1. Introduction

Additive manufacturing, commonly known as 3D printing, has been gaining increasing relevance across various industries due to its ability to manufacture components in a customized, efficient manner with complex geometries. Unlike traditional manufacturing methods, which typically involve material subtraction processes, 3D printing builds parts layer by layer, optimizing raw material usage and minimizing waste. In the electrical sector, this technology stands out for its potential to create new materials and customized devices, offering more efficient and tailored solutions to meet the industry’s specific demands. The growing demand for sustainable and efficient solutions has driven the development of new materials and technologies applicable to additive manufacturing. The ability to produce components in a customized and on-demand manner reduces reliance on external suppliers and shortens production time, representing a significant competitive advantage in the electrical sector. Additive manufacturing also provides flexibility in producing complex geometries that are challenging to achieve using traditional methods, along with the possibility of continuously adjusting and improving designs based on market needs [

1].

The use of specific materials is a fundamental aspect of the feasibility of 3D printing in the electrical sector. Among the various polymers available, PLA has stood out due to its biodegradability, ease of processing, and good surface properties in printed parts. Derived from renewable sources such as corn starch and sugarcane, PLA is widely used in additive manufacturing due to its ease of extrusion, low toxicity, and favorable mechanical properties [

2].

Despite its numerous advantages, PLA presents significant limitations when applied to the electrical sector. One of its main constraints is related to thermal resistance. PLA has a low glass transition temperature of approximately 60 °C, which compromises its structural stability in high-temperature environments. In electrical applications involving components exposed to elevated heat, such as transformers, motors, or lighting systems, this limitation can lead to material failure, affecting the integrity and durability of components [

3].

Another major challenge of PLA is its performance as an electrical insulator. While PLA exhibits adequate dielectric properties for some low-voltage applications, it lacks the necessary qualities to be used in high-voltage components, where efficient electrical insulation is crucial. This limits its applicability in devices requiring high electrical performance, such as cables, connectors, and other high-power systems [

4]. Therefore, it is essential to develop composites or PLA blends with other materials to enhance its thermal and electrical properties, expanding its application in the electrical sector.

The development of new formulations and composites with PLA is a growing area of research. Several studies are being conducted to improve the thermal, electrical, and mechanical properties of PLA, making it more suitable for demanding industrial applications. The addition of ceramic particles, carbon fibers, or carbon nanotubes, for example, has been shown to enhance the thermal and electrical conductivity of PLA, as well as increase its mechanical strength and thermal stability [

5]. These modifications could enable the use of PLA in more demanding applications within the electrical sector, offering more sustainable and efficient solutions.

Furthermore, new 3D printing processes, such as multi-material printing and selective laser sintering, have been explored to combine PLA with other polymers and advanced materials. These innovations can provide superior properties for printed components, increasing their suitability for various applications in the electrical sector [

6]. The evolution of these technologies and composite materials represents a significant opportunity for expanding the use of PLA in the development of customized and sustainable electrical devices. The outlook for additive manufacturing in the electrical sector using PLA is promising, especially with the continuous advancement of new materials and processing techniques. The ability to print components on demand, with optimized geometry and customized characteristics, represents a major competitive advantage for the electrical industry. The customization of parts and devices can lead to the creation of more efficient, cost-effective solutions tailored to specific consumer needs. However, for PLA to be widely adopted in the electrical sector, further research is essential to overcome its thermal and dielectric limitations. The advancement of PLA composites and the development of new 3D printing techniques that enable the fabrication of materials with improved electrical and thermal performance will be crucial for its large-scale application [

7]. Thus, additive manufacturing with PLA has the potential to revolutionize the electrical sector by providing innovative, sustainable, and high-performance solutions.

Therefore, this study aims to address the limitations of PLA in electrical applications by exploring material modifications that enhance its thermal and electrical performance. Specifically, it investigates how the incorporation of functional fillers—such as carbon-based or ceramic additives—can improve PLA’s properties, making it a viable candidate for high-performance components in the electrical sector. The central questions guiding this research are as follows: To what extent can PLA composites meet the thermal and dielectric demands of electrical systems? And which additive manufacturing strategies best support the processing of enhanced PLA materials for electrical applications? The innovative contribution of this work lies in proposing sustainable material alternatives through the development of PLA-based composites, aligned with advanced 3D printing techniques, to expand their applicability in producing efficient, customized electrical components. This integrative approach combines material science and additive manufacturing to offer new perspectives on sustainability and performance in the electrical industry.

