A Systematic Review of Mechanical Pretreatment Techniques of Wood Biomass for Bioenergy

Abstract

1. Introduction

Mechanical Pretreatment

2. Materials and Methods

3. Results

3.1. Initial Search Results and Data Collection

3.2. Duplicate Removal and Preliminary Screening

- Studies that focused on non-mechanical pretreatment methods, such as chemical, enzymatic, or thermochemical approaches (such as Song et al. [20]).

- Research unrelated to biofuel production, such as those exploring lignocellulosic biomass for applications in materials science, pharmaceuticals, or composite production (such as Patel et al. [46]).

- Papers discussing the characterization of biomass derived from algae and aquatic plants (such as Hütter et al. [47]).

3.3. Refinement of the Dataset and Final Selection

3.4. Manual Screening and Validation

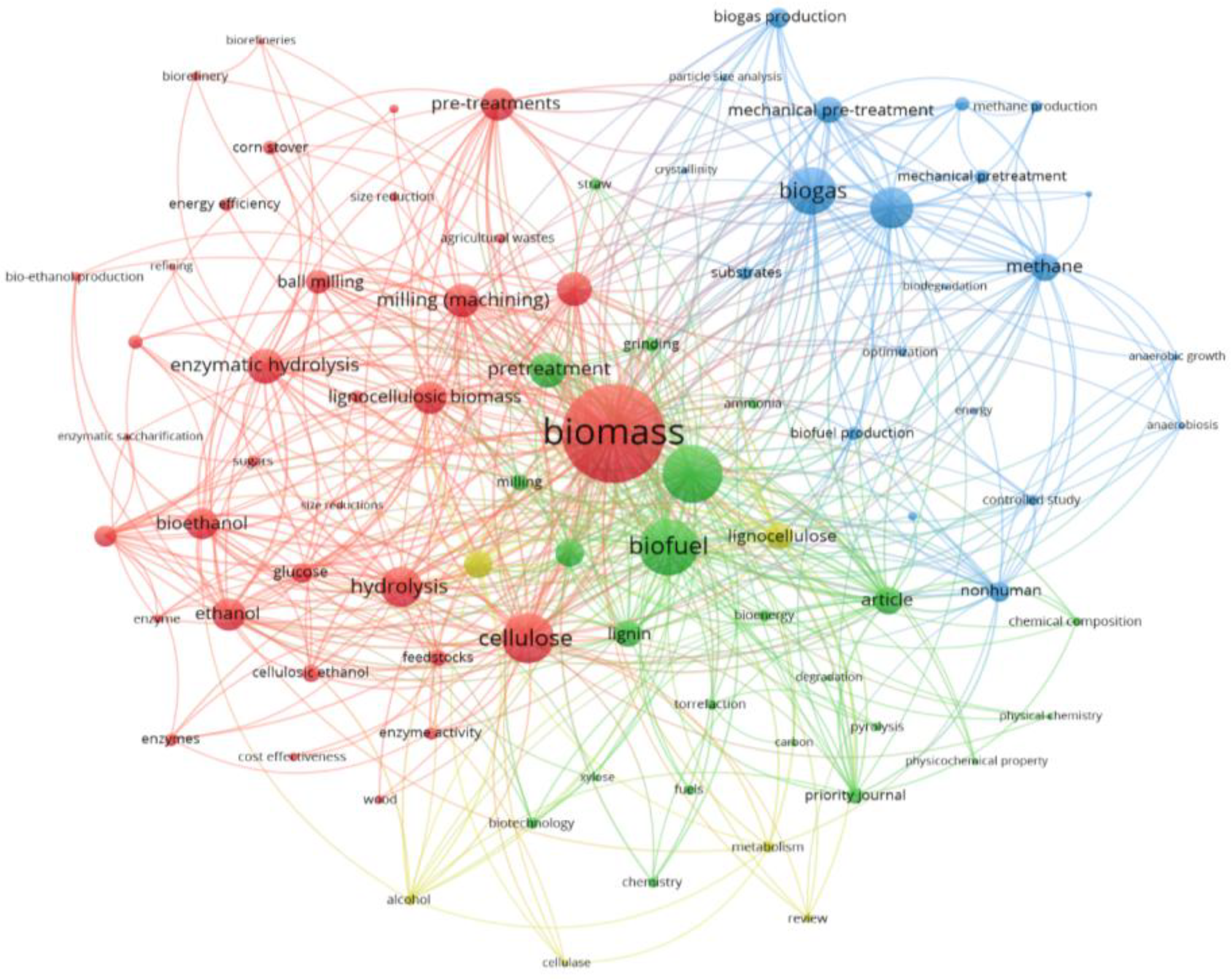

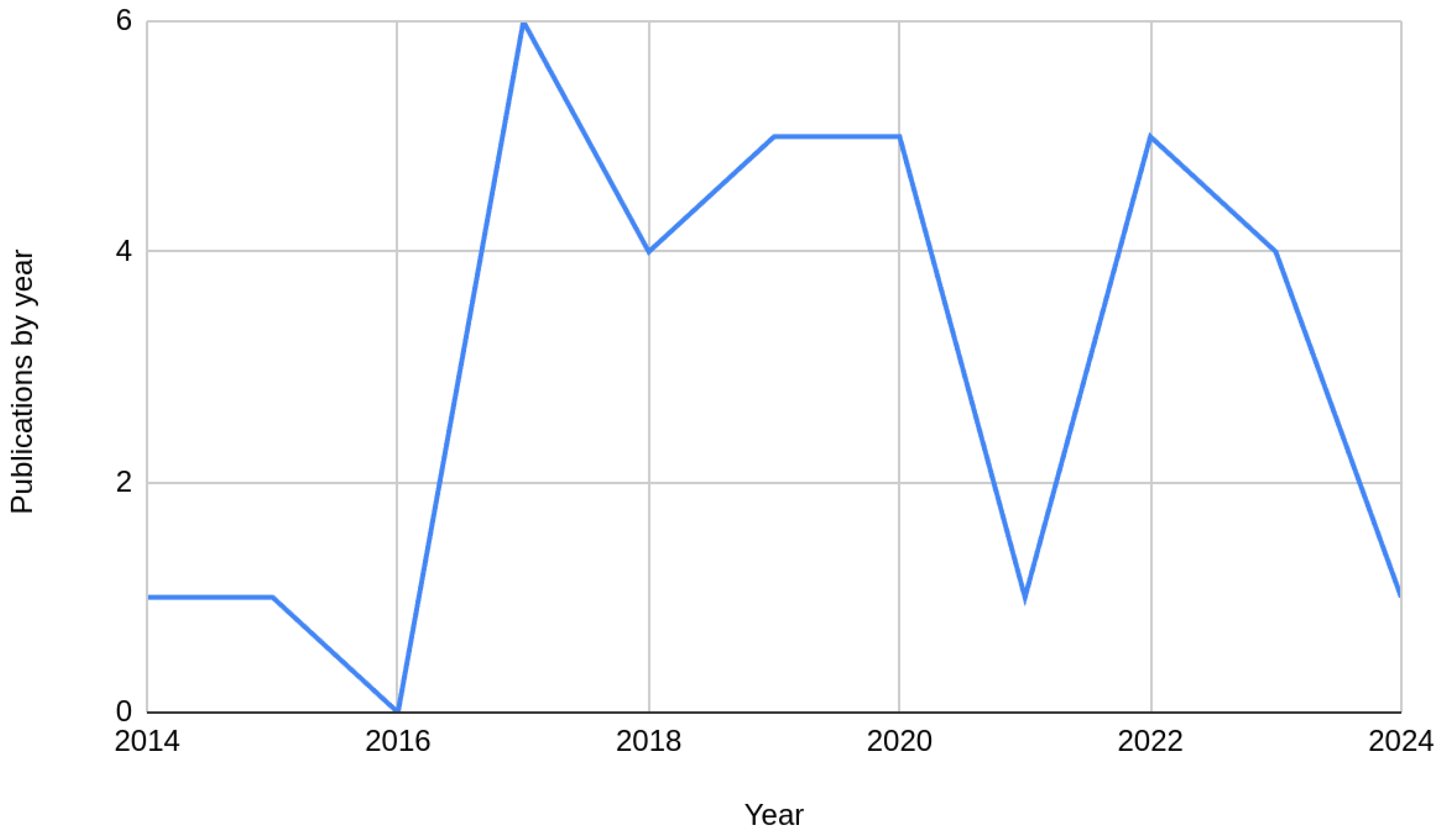

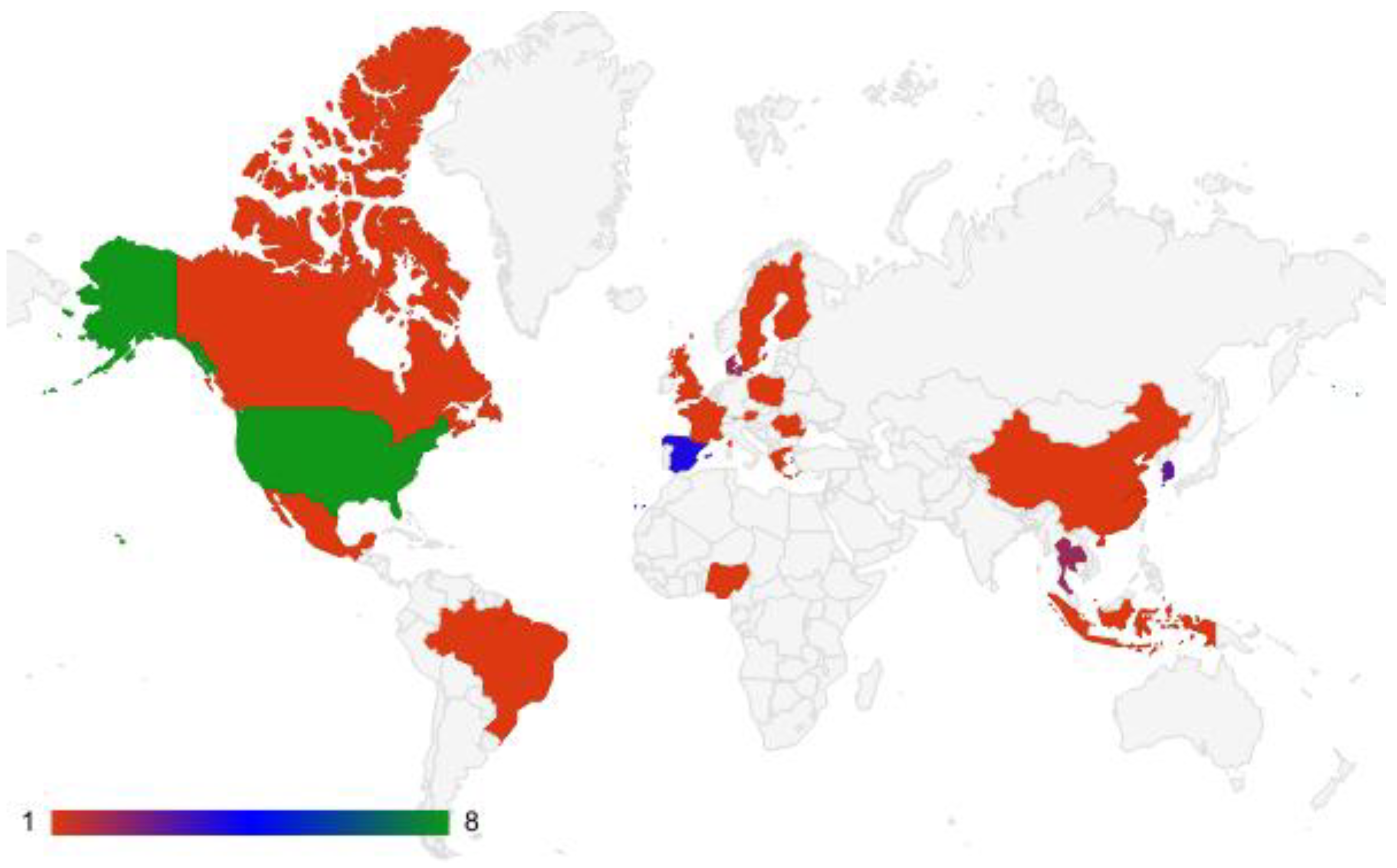

3.5. Analysis of Results

4. Discussion

