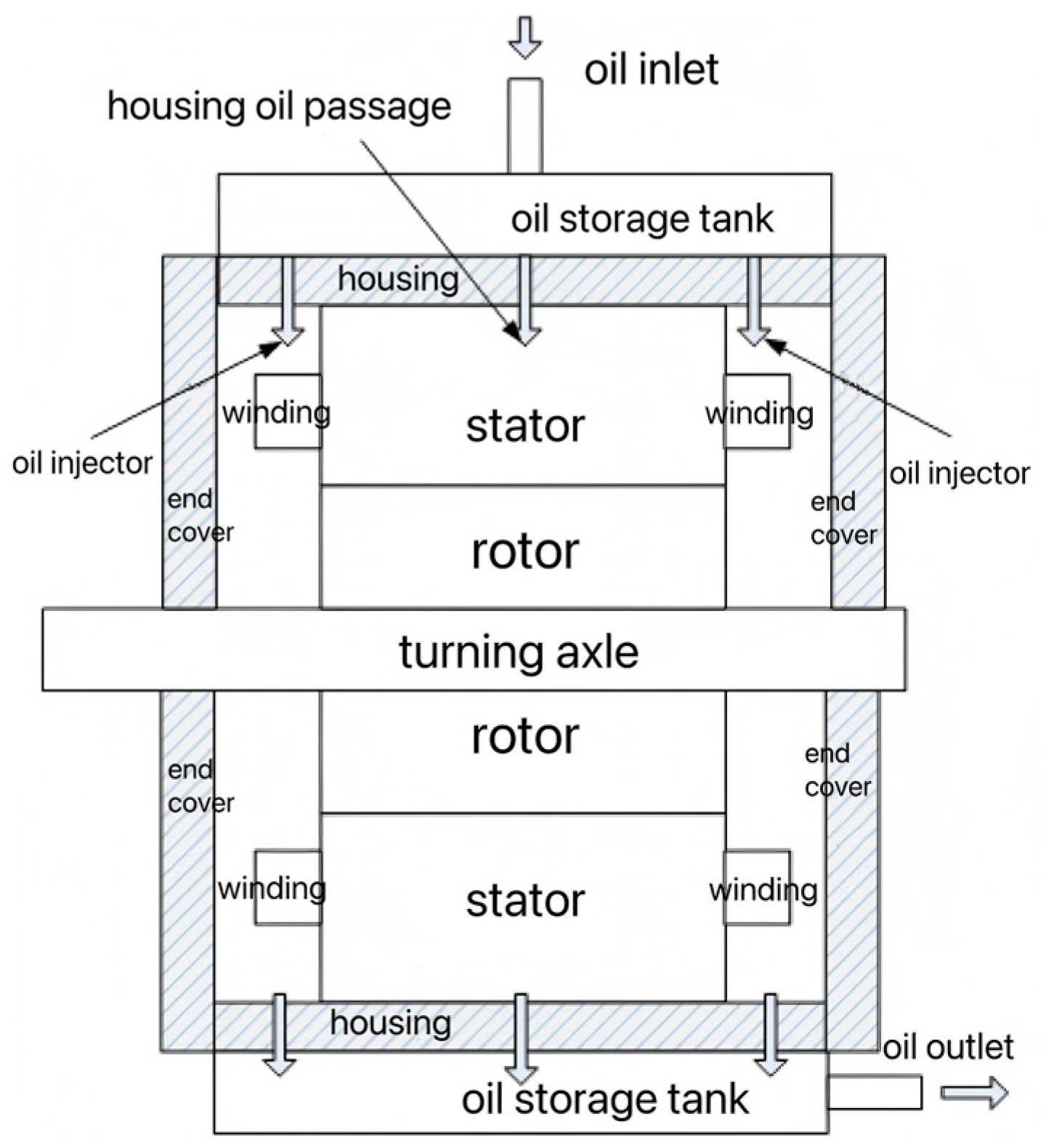

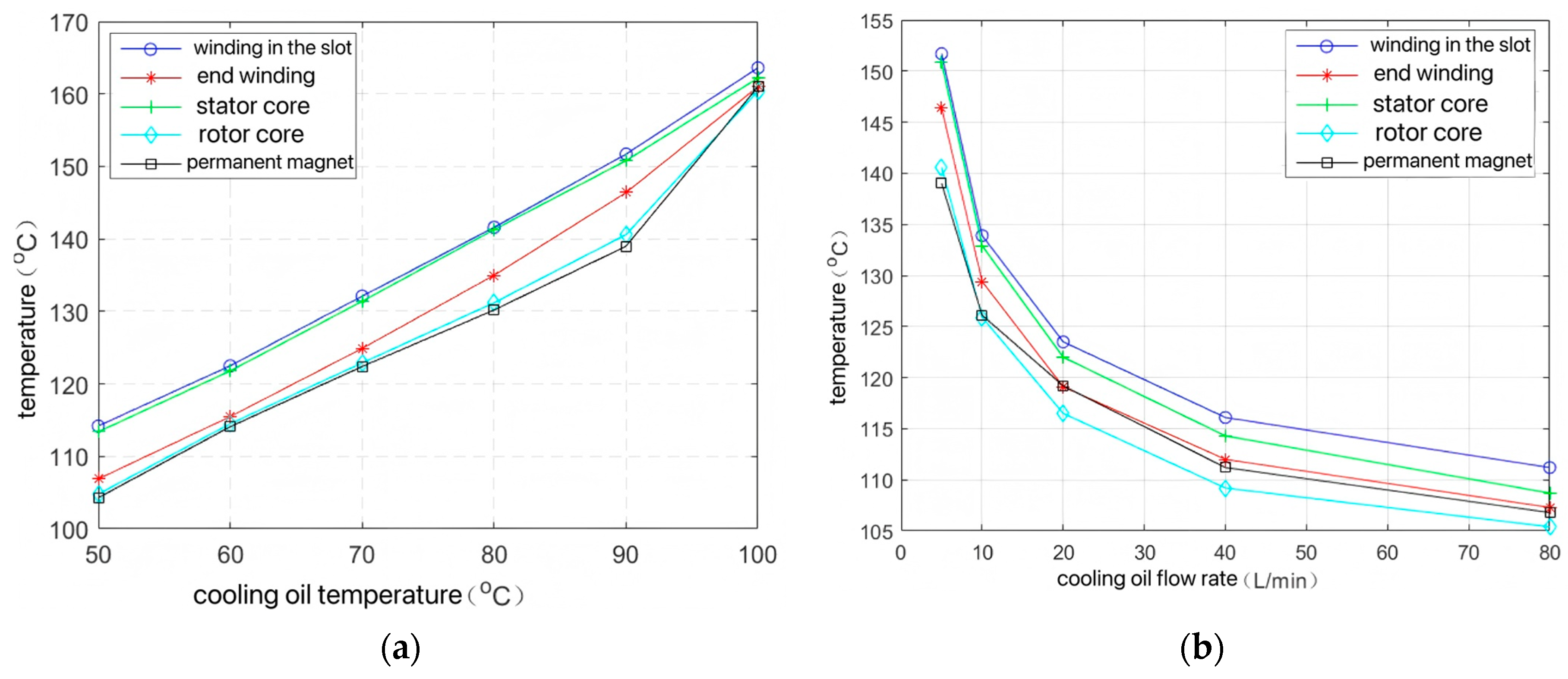

2.1. Design of Oil Jet Nozzles

The prototype stator windings adopt direct spray cooling, with two oil jet nozzles positioned above each end of the stator windings. The nozzle orifice size and placement directly determine the oil film thickness on the end windings, critically influencing their cooling effectiveness. Given the complexity of the end-winding oil spray paths, finite element analysis (FEA) and multivariate nonlinear fitting theory were employed to comprehensively analyze the impact of nozzle orifice size and positioning on the thermal dissipation performance of the motor’s end windings.

Assuming all heat losses from the end windings are removed by the cooling oil, Newton’s law of cooling gives the following:

where

is the copper loss of the end windings;

h and

Aendw are the convective heat transfer coefficient and convective heat transfer area of the end windings, respectively;

Tmax and

Tf are the maximum temperature on the end windings and the cooling oil temperature, respectively.

From Equation (1), the maximum temperature estimation formula for the motor’s end windings can be derived as follows:

where

is the heat dissipation factor of the end windings, defined as

=

hAendw.

As indicated by Equation (2), under constant end-winding losses, the maximum temperature rise of the motor’s end windings depends on the heat dissipation factor . A higher signifies superior cooling performance, while a lower value indicates inferior thermal management.

