Energy-Saving Solutions Applied in Belt Conveyors: A Literature Review

Abstract

:1. Introduction

2. Materials and Methods

2.1. Low-Friction and Energy-Efficient Belts

2.1.1. Modern Amp Miser Belts from Forbo Movement Systems

2.1.2. TransEvo Belts by Semperit

2.1.3. Habasit Energy-Saving Conveyor Belts

2.2. Variable-Frequency Drives (VFDs)

2.2.1. ABB Variable-Frequency Drives

2.2.2. Integration with Automation Systems

2.3. Intelligent Monitoring and Alignment Systems

2.3.1. Voith’s BeltGenius ALEX

2.3.2. Non-Destructive Testing

2.4. Preventive Maintenance and Operational Good Practices

2.4.1. Good Quality Lubricants

- Baseline Creation During Oil Addition: Establish a baseline when adding oil. If the intensity of the decibel level decreases and then starts to increase, it indicates that no more lubricant should be added. At that moment, the measurement will be set as the baseline.

- Comparative Method: Analyze the decibel levels of several conveyors operating under similar (ideally equal) conditions and loads. If the difference between them does not exceed 8 decibels, this measurement can be considered as the baseline.

- Long-Term Analysis: Monitor the decibel levels over an extended period, such as a month. If there are no significant changes, or only slight variations, these levels can serve as the baseline for future comparisons [35].

