Abstract

Accurate assessment of biomass fuel properties is essential for quality control and fair market pricing, particularly when dealing with variable moisture content (MC) in agricultural residues. This study investigates the use of near-infrared (NIR) spectroscopy to predict the lower heating value (LHV) and ash content of sugarcane leaf pellets while minimizing the interference caused by moisture variability. Sixty-two samples were scanned using an NIR spectrometer over three week-long storage periods to get different MCs with the same sample. Additionally, variable selection methods such as a genetic algorithm (GA) and moisture-related wavelength exclusion were explored. The optimal model for LHV prediction was developed using GA-PLS regression (Method II), provided a coefficient of determination (R2) of 0.80, a root mean square error of calibration (RMSEc) of 595.80 J/g, and a ratio of performance to deviation (RPD) of 1.74, indicating fair predictive performance. The ash content model showed moderate accuracy, with a maximum R2 of 0.61 and an RPD of 1.40. These findings suggest that the variables selected via GA in Method II were not relevant to MC; as Method II provided the best result, this indicates a low impact of MC, which may influence model construction in the future. Moreover, the findings also highlight the potential of NIR spectroscopy, combined with appropriate spectral preprocessing and wavelength optimization, as a rapid, non-destructive tool for evaluating biomass quality, enabling more precise control in bioenergy production and biomass trading.

1. Introduction

Currently, the demand for energy is significantly increasing, especially for clean and renewable energy, which will replace the use of fossil fuels. This helps solve the issues of the greenhouse effect, global warming, and PM 2.5 pollution. Renewable energy, particularly the use of biomass for energy production, is the most popular energy type due to its sustainability, as it is considered a replenishable resource. The use of renewable energy is considered carbon neutral [1,2]. Biomass is primarily sourced from fast-growing trees or agricultural waste products.

Sugarcane is an important economic crop globally, used for sugar production. For instance, in Thailand, sugarcane is grown over approximately 4.9 million acres, typically leaving behind 10 tons per acre of sugarcane leaves, which amounts to a significant quantity [3]. With the growing demand to reduce the burning of sugarcane leaves, both nationally and globally, there has been a market for purchasing sugarcane leaves for sale to biomass power plants. This helps reduce the burning of sugarcane in the fields while adding value to agricultural waste products.

For commercial purposes, the price of sugarcane leaves is set only by weight, which is influenced by moisture content, and this results in different levels of income. The parameters that indicate the quality of biomass are its calorific value and ash content. If the moisture content (MC) of sugarcane leaves is high, the heating value (HV) is low and the weight is high [4]. Similarly, if high-moisture sugarcane leaf bales are sold, they will have a lower energy content and a higher weight for the same volume. If purchasing decisions are based solely on weight, both buyers and farmers selling low-moisture sugarcane leaves will face significant price disadvantages.

The heating value consists of two components: the higher heating value (HHV) and the lower heating value (LHV). The HHV accounts for the total amount of energy released during combustion, including the latent heat of vaporization of water. In contrast, the LHV excludes this latent heat, resulting in a lower reported energy output. Essentially, the LHV reflects the energy potential of a substance under the assumption that it contains no moisture [5]. The LHV is more appropriate than the HHV for pricing sugarcane leaves, as it eliminates the confounding influence of variable moisture content. Currently, the trade in compressed sugarcane leaves is based solely on weight, which allows bales with high MC and contamination to be valued equally to cleaner, drier ones. This practice results in an unfair pricing system. Therefore, a rapid and reliable method for determining LHV is essential to ensure more accurate and equitable valuation in commercial transactions.

Near-infrared (NIR) spectroscopy is emerging as a powerful tool for evaluating the internal quality of food, agricultural products, and even biomass [6,7,8]. Its appeal lies in its speed, affordability, and versatility, making it ideal for process optimization, advanced control, and product improvement [9,10]. These advantages have extended beyond food and agriculture, finding applications in various industries to assess combustion characteristics [10]. Notably, the biofuel and bioenergy sectors are increasingly harnessing NIR techniques to predict biomass quality attributes accurately [8,9]. Posom et al. [6] used NIR to check the quality of pelletized biomass, including the MC, volatile matter, fixed carbon content, and ash content; it is a fast verification method, using energy values as an index for determining pricing together with weight. However, the current pricing system only uses weight. However, if the biomass has a high MC or contains other impurities like sand, the weight increases, and using weight alone for pricing cannot accurately determine the true calorific value [11]. Therefore, factors that impact the energy value measured by NIR include moisture content and ash quantity. Shi et al. [12] defined the higher heating value (HHV) as “the amount of heat released from the combustion of a certain amount of fuel, assuming its combustion product water returned to the liquid state at the end of the measurement, taking the latent heat of vaporization of product water into account”, while the LHV is the heat released under conditions where the product water remains in vapor form and its latent heat of vaporization is not recovered. The HHV can be determined using a bomb calorimeter and estimated by calculating ultimate or proximate analysis data. The LHV can be theoretically calculated as a function of the HHV by subtracting moisture content [13]. Thus, the LHV represents the real energy content and is an important parameter for estimating combustion process design parameters. Under actual operating conditions, the LHV is more useful than the HHV [14], though the HHV is more frequently reported.

To ensure reliable predictive modeling, this study places an emphasis on the quality and consistency of the experiment. Unlike many previous works that rely primarily on modeling techniques, this research integrates rigorous experimental protocols including repeated NIR spectral acquisition over three weeks and destructive laboratory analyses of LHV and ash content to capture the inherent variability in biomass samples. The novelty of this approach lies in the combination of wavelength selection with systematically acquired, high-quality reference data. This strategy not only improves model accuracy but also reinforces the importance of experimental tests in generating robust calibration datasets, particularly when working with heterogeneous materials such as biomass. The methodology provides a foundation for more reliable and transferable NIR-based models under varying storage and moisture conditions.

Since the LHV is the actual energy value of a material with no moisture involved, difficulty arises when scanning samples with varying moisture content, as this will affect the absorbance values of the infrared waves. This causes a significant difference in absorbance, even for the same material, when moisture content varies. To develop a model capable of predicting the LHV, which indicates the energy value of a material if moisture is not involved, this study aimed to create a model to predict LHV and ash content on a dry basis by using spectral selection techniques to eliminate the interference caused by moisture.

2. Materials and Methods

2.1. Sample Preparation

A total of sixty-two samples were produced at the Agricultural Machinery Research and Post-harvest Technology Center, Faculty of Engineering, Khon Kaen University. These samples were made from agricultural waste materials and transformed into pellets using a palletization machine (KN-D-200, Tianjin Zhengyao Machinery, Tianjin, China). The weight of each sample was about 200 g. Moreover, because this study aimed to estimate the decrement of biomass pellet properties from the production process, standardized biomass pellet samples, with a standardized pellet diameter of 6 mm, were used, and the MC was lower than 10%.

2.2. Spectral Data Collection

The goal of this research was to determine whether the spectra obtained from scanning pelletized sugarcane leaves with varying MC can still accurately predict the LHV and ash content of the pellets. The research was to identify a modeling technique for predicting the LHV and ash content of pelletized sugarcane leaves, even when the samples have different moisture levels. A total of 62 samples, each weighing approximately 200 g, were initially assigned to Week 1 and scanned using a near-infrared (NIR) spectrometer. Following the initial scan, all samples were stored for one week to allow natural moisture content (MC) reduction through evaporation. These samples were then designated as Week 2 and subsequently scanned. The same procedure was repeated for another week, after which the samples were designated as Week 3 and scanned again. Each weekly assignment was treated as an individual sample, reflecting the progressive decrease in moisture content over time.

