Properties of Pellets from Forest and Agricultural Biomass and Their Mixtures

Abstract

1. Introduction

2. Materials and Methods

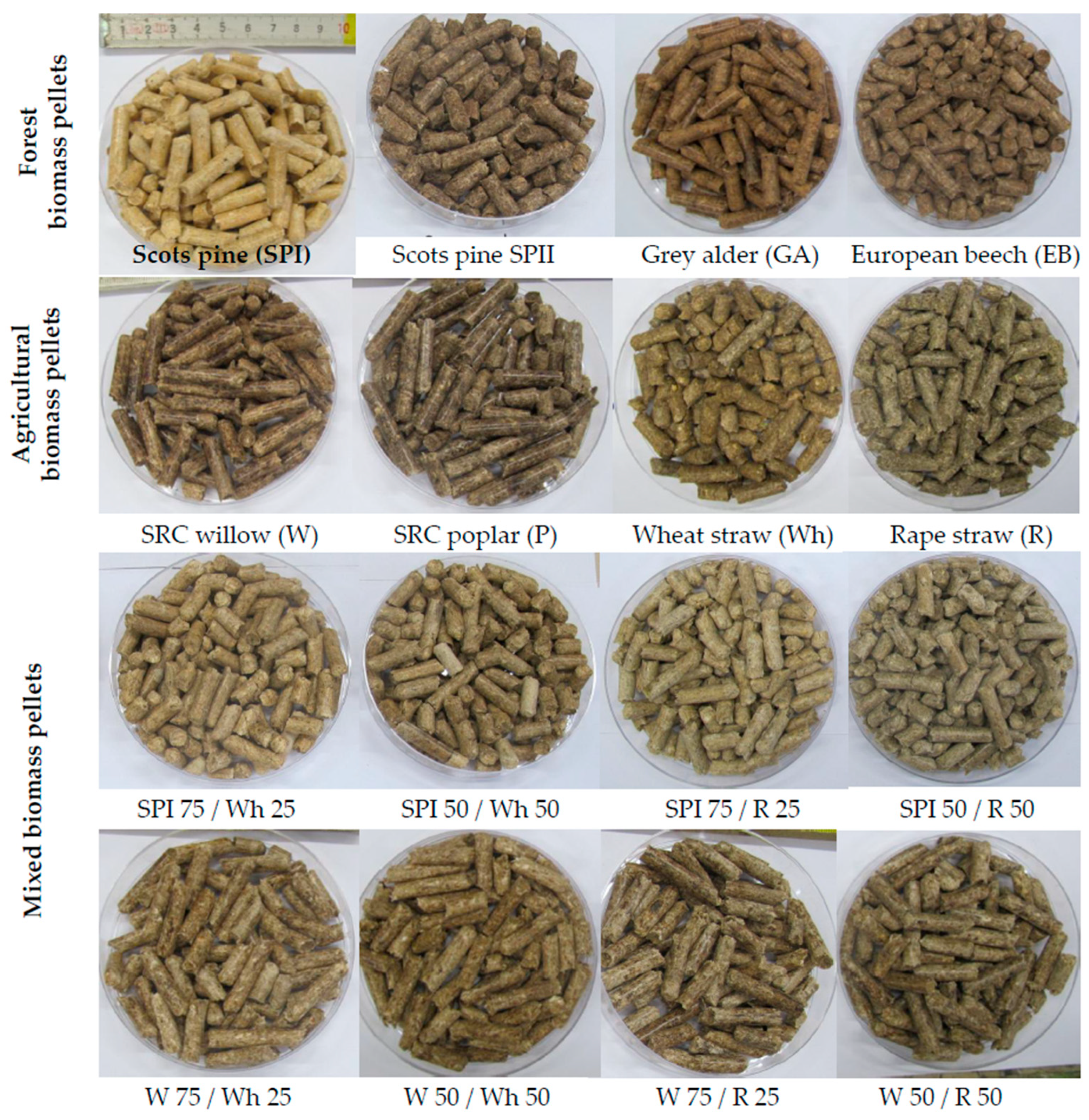

2.1. Materials of the Study

2.2. Laboratory Analyses and Comparison of Pellet Properties to Quality Standards

2.3. Statistical Analysis

3. Results and Discussion

3.1. Thermophysical Properties of Examined Pellet Types

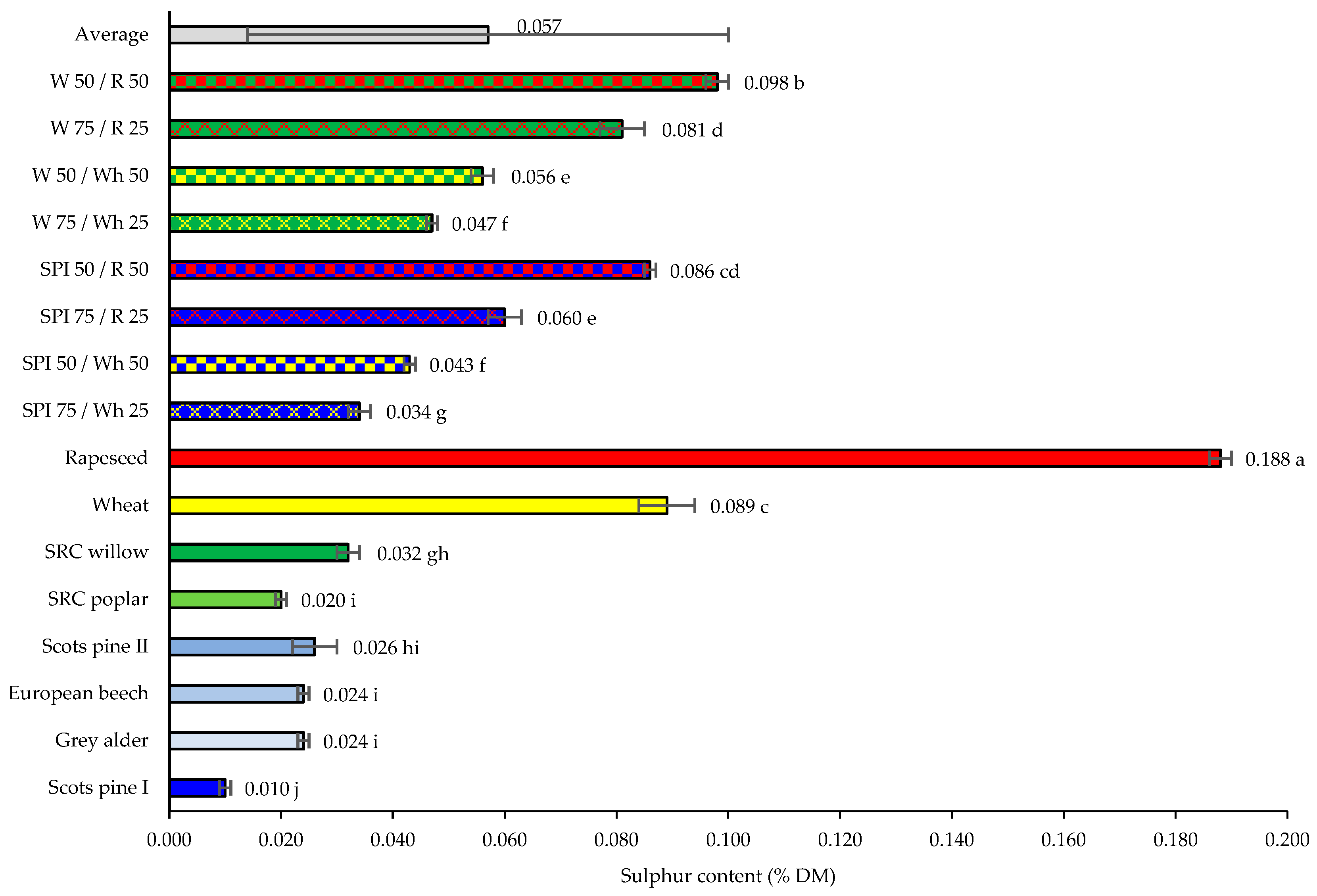

3.2. Elemental Composition of Pellets Under Study

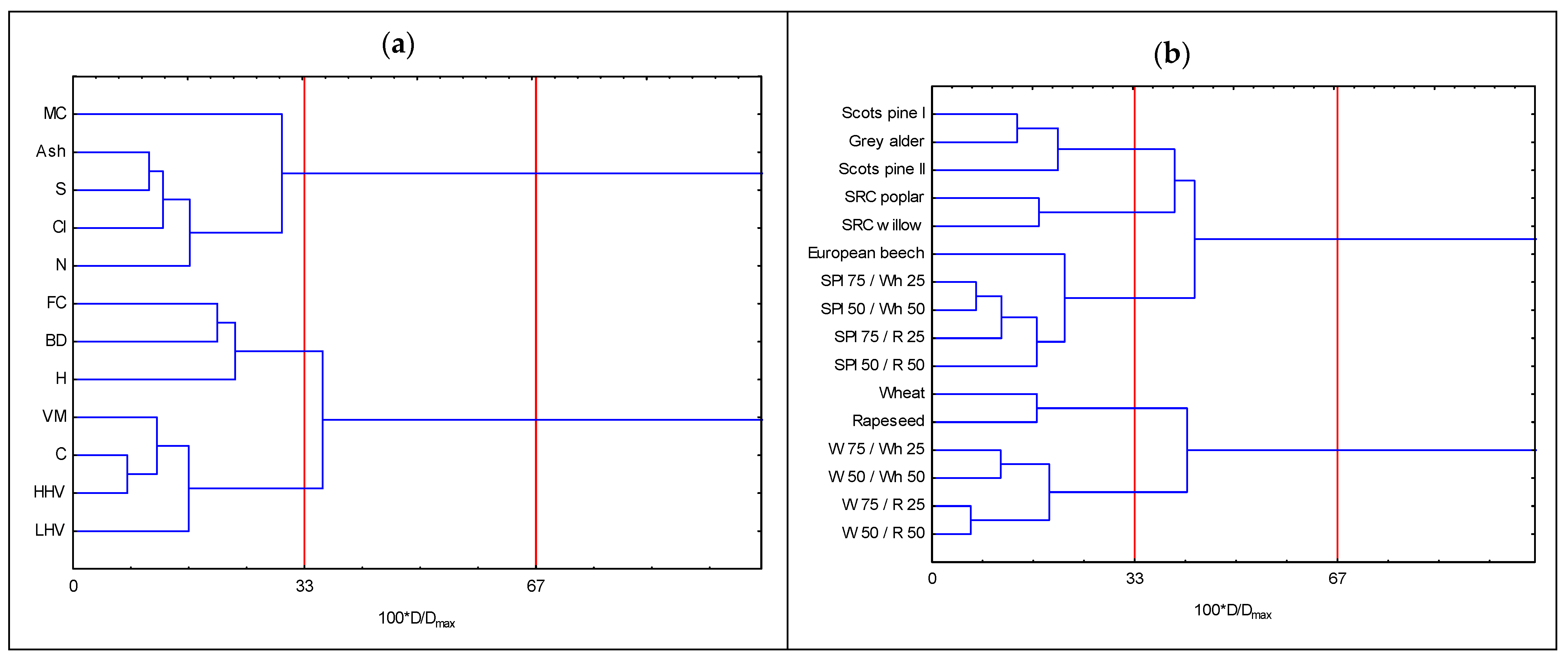

3.3. General Characteristics of Pellets from Forest Biomass, Agricultural Biomass, and Their Mixtures

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Statistics Poland. Energy from Renewable Sources in 2023; Central Statistical Office: Rzeszow, Poland, 2024. [Google Scholar]

- Picchio, R.; Latterini, F.; Venanzi, R.; Stefanoni, W.; Suardi, A.; Tocci, D.; Pari, L. Pellet Production from Woody and Non-Woody Feedstocks: A Review on Biomass Quality Evaluation. Energies 2020, 13, 2937. [Google Scholar] [CrossRef]

- Stolarski, J.; Wierzbicki, S.; Nitkiewicz, S.; Stolarski, M.J. Wood Chip Production Efficiency Depending on Chipper Type. Energies 2023, 16, 4894. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Warmiński, K.; Krzyżaniak, M.; Olba–Zięty, E.; Akincza, M. Bioenergy Technologies and Biomass Potential Vary in Northern European Countries. Renew. Sustain. Energy Rev. 2020, 133, 110238. [Google Scholar] [CrossRef]

- Statistics Poland. Statistical Yearbook of Forestry 2022; Statistical Publishing Establishment; Statistics Poland: Warsaw, Poland, 2022; p. 360. [Google Scholar]

