Experimental Investigation into the Energy Performance of a Biomass Recuperative Organic Rankine Cycle (ORC) for Micro-Scale Applications in Design and Off-Design Conditions

Abstract

1. Introduction

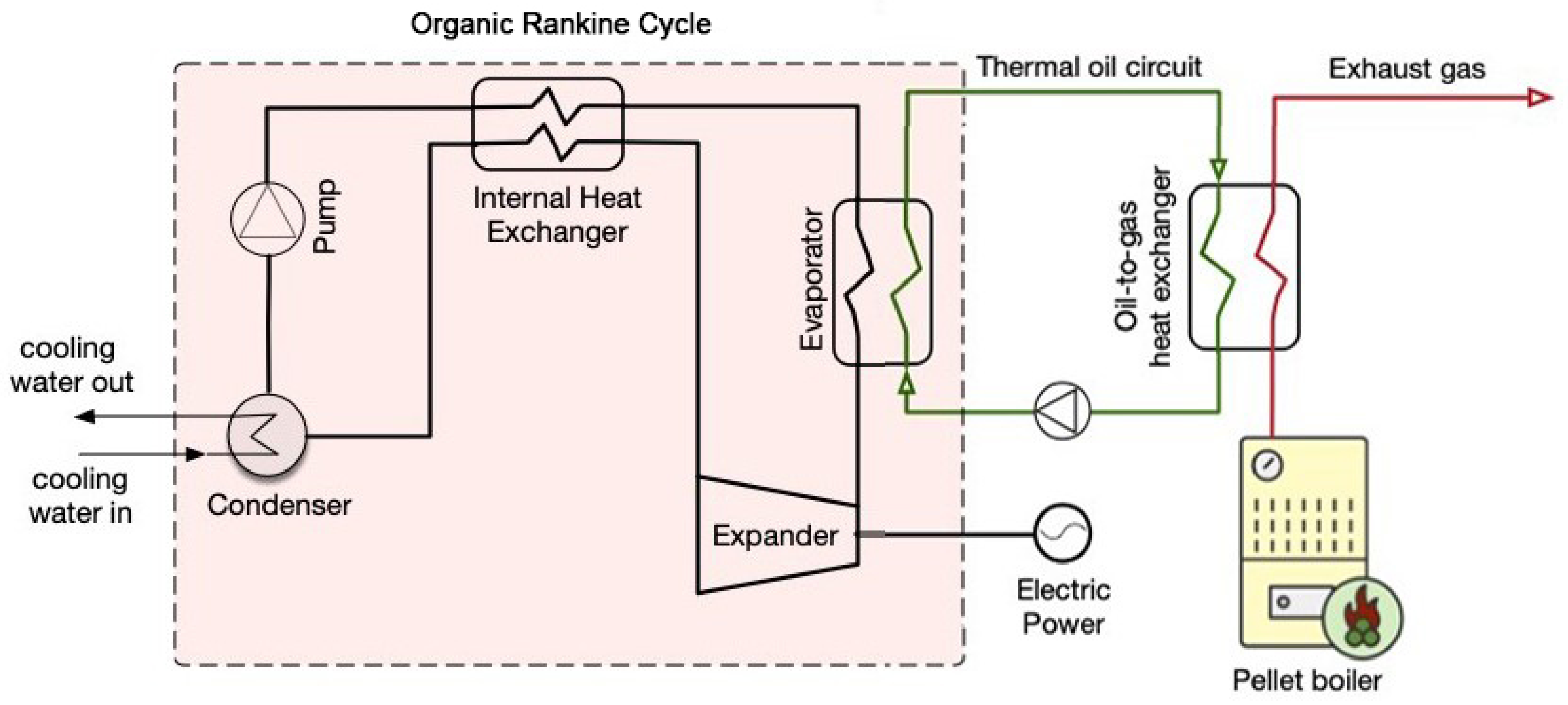

2. Materials and Methods

2.1. Biomass Boiler

2.2. Thermal Oil Circuit

2.3. Micro-ORC Unit

2.4. Data Acquisition

2.5. Experimental Analysis

2.5.1. Performance Metrics

