Comprehensive Experimental Study of Steam Flooding for Offshore Heavy Oil Recovery After Water Flooding

Abstract

1. Introduction

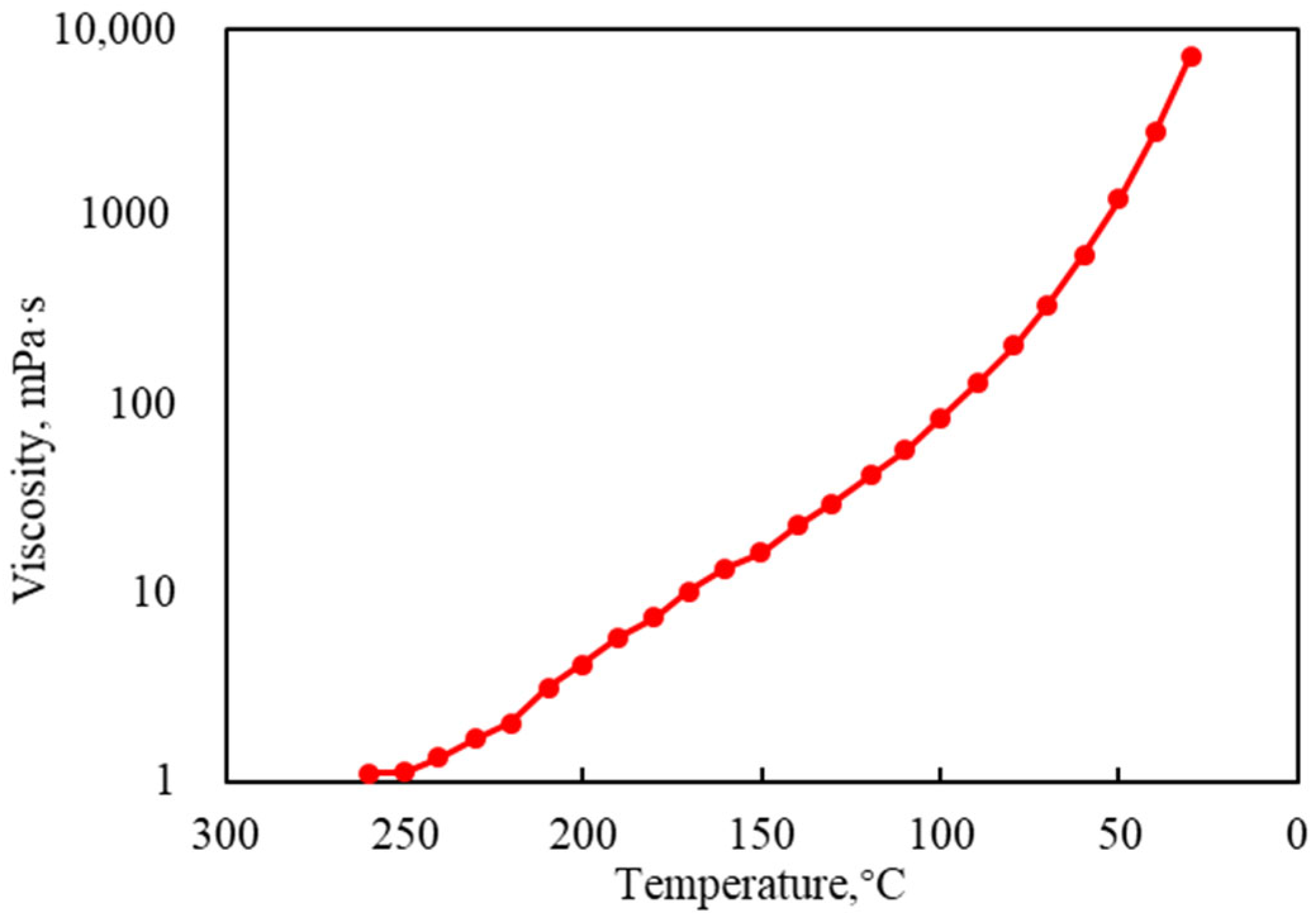

2. Experimental Materials

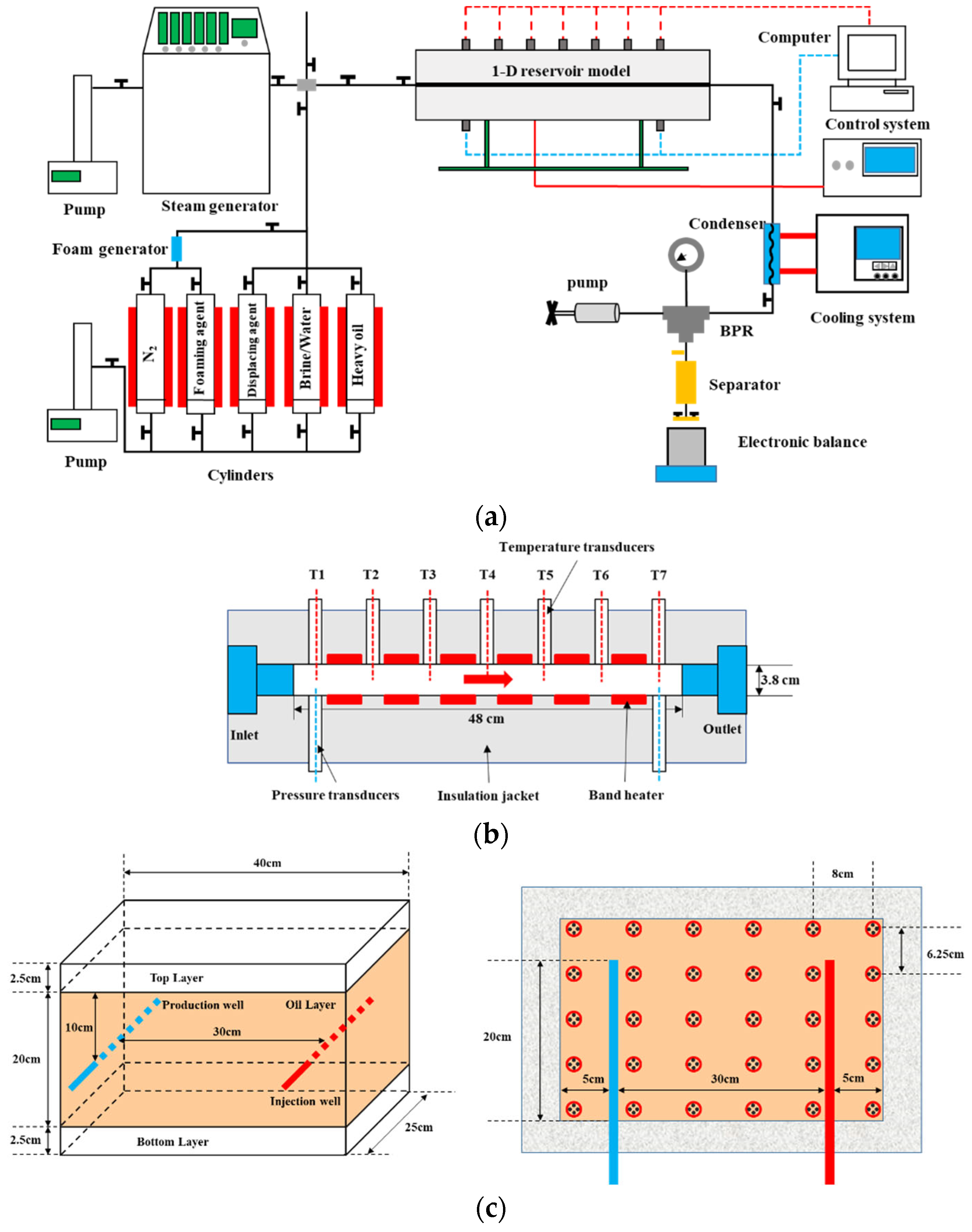

3. Experimental Apparatus

4. Experimental Procedures

4.1. 1-D Experiments

4.2. 3-D Experiments

5. Results and Discussion

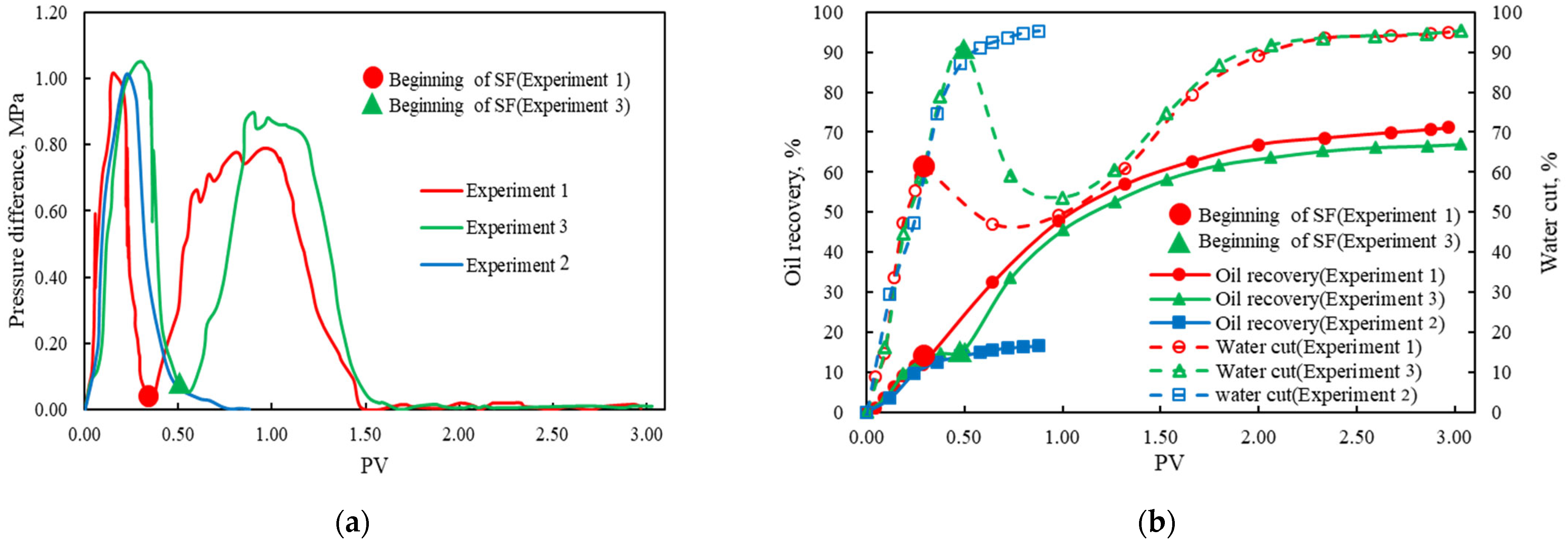

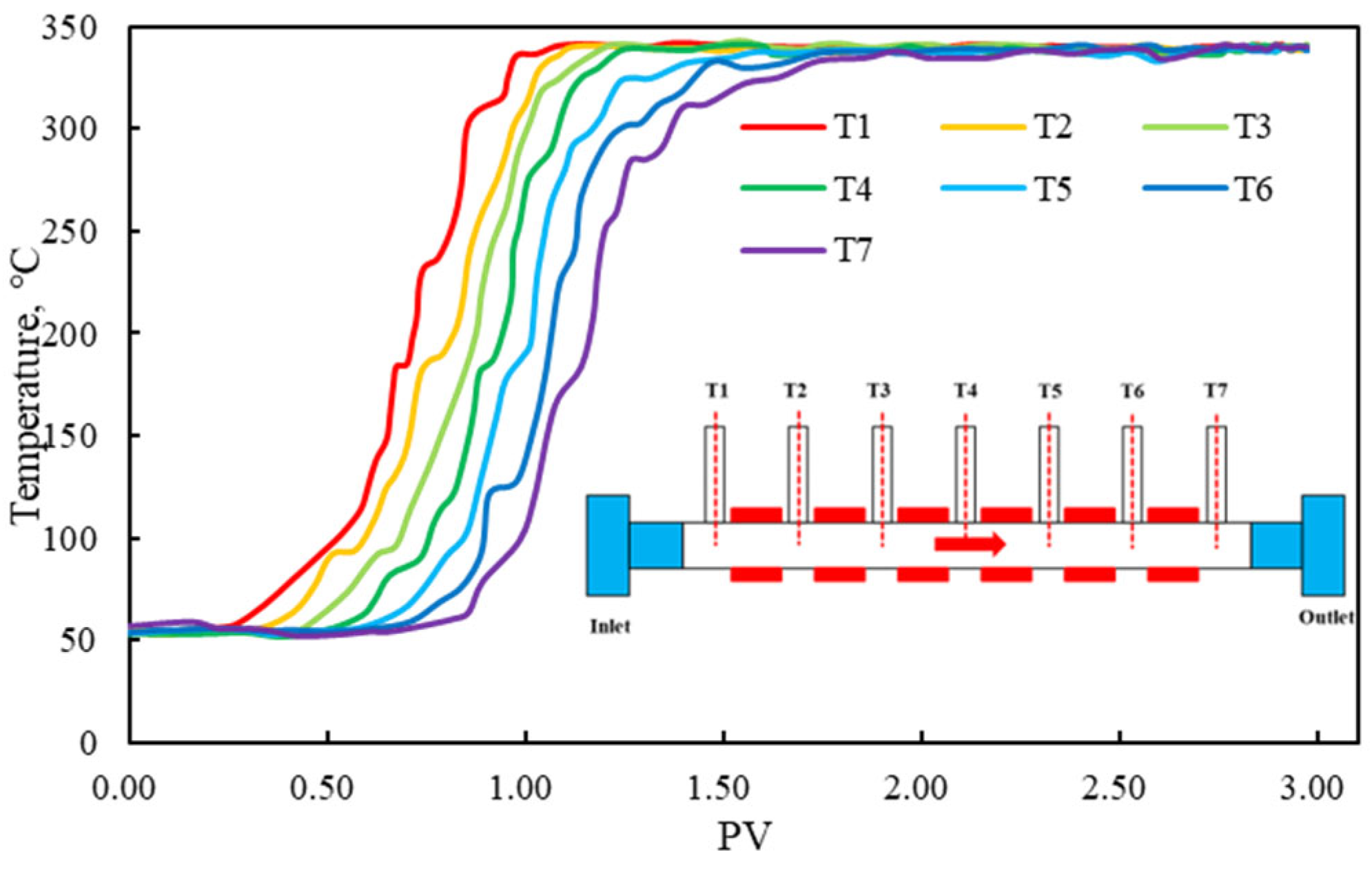

5.1. 1-D Experiments

5.1.1. Characterization of the SF After WF in the 1-D Reservoir Model