2. Three-Dimensional Printing and the Use of PLA

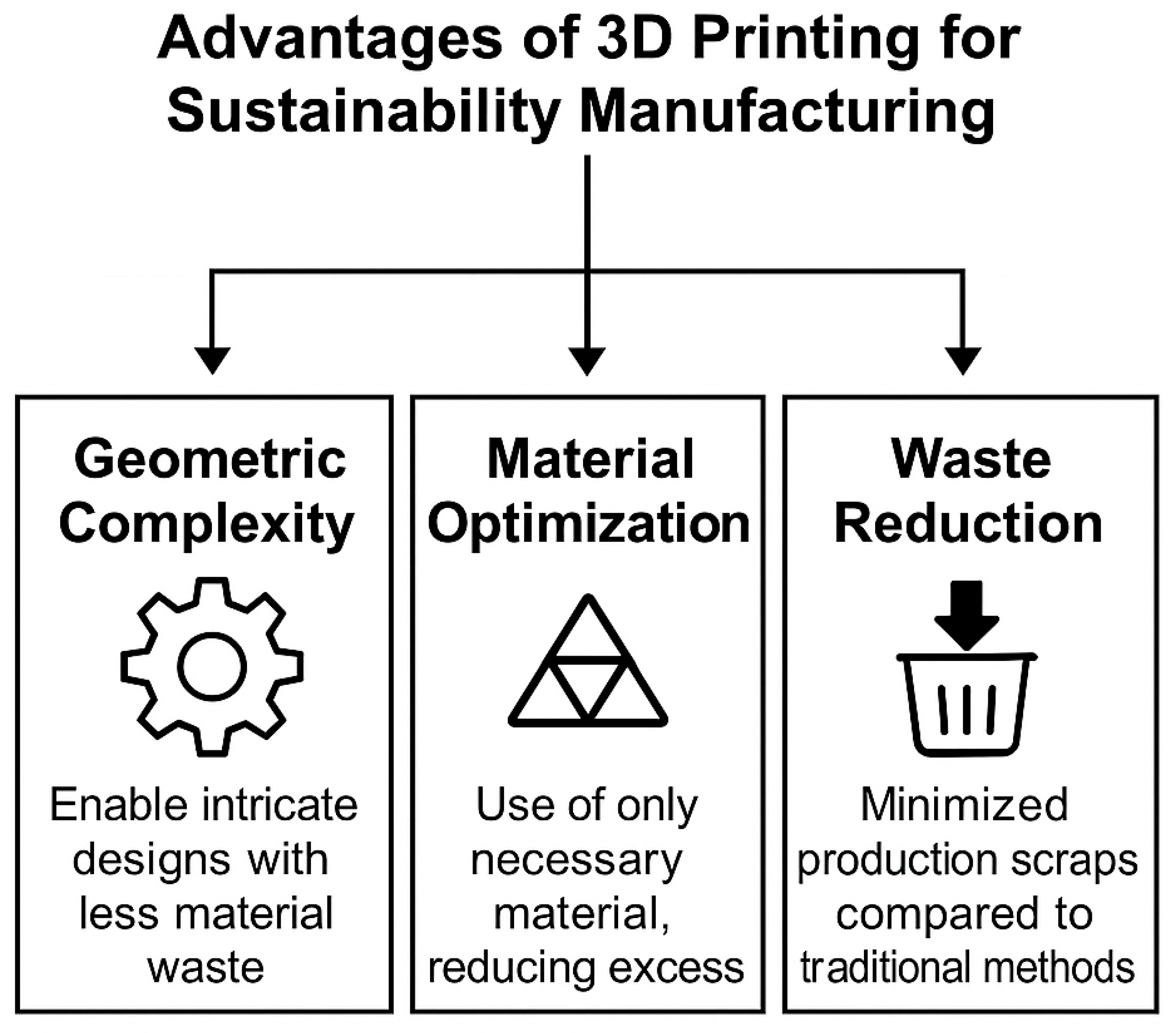

Three-dimensional printing, also known as additive manufacturing, is a technology that has transformed various industries, from automotive and medicine to electrical engineering and product design. Unlike traditional manufacturing methods, which rely on subtractive processes such as milling or machining, 3D printing builds objects layer by layer, offering significant advantages such as the ability to create complex geometries, optimize material usage, and reduce waste, as can be seen in

Figure 1.

Among the most popular 3D printing technologies are fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). Each of these technologies involves unique characteristics, advantages, and limitations that influence their applicability across different sectors. This article aims to explore the main 3D printing technologies, analyzing their differences, industrial applications, and impact on the future of manufacturing.

2.1. Fused Deposition Modeling (FDM): Popular Access Technology

Fused deposition modeling (FDM) is undoubtedly the most widely used 3D printing technology on the market, and it is especially popular in home environments, educational settings, and industrial rapid prototyping. This process is based on the extrusion of a heated thermoplastic filament, which is deposited layer by layer, allowing the formation of the desired object. FDM is one of the most cost-effective and operationally accessible technologies, making it highly attractive for beginners and small businesses [

8,

9].

The main advantage of FDM is its versatility in using different materials. Plastic filaments, such as PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), and PETG (polyethylene terephthalate glycol), among others, can be used in the process. PLA is popular due to its biodegradability, ease of processing, and low cost [

10,

11]. The use of eco-friendly materials, such as PLA, reinforces the growing trend toward more sustainable solutions in manufacturing. However, FDM also faces limitations, especially in terms of resolution and surface finish. The visible layers, resulting from the filament deposition, can compromise the aesthetics and precision of the final product, especially in highly complex parts [

12].

Although FDM is ideal for rapid prototypes and non-functional parts, its application in high-precision final components is more restricted. In sectors like automotive and aerospace, where precision is critical, other 3D printing technologies, such as SLA and SLS, are more suitable. However, for many other industries, FDM offers an effective and low-cost solution for prototypes and custom parts [

13,

14].

2.2. Stereolithography (SLA): High Precision and Detail

Stereolithography (SLA) is one of the oldest and most precise 3D printing technologies. In this process, an ultraviolet (UV) laser beam is used to solidify successive layers of a photosensitive resin. The laser selectively cures the resin, creating the object layer by layer with extreme precision and detailed finishing [

15]. SLA is widely used to create highly detailed prototypes, molds, and parts with complex geometries, and is very popular in the dental, jewelry, aerospace, and medical industries, where precision and resolution are essential.

One of the greatest advantages of SLA is its ability to produce parts with a much higher resolution compared to FDM. The precision and surface finish of parts printed using SLA are superior, making them ideal for models that require fine details and smooth surfaces. This quality is achieved through the photopolymerization of the resin, which allows for the creation of much more refined geometries. However, SLA also encounters some limitations. The need for photosensitive resins can make the process more expensive, and the curing of parts may require additional exposure to UV light to ensure structural robustness [

16].

Another important aspect is the need for temporary support during printing. SLA cannot print suspended parts without support, which can result in unwanted residues that need to be removed after the process. Furthermore, parts created with SLA are generally more fragile compared to those produced via FDM or SLS, limiting the application of SLA to prototypes and parts with low mechanical impact. However, the superior quality of the finish and the precision of the prints make SLA a preferred choice in many high-precision industries [

17,

18,

19].