4.1. Size Reduction

4.2. Densification

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, Z.; Ouyang, D.; Liu, D.; Zhao, X. Oxidative Pretreatment of Lignocellulosic Biomass for Enzymatic Hydrolysis: Progress and Challenges. Bioresour. Technol. 2023, 367, 128208. [Google Scholar] [CrossRef]

- Carnevale, M.; Santangelo, E.; Colantoni, A.; Paris, E.; Palma, A.; Vincenti, B.; Paolini, V.; Petracchini, F.; Salerno, M.; Di Stefano, V.; et al. Thermogravimetric Analysis of Olive Tree Pruning as Pyrolysis Feedstock. In Proceedings of the European Biomass Conference and Exhibition Proceedings, Virtual, 6–9 July 2020; pp. 581–584. [Google Scholar]

- Mujtaba, M.; Fernandes Fraceto, L.; Fazeli, M.; Mukherjee, S.; Savassa, S.M.; Araujo de Medeiros, G.; do Espírito Santo Pereira, A.; Mancini, S.D.; Lipponen, J.; Vilaplana, F. Lignocellulosic Biomass from Agricultural Waste to the Circular Economy: A Review with Focus on Biofuels, Biocomposites and Bioplastics. J. Clean. Prod. 2023, 402, 136815. [Google Scholar] [CrossRef]