- Gradziuk, P. The Economic Importance and Possibilities of Using Straw for Energy Purposes in Poland; Institute of Soil Science and Plant Cultivation State Research Institute: Puławy, Poland, 2015. [Google Scholar]

- Stolarski, M.J.; Welenc, M.; Krzyżaniak, M.; Olba-Zięty, E.; Stolarski, J.; Wierzbicki, S. Characteristics and Changes in the Properties of Cereal and Rapeseed Straw Used as Energy Feedstock. Energies 2024, 17, 1243. [Google Scholar] [CrossRef]

- Statistics Poland. Statistical Yearbook of Agriculture; Statistical Publishing Establishment; Statistics Poland: Warsaw, Poland, 2024; p. 437. [Google Scholar]

- Scordia, D.; Papazoglou, E.G.; Kotoula, D.; Sanz, M.; Ciria, C.S.; Pérez, J.; Maliarenko, O.; Prysiazhniuk, O.; von Cossel, M.; Greiner, B.E.; et al. Towards Identifying Industrial Crop Types and Associated Agronomies to Improve Biomass Production from Marginal Lands in Europe. GCB Bioenergy 2022, 14, 710–734. [Google Scholar] [CrossRef]

- Matyka, M.; Radzikowski, P. Productivity and Biometric Characteristics of 11 Varieties of Willow Cultivated on Marginal Soil. Agriculture 2020, 10, 616. [Google Scholar] [CrossRef]

- Jankowski, K.J.; Dubis, B.; Kozak, M. Sewage Sludge and the Energy Balance of Jerusalem Artichoke Production—A Case Study in North-Eastern Poland. Energy 2021, 236, 121545. [Google Scholar] [CrossRef]

- Acampora, A.; Civitarese, V.; Sperandio, G.; Rezaei, N. Qualitative Characterization of the Pellet Obtained from Hazelnut and Olive Tree Pruning. Energies 2021, 14, 4083. [Google Scholar] [CrossRef]

- Stachowicz, P.; Stolarski, M.J. Short Rotation Woody Crops and Forest Biomass Sawdust Mixture Pellet Quality. Ind. Crops Prod. 2023, 197, 116604. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Stachowicz, P.; Dudziec, P. Wood Pellet Quality Depending on Dendromass Species. Renew. Energy 2022, 199, 498–508. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Warmiński, K.; Krzyżaniak, M.; Olba–Zięty, E.; Stachowicz, P. Energy Consumption and Heating Costs for a Detached House over a 12-Year Period—Renewable Fuels versus Fossil Fuels. Energy 2020, 204, 117952. [Google Scholar] [CrossRef]

- Cardozo, E.; Malmquist, A. Performance Comparison between the Use of Wood and Sugarcane Bagasse Pellets in a Stirling Engine Micro-CHP System. Appl. Therm. Eng. 2019, 159, 113945. [Google Scholar] [CrossRef]

- Geelen, J.; Jossart, J.-M.; Karampinis, M.; Canon, J. Pellets. Statistical Report; Bioenergy Europe: Brussels, Belgium, 2024. [Google Scholar]

- Garcia, D.; Caraschi, J.; Ventorim, G.; Vieira, F.; Protásio, T. Comparative Energy Properties of Torrefied Pellets in Relation to Pine and Elephant Grass Pellets. BioResources 2018, 13, 2898–2906. [Google Scholar] [CrossRef]

- Thiffault, E.; Barrette, J.; Blanchet, P.; Nguyen, Q.N.; Adjalle, K. Optimizing Quality of Wood Pellets Made of Hardwood Processing Residues. Forests 2019, 10, 607. [Google Scholar] [CrossRef]

- Rastvorov, D.V.; Osintsev, K.V.; Toropov, E.V. Influence of Burner Form and Pellet Type on Domestic Pellet Boiler Performance. IOP Conf. Ser. Earth Environ. Sci. 2017, 87, 032034. [Google Scholar] [CrossRef]

- Monedero, E.; Portero, H.; Lapuerta, M. Combustion of Poplar and Pine Pellet Blends in a 50 KW Domestic Boiler: Emissions and Combustion Efficiency. Energies 2018, 11, 1580. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Warmiński, K.; Krzyżaniak, M.; Olba–Zięty, E. Cascaded Use of Perennial Industrial Crop Biomass: The Effect of Biomass Type and Pre-Treatment Method on Pellet Properties. Ind. Crops Prod. 2022, 185, 115104. [Google Scholar] [CrossRef]

- Attard, T.M.; Arshadi, M.; Nilsson, C.; Budarin, V.L.; Valencia-Reyes, E.; Clark, J.H.; Hunt, A.J. Impact of Supercritical Extraction on Solid Fuel Wood Pellet Properties and Off-Gassing during Storage. Green Chem. 2016, 18, 2682–2690. [Google Scholar] [CrossRef]

- Eisenbies, M.H.; Volk, T.A.; Amidon, T.E.; Shi, S. Influence of Blending and Hot Water Extraction on the Quality of Wood Pellets. Fuel 2019, 241, 1058–1067. [Google Scholar] [CrossRef]

- Jiang, L.; Yuan, X.; Xiao, Z.; Liang, J.; Li, H.; Cao, L.; Wang, H.; Chen, X.; Zeng, G. A Comparative Study of Biomass Pellet and Biomass-Sludge Mixed Pellet: Energy Input and Pellet Properties. Energy Convers. Manag. 2016, 126, 509–515. [Google Scholar] [CrossRef]

- Whittaker, C.; Shield, I. Factors Affecting Wood, Energy Grass and Straw Pellet Durability—A Review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Picchio, R.; Di Marzio, N.; Cozzolino, L.; Venanzi, R.; Stefanoni, W.; Bianchini, L.; Pari, L.; Latterini, F. Pellet Production from Pruning and Alternative Forest Biomass: A Review of the Most Recent Research Findings. Materials 2023, 16, 4689. [Google Scholar] [CrossRef]

- Rupasinghe, R.L.; Perera, P.; Bandara, R.; Amarasekera, H.; Vlosky, R. Insights into Properties of Biomass Energy Pellets Made from Mixtures of Woody and Non-Woody Biomass: A Meta-Analysis. Energies 2023, 17, 54. [Google Scholar] [CrossRef]