2.3. Selective Laser Sintering (SLS): Versatility and Durability

Selective laser sintering (SLS) is one of the most advanced 3D printing technologies, offering an effective solution to produce functional and complex parts, especially in industries that require durable materials with specific mechanical properties. In this process, a high-powered laser is used to sinter powder particles (usually nylon, polymers, or metals), fusing them together to create a solid structure layer by layer. One of the key advantages of SLS is that it does not require structural support, as the uncentered powder around the part acts as support during the process [

13,

20].

One of the main advantages of SLS over FDM and SLA is its ability to work with a wider range of materials, including engineering plastics such as nylon, which offer greater strength and flexibility. Additionally, SLS allows for the printing of parts with complex geometries without the need for additional support, which can reduce costs and production time. The use of materials like nylon, polyamide, and metals also makes SLS a preferred choice for applications requiring high mechanical strength, such as automotive, aerospace components, and medical devices [

21,

22].

Although SLS is a powerful technology, it also presents challenges, particularly in terms of cost. The need for high-powered laser equipment and the complexity of the process make SLS printing significantly more expensive compared to FDM. Additionally, the sintering of powders can result in rougher textures, which may require further post-processing to improve the surface quality of the parts [

23,

24].

2.4. Comparison of 3D Printing Technologies: Advantages and Disadvantages

The choice between FDM, SLA, and SLS heavily depends on the specific needs of each application. FDM is the most affordable and easy to operate, making it ideal for rapid prototyping and non-structural parts. Its relatively low cost and the variety of materials available make it a popular option for home use and small businesses.

On the other hand, SLA offers superior print quality and is highly effective for creating detailed, high-precision prototypes. However, the material limitations and the fragility of the printed parts restrict their applicability to low mechanical impact prototypes. Meanwhile, SLS, despite its high cost, is the best option for producing functional, high-strength parts. Its material versatility and the ability to print without support make it suitable for small-scale production and industrial parts that require high mechanical performance.

2.5. Impact of 3D Printing on Industries

Three-dimensional printing has revolutionized various industries, enabling greater customization, faster prototyping, and waste reduction. In the automotive industry, for example, the ability to produce on-demand parts reduces storage and transportation costs for replacement parts [

25]. In medicine, 3D printing has enabled the development of customized prosthetics and anatomical models for surgical planning [

26].

Additionally, additive manufacturing has been associated with sustainability. The reduction in material waste and on-demand production contribute to more efficient and less polluting manufacturing, aligned with the principles of the circular economy [

27]. However, the limitations of each technology, such as high costs and the limited strength of some materials, still represent challenges to overcome. Three-dimensional printing technologies such as FDM, SLA, and SLS offer a diverse range of solutions for different industrial needs, each with its advantages and limitations. The choice of the most appropriate technology depends on factors such as cost, material, precision, and specific application. As research and the development of new materials and 3D printing methods progress, it is expected that these technologies will continue to play a key role in transforming manufacturing, providing more efficient, sustainable, and customized solutions for a wide range of industries.

2.6. Evaluation of 3D Printing Techniques in the Context of Electrical Applications

Although FDM, SLA, and SLS each provide distinct advantages, their applicability to the electrical sector must be critically assessed based on key functional requirements. Thermal stability is essential in environments where components are exposed to heat generated via electrical currents or external sources. FDM, when using PLA, offers limited thermal resistance (~60 °C), which restricts its use in high-temperature scenarios. However, the incorporation of additives such as carbon fibers or nanoparticles can enhance this property, making FDM more viable for moderate thermal loads [

28].

Dielectric behavior is another fundamental parameter for electrical insulation and safety. PLA has inherently good insulating properties, making it suitable for low-voltage applications such as spacers, enclosures, and dielectric supports. SLA can also produce components with precise insulating geometries, but the photoresist used may exhibit variable dielectric responses, depending on formulation and post-processing conditions. SLS, on the other hand, can employ engineering-grade materials with tailored dielectric properties, making it the most promising among the three for high-performance insulation applications [

29].

In terms of mechanical strength, SLS surpasses both FDM and SLA by enabling the use of nylon-based polymers and composites with excellent tensile and impact resistance. While FDM can be enhanced via fiber reinforcement, its anisotropic behavior—due to layer-by-layer deposition—often limits mechanical performance in critical directions. SLA offers high resolution but suffers from material fragility, limiting its use of prototyping, rather than functional parts in the electrical sector [

30].

Lastly, from a sustainability perspective, FDM with PLA stands out due to the renewable origin and biodegradability of PLA, which aligns with eco-friendly manufacturing goals. However, waste from support structures and the low reusability of failed prints are still challenges. SLS offers material recycling possibilities with unhindered powder, but the energy demands of the laser process must be considered. SLA poses the greatest environmental concern due to resin toxicity and limited recyclability [

31].

The selection of a 3D printing technique for electrical applications should not be based solely on resolution or cost but on a multidimensional evaluation of thermal, dielectric, mechanical, and sustainability performance. Hybrid solutions, such as material modifications and multi-material printing, are essential to address these complex requirements in next-generation electrical devices.