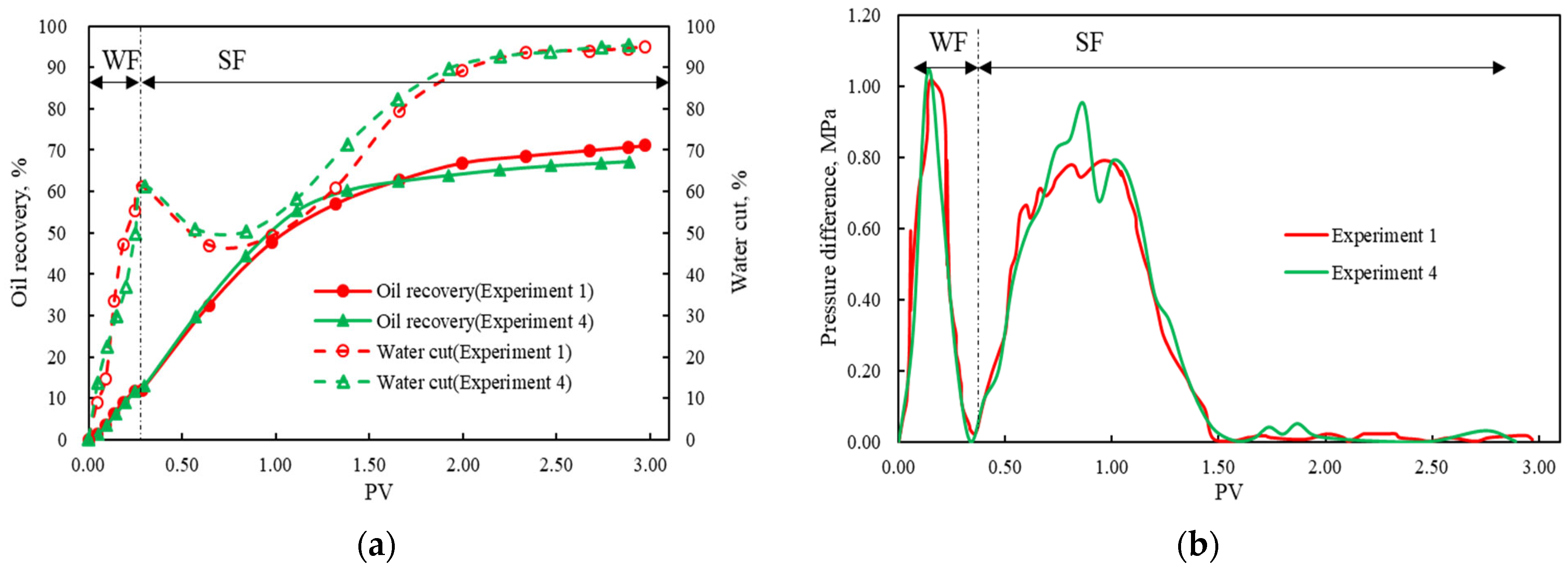

5.1.2. Feasibility of the SF After the WF Process

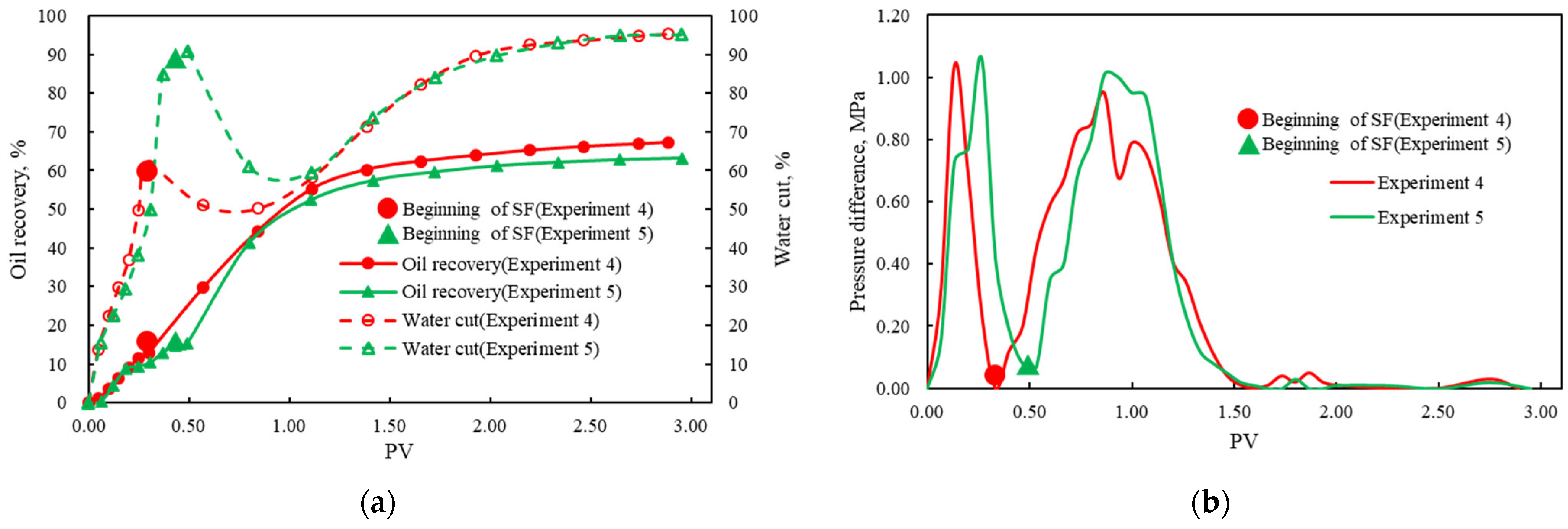

5.1.3. Effect of the Timing of SF

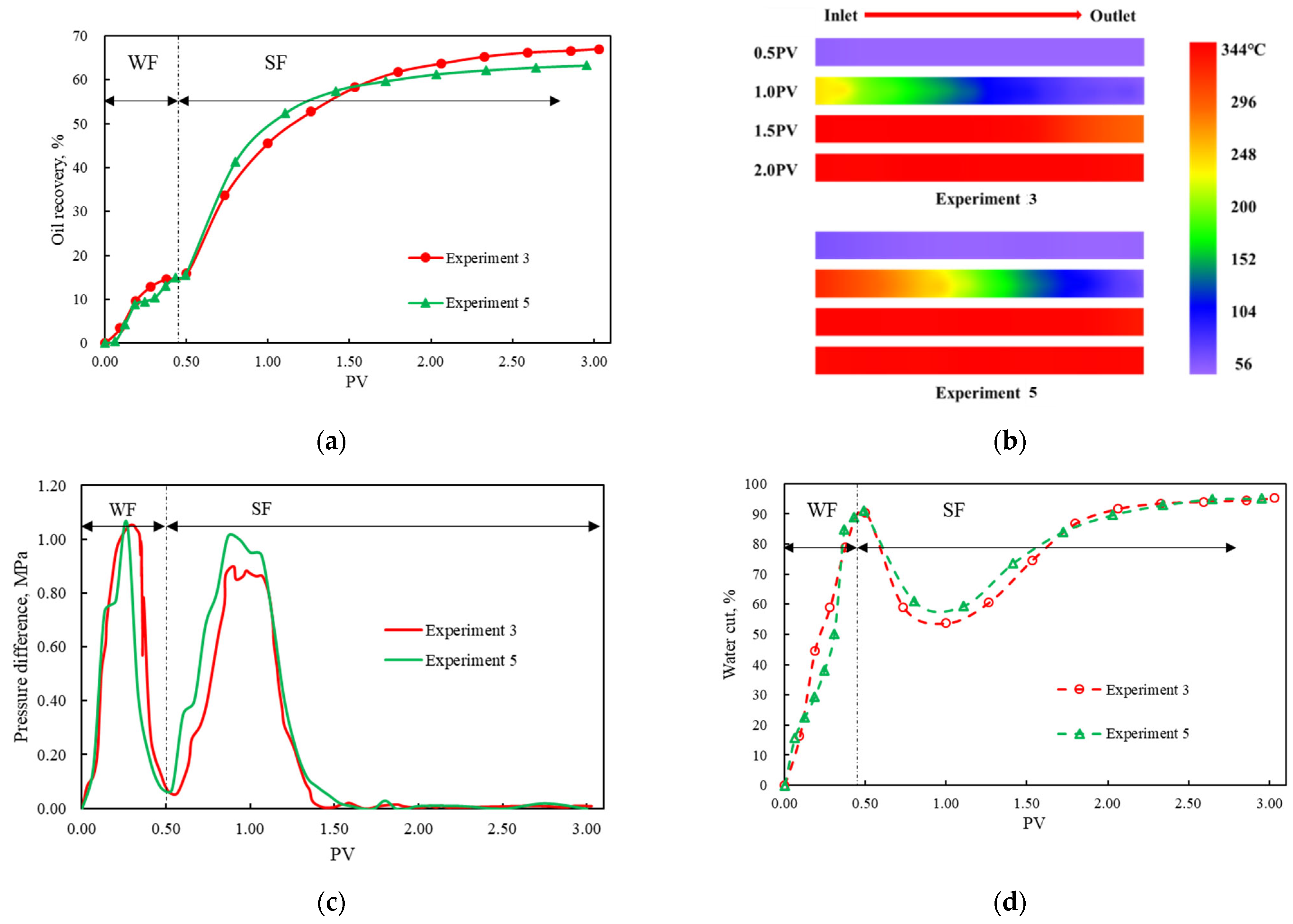

5.1.4. Effect of the Steam Injection Rate

5.1.5. Effect of the Chemical Agents

5.2. 3-D Experiments

5.2.1. Characterization of the SF After WF in the 3-D Reservoir Model

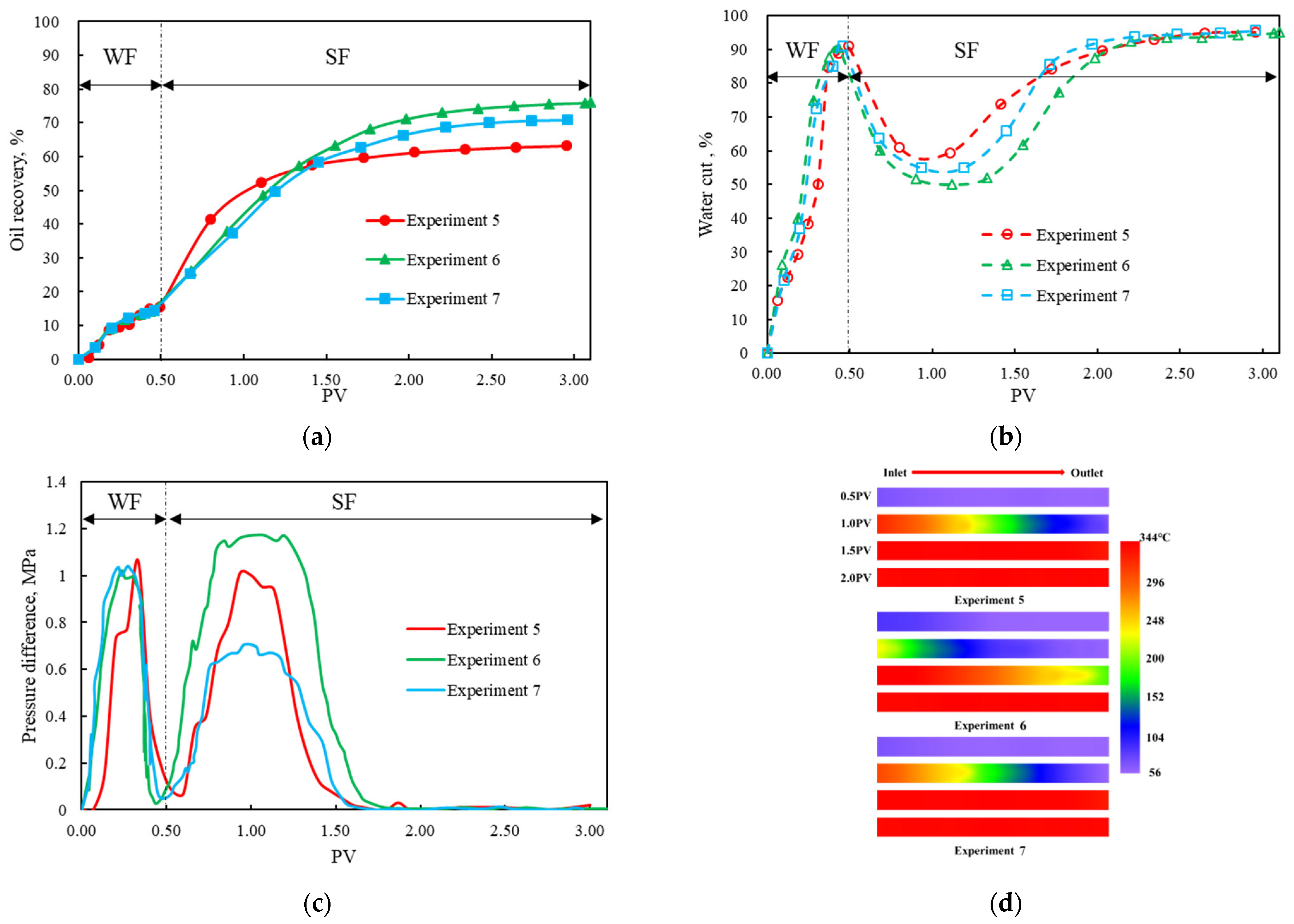

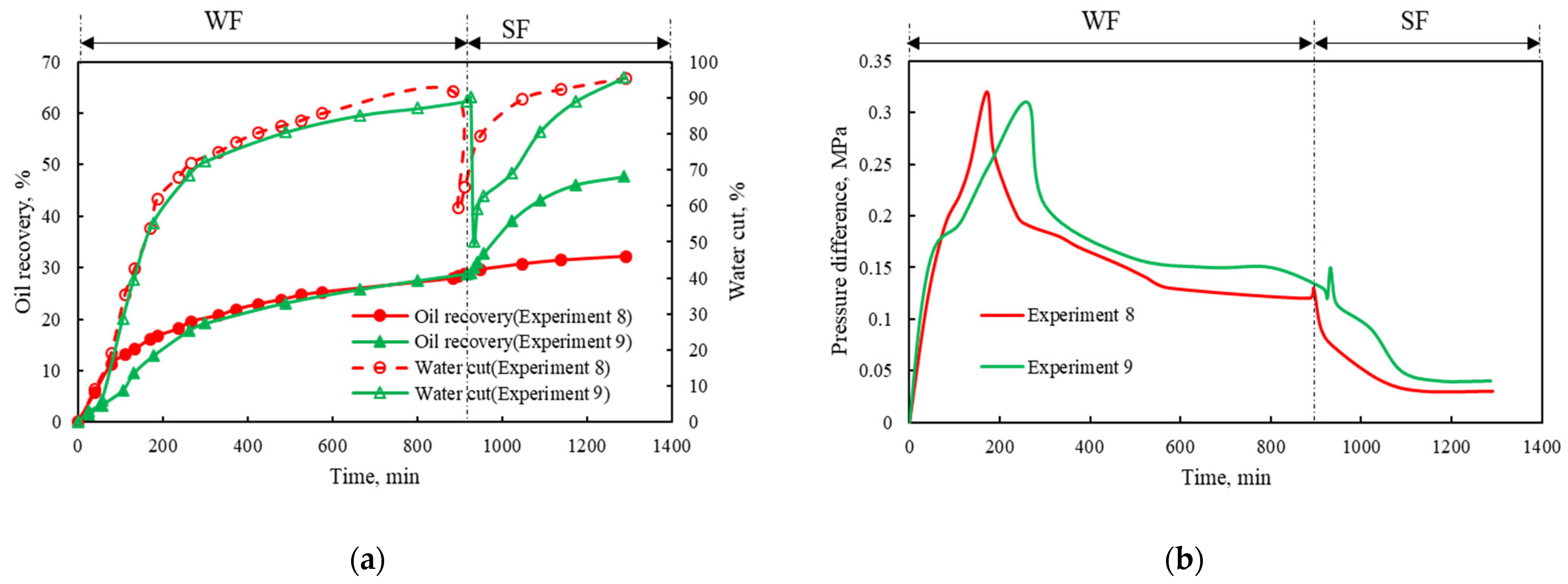

