1. Introduction

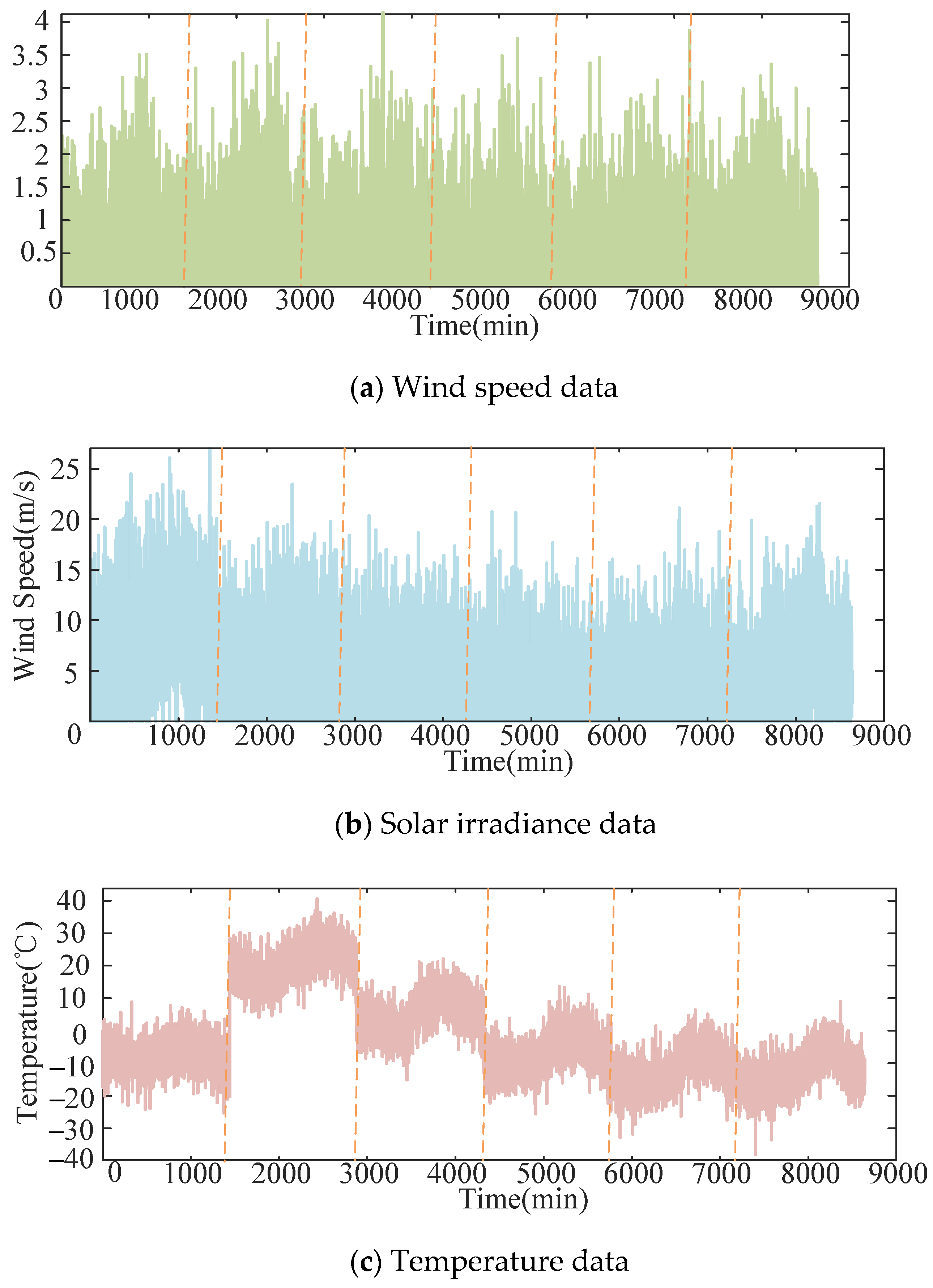

Over the years, the utilization of fossil fuels such as coal, petroleum, and natural gas has driven tremendous global development, with numerous industries including transportation, power generation, and manufacturing remaining heavily dependent on these energy sources. However, the extensive consumption of fossil fuels has precipitated imminent environmental pollution and energy scarcity issues in recent years, making the search for renewable energy alternatives to replace fossil fuels a fundamental solution to contemporary energy challenges. Against the backdrop of increasingly prominent energy concerns, China proposed in 2020 its dual carbon targets: achieving a “carbon peak” by 2030 and “carbon neutrality” by 2060. Since this declaration, the country’s new energy power generation sector has experienced rapid development [

1,

2,

3]. Among these, wind and photovoltaic (PV) power generation have experienced the most significant growth, with China maintaining its position as the global leader in installed wind-PV capacity. However, due to the inherent volatility of wind and solar power [

4], the electricity generated from these sources struggles to meet the stability requirements for large-scale grid integration, with a grid integration rate limited to approximately 30%. The real-time generation and consumption nature of electricity exacerbates widespread wind and solar curtailment, resulting in severe waste of human and material resources [

5,

6]. Consequently, to enhance the utilization of highly volatile and stochastic electricity from wind and solar power and absorb the otherwise wasted energy, it is imperative to explore novel approaches [

7].

Hydrogen energy, as a clean secondary energy source, boasts high energy density and enables large-capacity, long-term storage and transportation, making it widely applicable in transportation, industry, chemical production, and other fields [

8,

9]. Simultaneously, hydrogen energy has emerged as the “ultimate energy solution” that is most likely to address energy challenges in the 21st century, owing to its role as a versatile energy conversion hub and its pollution-free utilization. Currently, primary hydrogen production methods include fossil fuel-based hydrogen production, high-temperature decomposition of hydrogen-containing compounds, biomass-derived hydrogen, and water electrolysis. Steam methane reforming (SMR), a widely adopted fossil fuel-based method, offers mature technology and low costs but generates substantial CO emissions during production, exacerbating environmental pollution and undermining energy sustainability. Reference [