3. Applications for 3D Prototyping in the Electrical Sector

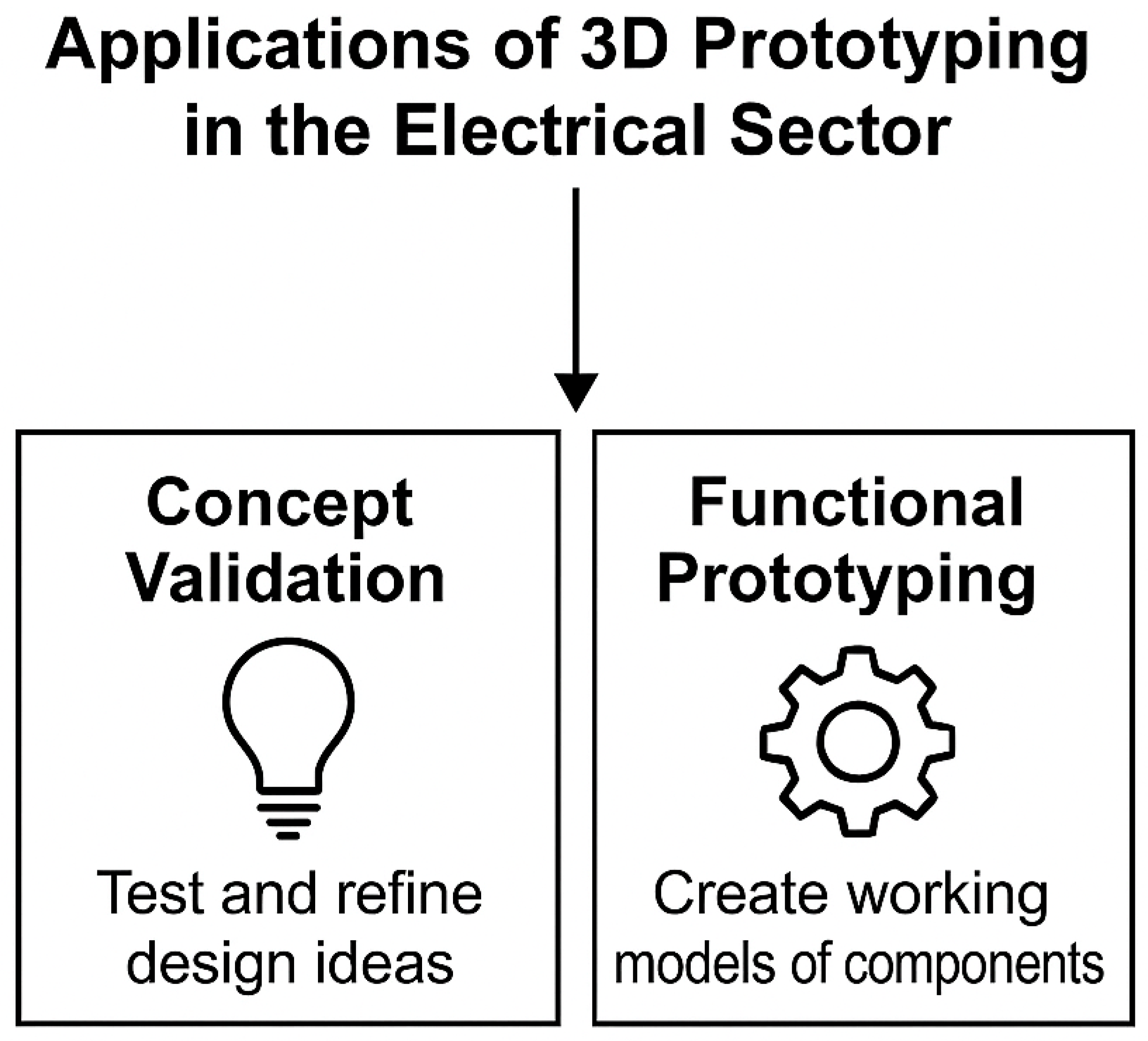

Three-dimensional prototyping has become an essential tool in the electrical sector, enabling the rapid and customized manufacturing of components with complex geometries. This technology allows the creation of functional prototypes for design testing, concept validation, and the development of new electrical devices, significantly reducing production time and costs [

32].

Figure 2 better explains the current process.

One of the main applications of 3D prototyping in the electrical sector is the manufacturing of supports and enclosures for electronic devices. Three-dimensional printing with PLA enables the production of custom enclosures for printed circuit boards (PCBs), connectors, and sensors, ensuring a better fit and protection against external factors [

33].

Additionally, it allows the creation of molds and support structures for electrical components, making the production process more flexible and efficient. Another relevant use is the production of electrical insulators and dielectric barriers. PLA, due to its good insulating properties, can be used to create spacers and protective covers that reduce the risk of short circuits. However, due to its thermal limitations, research has been exploring the modification of PLA with additives to improve its resistance to high temperatures and expand its applications [

34].

3.1. Electrical Components Produced in PLA

Additive manufacturing, particularly 3D printing using PLA, has been widely explored in the electrical sector due to its versatility, low cost, and dielectric properties [

35]. This technology allows for the creation of various electrical components, with a focus on the following.

Rapid prototyping of electrical devices: 3D printing in PLA enables the rapid manufacturing of functional prototypes for design testing and concept validation. This approach significantly reduces development time and costs associated with creating new products in the electrical industry [

36].

Enclosures and casings for electronic devices: PLA is frequently used in the production of supports for printed circuit boards (PCBs), protective housing, and custom molds. Its dimensional stability and ease of printing make it an ideal material for these applications [

37].

Electrical insulators: Due to its dielectric nature, PLA can be used in the production of protective barriers against short circuits. This makes it an interesting alternative for developing spacers, insulating supports, and protective covers for sensitive components [

38].

Despite these advantages, the use of PLA in the electrical sector faces challenges, particularly related to its limited thermal resistance and inferior mechanical properties when compared to more robust engineering polymers [

39].

3.2. Modification of PLA for Advanced Applications

To overcome the inherent limitations of PLA and expand its applications in the electrical sector, researchers have been exploring various material modification strategies. Some of the most promising approaches include the following.

Conductive composites: The incorporation of conductive nanomaterials, such as graphene and carbon nanotubes, into PLA enables the creation of conductive filaments. These modified materials can be used for manufacturing electrical traces, sensors, and 3D-printed antennas [

21].