- Singh Yadav, S.P.; Bhandari, S.; Bhatta, D.; Poudel, A.; Bhattarai, S.; Yadav, P.; Ghimire, N.; Paudel, P.; Paudel, P.; Shrestha, J.; et al. Biochar Application: A Sustainable Approach to Improve Soil Health. J. Agric. Food Res. 2023, 11, 100498. [Google Scholar] [CrossRef]

- Huang, C.; Li, R.; Tang, W.; Zheng, Y.; Meng, X. Improve Enzymatic Hydrolysis of Lignocellulosic Biomass by Modifying Lignin Structure via Sulfite Pretreatment and Using Lignin Blockers. Fermentation 2022, 8, 558. [Google Scholar] [CrossRef]

- Baksi, S.; Sarkar, U.; Villa, R.; Basu, D.; Sengupta, D. Conversion of Biomass to Biofuels through Sugar Platform: A Review of Enzymatic Hydrolysis Highlighting the Trade-off between Product and Substrate Inhibitions. Sustain. Energy Technol. Assess. 2023, 55, 102963. [Google Scholar] [CrossRef]

- Zhao, J.; Wei, X.; Li, L. The Potential for Storing Carbon by Harvested Wood Products. Front. For. Glob. Change 2022, 5, 1055410. [Google Scholar] [CrossRef]

