Study on the Influence Mechanisms of Reservoir Heterogeneity on Flow Capacity During Fracturing Flooding Development

Abstract

1. Introduction

2. Methods

2.1. Characterization Method for Dual-Porosity Dual-Permeability Models

2.1.1. Technical Development Approach

2.1.2. Determination of Fracturing Flooding Fracture Network Morphology

2.1.3. Determination of Stress Sensitivity in Fracture Systems

2.1.4. Establishment of Dual-Porosity Dual-Permeability Model

2.2. Development Performance of Fracturing Flooding in Heterogeneous Reservoirs

2.2.1. Production Performance Indicators

2.2.2. Production Performance Indicators

3. Simulation Results

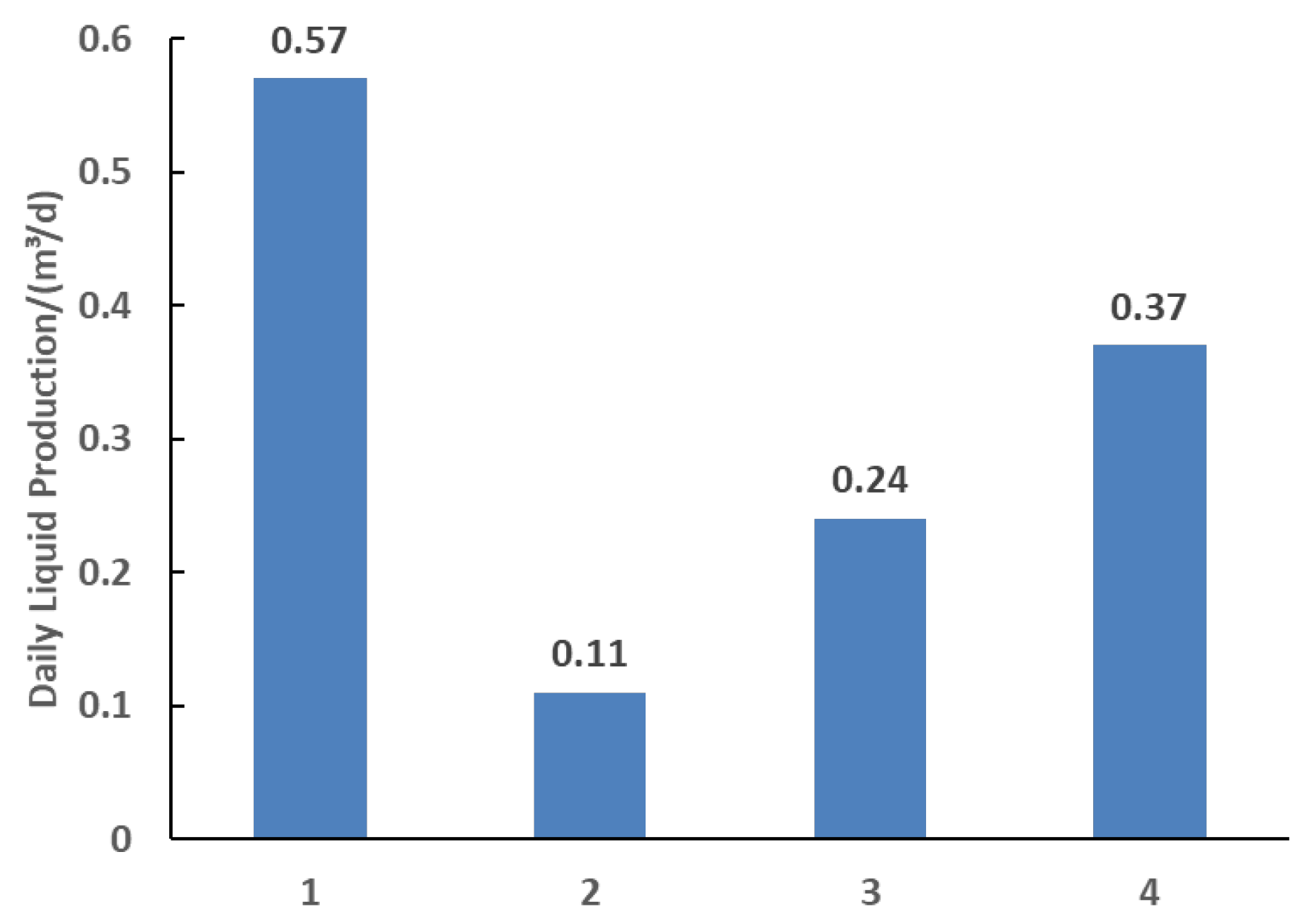

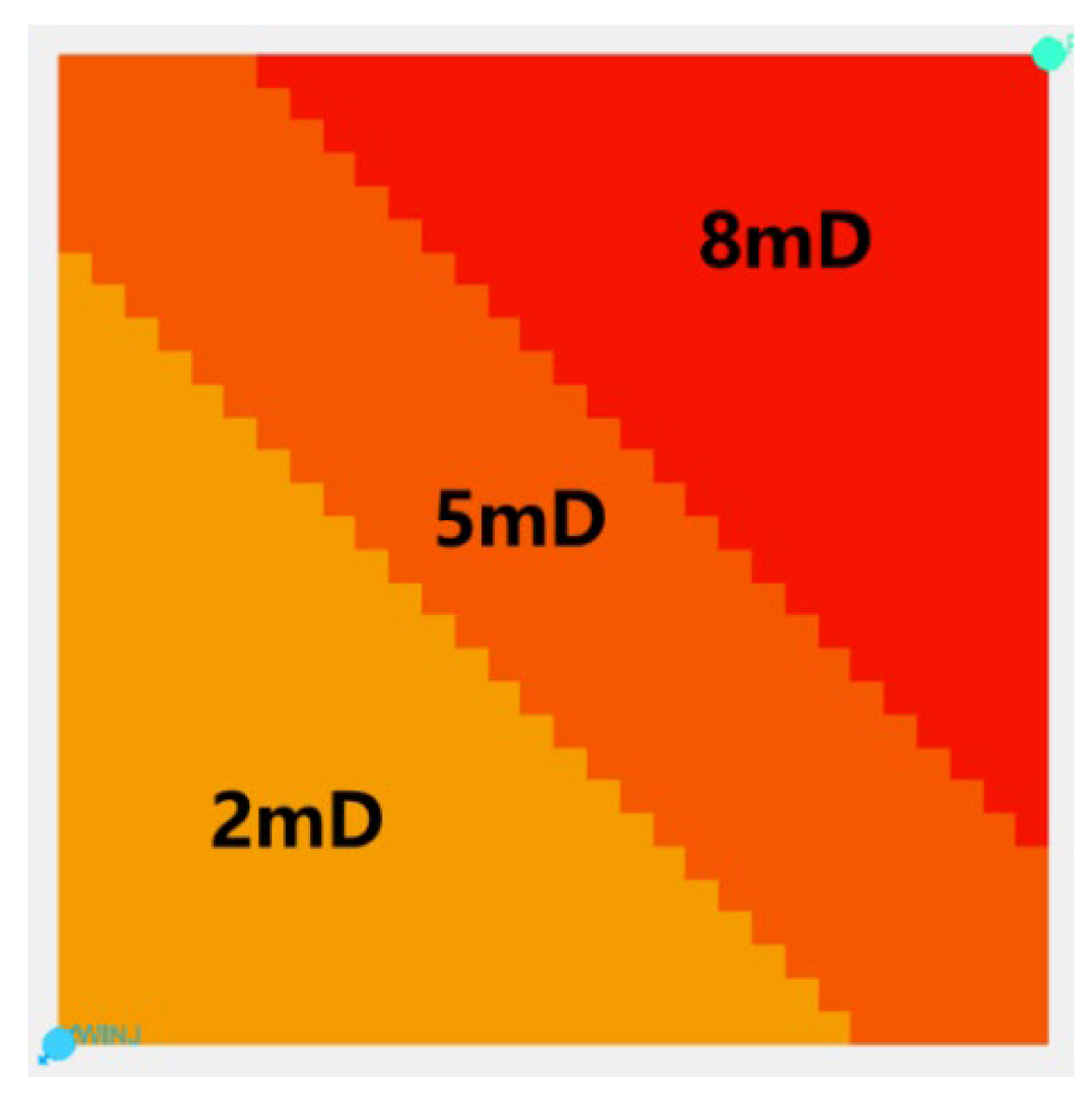

3.1. Influence Laws of Heterogeneous Distribution Patterns on Seepage Capacity

3.1.1. Modeling of Different Heterogeneous Distribution Patterns

3.1.2. Fracturing Flooding Seepage Capacity

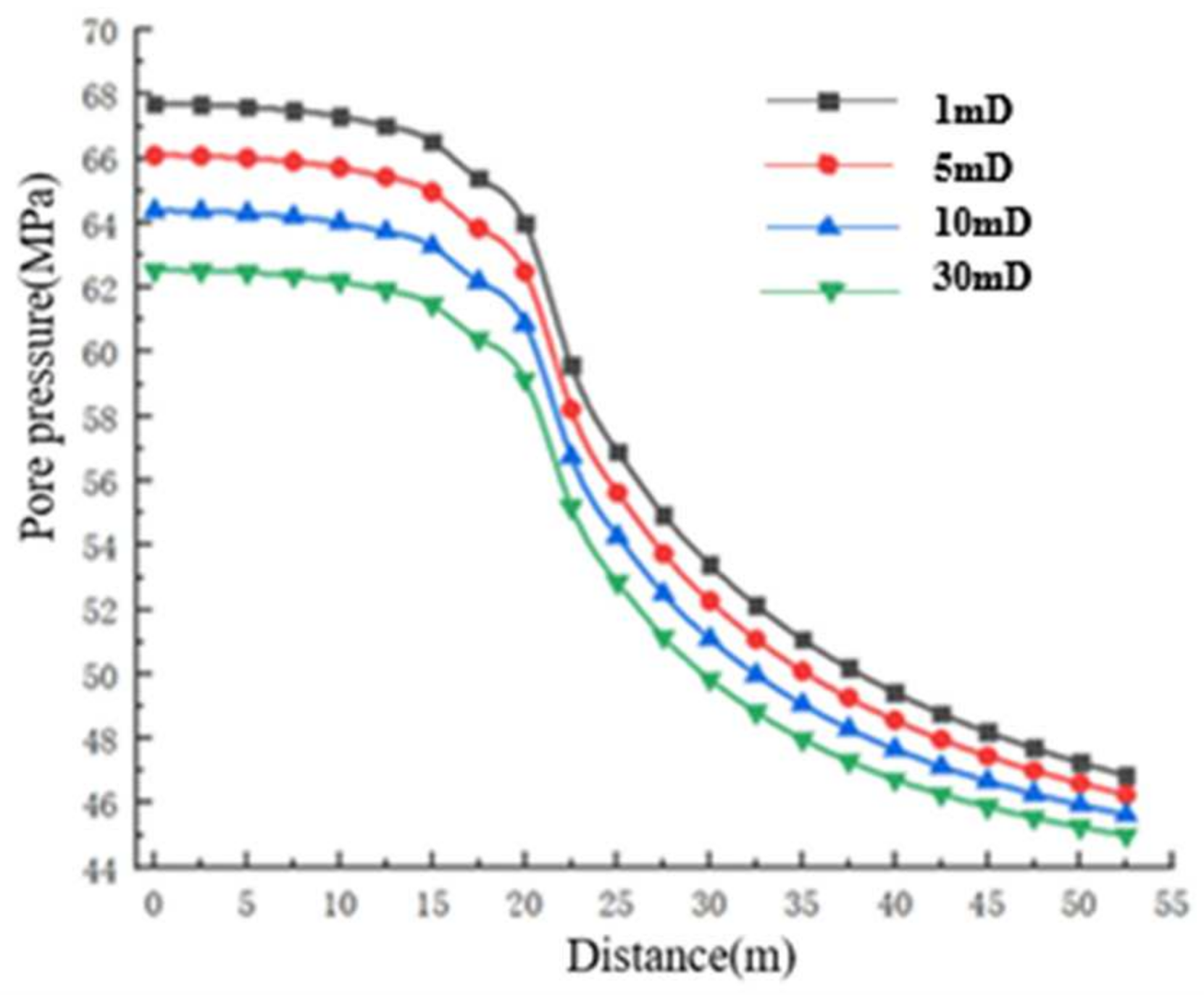

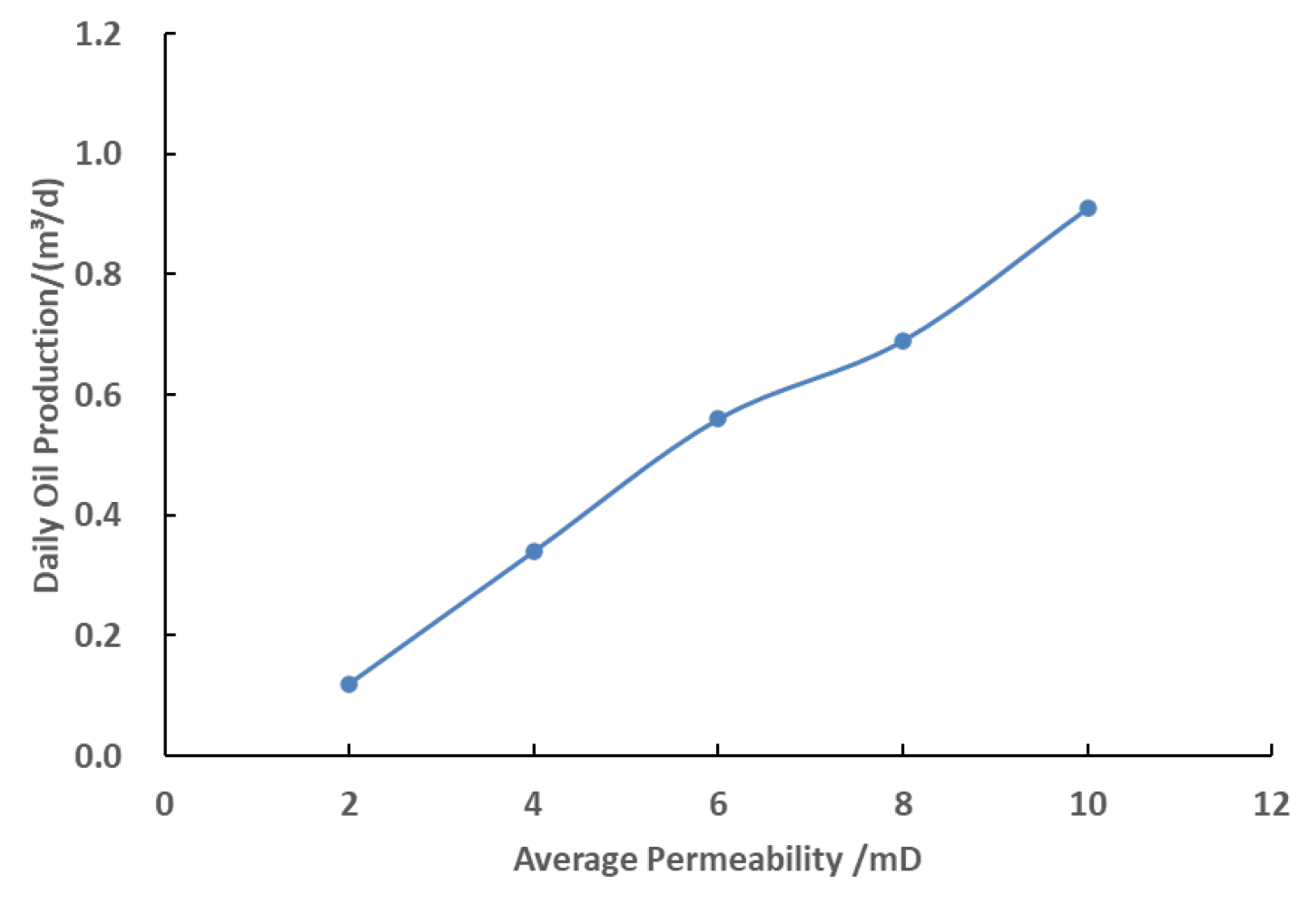

3.2. Influence of Permeability Gradation on Seepage Capacity Characteristics

3.2.1. Modeling of Different Heterogeneous Distribution Patterns

3.2.2. Fracturing Flooding Seepage Capacity