- Dujmović, M.; Šafran, B.; Jug, M.; Radmanović, K.; Antonović, A. Biomass Pelletizing Process. Drv. Ind. 2022, 73, 99–106. [Google Scholar] [CrossRef]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and Utilization of Fuel Pellets from Biomass: A Review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Ibrahim, M.M.; Younis, S.M.; Taieb, A.E.-A.Z.; Azzam, B.; Ghonimy, M. Design and Performance Assessment of a Pelleting Machine for Sustainable Biomass Pellet Fuel Production from Plant Residues. Sci. Rep. 2025, 15, 12879. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, S.K.; Mandø, M.; Rosenørn, A.B. Review of Die Design and Process Parameters in the Biomass Pelleting Process. Powder Technol. 2020, 364, 971–985. [Google Scholar] [CrossRef]

- Nath, B.; Chen, G.; Bowtell, L.; Nguyen-Huy, T. Pyrolysis of Wheat Straw Pellets in a Pilot-scale Reactor: Effect of Temperature and Residence Time. Energy Sci. Eng. 2024, 12, 3524–3539. [Google Scholar] [CrossRef]

- Nath, B.; Chen, G.; Bowtell, L.; Graham, E. Thermal Decomposition of Wheat Straw Pellets in a Nitrogen Environment: Characterization Using Thermogravimetric Analyzer. Case Stud. Therm. Eng. 2024, 64, 105457. [Google Scholar] [CrossRef]

- Aghaalikhani, A.; Savuto, E.; Di Carlo, A.; Borello, D. Poplar from Phytoremediation as a Renewable Energy Source: Gasification Properties and Pollution Analysis. Energy Procedia 2017, 142, 924–931. [Google Scholar] [CrossRef]

- Al-Qayim, K.; Nimmo, W.; Hughe, K.J.; Pourkashanian, M. Effect of Oxy-Fuel Combustion on Ash Deposition of Pulverized Wood Pellets. Biofuel Res. J. 2019, 6, 927–936. [Google Scholar] [CrossRef]

- Lyubov, V.K.; Malkov, A.V.; Alekseev, P.D. Boilers Slagging When Burning Wood Pellets. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1211, 012006. [Google Scholar] [CrossRef]

- Fraga, L.; Ferreira, E.; Ribeiro, P.; Castro, C.; Martins, J.; Teixeira, J.C. Combustion Instability and Ash Agglomeration in Wood Pellets Boiler. Energies 2023, 16, 6539. [Google Scholar] [CrossRef]

- Strandberg, A.; Carlborg, M.; Boman, C.; Broström, M. Ash Transformation During Single-Pellet Combustion of a Silicon-Poor Woody Biomass. Energy Fuels 2019, 33, 7770–7777. [Google Scholar] [CrossRef]

- Roy, M.M.; Dutta, A.; Corscadden, K. An Experimental Study of Combustion and Emissions of Biomass Pellets in a Prototype Pellet Furnace. Appl. Energy 2013, 108, 298–307. [Google Scholar] [CrossRef]

- Han, K.; Gao, J.; Qi, J. The Study of Sulphur Retention Characteristics of Biomass Briquettes during Combustion. Energy 2019, 186, 115788. [Google Scholar] [CrossRef]

- PN-EN ISO 18134-2; Solid Biofuels–Determination of Moisture Content–Dryer Method–Part 2: Total Moisture–Simplified Method. Polish Standardization Committee: Warsaw, Poland, 2014.

- PN-EN ISO 16948:2015-07; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. Polish Standardization Committee: Warsaw, Poland, 2015.

- PN-EN ISO 16994:2016-10; Solid Biofuels—Determination of Total Content of Sulfur and Chlorine. Polish Standardization Committee: Warsaw, Poland, 2016.

- PN-ISO 587:2000; Solid Fuels—Determination of Chlorine Using Eschka Mixture. Polish Standardization Committee: Warsaw, Poland, 2000.

- PN-EN ISO 18122:2016-01; Solid Biofuels—Determination of Ash Content. Polish Standardization Committee: Warsaw, Poland, 2016.

- PN-EN ISO 18123:2016-01; Solid Biofuels—Determination of Volatile Matter Content. Polish Standardization Committee: Warsaw, Poland, 2016.

- PN-EN ISO 18125:2017-07; Solid Biofuels—Determination of Calorific Value. Polish Standardization Committee: Warsaw, Poland, 2017.

- Stolarski, M.J.; Krzyżaniak, M.; Olba-Zięty, E.; Stolarski, J. Changes in Commercial Dendromass Properties Depending on Type and Acquisition Time. Energies 2023, 16, 7973. [Google Scholar] [CrossRef]

- Nath, B.; Chen, G.; Bowtell, L.; Mahmood, R.A. Assessment of Densified Fuel Quality Parameters: A Case Study for Wheat Straw Pellet. J. Bioresour. Bioprod. 2023, 8, 45–58. [Google Scholar] [CrossRef]

- Kachel, M.; Kraszkiewicz, A.; Subr, A.; Parafiniuk, S.; Przywara, A.; Koszel, M.; Zając, G. Impact of the Type of Fertilization and the Addition of Glycerol on the Quality of Spring Rape Straw Pellets. Energies 2020, 13, 819. [Google Scholar] [CrossRef]

- Samuelsson, R.; Larsson, S.H.; Thyrel, M.; Lestander, T.A. Moisture Content and Storage Time Influence the Binding Mechanisms in Biofuel Wood Pellets. Appl. Energy 2012, 99, 109–115. [Google Scholar] [CrossRef]

- Jachniak, E.; Holubcik, M. Characteristics of Pellets Made from Different Plant Materials. Proc. ECOpole 2015, 9, 95–101. [Google Scholar]

- Molenda, M.; Horabik, J.; Parafiniuk, P.; Oniszczuk, A.; Bańda, M.; Wajs, J.; Gondek, E.; Chutkowski, M.; Lisowski, A.; Wiącek, J.; et al. Mechanical and Combustion Properties of Agglomerates of Wood of Popular Eastern European Species. Materials 2021, 14, 2728. [Google Scholar] [CrossRef] [PubMed]

- Miranda, T.; Montero, I.; Sepúlveda, F.; Arranz, J.; Rojas, C.; Nogales, S. A Review of Pellets from Different Sources. Materials 2015, 8, 1413–1427. [Google Scholar] [CrossRef]

- Núñez-Retana, V.D.; Rosales-Serna, R.; Prieto-Ruíz, J.Á.; Wehenkel, C.; Carrillo-Parra, A. Improving the Physical, Mechanical and Energetic Properties of Quercus Spp. Wood Pellets by Adding Pine Sawdust. PeerJ 2020, 8, e9766. [Google Scholar] [CrossRef] [PubMed]