Fiber reinforcement: Adding carbon or glass fibers to PLA significantly improves its mechanical and thermal properties. This enables the production of components that are more resistant to heat and mechanical stress, making the material suitable for structural applications in electrical devices [

40].

Thermal and chemical treatments: Annealing and chemical treatments can be employed to improve the stability of PLA in high-temperature environments. These treatments help minimize material degradation and enhance its durability in critical applications [

41].

Research and development of new composites and processing techniques continue to push the boundaries of 3D printing with PLA, enabling its use in an increasing number of applications in the electrical industry. As new formulations are developed, 3D printing is expected to play an even more significant role in the manufacturing of customized and high-performance electrical components.

3.3. Three-Dimensionally Printed Embedded Compounds for Functional Applications

Recent advancements in composite structures combining PLA with metallic reinforcements, such as magnesium and stainless-steel wires or sheets, have demonstrated significant improvements in mechanical performance and thermal stability, addressing PLA’s limitations in electrical applications. Studies have shown that integrating surface-modified magnesium wires into PLA matrices enhances tensile and compressive strength, making these composites suitable for structural applications requiring both biodegradability and mechanical robustness. Similarly, the incorporation of continuous stainless-steel wires into PLA has been optimized to improve load transfer and interfacial bonding, resulting in composites with superior mechanical reliability. These developments expand the potential of PLA-based composites in the electrical sector, offering sustainable alternatives for components that demand enhanced mechanical and thermal properties [

42,

43].

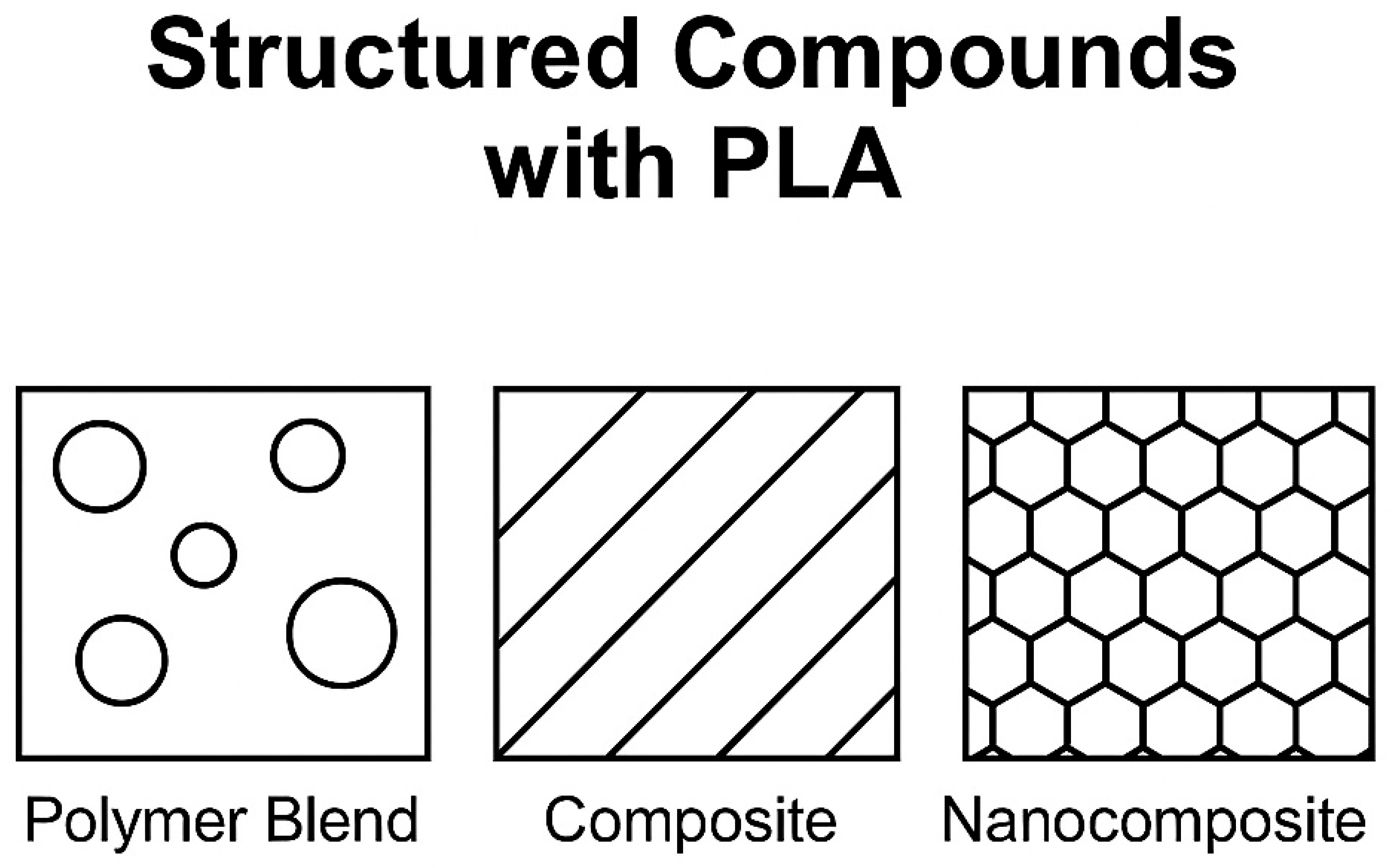

3.4. Composite Structures with PLA

Recent advancements in additive manufacturing have enabled the integration of sensors, electrodes, and biomedical devices directly within PLA-based structures, enhancing electrical functionality and expanding applications in printed electronics. By incorporating conductive nanomaterials such as graphene and carbon nanotubes into PLA matrices, researchers have developed composite filaments suitable for fabricating functional electronic components, including strain sensors, temperature sensors, and bioelectrodes. These 3D-printed devices offer benefits like customization, flexibility, and biocompatibility, making them ideal for applications in wearable technology and biomedical monitoring. Moreover, the use of multimaterial printing techniques allows for the simultaneous deposition of conductive and insulating materials, streamlining the fabrication process of complex electronic systems. Such innovations are paving the way to producing fully integrated, lightweight, and cost-effective electronic devices using sustainable materials like PLA [

44,

45].