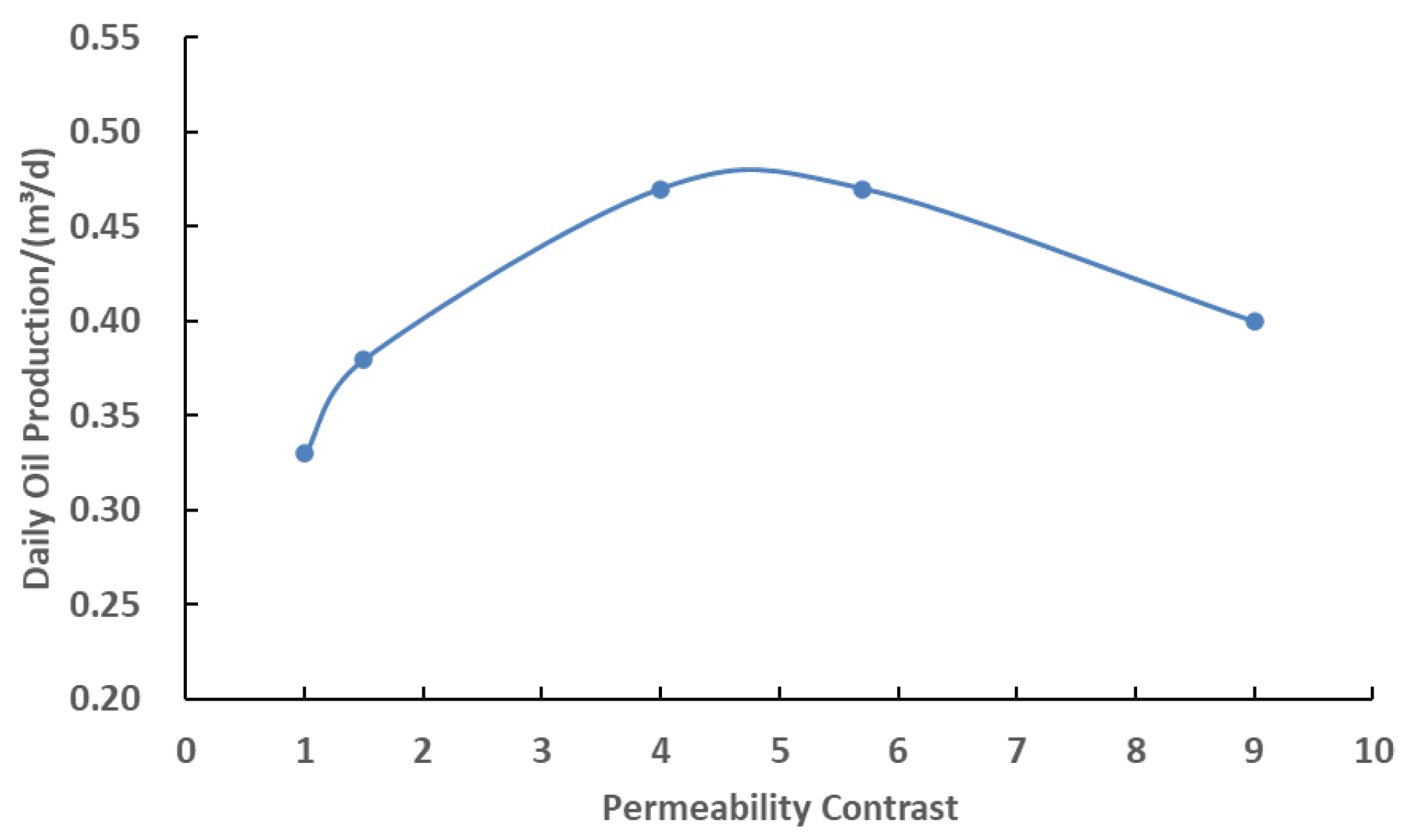

3.3. Influence of Heterogeneity Contrast on Seepage Capacity

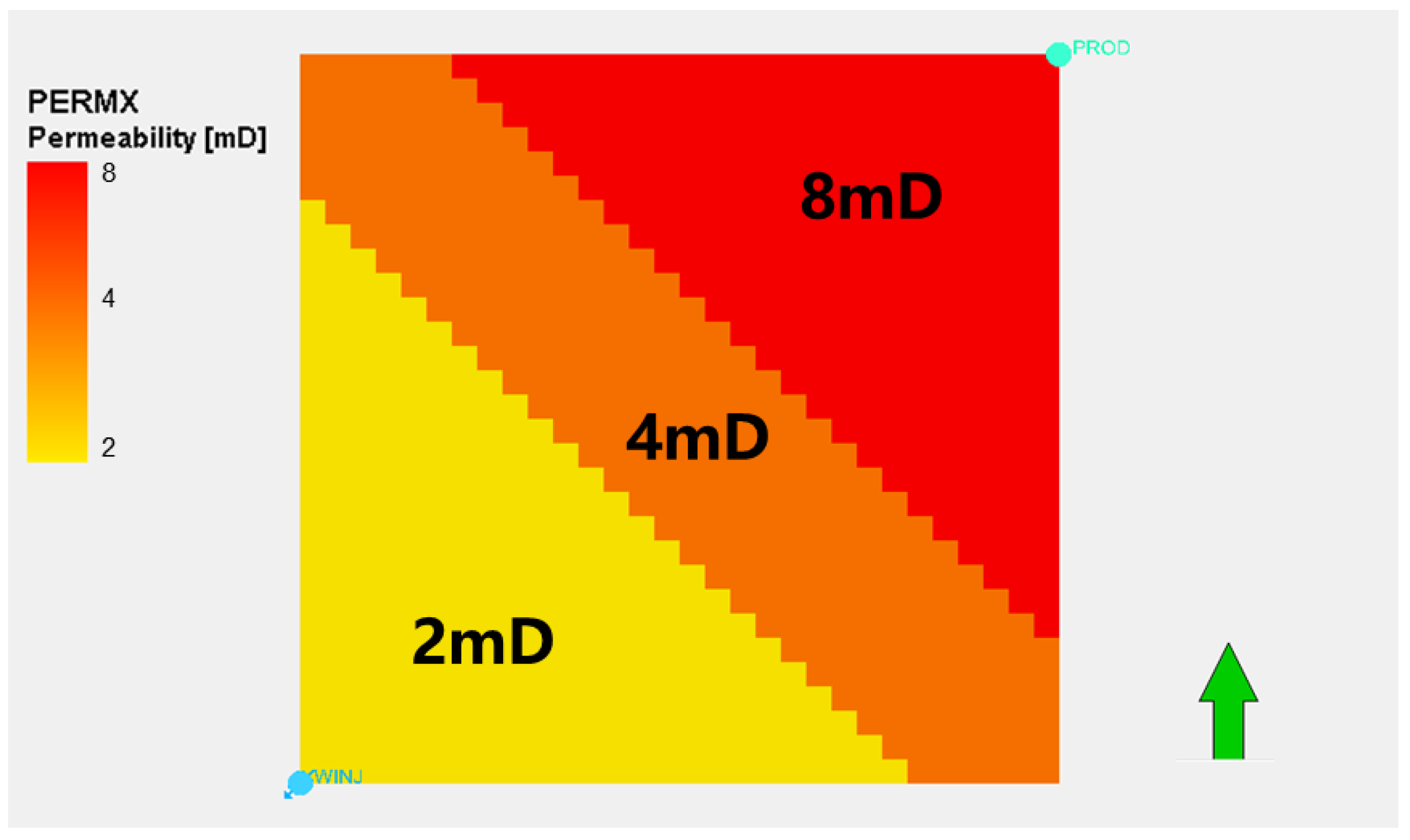

3.3.1. Modeling of Different Heterogeneous Distribution Patterns

3.3.2. Fracturing Flooding Seepage Capacity

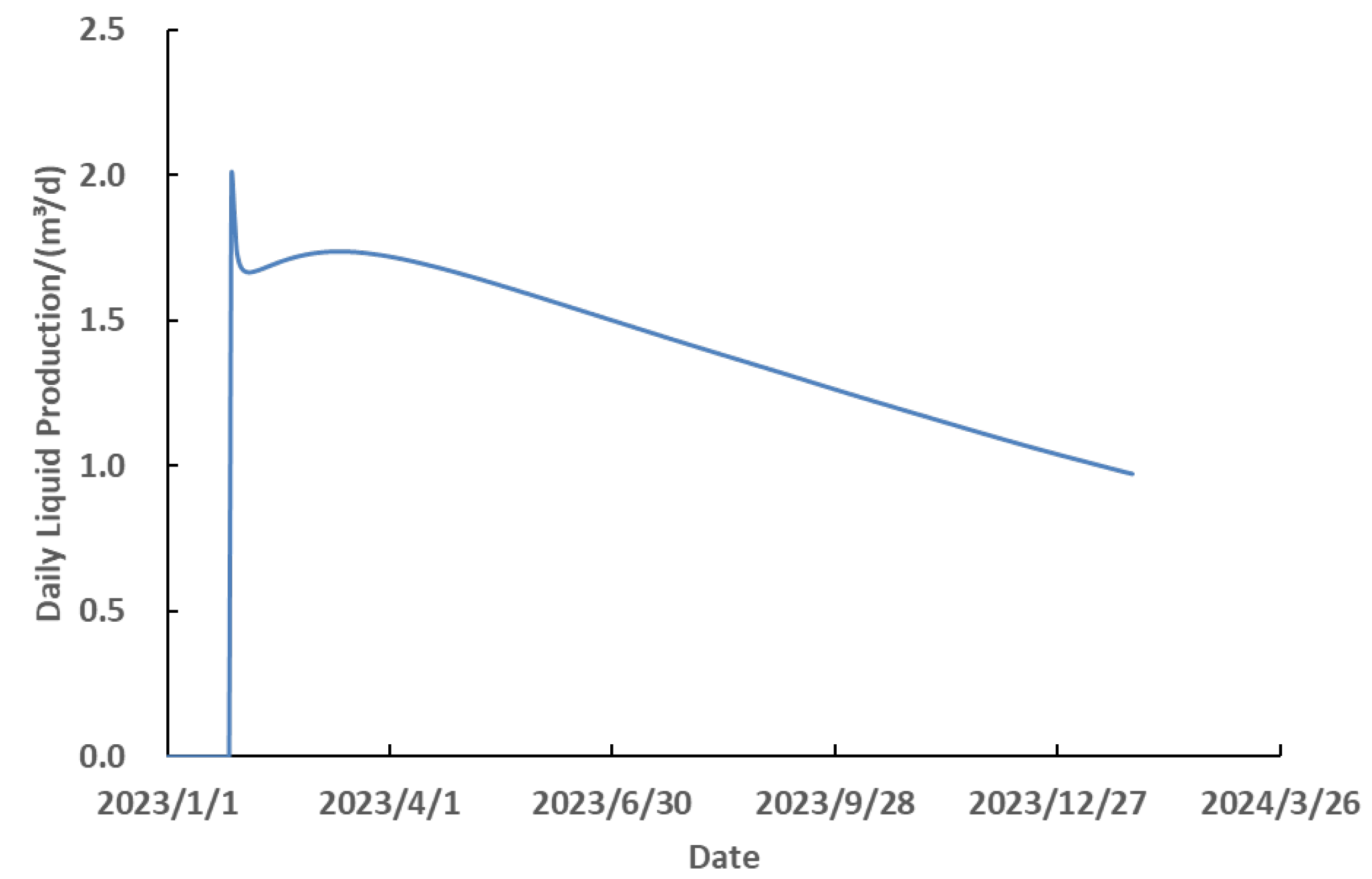

3.4. Influence of Heterogeneity Contrast on Seepage Capacity

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bao, X.Z. Research on high-pressure water injection development in low-permeability oilfields. Chem. Eng. Des. Commun. 2020, 46, 7–8. [Google Scholar]

