Gravity Energy Storage and Its Feasibility in the Context of Sustainable Energy Management with an Example of the Possibilities of Mine Shafts in Poland

Abstract

1. Introduction

- RQ1: What are the technical and economic limitations and the potential opportunities for implementing gravity energy storage in mine shafts in Poland?

- RQ2: To what extent can gravity energy storage in mine shafts represent a competitive solution compared to other energy storage methods, such as pumped-storage power plants or battery systems?

- RQ3: Is the concept of using mine shafts as gravity energy storage facilities consistent with the assumptions of sustainable energy transition and the plans for restructuring the mining industry in Poland?

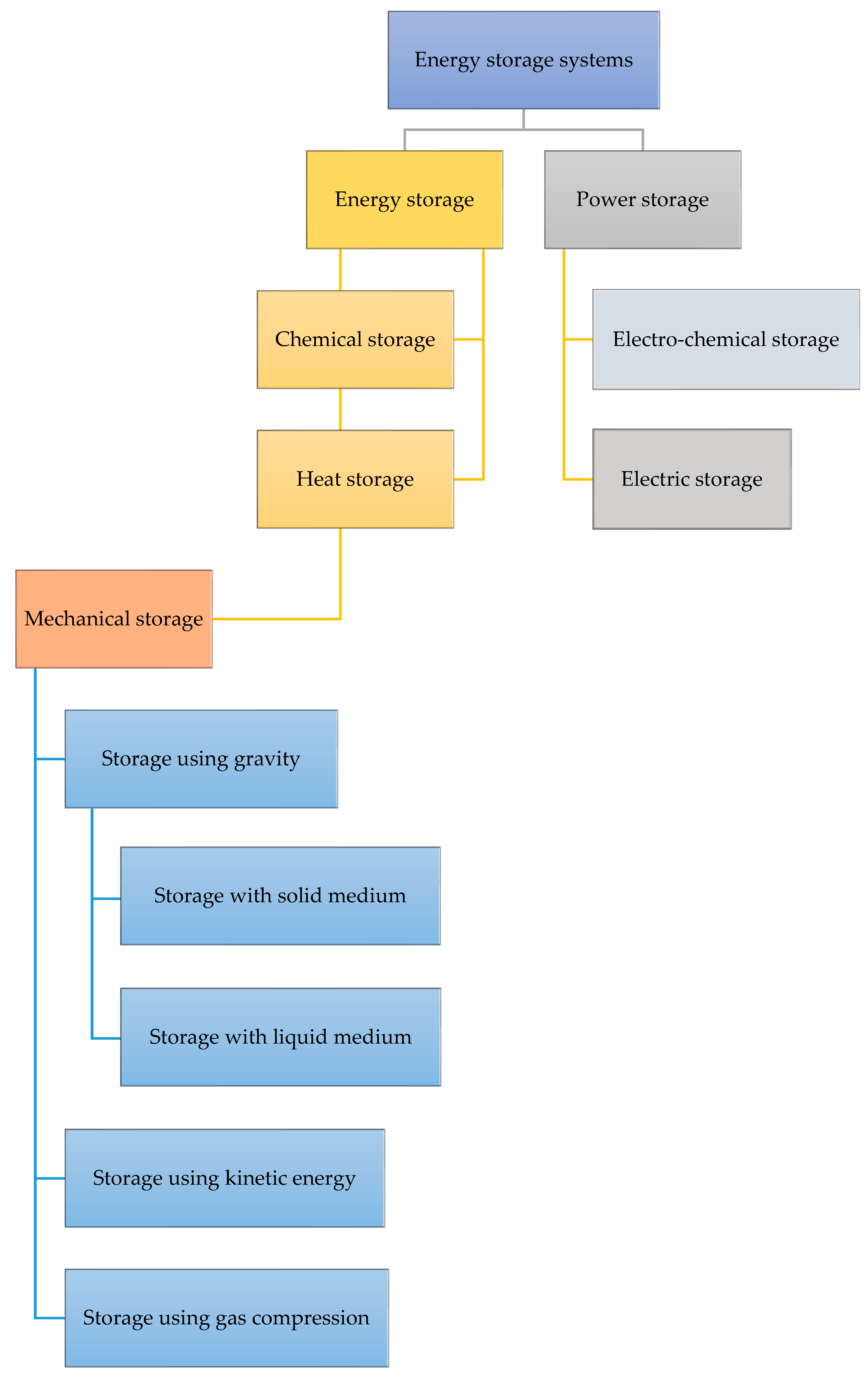

2. Background

- (i) Underground pumped-storage power plants in mine workings: In Finland, in the inactive Pyhäsalmi mine, the deepest mine shaft in Europe (with a depth of almost 1.5 km), a project is underway to build an underground pumped-storage power plant. The planned installation will have a capacity of 75 MW and an energy storage capacity of 530 MWh, utilizing the existing shafts and workings as the lower water reservoir. The project has received financial support from the European Union amounting to EUR 26.3 million [44].

- (ii) Gravity energy storage systems with a single or multiple weights: Energy storage technology based on lifting and lowering heavy weights in mine shafts (research on adapting this technology is currently underway in inactive mines such as Velenje in Slovenia, Pyhäsalmi in Finland, Darkov in the Czech Republic, and Grube Teutschenthal in Germany) [45].

- (iii) The world’s first gravity energy storage systems utilizing gravity blocks—constructed from waste materials such as construction debris, coal ash, or fiberglass—and designed for an operational lifespan of up to 50 years, have been established in China. A notable example is the China Tianying Rudong Gravity Energy Storage Project, located in Yangkou town, Rudong county, Nantong. This pioneering facility, with an initial capacity of 26 MW, is expected to reach a total energy storage capability of 100 MWh once it becomes fully operational by the end of 2025 [46].

- (iv) In Australia, the difference in height between two water reservoirs is used to store and generate electricity. (Snowy 2.0 project: The Snowy 2.0 project involves tunnelling through 27 km (17 miles) of rock to create a huge pipeline connecting two bodies of water. The elevation difference is 700 m (2296 feet). The energy gravity system would provide about 10% of Australia’s electricity production at full output [47].)

- (v) A recent study by the International Institute for Applied Systems Analysis (IIASA) introduced a novel concept for energy storage, involving the transportation of sand into decommissioned underground mines. This approach, known as underground gravity energy storage (UGES), generates electricity by lowering sand into the mine and harnessing its gravitational potential through regenerative braking systems [26]. According to the findings, a single mine could offer an energy storage capacity ranging from 10 to 100 GWh, depending on the use of 5 to 50 million tonnes of sand. The deeper and wider the shaft, the greater the potential for power generation, while the overall size of the mine determines the maximum energy that can be stored [26,48].