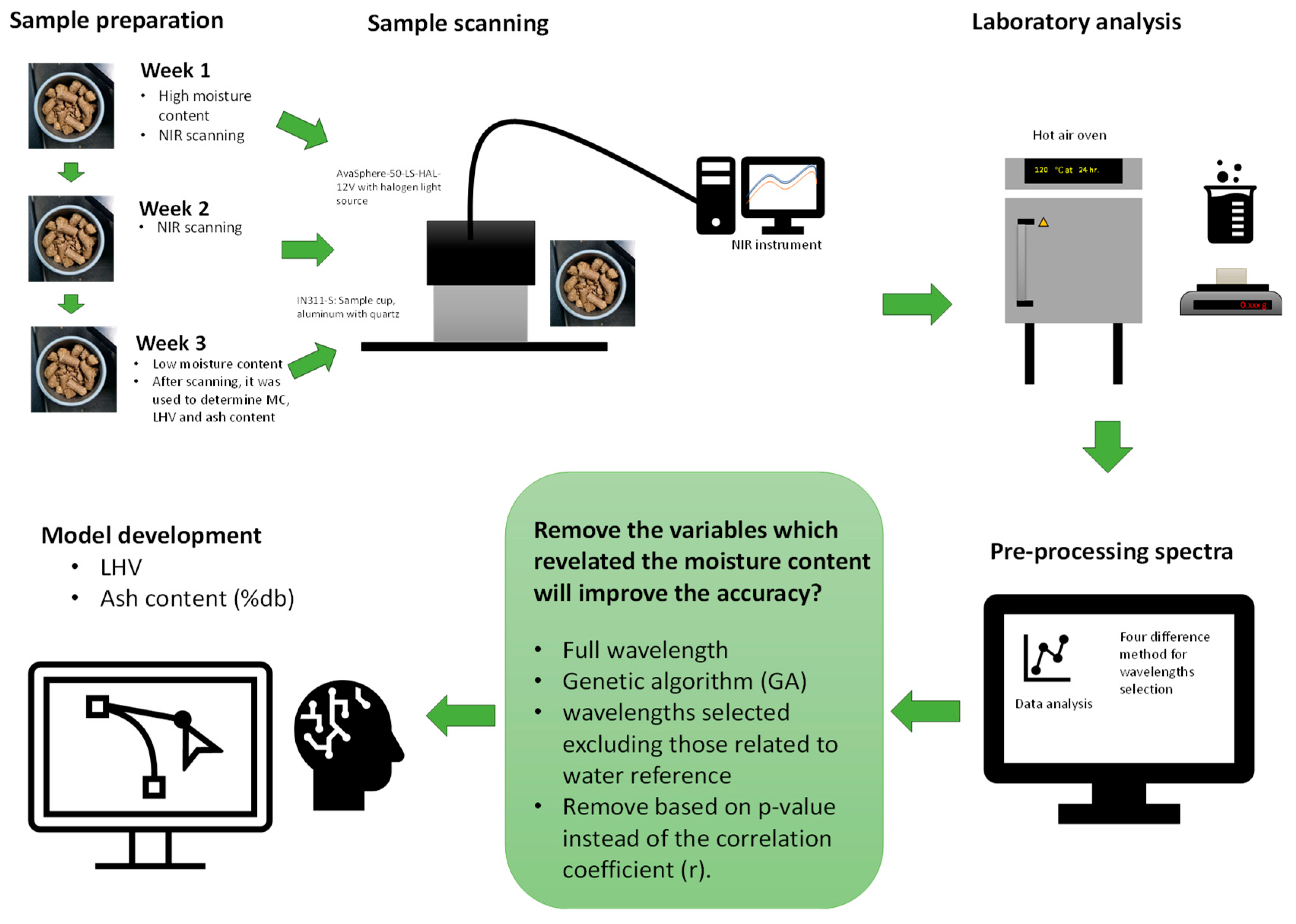

Each sample was placed in sample aluminum cup with quartz window (IN311-S, Bruker Cellular Analysis, Inc., Emeryville, CA, USA), then each sample was scanned using an integration time of 13.5 ms. The spectra were recorded in absorbance mode. Figure 1 shows the experiment set-up with an AvaSpec-NIR256/512-1.7-EVO spectrometer (AVANTES, Oude Apeldoornseweg, NS, Apeldoorn, The Netherlands) connected to integrating spheres, which are themselves connected to halogen light source (AvaSphere-50-LS-HAL-12V, Avantes, Oude Apeldoornseweg, NS, Apeldoorn, The Netherlands). This spectrometer provided bands of spectral data covering wavelengths from 860–1760 nm. Each sample was scanned ten times, and the resulting spectra were averaged into a single spectrum to match the reference values. These spectra obtained from the pellets were averaged to generate one spectrum.

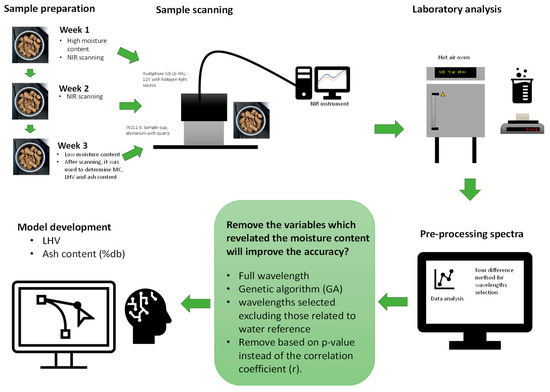

Figure 1.

Schematic illustration of the present study.

2.3. Reference Analysis

2.3.1. Moisture Content

The moisture content (MC) of the pellet samples was identified to develop the prediction model. The MC of the pellet samples was measured each week, then the pellet samples were placed in a plastic bag and weighed using a digital balance (ATX224, Shimadzu, Kyoto, Japan). After that, each sample was held at room temperature for about a week. The sample was then scanned again, placed in a plastic bag, and the weight loss was measured. This process was repeated for three weeks. In the final week, each sample was scanned, placed into a metal cup, and then put into a drying hot air oven (UF75, Memmert, Germany) and dried at 105 °C for 24 h until it reached a constant weight. The MC was calculated using the following Equation (1).

where W is the weight of the sample before drying and D is the weight of the sample after drying. Each sample was measured in duplicate. The MC calculated above is based on the weight loss after oven drying at 105 °C, which primarily removes free and physically bound water. However, it does not account for chemically bound hydrogen, which can persist in the biomass. While this residual hydrogen typically represents a small fraction, it may influence certain thermochemical properties and should be considered in more detailed elemental or combustion analyses. Nonetheless, for the purpose of NIR calibration and standard moisture determination.

2.3.2. Lower Heating Value

After scanning the Week 3 samples, each pellet sample was ground and then used to determine the analyte including the higher heating value (HHV) using an automatic dynamic bomb calorimeter (IKA® Werke, C5000, Staufen im Breisgau, Germany). The HHV can convert to the LHV directly when the moisture content is known, so the LHV was then determined as follows [15,16].

LHV = HHV − 2.443 × MC

2.3.3. Ash Content

After scanning the Week 3 samples, the ash content of each sample was also determined following the AOAC Official Methods of Analysis 21st ed., 2019, method 925.51. The ash content was obtained in terms of a wet basis. Then, it was calculated on a dry basis following Equation (3) as shown below.

where Ash content (%) is calculated from wet basis to dry basis and MC is the moisture content.

2.4. Standard Error of Laboratory of References Values

Before determining the MC, LHV, and ash content, the pellet samples were used to calculate the standard error of the laboratory (SEL). Based on duplicate analyses, the SEL for each parameter was computed according to Fearn [17] using the following:

where is the difference between duplicates and is the number of samples in the evaluation.

2.5. Model Development

In this study, the LHV, HHV, and ash content were determined in the final week of the experimental period. A total of 62 biomass samples were analyzed. NIR spectral data were collected from the same set of samples across three consecutive weeks, yielding 186 spectra (62 samples × 3 weeks).

The reference values obtained from the final week were assigned to the corresponding spectra of each sample from all three time points. Thus, each set of three spectra for a given sample shared the same reference value. This approach enabled the use of all 186 spectra for model development, improving the robustness and generalizability of the predictive models. Figure 1 shows the schematic diagram of the experiment. After collecting the NIR spectra and corresponding measured values, the spectra were extracted.

Prior to creating the calibration model, outliers in the spectra were found using principal component analysis (PCA). Standard values (Z-scores) for the pellet samples of LHV and ash content were computed to identify outliers in relation to the reference value for univariate outlier detection. A Z-score of greater than 3 or lower than −3 was considered an outlier [18,19], and that sample would then be removed. The NIR spectra exhibit notable differences, such as baseline offsets and high-frequency noise. Pre-treating the spectra was a standard procedure to maximize the performance of the calibration models. Consequently, several spectrum preprocessing methods were applied to eliminate the signal noise, including baseline offset correction and standard normal variate (SNV); first (D1) and second (D2) derivatives used Norris’s derivative with a gap and segment of 5 each [20].

After scanning the outliers, the samples were used to develop the calibration model via PLS regression. Then, the calibration set was developed by combining leave-one-out full cross-validation with partial least squares (PLS) regression. This allowed for the calculation of the ideal number of PLS factors for the model, or the point at which the root mean square error of cross-validation (RMSEcv) did not significantly decrease.

To optimize the prediction model, either the full wavelength or selected important wavelengths were used in this experiment. Details are shown below.