- Chen, J.; Ma, X.; Liang, M.; Guo, Z.; Cai, Y.; Zhu, C.; Wang, Z.; Wang, S.; Xu, J.; Ying, H. Physical–Chemical–Biological Pretreatment for Biomass Degradation and Industrial Applications: A Review. Waste 2024, 2, 451–473. [Google Scholar] [CrossRef]

- Moodley, P.; Trois, C. 2—Lignocellulosic Biorefineries: The Path Forward. In Sustainable Biofuels; Ray, R.C., Ed.; Applied Biotechnology Reviews; Academic Press: Cambridge, MA, USA, 2021; pp. 21–42. ISBN 978-0-12-820297-5. [Google Scholar]

- Aslanzadeh, S.; Ishola, M.M.; Richards, T.; Taherzadeh, M.J. Chapter 1—An Overview of Existing Individual Unit Operations. In Biorefineries; Qureshi, N., Hodge, D.B., Vertès, A.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 3–36. ISBN 978-0-444-59498-3. [Google Scholar]

- Mankar, A.R.; Pandey, A.; Modak, A.; Pant, K.K. Pretreatment of Lignocellulosic Biomass: A Review on Recent Advances. Bioresour. Technol. 2021, 334, 125235. [Google Scholar] [CrossRef]

- Cavailles, J.; Vaca-Medina, G.; Wu-Tiu-Yen, J.; Labonne, L.; Evon, P.; Peydecastaing, J.; Pontalier, P.-Y. Impact of Thermomechanical Pretreatment by Twin-Screw Extrusion on the Properties of Bio-Based Materials from Sugarcane Bagasse Obtained by Thermocompression. Bioresour. Technol. 2024, 414, 131642. [Google Scholar] [CrossRef]

- Ibitoye, S.E.; Mahamood, R.M.; Jen, T.-C.; Loha, C.; Akinlabi, E.T. An Overview of Biomass Solid Fuels: Biomass Sources, Processing Methods, and Morphological and Microstructural Properties. J. Bioresour. Bioprod. 2023, 8, 333–360. [Google Scholar] [CrossRef]

- Fia, A.Z.; Amorim, J. Microwave Pretreatment of Biomass for Conversion of Lignocellulosic Materials into Renewable Biofuels. J. Energy Inst. 2023, 106, 101146. [Google Scholar] [CrossRef]

- Bianchini, L.; Alemanno, R.; Di Stefano, V.; Cecchini, M.; Colantoni, A. Soil Compaction in Harvesting Operations of Phalaris arundinacea L. Land 2022, 11, 1031. [Google Scholar] [CrossRef]

- Karthikeyan, P.K.; Bandulasena, H.C.H.; Radu, T. A Comparative Analysis of Pre-Treatment Technologies for Enhanced Biogas Production from Anaerobic Digestion of Lignocellulosic Waste. Ind. Crops Prod. 2024, 215, 118591. [Google Scholar] [CrossRef]

- Mirmohamadsadeghi, S.; Karimi, K.; Azarbaijani, R.; Parsa Yeganeh, L.; Angelidaki, I.; Nizami, A.-S.; Bhat, R.; Dashora, K.; Vijay, V.K.; Aghbashlo, M.; et al. Pretreatment of Lignocelluloses for Enhanced Biogas Production: A Review on Influencing Mechanisms and the Importance of Microbial Diversity. Renew. Sustain. Energy Rev. 2021, 135, 110173. [Google Scholar] [CrossRef]

- Sabeeh, M.; Zeshan; Liaquat, R.; Maryam, A. Effect of Alkaline and Alkaline-Photocatalytic Pretreatment on Characteristics and Biogas Production of Rice Straw. Bioresour. Technol. 2020, 309, 123449. [Google Scholar] [CrossRef]

- Anukam, A.; Berghel, J. Biomass Pretreatment and Characterization: A Review. In Biotechnological Applications of Biomass; Basso, T.P., Basso, T.O., Basso, L.C., Eds.; IntechOpen: Rijeka, Italy, 2020. [Google Scholar]

- Song, X.; Zhang, M.; Zhang, K.; Pei, Z.J.; Wang, D. Effects of Screen Size on Biochemical Conversion of Big Bluestem Biomass for Biofuel Production. Adv. Mater. Sci. Eng. 2015, 2015, 947350. [Google Scholar] [CrossRef]

- Bianchini, L.; Costa, P.; Dell’omo, P.P.; Colantoni, A.; Cecchini, M.; Monarca, D. An Industrial Scale, Mechanical Process for Improving Pellet Quality and Biogas Production from Hazelnut and Olive Pruning. Energies 2021, 14, 1600. [Google Scholar] [CrossRef]

- Di Domenico, G.; Bianchini, L.; Di Stefano, V.; Venanzi, R.; Lo Monaco, A.; Colantoni, A.; Picchio, R. New Frontiers for Raw Wooden Residues, Biochar Production as a Resource for Environmental Challenges. C 2024, 10, 54. [Google Scholar] [CrossRef]