10] proposes a novel high-temperature decomposition method for hydrogen-containing compounds, pyrolyzing plastic waste to produce hydrogen and carbon nanotubes, achieving waste utilization while minimizing carbon emissions at relatively low costs. However, as most plastics contain carbon elements, this method cannot entirely avoid carbon emissions during hydrogen production, rendering it suboptimal for resolving energy challenges. Biomass-derived hydrogen utilizes renewable biomass as feedstock, absorbing CO2 during fermentation without generating carbon emissions, offering environmental friendliness and strong sustainability. Nevertheless, this process requires substantial water as a reaction medium, posing challenges for water-scarce regions, coupled with immature technology, scalability limitations, and high costs that hinder short-term commercialization [

11]. In contrast, renewable energy-powered water electrolysis produces hydrogen and oxygen through electrolyzers, effectively utilizing otherwise wasted wind and solar power while maintaining full-process cleanliness and zero pollution [

12]. Common electrolyzer types include alkaline electrolyzers (ALK), proton exchange membrane electrolyzers (PEM), and solid oxide electrolyzer cells (SOEC). Among these, alkaline electrolyzers feature simple structures, ease of manufacturing, low costs, and high technological maturity, making them the optimal choice for large-scale hydrogen production. Therefore, storing energy in hydrogen form through water electrolysis powered by wind and photovoltaic systems represents the most promising solution to energy challenges, aligning with future energy trends. Furthermore, off-grid hydrogen production using renewable energy avoids impacts on large power grids, justifying the adoption of decentralized production systems.

However, the inherent volatility and intermittency of wind and solar resources pose threats to the safe and stable operation of electrolyzers, as excessively low power input to electrolyzers may trigger explosion risks [

13]. Consequently, energy storage systems are typically integrated into off-grid hydrogen production setups to balance the mismatch between renewable power generation and hydrogen production demands. The resulting wind–solar-storage-hydrogen integrated system, which combines wind, solar, electrical, and hydrogen energy, constitutes a complex multi-energy system with intricate power allocation challenges among components. This complexity makes it difficult to simultaneously optimize multiple performance indicators, including system stability, renewable energy utilization rates, economic costs, and energy storage supply capacity [

14], ultimately severely hindering the advancement of renewable energy-based off-grid hydrogen production. Therefore, conducting research on power coordination optimization among devices in renewable off-grid hydrogen production systems to balance economic feasibility, operational stability, energy storage reliability, and wind–solar curtailment rates holds profound significance.

Extensive research has focused on the collaborative optimization of hydrogen-integrated multi-energy system (HIMES), primarily through three approaches: intelligent algorithms, data-driven machine learning, and rule-based power allocation. Intelligent algorithms construct multi-objective functions to seek global optima under constraints. Reference [

15] balanced power fluctuations, battery degradation, and energy losses in wind farms, while reference [

16] proposed a real-time energy management system using multidimensional piecewise linear function-based approximate dynamic programming (MPLF-ADP) to minimize operational costs under renewable uncertainties. However, these methods face high computational complexity and hardware dependence due to the multi-objective, multi-constrained nature of HIMES. Machine learning approaches, such as data-driven robust scheduling for hydrogen microgrids (H2-DCMG) [

17] and adaptive dynamic programming reinforcement learning [

18], offer data-driven solutions but require massive training datasets and GPU-accelerated hardware, limiting practical deployment. Rule-based methods excel in computational efficiency and interpretability. Reference [

19] maintained electrolyzer power above 40% of rated capacity to enhance efficiency, and reference [

20] combined fixed rules with improved particle swarm optimization for capacity configuration. However, existing rules oversimplify interactions between electrolyzer power limits and ESS state-of-charge (SOC) boundaries [

21,

22,

23], neglecting reserved energy allocation to counteract future extreme operating conditions, thereby compromising system-wide stability. A comprehensive comparison revealed that the commonly used power dispatch strategies for HIMES each exhibit distinct advantages and limitations across different operational aspects. However, since HIMES optimization inherently involves multi-objective trade-offs and aims for balanced performance across multiple criteria, integrating complementary methodologies can synergize their strengths. This approach enables more robust handling of diverse operational requirements while enhancing overall system efficiency and flexibility.

The multi-stage optimization of HIMES is currently being explored by scholars. To address the multi-factor uncertainties in rural multi-energy microgrids, Reference [

24] proposed a two-stage stochastic energy scheduling method. In the first stage, operational states of energy storage systems and power units are optimized to mitigate the negative impacts of uncertainties, while the second stage focuses on the real-time adjustment of output power from units and storage to rapidly adapt to fluctuating uncertainty factors. The two-stage optimization framework employs a progressive hedging algorithm to solve stochastic optimization problems, thereby enhancing computational efficiency. Reference [

25] proposed a two-stage robust optimization method: the first stage determines the battery charge/discharge states and electrolyzer on/off statuses, while the second stage enhances small-disturbance stability by incorporating output power constraints. References [

26,

27,

28] adopted a two-stage strategy for HIMES energy dispatch, with the first stage performing day-ahead deterministic scheduling and the second stage executing intraday rolling scheduling. Reference [

29] introduced a two-stage adaptive robust optimization framework for integrated energy and natural gas systems, where the first stage optimizes equipment configurations, and the second stage maximizes output while minimizing operational costs. Reference [

30] developed a solution algorithm based on Lyapunov optimization theory (LOT) and multi-agent deep reinforcement learning. It simplifies the cost minimization problem via LOT and subsequently solves it using the multi-agent advantage actor-aritic deep deterministic policy gradient (MAADDPG), combining the strengths of two power optimization methods. However, this approach exhibits high dependency on data and stringent hardware requirements. Reference [

31] proposed a bilayer energy management strategy: the first layer achieves optimal power allocation, and the second layer balances the SOC of energy storage to prolong battery lifespan.