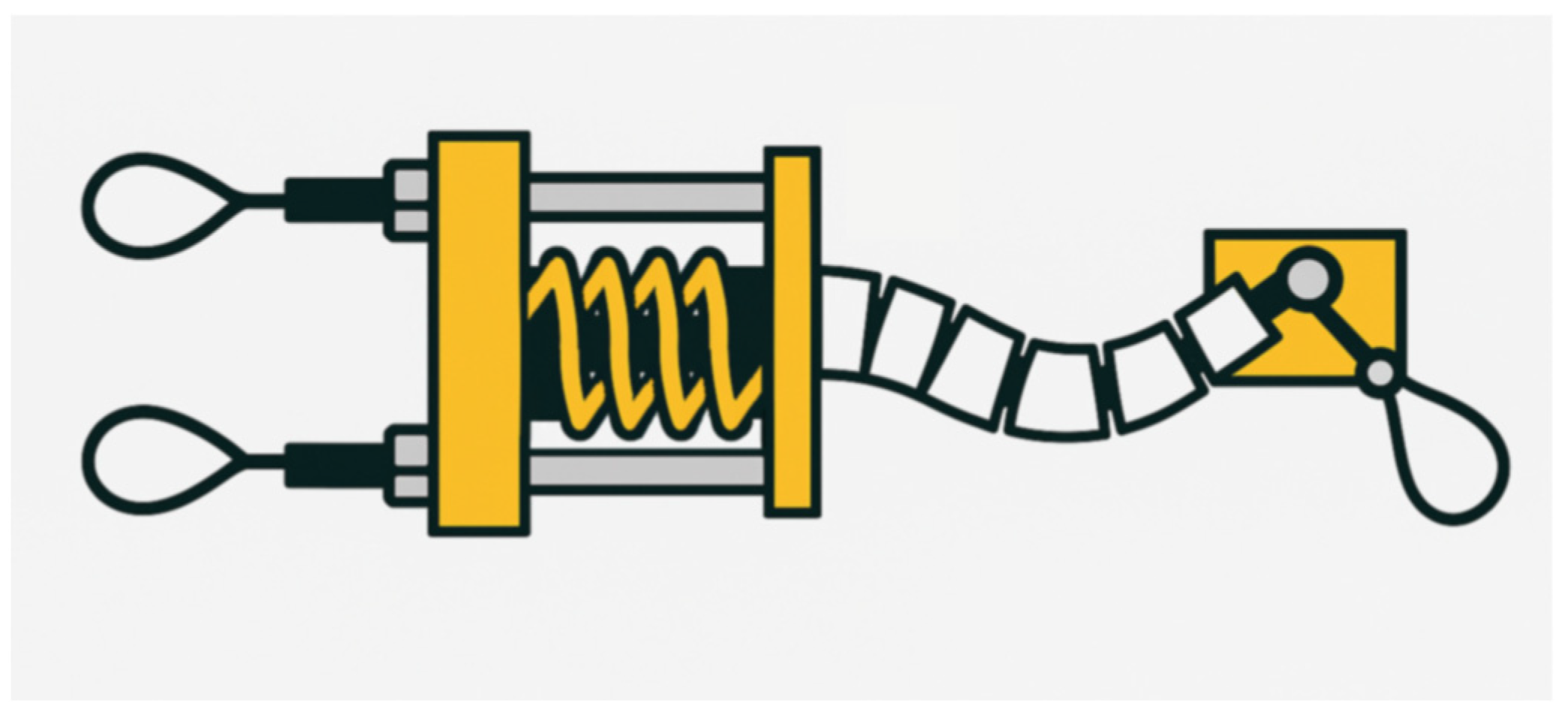

2.4.2. Properly Selected Cleaning Devices

2.4.3. Operational Good Practices

2.4.4. Refurbishing or Recycling

2.5. Automation and Smart Technologies

2.5.1. Integration of AI and IoT

2.5.2. Digital Twins

2.5.3. Remote Monitoring and Control Systems

2.6. Design Optimization

3. Applicability of Energy-Saving Solutions Based on Conveyor Type and Application

3.1. Implementation Challenges of Energy-Saving Technologies

- Habasit Eff-Line belts, which can reduce the energy consumption of a conveyor by up to 45%, are designed for medium or short conveyors operating in closed areas (warehouses, airports, or processing plants) where belt speeds are moderate.

- VFD solutions are the most cost-effective in conveying systems that operate with a traveling load, such as bulk material conveyors in underground and open pit mining, where dynamic speed control is beneficial due to the variable degree of conveyor loading. In the case of short, low-capacity conveyors operating with a constant load, the return on investment in VFD systems may be limited.

- Real-time alignment systems (e.g., BeltGenius ALEX by Voith), similarly to non-invasive diagnostic systems, generate the greatest benefits (in particular, extension of component lifetime and lack of unplanned downtime) in the mining industry. In the case of conveyors, for which failures caused by unplanned downtime can be associated with huge financial losses for the company. In turn, their use may not be justified conveyors with a low risk of failure.

3.2. Comparative Evaluation of Energy-Saving Technologies for Belt Conveyors

4. Results—Environmental and Economic Benefits

5. Future Research Directions and Development Perspectives

6. Conclusions

Funding

Conflicts of Interest

References

- Kulinowski, P. Directions for Reducing the Energy Consumption of Mining Belt Conveyors. MIAG 2022, 3, 21–27. [Google Scholar] [CrossRef]

- Bajda, M.; Hardygóra, M.; Marasová, D. Energy Efficiency of Conveyor Belts in Raw Materials Industry. Energies 2022, 15, 3080. [Google Scholar] [CrossRef]

- Zhang, S.; Xia, X. Modeling and Energy Efficiency Optimization of Belt Conveyors. Appl. Energy 2011, 88, 3061–3071. [Google Scholar] [CrossRef]

- ABB Group. Insights into Drives Technology. Need to Increase Energy Efficiency? Available online: https://global.abb (accessed on 22 April 2025).

- Voith Group. Voith Successfully Implements First BeltGenius ERIC System. Available online: https://www.voith.com (accessed on 22 April 2025).

- Siemens. Conveyor Technology—Innovative Solutions for Your Highest Demands. Available online: https://www.siemens.com (accessed on 22 April 2025).

- Synergy Automatics. A Guide to Energy Efficient Conveyor Systems. 2024. Available online: https://synergyautomatics.in (accessed on 22 April 2025).

- Bajda, M.; Jurdziak, L.; Pactwa, K.; Woźniak, J. Energy-Saving of Conveyor Belts in the Strategy and Reporting of Corporate Social Responsibility Initiatives of Producers. In Advances in Manufacturing Processes, Intelligent Methods and Systems in Production Engineering; Batako, A., Burduk, A., Karyono, K., Chen, X., Wyczółkowski, R., Eds.; Springer International Publishing: Cham, Switzerland, 2022; Volume 335, pp. 402–414. [Google Scholar] [CrossRef]

- Bajda, M.; Hardygóra, M. Analysis of the Influence of the Type of Belt on the Energy Consumption of Transport Processes in a Belt Conveyor. Energies 2021, 14, 6180. [Google Scholar] [CrossRef]