- Carrere, H.; Antonopoulou, G.; Affes, R.; Passos, F.; Battimelli, A.; Lyberatos, G.; Ferrer, I. Review of Feedstock Pretreatment Strategies for Improved Anaerobic Digestion: From Lab-Scale Research to Full-Scale Application. Bioresour. Technol. 2016, 199, 386–397. [Google Scholar] [CrossRef]

- Huang, B.; Luo, C.; Liao, X. Realization Path of Digitalization Promoting Collaborative Innovation Development between Urban and Rural Areas. For. Chem. Rev. 2021, 118–128. [Google Scholar] [CrossRef]

- Chozhavendhan, S.; Rajamehala, M.; Karthigadevi, G.; Praveenkumar, R.; Bharathiraja, B. A Review on Feedstock, Pretreatment Methods, Influencing Factors, Production and Purification Processes of Bio-Hydrogen Production. Case Stud. Chem. Environ. Eng. 2020, 2, 100038. [Google Scholar] [CrossRef]

- Ortega, J.O.; Mora Vargas, J.A.; Metzker, G.; Gomes, E.; da Silva, R.; Boscolo, M. Enhancing the Production of the Fermentable Sugars from Sugarcane Straw: A New Approach to Applying Alkaline and Ozonolysis Pretreatments. Renew. Energy 2021, 164, 502–508. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, Q.; Jiang, Z.; Yang, X.; Ji, Y. Enzymatic Hydrolysis of Pretreated Soybean Straw. Biomass Bioenergy 2007, 31, 162–167. [Google Scholar] [CrossRef]

- Arce, C.; Kratky, L. Mechanical Pretreatment of Lignocellulosic Biomass toward Enzymatic/Fermentative Valorization. IScience 2022, 25, 104610. [Google Scholar] [CrossRef]

- Tsapekos, P.; Kougias, P.G.; Angelidaki, I. Mechanical Pretreatment for Increased Biogas Production from Lignocellulosic Biomass; Predicting the Methane Yield from Structural Plant Components. Waste Manag. 2018, 78, 903–910. [Google Scholar] [CrossRef] [PubMed]

- Hamed, A.; Xia, Y.; Saha, N.; Klinger, J.; Lanning, D.N.; Dooley, J.H. Particle Size and Shape Effect of Crumbler® Rotary Shear-Milled Granular Woody Biomass on the Performance of Acrison® Screw Feeder: A Computational and Experimental Investigation. Powder Technol. 2023, 427, 118707. [Google Scholar] [CrossRef]

- Viňáš, J.; Brezinová, J.; Brezina, J.; Hermel, P. Innovation of Biomass Crusher by Application of Hardfacing Layers. Metals 2021, 11, 1283. [Google Scholar] [CrossRef]

- Cho, S.K.; Ju, H.J.; Lee, J.G.; Kim, S.H. Alkaline-Mechanical Pretreatment Process for Enhanced Anaerobic Digestion of Thickened Waste Activated Sludge with a Novel Crushing Device: Performance Evaluation and Economic Analysis. Bioresour. Technol. 2014, 165, 183–190. [Google Scholar] [CrossRef] [PubMed]

- Lomovskiy, I.; Bychkov, A.; Lomovsky, O.; Skripkina, T. Mechanochemical and Size Reduction Machines for Biorefining. Molecules 2020, 25, 5345. [Google Scholar] [CrossRef]

- Gallego-García, M.; Moreno, A.D.; Manzanares, P.; Negro, M.J.; Duque, A. Recent Advances on Physical Technologies for the Pretreatment of Food Waste and Lignocellulosic Residues. Bioresour. Technol. 2023, 369, 128397. [Google Scholar] [CrossRef]

- Veluchamy, A.; Hebert, H.L.; Meng, W.; Palmer, C.N.; Smith, B.H. Systematic Review and Meta-Analysis of Genetic Risk Factors for Neuropathic Pain. Pain 2018, 159, 825–848. [Google Scholar] [CrossRef]

- Tabil, L.; Adapa, P.; Kashaninejad, M. Biomass Feedstock Pre-Processing—Part 2: Densification. In Biofuel’s Engineering Process Technology; dos Santos Bernardes, M.A., Ed.; IntechOpen: Rijeka, Italy, 2011. [Google Scholar]

- Albashabsheh, N.T.; Heier Stamm, J.L. Optimization of Lignocellulosic Biomass-to-Biofuel Supply Chains with Densification: Literature Review. Biomass Bioenergy 2021, 144, 105888. [Google Scholar] [CrossRef]

- Sarker, T.R.; Nanda, S.; Meda, V.; Dalai, A.K. Densification of Waste Biomass for Manufacturing Solid Biofuel Pellets: A Review. Environ. Chem. Lett. 2023, 21, 231–264. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, M.; Wang, D. A Comprehensive Investigation on the Effects of Biomass Particle Size in Cellulosic Biofuel Production. J. Energy Resour. Technol. 2018, 140, 041804. [Google Scholar] [CrossRef]

- Sithole, T.; Pahla, G.; Mashifana, T.; Mamvura, T.; Dragoi, E.-N.; Saravanan, A.; Sadeghifar, H. A Review of the Combined Torrefaction and Densification Technology as a Source of Renewable Energy. Alex. Eng. J. 2023, 82, 330–341. [Google Scholar] [CrossRef]