A systematic review of studies related to two-stage optimization in HES systems was conducted, with the findings summarized in

Table 1. The table reveals that most two-stage power optimization frameworks decompose distinct tasks into sequential stages, whereas few integrate complementary power dispatch methodologies for the same objective. Only reference [

30] synergized intelligent algorithm-based power optimization with AI-driven machine learning to enhance adaptability across varying operating conditions. Reference [

24] implemented the optimization of equipment operational states across both stages, yet relied solely on intelligent optimization algorithms for problem-solving in both phases without leveraging the complementary strengths of different methodologies. Beyond the aforementioned literature on two-stage optimization for HESs systems, Reference [

32] investigated triggering mechanisms for secondary control in DC microgrids. By integrating distributed self-triggered (TED) and distributed event-triggered (STED) mechanisms, the authors proposed a novel hybrid distributed triggering mechanism (HTED). This approach eliminates the high demands for continuous sampling and state monitoring inherent in TED while overcoming the conservativeness of STED, offering valuable insights for integrating diverse optimization methods in HESS systems. Furthermore, for renewable energy off-grid hydrogen production systems, the power supply capability of energy storage is crucial. Optimizing energy storage states and reserving partial energy storage capacity can enhance the full-cycle charge–discharge capability of energy storage systems, thereby improving hydrogen production system stability and reducing wind and solar curtailment rates. However, a literature review revealed that while numerous studies have considered the lifespan degradation caused by energy storage charge–discharge cycles, none have addressed the allocation of reserved energy storage capacity during normal electrolyzer operations to mitigate potential adverse operating conditions in future scenarios.

To address the aforementioned limitations, this study develops a deterministic power dispatch framework that prioritizes reserving differentiated energy storage buffer capacities tailored to the electrolyzer’s real-time operating conditions. This approach proactively mitigates adverse electrolyzer operating scenarios, thereby enhancing global hydrogen production stability. A refined power dispatch protocol is formulated by deeply coupling the electrolyzer’s dynamic states with the energy storage’s SOC, improving the system’s adaptability to fluctuating renewable generation. Furthermore, the proposed two-stage collaborative power optimization synergizes rule-based dispatch with intelligent algorithms, achieving rapid power allocation while ensuring globally balanced performance. The specific contributions are as follows:

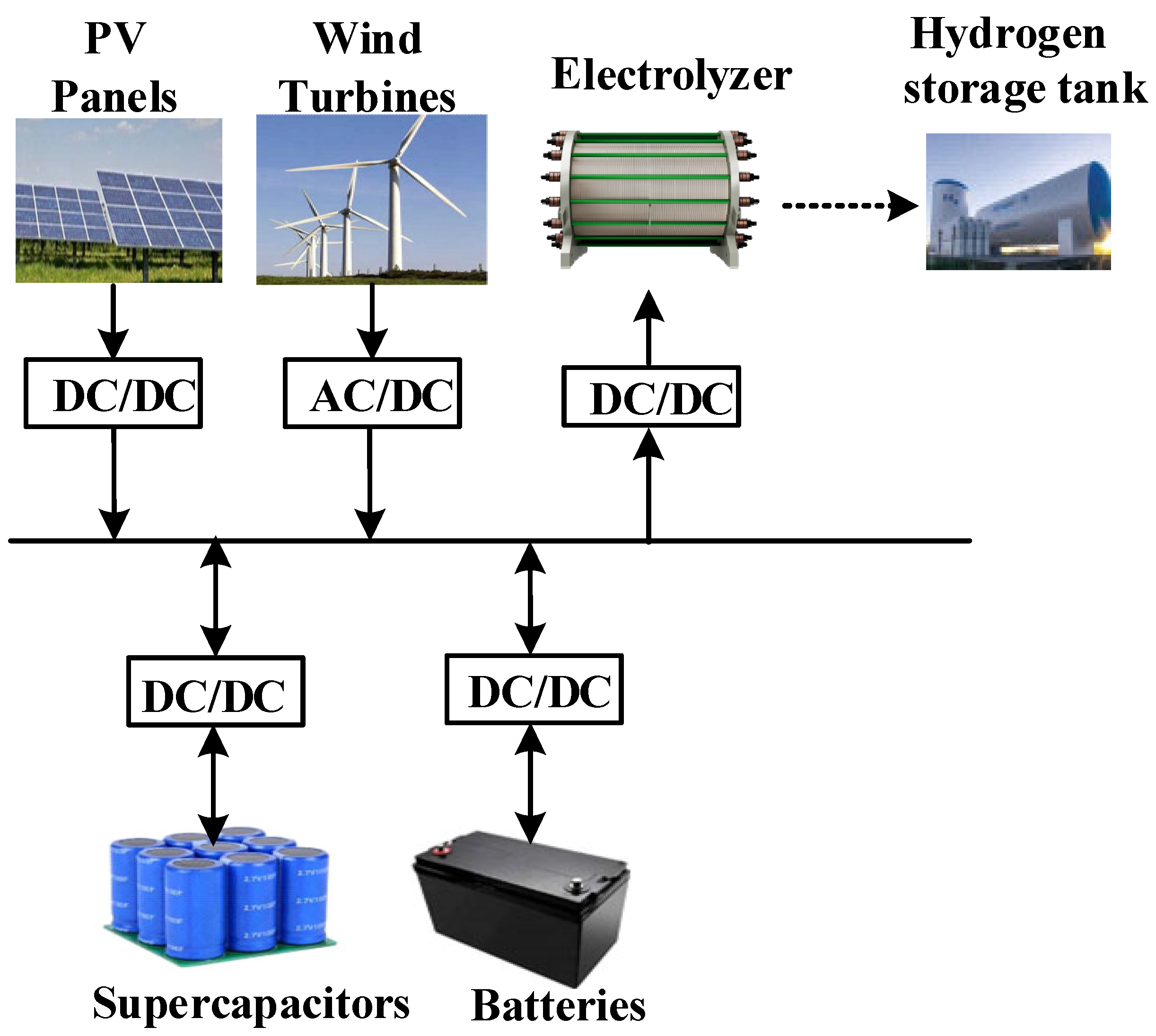

(1) An off-grid wind-PV-storage hydrogen production system model is established, where a HESS (comprising batteries and supercapacitors) mitigates long-term and transient power imbalances.

(2) Conventional power dispatch rules solely consider simplistic interactions between electrolyzer power boundaries and storage SOC limits, leading to suboptimal storage dispatchability and unstable electrolyzer operation. This work introduces a refined rule library that incorporates multi-condition electrolyzer–storage interactions and adaptive buffer energy reservation, significantly enhancing dispatch granularity and robustness.

(3) To overcome the poor adaptability and global optimality limitations of deterministic rules under renewable variability, a two-stage collaborative optimization strategy is proposed:

Stage I: Rapidly allocates electrolyzer power and preliminary HESS power via buffer-energy-aware refined rules, reducing nonlinear optimization complexity.