Figure 3 demonstrates these possible structures.

4. Challenges and Limitations

Three-dimensional printing using PLA has gained attention in additive manufacturing due to its biodegradability, ease of processing, and good dimensional stability. However, its use in the electrical sector still faces considerable challenges, primarily regarding thermal resistance, mechanical properties, and electrical conductivity. In this context, scientific and technological advancements are being explored to overcome these limitations and expand PLA’s applications in electrical and electronic devices.

4.1. Thermal Resistance

One of the primary challenges of using PLA in the electrical industry is its low thermal resistance. PLA has a glass transition temperature of around 60 °C, meaning it softens and deforms structurally above this value [

46]. These characteristic limits its application in devices that operate under high-temperature conditions, such as electric motor components, transformers, and heat-dissipating connectors. To mitigate this limitation, several strategies are being explored, including the following.

Reinforcement with ceramics and high-thermal-resistance polymers: the addition of ceramic particles such as aluminum oxide and silica has shown improvements in PLA’s thermal stability, reducing its tendency to deform at elevated temperatures [

41].

Chemical modification of PLA: structural modifications like copolymerization and chemical crosslinking have been studied to enhance PLA’s thermal resistance without compromising its biodegradable properties [

47].

Post-processing thermal treatments: techniques like controlled annealing can improve PLA’s thermal stability by increasing its crystallinity, making it more resistant to thermal softening [

48].

Despite these advances, PLA’s thermal resistance still does not reach the levels of materials like polycarbonate (PC) or acrylonitrile butadiene styrene (ABS), limiting its application in more demanding industrial environments.

Table 1 demonstrates such comparisons.

4.2. Mechanical Properties

Another relevant limitation of PLA in the electrical sector is related to its mechanical properties. PLA has lower impact and tensile strength compared to engineering plastics like ABS and PC, which restricts its use in applications requiring high mechanical robustness [

51]. To address this deficiency, several strategies are being explored:

Plasticizer addition: the incorporation of compatible plasticizers can improve PLA’s flexibility, reducing its brittleness and making it more resistant to impact [

21].

Optimization of printing parameters: Factors such as extrusion temperature, printing speed, and layer orientation can significantly influence the mechanical properties of 3D-printed PLA parts. Studies indicate that an optimized setup can increase mechanical strength by up to 40% [

52].

Reinforcement with carbon and glass fibers: Incorporating carbon and glass fibers into PLA enhances its mechanical strength, enabling its use in structural components within electrical and electronic systems [

53]. Despite these improvements, the inherent brittleness of PLA still presents a challenge for applications requiring high resistance to impact and mechanical fatigue.

4.3. Electrical Conductivity

Pure PLA is a dielectric material, meaning it does not conduct electricity, which limits its direct application in conductive components within the electrical industry. However, recent advances in the formulation of PLA composites doped with conductive nanoparticles have shown promising results in modifying its electrical conductivity [

54]. Some of the most relevant approaches include the following.

Incorporation of metallic nanoparticles: Adding silver, copper, and nickel nanoparticles to PLA can enhance its electrical conductivity. Studies suggest that introducing up to 20% silver into PLA can significantly improve its conductivity, making it suitable for producing flexible printed circuits and electronic sensors [

21].

Use of carbon nanotubes and graphene: Carbon nanotubes and graphene are highly conductive materials and have been explored as dopants in PLA to create composites with improved electrical properties. Research indicates that adding just 5% graphene can reduce PLA’s electrical resistivity by up to 10

4 times, enabling its use in antennas, electromagnetic shielding, and conductive traces in printed circuit boards [

34].

Conductive polymerization techniques: Chemical modifications to PLA’s structure, combined with conductive polymers like poly(3,4-ethylenedioxythiophene) (PEDOT) and polyaniline, have been investigated to improve its electrical conductivity without compromising its mechanical and thermal properties [

41].

These approaches open new possibilities for 3D printing in PLA for the manufacturing of electronic components, sensors, and electrical circuits. However, challenges such as the homogeneous dispersion of conductive materials in PLA and chemical compatibility between the additives and the polymer matrix still need to be overcome to enable large-scale production. Three-dimensional printing in PLA holds great potential for the electrical industry, but its thermal, mechanical, and electrical limitations still present significant challenges. Ongoing research in modifying PLA through composites, additives, and processing techniques has shown promising advances in expanding its applications. As new formulations and technologies emerge, PLA is expected to be more widely used in the manufacturing of customized and sustainable electrical components.

5. Future Perspectives

Additive manufacturing has evolved rapidly, and 3D printing with PLA has been shown to be a promising technology for various applications in the electrical sector. However, its limitations require technological advancements that enable the expansion of its use. Current research focuses on the development of new composites, the integration of multiple materials, and the evolution toward 4D printing with smart materials. These advancements could transform the electrical industry, allowing the creation of more efficient and sustainable devices.

5.1. Development of New Composites

One of the main strategies to expand PLA applications in the electrical sector is the development of advanced composites that combine PLA’s biodegradability with enhanced mechanical, electrical, and thermal properties. The incorporation of functional fillers, such as carbon nanotubes, metal oxides, and polymer fibers, has been widely studied to improve these characteristics.