2.1. Examples of Energy Storage in Coal Mines

2.1.1. Pumped Hydro Energy Storage (PHES)

2.1.2. Compressed Air Energy Storage (CAES)

2.1.3. Battery Storage Systems

2.1.4. Hybrid Systems and Integration

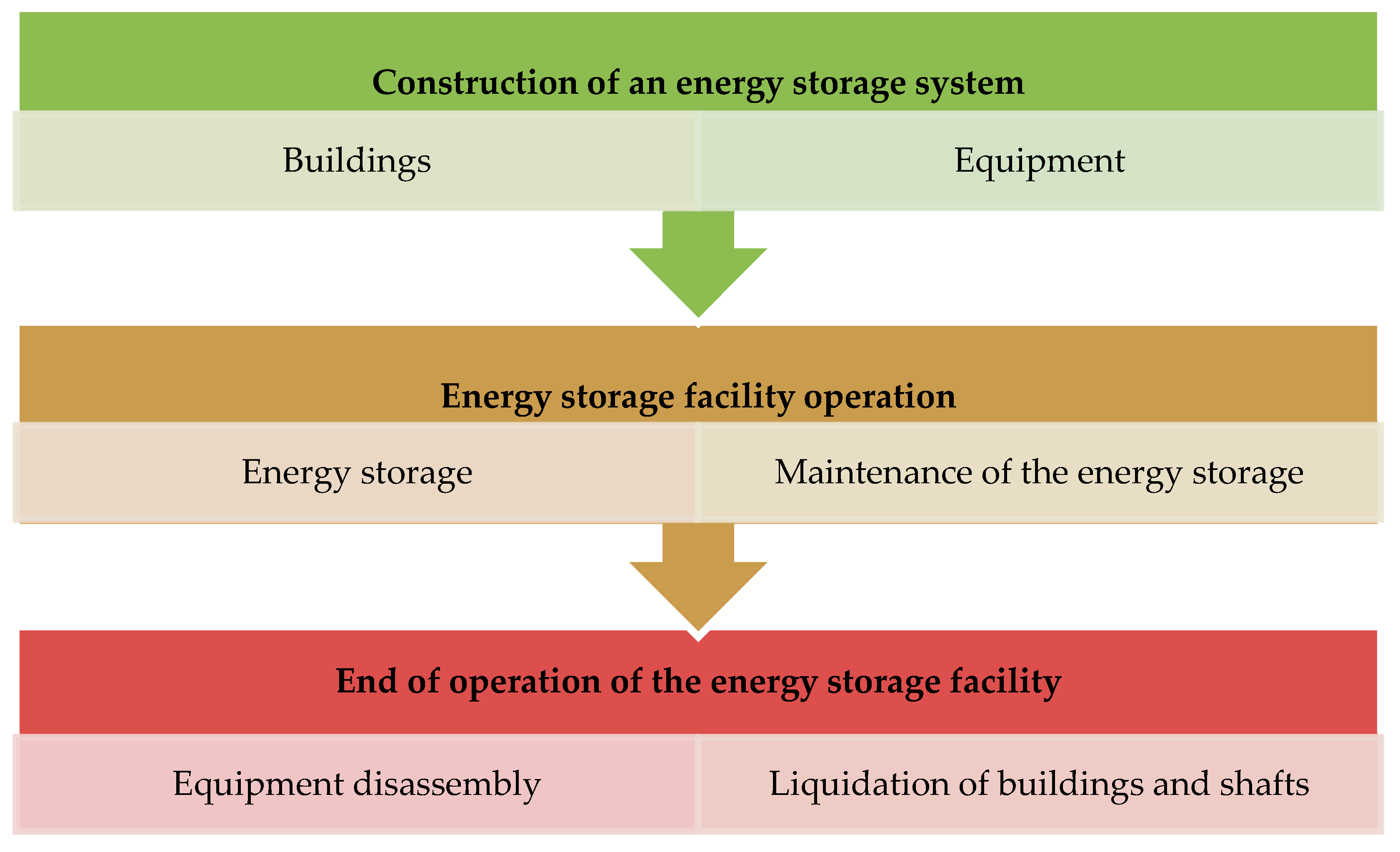

3. Study Method

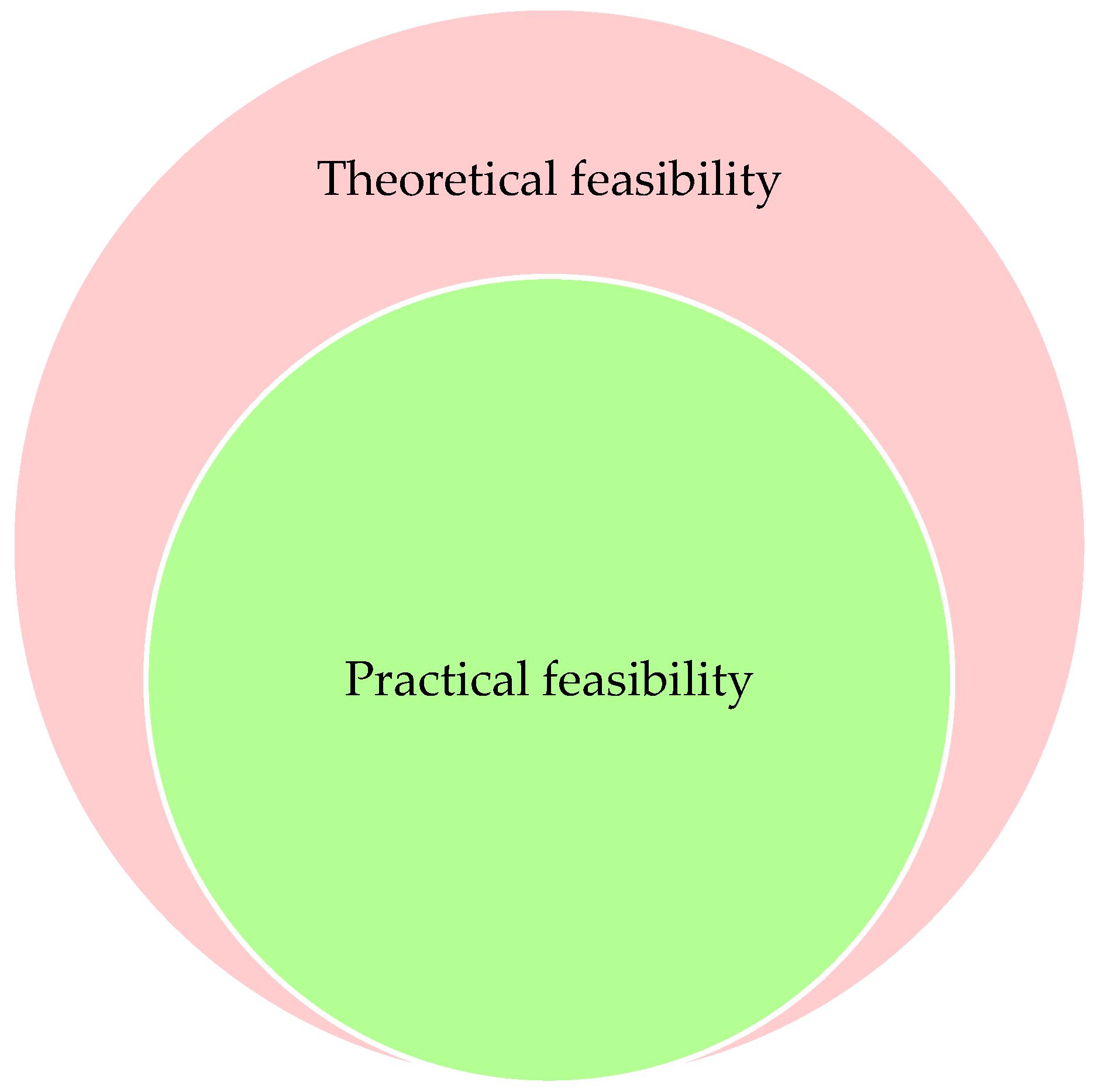

- Theoretical feasibility refers to the compliance of a proposed project with fundamental natural laws—such as those of physics, mechanics, or thermodynamics—indicating that the concept is scientifically sound and does not violate established principles [67].

- Practical or situational feasibility, on the other hand, indicates that the project or process can be realistically implemented within a given context, taking into account specific local conditions such as time, location, and available resources.

- Financial or, more broadly, economic constraints;

- Restrictions resulting from applicable standards and legal regulations at the time and place of project implementation;

- Limitations resulting from the availability and skills of human resources along with the existing patterns of social culture in the place and time of the project;

- Local constraints such as terrain, climate, geological structure or locally available infrastructure.