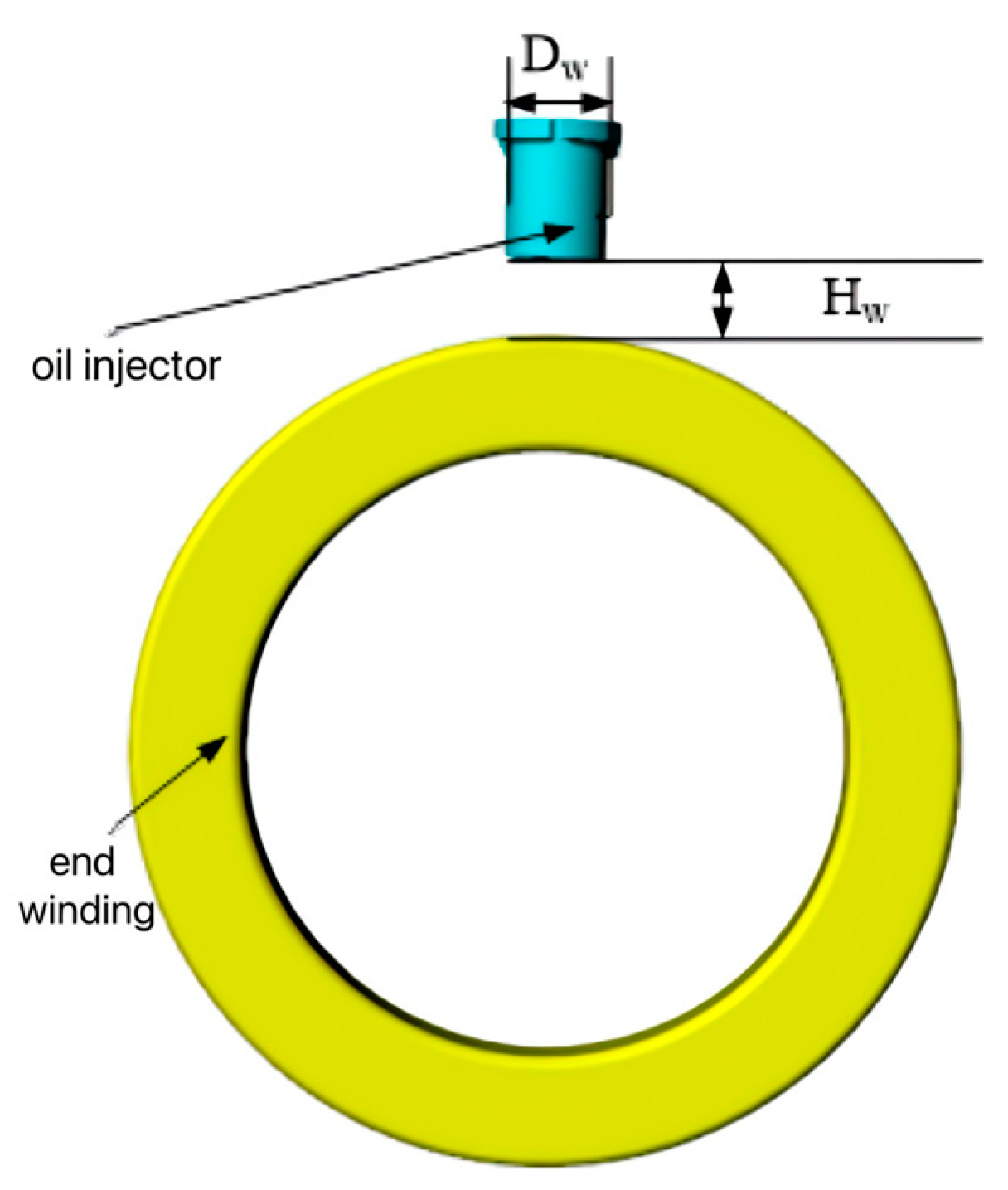

Figure 2 shows the simulation model of the oil jet nozzle and end windings, where the nozzle diameter is denoted as

Dw, and the height of the end windings is

Hw. The simulation parameters include an inlet oil temperature of 90 °C, an inlet flow rate of 5 L/min (automatic transmission fluid, thermal conductivity: 0.2 W/m·°C, specific heat capacity: 1963 J/(kg·°C), density: 846 kg/m

3, dynamic viscosity: 0.0066 Pa·s), and copper losses of 474.7 W per end winding. A 3D finite element simulation was conducted to analyze the influence of nozzle diameter

Dw and end-winding height

Hw on the average convective heat transfer coefficient (

haverage) of the end-winding surfaces. Since the surface area of the end windings is fixed, a higher

haverage directly increases the heat dissipation factor (

), thereby improving cooling performance.