2.5.2. Experimental Uncertainty

3. Results and Discussion

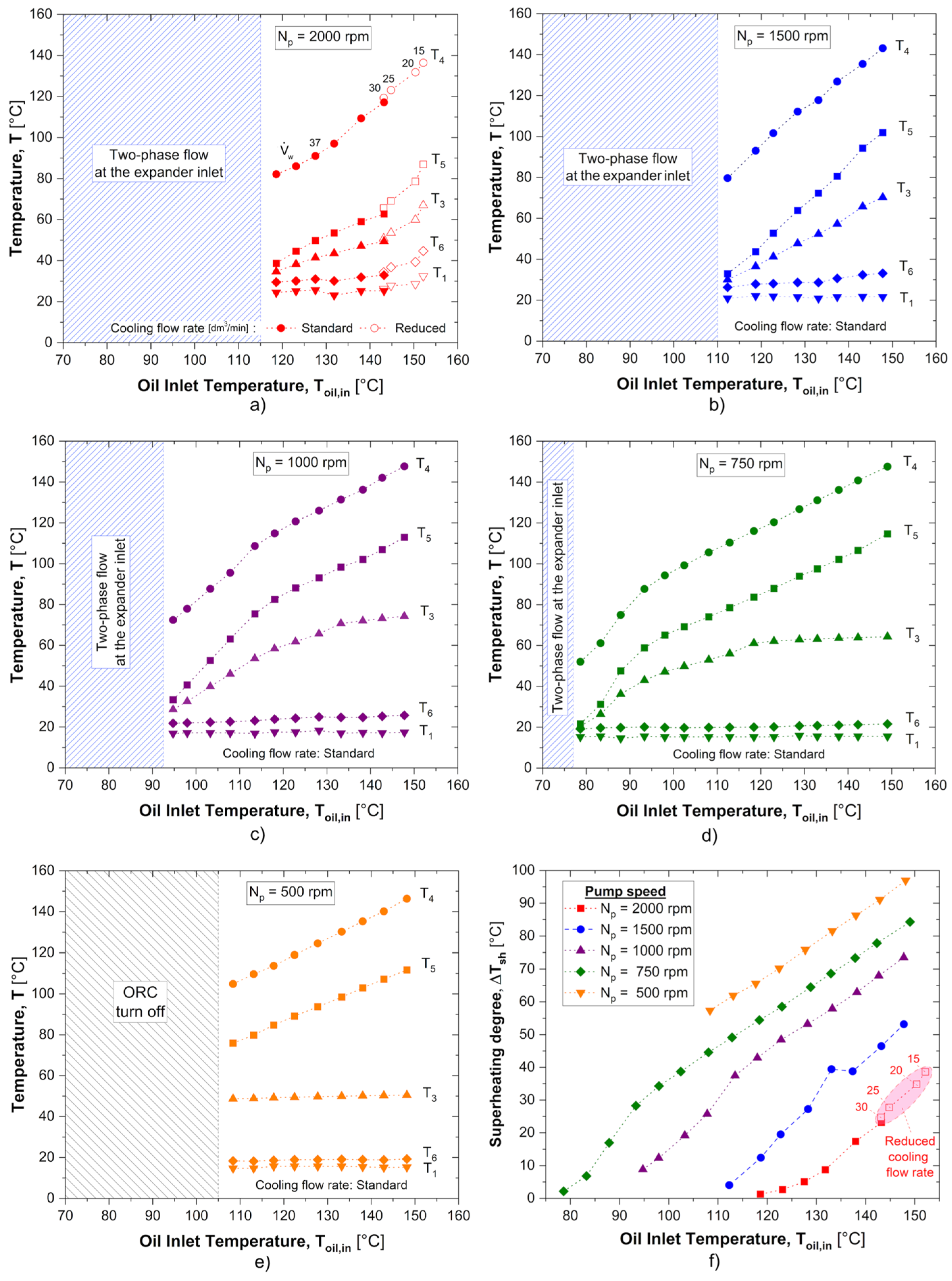

3.1. Micro-ORC Operating Range

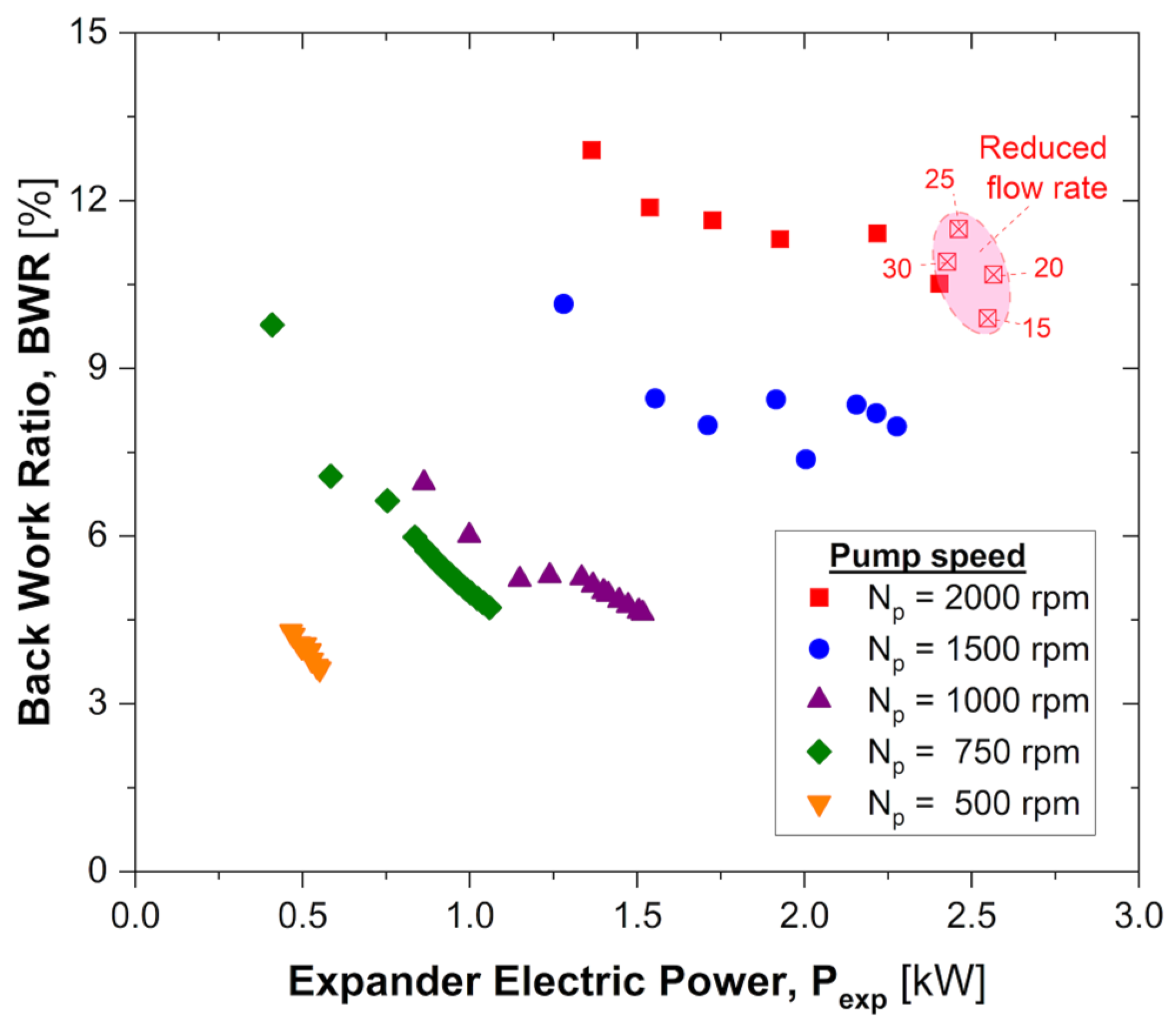

3.2. Influence of Operating Conditions on ORC Global Performance

3.3. Suggested Configurations

4. Conclusions

- Key parameters affecting the ORC performance include pump speed, thermal oil temperature, and the superheating degree at the entrance of the expander.