- Shankar Tumuluru, J.; Richard Hess, J. A Review on Biomass Densification for Energy Applications. Ind. Biotechnol. 2011, 7, 384–401. [Google Scholar] [CrossRef]

- Kamdem, B.M.; Lemaire, R.; Nikiema, J. Insight into the Production Factors Influencing the Physicochemical Properties of Densified Briquettes Comprising Wood Shavings and Rice Husk. Ind. Crops Prod. 2025, 223, 120134. [Google Scholar] [CrossRef]

- Clarke, S.; Preto, F. 11-035—Biomass Densification for Energy Production; Ministry of Agriculture, Food and Rural Affairs: Guelph, ON, Canada, 2011.

- Bajwa, D.S.; Peterson, T.; Sharma, N.; Shojaeiarani, J.; Bajwa, S.G. A Review of Densified Solid Biomass for Energy Production. Renew. Sustain. Energy Rev. 2018, 96, 296–305. [Google Scholar] [CrossRef]

- PRISMA Extension for Scoping Reviews (PRISMA-ScR): Checklist and Explanation. Ann. Intern. Med. 2018, 169, 467–473. [CrossRef]

- Patel, A.; Mikes, F.; Matsakas, L. An overview of current pretreatment methods used to improve lipid extraction from oleaginous microorganisms. Molecules 2018, 23, 1562. [Google Scholar] [CrossRef]

- Hütter, M.; Sailer, G.; Hülsemann, B.; Müller, J.; Poetsch, J. Impact of Thermo-Mechanical Pretreatment of Sargassum muticum on Anaerobic Co-Digestion with Wheat Straw. Fermentation 2023, 9, 820. [Google Scholar] [CrossRef]

- Lindner, C.; Thomsen, I.; Wahl, B.; Ugur, M.; Sethi, M.K.; Friedrichsen, M.; Smoczek, A.; Ott, S.; Baumann, U.; Suerbaum, S.; et al. Diversification of Memory B Cells Drives the Continuous Adaptation of Secretory Antibodies to Gut Microbiota. Nat. Immunol. 2015, 16, 880–888. [Google Scholar] [CrossRef]

- Bharadwaj, A.; Holwerda, E.K.; Regan, J.M.; Lynd, L.R.; Richard, T.L. Enhancing Anaerobic Digestion of Lignocellulosic Biomass by Mechanical Cotreatment. Biotechnol. Biofuels Bioprod. 2024, 17, 76. [Google Scholar] [CrossRef]

- Juneja, A.; Kumar, D.; Singh, V.K.; Yadvika; Singh, V. Chemical Free Two-Step Hydrothermal Pretreatment to Improve Sugar Yields from Energy Cane. Energies 2020, 13, 5805. [Google Scholar] [CrossRef]

- Gu, Y.M.; Kim, S.; Sung, D.; Sang, B.I.; Lee, J.H. Feasibility of Continuous Pretreatment of Corn Stover: A Comparison of Three Commercially Available Continuous Pulverizing Devices. Energies 2019, 12, 1422. [Google Scholar] [CrossRef]

- Victorin, M.; Davidsson, Å.; Wallberg, O. Characterization of Mechanically Pretreated Wheat Straw for Biogas Production. Bioenergy Res. 2020, 13, 833–844. [Google Scholar] [CrossRef]

- Wang, Q.; Han, K.; Gao, J.; Li, H.; Lu, C. The Pyrolysis of Biomass Briquettes: Effect of Pyrolysis Temperature and Phosphorus Additives on the Quality and Combustion of Bio-Char Briquettes. Fuel 2017, 199, 488–496. [Google Scholar] [CrossRef]

- Font, R.; Villar, E.; Garrido, M.A.; Moreno, A.I.; Gómez-Rico, M.F.; Ortuño, N. Study of the Briquetting Process of Walnut Shells for Pyrolysis and Combustion. Appl. Sci. 2023, 13, 6285. [Google Scholar] [CrossRef]

- Hammado, N.; Utomo, S. Budiyono Characteristic Lignocellulose of Sago Solid Waste for Biogas Production. J. Appl. Eng. Sci. 2020, 18, 157–164. [Google Scholar] [CrossRef]

- Gu, Y.M.; Kim, H.; Sang, B.-I.; Lee, J.H. Effects of Water Content on Ball Milling Pretreatment and the Enzymatic Digestibility of Corn Stover. Water-Energy Nexus 2018, 1, 61–65. [Google Scholar] [CrossRef]

- Díaz-González, A.; Luna, M.Y.P.; Morales, E.R.; Saldaña-Trinidad, S.; Blanco, L.R.; de la Cruz-Arreola, S.; Pérez-Sariñana, B.Y.; Robles-Ocampo, J.B. Assessment of the Pretreatments and Bioconversion of Lignocellulosic Biomass Recovered from the Husk of the Cocoa Pod. Energies 2022, 15, 3544. [Google Scholar] [CrossRef]

