | 9200/11,600/14,000 | 300/400/500 |

| Classification of Treatment Process | Treatment Amount, m3/d | Inlet Water Oil Content, mg/L | Inlet Water Suspended Solids Content of, mg/L |

|---|---|---|---|

| class I | 13,600/14,800/16,000 | 100/300/500 | 100/300/500 |

| class II | 4400/8000/11,600 | 100/200/300 | 100/200/300 |

| class III | 9200/11,600/14,000 | 50/100/150 | 50/100/150 |

| Filter Material Type | Particle Size Distribution of Filter Material, mm | Average Particle Size of Filter Material, mm | Viscous Resistance Coefficient, 108 m−2 | Inertial Drag Coefficient, 104 m−1 |

|---|---|---|---|---|

| Quartz sand filter material of primary filtration | 0.8~1.2 | 0.8 | 9.5776 | 3.1365 |

| Magnetite filter material of primary filtration | 0.4~0.8 | 0.6 | 11.2732 | 2.9778 |

| Quartz sand filter material of secondary filtration | 0.5~0.8 | 0.6 | 17.0268 | 4.1820 |

| Magnetite filter material of secondary filtration | 0.25~0.5 | 0.4 | 25.3647 | 4.4667 |

| Serial Number | Treatment Amount, m3/d | Oil Content, mg/L | Suspended Solids Content, mg/L |

|---|---|---|---|

| 1 | 13,554 | 146.2 | 153.6 |

| 2 | 13,782 | 135.7 | 140.9 |

| 3 | 13,888 | 139.5 | 146.4 |

| 4 | 12,590 | 143.7 | 155.9 |

| 5 | 13,246 | 132.6 | 146.5 |

| 6 | 14,403 | 134.3 | 144.3 |

| 7 | 12,159 | 145.5 | 147.7 |

| 8 | 13,692 | 141.3 | 143.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Wang, M.; Jing, K.; Hong, J.; Bu, F.; Wang, Z. Numerical Simulation of Treatment Capacity and Operating Limits of Alkali/Surfactant/Polymer (ASP) Flooding Produced Water Treatment Process in Oilfields. Energies 2025, 18, 3420. https://doi.org/10.3390/en18133420

Zhu J, Wang M, Jing K, Hong J, Bu F, Wang Z. Numerical Simulation of Treatment Capacity and Operating Limits of Alkali/Surfactant/Polymer (ASP) Flooding Produced Water Treatment Process in Oilfields. Energies. 2025; 18(13):3420. https://doi.org/10.3390/en18133420

Chicago/Turabian StyleZhu, Jiawei, Mingxin Wang, Keyu Jing, Jiajun Hong, Fanxi Bu, and Zhihua Wang. 2025. "Numerical Simulation of Treatment Capacity and Operating Limits of Alkali/Surfactant/Polymer (ASP) Flooding Produced Water Treatment Process in Oilfields" Energies 18, no. 13: 3420. https://doi.org/10.3390/en18133420

APA StyleZhu, J., Wang, M., Jing, K., Hong, J., Bu, F., & Wang, Z. (2025). Numerical Simulation of Treatment Capacity and Operating Limits of Alkali/Surfactant/Polymer (ASP) Flooding Produced Water Treatment Process in Oilfields. Energies, 18(13), 3420. https://doi.org/10.3390/en18133420