- The micro-scale unit demonstrates flexibility in operation, achieving a maximum net electric power of 2.30 kW at the highest pump speed (2000 rpm) and a thermal oil temperature of 152.2 °C. Conversely, the minimum electric power is 0.42 kW at a thermal oil temperature of 113.2 °C and a pump speed of 500 rpm.

- The investigated biomass-fired recuperative ORC achieves a maximum electric efficiency of 8.55% with a pump speed of 1000 rpm. In this condition, the net power output and thermal oil temperature are 1.37 kW and 133.2 °C, respectively.

- The system effectiveness increases with increasing superheating degree, plateauing above approximately 40 °C. While pump speed also influences efficiency, above 1000 rpm, performance depends primarily on superheating degree.

- A single exponential curve correlates all the experimental data if plotted as the normalised electric efficiency as a function of the superheating degree at the entrance of the expander. This result highlights the potential of using a normalised curve to predict the performance of different micro-ORC systems, significantly reducing the time and cost associated with experimental investigations and facilitating real-time data validation during measurement campaigns.

- A strategy to maximise ORC performance involves adjusting the pump speed to ensure adequate superheating of the working fluid according to the available thermal power.

- The experimental investigation conducted illustrates that the analysed biomass recuperative ORC could represent a viable option for micro-scale applications. The system exhibits robust performance across a broad spectrum of operating conditions and could contribute to a sustainable shift towards effective decentralised renewable energy production and the achievement of UN Sustainable Development Goals for affordable and clean energy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Acronyms | |

| EU | European Union |

| GHG | Greenhouse gas |

| GWP | Global warming potential |

| IHE | Internal heat exchanger |

| ME | Maximum efficiency |

| MP | Maximum power |

| ODP | Ozone depletion potential |

| PHEX | Plate heat exchanger |

| SDGs | Sustainable development goals |

| Symbols | |

| Correlation coefficient [-] | |

| Correlation coefficient [-] | |

| Correlation coefficient [-] | |

| Correlation coefficient [bar] | |

| Back work ratio [%] | |

| Correlation coefficient [-] | |

| Specific heat capacity [J/(kg K)] | |

| Dimensionless minimum distance [-] | |

| Overall uncertainty on the generic quantity [-] | |

| Pressure difference [bar] | |

| Superheating degree [°C] | |

| Uncertainty of the generic measurement [%] | |

| Generic quantity [-] | |

| Relative uncertainty [%] | |

| Mass flow rate [kg/s] | |

| Rotational speed [rpm] | |

| Efficiency [-] | |

| Normalised electric efficiency [-] | |

| Power [W] | |

| Pressure [Pa] | |

| Thermal power [W] | |

| Temperature [°C] | |

| Volumetric flow rate [m3/s] | |

| Subscripts | |

| Auxiliary boiler | |

| Condenser | |

| Electric | |

| Evaporator | |

| Expander | |

| Generic operating condition | |

| Inlet | |

| Maximum | |

| Minimum | |

| Net power | |

| Thermal oil | |

| Outlet | |

| Pump | |

| Superheating | |

| Thermal | |

| Water | |

References

- United Nations Environment Programme. Emissions Gap Report 2023: Broken Record—Temperatures Hit New Highs, yet World Fails to Cut Emissions (Again); United Nations Environment Programme: Nairobi, Kenya, 2023; ISBN 978-92-807-4098-1. [Google Scholar]

- COP28; IRENA; GRA. Tripling Renewable Power and Doubling Energy Efficiency by 2030 Crucial Steps Towards 1.5 °C; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2023; ISBN 978-1-5231-5736-5. [Google Scholar]

- Gonidaki, D.; Bellos, E. A Detailed Review of Organic Rankine Cycles Driven by Combined Heat Sources. Energies 2025, 18, 526. [Google Scholar] [CrossRef]

- Evro, S.; Oni, B.A.; Tomomewo, O.S. Global Strategies for a Low-Carbon Future: Lessons from the US, China, and EU’s Pursuit of Carbon Neutrality. J. Clean. Prod. 2024, 461, 142635. [Google Scholar] [CrossRef]

- United Nations. Paris Agreement; United Nations: New York City, NY, USA, 2015. [Google Scholar]

- United Nations. Sustainable Development Goals. Available online: https://sdgs.un.org/goals (accessed on 16 December 2024).

- Okunevičiūtė Neverauskienė, L.; Dirma, V.; Tvaronavičienė, M.; Danilevičienė, I. Assessing the Role of Renewable Energy in the Sustainable Economic Growth of the European Union. Energies 2025, 18, 760. [Google Scholar] [CrossRef]

- Nagaj, R.; Gajdzik, B.; Wolniak, R.; Grebski, W.W. The Impact of Deep Decarbonization Policy on the Level of Greenhouse Gas Emissions in the European Union. Energies 2024, 17, 1245. [Google Scholar] [CrossRef]

- European Council. Fit to 55. Available online: https://www.consilium.europa.eu/en/policies/green-deal/fit-for-55-the-eu-plan-for-a-green-transition/ (accessed on 16 December 2024).

- European Commission. The European Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 16 December 2024).