- Method I: This involved using the complete spectrum of wavelengths without filtering or selection. By including all available wavelengths, the model had access to the full range of spectral information. This approach may improve model accuracy but can also increase computational complexity and the risk of overfitting.

- Method II: This method used a genetic algorithm (GA) to select wavelengths relevant to water content. The variables not selected for water content were then used separately to develop models for the lower heating value (LHV) and ash content. This approach aimed to optimize variable selection for each target property.

- Method III: This method was applied to the wavelengths selected excluding those related to water reference [21,22,23]. It removed variables relevant to water in the ranges of 960–1024 nm and 1402–1512 nm. Then, remaining variables were used to develop the models.

- Method IV: This method removed variables following the coefficient of correlation (r) with water, selecting wavelengths excluding water-related bands with a p-value less than 0.05.

2.6. Model Performance Evaluation

The statistical metrics for the prediction model included the coefficient of determination (R2), root mean square error of calibration (RMSEc), root mean square error of leave-one-out cross validation (RMSEcv), and ratio of prediction to standard deviation (RPD).

The effectiveness of the NIR model was assessed using ratio of performance deviation (RPD) values. The RPD is a statistical metric used to evaluate the accuracy of predictive models, particularly in the context of time series forecasting and regression analysis. It compares the error of a predictions model to the range of the actual observed data. The RPD value is an indicator widely used in various agricultural applications [24]. Furthermore, according to Chang et al. [25], who used RPD categories help evaluate model performance for inhomogeneous materials, an RPD value below 1.4 indicates a non-reliable model, a value between 1.4 and 2 indicates a fair model, and a value above 2 signifies an excellent model. Several studies have utilized this scale, such as Wang et al. [26], who employed RPD when using portable NIR instruments to predict the soluble solids content (SSC) in European pears. In the biomass pellet and energy section, Li et al. [27] also used NIR spectroscopy techniques to measure the calorific value and ash content of sand shrubs.

3. Results and Discussion

3.1. NIR Spectra Profiles of Pellet Samples

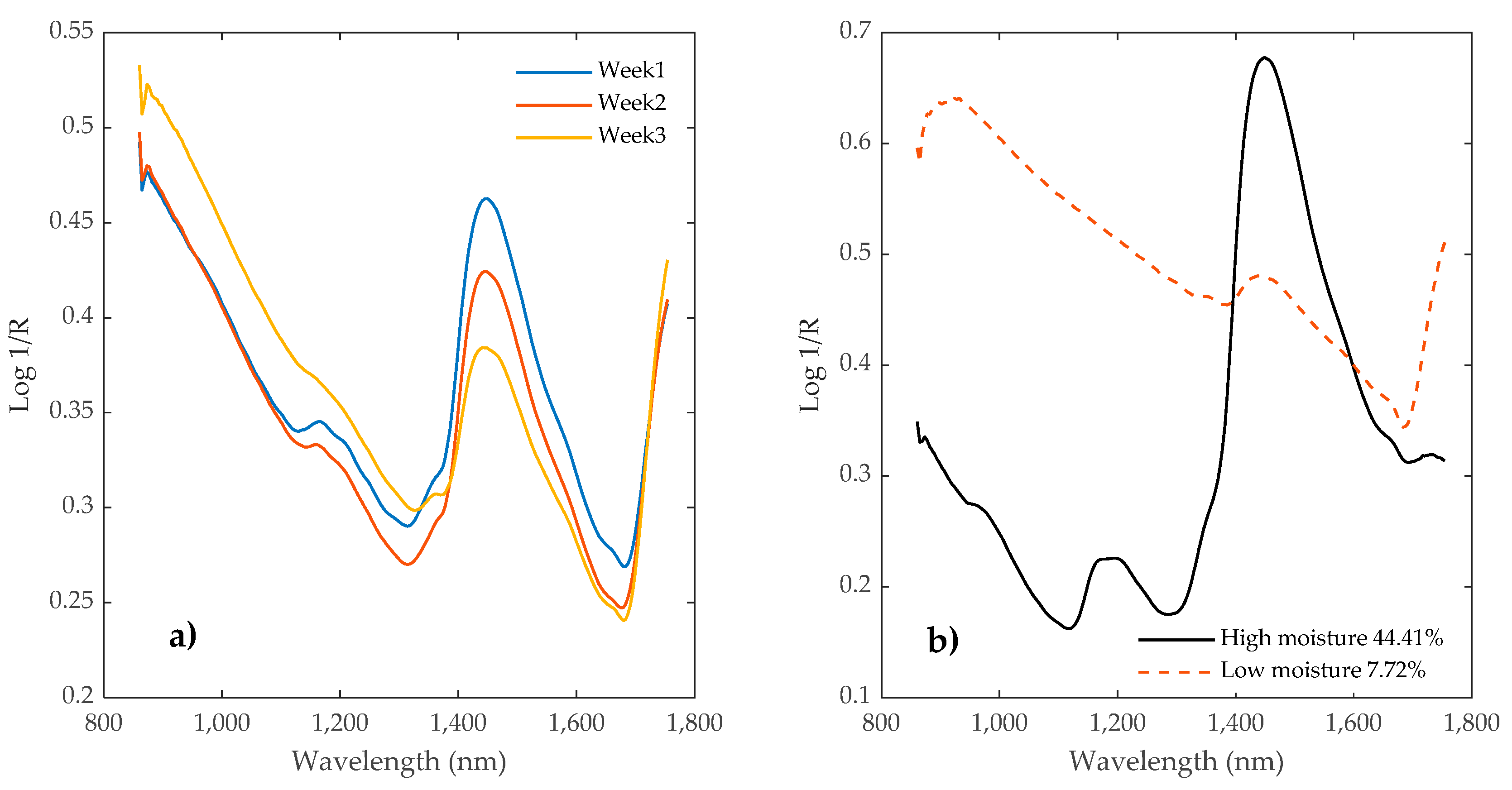

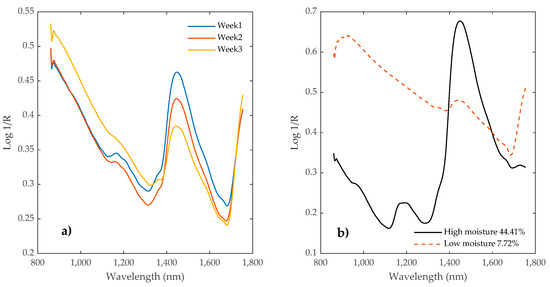

Figure 2 illustrates the NIR spectra, which were visualized by plotting the spectral data of wavelength and absorbance. The figure reveals that each wavelength, ranging from 860 to 1760 nm, represents a complex signal resulting from numerous overlapping observations. These overlaps occur due to the first and second overtones as well as the combination of fundamental vibrations. Figure 2a demonstrated the average spectra of pellets collected from different periods of time including Week 1, Week 2, and Week 3. At Week 1 they had the highest absorption compared to Week 2 and Week 3 because they had the highest moisture content. Figure 2b shows a sample at two moisture levels, high moisture (44.41%, solid black line) and low moisture (7.72%, dashed red line), demonstrating that distinct absorption features corresponding to water content are observable, particularly around 1450 nm, indicating strong sensitivity of the spectral response to moisture variation [28].

Figure 2.

Near-infrared (NIR) absorbance spectra expressed as Log(1/R). (a) Spectral profiles of samples measured at three weekly points, illustrating temporal variations in reflectance. (b) Comparison of spectral profiles for samples with high moisture content (44.41%) and low moisture content (7.72%), demonstrating the influence of moisture levels.

3.2. Statistical Data of LHV and Ash Content

Table 1 presents the statistical characteristics of MC, LHV, and ash content of sugarcane leaf pellets measured over three distinct storage periods. The table includes maximum, minimum, mean, and standard deviation (SD) values for each parameter. For Week 1, the MC ranged from 13.83% to 44.41%, with a mean of 22.67% and a standard deviation of 7.30%, indicating a wide variability in sample moisture at the initial stage. In Week 2, a similar pattern was observed, with MC values slightly reduced, ranging from 11.72% to 43.57% and the average value and SD were 21.96% and 6.01%, respectively. For Week 3, the MC had further decreased, showing a narrower range from 7.72% to 34.84% and reduced variability with an SD of 5.20%. This trend reflects progressive evaporation of the samples during storage. After scanning the Week 3 samples, these samples were measured for LHV and ash content. The LHV ranged from 11,984.00 to 18,300.50 J/g, with an average value of 15,973.78 J/g and an SD of 1368.38 J/g, demonstrating considerable variation in energy content. The ash content ranged from 2.21% to 28.77%, with a mean of 11.82% and SD of 6.22%, indicating a broad spread of mineral residue among the samples. Therefore, the decreasing MC across storage weeks suggests an evaporation effect, which was critical for improving energy quality. The data also displayed the intrinsic variability in LHV and ash content, which may be influenced by both the biomass composition and the residual moisture content. These findings emphasize the importance of monitoring storage conditions and accounting for MC when evaluating the fuel properties of biomass pellets.