- Kang, W.-L.; Zhou, B.-B.; Issakhov, M.; Gabdullin, M. Advances in enhanced oil recovery technologies for low-permeability reservoirs. Pet. Sci. 2022, 19, 1622–1640. [Google Scholar] [CrossRef]

- Song, H.G. Application of ultra-high-pressure water injection technology in low-permeability reservoirs in Jianghan Oilfield. J. Jianghan Pet. Univ. Staff. Work. 2012, 25, 30–32. [Google Scholar]

- Wang, Y. Accurate determination method of formation pore pressure in fractured shale gas reservoirs. Pet. Drill. Tech. 2020, 48, 29–34. [Google Scholar]

- Li, X.L.; You, L.J.; Kang, Y.L.; Liu, J.; Chen, M.; Zeng, T.; Hao, Z. Investigation on the thermal cracking of shale under different cooling modes. J. Nat. Gas Sci. Eng. 2022, 97, 104359. [Google Scholar] [CrossRef]

- Shi, M.X.; Liu, Z.D.; Yang, X.F.; Yang, J.R.; Chen, X.J.; Liu, H.Z.; Cao, J.L. Review and prospects of geophysical logging prediction technology for formation pore pressure. Prog. Geophys. 2020, 35, 1845–1853. [Google Scholar]

- Fan, Q.L.; Wu, E.Z. Study on formation pressure variation after waterflood development in Daqing Oilfield. Pet. Explor. Dev. 1990, 6, 58–63+57. [Google Scholar]

- Shanley, K.W.; Cluff, R.M.; Robinson, J.W. Factors controlling prolific gas production from low-permeability sandstone reservoirs: Implications for resource assessment, prospect development, and risk analysis. AAPG Bull. 2004, 88, 1083–1121. [Google Scholar] [CrossRef]

- Li, N. Oil-water movement patterns in delta front of Haiwaihe Oilfield. Chem. Eng. Equip. 2013, 3, 100–102. [Google Scholar]

- Cui, C.; Wang, J.; Qian, Y.; Li, J.; Lu, S. Fracturing–flooding for low-permeability oil reservoirs: A coupled model integrating DDM and black-oil model. Rock Mech. Rock Eng. 2025, 58, 4069–4089. [Google Scholar] [CrossRef]