- European Parliament and Council Directive (EU). 2023/2413 of the European Parliament and of the Council of 18 October 2023 Amending Directive (EU) 2018/2001, Regulation (EU) 2018/1999 and Directive 98/70/EC as Regards the Promotion of Energy from Renewable Sources, and Repealing Council Directive (EU) 2015/652; European Parliament and Council Directive (EU): Luxembourg, 2023. [Google Scholar]

- European Parliament and Council Directive (EU). 2023/1791 of the European Parliament and of the Council of 13 September 2023 on Energy Efficiency and Amending Regulation (EU) 2023/955 (Recast); European Parliament and Council Directive (EU): Luxembourg, 2023. [Google Scholar]

- Pylak, K.; Pizoń, J.; Łazuka, E. Evolution of Regional Innovation Strategies Towards the Transition to Green Energy in Europe 2014–2027. Energies 2024, 17, 5669. [Google Scholar] [CrossRef]

- Lu, P.; Liang, Z.; Luo, X.; Xia, Y.; Wang, J.; Chen, K.; Liang, Y.; Chen, J.; Yang, Z.; He, J.; et al. Design and Optimization of Organic Rankine Cycle Based on Heat Transfer Enhancement and Novel Heat Exchanger: A Review. Energies 2023, 16, 1380. [Google Scholar] [CrossRef]

- Corigliano, O.; Algieri, A.; Fragiacomo, P. Turning Data Center Waste Heat into Energy: A Guide to Organic Rankine Cycle System Design and Performance Evaluation. Appl. Sci. 2024, 14, 6046. [Google Scholar] [CrossRef]

- Shah Irshad, A.; Naseer Zakir, M.; Shah Rashad, S.; Elsayed Lotfy, M.; Mikhaylov, A.; Elkholy, M.H.; Pinter, G.; Senjyu, T. Comparative Analyses and Optimizations of Hybrid Biomass and Solar Energy Systems Based upon a Variety of Biomass Technologies. Energy Convers. Manag. X 2024, 23, 100640. [Google Scholar] [CrossRef]

- Cao, J.; Zheng, L.; Zheng, Z.; Peng, J.; Hu, M.; Wang, Q.; Leung, M.K.H. Recent Progress in Organic Rankine Cycle Targeting Utilisation of Ultra-Low-Temperature Heat towards Carbon Neutrality. Appl. Therm. Eng. 2023, 231, 120903. [Google Scholar] [CrossRef]

- Falbo, L.; Perrone, D.; Morrone, P.; Algieri, A. Integration of Biodiesel Internal Combustion Engines and Transcritical Organic Rankine Cycles for waste-heat Recovery in small-scale Applications. Int. J. Energy Res. 2022, 46, 5235–5249. [Google Scholar] [CrossRef]

- Heidarnejad, P.; Genceli, H.; Hashemian, N.; Asker, M.; Al-Rawi, M. Biomass-Fueled Organic Rankine Cycles: State of the Art and Future Trends. Energies 2024, 17, 3788. [Google Scholar] [CrossRef]

- Wieland, C.; Schifflechner, C.; Dawo, F.; Astolfi, M. The Organic Rankine Cycle Power Systems Market: Recent Developments and Future Perspectives. Appl. Therm. Eng. 2023, 224, 119980. [Google Scholar] [CrossRef]

- Market Research Future Organic Rankine Cycle Market Research Report. Available online: https://www.marketresearchfuture.com/reports/organic-rankine-cycle-market-22975 (accessed on 16 April 2025).

- Wieland, C.; Schifflechner, C.; Braimakis, K.; Kaufmann, F.; Dawo, F.; Karellas, S.; Besagni, G.; Markides, C.N. Innovations for Organic Rankine Cycle Power Systems: Current Trends and Future Perspectives. Appl. Therm. Eng. 2023, 225, 120201. [Google Scholar] [CrossRef]

- Mascuch, J.; Novotny, V.; Spale, J.; Vodicka, V.; Zeleny, Z. Experience from Set-up and Pilot Operation of an in-House Developed Biomass-Fired ORC Microcogeneration Unit. Renew. Energy 2021, 165, 251–260. [Google Scholar] [CrossRef]

- Feng, Y.; Liang, H.; Xu, K.; Wang, Y.; Lu, Y.; Lin, C.-H.; Hung, T.-C. Experimental Study on the Performance of a Great Progress 10 kW Organic Rankine Cycle for Low-Grade Heat Source Based on Scroll-Type Expander. Energy 2023, 284, 128627. [Google Scholar] [CrossRef]

- Carraro, G.; Bori, V.; Lazzaretto, A.; Toniato, G.; Danieli, P. Experimental Investigation of an Innovative Biomass-Fired Micro-ORC System for Cogeneration Applications. Renew. Energy 2020, 161, 1226–1243. [Google Scholar] [CrossRef]

- Naseri, A.; Moradi, R.; Norris, S.; Subiantoro, A. Experimental Investigation of a Revolving Vane Expander in a Micro-Scale Organic Rankine Cycle System for Low-Grade Waste Heat Recovery. Energy 2022, 253, 124174. [Google Scholar] [CrossRef]

- Kaczmarczyk, T.Z.; Żywica, G.; Ihnatowicz, E. Experimental Research on Scroll Expanders Operating in Parallel in an Organic Rankine Cycle System with a Biomass Boiler. Energy Convers. Manag. 2020, 224, 113390. [Google Scholar] [CrossRef]

- Wu, T.; Cai, S.; Yao, Z.; Yin, X.; Ma, X.; Gao, X.; Xie, F.; Yang, H.; Shen, X.; Shao, L. Design and Optimization of the Radial Inflow Turbogenerator for Organic Rankine Cycle System Based on the Genetic Algorithm. Appl. Therm. Eng. 2024, 253, 123749. [Google Scholar] [CrossRef]