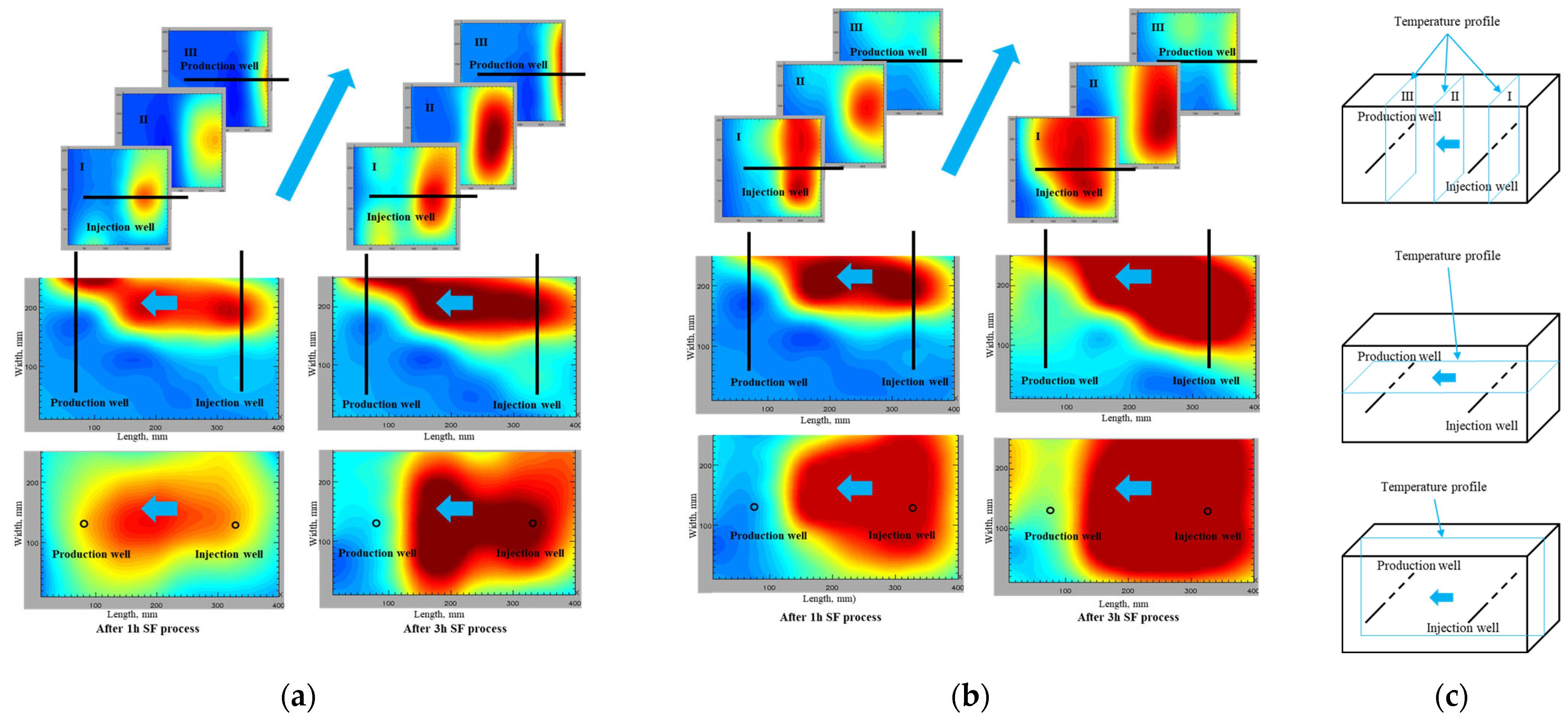

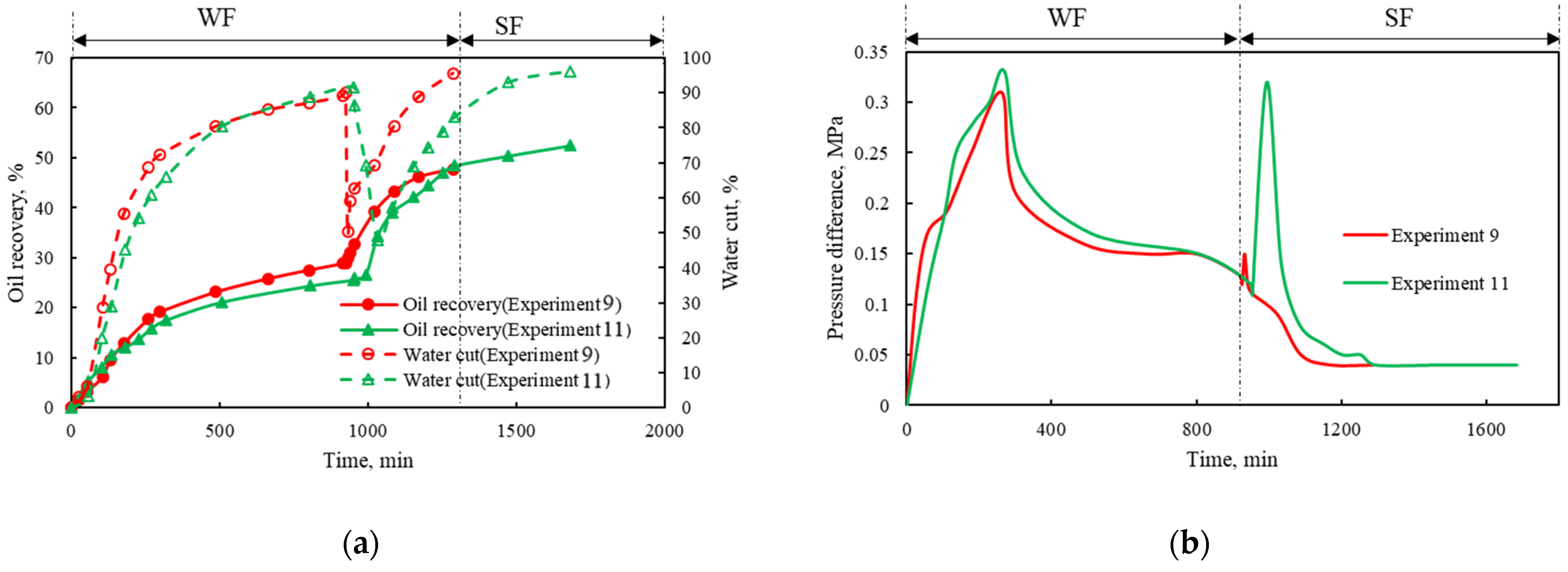

5.2.2. Effect of the Steam Injection Rate

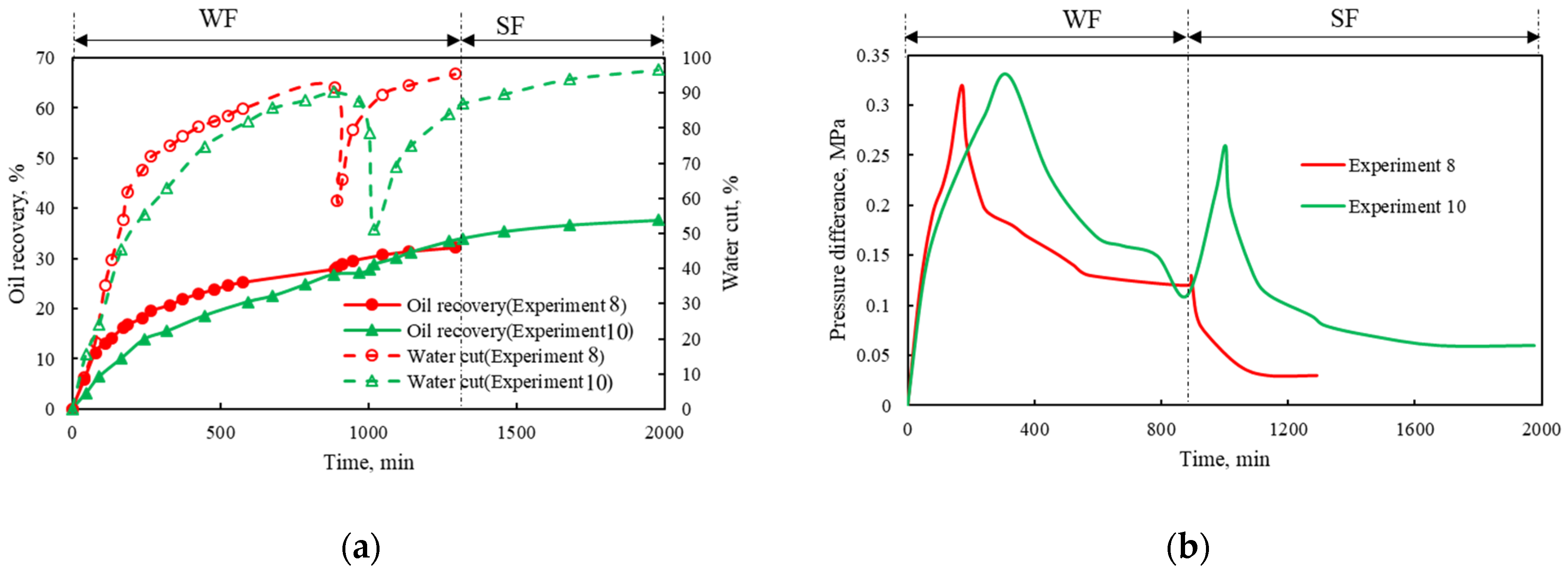

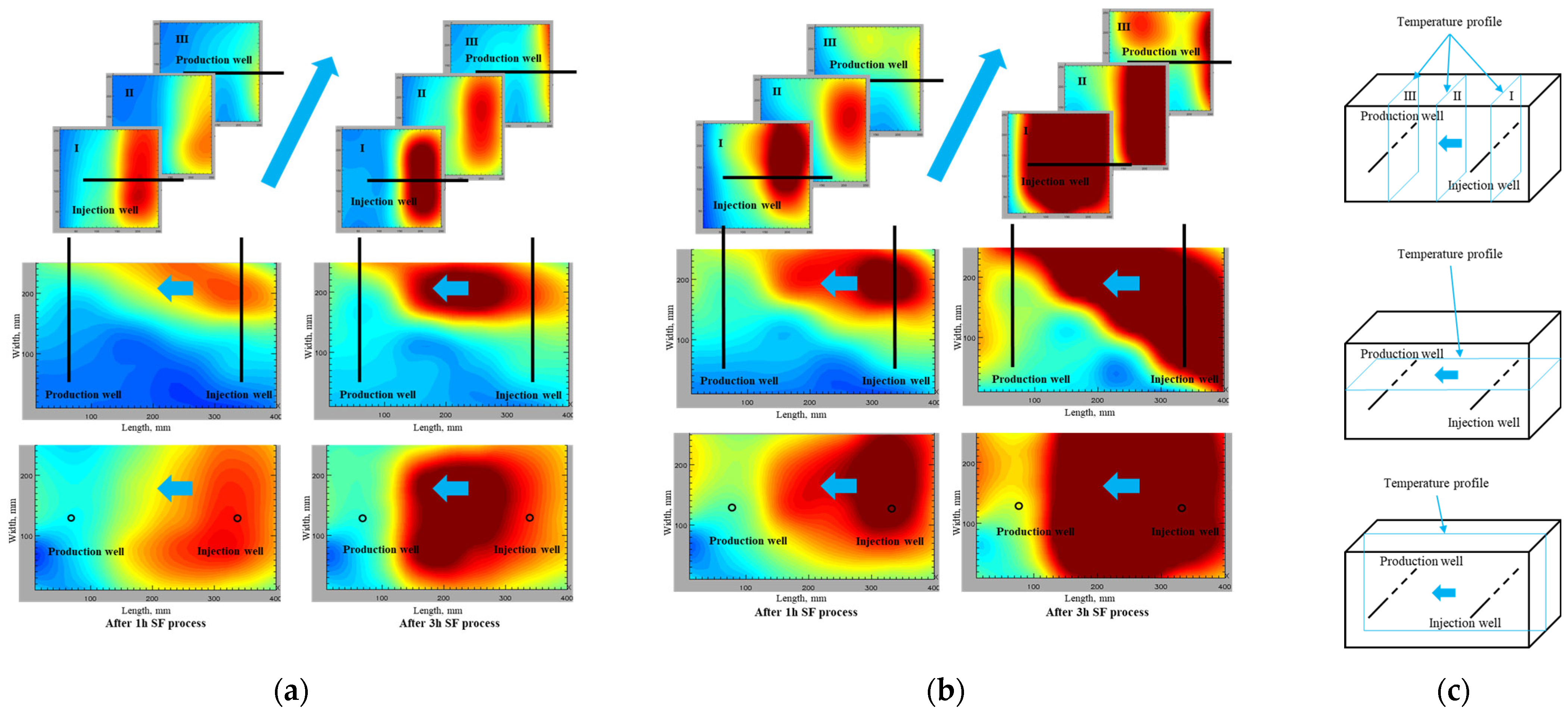

5.2.3. Effect of Chemical Agents

6. Conclusions

- For offshore heavy oil reservoirs after WF processes, the SF processes should start as early as possible if the economic conditions permit. When the SF started earlier, the residual oil saturation after the WF process was high, and the water channeling was not yet formed, which was beneficial for the subsequent SF process.

- For 1-D experiments, the SF process with a lower steam injection rate has better performance. However, the performance of the SF process was enhanced with the increase in steam injection rate in the 3-D experiments. The inconsistent results may result from the different experimental models and operational parameters. Comprehensively considering the results of 1-D and 3-D experiments, it can be concluded that it is extremely important to choose an appropriate steam injection rate for SF after WF processes.

- For 1-D experiments, the final oil recovery increased from 63.21% to 76.04% and the water cut decreased rapidly from 90.54% to 50.07% as the nitrogen foam was injected. The addition of nitrogen foam selectively blocked the water channeling, with high permeability formed in the previous WF process, resulting in the delayed occurrence of steam breakthrough. Furthermore, the foaming agent as a surfactant reduced the oil–water interfacial tension, resulting in increased final oil recovery.

- For 1-D experiments, the addition of the displacing agent in the injected steam improved the performance of the SF process (s higher final oil recovery, a lower water cut, and a longer time for the large pressure difference) because the displacing agent in the SF process altered the wettability of sand surface from oil-wet to water-wet and increased the displacement efficiency by emulsification and IFT reduction and, in turn, improved the performance of the SF process.