Table 1.

Statistical characteristics of MC, LHV, and ash content at different time points.

Table 2 provides statistical data on total biomass pellet samples. This presents the main three parameters of biomass pellets, namely MC, LHV, and ash content. A substantial sample size of 186 pellet specimens was analyzed for MC and LHV, with ash content measured in 62 samples. For MC it exhibited considerable variability, ranging from 7.72% to 44.41%, with a mean value of 20.50%. This expected variance reflects different biomass sources, processing conditions, and storage environments. The relatively high average MC may impact combustion efficiency and energy density. The LHV ranged from 11,984.00 J/g to 18,300.50 J/g, which was a wide range. The SD of the LHV indicate significant energy content variability among different biomass pellet sources. Ash content analysis revealed considerable heterogeneity, with values spanning from 2.21% to 28.77% and averaging 12.04%. This wide range suggests diverse feedstock compositions, with high-ash samples potentially containing more bark, agricultural residues, or contaminants. The high maximum ash content would be problematic in many combustion applications due to increased fouling potential and reduced heating efficiency [29,30].

Table 2.

Statistical data on the MC, HHV, LHV, and ash content obtained from biomass pellets.

Table 3 presents the standard error of laboratory (SEL) measurements for three parameters of biomass pellets. These parameters assessed were MC, LHV, and ash content, all of which are critical for evaluating the quality and energy potential of biomass fuel. Each parameter was measured across 62 replicate samples to assess the consistency and reliability of the laboratory procedures.

Table 3.

Standard error of laboratory (SEL) for determining characteristics of biomass pellet.

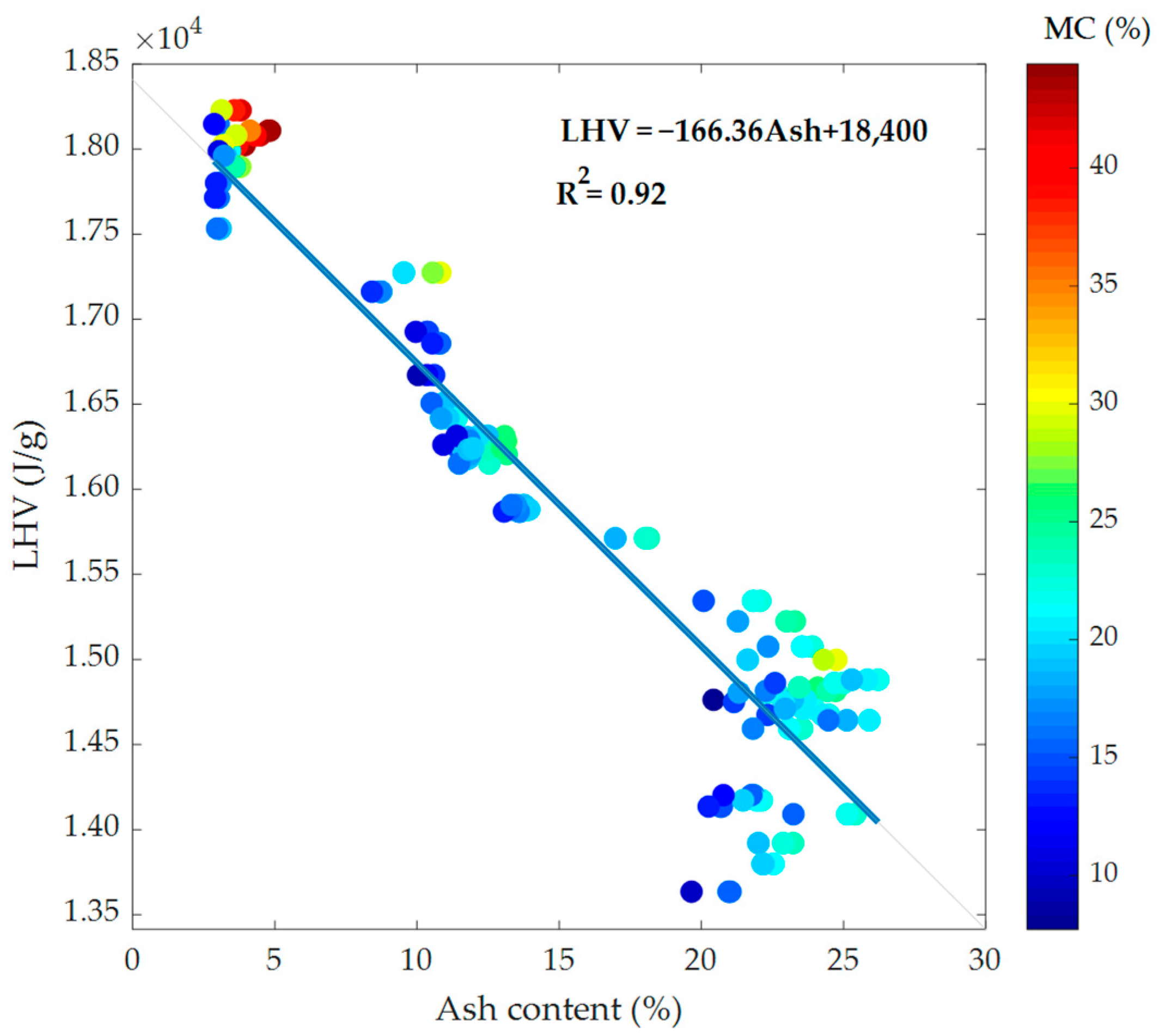

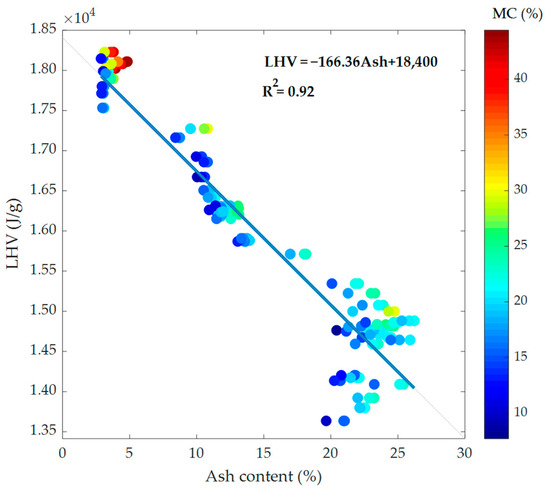

Figure 3 illustrates the relationship between LHV and ash content. The results show that the LHV decreased with increasing ash content, having an empirical model of LHV = −166.36 Ash + 18,400, and r2 of 0.92. The results are similar to the research of Nielsen et al. [31,32], who reported the energy content of biomass was determined by its calorific value, including HHV and LHV, which are influenced by biomass elemental composition, ash content, and MC. MC is the most important factor that influences the calorific value of biomass. Both moisture and ash content decrease the energy yield of biomass fuels. While moisture reduces energy due to evaporation losses, ash content reduces the proportion of combustible material. Therefore, biomass with low moisture and low ash content is preferred for efficient energy generation [33]. In addition, this study was similar to the reported of Posom et al. [4], who applied NIR spectroscopy to the evaluation of the moisture content (MC) and higher heating value (HHV) of Leucaena leucocephala pellets and found that the MC and HHV of Leucaena leucocephala pellets increased with decreasing moisture content.

Figure 3.

Lower heating value (LHV) as a function of ash content, colored by moisture content (MC). A negative correlation between LHV and ash content is observed, with moisture content also influencing the LHV.