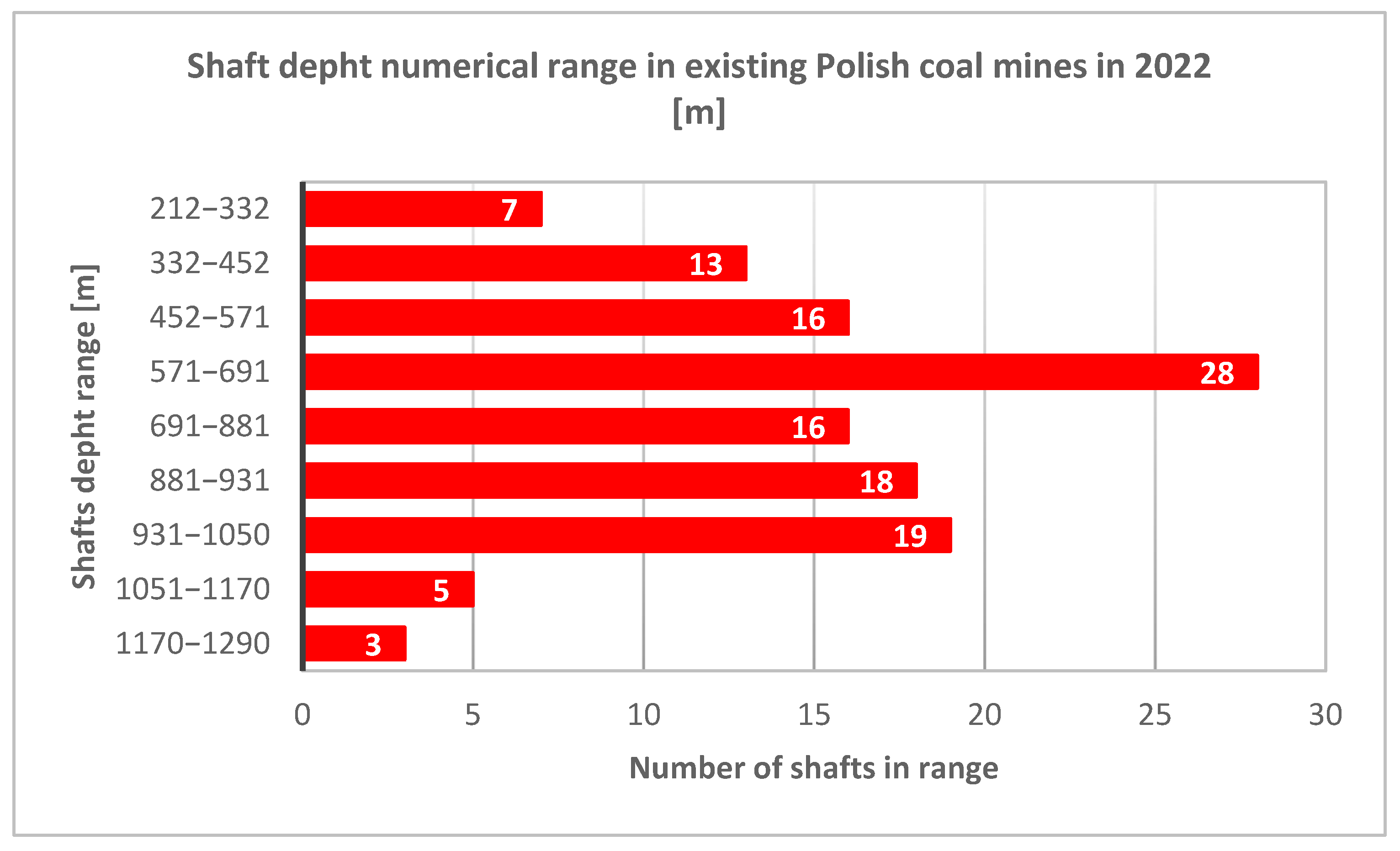

4. Results of Analysis

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aneke, M.; Wang, M. Energy storage technologies and real life applications—A state of the art review. Appl. Energy 2016, 179, 350–377. [Google Scholar] [CrossRef]

- Quaranta, E.; Boes, R.M.; Hunt, J.D.; Szabò, S.; Tattini, J.; Pistocchi, A. Considerations on the existing capacity and future potential for energy storage in the European Union’s hydropower reservoirs and pumped-storage hydropower. J. Energy Storage 2024, 104, 114431. [Google Scholar] [CrossRef]

- Tong, W.; Lu, Z.; Sun, J.; Zhao, G.; Han, M.; Xu, J. Solid gravity energy storage technology: Classification and comparison. Energy Rep. 2022, 8, 926–934. [Google Scholar] [CrossRef]

- Tong, W.; Lu, Z.; Chen, W.; Han, M.; Zhao, G.; Wang, X.; Deng, Z. Solid gravity energy storage: A review. J. Energy Storage 2022, 53, 105226. [Google Scholar] [CrossRef]

- Morstyn, T.; Botha, C.D. Gravitational Energy Storage with Weights. Encyclopedia. Available online: www.marketsandmarkets.com/Market-Reports/gravity-energy-storage-market-213578483.html (accessed on 17 March 2025).