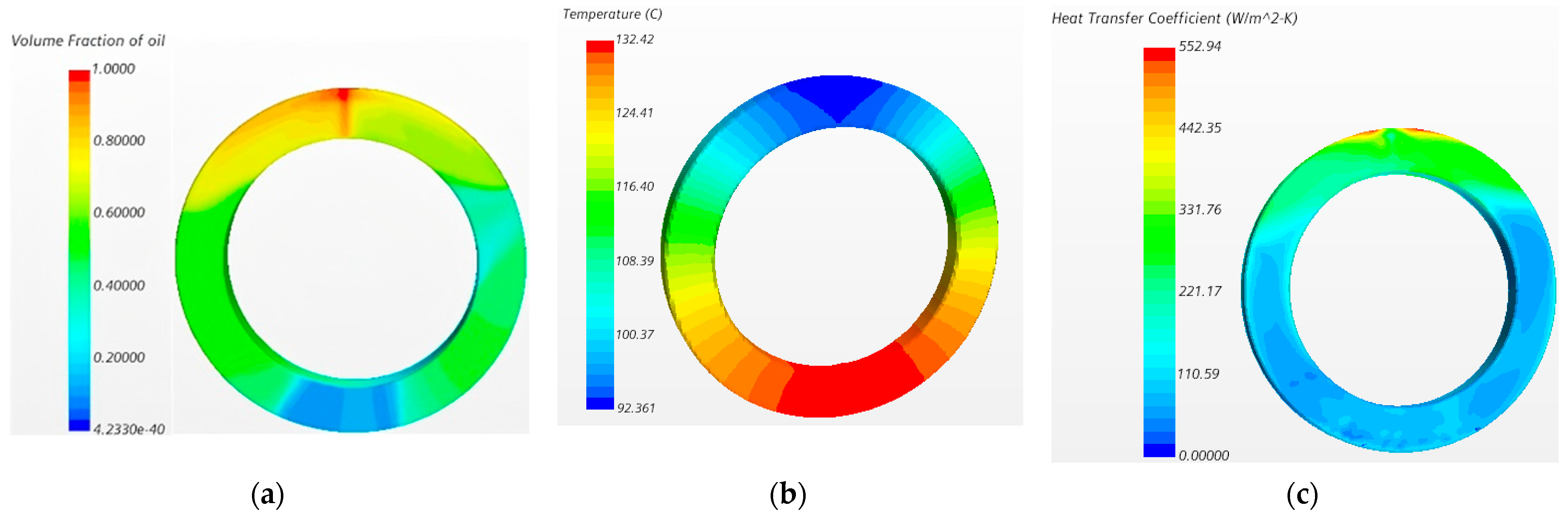

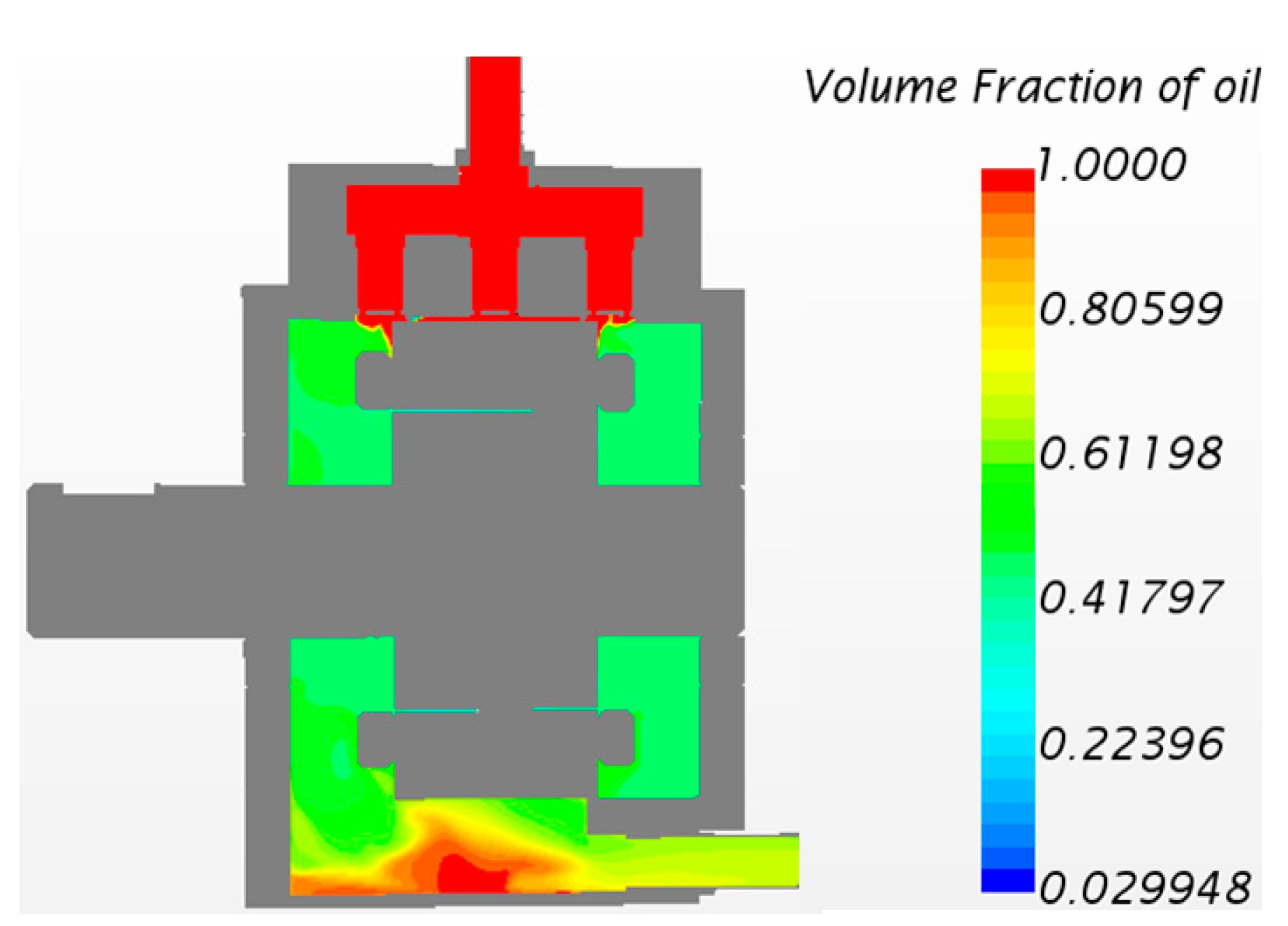

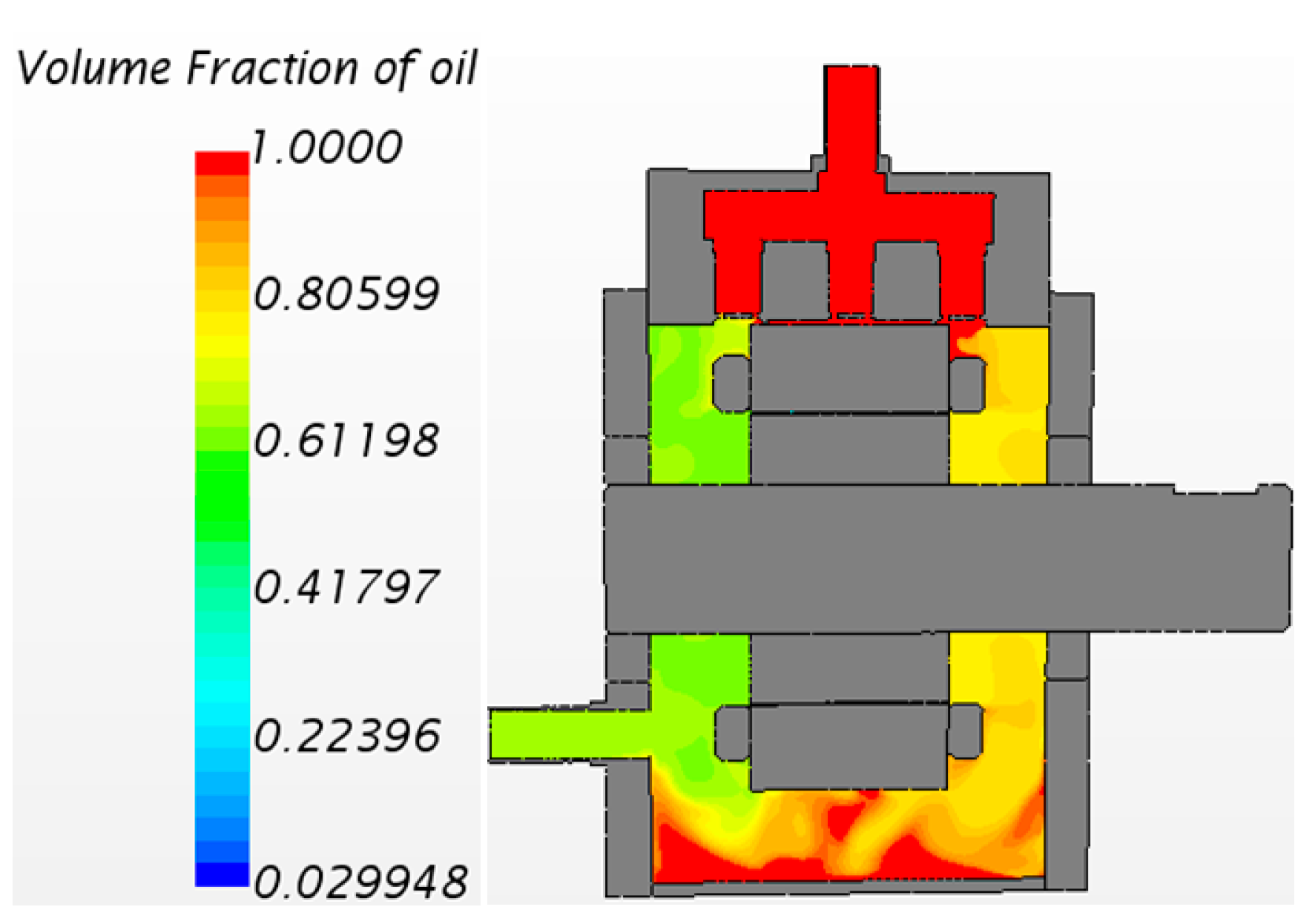

Figure 3 shows the temperature rise simulation results of the end windings with an oil jet nozzle orifice diameter of 1 mm and a vertical position height of 16 mm. In the simulation: value = 1 indicates the corresponding region is fully occupied by cooling oil; value = 0 indicates the region is entirely filled with air. The results reveal that directly below the nozzle, the end windings exhibit the highest concentration of cooling oil, leading to the maximum convective heat transfer coefficient and the lowest temperature of 92.4 °C. Under gravity, the cooling oil flows along the end surfaces of the windings. However, at the bottommost section of the end windings, the oil coverage diminishes significantly, resulting in the highest localized temperature of 132.4 °C.

Using the same analytical method, by varying two parameters—the nozzle orifice diameter and vertical position height—we obtained 49 distinct configurations of the average convective heat transfer coefficient (

haverage (W/m

2/K)) for the end-winding surfaces, as detailed in

Table 1.

Using multivariate nonlinear regression theory, the simulation data from

Table 1 were fitted to derive the nonlinear relationship between the convective heat transfer coefficient (

haverage) and the nozzle diameter (

Dw) and vertical position height (

Hw). The analytical procedure is as follows [

19]:

Establish the regression function

where

is the estimated value of the dependent variable

Y;

Xi are the independent variables;

b0 and

bi represent the constant term and regression coefficients, respectively.

Residual calculation

where

yk and

represent the observed value and calculated value of the dependent variable, respectively;

ek denotes the deviation between the observed and calculated values;

k indicates the observation index.

The objective function of regression analysis:

Based on Equations (3)–(5) and the data from

Table 1, the expression for the average convective heat transfer coefficient (

haverage) of the end-winding surfaces was derived through regression fitting.