Stage II: Optimizes inter-storage (battery–supercapacitor) power distribution using an improved multi-objective particle swarm optimization (IMOPSO) algorithm, minimizing unit hydrogen production cost and battery depth of discharge (DOD). This achieves globally balanced optimality for both electrolyzer and storage operations.

(4) Comparative analyses using three conventional rule-based methods demonstrate that the proposed approach reduces the system power shortage rate, wind/solar curtailment rate, and storage cycling losses while balancing economic efficiency, hydrogen production stability, and battery longevity.

Section 2 details the off-grid wind-PV-storage hydrogen system architecture and mathematical modeling.

Section 3 elaborates on the two-stage collaborative power optimization strategy.

Section 4 validates the proposed method against three benchmark strategies through case simulations, with results analyzed. The concluding section summarizes key findings.

3. Two-Stage Collaborative Power Optimization Strategy

3.1. Stage I: System Power Dispatch Rules

Traditional deterministic rule-based power allocation methods are often confined to simple interactions between the upper/lower limits of electrolyzer power and energy storage constraints, neglecting the critical consideration of how much reserved energy storage should be allocated under specific electrolyzer operating conditions during power shortages to mitigate future adverse scenarios. This oversight leads to inadequate global energy supply capacity and unstable hydrogen production in electrolyzers. To address this, this paper proposes a power allocation rule for the first operational stage that deeply integrates renewable generation, electrolyzer operating conditions, and reserved storage energy. This rule establishes energy storage supply priorities for different electrolyzer operating conditions under varying renewable generation levels, retaining appropriate reserved energy during permissible electrolyzer conditions to enhance comprehensive storage supply capability and ensure stable electrolyzer operation.

When renewable generation exceeds the electrolyzer’s rated power, the electrolyzer operates in high-efficiency, high-speed hydrogen production mode at rated power

. For sustained power surplus, the electrolyzer temporarily operates in an overload condition at 1.2

to increase hydrogen output. During this phase, the hybrid energy storage system charges, with batteries and supercapacitors jointly absorbing the surplus power. The initial power allocation rules for hybrid storage charging are detailed in

Table 2, where

represents the difference between renewable generation and the electrolyzer’s rated power,

and

denote the maximum charge/discharge power of batteries and supercapacitors respectively, and

and

indicate the respective charging powers. The specific rules are as follows:

(1) When , both storage units charge at maximum capacity, with excess power beyond their maximum charging limits being curtailed as renewable energy waste.

(2) For , the battery charges at while the supercapacitor supplements the remaining . No curtailment occurs unless the combined charging exceeds the hybrid storage capacity limits.

(3) When , only the supercapacitor charges. If , the supercapacitor charges at with surplus power curtailed. Otherwise, the supercapacitor charges at without curtailment.

When renewable generation falls below the electrolyzer’s rated power, hybrid storage discharges. The electrolyzer power command and storage supply priority are determined based on the electrolyzer’s hydrogen production conditions during power shortages while preserving appropriate reserved energy for future adverse scenarios. This process involves three key steps:

(1) Reserved Energy Assessment: Evaluate battery and supercapacitor reserved energy using the initial state of charge (SOC) threshold of 0.5. SOC values above 0.5 indicate sufficient reserved energy to withstand potential adverse conditions.

(2) Adaptive Power Command Allocation: Develop storage supply priorities for various electrolyzer conditions through the integrated consideration of reserved energy. As illustrated in

Figure 3, where

represents total renewable power,

,

denote previous SOC values, and

is the electrolyzer power command, the rule is as follows: With sufficient reserved energy, the electrolyzer operates at

regardless of current conditions. With insufficient reserved energy, four operational scenarios are addressed:

(1) When the electrolyzer experiences a power shortage and operates under prohibited operating conditions, the power command for the electrolyzer is set to . The priority is to prevent electrolyzer shutdown, followed by transitioning it to the more favorable medium-speed hydrogen production condition with high efficiency.

(2) When the electrolyzer operates in the low-speed hydrogen production condition with high efficiency during power shortage, its power command is adjusted to to elevate it to the medium-speed hydrogen production condition with high efficiency.

(3) For electrolyzers already operating in the medium-speed hydrogen production condition with high efficiency during power shortage, the power command is increased to to upgrade it to the optimal high-speed hydrogen production condition with high efficiency.

(4) When the electrolyzer operates in the optimal high-speed hydrogen production condition with high efficiency during power shortage, the power command is maintained at the total wind–solar power generation to preserve this ideal operating mode while reserving energy storage capacity without discharge.

This strategy ensures that when energy storage reserves are insufficient, priority power supply demands under each electrolyzer operating condition are satisfied while retaining appropriate stored energy. This approach enhances the system’s capability to address severe electrolyzer operating conditions throughout the year.

(3) Integrating the reserved energy status of batteries and supercapacitors, i.e., perform preliminary power allocation for hybrid energy storage. To reduce the complexity of the second-stage optimization problem, the preliminary allocation of hybrid energy storage power is required. During hybrid energy storage discharge, energy storage components with sufficient reserved energy assume the discharge responsibility. If both components have sufficient reserved energy, the battery handles small power fluctuations while the supercapacitor addresses large power fluctuations. When both lack sufficient reserved energy, both storage units discharge within their respective minimum capacity constraints to supplement the electrolyzer’s power deficit. The initial power allocation rules for battery and supercapacitor discharge are shown in

Table 3, where

and

represent the battery and supercapacitor discharge power, respectively, and

denotes the difference between the electrolyzer power command and renewable generation. Specific cases are as follows:

(1) When and , both the battery and supercapacitor have sufficient reserved energy; when and , both lack sufficient reserved energy. Under these two conditions, both the battery and supercapacitor discharge jointly to achieve the electrolyzer power command. Specific rules include:

When , both the battery and supercapacitor discharge at maximum power to supplement the electrolyzer deficit.

When , the battery discharges at rated power , while the supercapacitor supplements the remaining power deficit at .

When , to reduce charge–discharge losses, the battery reserves energy and does not discharge, with only the supercapacitor discharging. If , the supercapacitor discharges at maximum power ; otherwise, it discharges at .

(2) When and , the battery has sufficient reserved energy while the supercapacitor does not. In this case, the battery alone discharges to address the electrolyzer power deficit. If , the battery discharge power is ; otherwise, it is .

(3) When and , the supercapacitor has sufficient reserved energy while the battery does not. Here, the supercapacitor alone discharges to address the electrolyzer power deficit. If , the supercapacitor discharge power is ; otherwise, it is .