- Galetakis, M.; Biotakis, G.; Deligiorgis, V.; Varouchakis, E. Transforming Decommissioned Mines to a Gravity Energy Storage System. Mater. Proc. 2023, 15, 14. [Google Scholar] [CrossRef]

- Li, L.; Wang, B.; Jiao, K.; Ni, M.; Du, Q.; Liu, Y.; Li, B.; Ling, G.; Wang, C. Comparative techno-economic analysis of large-scale renewable energy storage technologies. Energy AI 2023, 14, 100282. [Google Scholar] [CrossRef]

- Jennings, A. Conveyor Energy Storage: A Battery and Pumped Hydro Alternative, Power-News and Technology for the Global Energy Industry. 2020. Available online: https://www.powermag.com/conveyor-energy-storage-a-battery-and-pumped-hydro-alternative/ (accessed on 7 June 2025).

- Hossain, E.; Faruque, H.M.R.; Sunny, M.S.H.; Mohammad, N.; Nawar, N. A comprehensive review on energy storage systems: Types, applications, and challenges. Energies 2020, 13, 2781. [Google Scholar] [CrossRef]

- Koolen, D.; De Felice, M.; Busch, S. Flexibility Requirements and the Role of Storage in Future European Power Systems; Publications Office of the European Union: Luxembourg, 2023. [Google Scholar] [CrossRef]

- Quaranta, E.; Georgakaki, A.; Letout, S.; Mountraki, A.; Ince, E.; Gea Bermudez, J. Clean Energy Technology Observatory: Hydropower and Pumped-Storage Hydropower in the EUROPEAN Union—2024 Status Report on Technology Development, Trends, Value Chains and Markets; Publications Office of the European Union: Luxembourg, 2024; Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC139225 (accessed on 17 March 2025).

- Overall Strategic Analysis of Clean Energy Technology in the European Union. Strategic Analysis and Outlook. General Publications, European Comission,6 February 2025. Available online: https://setis.ec.europa.eu/publications-and-documents/clean-energy-technology-observatory/ceto-reports-2024_en (accessed on 20 May 2025).

- Goal 17: Revitalize the Global Partnership for Sustainable Development. Sustainable Development Goals. United Nations. Available online: https://sdgs.un.org/goals/goal17 (accessed on 17 March 2025).

- Zillman, D.; Godden, L.; Paddock, L.; Roggenkamp, M. Regulating electricity storage in the European Union: How to balance technical and legal innovation. In Innovation in Energy Law and Technology: Dynamic Solutions for Energy Transitions; Zillman, D., Godden, L., Paddock, L., Roggenkamp, M., Eds.; Oxford University Press: Oxford, UK, 2018; pp. 155–172. [Google Scholar]

- Zhou, C.; Richardson-Barlow, C.; Fan, L.; Cai, H.; Zhang, W.; Zhang, Z. Towards organic collaborative governance for a more sustainable environment: Evolutionary game analysis within the policy implementation of China’s net-zero emissions goals. J. Environ. Manag. 2025, 373, 123765. [Google Scholar] [CrossRef]

- Directive (EU) 2019/944. It Was Amended in 2024 by Directive (EU) 2024/1711: Directive (EU) 2024/1711 of the European Parliament and of the Council of 13 June 2024 Amending Directives (EU) 2018/2001 and (EU) 2019/944 as Regards Improving the Union’s Electricity Market Design (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/eli/dir/2024/1711/oj/eng (accessed on 25 March 2025).

- European Commission. A Clean Planet for All: A European Strategic Long-Term Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy: Brussels, Belgium, 28 November 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52018DC0773 (accessed on 25 March 2025).

- United Nations. Paris Agreement. United Nations Framework Convention on Climate Change. 2015. Available online: https://unfccc.int/sites/default/files/english_paris_agreement.pdf (accessed on 20 April 2025).

- Ozturk, Z.; Demirci, A.; Terkes, M.; Yumurtaci, R. Optimal planning of solar PV-based electric vehicle charging stations empowered by energy storage system: Feasibility and green charge potential. Renew. Energy 2025, 255, 123715. [Google Scholar] [CrossRef]

- Li, C.; Yao, M.; Yao, X.; Li, C. A hybrid processing technology for fabricating lead zirconate-based ceramics with high energy storage density, high efficiency, and low sintering temperature. J. Mater. 2025, 11, 101077. [Google Scholar] [CrossRef]

- Qin, Z.; Ma, J.; Zhu, M.; Khan, T. Advancements in energy storage technologies: Implications for sustainable energy strategy and electricity supply towards sustainable development goals. Energy Strateg. Rev. 2025, 59, 101710. [Google Scholar] [CrossRef]