This formula serves as a critical design basis for selecting the nozzle diameter and vertical positioning height in stator end-winding spray cooling systems, enabling rapid optimization of oil-jet nozzle configurations.

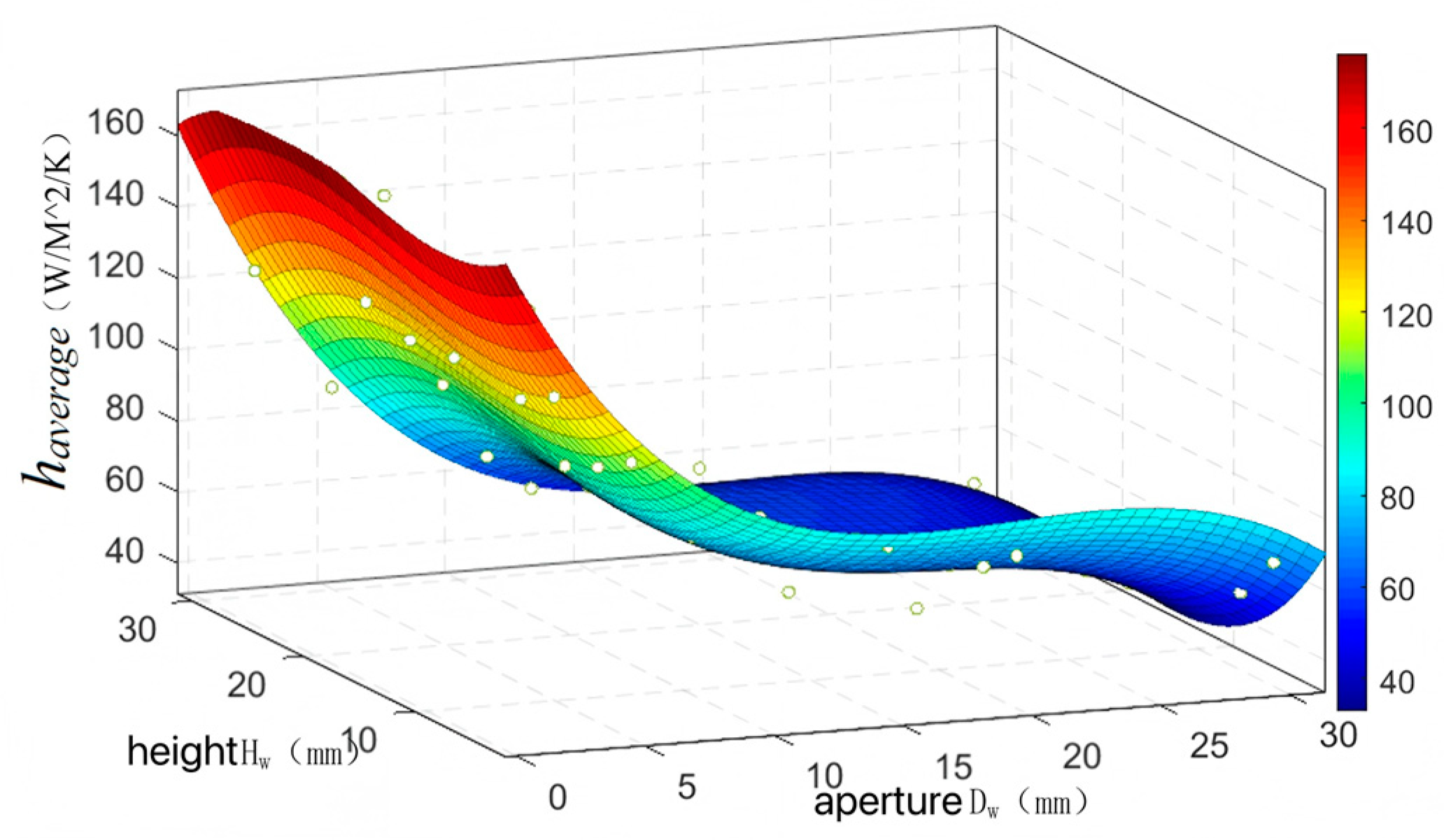

As calculated from Equation (6),

Figure 4 illustrates the relationship between the average convective heat transfer coefficient

haverage of the end-winding surfaces and the nozzle diameter

Dw and positioning height

Hw. The results demonstrate that

haverage decreases with increasing nozzle diameter, while the positioning height exhibits a nonlinear correlation with the heat transfer coefficient. Design optimization requires a comprehensive consideration of factors including pump power, spatial constraints, cost, and manufacturing feasibility.

Based on Equation (6), the heat dissipation factor of the end windings is obtained as follows:

where

lendw is the length of the end windings,

Dts and

Dis denote the tooth root diameter and stator inner diameter of the motor, respectively.