- Spale, J.; Jun, G.C.; Novotny, V.; Streit, P.; Weiß, A.P.; Kolovratnik, M. Development of a 10 kW Class Axial Impulse Single Stage Turboexpander for a Micro-CHP ORC Unit. EPJ Web Conf. 2022, 264, 01044. [Google Scholar] [CrossRef]

- Villarino, Y.T.; Rial, L.P.; Rodríguez-Abalde, Á. Assessment of a Residual Biomass Micro-Combined Heat and Power System Based on an Organic Rankine Cycle Coupled to a Boiler. J. Environ. Manag. 2022, 301, 113832. [Google Scholar] [CrossRef] [PubMed]

- Perrone, D.; Falbo, L.; Morrone, P.; Algieri, A. Techno-Economic Investigation of Integrated Biodiesel Internal Combustion Engines and Transcritical Organic Rankine Cycles for Small-Scale Combined Heat and Power Generation. Energy Convers. Manag. X 2023, 20, 100426. [Google Scholar] [CrossRef]

- Feng, Y.; Xu, K.; Zhang, Q.; Hung, T.-C.; He, Z.; Xi, H.; Rasheed, N. Experimental Investigation and Machine Learning Optimization of a Small-Scale Organic Rankine Cycle. Appl. Therm. Eng. 2023, 224, 120120. [Google Scholar] [CrossRef]

- Zhang, Y.; Tsai, Y.-C.; Ren, X.; Tuo, Z.; Wang, W.; Gong, L.; Hung, T.-C. Experimental Study of the External Load Characteristics on a Micro-Scale Organic Rankine Cycle System. Energy 2024, 306, 132453. [Google Scholar] [CrossRef]

- Mascuch, J.; Novotny, V.; Vodicka, V.; Spale, J.; Zeleny, Z. Experimental Development of a Kilowatt-Scale Biomass Fired Micro—CHP Unit Based on ORC with Rotary Vane Expander. Renew. Energy 2020, 147, 2882–2895. [Google Scholar] [CrossRef]

- Liu, C.; Wang, S.; Zhang, C.; Li, Q.; Xu, X.; Huo, E. Experimental Study of Micro-Scale Organic Rankine Cycle System Based on Scroll Expander. Energy 2019, 188, 115930. [Google Scholar] [CrossRef]

- Qiu, K.; Entchev, E. A Micro-CHP System with Organic Rankine Cycle Using R1223zd(E) and n-Pentane as Working Fluids. Energy 2022, 239, 121826. [Google Scholar] [CrossRef]

- Wang, Z.; Pan, H.; Xia, X.; Xie, B.; Peng, D.; Yang, H. Experimental Investigation on Steady and Dynamic Performance of Organic Rankine Cycle with R245fa/R141b under Different Cooling and Expander Speed Conditions. Energy 2022, 241, 122511. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, Y.; Xia, X.; Pan, H.; Zhang, S.; Liu, Z. Experimental Evaluation of Organic Rankine Cycle Using Zeotropic Mixture under Different Operation Conditions. Energy 2023, 264, 126188. [Google Scholar] [CrossRef]

- Zhang, H.-H.; Zhang, Y.-F.; Feng, Y.-Q.; Chang, J.-C.; Chang, C.-W.; Xi, H.; Gong, L.; Hung, T.-C.; Li, M.-J. The Parametric Analysis on the System Behaviors with Scroll Expanders Employed in the ORC System: An Experimental Comparison. Energy 2023, 268, 126713. [Google Scholar] [CrossRef]

- Luo, J.; Lu, P.; Chen, K.; Luo, X.; Chen, J.; Liang, Y.; Yang, Z.; Chen, Y. Experimental and Simulation Investigation on the Heat Exchangers in an ORC under Various Heat Source/Sink Conditions. Energy 2023, 264, 126189. [Google Scholar] [CrossRef]

- Fatigati, F.; Vittorini, D.; Cipollone, R. Dynamic Response of a Micro-Scale ORC-Based Power Unit Fed by Solar Flat Panels. Appl. Therm. Eng. 2024, 243, 122546. [Google Scholar] [CrossRef]

- Eyerer, S.; Dawo, F.; Schifflechner, C.; Niederdränk, A.; Spliethoff, H.; Wieland, C. Experimental Evaluation of an ORC-CHP Architecture Based on Regenerative Preheating for Geothermal Applications. Appl. Energy 2022, 315, 119057. [Google Scholar] [CrossRef]

- Agung Pambudi, N.; Wibowo, S.; Ranto; Huat Saw, L. Experimental Investigation of Organic Rankine Cycle (ORC) for Low Temperature Geothermal Fluid: Effect of Pump Rotation and R-134 Working Fluid in Scroll-Expander. Energy Eng. 2021, 118, 1565–1576. [Google Scholar] [CrossRef]

- Spale, J.; Vodicka, V.; Zeleny, Z.; Pavlicko, J.; Mascuch, J.; Novotny, V. Scaling up a Woodchip-Fired Containerized CHP ORC Unit toward Commercialization. Renew. Energy 2022, 199, 1226–1236. [Google Scholar] [CrossRef]

- European Commission; Joint Research Centre. The Use of Woody Biomass for Energy Production in the EU; Publications Office: Luxembourg, 2021. [Google Scholar]

- Backa, A.; Čajová Kantová, N.; Nosek, R.; Patsch, M. Evaluating the Combustion of Various Biomass Pellets in a Small Heat Source with Underfeed Pellet Burner: Heat Output, Gas Emission and Ash Melting Behavior. J. Energy Inst. 2025, 118, 101936. [Google Scholar] [CrossRef]

- Asif, Z.; Chen, Z.; Wang, H.; Zhu, Y. Update on Air Pollution Control Strategies for Coal-Fired Power Plants. Clean Technol. Environ. Policy 2022, 24, 2329–2347. [Google Scholar] [CrossRef]