3.3. PLS Regression Results of the LHV and Ash Content of the Pellet Samples

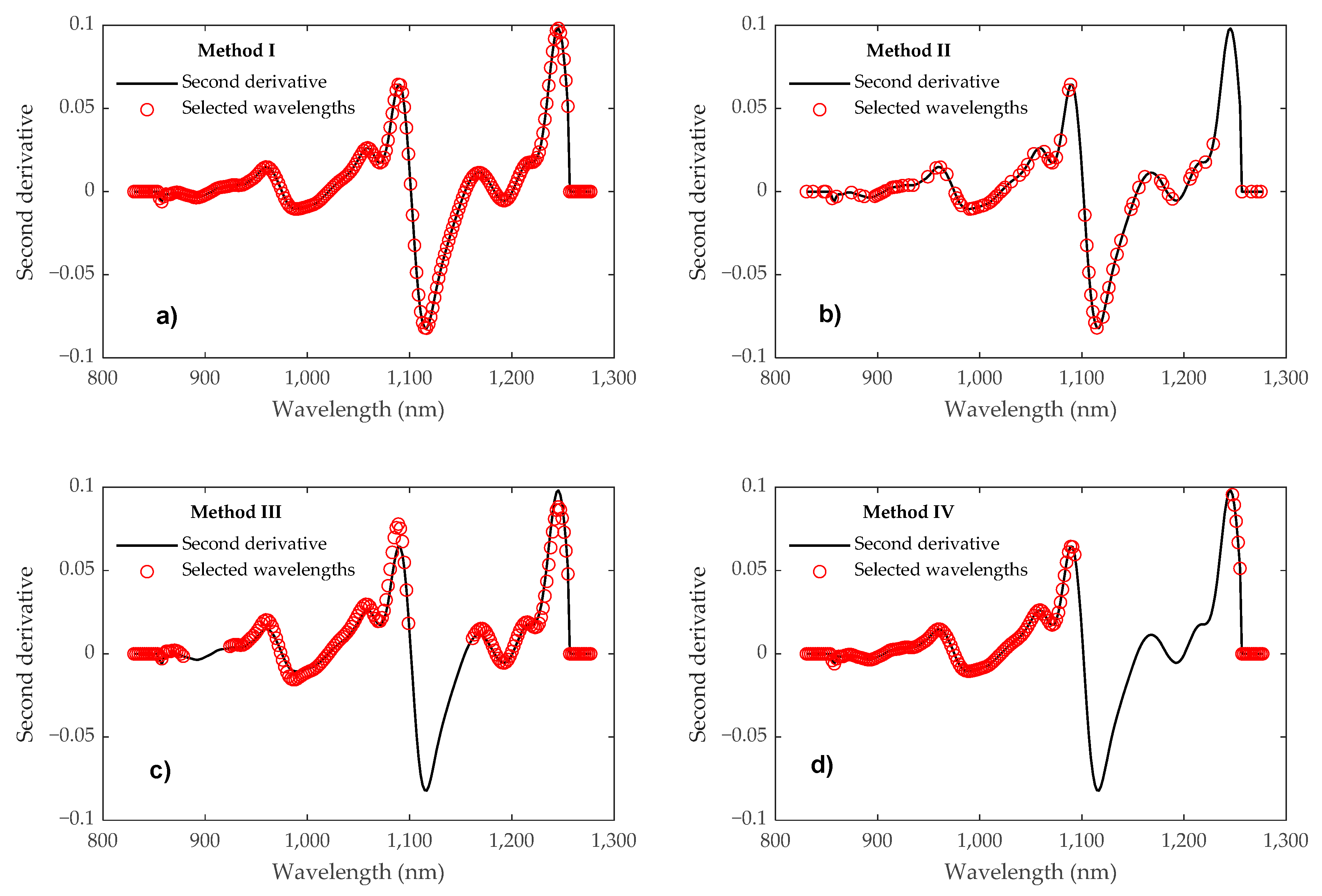

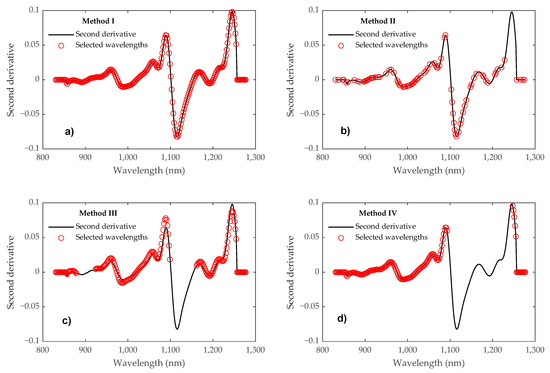

Figure 4 illustrates the average spectrum of biomass pellets in the 860–1760 nm region, highlighting selected wavelengths identified by four different variable selection methodologies. All these methods highlight the impact of wavelength selection techniques on spectral feature retention and model interpretability. Such comparative analyses were critical for optimizing NIR models used in biomass characterization, where precision and robustness are paramount.

Figure 4.

Average spectrum of biomass pellets showing selected wavelengths using four different methods within the 860–1760 nm region. (a) Method I: Full wavelength range used. (b) Method II: Wavelengths selected using a genetic algorithm (GA). (c) Method III: Wavelengths selected excluding those related to water. (d) Method IV: Wavelengths selected excluding water-related bands with a p-value less than 0.05.

The results of the PLS regression of the models for the LHV and ash content of the biomass pellet samples are shown in Table 4. The calibration model was developed using the wavelength range of 860–1760 nm. The results show the findings for the models developed using different methods, including Method I (developed from full wavelength with the number of variables reaching 225), Method II (developed using spectra selected from GA-PLS), Method III (full wavelength excluding wavelengths related to water [21,22,23], and Method IV (developed using the correlation between measured value and variables with p-value < 0.05). Several preprocessing methods were compared to evaluate their influence on the predictive performance of the models for LHV and ash content. The results show that the best performing models were developed using the second derivative (D2) technique, which outperformed models based on raw and SNV-preprocessed spectra. The superiority of the second derivative is attributed to its ability to enhance minor yet informative spectral features, suppress background noise, and eliminate baseline drifts caused by scattering effects. This preprocessing method increases spectral resolution and emphasizes chemically relevant variations, thereby improving model accuracy and robustness in capturing meaningful relationships between NIR spectra and LHV and ash content.

Table 4.

Results of PLS regression of biomass pellet LHV and ash content.