5.1.1. Nanofillers for Property Enhancement

The addition of conductive nanofillers, such as graphene and carbon nanotubes (CNTs), significantly improves the electrical conductivity of PLA, making it a viable material for flexible electronic components and electrical sensors [

50]. Furthermore, these nanomaterials enhance the thermal and mechanical resistance of PLA, enabling its application in devices exposed to temperature variations and high mechanical stresses [

55].

On the other hand, metal oxides, such as TiO

2 and Al

2O

3, are used to improve the dielectric properties of PLA, making it an excellent electrical insulator for applications in encapsulating electronic components and electromagnetic shielding [

56]. One of the main strategies to expand PLA applications in the electrical sector is development.

5.1.2. Engineering Polymers

Another promising approach involves blending PLA with high-performance polymers, such as polycarbonate (PC) and polyetheretherketone (PEEK). These blends enhance the mechanical and thermal resistance of PLA, making it suitable for producing structural parts in complex electrical systems [

57]. Studies show that copolymerization and chemical crosslinking can also increase PLA’s stability at high temperatures, expanding its applications in industrial environments.

5.2. Multimaterial Additive Manufacturing

Multimaterial additive manufacturing allows the printing of hybrid components, combining different types of materials into a single part. This approach enables the creation of custom electrical devices with optimized characteristics for each application.

5.2.1. Three-Dimensional Printing with Conductors and Insulators

One of the most promising applications of multimaterial printing is the direct printing of electronic circuits. Combining PLA with conductive materials, such as silver ink or copper-loaded filaments, enables the creation of flexible integrated circuits and custom electrode devices [

58]. This can enable the production of sensors embedded in plastic structures, optimizing the design of electronic components.

5.2.2. Integration of Functional Materials

In addition to electrical conductors, multimaterial printing can be used to combine PLA with magnetic or semiconducting materials, creating innovative devices such as printed magnetic sensors and plastic transistors. Research indicates that integrating PLA with semiconducting polymers can lead to the development of printed transistors for low-cost, high-performance circuits [

59].

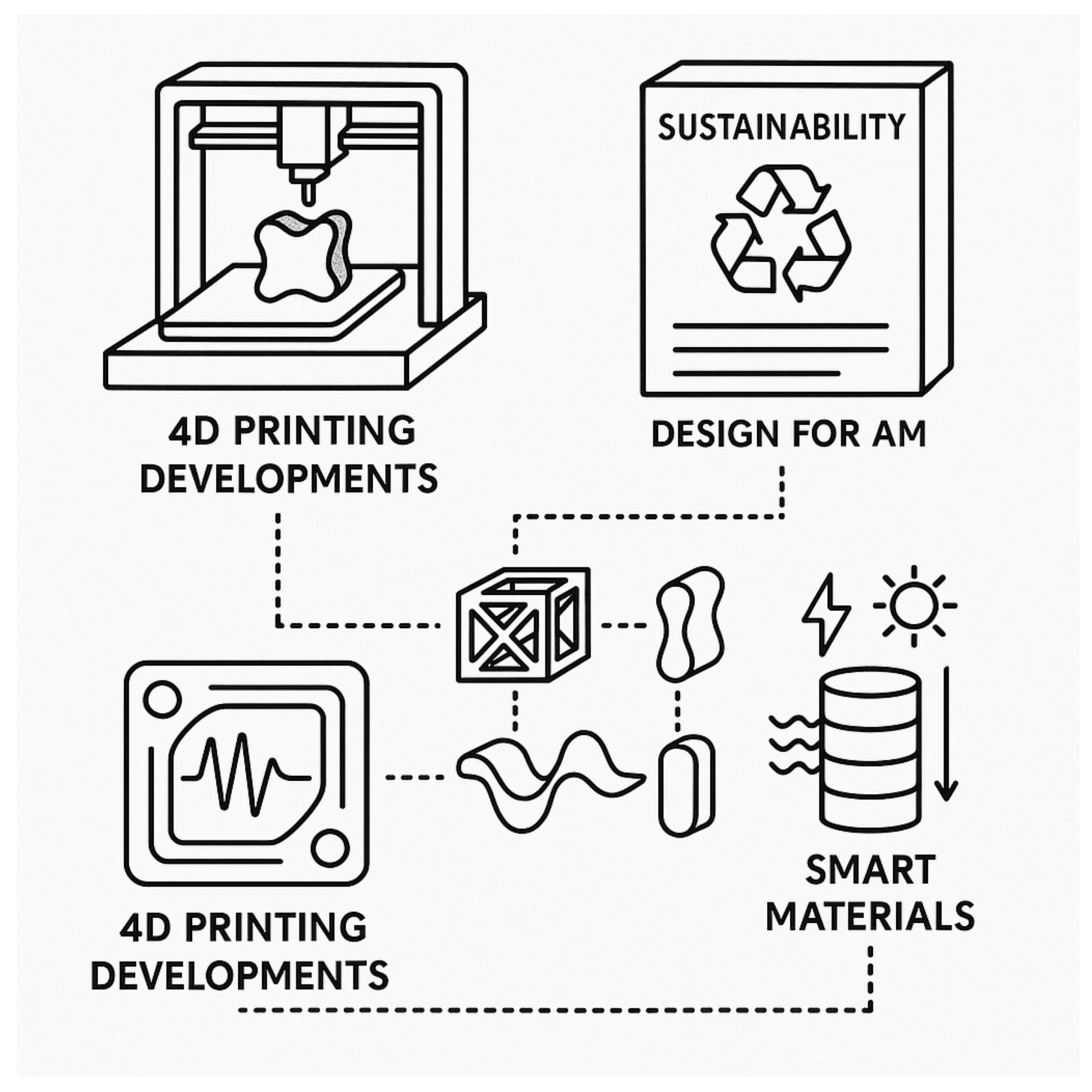

5.2.3. Four-Dimensional Printing and Smart Materials

Four-dimensional printing represents the next evolution in additive manufacturing, allowing the creation of structures that adapt to external stimuli such as temperature, humidity, and electric fields. In the electrical sector, this technology could revolutionize the production of autonomous devices and smart sensors.