- The nitrogen foam and displacing agent had synergistic effects on the performance of the SF after the WF processes. Compared with the pure SF process, the SF process with the addition of the nitrogen foam and displacing agent had a higher final oil recovery, a higher maximum reduction of water cut, a larger pressure difference, a larger steam chamber, and a higher reservoir temperature in the 3-D experiments.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Q.; Li, Q.C.; Cao, H.Q.; Wu, J.J.; Wang, F.L.; Wang, Y.L. The crack propagation behaviour of CO2 fracturing fluid in unconventional low permeability reservoirs: Factor analysis and mechanism revelation. Processes 2025, 13, 159. [Google Scholar] [CrossRef]

- Li, Q.C.; Li, Q.; Wu, J.J.; Li, X.Z.; Li, H.B.; Cheng, Y.F. Wellhead stability during development process of hydrate reservoir in the northern south china sea: Evolution and mechanism. Processes 2025, 13, 40. [Google Scholar] [CrossRef]

- Kang, X.D.; Zhang, J. Surfactant Polymer (SP) Flooding Pilot Test on Offshore Heavy Oil Field in Bohai Bay, China. In Proceedings of the SPE Enhanced Oil Recovery Conference (SPE), Kuala Lumpur, Malaysia, 2–4 July 2013. [Google Scholar]

- Hein, F.J. Geology of bitumen and heavy oil: An overview. J. Pet. Sci. Eng. 2017, 154, 551–563. [Google Scholar] [CrossRef]

- Huang, S.J.; Cao, M.; Cheng, L.S. Experimental study on the mechanism of enhanced oil recovery by multi-thermal fluid in offshore heavy oil. Int. J. Heat Mass Transf. 2018, 122, 1074–1084. [Google Scholar] [CrossRef]

- Zhao, Q.Y.; Guo, L.J.; Wang, Y.C.; Jin, H.; Chen, L.; Huang, Z.J. Enhanced oil recovery and in situ upgrading of heavy oil by supercritical water injection. Energy Fuels 2020, 34, 360–367. [Google Scholar] [CrossRef]

- Zheng, W.; Tan, X.H.; Jiang, W.D.; Xie, H.J.; Pei, H.H. Investigation of nanoclay-surfactant-stabilized foam for improving oil recovery of steam flooding in offshore heavy oil reservoirs. ACS Omega 2021, 6, 22709–22716. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.F.; Zhang, Y.Y.; Chen, H.J.; Duan, X.W.; Hu, W.T.; Zhang, X.S. Feasibility of Thermal Oil Recovery Processes in Offshore Heavy Oil Reservoirs: Simulations and Experiments. In Proceedings of the Offshore Technology Conference Asia (OTC), Kuala Lumpur, Malaysia, 22–25 March 2016. [Google Scholar]

- Li, Y.L.; Su, Y.C.; Yang, W.; Meng, P.; Wang, L.L. Research and Practice of Chemical Flooding on Offshore Heavy Oilfield in Bohai Bay of China. In Proceedings of the Offshore Technology Conference Asia (OTC), Kuala Lumpur, Malaysia, 27 October 2020. [Google Scholar]

- Dadlani, H.; Jain, G.; Saikia, S. Heavy Oil Polymer Pilot with Active Bottom Water Drive—A Success Story. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Virtual, 4 October 2021. [Google Scholar]

- Zhong, L.; Dong, Z.; Hou, J.; Li, Y.; Sun, Y.; Zhao, L.; Lu, W.; Qin, F. Investigation on Principles of Enhanced Offshore Heavy Oil Recovery by Coinjection of Steam with Flue Gas. In Proceedings of the SPE Enhanced Oil Recovery Conference (SPE), Kuala Lumpur, Malaysia, 2–4 July 2013. [Google Scholar]

- Liu, Y.; Zou, J.; Meng, X.; Zhong, L.; Wang, Q.; Zhang, W.; Zhou, F.; Han, X. Progress in Bohai Offshore Heavy Oil Thermal Recovery. In Proceedings of the Offshore Technology Conference Asia (OTC), Kuala Lumpur, Malaysia, 22 March 2016. [Google Scholar]

- Sun, Y.T.; Zhao, L.C.; Lin, T.; Liu, H.T.; Sun, Y.P.; Zhong, L.G.; Dong, Z.X.; Hou, J.R.; Li, Y.Q. Case Study: Thermal Enhance Bohai Offshore Heavy Oil Recovery by Co-Stimulation of Steam and Gases. In Proceedings of the SPE Heavy Oil Conference-Canada, Calgary, AB, Canada, 11–13 June 2013. [Google Scholar]

- Liu, Y.G.; Zou, J.; Meng, X.H.; Han, X.D.; Sun, Y.T.; Zhang, W.; Zhou, F.Y.; Fang, J.C. Treatment Technology of Steam Breakthrough for Offshore Heavy Oil Reservoirs Developed by Huff and Puff with Multi-Component Thermal Fluid. In Proceedings of the SPE Asia Pacific Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 11–13 August 2015. [Google Scholar]

- Qin, W.T.; Luo, P.Y.; Wojtanowicz, A.K. Improving Oil Recovery in Offshore Heavy Oil Underlain by Large Aquifer. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016. [Google Scholar]

- Kukharova, T.; Maltsev, P.; Novozhilov, I. Development of a control system for pressure distribution during gas production in a structurally complex field. Appl. Syst. Innov. 2025, 8, 51. [Google Scholar] [CrossRef]

- Skoczylas, P.; Sawafi, M.; Salem, B.A.; Al Jabri, S.; Zadjali, A.; Ponomarenko, R. Successful Application of All-Metal PCP in CSS and Steam Flood to Unlock Hard-To-Recover Oil Resources. In Proceedings of the SPE Artificial Lift Conference and Exhibition—Americas, The Woodlands, TX, USA, 19 August 2024. [Google Scholar]

- Jimenez, J. The Field Performance of SAGD Projects in Canada. In Proceedings of the International Petroleum Technology Conference, Kuala Lumpur, Malaysia, 3–5 December 2008. [Google Scholar]

- Liu, J.F.; Wu, X.M.; Sun, S.G.; Hao, L. The Application of Complex Displacement in Cyclic Steam Stimulation CSS & Steam Flooding SF Development in Liaohe Oilfield: A Field Performance Study. In Proceedings of the SPE Canadian Energy Technology Conference, Calgary, AB, Canada, 11–13 March 2022. [Google Scholar]

- Aksenov, M.; Lachugin, D.; Nukhaev, M.; Rymarenko, K.; Telkov, V.; Gaidukov, L.; Vologodskiy, K.; Khramov, D. Specifics and Challenges of Heavy Oil Production in Northen Siberia Illustration Based on Biggest Heavy Oil Project in Russia. In Proceedings of the SPE Heavy Oil Conference-Canada, Calgary, AB, Canada, 11–13 June 2013. [Google Scholar]

- Agarwal, A.; Kovscek, A.R. Producer Well Temperature Control and Optimal Oil Production During a Steamflood. In Proceedings of the SPE Western Regional Meeting, Bakersfield, CA, USA, 23–27 April 2017. [Google Scholar]

- Yuan, Z.; Liu, P.C.; Zhang, S.F.; Li, X.L.; Shi, L.X.; Jin, R.F. Experimental study and numerical simulation of nitrogen-assisted SAGD in developing heavy oil reservoirs. J. Pet. Sci. Eng. 2018, 162, 325–332. [Google Scholar] [CrossRef]

- Dong, X.H.; Liu, H.Q.; Chen, Z.X.; Wu, K.L.; Lu, N.; Zhang, Q.C. Enhanced oil recovery techniques for heavy oil and oilsands reservoirs after steam injection. Appl. Energy 2019, 239, 1190–1211. [Google Scholar] [CrossRef]

- Sun, X.F.; Cai, J.M.; Li, X.Y.; Zheng, W.; Wang, T.C.; Zhang, Y.Y. Experimental investigation of a novel method for heavy oil recovery using supercritical multithermal fluid flooding. Appl. Therm. Eng. 2021, 185, 116330. [Google Scholar] [CrossRef]

- Sun, X.F.; Wei, C.K.; Zhang, Q.Q.; Cai, J.M.; Wang, X.; Wang, Y.; Zhang, Y.Y. Development of a generalized experimental methodology for investigating the role of steam quality on steamflooding performance. SPE J. 2023, 28, 401–414. [Google Scholar] [CrossRef]

- Pang, Z.X.; Qi, P.; Zhang, F.Y.; Ge, T.T.; Liu, H.Q. The experimental analysis of the role of flue gas injection for horizontal well steam flooding. J. Energy Resour. Technol. 2018, 140, 102902. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Chen, H.J.; Sun, X.F.; Duan, X.W.; Hu, W.T.; Zhang, X.S. Optimization of thermal recovery strategies for offshore heavy oil reservoirs in Bohai Bay, China. Pet. Sci. Technol. 2016, 34, 139–144. [Google Scholar] [CrossRef]