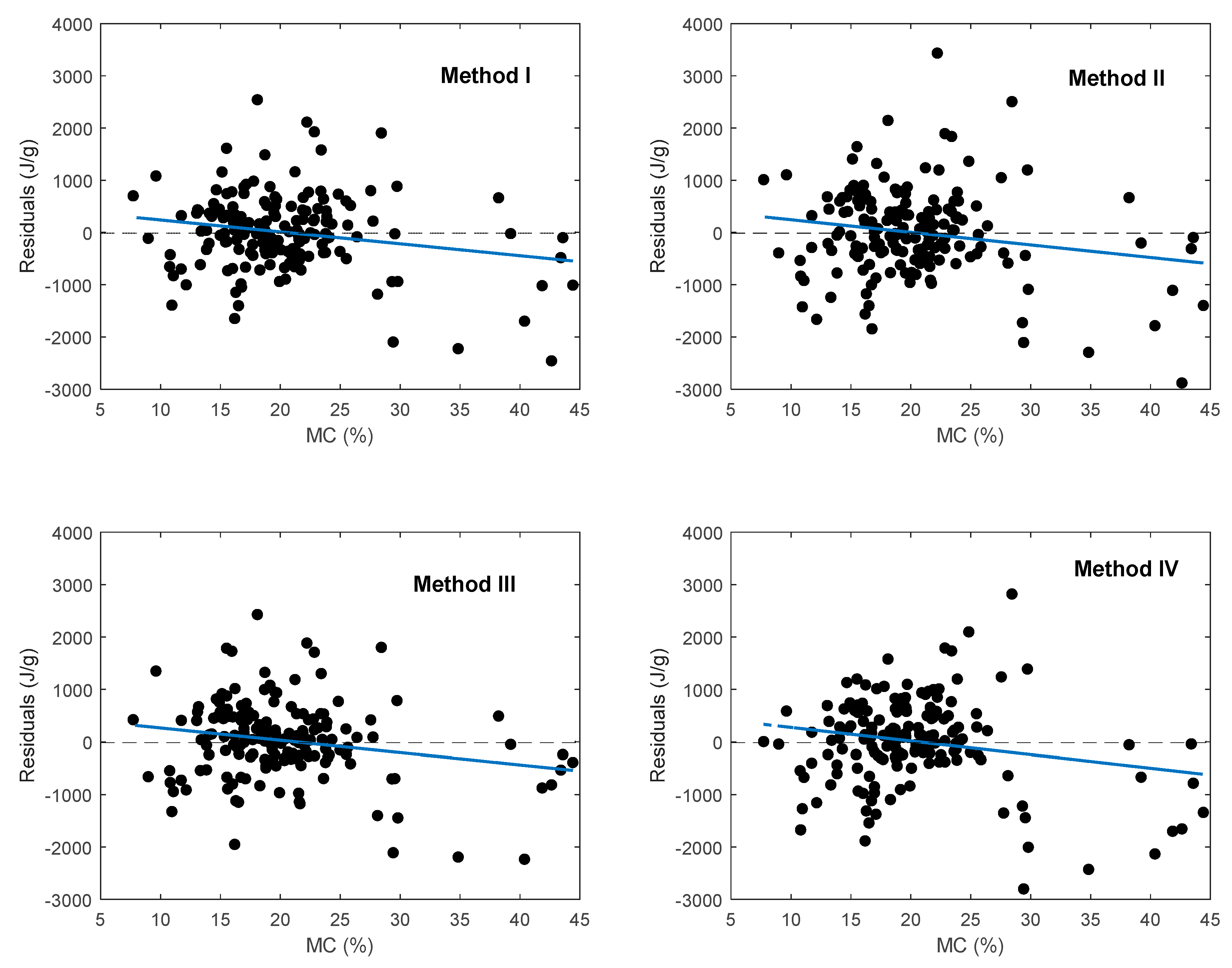

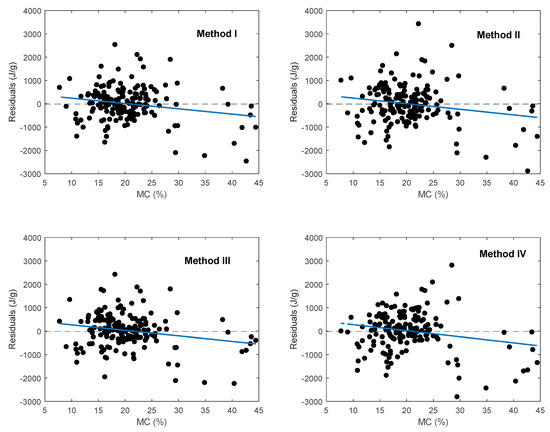

Furthermore, the influence of moisture content (MC) on model performance was evaluated by plotting MC against the residuals (measured values/predicted values), as shown in Figure 5. This analysis revealed that moisture content (MC) had minimal impact on the overall prediction accuracy. However, a slight trend was observed such that as MC increased. Notably, residuals tended to become negative when the moisture content exceeded approximately 27%, indicating a systematic underestimation by the model at higher moisture levels.

Figure 5.

Residual plots showing the distribution of prediction errors against moisture content for Methods I, II, III, and IV.

Specifically, a broader spread of residuals at the highpoint of the MC range, along with the presence of several outliers, suggests that the model’s predictive accuracy varies across the full spectrum of MC values.

These findings indicate that, while using a GA enhances overall model performance by selecting informative wavelengths, it may not fully capture non-linear or complex interactions between MC and spectral features. Additionally, other unmodeled sample attributes such as pellets size, bulk density, and the presence of co-varying chemical constituents might contribute to the residual variance.

Therefore, the residual structure observed highlights the inherent complexity of modeling heterogeneous biological materials. Although GA-based wavelength selection improves robustness, further refinement is necessary. Future work should explore the integration of non-linear modeling techniques or the inclusion of auxiliary variables to better account for the residual variance caused by MC and other confounding factors.

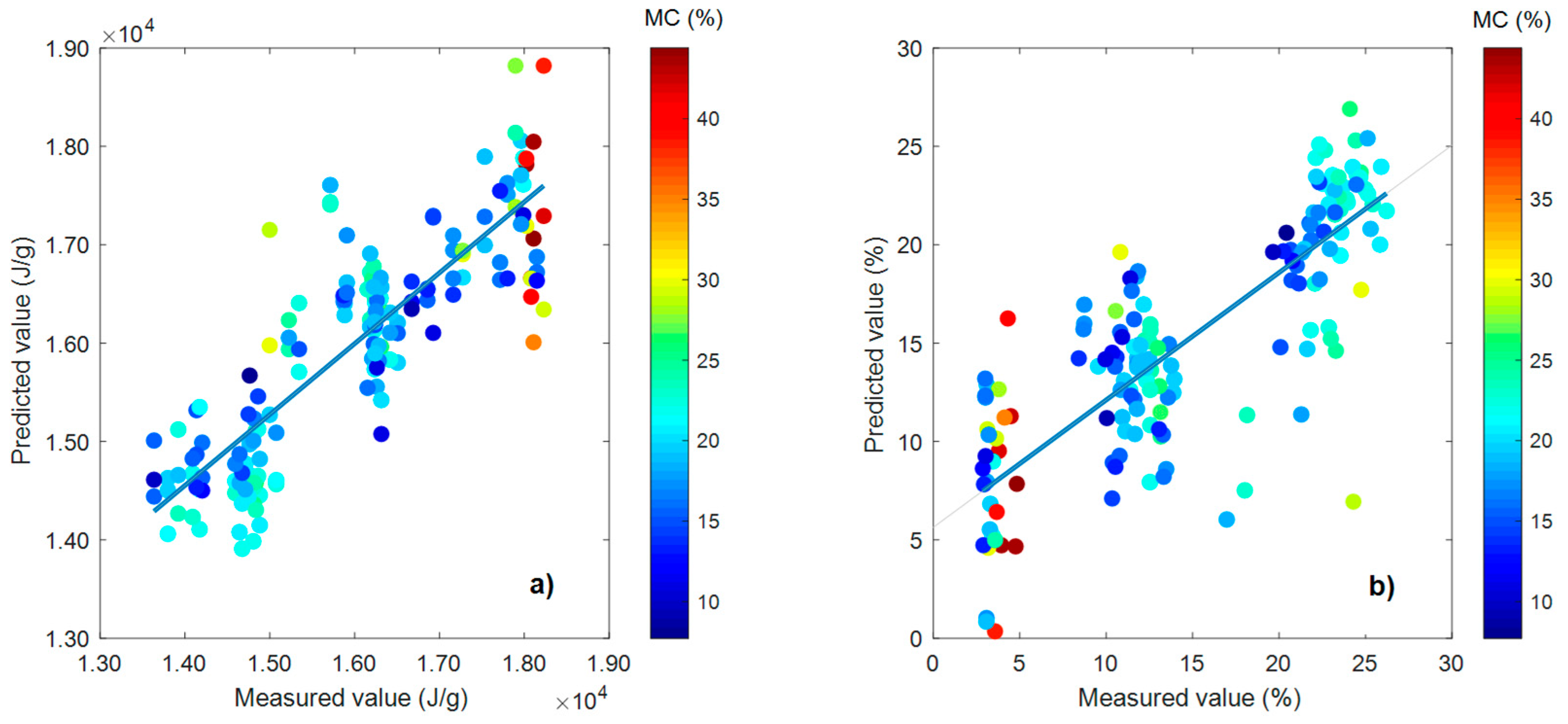

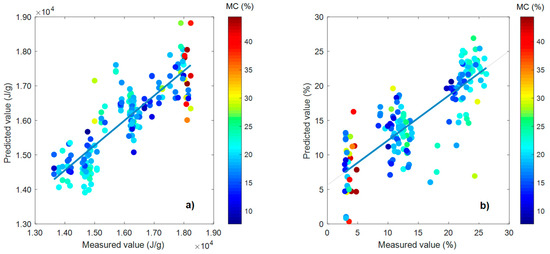

The results of the LHV model indicate that the performance of Methods I, II, and III was generally comparable, with R2cv values around 0.70 and RMSEp ranging from 728.21 to 735.98 J/g. Among these, Method II—developed using second derivative (D2) spectra combined with GA-selected wavelengths—demonstrated the best performance. This model achieved an R2 of 0.80, a standard error of calibration (SEC) of 595.80 J/g, an R2cv of 0.70, a standard error of cross-validation (SEcv) of 728.21 J/g, and an RPD of 1.74. The RPD of this model was 1.74, indicating that the model rates as fair [25]. Generally, Williams [34,35,36] explained that an RPD value above 4.1 is considered excellent, while Chang et al. [25,26] explained the values of RPD above 2 are acceptable for many applications [25,26]. This means that the model for predicted LHV was unreliable [25]. Meanwhile, the RPD was 1.74, indicating that the model rates as fair. Therefore, the model was fair for the approximation of heating value. Posom and Sirisomboon [11] also reported that their model for the heating value of J. curcas kernel oil extracted residue showed R2 of 0.860, RMSEp of 360 J/g, bias of 17.0 J/g, and RPD of 2.60. The model proved suitable for approximating the heating value because it displayed a low bias of about 0.10% of the mean value. Figure 6 displays the scatter plot of actual values and predicted values. In addition, the study of Sundaram et al. [37], who applied FT-NIR to estimate the MC of wood pellets, discovered that the best model was developed with the first derivative. It gave the accuracy of R2p and RMSEp as 0.95 and 0.78, respectively. This discrepancy was attributed to the high variation in MC within the pellet samples, which directly impacted the model’s accuracy. In contrast, the applied NIR technology to measure the calorific value such as the HHV and the LHV provided better results because the FT-NIR spectrometer provided a wide range of NIR spectra. According to Nakawajana et al. [38] and Gillespie et al. [39], these were explained by the vibration band of CH2 and HC=CH in the cellulose and lignin structure, which had a high impact on their HHV and LHV models. Hence, this result suggests that the model accuracy could be used to screen the properties of biomass pellets stored for different time periods.