- Lisowski, A.; Matkowski, P.; Dąbrowska, M.; Piątek, M.; Świętochowski, A.; Klonowski, J.; Mieszkalski, L.; Reshetiuk, V. Particle Size Distribution and Physicochemical Properties of Pellets Made of Straw, Hay, and Their Blends. Waste Biomass Valori. 2020, 11, 63–75. [Google Scholar] [CrossRef]

- Lee, J.S.; Sokhansanj, S.; Lau, A.K.; Lim, C.J. Physical Properties of Wood Pellets Exposed to Liquid Water. Biomass Bioenergy 2020, 142, 105748. [Google Scholar] [CrossRef]

- Poddar, S.; Kamruzzaman, M.; Sujan, S.M.A.; Hossain, M.; Jamal, M.S.; Gafur, M.A.; Khanam, M. Effect of Compression Pressure on Lignocellulosic Biomass Pellet to Improve Fuel Properties: Higher Heating Value. Fuel 2014, 131, 43–48. [Google Scholar] [CrossRef]

- Holubcik, M.; Jandacka, J.; Durcansky, P. Energy Properties of Wood Pellets Made from the Unusual Woody Plants. AIP Conf. Proc. 2016, 1768, 020013. [Google Scholar]

- Nosek, R.; Werle, S.; Borsukiewicz, A.; Żelazna, A.; Łagód, G. Investigation of Pellet Properties Produced from a Mix of Straw and Paper Sludge. Appl. Sci. 2020, 10, 5450. [Google Scholar] [CrossRef]

- Gaze, B. Określenie Dominującego Mechanizmu Powstawania NOx w Kotłach Małej Mocy Zasilanych Biomasą. Przemysł Chem. 2020, 1, 70–75. [Google Scholar] [CrossRef]

- Oh, J.-H.; Hwang, J.-S.; Cha, D.-S. Fuel Properties of Woody Pellets in Domestic Markets of Korea. J. For. Environ. Sci. 2014, 30, 362–369. [Google Scholar] [CrossRef]

- Fohr, J.; Ranta, T.; Suikki, J.; Soininen, H. Manufacturing of Torrefied Pellets without a Binder from Different Raw Wood Materials in the Pilot Plant. Wood Res. 2017, 62, 481–494. [Google Scholar]

- Gehrig, M.; Wöhler, M.; Pelz, S.; Steinbrink, J.; Thorwarth, H. Kaolin as Additive in Wood Pellet Combustion with Several Mixtures of Spruce and Short-Rotation-Coppice Willow and Its Influence on Emissions and Ashes. Fuel 2019, 235, 610–616. [Google Scholar] [CrossRef]

- Carvalho, L.; Wopienka, E.; Pointner, C.; Lundgren, J.; Verma, V.K.; Haslinger, W.; Schmidl, C. Performance of a Pellet Boiler Fired with Agricultural Fuels. Appl. Energy 2013, 104, 286–296. [Google Scholar] [CrossRef]

- Hroncová, E.; Ladomerský, J. The Environmental and Energy Potential of Incinerating Various Biomass Mixtures. Adv. Mat. Res. 2014, 1001, 114–117. [Google Scholar] [CrossRef]

- Jasinskas, A.; Kleiza, V.; Streikus, D.; Domeika, R.; Vaiciukevičius, E.; Gramauskas, G.; Valentin, M.T. Assessment of Quality Indicators of Pressed Biofuel Produced from Coarse Herbaceous Plants and Determination of the Influence of Moisture on the Properties of Pellets. Sustainability 2022, 14, 1068. [Google Scholar] [CrossRef]

- Kallis, K.X.; Pellegrini Susini, G.A.; Oakey, J.E. A Comparison between Miscanthus and Bioethanol Waste Pellets and Their Performance in a Downdraft Gasifier. Appl. Energy 2013, 101, 333–340. [Google Scholar] [CrossRef]

- Pham, X.-H.; Piriou, B.; Salvador, S.; Valette, J.; Van de Steene, L. Oxidative Pyrolysis of Pine Wood, Wheat Straw and Miscanthus Pellets in a Fixed Bed. Fuel Process. Technol. 2018, 178, 226–235. [Google Scholar] [CrossRef]

- Kalinauskaite, S.; Sakalauskas, A.; Sarauskis, E.; Jasinskas, A.; Ahlhaus, M. Relation of Energy Content Variations of Straw to the Fraction Size, Humidity, Composition and Environmental Impact. Agron. Res. 2013, 11, 319–328. [Google Scholar]

- Dias, G.M.; Ayer, N.W.; Kariyapperuma, K.; Thevathasan, N.; Gordon, A.; Sidders, D.; Johannesson, G.H. Life Cycle Assessment of Thermal Energy Production from Short-Rotation Willow Biomass in Southern Ontario, Canada. Appl. Energy 2017, 204, 343–352. [Google Scholar] [CrossRef]

- Civitarese, V.; Acampora, A.; Sperandio, G.; Assirelli, A.; Picchio, R. Production of Wood Pellets from Poplar Trees Managed as Coppices with Different Harvesting Cycles. Energies 2019, 12, 2973. [Google Scholar] [CrossRef]

- Kang, S.; Sim, B.; Kim, J. Volume and Mass Measurement of a Burning Wood Pellet by Image Processing. Energies 2017, 10, 603. [Google Scholar] [CrossRef]

- Santana, D.A.R.; Scatolino, M.V.; Lima, M.D.R.; de Oliveira Barros Junior, U.; Garcia, D.P.; Andrade, C.R.; de Cássia Oliveira Carneiro, A.; Trugilho, P.F.; de Paula Protásio, T. Pelletizing of Lignocellulosic Wastes as an Environmentally Friendly Solution for the Energy Supply: Insights on the Properties of Pellets from Brazilian Biomasses. Environ. Sci. Pollut. Res. 2021, 28, 11598–11617. [Google Scholar] [CrossRef]

- Lee, Y.; Yang, W.; Chae, T.; Kang, B.; Park, J.; Ryu, C. Comparative Characterization of a Torrefied Wood Pellet under Steam and Nitrogen Atmospheres. Energy Fuels 2018, 32, 5109–5114. [Google Scholar] [CrossRef]

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Characterization of Spanish Biomass Wastes for Energy Use. Bioresour. Technol. 2012, 103, 249–258. [Google Scholar] [CrossRef]