- Kawalec, W.; Suchorab, N.; Konieczna-Fuławka, M.; Król, R. Specific Energy Consumption of a Belt Conveyor System in a Continuous Surface Mine. Energies 2020, 13, 5214. [Google Scholar] [CrossRef]

- Kiriia, R.; Shyrin, L. Reducing the Energy Consumption of the Conveyor Transport System of Mining Enterprises. E3S Web Conf. 2019, 109, 36. [Google Scholar] [CrossRef]

- Forbo Movement Systems. Amp Miser Energy Saving Conveyor Belts 2024. Available online: https://www.forbo.com/ (accessed on 28 April 2025).

- Semperit. Energy Saving Cover—TransEvo. Available online: https://conveyor-belts.semperitgroup.com/ (accessed on 28 April 2025).

- Habasit. Reduce Your Running Costs and Your Carbon Footprint. Available online: https://www.habasit.com/ (accessed on 28 April 2025).

- Yang, C.; Liu, J.; Li, H.; Zhou, L. Energy Modeling and Parameter Identification of Dual-Motor-Driven Belt Conveyors without Speed Sensors. Energies 2018, 11, 3313. [Google Scholar] [CrossRef]

- Mathaba, T.; Xia, X. Optimal and Energy Efficient Operation of Conveyor Belt Systems with Downhill Conveyors. Energy Effic. 2017, 10, 405–417. [Google Scholar] [CrossRef]

- Ji, J.; Miao, C.; Li, X.; Liu, Y. Speed Regulation Strategy and Algorithm for the Variable-Belt-Speed Energy-Saving Control of a Belt Conveyor Based on the Material Flow Rate. PLoS ONE 2021, 16, e0247279. [Google Scholar] [CrossRef]

- Ji, J.; Miao, C.; Li, X. Research on the Energy-Saving Control Strategy of a Belt Conveyor with Variable Belt Speed Based on the Material Flow Rate. PLoS ONE 2020, 15, e0227992. [Google Scholar] [CrossRef]

- ABB. Variable-Speed Drives for Belt-Conveyor Systems. A Project Report of the Revamp of a Lignite Conveyor Line; ABB Process Industries: Cottbus, Germany, 2000. [Google Scholar]

- Wang, N.; Hu, J. Design of Speed Regulation Remote Monitoring System of Belt Conveyor; Atlantis Press: Shenyang, China, 2015. [Google Scholar]

- Shareef, I.R.; Hussein, H.K. Implementation of Artificial Neural Network to Achieve Speed Control and Power Saving of a Belt Conveyor System. EEJET 2021, 2, 44–53. [Google Scholar] [CrossRef]

- Molnár, V.; Fedorko, G.; Husáková, N.; Král’, J., Jr.; Ferdynus, M. Energy Calculation Model of an Outgoing Conveyor with Application of a Transfer Chute with the Damping Plate. Mech. Sci. 2016, 7, 167–177. [Google Scholar] [CrossRef]

- Ibekwe, K.I.; Fabuyide, A.; Hamdan, A.; Ilojianya, V.I. Emmanuel Augustine Etukudoh Energy Efficiency through Variable Frequency Drives: Industrial Applications in Canada, USA, and Africa. Int. J. Sci. Res. Arch. 2024, 11, 730–736. [Google Scholar] [CrossRef]

- Wang, L.; Li, H.; Huang, J.; Zeng, J.; Tang, L.; Wu, W.; Luo, Y. Research on and Design of an Electric Drive Automatic Control System for Mine Belt Conveyors. Processes 2023, 11, 1762. [Google Scholar] [CrossRef]

- Akparibo, A.R.; Normanyo, E. Application of Resistance Energy Model to Optimising Electric Power Consumption of a Belt Conveyor System. IJECE 2020, 10, 2861–2873. [Google Scholar] [CrossRef]

- Voith BeltGenius ALEX: Optimized Belt Alignment Reduces the Energy Consumption and Idler Wear of Conveyor Systems. Available online: https://www.mining.com (accessed on 29 April 2025).