- Tran, H.; Juno, E.; Arunachalam, S. Emissions of Wood Pelletization and Bioenergy Use in the United States. Renew. Energy 2023, 219, 119536. [Google Scholar] [CrossRef]

- Morrone, P.; Amelio, M.; Algieri, A.; Perrone, D. Hybrid Biomass and Natural Gas Combined Cycles: Energy Analysis and Comparison between Different Plant Configurations. Energy Convers. Manag. 2022, 267, 115874. [Google Scholar] [CrossRef]

- Zygmunt Kaczmarczyk, T. Experimental Research of a Small Biomass Organic Rankine Cycle Plant with Multiple Scroll Expanders Intended for Domestic Use. Energy Convers. Manag. 2021, 244, 114437. [Google Scholar] [CrossRef]

- Zhang, Q.; Feng, Y.-Q.; Xu, K.-J.; Liang, H.-J.; Liu, Z.-N.; Zhao, C.-Y.; Wang, Y.-Z.; Sapin, P.; Markides, C.N. Dynamic Behaviour and Performance Evaluation of a Biomass-Fired Organic Rankine Cycle Combined Heat and Power (ORC-CHP) System under Different Control Strategies. Appl. Therm. Eng. 2024, 248, 123236. [Google Scholar] [CrossRef]

- Douvartzides, S.; Tsiolikas, A.; Charisiou, N.; Souliotis, M.; Karayannis, V.; Taousanidis, N. Energy and Exergy-Based Screening of Various Refrigerants, Hydrocarbons and Siloxanes for the Optimization of Biomass Boiler–Organic Rankine Cycle (BB–ORC) Heat and Power Cogeneration Plants. Energies 2022, 15, 5513. [Google Scholar] [CrossRef]

- Mota-Babiloni, A.; Amat-Albuixech, M.; Molés-Ribera, F.; Navarro-Esbrí, J. Techno-Economic Feasibility of Organic Rankine Cycles (ORC) for Waste Heat Recovery. In Heat Energy Recovery for Industrial Processes and Wastes; Borge-Diez, D., Rosales-Asensio, E., Eds.; Green Energy and Technology; Springer International Publishing: Cham, Switzerland, 2023; pp. 105–137. ISBN 978-3-031-24373-8. [Google Scholar]

- Vilasboas, I.F.; Dos Santos, V.G.S.F.; Ribeiro, A.S.; Da Silva, J.A.M. Surrogate Models Applied to Optimized Organic Rankine Cycles. Energies 2021, 14, 8456. [Google Scholar] [CrossRef]

- Damarseckin, S.; Junior Kane, S.Y.; Atiz, A.; Karakilcik, M.; Sogukpinar, H.; Bozkurt, I.; Oyucu, S.; Aksoz, A. A Comparative Review of ORC and R-ORC Technologies in Terms of Energy, Exergy, and Economic Performance. Heliyon 2024, 10, e40575. [Google Scholar] [CrossRef]

- Qiu, G.; Shao, Y.; Li, J.; Liu, H.; Riffat, S.B. Experimental Investigation of a Biomass-Fired ORC-Based Micro-CHP for Domestic Applications. Fuel 2012, 96, 374–382. [Google Scholar] [CrossRef]

- Kaczmarczyk, T.Z.; Żywica, G.; Ihnatowicz, E. Experimental Study of a Low-Temperature Micro-Scale Organic Rankine Cycle System with the Multi-Stage Radial-Flow Turbine for Domestic Applications. Energy Convers. Manag. 2019, 199, 111941. [Google Scholar] [CrossRef]

- Mascuch, J.; Novotny, V.; Vodicka, V.; Zeleny, Z. Towards Development of 1–10 kW Pilot ORC Units Operating with Hexamethyldisiloxane and Using Rotary Vane Expander. Energy Procedia 2017, 129, 826–833. [Google Scholar] [CrossRef]

- Feng, Y.-Q.; Wu, Y.-Z.; Zhang, Q.; Liu, Z.-N.; Wang, X.-X.; Hung, T.-C.; Yu, H.-S.; He, Z.-X. Experiment Investigation and Machine Learning Prediction of a Biomass-Fired Organic Rankine Cycle Combined Heating and Power System under Various Heat Source Temperatures and Mass Flow Rates. Energy 2025, 324, 135841. [Google Scholar] [CrossRef]

- Moradi, R.; Cioccolanti, L. Modelling Approaches of Micro and Small-Scale Organic Rankine Cycle Systems: A Critical Review. Appl. Therm. Eng. 2024, 236, 121505. [Google Scholar] [CrossRef]

- Widianti, T.; Firdaus, H. A Decade of Organic Rankine Cycle Research Trends and Evolution: A Bibliometric Analysis. Evergreen 2024, 11, 2479–2503. [Google Scholar] [CrossRef]

- Jiménez-García, J.C.; Ruiz, A.; Pacheco-Reyes, A.; Rivera, W. A Comprehensive Review of Organic Rankine Cycles. Processes 2023, 11, 1982. [Google Scholar] [CrossRef]

- Fatigati, F.; Cipollone, R. The Benefits of a Recuperative Layout of an ORC-Based Unit Fed by a Solar-Assisted Reservoir Operating as a Micro-Cogeneration Plant. Energy Convers. Manag. 2024, 300, 117888. [Google Scholar] [CrossRef]

- Kaczmarczyk, T.Z.; Żywica, G. Experimental Study of the Effect of Load and Rotational Speed on the Electrical Power of a High-Speed ORC Microturbogenerator. Appl. Therm. Eng. 2024, 238, 122012. [Google Scholar] [CrossRef]

- Woodco. E-Compact Prestige 25P/40P; Installation and Operation Manual; Woodco: Sydney, Australia, 2017. [Google Scholar]

- Therminol. Therminol SP Heat Transfer Fluid. Available online: https://www.therminol.com/product/71093454 (accessed on 16 December 2024).