As shown in

Table 3, when the reserved energy of both the battery and supercapacitor is insufficient, appropriate energy reserves must be maintained. The magnitude of reserved energy is determined based on the electrolyzer’s power deficit conditions: When the electrolyzer operates in non-ideal hydrogen production modes, energy storage reserves partial energy, with discharged energy only being sufficient to elevate the electrolyzer to relatively favorable hydrogen production modes; Meanwhile, when the electrolyzer operates under optimal conditions, more energy is reserved with complete discharge prohibition. Consequently, the proposed power allocation rules for this hybrid energy storage-based, off-grid hydrogen production system not only ensure real-time operational improvements for the electrolyzer but also establish 0.5 SOC as the threshold for assessing energy storage reserve adequacy. This strategy retains appropriate energy reserves in storage devices, enhances the system’s ability to withstand future harsh operating conditions of the electrolyzer, and ultimately improves the stability of hydrogen production.

3.2. Stage II: HESS Power Optimization Strategy

The rules design in Stage I primarily aims to enhance electrolyzer stability and improve energy storage power supply capability but neglects the charging–discharging health status of the energy storage. Consequently, the derived electrolyzer power commands are already near-optimal, while the hybrid energy storage (battery and supercapacitor) power allocation fails to achieve global optimality. Therefore, it is necessary to optimize the hybrid energy storage power based on the electrolyzer power commands and preliminary storage power allocation from Stage I, thereby improving the storage’s charging–discharging capability. Additionally, it is worth noting that the preliminary power allocation in Stage I significantly reduces the solving complexity of Stage II.

3.2.1. Objective Function

To enhance the system’s economic performance, the first objective is to minimize the unit hydrogen production cost of the wind-PV off-grid hydrogen production system. Meanwhile, since energy storage degradation is related to the DOD, and the supercapacitor’s cycle life can cover the entire operational period, only battery degradation is considered. Therefore, the second objective is to minimize the deviation between the battery’s actual DoD and its initial DoD. The overall objective function is formulated as:

where

is the total objective function,

and

are the first and second objective functions, respectively, and

and

are the weights of the first and second objectives. Here, enhancing economic performance and reducing battery degradation are considered equally important, and the weights are set as:

The expression for the first objective function is:

where

is the unit hydrogen production cost,

is the annualized investment cost,

is the annualized operational and maintenance cost,

is the annualized replacement cost, and

is the annual hydrogen production mass.

The expression for the second objective function is:

where

is the deviation between the battery’s integrated depth of discharge and the initial depth of discharge,

is the battery’s depth of discharge at time

, 0.5 is the initial depth of discharge, and

is the number of sampling points.

3.2.2. Constraints

(1) Power Balance Constraint:

To ensure stable operation of the wind-PV off-grid hydrogen production system, the following constraint must be satisfied:

where

,

, and

represent the electrolyzer input power, renewable power curtailment, and load shedding power at time t, respectively.

(2) Battery Power Constraint:

According to the hybrid energy storage system operation strategy, the battery charging and discharging power is constrained as:

(3) Supercapacitor Power Constraint:

The supercapacitor charging and discharging power is constrained as:

(4) Energy Storage State Constraint:

To prevent accelerated degradation due to the overcharging or over-discharging of the battery and supercapacitor, their states of charge are constrained as:

3.2.3. Improved Multi-Objective Particle Swarm Optimization Algorithm(IMOPSO)

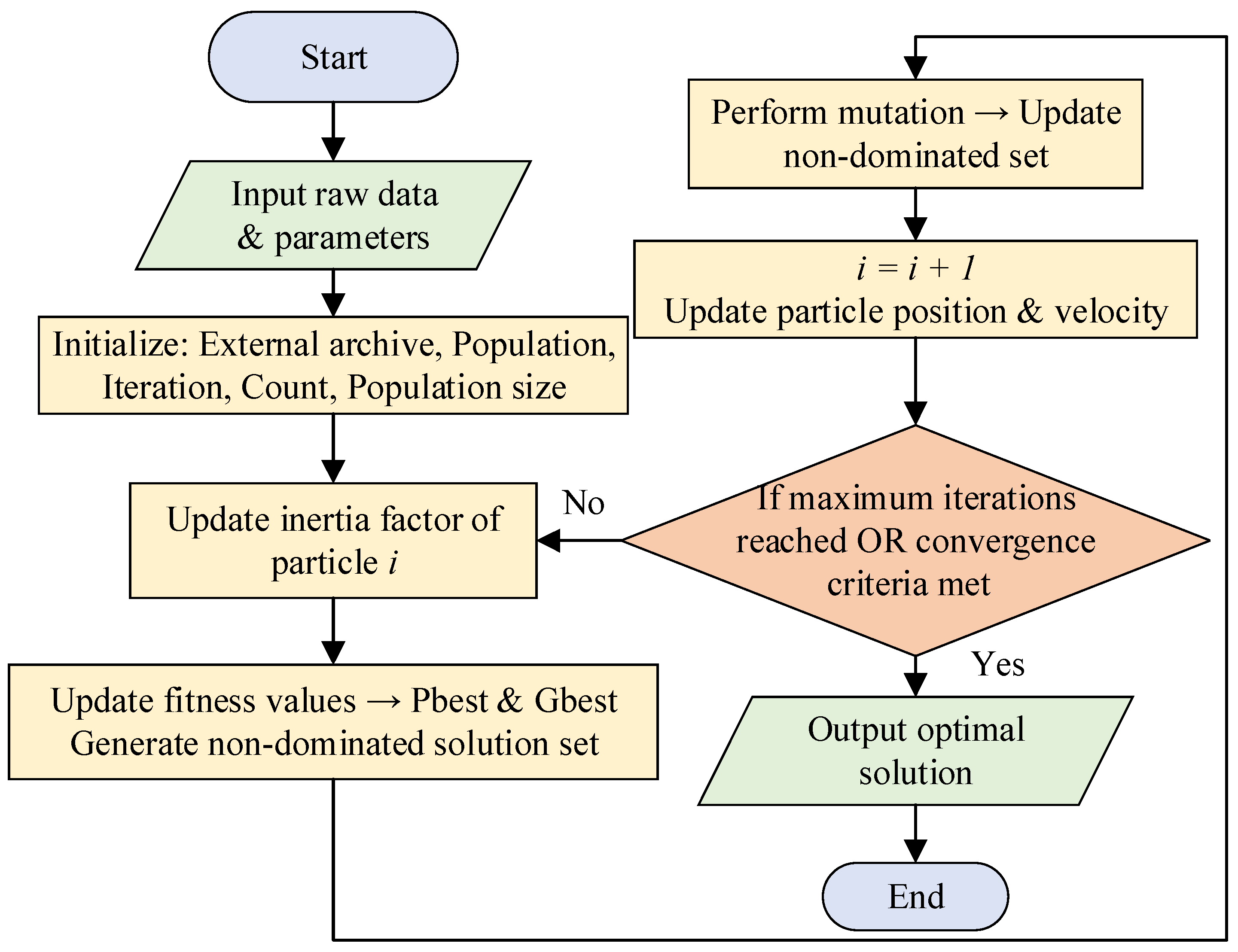

To prevent the optimization results from falling into local optima, an adaptive inertia factor and adaptive mutation factor are introduced to improve the multi-objective particle swarm optimization algorithm. The algorithm flowchart is shown in

Figure 4. The algorithm solving steps are as follows [

37]:

(1) Establish the operation and optimization objective models for the wind-PV off-grid hydrogen production system equipment and set the system-related parameters.

(2) Initialize the population and external archive, set the initial equilibrium point, initial particle positions, and flight velocities, and define their upper and lower bounds; and set the maximum iteration count to 50 and the population size to 100.

(3) Calculate inertia factor

. To avoid local optima, adaptive inertia factor

is introduced, expressed as:

where

and

are the upper and lower bounds of the inertia factor,

is the current iteration number, and

is the maximum iteration count.

(4) Calculate the fitness of each particle, compare to obtain the local and global optimal solutions, and form a non-dominated solution set.

(5) To expand the shrinking search space, an adaptive mutation factor is introduced to mutate the non-dominated solutions. The mutation factor

is defined as:

where

is the mutation rate.

(6) Update and maintain the non-dominated solution set.

(7) Update the particle velocities and positions.

(8) Repeat Steps (3)–(7) until the maximum iteration count is reached, then output the non-dominated solution set.