- Michalak, A.; Hebda-Sobkowicz, J.; Wodecki, J.; Szabat, K.; Wolkiewicz, M.; Weisse, S.; Valire, J.; Zimroz, R.; Wyłomańska, A. Enhancement of Cyclic Spectral Coherence Map by Statistical Testing Approach—Application to Bearing Faults Diagnosis in Electric Motors. Meas. Sci. Technol. 2025, 36, 016169. [Google Scholar] [CrossRef]

- Błażej, R.; Jurdziak, L.; Kirjanów-Błażej, A.; Rzeszowska, A.; Kostrzewa, P. Improving the effectiveness of the DiagBelt+ diagnosticsystem—Analysis of the impact of measurement parameters on the quality of signals. Eksploat. Niezawodn.-Maint. Reliab. 2024, 26, 187275. [Google Scholar] [CrossRef]

- Improving the Effectiveness of the DiagBelt+ Diagnostic System—Analysis of the Impact of Measurement Parameters on the Quality of Signals. Available online: https://www.researchgate.net/publication/380952189_Improving_the_effectiveness_of_the_DiagBelt_diagnostic_system_-_analysis_of_the_impact_of_measurement_parameters_on_the_quality_of_signals (accessed on 27 May 2025).

- Blazej, R.; Zimroz, R.; Jurdziak, L.; Hardygora, M.; Kawalec, W. Conveyor Belt Condition Evaluation via Non-Destructive Testing Techniques. In Mine Planning and Equipment Selection; Drebenstedt, C., Singhal, R., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 1119–1126. ISBN 9783319026770. [Google Scholar]

- Błażej, R.; Sawicki, M.; Konieczna, M.; Kozłowski, T.; Kirjanów, A. Automatic analysis of themrograms as a means for estimatingtechnical of a gear system. Diagnostyka 2016, 17, 43–48. [Google Scholar]

- Luo, J.; Huang, W.; Zhang, S. Energy Cost Optimal Operation of Belt Conveyors Using Model Predictive Control Methodology. J. Clean. Prod. 2015, 105, 196–205. [Google Scholar] [CrossRef]

- Kulinowski, P.; Kasza, P.; Zarzycki, J. Influence of Design Parameters of Idler Bearing Units on the Energy Consumption of a Belt Conveyor. Sustainability 2021, 13, 437. [Google Scholar] [CrossRef]

- Antoniak, J. Theoretical basis and industrial applications of energy—Saving and increased durability belt conveyors. Acta Montan. Slovaca Ročník 2003, 8, 2–3. [Google Scholar]

- Available online: https://www.conveyoroller.com/new/Conveyor-idler-oil-maintenance (accessed on 30 April 2025).

- Available online: https://www.hiconveyor.com/product/Belt_Cleaner.html (accessed on 30 April 2025).

- Mu, Y.; Yao, T.; Jia, H.; Yu, X.; Zhao, B.; Zhang, X.; Ni, C.; Du, L. Optimal Scheduling Method for Belt Conveyor System in Coal Mine Considering Silo Virtual Energy Storage. Appl. Energy 2020, 275, 115368. [Google Scholar] [CrossRef]

- Rubber Conveyor Belt Refurbishing and Recycling Services. Available online: https://www.moormarine.com/ (accessed on 30 April 2025).

- Wen, L.; Liang, B.; Zhang, L.; Hao, B.; Yang, Z. Research on Coal Volume Detection and Energy-Saving Optimization Intelligent Control Method of Belt Conveyor Based on Laser and Binocular Visual Fusion. IEEE Access 2024, 12, 75238–75248. [Google Scholar] [CrossRef]

- Oette, C.; Küfner, T.; Reger, A.; Boehner, J. Lean Data Services: Detection of Operating States in Energy Profiles of Intralogistics Systems by Using Big Data Analytics. AMM 2016, 856, 73–81. [Google Scholar] [CrossRef]

- Fedorko, G. Implementation of Industry 4.0 in the Belt Conveyor Transport. MATEC Web Conf. 2019, 263, 01001. [Google Scholar] [CrossRef]

- Bondoc, A.E.; Tayefeh, M.; Barari, A. LIVE Digital Twin: Developing a Sensor Network to Monitor the Health of Belt Conveyor System. IFAC-Pap. 2022, 55, 49–54. [Google Scholar] [CrossRef]

- Xu, Z.; Sun, Z.; Li, J. Research on Coal Flow Visual Detection and the Energy-Saving Control Method Based on Deep Learning. Sustainability 2024, 16, 5783. [Google Scholar] [CrossRef]

- Conveying Innovations from Thyssenkrupp. 2020. Available online: https://www.bulkhandlingreview.com.au/ (accessed on 3 May 2025).