- Zhang, S.L.; Zhang, Y.T.; Wang, S.H.; Liu, S.Q.; Li, X.L.; Li, S.L. Status of Heavy-Oil Development in China. In Proceedings of the SPE International Thermal Operations and Heavy Oil Symposium, Calgary, AB, Canada, 1–3 November 2005. [Google Scholar]

- Shandrygin, A.N.; Lutfullin, A. Current Status of Enhanced Recovery Techniques in the Fields of Russia. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. [Google Scholar]

- Pang, Z.X.; Liu, H.Q.; Zhu, L. A laboratory study of enhancing heavy oil recovery with steam flooding by adding nitrogen foams. J. Pet. Sci. Eng. 2015, 128, 184–193. [Google Scholar] [CrossRef]

- Wu, Z.B.; Liu, H.Q.; Pang, Z.X.; Wu, C.; Gao, M. Pore-scale experiment on blocking characteristics and EOR mechanisms of nitrogen foam for heavy oil: A 2D visualized study. Energy Fuels 2016, 30, 9106–9113. [Google Scholar] [CrossRef]

- Pu, W.F.; Gao, H.; Li, Y.B.; Luo, Q. Performance and mechanisms of enhanced oil recovery via CO2 assisted steam flooding technique in high heterogeneity heavy oil reservoir: Pvt and 3D experimental studies. Pet. Sci. Technol. 2020, 38, 823–835. [Google Scholar] [CrossRef]

- Lu, T.; Xu, Z.T.; Ban, X.C.; Peng, D.L.; Li, Z.M. Effect of flue gas on steam chamber expansion in steamflooding. SPE J. 2022, 27, 399–409. [Google Scholar] [CrossRef]

- Lyu, X.C.; Liu, H.Q.; Pang, Z.X.; Sun, Z.X. Visualized study of thermochemistry assisted steam flooding to improve oil recovery in heavy oil reservoir with glass micromodels. Fuel 2018, 218, 118–126. [Google Scholar] [CrossRef]

- Wang, Y.W.; Liu, H.Q.; Zhang, Q.C.; Chen, Z.X.; Wang, J.; Dong, X.H.; Chen, F.X. Pore-scale experimental study on eor mechanisms of combining thermal and chemical flooding in heavy oil reservoirs. J. Pet. Sci. Eng. 2020, 185, 106649. [Google Scholar] [CrossRef]

- Bagheri, S.R.; Clark, H.P. Steam-Foam Technology as an Option to Improve Steam Drive Efficiency. In Proceedings of the SPE Kuwait Oil and Gas Show and Conference, Mishref, Kuwait, 11–14 October 2015. [Google Scholar]

- Pratama, R.A.; Babadagli, T. Tertiary-recovery improvement of steam injection using chemical additives: Pore-scale understanding of challenges and solutions through visual experiments. SPE J. 2021, 26, 1552–1571. [Google Scholar] [CrossRef]

- Feng, G.Q.; Li, Y.; Yang, Z.D. Performance evaluation of nitrogen-assisted steam flooding process in heavy oil reservoir via numerical simulation. J. Pet. Sci. Eng. 2020, 189, 106954. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, Y.J.; Liu, P.C.; Zhou, Y.; Qi, Z.Y.; Shi, L.X.; Xi, C.F.; Zhang, Z.Y.; Wang, C.; Hua, D.D. Experimental and numerical investigation on extra-heavy oil recovery by steam injection using vertical injector -horizontal producer. J. Pet. Sci. Eng. 2021, 205, 108945. [Google Scholar] [CrossRef]

- Wang, C.; Zhong, L.G.; Cao, Z.J.; Liu, Y.G.; Zou, J.; Wang, Q.X. Synergistic collaboration between a viscosity reducer and a surfactant for in situ emulsion formation to enhance heavy-oil recovery. Energy Fuels 2020, 34, 95–102. [Google Scholar] [CrossRef]

- Liu, J.B.; Zhong, L.G.; Lyu, C.H.; Liu, Y.G.; Zhang, S.J. W/O emulsions generated by heavy oil in porous medium and its effect on re-emulsification. Fuel 2022, 310, 122344. [Google Scholar] [CrossRef]

| Ion Content | Salinity, mg/L |

|---|---|

| K++Na+ | 2746.46 |

| Mg2+ | 43.29 |

| Ca2+ | 429.26 |

| Cl−1 | 4974.34 |

| SO42− | 46.18 |

| HCO3− | 189.77 |

| CO32− | 0 |

| I− | 0.25 |

| Br− | 15.02 |

| Fe2+ | 0.03 |

| Fe3+ | 0.07 |

| Experiment No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model type | 1-D | 1-D | 1-D | 1-D | 1-D | 1-D | 1-D | 3-D | 3-D | 3-D | 3-D |

| Permeability, mD | 2090 | 2050 | 2030 | 2150 | 2080 | 2010 | 2070 | 2594 | 2502 | 2540 | 2523 |

| Porosity, % | 56.02 | 55.23 | 56.24 | 55.98 | 55.98 | 56.02 | 56.24 | 35.88 | 35.16 | 34.90 | 34.55 |

| Initial oil saturation, % | 94.88 | 94.39 | 95.22 | 95.02 | 94.89 | 94.88 | 95.22 | 81.83 | 83.48 | 86.81 | 85.98 |

| Timing of SF (water cut), % | 60 | 90 | 60 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | |

| Brine injection rate, mL/min | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 10 | 10 | 10 | 10 |

| Steam injection rate, mL/min | 5 | / | 5 | 10 | 10 | 10 | 10 | 10 | 30 | 10 | 30 |

| Steam injection temperature, °C | 340 | / | 340 | 340 | 340 | 340 | 340 | 340 | 340 | 340 | 340 |

| The type of chemical agents | / | / | / | / | / | Foaming agent | Displacing agent | / | / | Foaming agent, Displacing agent | Foaming agent, Displacing agent |

| Slug size of chemical agents, PV | / | / | / | / | / | 0.5 | 1.5 | / | / | 0.1, 0.1 | 0.1, 0.1 |

| The concentration of chemical agents, wt.% | / | / | / | / | / | 1 | 1 | / | / | 1 | 1 |

| Final oil recovery, % | 71.13 | 1 | 67.01 | 67.25 | 63.21 | 76.04 | 70.79 | 32.17 | 47.74 | 37.64 | 52.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Liu, Y.; Zou, J.; Wang, Q.; Wang, Z.; Zhao, Y.; Sun, X. Comprehensive Experimental Study of Steam Flooding for Offshore Heavy Oil Recovery After Water Flooding. Energies 2025, 18, 3140. https://doi.org/10.3390/en18123140

Zhang W, Liu Y, Zou J, Wang Q, Wang Z, Zhao Y, Sun X. Comprehensive Experimental Study of Steam Flooding for Offshore Heavy Oil Recovery After Water Flooding. Energies. 2025; 18(12):3140. https://doi.org/10.3390/en18123140

Chicago/Turabian StyleZhang, Wei, Yigang Liu, Jian Zou, Qiuxia Wang, Zhiyuan Wang, Yongbin Zhao, and Xiaofei Sun. 2025. "Comprehensive Experimental Study of Steam Flooding for Offshore Heavy Oil Recovery After Water Flooding" Energies 18, no. 12: 3140. https://doi.org/10.3390/en18123140

APA StyleZhang, W., Liu, Y., Zou, J., Wang, Q., Wang, Z., Zhao, Y., & Sun, X. (2025). Comprehensive Experimental Study of Steam Flooding for Offshore Heavy Oil Recovery After Water Flooding. Energies, 18(12), 3140. https://doi.org/10.3390/en18123140