- Han, L.; Chen, J.S.; Chen, L. Study on diffusion radius and numerical simulation of curtain grouting. Rock Soil Mech. 2012, 33, 2235–2240. [Google Scholar]

- Luan, J.; Dong, P.C.; Zheng, J.L. Experimental studies on reaction laws during the process of air injection into the oil reservoirs with low permeability. J. Pet. Sci. Eng. 2020, 194, 107526. [Google Scholar] [CrossRef]

- Yang, Z.Q.; Lu, J.; Wang, Y.; Zhang, Z.W.; Yang, Y.; Zhu, Y.Y.; Zhang, J.; Guo, Y.F.; Chen, X.G. Power-law fluid cylindrical permeation grouting mechanism considering tortuosity effect of porous media. Chin. J. Rock Mech. Eng. 2021, 40, 410–418. [Google Scholar]

- Xu, J.Q.; Chang, Y.L.; An, J.L.; Wang, Y.Q. Development test of water injection system in Wendong Oilfield. Inn. Mong. Petrochem. Ind. 2011, 37, 140–142. [Google Scholar]

- Di, S.Y.; Cheng, S.Q.; Bai, W.P.; Wei, C.; Wang, Y.; Qin, J.Z. Mechanism and application of dynamic fracture propagation in tight oil reservoirs. Chin. J. Theor. Appl. Mech. 2021, 53, 2141–2155. [Google Scholar]

- Austad, T.; Rezaeidoust, A.; Puntervold, T. Chemical Mechanism of Low Salinity Water Flooding in Sandstone Reservoirs. In Proceedings of the SPE Improved Oil Recovery Conference, SPE 129767, Tulsa, OK, USA, 24 April 2010. [Google Scholar]

- Zhao, M.L. Numerical Simulation Study of CO2-Water Two-Phase Transport in Porous Media. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2013. [Google Scholar]

- Gao, Z.H.; Zhai, X.Y.; Wang, J.D. Study on distribution law of abnormal formation pressure after waterflood development in Daqing Oilfield. Pet. Geol. Oilfield Dev. Daqing 2005, 1, 51–53+108. [Google Scholar]

- Tian, X.F.; Cheng, L.S.; Li, C.L.; Li, C.Y.; Zhang, M.Y.; Jiang, L.W.; Hou, T.; Li, Q.; Wang, H.L. Calculation model of liquid-measured stress sensitivity in tight oil reservoirs. Chin. J. Comput. Phys. 2015, 32, 334–342. [Google Scholar]

- Pu, C.S.; Zheng, H.; Yang, Z.P.; Gao, Z.D. Research status and development trends of complex fracture formation mechanism in staged volume fracturing of horizontal wells. Acta Pet. Sin. 2020, 41, 1734–1743. [Google Scholar]

- Katende, A.; Sagala, F. A critical review of low salinity water flooding: Mechanism, laboratory and field application. J. Mol. Liq. 2019, 278, 627–649. [Google Scholar] [CrossRef]

- Qu, Y.N.; Ding, J.X.; Zou, X.Y.; Han, A.W. Production characteristics and influencing factors of waterflood development in low-permeability oilfields. China Pet. Chem. Stand. Qual. 2021, 41, 42–43. [Google Scholar]

- Zhao, Z.; Jiang, S.; Lei, T.; Wang, J.; Zhang, Y. Optimization of key parameters of fracturing flooding development in offshore reservoirs with low permeability based on numerical modeling approach. J. Mar. Sci. Eng. 2025, 13, 282. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Yang, Y.; Sun, Z.G. Physical simulation and quantitative characterization of fractures in fracturing flooding development of low-permeability reservoirs. Pet. Geol. Recovery Effic. 2022, 29, 143–149. [Google Scholar]

- China Petroleum Exploration and Development Research Institute (RIPED). Global Petroleum E&D Trends and Company Dynamics (2021); Petroleum Industry Press: Houston, TX, USA, 2021. [Google Scholar]

- Wang, X.; Yu, W.; Xie, Y.; He, Y.; Xu, H.; Chu, X.; Li, C. Numerical simulation of the dynamic behavior of low permeability reservoirs under fracturing-flooding based on a dual-porous and dual-permeable media model. Energies 2024, 17, 6203. [Google Scholar] [CrossRef]

- Cao, H.; Zhang, G.; Li, S.; Zhou, D.; Yu, C.; Sun, Q. Fracturing initiation and breakdown pressures in fracturing-flooding sandstone reservoirs. Rock Mech. Rock Eng. 2024, 44, 34–37. [Google Scholar] [CrossRef]

- Sun, Y.Z. Performance comparison and application of oil displacement agents in tertiary oil recovery. Chem. Eng. Equip. 2022, 9, 85–86. [Google Scholar]

- Xiang, H.; Feng, N.; Zhi, W.D. Research and application of surfactant injection technology for enhanced oil recovery in low-permeability reservoirs. Chem. Eng. 2022, 36, 42–45+95. [Google Scholar]

- Tong, X.G.; Zhang, G.Y.; Wang, Z.M. Potential and distribution of global oil and gas resources. Pet. Explor. Dev. 2018, 45, 727–736. [Google Scholar] [CrossRef]