- Juszczak, M.; Lossy, K. Pollutant Emission from a Heat Station Supplied with Agriculture Biomass and Wood Pellet Mixture. Chem. Process Eng. 2012, 33, 231–242. [Google Scholar] [CrossRef]

- Yub Harun, N.; Parvez, A.M.; Afzal, M.T. Process and Energy Analysis of Pelleting Agricultural and Woody Biomass Blends. Sustainability 2018, 10, 1770. [Google Scholar] [CrossRef]

- Azócar, L.; Hermosilla, N.; Gay, A.; Rocha, S.; Díaz, J.; Jara, P. Brown Pellet Production Using Wheat Straw from Southern Cities in Chile. Fuel 2019, 237, 823–832. [Google Scholar] [CrossRef]

- Kucinskas, V.; Jasinskas, A.; Butkus, V.; Jotautiene, E.; Pocius, A. Environmental Assessment of Sawdust Blends with Glycerol Burning. In Proceedings of the 14th International Scientific Conference “Engineering for Rural Development”, Jelgava, Latvia, 20–22 May 2015; pp. 336–341. [Google Scholar]

- Bartocci, P.; Barbanera, M.; D’Amico, M.; Laranci, P.; Cavalaglio, G.; Gelosia, M.; Ingles, D.; Bidini, G.; Buratti, C.; Cotana, F.; et al. Thermal Degradation of Driftwood: Determination of the Concentration of Sodium, Calcium, Magnesium, Chlorine and Sulfur Containing Compounds. Waste Manag. 2017, 60, 151–157. [Google Scholar] [CrossRef]

- Magdziarz, A.; Wilk, M.; Gajek, M.; Nowak-Woźny, D.; Kopia, A.; Kalemba-Rec, I.; Koziński, J.A. Properties of Ash Generated during Sewage Sludge Combustion: A Multifaceted Analysis. Energy 2016, 113, 85–94. [Google Scholar] [CrossRef]

| Pellet Type | Biomass Type | Species | Species Share (% w/w, Dry Basis) | Pellet Code |

|---|---|---|---|---|

| Scots pine I | Forest biomass–sawdust from debarked wood | Scots pine (Pinus sylvestris L.) | 100 | SPI |

| Grey alder | Forest biomass–chips from non-debarked wood | Grey alder (Alnus incana (L.) Moench), | 100 | GA |

| European beech | Forest biomass–chips from non-debarked sawmill residues | European beech (Fagus sylvatica L.) | 100 | EB |

| Scots pine II | Forest biomass–chips from branches from forest logging | Scots pine (Pinus sylvestris L.) | 100 | SPII |

| SRC poplar | Agricultural biomass–chips from seasoned four-year-old SRC poplar shoots | Poplar (Populus nigra × P. maximowiczii Henry) | 100 | P |

| SRC willow | Agricultural biomass–chips from seasoned four-year-old SRC willow shoots | Willow (Salix viminalis L.) | 100 | W |

| Wheat | Agricultural biomass–wheat straw collected after winter wheat harvesting | Wheat (Triticum aestivum L.) | 100 | Wh |

| Rapeseed | Agricultural biomass–rapeseed straw collected after winter rapeseed harvesting | Rapeseed (Brassica napus L.) | 100 | R |

| Scots pine I/wheat | Forest biomass–sawdust from debarked wood, and agricultural biomass–wheat straw | Scots pine/Wheat | 75/25 | SPI 75/Wh 25 |

| Scots pine I/wheat | Scots pine/Wheat | 50/50 | SPI 50/Wh 50 | |

| Scots pine I/rapeseed | Forest biomass–sawdust from debarked wood, and agricultural biomass–rapeseed straw | Scots pine/Rapeseed | 75/25 | SPI 75/R 25 |

| Scots pine I/rapeseed | Scots pine/Rapeseed | 50/50 | SPI 50/R 50 | |

| SRC willow/wheat | Agricultural biomass–chips from seasoned four-year-old SRC willow shoots, and agricultural biomass–wheat straw | Willow/Wheat | 75/25 | W 75/Wh 25 |

| SRC willow/wheat | Willow/Wheat | 50/50 | W 50/Wh 50 | |

| SRC willow/rapeseed | Agricultural biomass–chips from seasoned four-year-old SRC willow shoots, and agricultural biomass–wheat straw | Willow/Rapeseed | 75/25 | W 75/R 25 |

| SRC willow/rapeseed | Willow/Rapeseed | 50/50 | W 50/R 50 |

| Feature | Classes | |||||

|---|---|---|---|---|---|---|

| A1 | A2 | B | I1 | I2 | I3 | |

| Bulk density (kg m−3) | 600–750 | 600–750 | 600–750 | ≥600 | ≥600 | ≥600 |

| Moisture (%) | ≤10.0 | ≤10.0 | ≤10.0 | ≤10.0 | ≤10.0 | ≤10.0 |

| Ash content (% DM) | ≤0.7 | ≤1.2 | ≤2.0 | ≤1.0 | ≤1.5 | ≤3.0 |

| LHV (GJ Mg−1) | ≥16.5 | ≥16.5 | ≥16.5 | ≥16.5 | ≥16.5 | ≥16.5 |

| N (% DM) | ≤0.3 | ≤0.5 | ≤1.0 | ≤0.3 | ≤0.3 | ≤0.6 |

| S (% DM) | ≤0.04 | ≤0.04 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 |

| Cl (% DM) | ≤0.02 | ≤0.02 | ≤0.03 | ≤0.03 | ≤0.05 | ≤0.1 |

| Feature | PFI | KFRI | |||||

|---|---|---|---|---|---|---|---|

| Premium | Standard | Utility | Grade 1 | Grade 2 | Grade 3 | Grade 4 | |

| Bulk density (kg m−3) | 640.74–768.89 | 608.70–768.89 | 608.70–768.89 | ≥640 | ≥600 | ≥550 | ≥500 |