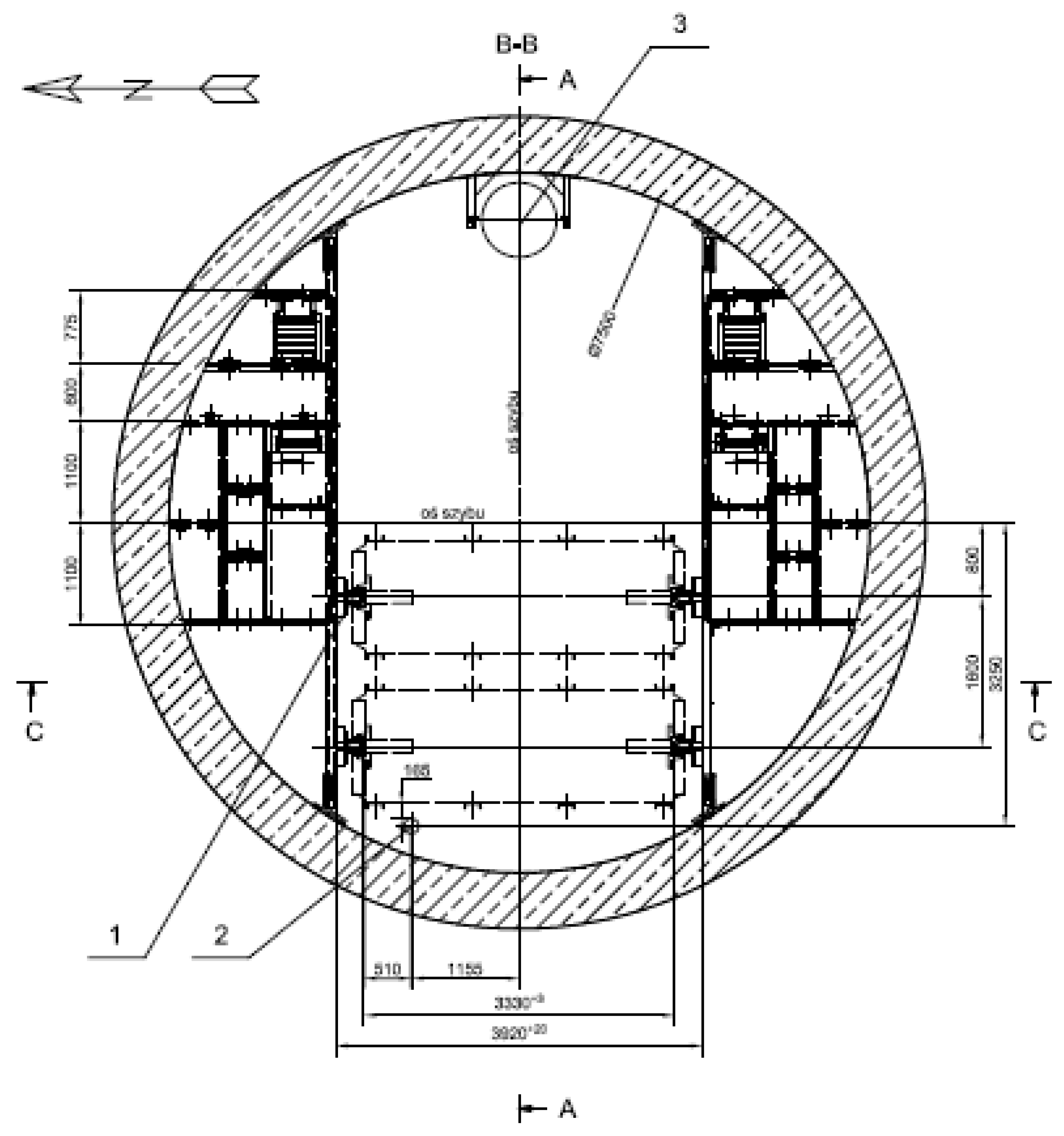

- Korski, J.; Rak, Z. Magazynowanie energii w szybach kopalnianych—Grawitacyjny magazyn z cięgnem łańcuchowym. In Proceedings of the Komtech, Szczyrk, Poland, 4–6 November 2024. [Google Scholar] [CrossRef]

- Matos, C.R.; Carneiro, J.F.; Silva, P.P. Overview of large-scale underground energy storage technologies for integration of renewable energies and criteria for reservoir identification. J. Energy Storage 2019, 21, 241–258. [Google Scholar] [CrossRef]

- Siostrzonek, T. The mine shaft energy storage system—Implementation threats and opportunities. Energies 2024, 16, 5615. [Google Scholar] [CrossRef]

- Kula, J.; Kamiński, P.; Stecuła, K.; Prostański, D.; Matusiak, P.; Kowol, D.; Kopacz, M.; Olczak, P. Technical and Economic Aspects of Electric Energy Storage in a Mine Shaft. Budryk Case Study 2021, 14, 7337. [Google Scholar]

- Hunt, J.D.; Zakeri, B.; Jurasz, J.; Tong, W.; Dąbek, P.B.; Brandão, R.; Patro, E.R.; Đurin, B.; Filho, W.L.; Wada, Y.; et al. Underground Gravity Energy Storage: A Solution for Long-Term Energy Storage. Energies 2023, 16, 825. [Google Scholar] [CrossRef]

- Korski, J. Solid gravity energy storage in mine shafts—Feasibility and functionality. Min. Mach. 2024, 42, 232–239. [Google Scholar]

- Tobór-Osadnik, K.; Gajdzik, B.; Strzelec, G. Configurational Path of Decarbonisation Based on Coal Mine Methane (CMM): An Econometric Model for the Polish Mining Industry. Sustainability 2023, 15, 9980. [Google Scholar] [CrossRef]

- Gajdzik, B.; Tobór-Osadnik, K.; Wolniak, R.; Grebski, W.W. European Climate Policy in the Context of the Problem of Methane Emissions from Coal Mines in Poland. Energies 2024, 17, 2396. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, F.; Ling, Y.; Wei, K.; Kang, J. Overview and Outlook on Utilization Technologies of Low-Concentration Coal Mine Methane. Energy Fuels 2021, 35, 15398–15423. [Google Scholar] [CrossRef]

- Kaczmarek, J. The Balance of Outlays and Effects of Restructuring Hard Coal Mining Companies in Terms of Energy Policy of Poland PEP 2040. Energies 2022, 15, 1853. [Google Scholar] [CrossRef]

- Likwidacja Kopalń na Nowych Zasadach (Title in Polish). Document. Available online: https://www.prawo.pl/biznes/likwidacja-kopaln-na-nowych-zasadach-jest-projekt-ustawy,530875.html (accessed on 17 May 2025).

- Energy Policy of Poland (EPP2040) Until 2040, (Title in Polish) Polityka Energetyczna Polski do 2040 r. (PEP2040). Available online: https://www.gov.pl/web/klimat/polityka-energetyczna-polski (accessed on 11 May 2023).

- INSTRAT: Kopalnie w Polsce—Zaktualizowana Baza na Energy.Instrat.pl. Available online: https://instrat.pl/kopalnie-w-polsce-aktualizacja-2024/#:~:text=Wed%C5%82ug%20stanu%20na%20grudzie%C5%84%202024,oraz%205%20z%C5%82%C3%B3%C5%BC%20w%C4%99gla%20brunatnego (accessed on 20 April 2025).

- Report (Title in Polish) Polska Ścieżka Transformacji Energetycznej; Polski Komitet Energii Elektrycznej: Warszawa, Poland. 2022. Available online: https://pkee.pl/publications/raport-ey-i-pkee-polska-sciezka-transformacji-energetycznej/ (accessed on 27 May 2023).