- Ziemiński, K.; Kowalska-Wentel, M. Effect of Different Sugar Beet Pulp Pretreatments on Biogas Production Efficiency. Appl. Biochem. Biotechnol. 2017, 181, 1211–1227. [Google Scholar] [CrossRef]

- Al Afif, R.; Pfeifer, C. Enhancement of Methane Yield from Cotton Stalks by Mechanical Pre-Treatment. Carbon. Resour. Convers. 2021, 4, 164–168. [Google Scholar] [CrossRef]

- Dahunsi, S.O. Mechanical Pretreatment of Lignocelluloses for Enhanced Biogas Production: Methane Yield Prediction from Biomass Structural Components. Bioresour. Technol. 2019, 280, 18–26. [Google Scholar] [CrossRef] [PubMed]

- Phojaroen, J.; Jiradechakorn, T.; Kirdponpattara, S.; Sriariyanun, M.; Junthip, J.; Chuetor, S. Performance Evaluation of Combined Hydrothermal-Mechanical Pretreatment of Lignocellulosic Biomass for Enzymatic Enhancement. Polymer 2022, 14, 2313. [Google Scholar] [CrossRef]

- Raud, M.; Orupõld, K.; Rocha-Meneses, L.; Rooni, V.; Träss, O.; Kikas, T. Biomass Pretreatment with the Szego MillTM for Bioethanol and Biogas Production. Processes 2020, 8, 1327. [Google Scholar] [CrossRef]

- Barakat, A.; Mayer-Laigle, C.; Solhy, A.; Arancon, R.A.D.; De Vries, H.; Luque, R. Mechanical Pretreatments of Lignocellulosic Biomass: Towards Facile and Environmentally Sound Technologies for Biofuels Production. RSC Adv. 2014, 4, 48109–48127. [Google Scholar] [CrossRef]

- Zhang, H.; Fredriksson, M.; Mravec, J.; Felby, C. Hydration of Straw Briquette. BioResources 2017, 12, 9024–9037. [Google Scholar] [CrossRef]

- San Miguel, G.; Fernández-Olmedilla, D.; Sánchez-Godoy, F. Drying of Prickly Pear (Opuntia Ficus-Indica (L.) Miller) and Its Potential as a Solid Biofuel. Agronomy 2022, 12, 2231. [Google Scholar] [CrossRef]

- de Oliveira e Silva, A.; Garcia, F.P.; Perazzini, M.T.B.; Perazzini, H. Design and Economic Analysis of a Pre-Treatment Process of Coffee Husks Biomass for an Integrated Bioenergy Plant. Environ. Technol. Innov. 2023, 30, 103131. [Google Scholar] [CrossRef]

- Nahar, N.; Pryor, S.W. Effects of Reduced Severity Ammonia Pretreatment on Pelleted Corn Stover. Ind. Crops Prod. 2017, 109, 163–172. [Google Scholar] [CrossRef]

- Wolfrum, E.J.; Nagle, N.J.; Ness, R.M.; Peterson, D.J.; Ray, A.E.; Stevens, D.M. The Effect of Biomass Densification on Structural Sugar Release and Yield in Biofuel Feedstock and Feedstock Blends. Bioenergy Res. 2017, 10, 478–487. [Google Scholar] [CrossRef]

- Torreiro, Y.; Pérez, L.; Piñeiro, G.; Pedras, F.; Rodríguez-Abalde, A. The Role of Energy Valuation of Agroforestry Biomass on the Circular Economy. Energies 2020, 13, 2516. [Google Scholar] [CrossRef]

- Tao, L.; Junting, P.; Xi, M.; Hailong, H.; Yan, L.; Xia, X.; Ruyi, H.; Zili, M. Improving Agricultural Straw Preparation Logistics Stream in Bio-Methane Production: Experimental Studies and Application Analysis. 3 Biotech. 2017, 7, 283. [Google Scholar] [CrossRef]

- Bianchini, L.; Colantoni, A.; Venanzi, R.; Cozzolino, L.; Picchio, R. Physicochemical Properties of Forest Wood Biomass for Bioenergy Application: A Review. Forests 2025, 16, 702. [Google Scholar] [CrossRef]

| Treatment | Biomass Feedstock | Machines/System | Particle Size After Treatment | Key Effect | Reference |

|---|---|---|---|---|---|

| Attrition milling | Corn stover | Attrition mill | 73.5% < 100 µm; mean 61.3 ± 3.3 µm | Enzymatic conversion 79.8%; low phenolics production | [56] |

| Ball milling | Corn stover, Switchgrass | Ball mill, air classifier mill, high-speed mill; ball milling | Reduced significantly (not specified); Not specified; Reduced; Similar for all, mean D not specified | Increased glucose yield to 66.96%; Increased biogas production by 5–13%; Glucose yield: ACM 49%, HSM 44%, CBM 29% | [39,49,51] |

| Disk milling | Energy cane bagasse | Disk mill | Not specified, post 2 mm grinding | Highest glucose (5.4%) and xylose (2.15%) with disk milling after LHW at 200 °C | [48] |