6. Conclusions

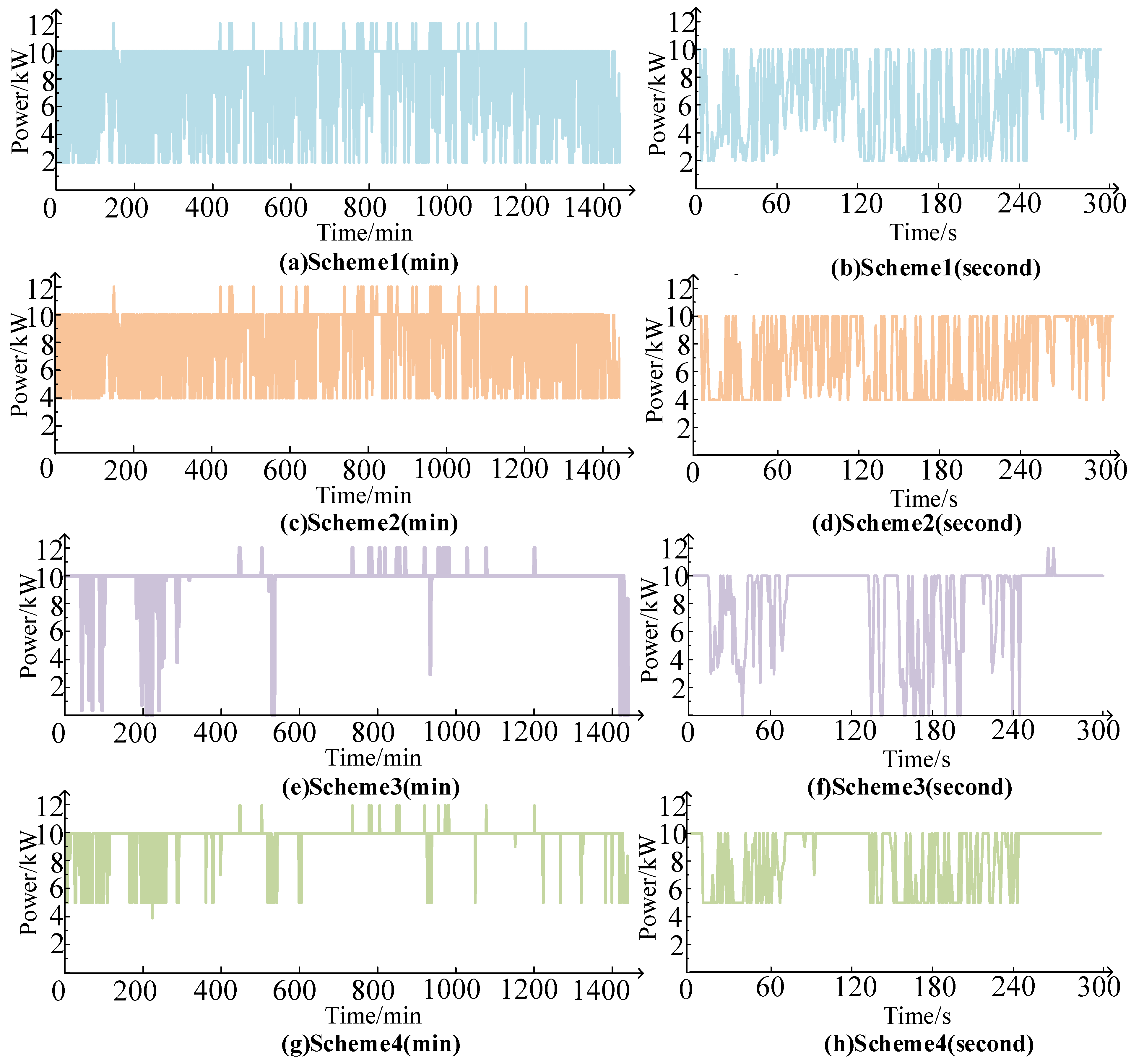

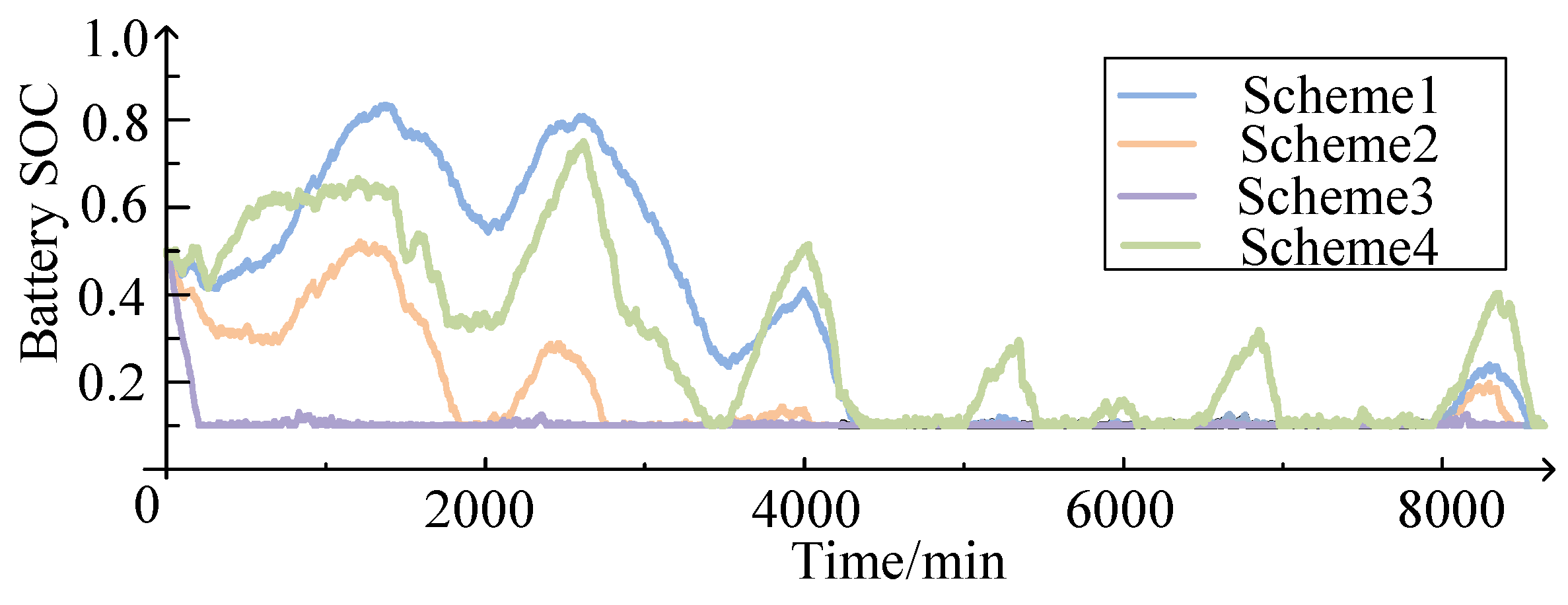

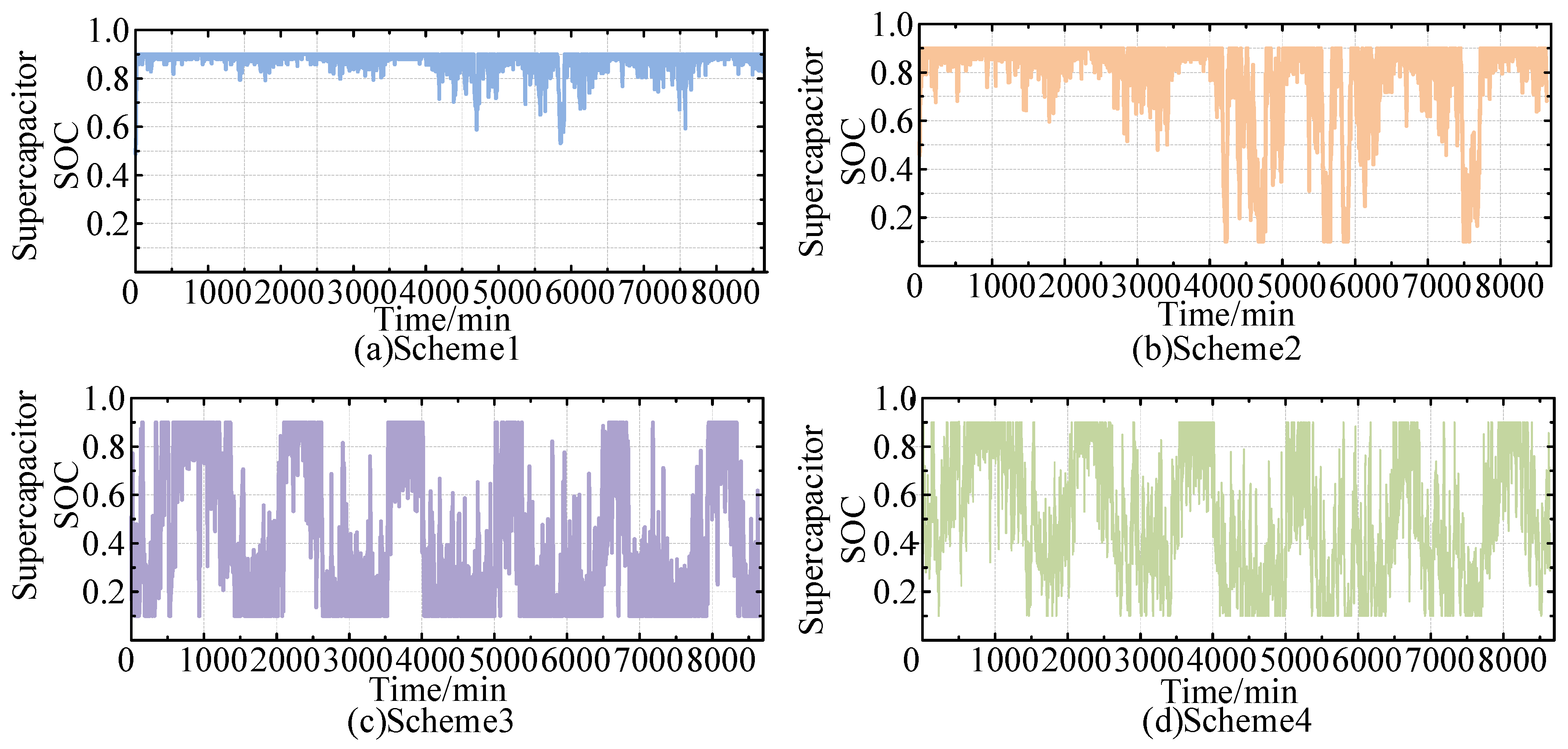

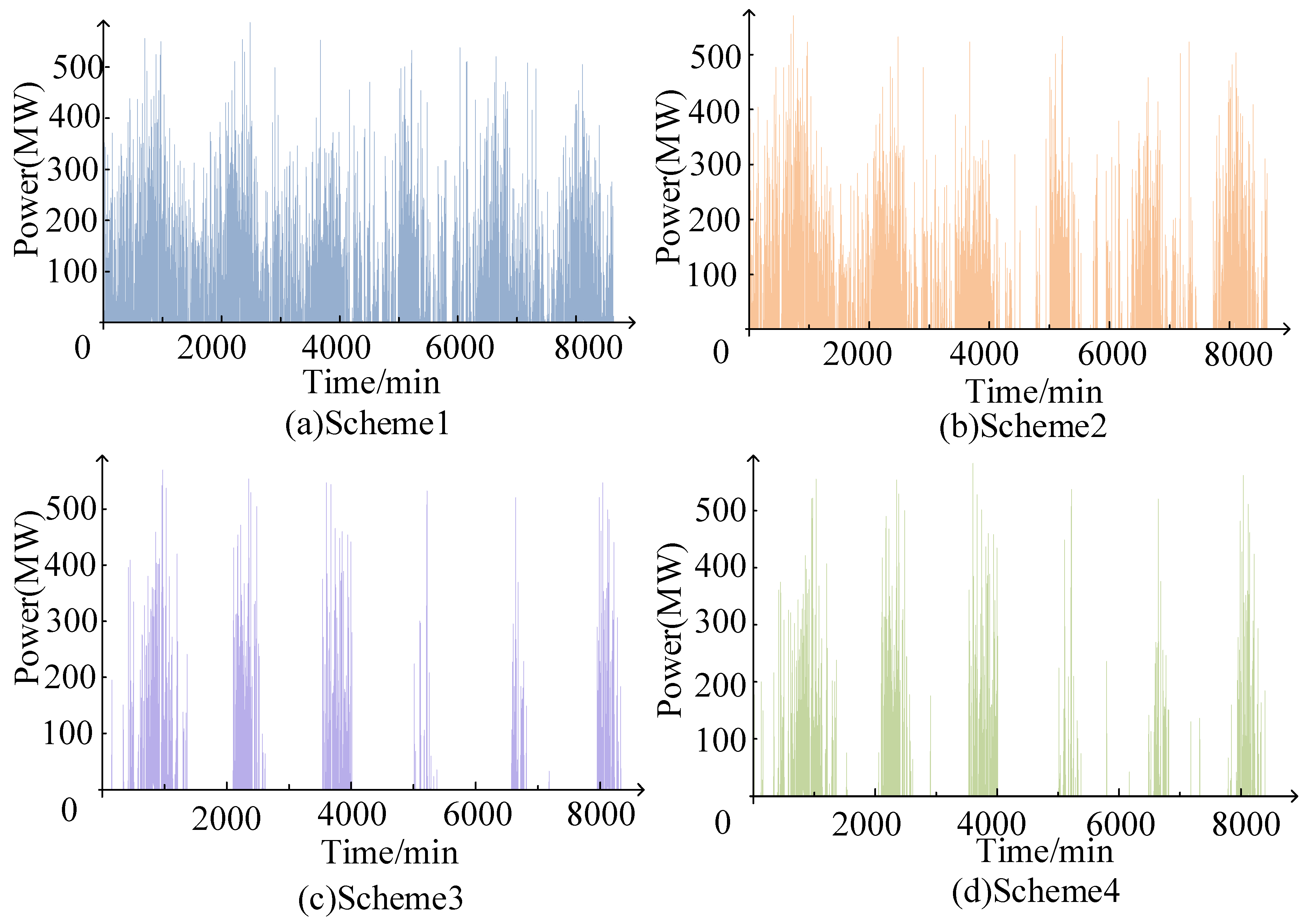

This paper proposes a two-stage collaborative power optimization method for wind–solar off-grid hydrogen production systems considering energy storage reserve capacity, demonstrating superior performance compared to traditional rule-based allocation approaches. The key conclusions are as follows:

(1) The proposed method enhanced hydrogen production stability. The first-stage power allocation rules enabled flexible adjustment of electrolyzer power commands between and based on storage reserve adequacy and power-deficit operating conditions. Compared to fixed power command strategies at , , and , this approach reduced average hydrogen power fluctuations by 59.22%, 48.72%, and 0.08% respectively.

(2) The first-stage rules, allowing electrolyzer power commands to fluctuate between and , increased hydrogen yield while reducing unit production costs. Compared to fixed hydrogen production commands at and , the proposed method decreased power deficit rates by 52.41% and 43.51%, thereby boosting hydrogen output by 22.67% and 14.09% respectively. With constant construction costs, unit hydrogen production costs were reduced by 17.98% and 11.63%.

(3) The method improved energy storage charging/discharge capabilities, thereby enhancing hydrogen production safety and reducing renewable energy curtailment. The first-stage rules for reserve storage energy were as follows: When SOC fell below 0.5, additional reserves were maintained for future adverse conditions; above 0.5, no reserves were preserved. The second stage employed an enhanced multi-objective particle swarm optimization algorithm to optimize battery SOC, resulting in smaller deviations from the initial 0.5 SOC and enhanced charge–discharge flexibility compared to conventional methods. Improved discharge capability reduced annual system shutdowns by 70.14% compared to fixed power command , while enhanced charging capacity decreased renewable curtailment rates by 62.10% and 53.40% versus fixed commands and .

In conclusion, this work presents an innovative solution to power allocation challenges in renewable-powered off-grid hydrogen systems, providing theoretical foundations for engineering high-volatility renewable hydrogen systems. Future research will explore machine learning-based power optimization methods and integrate probabilistic renewable power forecasting to enhance optimization foresight, advancing renewable hydrogen technology toward commercial viability.