- Ji, D.; Cai, H.; Ye, Z.; Luo, D.; Wu, G.; Romagnoli, A. Comparison between Thermoelectric Generator and Organic Rankine Cycle for Low to Medium Temperature Heat Source: A Techno-Economic Analysis. Sustain. Energy Technol. Assess. 2023, 55, 102914. [Google Scholar] [CrossRef]

- Mana, A.A.; Kaitouni, S.I.; Kousksou, T.; Jamil, A. Enhancing Sustainable Energy Conversion: Comparative Study of Superheated and Recuperative ORC Systems for Waste Heat Recovery and Geothermal Applications, with Focus on 4E Performance. Energy 2023, 284, 128654. [Google Scholar] [CrossRef]

- Sim, J.-B.; Yook, S.-J.; Kim, Y.W. Development of 180 kW Organic Rankine Cycle (ORC) with a High-Efficiency Two-Stage Axial Turbine. Energies 2023, 16, 7112. [Google Scholar] [CrossRef]

- Moradi, R.; Villarini, M.; Cioccolanti, L. Experimental Modeling of a Lubricated, Open Drive Scroll Expander for Micro-Scale Organic Rankine Cycle Systems. Appl. Therm. Eng. 2021, 190, 116784. [Google Scholar] [CrossRef]

- Abbas, W.K.A.; Baumhögger, E.; Vrabec, J. Experimental Investigation of Organic Rankine Cycle Performance Using Alkanes or Hexamethyldisiloxane as a Working Fluid. Energy Convers. Manag. X 2022, 15, 100244. [Google Scholar] [CrossRef]

- Algieri, A.; Bova, S.; De Bartolo, C. Experimental and Numerical Investigation on the Effects of the Seeding Properties on LDA Measurements. J. Fluids Eng. 2005, 127, 514–522. [Google Scholar] [CrossRef]

- Doebelin, E.O. Measurement Systems: Application and Design, 5th ed.; McGraw-Hill Series in Mechanical Engineering; McGraw-Hill Higher Education: Boston, MA, USA, 2004; ISBN 978-0-07-119465-5. [Google Scholar]

- Li, Z.; Yu, X.; Wang, L.; Jiang, R.; Yu, X.; Huang, R.; Wu, J. Comparative Investigations on Dynamic Characteristics of Basic ORC and Cascaded LTES-ORC under Transient Heat Sources. Appl. Therm. Eng. 2022, 207, 118197. [Google Scholar] [CrossRef]

- Daniarta, S.; Nemś, M.; Kolasiński, P. A Review on Thermal Energy Storage Applicable for Low- and Medium-Temperature Organic Rankine Cycle. Energy 2023, 278, 127931. [Google Scholar] [CrossRef]

- Algieri, A.; Morrone, P. Thermo-Economic Investigation of Solar-Biomass Hybrid Cogeneration Systems Based on Small-Scale Transcritical Organic Rankine Cycles. Appl. Therm. Eng. 2022, 210, 118312. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A.; Ahmadi, P. Optimization of Energy Systems, 1st ed.; Wiley: Hoboken, NJ, USA, 2017; ISBN 978-1-118-89443-9. [Google Scholar]

| Electric Power | System Configuration | Heat Transfer Fluid | Hot Source Temperature | Expander Inlet Temperature | Thermal Efficiency | Electric Efficiency | |

|---|---|---|---|---|---|---|---|

| [kW] | [-] | [-] | [°C] | [°C] | [%] | [%] | |

| [50] | 0.03–1.2 | Recuperative | Thermal oil | 179–204 | 122–177 | - | 3.1–3.3 |

| [25] | 1.0–2.1 | Recuperative | Thermal oil | 130–155 | 110–125 | - | 4.8–7.3 |