Figure 4 illustrates 4D printing performance.

An advanced branch of additive manufacturing enables the creation of dynamic structures capable of morphing or adapting in response to external stimuli such as heat, moisture, or electric fields. In the electrical sector, this approach has enabled the development of self-actuating insulators, reconfigurable conductive pathways, and sensors with autonomous response capabilities. Recent investigations have demonstrated multifunctional PLA composites integrated with shape-memory alloys and conductive nanomaterials, yielding devices that alter geometry or conductivity based on operational conditions. These systems have potential applications in adaptive circuit protection, thermal management, and flexible power systems [

60].

5.2.4. Shape-Memory Materials

Shape-memory polymers are materials that can change configuration in response to external stimuli. The combination of PLA with responsive polymers, such as thermos-responsive polyurethanes and electroactive polymers, enables the creation of electrical devices that automatically adjust to environmental conditions [

61].

For example, electrical sensors made from modified PLA can change shape when heated, allowing the fabrication of automatic connectors and self-adjusting devices in electronic circuits [

4]. Four-dimensional printing represents the next evolution in additive manufacturing, allowing the creation of structures that adapt to external.

5.2.5. Piezoelectric and Electrosensitive Materials

Piezoelectric materials convert mechanical energy into electrical energy and are widely used in pressure sensors and energy harvesting devices. Four-dimensional printing can be used to develop ultrathin impact sensors that adjust their electrical properties according to the intensity of the applied force [

62].

Furthermore, electrosensitive polymers enable the creation of devices that change their electrical properties in response to applied voltage. This could lead to the development of adjustable capacitors and variable resistors, enabling a new generation of dynamic electronic circuits [

63]. The future perspectives of 3D printing with PLA in the electrical sector are extremely promising. The development of advanced composites, multimaterial additive manufacturing, and the evolution toward 4D printing could transform how electrical devices are designed and manufactured. As new technologies emerge, PLA is expected to play a fundamental role in the production of more sustainable, efficient, and adaptable electrical components to meet the needs of modern industry.

5.3. Sustainability Considerations

The sustainability profile of PLA-based 3D printing is increasingly relevant in modern manufacturing ecosystems. Studies have demonstrated that PLA’s use in electrical components—such as photocatalysts and electrocatalyst supports—significantly reduces carbon emissions and energy input, especially when combined with decentralized, small-scale production models [

64]. Environmental benefits are complemented by economic and social gains, as 3D printing with PLA supports localized, on-demand manufacturing and reduces reliance on complex supply chains. Life-cycle assessments (LCA) of PLA–metal oxide hybrids for electrocatalysis have reported enhanced performance with minimal environmental impact, further underscoring its potential for eco-innovative applications [

49,

65].

5.4. Design for Additive Manufacturing (DfAM)

The geometric flexibility offered via 3D printing enables entirely new paradigms in the design of electrical components. Traditional limitations in part geometry, material distribution, and internal structuring can now be overcome through topology optimization and functional integration. This allows for the fabrication of lattice-structured heat sinks, embedded wiring channels, and multi-functional insulation architectures within a single printed unit. PLA-based DfAM strategies have recently enabled the design of compact enclosures with passive cooling, reduced electromagnetic interference, and enhanced electrical safety. These advances not only optimize component performance but also reduce material waste and simplify assembly [

66,

67].

6. Conclusions

Three-dimensional printing with PLA has significant potential for applications in the electrical sector, particularly in rapid prototyping and the production of custom components. Its ease of processing, biodegradability, and excellent surface quality make PLA an attractive material for various applications in the electrical industry. However, its low thermal resistance, limited mechanical properties, and lack of electrical conductivity are challenges that restrict its use in more demanding applications. Improving the thermal properties of PLA is one of the primary challenges facing the industry. With a glass transition temperature of around 60 °C, the material can deform when exposed to high temperatures, compromising its structural stability and functionality in electrical equipment. To mitigate this issue, recent research has explored the incorporation of thermal fillers and the development of polymer blends that enhance its heat resistance. The addition of materials like metal oxides and engineering polymers has shown promising results, enabling PLA to be used in applications requiring higher thermal stability.

In addition to thermal limitations, the mechanical properties of PLA also represent a barrier to its widespread adoption in the electrical sector. While it achieves good rigidity and dimensional stability, its impact and tensile strength are lower than those of other widely used polymers in the industry, such as ABS and polycarbonate. As a solution, researchers have been studying the incorporation of carbon and glass fibers, as well as the use of plasticizers that improve flexibility and durability in PLA 3D-printed parts.

The most critical limitation of PLA in the electrical sector is its lack of electrical conductivity. As an insulating polymer, its use in conductive circuits and electronic components is restricted. However, advancements in the formulation of PLA composites with carbon nanotubes, graphene, and metallic particles have shown great potential to overcome this barrier. These materials enable the creation of conductive filaments for 3D printing, allowing for the development of sensors, flexible circuits, and custom electroconductive devices. Multimaterial printing, which combines PLA with other polymers or metals, has also been explored as an innovative solution to this limitation.

Additive manufacturing technologies are evolving to enable greater functionality of electrical components made with PLA. Four-dimensional printing, which introduces the ability to respond to external stimuli, represents a significant advancement for the creation of self-adaptive devices. PLA-printed sensors modified with responsive materials can be used in applications that require flexibility and automatic adjustment to environmental conditions. Given these advancements, PLA is expected to continue playing a significant role in the electrical industry, particularly as new composites and printing techniques are developed. Research into new materials and the integration of innovative technologies, such as multimaterial manufacturing and 4D printing, could expand PLA applications, making it a viable and sustainable alternative for producing customized, high-performance electrical components.