- Rafał, K.; Grabowski, P. Magazynowanie energii. Energetyka ACADEMIA Mag. Pol. Akad. Nauk. 2021, 1, 34–40. [Google Scholar] [CrossRef]

- Saigustia, C.; Robak, S. Review of Potential Energy Storage in Abandoned Mines in Poland. Energies 2021, 14, 6272. [Google Scholar] [CrossRef]

- Morstyn, T.; Chilcott, M.; McCulloc, M.D. Gravity energy storage with suspended weights for abandoned mine shafts. Appl. Energy 2019, 239, 201–206. [Google Scholar] [CrossRef]

- Kawalec, W.; Król, R. Generating of Electric Energy by a Declined Overburden Conveyor in a Continuous Surface Mine. Energies 2021, 14, 4030. [Google Scholar] [CrossRef]

- Schnepper, T.; Kühn, M.; Kempka, T. Pumped hydropower storage operation in open-pit lignite mines does not compromise the pit lake and groundwater chemistry (no. EGU24-3947). In Proceedings of the Copernicus Meetings, Vienna, Austria, 14–19 April 2024. [Google Scholar]

- Krassakis, P.; Karavias, A.; Zygouri, E.; Roumpos, C.; Louloudis, G.; Pyrgaki, K.; Koukouzas, N.; Kempka, T.; Karapanos, D. GIS-Based Assessment of Hybrid Pumped Hydro Storage as a Potential Solution for the Clean Energy Transition: The Case of the Kardia Lignite Mine, Western Greece. Sensors 2023, 23, 593. [Google Scholar] [CrossRef]

- Menéndez, J.; Fern’andez-Oro, J.M.; Galdo, M.; Loredo, J. Efficiency analysis of underground pumped storage hydropower plants. J. Energy Storage 2020, 28, 101234. [Google Scholar] [CrossRef]

- Przekształcanie Opuszczonych Kopalń W Baterie Grawitacyjne. Magazyn Fotowoltaika News, 7 February 2023. Available online: https://magazynfotowoltaika.pl/przeksztalcanie-opuszczonych-kopaln-w-baterie-grawitacyjne/ (accessed on 25 April 2025).

- First Commercial Gravity Storage for Energy Planned in Finnish Mine. Available online: https://www.mining.com/first-commercial-gravity-storage-for-energy-planned-in-finnish-mine/ (accessed on 7 June 2025).

- Bentham, J. Europe’s mines look to gravity energy storage for green future. Global Mining Review, 13 May 2024. Available online: https://www.globalminingreview.com/mining/13052024/europes-mines-look-to-gravity-energy-storage-for-green-future/ (accessed on 25 March 2025).

- World’s First 26MW Gravity Energy Storage Project Nears Completion in Rudong. 2024. Available online: https://en.nantong.gov.cn/2024-06/21/c_998345.htm (accessed on 20 April 2025).

- Mercer, P. (Snowy 2.0) Australia’s divisive plan for a vast underground ’battery’ Snowy 2.0 project. BBC, 17 October 2019. Available online: https://www.bbc.com/news/world-australia-49202175 (accessed on 20 March 2025).

- Morgan, S. Decommissioned Mines Converted to Energy Storage. News 7 March 2023, I.M3, Institute of Materials, Minerals Mining, News. Available online: https://www.iom3.org/resource/decommissioned-mines-converted-to-energy-storage.html (accessed on 7 June 2025).

- Bluszcz, A.; Tobór-Osadnik, K.; Tomiczek, K.; Mansor, N.S.; Awang, H. The use of geomatics tools in critical infrastructure management. Inżynieria Miner. 2023, 1, 169–174. [Google Scholar] [CrossRef]

- Bluszcz, A.; Tobór-Osadnik, K.; Manowska, A.; Smetana, M. Functionalities of geoinformatic systems in crisis events caused by climate change. In Proceedings of the 24th International Multidisciplinary Scientific GeoConference SGEM 2024, Albena, Bulgaria, 1–7 July 2024. [Google Scholar] [CrossRef]

- Cahyono, M. Hybrid Models for Solving the Colebrook–White Equation Using Artificial Neural Networks. Fluids 2022, 7, 211. [Google Scholar] [CrossRef]

- Ostraszewski, M.; Jurasz, J.; Kaźmierczak, B. Transforming Coal Pits into Renewable Energy Sources: The Potential of Pumped Hydro Energy Storage in the Bełchatów Lignite Mine. In Proceedings of the EGU General Assembly Conference Abstracts, Vienna, Austria, 14–19 April 2024; p. 6474. [Google Scholar]

- Álvarez, H.; Domínguez, G.; Ordóñez, A.; Menéndez, J.; Álvarez, R.; Loredo, J. Mine Water for the Generation and Storage of Renewable Energy: A Hybrid Hydro–Wind System. Int. J. Environ. Res. Public Health 2021, 18, 6758. [Google Scholar] [CrossRef]

- Gao, R.; Wu, F.; Zou, Q.; Chen, J. Optimal dispatching of wind-PV-mine pumped storage power station: A case study in Lingxin Coal Mine in Ningxia Province, China. Energy 2022, 243, 123061. [Google Scholar] [CrossRef]

- Schmidt, F.; Menéndez, J.; Konietzky, H.; Pascual-Muñoz, P.; Castro, J.; Loredo, J.; Sánchez, A.B. Converting closed mines into giant batteries: Effects of cyclic loading on the geomechanical performance of underground compressed air energy storage systems. J. Energy Storage 2020, 32, 101882. [Google Scholar] [CrossRef]

- Prado, L.Á.D.; Menéndez, J.; Bernardo-Sánchez, A.; Galdo, M.; Loredo, J.; Fernández-Oro, J.M. Thermodynamic analysis of compressed air energy storage (CAES) reservoirs in abandoned mines using different sealing layers. Appl. Sci. 2021, 11, 2573. [Google Scholar] [CrossRef]

- Bartela, Ł. A hybrid energy storage system using compressed air and hydrogen as the energy carrier. Energy 2020, 196, 117088. [Google Scholar] [CrossRef]

- Yuan, L.; Tang, W.; Thomas, R.A.; Soles, J. Experimental study on suppression of lithium iron phosphate battery fires. Min. Metall. Explor. 2024, 41, 637–645. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; Zhou, Y.; Niu, J. An energy storage system for smart coal mine emergency power supply. Energy Storage Sci. Technol. 2015, 4, 104. [Google Scholar] [CrossRef]

- Baigorri, J.; Zaversky, F.; Astrain, D. Massive grid-scale energy storage for next-generation concentrated solar power: A review of the potential emerging concepts. Renew. Sustain. Energy Rev. 2023, 185, 113633. [Google Scholar] [CrossRef]

- Tan, K.M.; Babu, T.S.; Ramachandaramurthy, V.K.; Kasinathan, P.; Solanki, S.G.; Raveendran, S.K. Empowering smart grid: A comprehensive review of energy storage technology and application with renewable energy integration. J. Energy Storage 2021, 39, 102591. [Google Scholar] [CrossRef]

- Zhou, K.; Yang, S.; Chen, Z.; Ding, S. Optimal load distribution model of microgrid in the smart grid environment. Renew. Sustain. Energy Rev. 2014, 35, 304–310. [Google Scholar] [CrossRef]