| Grinding | Cocoa pod husk; Pine needles, bark, branches; Sugar beet pulp | Grinder | 2.5 mm; Reduced (not quantified); <10 mm | Biogas yield increased by 20.2% compared to untreated; Increases surface area and reduces crystallinity, aiding microbial digestion; Methane yield: 115–164 NmL/g (needles), lower for bark/litter | [57,58] |

| Hammer milling | Wheat straw | Hammer mill, roll mill, extrusion | 0.25–1 mm analyzed; not always specified for each method | Roll milling increased methane potential by 21%; extrusion increased production rate | [52] |

| Knife milling/Cutting | Big bluestem | Knife milling (1, 2, 4, 8 mm) | 1–8 mm | Larger screen size reduced energy use; higher sugar yield with 2 mm | [20] |

| Other/Combined | Corncob, Cotton stalks, Various grasses | Centrifugal milling, mechanical milling | 0.5–65 mm; highest yield at 0.5 mm; Not specified; Not detailed | Methane yield increased by 26%; Fermentable sugars yield 0.488 g/g biomass; Methane yield increased by up to 22% | [59,60,61] |

| Shearing (Brush/Roller) | Meadow grass | Shearing/Brush + steel roller | Reduced (not quantified) | Methane yield increased by 20–27% depending on treatment intensity | [29] |

| Szego milling | Barley straw | Szego Mill™ | Down to <0.2 mm in nitrogen-assisted wet milling | Glucose up to 7 g/L; ethanol 3.4–6.7 g/L; +6–11% methane rate | [62] |

| Treatment | Biomass Feedstock | Machine/System | Advantages | Disadvantages | Reference |

|---|---|---|---|---|---|

| Briquetting | Walnut shell | Hydraulic piston press (Mega KcK-50) | Reduction of operating costs; Low ash content (about 1.1–1.2%) and high calorific value; Good density and durability; Clean combustion | Sensitivity to moisture; Variability in raw material quality | [54] |

| Briquetting | Corn stover | (i) Shredder machine 9RS-600 against (ii) Ring die briquette machine (9SYH-1200) | Increase in methane yield (66.74%, ii higher than i); Better digestive performance (CH4 and VFA); Reduction of logistics costs; Improving energy sustainability | Higher energy consumption: the electrical input is 247.2% higher than in (i), due to the energy required for the briquetting process | [70] |

| Pelleting | Corn stover | SAA—Soaking in Aqueous Ammonia | Reduction of pre-treatment severity (90% glucose yields can be obtained by pelletizing); Decreased enzyme load (it is possible to reduce the use of enzymes up to 80% while maintaining high sugar yields); Reduction of hydrolysis times (58%) | Energy costs of pelletizing; Additional costs for ammonia management | [67] |

| Briquetting | Wheat Straw | Briquetting press BP 6510 | Better absorption of water (due to the reduced size of the fibers and the reduced presence of intracellular air); Improved ease of biomass transport and storage; Preservation of cell morphology | Yield in fermentable sugars unchanged; Possible increase in recalcitrance | [64] |

| Pelleting | Mixed biomass (corn stover, miscanthus, switchgrass, poplar) | Bliss Pioneer B35A-75; | Slight increase in total sugar yield | Variability between biomass (the hybrid poplar required higher pretreatment temperatures and showed lower yields compared to herbaceous biomass) | [68] |

| Pelleting | Mixed biomass (Vitis spp., Actinidia spp., Erica spp., Cytisus spp., Pinus spp.) | Cylindrical pelletizer producing pellets of 6 mm diameter and 18 mm length | Reduction of transport costs; Exploitation of residual biomass | High moisture content; Costs of collection | [69] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Domenico, G.; Cioccolo, E.; Bianchini, L.; Venanzi, R.; Colantoni, A.; Picchio, R.; Cozzolino, L.; Di Stefano, V. A Systematic Review of Mechanical Pretreatment Techniques of Wood Biomass for Bioenergy. Energies 2025, 18, 3294. https://doi.org/10.3390/en18133294

Di Domenico G, Cioccolo E, Bianchini L, Venanzi R, Colantoni A, Picchio R, Cozzolino L, Di Stefano V. A Systematic Review of Mechanical Pretreatment Techniques of Wood Biomass for Bioenergy. Energies. 2025; 18(13):3294. https://doi.org/10.3390/en18133294

Chicago/Turabian StyleDi Domenico, Giorgia, Elisa Cioccolo, Leonardo Bianchini, Rachele Venanzi, Andrea Colantoni, Rodolfo Picchio, Luca Cozzolino, and Valerio Di Stefano. 2025. "A Systematic Review of Mechanical Pretreatment Techniques of Wood Biomass for Bioenergy" Energies 18, no. 13: 3294. https://doi.org/10.3390/en18133294

APA StyleDi Domenico, G., Cioccolo, E., Bianchini, L., Venanzi, R., Colantoni, A., Picchio, R., Cozzolino, L., & Di Stefano, V. (2025). A Systematic Review of Mechanical Pretreatment Techniques of Wood Biomass for Bioenergy. Energies, 18(13), 3294. https://doi.org/10.3390/en18133294