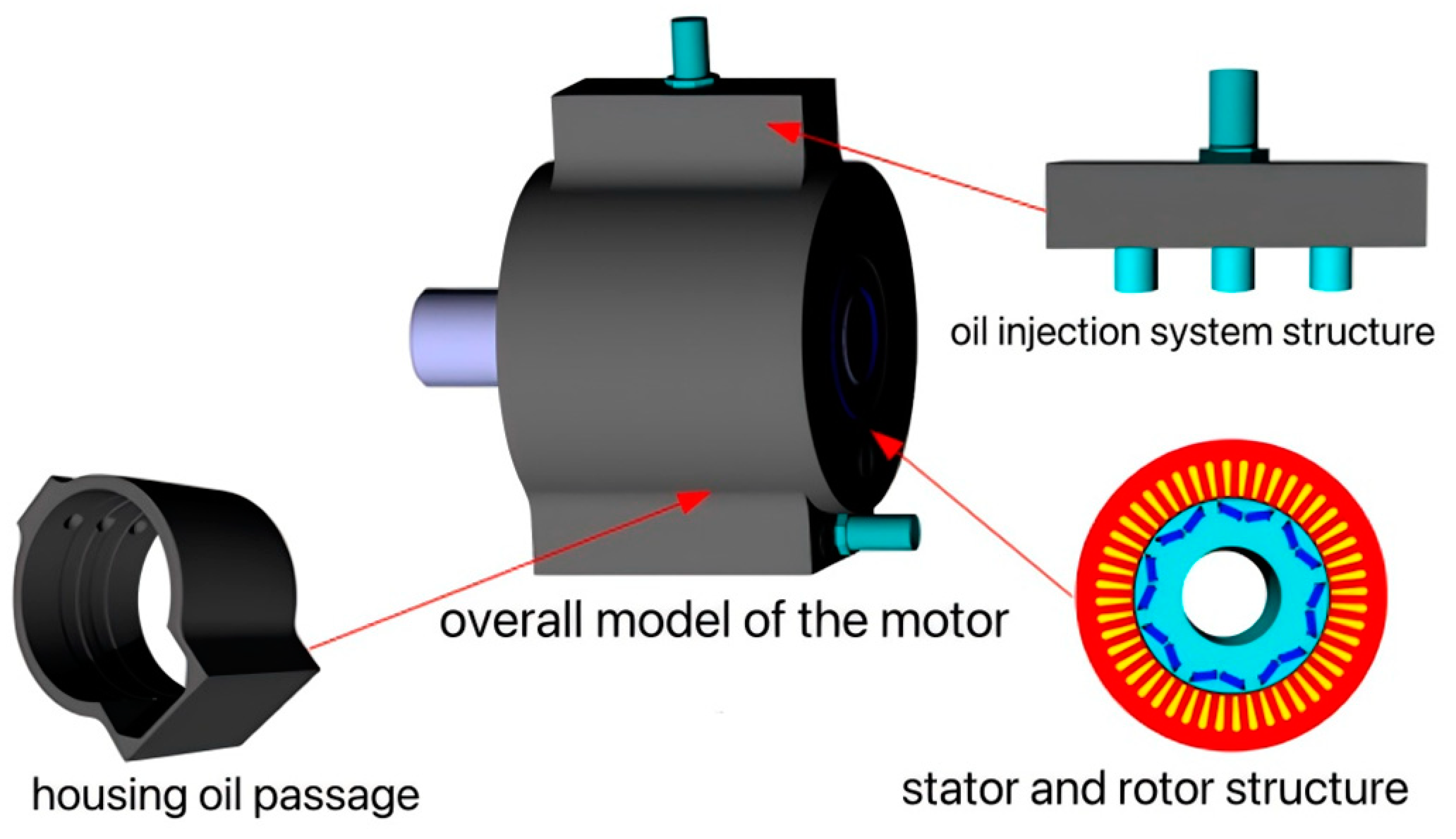

2.2. Design of Housing Oil Channels

Given the manufacturing challenges and poor feasibility of axial helical oil grooves on the inner wall of the motor housing, as well as the adverse impact of stator yoke oil channels on the magnetic circuit, this chapter adopts a circular groove structure on the housing inner wall. The width and depth of the housing oil channels critically determine the thermal dissipation performance of the stator core, while also requiring careful consideration of the housing’s mechanical structural strength.