- Bąk, P.; Sukiennik, M.; Kowal, B. The Main Drivers of the Raw Materials and ICT Sectors in Poland Using PESTEL Analysis. Energies 2025, 18, 1987. [Google Scholar] [CrossRef]

- Götz, M.; Lefebvre, J.; Mörs, F.; Koch, A.M.; Graf, F.; Bajohr, S.; Kolb, T. Renewable Power-to-Gas: A technological and economic review. Renew. Energy 2016, 85, 1371–1390. [Google Scholar] [CrossRef]

- Menéndez, J.; Ordóñez, A.; Álvarez, R.; Loredo, J. Energy from closed mines: Underground energy storage and geothermal applications. Renew. Sustain. Energy Rev. 2019, 108, 498–512. [Google Scholar] [CrossRef]

- Andrusikiewicz, W. Możliwości magazynowania gazu ziemnego i energii w utworach solnych na terenie Polski (Potential for natural gas and energy storage in salt formations in Poland). Inżynieria Miner. 2024, 2, 143–150. [Google Scholar]

- Kiliński, A. Przemysłowe Procesy Realizacji: Podstawy Teorii; WNT: Warszawa, Poland, 1976. [Google Scholar]

- Halliday, D.; Resnick, R. Fundamentals of Physics, 12th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2023. [Google Scholar]

- Zmysłowski, T. Górnicze Maszyny Wyciągowe: Część mechaniczna; Śląsk Sp. z o.o.: Warszawa, Poland, 2004. [Google Scholar]

- Gajdzik, B.; Wolniak, R.; Grebski, W. Electricity and heat demand in steel industry technological processes in Industry 4.0 conditions. Energies 2023, 16, 787. [Google Scholar] [CrossRef]

- Gajdzik, B.; Wolniak, R.; Grebski, W. An econometric model of the operation of the steel industry in Poland in the context of process heat and energy consumption. Energies 2022, 15, 7909. [Google Scholar] [CrossRef]

- Stecuła, K.; Wolniak, R.; Grebski, W.W. AI-Driven Urban Energy Solutions—From Individuals to Society: A Review. Energies 2023, 16, 7988. [Google Scholar] [CrossRef]

- Gajdzik, B.; Wolniak, R.; Grebski, W. An Econometric Analysis of CO2 Emission Intensity in Poland’s Blast Furnace–Basic Oxygen Furnace Steelmaking Process. Sustainability 2025, 17, 4045. [Google Scholar] [CrossRef]

- Qin, T.; Li, Y.; Quang, L.; Yao, Y.; Yang, L. A Novel Integrated Energy Management Strategy of Energy Storage System for a Pure Electric-Driven Mining Hydraulic Excavator. Chin. J. Mech. Eng. (Engl. Ed.) 2025, 38, 58. [Google Scholar] [CrossRef]

- Tardy, A.; Rousse, D.R.; Mungyeko Bisulandu, B.-J.R.; Ilinca, A. Enhancing Energy Sustainability in Remote Mining Operations Through Wind and Pumped-Hydro Storage; Application to Raglan Mine, Canada. Energies 2025, 18, 2184. [Google Scholar] [CrossRef]

- Jiang, J.; Cao, Y.; Li, G.; Zhao, J.; Liu, C. Using Industrial Mining Solid Waste through Conversion to Phase-Change Materials for Thermal Energy Storage. ChemPlusChem 2025, 90, e202400519. [Google Scholar] [CrossRef]

- Lyu, J.; Han, W.; Zhang, X.; Pan, Y.; Dai, L. Evolution Law of the Activation and Energy Storage of Fault with Hard Rock Bridge under Mining Influence. Meitan Xuebao/J. China Coal Soc. 2025, 50, 901–916. [Google Scholar]

- Yixi, C.; Liu, X.; Li, Y.; Danzeng, B.; Wang, L. Optimal Configuration Strategy of Energy Storage Considering Flexible Response of High Energy-Consuming Industrial and Mining Loads in Independent Microgrid. Front. Energy Res. 2025, 13, 1536668. [Google Scholar] [CrossRef]

- Zhao, P.; Chang, Z.; Li, S.; Shao, Q.; Pei, W. Study on Time-Varying Mechanism of Energy Dissipation Structure in Depressed-Pressure Gas Transport and Storage Area of Inclined Thick Coal Seam Mining. Zhongguo Kuangye Daxue Xuebao/J. China Univ. Min. Technol. 2025, 54, 202–214. [Google Scholar]

- Liu, Q.; Tong, Y.; Liu, B.; Yang, J.; Feng, Y. Life Cycle Cost-Oriented Optimization of Hybrid Energy Storage System for Mining Haul Truck. In Proceedings of the 19th Annual Conference of China Electrotechnical Society; Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2025; Volume 1406, pp. 112–120. [Google Scholar]

- Li, Y.; Wang, L.; Liu, X.; Danzeng, B.; Xia, Q. Coordinated Optimization Method of Energy Storage and Flexible Demand Response for Industrial and Mining Loads. J. Web Eng. 2025, 44, 167–192. [Google Scholar] [CrossRef]

- Zhang, P.-F.; Gu, X.-B.; Guo, W.-Y.; Zhu, Z.-Q.; Guo, L. Bending Energy Storage Mechanical Model of Layered Composite Roof Structure in Coal Mining. Sci. Rep. 2024, 14, 30976. [Google Scholar] [CrossRef]

- Tang, Q.; Hu, M.; Bian, Y.; Peng, X.; Li, K. Optimal Energy Efficiency Control Framework for Distributed Drive Mining Truck Power System with Hybrid Energy Storage: A Vehicle-Cloud Integration Approach. Appl. Energy 2024, 374, 123989. [Google Scholar] [CrossRef]

- Nuñez, S.M.; Trujillo Preuss, F.E.; Masip Macía, Y. Numerical Study for the Design of a Thermal Energy Storage System with Multiple Tunnels Based on Phase Change Material: Case Study Mining in Chile (Thermal Storage in Off-Grid Industrial Applications). Appl. Sci. 2024, 14, 3690. [Google Scholar] [CrossRef]

- Ochmann, J.; Jurczyk, M.; Rusin, K.; Bartela, Ł.; Uchman, W. Solution for Post-Mining Sites: Thermo-Economic Analysis of a Large-Scale Integrated Energy Storage System. Energies 2024, 17, 1970. [Google Scholar] [CrossRef]

- Yang, Y.; Cao, M.; Zhao, W.; Zhong, Y.; Lyu, P. Optimal Operation Model of Complex Integrated Energy System for Mining Areas with Coalbed Methane and Compressed Air Energy Storage. Zhongguo Dianji Gongcheng Xuebao/Proc. Chin. Soc. Electr. Eng. 2024, 44, 2257–2269. [Google Scholar]