| Moisture (%) | ≤8.0 | ≤10.0 | ≤10.0 | ≤10 | ≤10 | ≤15 | ≤15 |

| Ash content (% DM) | ≤1.0 | ≤2.0 | ≤6.0 | ≤0.7 | ≤1.5 | ≤3.0 | ≤6.0 |

| LHV (GJ Mg−1) | N/A | N/A | N/A | ≥18.0 | ≥18.0 | ≥16.9 | ≥16.9 |

| N (% DM) | N/A | N/A | N/A | <0.3 | <0.5 | <0.7 | <1.0 |

| S (% DM) | N/A | N/A | N/A | <0.05 | <0.05 | <0.05 | <0.05 |

| Cl (% DM) | ≤0.03 | ≤0.03 | ≤0.03 | <0.05 | <0.05 | <0.05 | <0.05 |

| Feature | F | p-Value |

|---|---|---|

| Moisture content—MC (%) | 277.6 | <0.001 * |

| Fixed carbon content—FC (% DM) | 124.0 | <0.001 * |

| Volatile matter content—VM (% DM) | 303.7 | <0.001 * |

| Ash content—Ash (% DM) | 2952.7 | <0.001 * |

| Higher heating value—HHV (MJ kg−1 DM) | 474.9 | <0.001 * |

| Lower heating value—LHV (MJ kg−1) | 639.8 | <0.001 * |

| Bulk density—BD (kg m−3) | 138.4 | <0.001 * |

| Carbon content—C (% DM) | 349.7 | <0.001 * |

| Hydrogen content—H (% DM) | 39.3 | <0.001 * |

| Nitrogen content—N (% DM) | 1151.4 | <0.001 * |

| Sulphur content—S (% DM) | 1198.7 | <0.001 * |

| Chlorine content—Cl (% DM) | 492.7 | <0.001 * |

| Pellet Type | MC (%) | FC (% DM) | VM (% DM) | Bulk Density (kg m−3) | HHV (GJ Mg−1 DM) |

|---|---|---|---|---|---|

| Scots pine I | 5.07 ± 0.03 jk | 21.59 ± 0.26 bc | 77.97 ± 0.25 ab | 705.45 ± 6.15 c | 20.31 ± 0.05 a |

| Grey alder | 4.73 ± 0.02 k | 21.27 ± 0.02 c | 77.43 ± 0.08 de | 751.25 ± 1.95 b | 19.86 ± 0.01 b |

| European beech | 6.73 ± 0.01 e | 19.63 ± 0.04 g | 78.21 ± 0.08 a | 727.00 ± 3.01 bc | 19.87 ± 0.03 b |

| Scots pine II | 5.31 ± 0.10 ij | 21.65 ± 0.21 b | 75.83 ± 0.11 fg | 705.70 ± 3.70 c | 19.94 ± 0.01 b |

| SRC poplar | 9.32 ± 0.01 a | 20.48 ± 0.05 ef | 77.81 ± 0.02 bc | 778.90 ± 11.30 a | 19.71 ± 0.04 c |

| SRC willow | 8.25 ± 0.48 bc | 22.23 ± 0.13 a | 76.08 ± 0.07 f | 797.45 ± 10.15 a | 19.61 ± 0.01 d |

| Wheat | 7.58 ± 0.04 d | 20.90 ± 0.05 d | 74.98 ± 0.10 i | 628.85 ± 6.45 efg | 19.11 ± 0.04 g |

| Rapeseed | 8.19 ± 0.01 bc | 19.65 ± 0.02 g | 75.35 ± 0.07 h | 607.85 ± 3.55 g | 18.91 ± 0.02 h |

| Scots pine I 75/wheat 25 | 8.26 ± 0.09 b | 20.86 ± 0.19 d | 77.63 ± 0.17 cd | 644.23 ± 5.77 def | 19.90 ± 0.01 b |

| Scots pine I 50/wheat 50 | 7.84 ± 0.18 cd | 20.58 ± 0.12 def | 77.29 ± 0.11 e | 622.79 ± 7.98 fg | 19.76 ± 0.03 c |

| Scots pine I 75/rapeseed 25 | 6.52 ± 0.06 ef | 20.61 ± 0.01 def | 77.84 ± 0.03 bc | 653.08 ± 6.92 de | 19.89 ± 0.02 b |

| Scots pine I 50/rapeseed 50 | 6.73 ± 0.04 e | 20.36 ± 0.09 f | 77.28 ± 0.04 e | 633.64 ± 3.64 efg | 19.74 ± 0.03 c |

| SRC willow 75/wheat 25 | 6.15 ± 0.02 fg | 21.69 ± 0.12 b | 75.67 ± 0.19 gh | 663.75 ± 8.75 d | 19.45 ± 0.05 e |

| SRC willow 50/wheat 50 | 6.55 ± 0.04 ef | 21.54 ± 0.01 bc | 75.46 ± 0.01 h | 646.36 ± 6.45 def | 19.19 ± 0.03 fg |

| SRC willow 75/rapeseed 25 | 5.89 ± 0.05 gh | 20.73 ± 0.01 de | 76.12 ± 0.01 f | 661.64 ± 1.22 d | 19.28 ± 0.02 f |

| SRC willow 50/rapeseed 50 | 5.72 ± 0.11 hi | 20.57 ± 0.02 def | 75.91 ± 0.02 fg | 635.15 ± 7.85 ef | 19.23 ± 0.02 f |

| On average | 6.80 ± 1.30 | 20.90 ± 0.72 | 76.68 ± 1.08 | 678.94 ± 27.57 | 19.61 ± 0.37 |

| Feature | MC (%) | FC (% DM) | VM (% DM) | Ash (% DM) | HHV (MJ kg−1 DM) | LHV (MJ kg−1) | BD (kg m−3) | C (% DM) | H (% DM) | S (% DM) | N (% DM) | Cl (% DM) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MC (%) | 1.00 | −0.30 * | 0.01 | 0.18 | −0.26 | −0.73 * | 0.03 | −0.09 | −0.20 | 0.19 | 0.10 | 0.26 |

| FC (% DM) | 1.00 | −0.27 | −0.35 * | 0.22 | 0.31 * | 0.38 * | 0.19 | 0.22 | −0.50 * | −0.02 | −0.39 * | |

| VM (% DM) | 1.00 | −0.80 * | 0.80 * | 0.55 * | 0.34 * | 0.84 * | 0.33 * | −0.56 * | −0.85 * | −0.52 * | ||

| Ash (% DM) | 1.00 | −0.90 * | −0.71 * | −0.56 * | −0.94 * | −0.48 * | 0.83 * | 0.82 * | 0.75 * | |||

| HHV (MJ kg−1 DM) | 1.00 | 0.84 * | 0.45 * | 0.91 * | 0.30 * | −0.78 * | −0.93 * | −0.75 * | ||||

| LHV (MJ kg−1) | 1.00 | 0.29 * | 0.67 * | 0.26 | −0.65 * | −0.71 * | −0.67 * | |||||