- Ding, S.W.; Xi, Y.; Liu, G.W. Adaptability of different CO2 injection methods for enhanced oil recovery and geological storage in low-permeability reservoirs. Pet. Geol. Recovery Effic. 2023, 30, 104–111. [Google Scholar]

- Liu, F.N.; Zhang, X.Y.; Fu, C.Y. Experimental study on the effect of injection media on recovery factor in ultra-low permeability reservoirs. Petrochem. Technol. 2022, 29, 159–161. [Google Scholar]

- Fan, Y.M. Classification evaluation of undeveloped reserves in low-permeability reservoirs based on development technologies. Pet. Geol. Exp. 2022, 44, 337–341. [Google Scholar]

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Permeability /mD | 5.5 | Hydraulic conductivity/(m/s) | 1 × 10−7 |

| Porosity/% | 10.8 | Fracture pressure/MPa | 58 |

| Fluid leakage | 1 × 10−10 | Initial pore pressure/MPa | 30 |

| Young’s modulus /GPa | 30 | σH/MPa | 55 |

| Poisson’s ratio | 0.28 | σh/MPa | 45 |

| Viscosity/cP | 1 | Displacement/(m3/d) | 800 |

| Formation Pressure/MPa | Porosity Factor | Conductivity Factor |

|---|---|---|

| 20 | 0.99 | 0.8 |

| 30 | 1.0 | 1.0 |

| 40 | 1.6 | 50 |

| 50 | 1.6 | 100 |

| 60 | 1.8 | 150 |

| 70 | 1.9 | 180 |

| 80 | 1.9 | 200 |

| Non-Uniform Distribution Patterns | Daily Liquid Production per Unit Thickness/(m³/d) |

|---|---|

| Low-to-high permeability distribution | 0.57 |

| High-to-low permeability distribution | 0.11 |

| Central-low/edge-high distribution | 0.24 |

| Central-high/edge-low distribution | 0.37 |

| Non-Uniform Distribution Patterns | Daily Oil Production per Unit Thickness/(m³/d) |

|---|---|

| Low-to-high permeability distribution | 0.46 |

| High-to-low permeability distribution | 0.09 |

| Central-low/edge-high distribution | 0.2 |

| Central-high/edge-low distribution | 0.3 |

| Average Permeability/mD | Daily Liquid Production per Unit Thickness/(m³/d) |

|---|---|

| 2 | 0.15 |

| 4 | 0.41 |

| 6 | 0.69 |

| 8 | 0.85 |

| 10 | 1.11 |

| Average Permeability/mD | Daily Liquid Production per Unit Thickness/(m³/d) |

|---|---|

| 2 | 0.12 |

| 4 | 0.34 |

| 6 | 0.56 |

| 8 | 0.69 |

| 10 | 0.91 |

| Permeability Contrast | Daily Liquid Production per Unit Thickness/(m³/d) |

|---|---|

| 1 | 0.41 |

| 1.5 | 0.46 |

| 4 | 0.58 |

| 5.7 | 0.58 |

| 9 | 0.48 |

| Permeability Contrast | Daily Liquid Production per Unit Thickness/(m³/d) |

|---|---|

| 1 | 0.33 |

| 1.5 | 0.38 |

| 4 | 0.47 |

| 5.7 | 0.47 |

| 9 | 0.4 |

| Water Injection Volume/PV | Daily Liquid Production/(m³/d) | Daily Oil Production/(m³/d) |

|---|---|---|

| 0.03 | 0.17 | 0.14 |

| 0.04 | 0.62 | 0.52 |

| 0.05 | 1.32 | 1.1 |

| 0.06 | 1.74 | 1.42 |

| 0.07 | 2.04 | 1.64 |

| 0.08 | 2.29 | 1.83 |

| 0.09 | 2.57 | 2.03 |

| 0.1 | 2.88 | 2.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Niu, B.; Huang, L.; Zhang, L.; Hao, Y.; Yue, Z. Study on the Influence Mechanisms of Reservoir Heterogeneity on Flow Capacity During Fracturing Flooding Development. Energies 2025, 18, 3279. https://doi.org/10.3390/en18133279

Xu H, Niu B, Huang L, Zhang L, Hao Y, Yue Z. Study on the Influence Mechanisms of Reservoir Heterogeneity on Flow Capacity During Fracturing Flooding Development. Energies. 2025; 18(13):3279. https://doi.org/10.3390/en18133279

Chicago/Turabian StyleXu, Haimin, Baolun Niu, Li Huang, Lei Zhang, Yongmao Hao, and Zichao Yue. 2025. "Study on the Influence Mechanisms of Reservoir Heterogeneity on Flow Capacity During Fracturing Flooding Development" Energies 18, no. 13: 3279. https://doi.org/10.3390/en18133279

APA StyleXu, H., Niu, B., Huang, L., Zhang, L., Hao, Y., & Yue, Z. (2025). Study on the Influence Mechanisms of Reservoir Heterogeneity on Flow Capacity During Fracturing Flooding Development. Energies, 18(13), 3279. https://doi.org/10.3390/en18133279