- Schmidt, F.; Menéndez, J.; Konietzky, H.; Álvarez, L.; Bernardo-Sánchez, A. Technical Feasibility of Lined Mining Tunnels in Closed Coal Mines as Underground Reservoirs of Compressed Air Energy Storage Systems. J. Energy Storage 2024, 78, 110055. [Google Scholar] [CrossRef]

- Liao, Y.; Wang, T.; Ren, Z.; Li, J.; Zou, X. Multi-Well Combined Solution Mining for Salt Cavern Energy Storages and Its Displacement Optimization. Energy 2024, 288, 129792. [Google Scholar] [CrossRef]

- Sheng, X.; Yang, Q.; Ye, R.; Tao, L.; Zhang, Z. Big Data Feature Mining Method for Energy Storage System of Photovoltaic Power Station in Typical Scenarios. In Proceedings of the 2024 IEEE 4th International Conference on Information Technology, Big Data and Artificial Intelligence (ICIBA 2024), Beijing, China, 6 December 2024; pp. 569–574. [Google Scholar]

- Parker, M.O.; Masrani, S. Overcoming Technological Path Dependency: Role of Dynamic Capabilities, Deliberate and Emergent Actions. Strategy Leadersh. 2025, 53, 393–414. [Google Scholar] [CrossRef]

- Meijer, A.; Thaens, M. Path Dependency of Smart Cities: How Technological and Social Legacies Condition Smart City Development. In Smart Cities and Smart Governance; Public Administration and Information Technology; Springer: Berlin/Heidelberg, Germany, 2021; Volume 37, pp. 31–42. [Google Scholar]

- Vadén, T.; Majava, A.; Toivanen, T.; Hakala, E.; Eronen, J.T. To Continue to Burn Something? Technological, Economic and Political Path Dependencies in District Heating in Helsinki, Finland. Energy Res. Soc. Sci. 2019, 58, 101270. [Google Scholar] [CrossRef]

- Onufrey, K.; Bergek, A. Self-Reinforcing Mechanisms in a Multi-Technology Industry: Understanding Sustained Technological Variety in a Context of Path Dependency. Ind. Innov. 2015, 22, 523–551. [Google Scholar] [CrossRef]

- Ntostoglou, E.; Martin, V.; Khatiwada, D.; Urban, F. Path-Dependencies in the Transition to Sustainable Biowaste Valorization: Lessons from a Socio-Technical Analysis of Sweden and Greece. Waste Manag. 2025, 192, 47–57. [Google Scholar] [CrossRef]

- Kim, J.; Yoon, J.; Lee, J.-D. Technological Speciation: Navigating New Needs Through Trial and Error—A Rifle Case Study. J. Evol. Econ. 2024, 34, 927–952. [Google Scholar] [CrossRef]

- Streb, J. The Cliometric Study of Innovations. In Handbook of Cliometrics, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2024; pp. 447–468. [Google Scholar]

- Chiodo, M.; Müller, D.; Sienknecht, M. Educating AI Developers to Prevent Harmful Path Dependency in AI Resort-to-Force Decision Making. Aust. J. Int. Aff. 2024, 78, 210–219. [Google Scholar] [CrossRef]

- Nye, D.E. A Model for Heterogeneous Energy Transitions. Archimedes 2023, 67, 21–50. [Google Scholar]

- Taberna, A.; Filatova, T.; Roventini, A.; Lamperti, F. Coping with Increasing Tides: Evolving Agglomeration Dynamics and Technological Change Under Exacerbating Hazards. Ecol. Econ. 2022, 202, 107588. [Google Scholar] [CrossRef]

- Kuo, C.-I. The Adoption Speed of Scientific Knowledge: The Moderating Role of Path Dependency on Scientific Knowledge. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management, Kuala Lumpur, Malaysia, 7–10 December 2022; pp. 1321–1326. [Google Scholar]

- Castillo, A.A. Digital Transformation and the Public Sector Workforce: An Exploration and Research Agenda. In Proceedings of the 14th International Conference on Theory and Practice of Electronic Governance, Athens, Greece, 6–8 October 2021; pp. 471–475. [Google Scholar]

- de Percy, M.; Batainah, H. Identifying Historical Policy Regimes in the Canadian and Australian Communications Industries Using a Model of Path Dependent, Punctuated Equilibrium. Policy Stud. 2021, 42, 42–59. [Google Scholar] [CrossRef]

- Bondarenko, A.V.; Islamov, S.R.; Ignatyev, K.V.; Mardashov, D.V. Laboratory Studies of Polymer Compositions for Well-Kill under Increased Fracturing. Perm J. Pet. Min. Eng. 2020, 20, 37–48. [Google Scholar] [CrossRef]

- Cavalheiro, E.A.; Oliveira, I.R.; Leandro, D.; Kontz, L.B. Governance, development, and environment: Pathways to a sustainable future. Sustain. Futures 2025, 10, 100813. [Google Scholar] [CrossRef]

- Belousov, A.; Lushpeev, V.; Sokolov, A.; Sultanbekov, R.; Tyan, Y.; Ovchinnikov, E.; Shvets, A.; Bushuev, V.; Islamov, S. Experimental Research of the Possibility of Applying the Hartmann–Sprenger Effect to Regulate the Pressure of Natural Gas in Non-Stationary Conditions. Processes 2025, 13, 1189. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tobór-Osadnik, K.; Korski, J.; Gajdzik, B.; Wolniak, R.; Grebski, W. Gravity Energy Storage and Its Feasibility in the Context of Sustainable Energy Management with an Example of the Possibilities of Mine Shafts in Poland. Energies 2025, 18, 3374. https://doi.org/10.3390/en18133374

Tobór-Osadnik K, Korski J, Gajdzik B, Wolniak R, Grebski W. Gravity Energy Storage and Its Feasibility in the Context of Sustainable Energy Management with an Example of the Possibilities of Mine Shafts in Poland. Energies. 2025; 18(13):3374. https://doi.org/10.3390/en18133374

Chicago/Turabian StyleTobór-Osadnik, Katarzyna, Jacek Korski, Bożena Gajdzik, Radosław Wolniak, and Wieslaw Grebski. 2025. "Gravity Energy Storage and Its Feasibility in the Context of Sustainable Energy Management with an Example of the Possibilities of Mine Shafts in Poland" Energies 18, no. 13: 3374. https://doi.org/10.3390/en18133374

APA StyleTobór-Osadnik, K., Korski, J., Gajdzik, B., Wolniak, R., & Grebski, W. (2025). Gravity Energy Storage and Its Feasibility in the Context of Sustainable Energy Management with an Example of the Possibilities of Mine Shafts in Poland. Energies, 18(13), 3374. https://doi.org/10.3390/en18133374