| BD (kg m−3) | 1.00 | 0.42 * | 0.29 * | −0.65 * | −0.21 | −0.83 * | ||||||

| C (% DM) | 1.00 | 0.40 * | −0.71 * | −0.91 * | −0.66 * | |||||||

| H (% DM) | 1.00 | −0.27 | −0.18 | −0.31 * | ||||||||

| S (% DM) | 1.00 | 0.64 * | 0.80 * | |||||||||

| N (% DM) | 1.00 | 0.51 * | ||||||||||

| Cl (% DM) | 1.00 |

| Pellet Type | C (% DM) | H (% DM) | N (% DM) | Cl (% DM) |

|---|---|---|---|---|

| Scots pine I | 56.35 ± 0.21 a | 6.57 ± 0.08 a | 0.10 ± 0.01 k | 0.003 ± 0.001 h |

| Grey alder | 55.11 ± 0.07 bcd | 6.32 ± 0.06 cd | 0.30 ± 0.01 g | 0.005 ± 0.002 fgh |

| European beech | 53.45 ± 0.46 fg | 6.13 ± 0.06 f | 0.29 ± 0.02 g | 0.010 ± 0.001 fg |

| Scots pine II | 53.29 ± 0.12 g | 6.09 ± 0.07 f | 0.31 ± 0.01 g | 0.004 ± 0.001 gh |

| SRC poplar | 54.38 ± 0.17 de | 6.43 ± 0.04 abcd | 0.40 ± 0.02 f | 0.011 ± 0.002 f |

| SRC willow | 54.19 ± 0.36 ef | 6.38 ± 0.09 abcd | 0.57 ± 0.01 e | 0.010 ± 0.001 f |

| Wheat | 47.40 ± 0.22 l | 6.02 ± 0.01 f | 0.76 ± 0.04 b | 0.074 ± 0.005 a |

| Rapeseed | 48.38 ± 0.20 k | 6.04 ± 0.02 f | 0.84 ± 0.01 a | 0.071 ± 0.003 a |

| Scots pine I 75/wheat 25 | 55.75 ± 0.14 ab | 6.30 ± 0.05 de | 0.12 ± 0.02 jk | 0.036 ± 0.001 d |

| Scots pine I 50/wheat 50 | 55.37 ± 0.35 bc | 6.16 ± 0.05 ef | 0.15 ± 0.01 ij | 0.046 ± 0.001 c |

| Scots pine I 75/rapeseed 25 | 55.61 ± 0.20 ab | 6.11 ± 0.01 f | 0.17 ± 0.01 i | 0.040 ± 0.001 cd |

| Scots pine I 50/rapeseed 50 | 54.83 ± 0.08 cde | 6.52 ± 0.05 ab | 0.22 ± 0.02 h | 0.056 ± 0.002 b |

| SRC willow 75/wheat 25 | 52.19 ± 0.31 h | 6.28 ± 0.02 de | 0.62 ± 0.02 d | 0.025 ± 0.003 e |

| SRC willow 50/wheat 50 | 50.51 ± 0.34 ij | 6.17 ± 0.05 ef | 0.69 ± 0.01 c | 0.060 ± 0.001 b |

| SRC willow 75/rapeseed 25 | 51.08 ± 0.32 i | 6.46 ± 0.03 abc | 0.70 ± 0.02 c | 0.038 ± 0.002 d |

| SRC willow 50/rapeseed 50 | 50.29 ± 0.12 j | 6.46 ± 0.01 abc | 0.76 ± 0.01 b | 0.057 ± 0.002 b |

| On average | 53.01 ± 2.70 | 6.28 ± 0.18 | 0.44 ± 0.26 | 0.034 ± 0.025 |

| Feature | Mean | Median | Minimum Value | Maximum Value | Lower Quartile | Upper Quartile | Coefficient of Variation (%) |

|---|---|---|---|---|---|---|---|

| MC (%) | 6.80 | 6.64 | 4.71 | 9.33 | 5.83 | 7.93 | 19.12 |

| FC (% DM) | 20.90 | 20.73 | 19.59 | 22.36 | 20.50 | 21.54 | 3.44 |

| VM (% DM) | 76.68 | 76.67 | 74.88 | 78.29 | 75.78 | 77.75 | 1.40 |

| Ash (% DM) | 2.47 | 2.25 | 0.43 | 5.04 | 1.60 | 3.08 | 47.97 |

| HHV (MJ kg−1 DM) | 19.61 | 19.72 | 18.91 | 20.36 | 19.26 | 19.88 | 1.89 |

| LHV (MJ kg−1) | 16.92 | 16.86 | 16.03 | 17.95 | 16.60 | 17.24 | 2.83 |

| BD (kg m−3) | 678.94 | 658.41 | 604.30 | 797.60 | 635.23 | 717.80 | 8.48 |

| C (% DM) | 53.01 | 53.87 | 47.18 | 56.56 | 50.81 | 55.14 | 5.09 |

| H (% DM) | 6.28 | 6.27 | 6.01 | 6.65 | 6.11 | 6.46 | 2.90 |

| N (% DM) | 0.44 | 0.36 | 0.10 | 0.85 | 0.20 | 0.69 | 58.54 |

| S (% DM) | 0.057 | 0.045 | 0.010 | 0.188 | 0.025 | 0.084 | 75.27 |

| Cl (% DM) | 0.034 | 0.037 | 0.002 | 0.079 | 0.010 | 0.057 | 71.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stolarski, M.J.; Krzyżaniak, M.; Olba-Zięty, E. Properties of Pellets from Forest and Agricultural Biomass and Their Mixtures. Energies 2025, 18, 3137. https://doi.org/10.3390/en18123137

Stolarski MJ, Krzyżaniak M, Olba-Zięty E. Properties of Pellets from Forest and Agricultural Biomass and Their Mixtures. Energies. 2025; 18(12):3137. https://doi.org/10.3390/en18123137

Chicago/Turabian StyleStolarski, Mariusz Jerzy, Michał Krzyżaniak, and Ewelina Olba-Zięty. 2025. "Properties of Pellets from Forest and Agricultural Biomass and Their Mixtures" Energies 18, no. 12: 3137. https://doi.org/10.3390/en18123137

APA StyleStolarski, M. J., Krzyżaniak, M., & Olba-Zięty, E. (2025). Properties of Pellets from Forest and Agricultural Biomass and Their Mixtures. Energies, 18(12), 3137. https://doi.org/10.3390/en18123137