- Kirjanów-Błażej, A.; Jurdziak, L.; Burduk, R.; Błażej, R. Forecast of the Remaining Lifetime of Steel Cord Conveyor Belts Based on Regression Methods in Damage Analysis Identified by Subsequent DiagBelt Scans. Eng. Fail. Anal. 2019, 100, 119–126. [Google Scholar] [CrossRef]

- Kulinowski, P.; Kasza, P.; Zarzycki, J. Methods of Testing of Roller Rotational Resistance in Aspect of Energy Consumption of a Belt Conveyor. Energies 2022, 16, 26. [Google Scholar] [CrossRef]

- Polishchuk, L.; Piontkevych, O.; Burdeinyi, M.; Trehubov, V. Justification for Choosing the Type of Belt Conveyor Drive. JMET 2024, 19, 115–122. [Google Scholar] [CrossRef]

- Chiorino. Reducing Energy Consumption with Eco-Friendly Conveyor Belt Solutions. 2025. Available online: https://www.chiorinoukblog.com/ (accessed on 4 May 2025).

- Materials Handling. Reducing the Carbon Footprint of Industrial Conveyor Belt Manufacture. 18 March 2022. Available online: https://www.agg-net.com (accessed on 4 May 2025).

- Conveyor Equipment Manufacturers Association (CEMA). 7th Belt Conveyors for Bulk Materials, with Metric Conversion USA; CEMA: Minato City, Japan, 2021. [Google Scholar]

- ISO 50001; International Standard for Energy Management Systems. International Organization for Standardization: Geneva, Switzerland, 2018.

| Technology | Energy Savings [%] | Best Application Context | Implementation Complexity | Key Benefits | Main Limitations |

|---|---|---|---|---|---|

| Amp Miser® belts (Forbo, Siegling GmbH, Lilienthalstrasse, Hannover) | Up to 50% [12] | Long conveyors, indoor conveyors | Low | Low friction, TÜV certified, long belt life | Limited applicability in harsh environments |

| TransEvo® belts (Semperit Group, Vienna, Austria) | Up to 25% [13] | Mining | Medium | Lower rolling resistance, lighter belts, mining-ready | Higher material cost; mining-specific implementation |

| Eff-Line (Habasit International AG, Reinach, Switzerland) | Up to 45% [14] | Indoor conveyors | Low | Lower sliding resistance, water-based impregnation | Less suited for high load, outdoor conveyors |

| VFD Systems (ABB, Oerlikon, Switzerland) | Up to 20% [19] | Variable-load, high-capacity conveyors, mining | High | Real-time speed control, less wear, scalable | High upfront cost, complex integration |

| BeltGenius ALEX (Voith GmBH, Heidenheim an der Brenz, Germany) | ~10% [26] | Long conveyors, mining | Medium | Misalignment detection, extends idler life | Requires sensor installation and integration |

| Non-Destructive Testing Systems | Indirect [28,29,31] | Steel cord belts, safety critical systems, mining | High | Prevents failures, extends component lifespan | Signal acquisition, training-intensive |

| Digital Twin and IoT-based Systems | Indirect but significant | Complex, integrated conveyor systems, mining | Very high | Predictive maintenance, operational simulation | Requires fully digital infrastructure |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konieczna-Fuławka, M. Energy-Saving Solutions Applied in Belt Conveyors: A Literature Review. Energies 2025, 18, 3019. https://doi.org/10.3390/en18123019

Konieczna-Fuławka M. Energy-Saving Solutions Applied in Belt Conveyors: A Literature Review. Energies. 2025; 18(12):3019. https://doi.org/10.3390/en18123019

Chicago/Turabian StyleKonieczna-Fuławka, Martyna. 2025. "Energy-Saving Solutions Applied in Belt Conveyors: A Literature Review" Energies 18, no. 12: 3019. https://doi.org/10.3390/en18123019

APA StyleKonieczna-Fuławka, M. (2025). Energy-Saving Solutions Applied in Belt Conveyors: A Literature Review. Energies, 18(12), 3019. https://doi.org/10.3390/en18123019