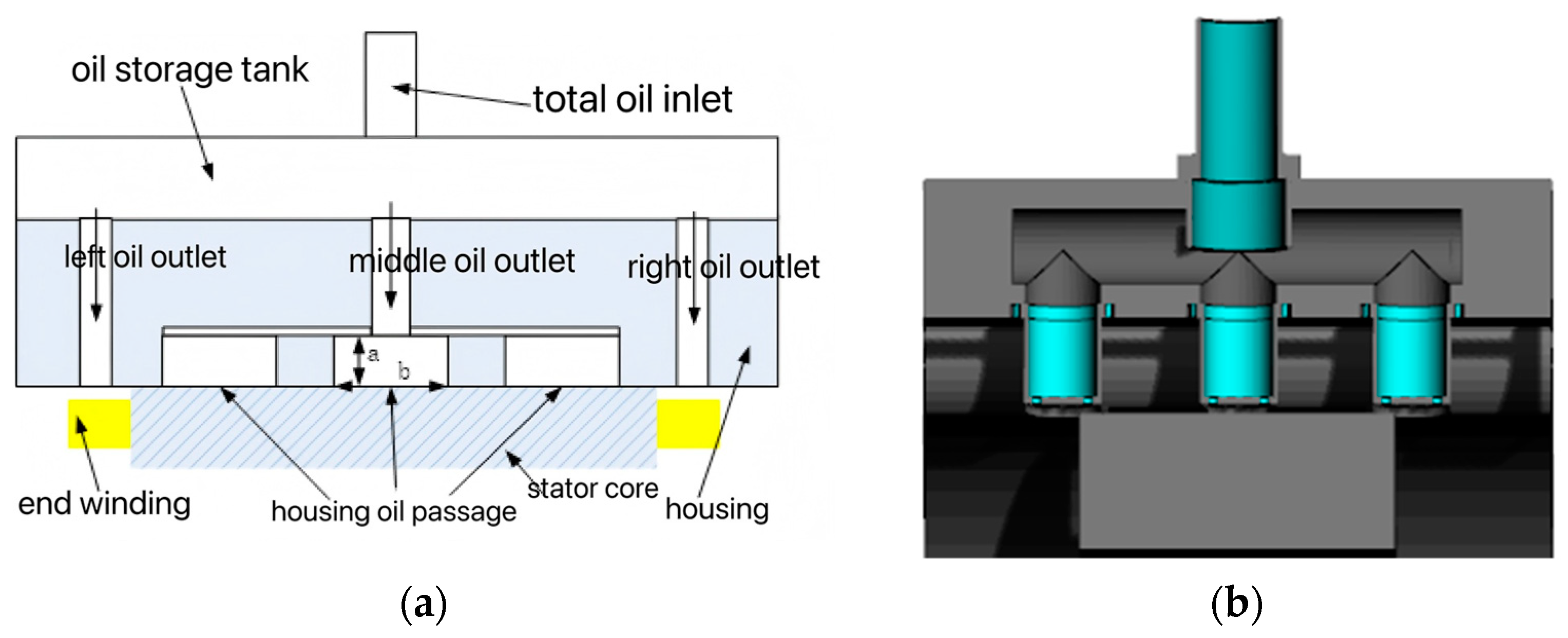

As illustrated in

Figure 5, each oil channel operates independently. Cooling oil flows from the main inlet into the top oil reservoir, then distributes through intermediate ports to the housing oil channels, and finally collects in the bottom oil reservoir. Within the channels, the oil flow exhibits three distinct regimes, and the convective heat transfer coefficient under each regime is determined by the Nusselt number (

Nu), calculated as follows [

20]:

where

Re and

Pr are the Reynolds number and Prandtl number, respectively;

d and

l represent the hydraulic diameter and length of the housing oil channels, respectively;

Prf and

Prw represent the Prandtl numbers calculated with the fluid temperature and the wall temperature as the characteristic temperatures, respectively.

Under specified flow rate and pressure design requirements, the head loss within the housing oil channels directly impacts their cooling effectiveness. Since each housing oil channel has no joints or bends, the cooling oil flow experiences only frictional head loss (also termed major head loss) along the straight channel segments. This loss is proportional to the channel length

l and inversely proportional to the hydraulic diameter

d. The head loss can be calculated using the following formula:

In the equation, represents the frictional head loss coefficient, Voil is the velocity of the cooling oil within the channel, and g denotes the gravitational acceleration.

Assuming all heat generated by the stator core and slot windings is dissipated by the cooling oil in the housing oil channels, the heat dissipation factor of the housing oil channels () can be derived using the same computational method as Equation (2). A higher indicates a stronger cooling capacity of the oil channels. By optimizing the cross-sectional dimensions of the channels, can be maximized. Additionally, the motor housing must satisfy mechanical structural strength requirements.

Within the housing oil channels, the cooling oil flow velocity (

V), hydraulic diameter (

d), convective heat transfer coefficient (

hfo), and heat transfer area of the oil channels (

Afo) can be calculated using Equation (10):

In the equation, Qi is the total inlet oil flow rate; and are the dynamic viscosity of the fluid and the thermal conductivity of the cooling oil, respectively; a and b are the depth and width dimensions of the housing oil channels, respectively; Dos is the outer diameter of the motor stator; Nf is the number of oil channels in the housing.

Combining Equations (8) and (10), the formula for calculating the heat dissipation factor (

) of the housing oil channels is derived as follows:

Based on the above, the design methodology for the housing oil channel of PMSMs-EVs can be summarized as follows: Under specified flow rate and pressure requirements, calculate the cooling oil velocity within the housing oil channel, the hydraulic diameter of the channel, and the Reynolds number using Formula (10). Combined with Formulas (8) and (10), determine the flow regime based on the Reynolds number, then compute the corresponding average Nusselt number and convective heat transfer coefficient. Subsequently, calculate the housing heat dissipation factor using Formula (11)—a higher heat dissipation factor indicates better cooling performance. Finally, validate the mechanical structural strength of the motor housing using finite element software to select the optimal dimensional parameters for the housing oil channel.