| [30] | 1.5–3.6 | Recuperative | Water | 82–98 | - | - | 4.0–9.4 ** |

| [56] | 0.82–0.86 | Recuperative | Water | 110–129 | ≤126.6 | - | 1.3–1.4 |

| [57] | 0.2–2.1 * | Recuperative | Thermal oil | ≤200 | ≤180 | 5.0–6.5 | - |

| [58] | 0.6–1.2 | Recuperative | Thermal oil | ≤350 | ≤210 | - | 2.8 |

| [58] | 1.0 | Simple | Flue gas | 280–350 | 155–166 | - | 4.2 |

| [34] | 1.87 | Simple | Flue gas | ≤650 | ≤192 | - | 2.5 |

| [59] | 1.19–1.53 * | Simple | Water | 110–130 | 100–115 | 9.5–12.1 | - |

| Feature | Value |

|---|---|

| Length | 3.15–40 mm |

| Diameter | 6 mm ± 1 mm |

| Lower heating value (LHV) | 16.3 ÷ 19.0 MJ/kg |

| Ash content | <0.7% |

| Max sulphur content | <0.03% |

| Max nitrogen content | <0.3% |

| Max chlorine content | <0.02% |

| Properties | |

|---|---|

| Commercial name | Therminol SP |

| Composition | Synthetic hydrocarbon mixture |

| Appearance | Clear yellow liquid |

| Maximum bulk temperature | 315 °C |

| Normal boiling point | 335 °C |

| Flash point | 177 °C |

| Autoignition temperature | 366 °C |

| Kinematic viscosity at 100 °C | 19 mm2/s |

| Pour point | −40 °C |

| Mean molecular weight | 320 |

| Density at 15 °C | 875 kg/m3 |

| Maximum moisture content | <150 ppm |

| Properties | Unit | Value |

|---|---|---|

| Name | [-] | R245fa |

| Normal boiling point | [°C] | 15 |

| Critical temperature | [°C] | 154 |

| Critical pressure | [bar] | 36.5 |

| Molar mass | [kg/kmol] | 134 |

| GWP | [-] | 1030 |

| ODP | [-] | 0 |

| Properties | Unit | Evaporator | IHE | Condenser |

|---|---|---|---|---|

| Hot side volume | [dm3] | 2.66 | 1.89 | 2.62 |

| Cold side volume | [dm3] | 2.78 | 1.95 | 2.71 |

| Number of plates | [-] | 50 | 62 | 66 |

| Heat transfer surface | [m2] | 2.47 | 1.69 | 2.42 |

| Max working pressure | [bar] | 36 | 28 | 27 |

| Width of plate heat exchanger | [mm] | 119 | 117 | 119 |

| Length of plate heat exchanger | [mm] | 479 | 234 | 320 |

| Gap between plates | [mm] | 2.25 | 2.34 | 2.24 |

| Port area | [cm2] | 4.52 | 8.54 | 8.54 |

| Plate thickness | [mm] | 0.4 | 0.4 | 0.4 |

| Chevron angle | [°] | 60 | 60 | 60 |

| Material | [-] | Stainless steel | Stainless steel | Stainless steel |

| Meter Type | Physical Principle of Measurement | Measuring Range | Uncertainty |

|---|---|---|---|

| Energy meter | Power meter | 0–5000 W | 1% |

| Oil flow meter | Variable area flow meter | 100–1800 L/h | 1.5% |

| Water flow meter | Vortex | 9–150 L/min | 1 L/min |

| Temperature meter | PT 1000 | −50–200 °C | ±0.9 °C |

| Temperature meter | K-type thermocouples | −40–1100 °C | ±1.5 °C |

| Pressure meter | Sealed gauge | 0–30 (abs) | 1.5% |

| Pump Speed | Expander Speed | Thermal Oil Inlet Temperature | Thermal Oil Flow Rate | Cooling Water Inlet Temperature | Cooling Water Flow Rate |

|---|---|---|---|---|---|

| [rpm] | [rpm] | [°C] | [dm3/h] | [°C] | [dm3/min] |

| 2000 | 2000 | 118.6–143.2 | 1000 | 15 | 37 |

| 1500 | 2000 | 112.3–147.8 | 1000 | 15 | 37 |

| 1000 | 2000 | 94.7–147.8 | 1000 | 15 | 37 |

| 750 | 2000 | 78.6–149.0 | 1000 | 15 | 37 |

| 500 | 2000 | 108.4–148.1 | 1000 | 15 | 37 |

| 2000 | 2000 | 141.6–152.2 | 1000 | 15 | 15–30 |

| Parameter | Relative Uncertainty |

|---|---|

| Evaporator thermal power | ±2.6% |

| Condenser thermal power | ±5.2% |

| Electric efficiency | ±2.8% |

| Back work ratio | ±1.9% |

| ORC Configuration | ||||

|---|---|---|---|---|

| Parameter | Unit | Maximum Power (MP) | Maximum Efficiency (ME) | Suggested (S) |

| Electric power | [kW] | 2.296 | 1.376 | 2.095 |

| Electric efficiency | [%] | 7.94 | 8.55 | 8.46 |

| Evaporator thermal power | [kW] | 28.912 | 16.096 | 24.746 |

| Expander electric power | [kW] | 2.548 | 1.446 | 2.276 |

| Pump electric power | [kW] | 0.252 | 0.070 | 0.181 |

| Back work ratio | [%] | 9.89 | 4.84 | 7.96 |

| Expander speed | [rpm] | 2000 | 2000 | 2000 |

| Pump speed | [rpm] | 2000 | 1000 | 1500 |

| Pump pressure inlet | [bar] | 2.486 | 1.250 | 1.464 |

| Expander pressure inlet | [bar] | 12.016 | 6.688 | 10.053 |

| Pressure difference | [bar] | 9.529 | 5.438 | 8.589 |

| Inlet thermal oil temperature | [°C] | 152.2 | 133.2 | 147.8 |

| Pump temperature inlet | [°C] | 32.5 | 17.0 | 21.7 |

| Expander temperature inlet | [°C] | 136.4 | 131.4 | 143.1 |

| Superheating degree | [°C] | 38.6 | 57.9 | 53.2 |

| Cooling water flow rate | [dm3/min] | 15.0 | 37.0 | 37.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Falbo, L.; Algieri, A.; Morrone, P.; Perrone, D. Experimental Investigation into the Energy Performance of a Biomass Recuperative Organic Rankine Cycle (ORC) for Micro-Scale Applications in Design and Off-Design Conditions. Energies 2025, 18, 3201. https://doi.org/10.3390/en18123201

Falbo L, Algieri A, Morrone P, Perrone D. Experimental Investigation into the Energy Performance of a Biomass Recuperative Organic Rankine Cycle (ORC) for Micro-Scale Applications in Design and Off-Design Conditions. Energies. 2025; 18(12):3201. https://doi.org/10.3390/en18123201

Chicago/Turabian StyleFalbo, Luigi, Angelo Algieri, Pietropaolo Morrone, and Diego Perrone. 2025. "Experimental Investigation into the Energy Performance of a Biomass Recuperative Organic Rankine Cycle (ORC) for Micro-Scale Applications in Design and Off-Design Conditions" Energies 18, no. 12: 3201. https://doi.org/10.3390/en18123201

APA StyleFalbo, L., Algieri, A., Morrone, P., & Perrone, D. (2025). Experimental Investigation into the Energy Performance of a Biomass Recuperative Organic Rankine Cycle (ORC) for Micro-Scale Applications in Design and Off-Design Conditions. Energies, 18(12), 3201. https://doi.org/10.3390/en18123201