Figure 6.

Predicted versus measured values for (a) energy content (J/g) and (b) ash content (%) of biomass samples using GA-PLS regression modeling. Each point represents a sample, color-coded by its moisture content (MC, %). Higher moisture levels tend to influence prediction accuracy, especially for ash content.

For ash content models, our comparative assessment of ash content prediction in biomass pellets using PLS regression across four modeling approaches (Methods I–IV) employed various spectral preprocessing techniques. The models were developed using NIR spectral data with differing numbers of variables (ranging from 87 to 225), depending on the method of variable selection. The overall model display indicates that ash content prediction from NIR spectra is challenging, with moderate to low predictive ability observed across all models and preprocessing techniques. The highest-performing configuration was obtained using Method I with D2 preprocessing, achieving an R2cv of 0.46, RMSEcv of 6.03%, and RPD of 1.36. This suggests limited model generalization and indicates that the model can be used only for rough screening or classification rather than accurate quantitative prediction [36]. For Method I, D2 preprocessing clearly outperformed other techniques, with raw, SNV, and baseline correction methods yielding R2cv values less than 0.43 and RPD values around 1.29–1.33. A similar trend was observed in Method II, where D2 preprocessing slightly improved the model (R2cv = 0.40, RPD = 1.30) over raw spectra and SNV preprocessing, which provided weaker performances with R2cv of 0.36–0.38. These results support the conclusion that D2 preprocessing enhances the spectral resolution and reduces baseline variations, which slightly improves the predictive modeling of ash content. Moreover, this result was similar to that of Posom and Sirisomboon [40]: to estimate ash content in bamboo, they achieved a model with R2, RMSEE, and RPD values of 0.51, 0.77%, 1.44, respectively. They comment that the NIR method is still not recommended. The NIR method should be able to predict the properties of bamboo samples which are suitable for achieving higher efficiency for the biomass conversion process. Williams [36] explained that, despite the limited predictive accuracy, further model development was considered unnecessary in that study. In the current analysis, the model’s poor performance was likely due to the characteristics of the samples used. Ash content does not effectively absorb NIR radiation, and the narrow distribution of reference ash content values constrained the model’s ability to generalize. As a result, the NIR-based prediction model for ash content was not found to be reliable under these conditions. Figure 6 presents the performance of the best model in predicting the LHV and ash content of the biomass samples. The scatter plots depict the relationship between predicted and experimentally measured values for each property.

The limited success of ash content prediction may stem from the weak absorptive features of mineral components in the NIR region. Ash content-related compounds often exhibit low molar absorptivity, and their signals may be overshadowed by stronger organic overtones or noise in the spectra [27]. Additionally, ash content in biomass pellets may be influenced by several minor inorganic constituents, which complicate the calibration process due to their indirect and diffuse spectral representation.

Therefore, derivative-based preprocessing (particularly D2) slightly enhances model performance for ash content prediction, though the models remain insufficient for precise analytical applications. The low R2cv values below 0.46 and RPDs below 1.4 across all methods suggest that the current models are better suited for approximate classification rather than accurate quantification of ash content.

4. Conclusions

This study has reported the potential of NIR to monitor essential physicochemical characteristics of biomass pellets, including LHV and ash content, over three different storage durations. The experimental approach combined wavelength selection algorithms with spectral preprocessing techniques to reduce the influence of MC on model accuracy. Through a methodical comparison of various modeling methods, Method II, which integrated D2 preprocessing with GA wavelength selection, was identified as the most accurate for predicting LHV. Conversely, Method I used D2 preprocessing produced a more reliable model for estimating ash content. Notably, this research sheds light on how MC and its associated spectral interference affect biomass quality modeling. While the LHV model demonstrated moderate predictive capability suitable primarily for screening purposes, the ash content model presented stronger reliability and is applicable for quality control screening in industrial settings. Practically, these findings support the use of NIR technology as an efficient tool for onsite screening, quality monitoring, and process optimization in biomass and bioenergy industries. NIR spectroscopy could substantially reduce dependence on labor-intensive and costly traditional methods, thereby speeding up decision-making related to biomass management and storage. Additionally, the methodology presented here provides a valuable basis for future studies focused on enhancing model robustness under varying environmental and operational conditions.

Author Contributions

Conceptualization, K.M. and J.P.; methodology, K.M. and J.P.; software, K.M.; validation, K.P. and N.K.; formal analysis, K.M. and J.P.; investigation, K.M. and J.P.; resources, K.P. and N.K.; data curation, K.P. and N.K.; writing—original draft preparation, K.M. and J.P.; writing—review and editing, K.M. and J.P.; visualization N.K.; supervision, K.M. and J.P.; project administration, J.P.; funding acquisition, J.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research project is supported by Research and Graduate Studies, Khon Kaen University. Center for Alternative Energy Research and Development, Khon Kaen University, Thailand.

Data Availability Statement

The authors do not have permission to share data.

Acknowledgments

We would also like to thank the Department of Research and Graduate Studies, Khon Kaen University, Thailand, for their research support. We also would like to acknowledge the Agricultural Machinery Research and Post-harvest Technology Center, Faculty of Engineering, Khon Kaen University, for provided the material sample for this experiment. During the preparation of this work the authors used ChatGPT 4.o in order to check and correct grammatical errors. After using this tool/service, the authors reviewed and edited the content as needed and take full responsibility for the content of the publication.

Conflicts of Interest

The authors declare that they have no known conflicts of financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Abbreviations

| D1 | First Derivative |

| D2 | Second Derivative |

| GA | Genetic Algorithms |

| HHV | Higher Heating Value |

| LHV | Lower Heating Value |

| MC | Moisture Content |

| NIR | Near Infrared |

| PLS | Partial Least Squares |

| r | Coefficient of correlation |

| R2 | Coefficient of Determination |

| RMSEc | Root Mean Square Error of Calibration |

| RMSEcv | Root Mean Square Error of Cross-Validation |

| RPD | Ratio of Performance Deviation |

| SD | Standard Deviation |

| SEL | Standard Error of Laboratory |

| SNV | Standard Normal Variate |

References

- Fiorino, D.J. Renewable Energy. In Elgar Encyclopedia of Climate Policy; Edward Elgar Publishing: Cheltenham, UK, 2024; pp. 190–194. [Google Scholar] [CrossRef]

- Sakilu, O.B.; Chen, H. Realizing Carbon Neutrality in Top-Emitter Countries: Do Green Technology Innovation, Renewable Energy, Financial Development, and Environmental Tax Matters? Sustainability 2024, 17, 37. [Google Scholar] [CrossRef]

- Paopun, Y.; Thanomchat, P. Analysis of Biosilica in Sugarcane Leaves. Microsc. Microanal. Res. 2022, 35, 5–9. [Google Scholar]

- Posom, J.; Shrestha, A.; Saechua, W.; Sirisomboon, P. Rapid Non-Destructive Evaluation of Moisture Content and Higher Heating Value of Leucaena leucocephala Pellets Using Near Infrared Spectroscopy. Energy 2016, 107, 464–472. [Google Scholar] [CrossRef]

- Choi, H.L.; Sudiarto, S.I.A.; Renggaman, A. Prediction of Livestock Manure and Mixture Higher Heating Value Based on Fundamental Analysis. Fuel 2014, 116, 772–780. [Google Scholar] [CrossRef]

- Posom, J.; Sirisomboon, P. Evaluation of Lower Heating Value and Elemental Composition of Bamboo Using Near Infrared Spectroscopy. Energy 2017, 121, 147–158. [Google Scholar] [CrossRef]

- Skvaril, J.; Kyprianidis, K.G.; Dahlquist, E. Applications of Near-Infrared Spectroscopy (NIRS) in Biomass Energy Conversion Processes: A Review. Appl. Spectrosc. Rev. 2017, 52, 675–728. [Google Scholar] [CrossRef]

- Lestander, T.A.; Rhén, C. Multivariate NIR Spectroscopy Models for Moisture, Ash and Calorific Content in Biofuels Using Bi-Orthogonal Partial Least Squares Regression. Analyst 2005, 130, 1182–1189. [Google Scholar] [CrossRef]

- Pitak, L.; Laloon, K.; Wongpichet, S.; Sirisomboon, P.; Posom, J. Machine Learning-Based Prediction of Selected Parameters of Commercial Biomass Pellets Using Line Scan Near Infrared-Hyperspectral Image. Processes 2021, 9, 316. [Google Scholar] [CrossRef]

- Pitak, L.; Sirisomboon, P.; Saengprachatanarug, K.; Wongpichet, S.; Posom, J. Rapid Elemental Composition Measurement of Commercial Pellets Using Line-Scan Hyperspectral Imaging Analysis. Energy 2021, 220, 119698. [Google Scholar] [CrossRef]

- Posom, J.; Sirisomboon, P. Evaluation of the Moisture Content of Jatropha curcas Kernels and the Heating Value of the Oil-Extracted Residue Using Near-Infrared Spectroscopy. Biosyst. Eng. 2015, 130, 52–59. [Google Scholar] [CrossRef]

- Shi, H.; Mahinpey, N.; Aqsha, A.; Silbermann, R. Characterization, Thermochemical Conversion Studies, and Heating Value Modeling of Municipal Solid Waste. Waste Manag. 2016, 48, 34–47. [Google Scholar] [CrossRef]

- Cordero, T.; Marquez, F.; Rodriguez-Mirasol, J.; Rodriguez, J.J. Predicting Heating Values of Lignocellulosics and Carbonaceous Materials from Proximate Analysis. Fuel 2001, 80, 1567–1571. [Google Scholar] [CrossRef]

- Demirbas, A. Effects of Moisture and Hydrogen Content on the Heating Value of Fuels. Energy Sources Part A Recovery Util. Environ. Eff. 2007, 29, 649–655. [Google Scholar] [CrossRef]

- Komilis, D.; Kissas, K.; Symeonidis, A. Effect of Organic Matter and Moisture on the Calorific Value of Solid Wastes: An Update of the Tanner Diagram. Waste Manag. 2014, 34, 249–255. [Google Scholar] [CrossRef] [PubMed]

- Erdoğan, S. LHV and HHV Prediction Model Using Regression Analysis with the Help of Bond Energies for Biodiesel. Fuel 2021, 301, 121065. [Google Scholar] [CrossRef]

- Fearn, T. Calculating Standard Deviations. NIR News 2005, 16, 7–8. [Google Scholar] [CrossRef]

- Meier, K.J.; Brudney, J.L.; Bohte, J. Applied Statistics for Public and Nonprofit Administration; Cengage Learning: Boston, MA, USA, 2009; ISBN 0495501107. [Google Scholar]

- Cheepsomsong, T.; Sangwanangkul, P.; Puttipipatkajorn, A.; Terdwongworakul, A.; Puttipipatkajorn, A.; Kulmutiwat, S.; Phuangsombut, A. Multi-parameter Index for Durian Maturity and Its Prediction Using Miniature Near Infrared Spectrometer. Postharvest Biol. Technol. 2023, 205, 112487. [Google Scholar] [CrossRef]

- Hopkins, D.W. What Is a Norris Derivative? NIR News 2001, 12, 3–5. [Google Scholar] [CrossRef]

- Büning-Pfaue, H. Analysis of Water in Food by Near Infrared Spectroscopy. Food Chem. 2003, 82, 107–115. [Google Scholar] [CrossRef]

- Curcio, J.A.; Petty, C.C. The Near Infrared Absorption Spectrum of Liquid Water. J. Opt. Soc. Am. 1951, 41, 302–304. [Google Scholar] [CrossRef]

- Goldstein, R.; Penner, S.S. The Near-Infrared Absorption of Liquid Water at Temperatures between 27 and 209 °C. J. Quant. Spectrosc. Radiat. Transf. 1964, 4, 441–451. [Google Scholar] [CrossRef]

- Williams, P.; Norris, K. Near-Infrared Technology in the Agricultural and Food Industries, 2nd ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 1987. [Google Scholar]

- Chang, C.W.; Laird, D.A.; Mausbach, M.J.; Hurburgh, C.R. Near-Infrared Reflectance Spectroscopy–Principal Components Regression Analyses of Soil Properties. Soil Sci. Soc. Am. J. 2001, 65, 480–490. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.; Chen, Z.; Han, D. Development of Multi-Cultivar Models for Predicting the Soluble Solid Content and Firmness of European Pear (Pyrus communis L.) Using Portable Vis–NIR Spectroscopy. Postharvest Biol. Technol. 2017, 129, 143–151. [Google Scholar] [CrossRef]

- Li, Y.; Xu, H.; Lan, X.; Wang, J.; Su, X.; Bai, X.; Via, B.K.; Pei, Z. Predicting Calorific Value and Ash Content of Sand Shrub Using Vis-NIR Spectra and Various Chemometrics. Renew. Energy 2024, 230, 120805. [Google Scholar] [CrossRef]

- Osborne, B.G.; Fearn, T.; Hindle, P.H. Practical NIR Spectroscopy with Applications in Food and Beverage Analysis; Longman Scientific & Technical: Harlow, Essex, UK, 1993. [Google Scholar]

- Unchaisri, T.; Fukuda, S. Investigation of Ash Formation and Deposit Characteristics in CFB Co-Combustion of Coal with Various Biomass Fuels. J. Energy Inst. 2022, 105, 42–52. [Google Scholar] [CrossRef]

- Scown, C.D.; Baral, N.R.; Tanjore, D.; Rapp, V. Matching Diverse Feedstocks to Conversion Processes for the Future Bioeconomy. Curr. Opin. Biotechnol. 2023, 84, 103017. [Google Scholar] [CrossRef]

- Neacsu, A.; Gheorghe, D. Characterization of Some Co-Fired Agricultural By-Products for Energetic Use. J. Mex. Chem. Soc. 2022, 66, 408–420. [Google Scholar] [CrossRef]

- Nielsen, N.P.K.; Gardner, D.J.; Poulsen, T.; Felby, C. Importance of Temperature, Moisture Content, and Species for the Conversion Process of Wood Residues into Fuel Pellets. Wood Fiber Sci. 2009, 41, 414–425. [Google Scholar]

- Demirbas, A. Relationships Between Heating Value and Lignin, Moisture, Ash and Extractive Contents of Biomass Fuels. Energy Explor. Exploit. 2002, 20, 105–111. [Google Scholar] [CrossRef]

- Williams, P. Near-Infrared Technology—Getting the Best out of Light. In A Short Course in the Practical Implementation of Near-Infrared Spectroscopy for the User, 5.4 ed.; PDK Grain: Nanaimo, BC, Canada, 2010. [Google Scholar]

- Williams, P.; Manley, M.; Antoniszyn, J. Near Infrared Technology: Getting the Best out of Light; African Sun Media: Stellenbosch, South Africa, 2019; Available online: https://books.google.co.th/books?id=xSSyDwAAQBAJ (accessed on 23 March 2025).

- Williams, P. Near-Infrared Technology—Getting the Best out of Light, 5.0 ed.; PDK Grain: Nanaimo, BC, Canada, 2007. [Google Scholar]

- Sundaram, J.; Mani, S.; Kandala, C.V.K.; Holser, R.A. Application of NIR Reflectance Spectroscopy on Rapid Determination of Moisture Content of Wood Pellets. Am. J. Anal. Chem. 2015, 6, 923–932. [Google Scholar] [CrossRef]

- Nakawajana, N.; Posom, J.; Paeoui, J. Prediction of Higher Heating Value, Lower Heating Value and Ash Content of Rice Husk Using FT-NIR Spectroscopy. Eng. J. 2018, 22, 45–56. [Google Scholar] [CrossRef]

- Gillespie, G.D.; Everard, C.D.; McDonnell, K.P. Prediction of Biomass Pellet Quality Indices Using Near Infrared Spectroscopy. Energy 2015, 80, 582–588. [Google Scholar] [CrossRef]

- Posom, J.; Sirisomboon, P. Evaluation of the Higher Heating Value, Volatile Matter, Fixed Carbon and Ash Content of Ground Bamboo Using Near Infrared Spectroscopy. J. Near Infrared Spectrosc. 2017, 25, 301–310. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).