Abstract

Enhancing the operational flexibility and environmental performance of coal-fired boilers under wide-load conditions presents a critical challenge in China’s low-carbon transition, particularly for low-quality coals (LQCs) with abundant reserves, poor combustibility, and high NOx emissions. To overcome the intrinsically low reactivity of LQC, peak-shaving performance and combustion behavior were systematically investigated on an MW-grade pilot-scale test platform employing the fuel modification strategy in this study. Stable fuel modification was achieved without any auxiliary energy for LQCs and Shenmu bituminous coal (SBC) across a load range of 20~83% and 26~88%, respectively, demonstrating the excellent fuel reactivity and strengthened release control of volatile and nitrogenous species. The modified LQC exhibited ignition, combustion, and burnout characteristics comparable to Shouyang lean coal (SLC), enabling a “dimensionality-reduction utilization” strategy. The double-side fuel modification device (FMD) operation maintained axially symmetric temperatures (<1250 °C) in horizontal combustion chambers, while single-side operation caused thermal asymmetry, with peak temperatures skewed toward the FMD side (<1200 °C). Original NOx emissions were effectively suppressed, remaining below 106.89 mg/m3 (@6%O2) for LQC and 122.76 mg/m3 (@6%O2) for SBC over broad load ranges, and even achieved ultra-low original NOx emissions (<50 mg/m3). Distinct load-dependent advantages were observed for each coal type: SBC favored high-load thermal uniformity and low-load NOx abatement, whereas LQC exhibited the inverse trend. These findings underscore the importance of a load-adaptive coal selection and FMD operation mode. This study provides both theoretical insights and engineering guidance for retrofitting coal-fired power units toward flexible, low-emission operation under deep peak-shaving scenarios.

1. Introduction

In the midst of the pursuit of a clean, efficient, and low-carbon energy transition, enhancing the operational flexibility of coal-fired boilers has emerged as a pivotal issue [1]. As China strives for a “carbon peak and carbon neutrality”, coal-fired boilers have to adapt to the demands of deep load-following and handle the fluctuations resulting from the large-scale integration of renewable energy [2]. Given China’s unique energy resources and the intermittency of renewable energy sources, the coordinated development of coal-fired and renewable power generation is indispensable for a reliable power supply [3], enhanced system regulation capabilities, and advancement towards green low-carbon development [4].

Under the current energy situation, as high-quality resources diminish, low-quality coal (LQC) such as anthracite (Vdaf ≤ 10%) and lean coal (10% ≤ Vdaf ≤ 20%), although abundant, possess lower heating values [5]. Due to economic considerations in the fuel markets and the power generation, LQC is increasingly utilized for combustion in power plants [6]. Regions like Shanxi and Guizhou benefited from favorable geographical and transport conditions, relying heavily on these LQCs for the fuel supply [7]. However, the current combustion technologies encounter ignition difficulties and reduced combustion efficiency (η) when dealing with LQC, especially under low-load conditions, where problems such as unstable combustion or flame extinction occurs, restricting wide-load operation [8,9]. While measures such as higher combustion temperatures and prolonged residence times are employed to cope with these issues, they frequently lead to increased NOx emissions [10]. Therefore, achieving efficient combustion alongside safe operations with minimal NOx emissions for LQC boilers operating at wide loads represents a central challenge for current technological advancements.

For tangential and opposed combustion boilers, researchers have introduced innovative technologies like micro-oil ignition, plasma ignition, and oxygen-enriched ignition, coupled with stable combustion burners, to enhance low-load stability. For instance, Tuttle et al. [11] realized a low-load stable operation in a 490 MW tangentially coal-fired boiler. Ibrahimoglu et al. [12] employed plasma ignition in a 44 MWe tangential combustion boiler, utilizing high-density plasma to achieve stable combustion at a 40% load, while Zhao et al. [13] demonstrated that plasma-assisted ignition reduced pulverized coal ignition delays and improved combustion. V.E. Messerle et al. [14] evaluated the advantage of the plasma technology of coal combustion over conventional technology for a low-rank bituminous coal with a 40% ash content through numerical investigation, demonstrating that the plasma-assisted combustion technology could reduce NOx emissions and enhance η. In terms of facilitating low-load stable combustion, the above techniques are typically more applicable to tangential or opposed combustion boilers designed for burning high volatile coal (Vdaf ≥ 20%). However, in the case of another type of boiler named the W-flame boiler [15], given that the particle residence time can be elongated, it proves conducive to the burnout of low-quality fuels. Nonetheless, it still encounters challenges such as elevated initial and operational costs along with hardships in attaining stable low-load combustion and low NOx emission when using LQC.

Currently, the research on stable combustion in LQC boilers at low loads (≤30%) remains restricted. In practical operations, coal-fired boilers have to use oil fuel at low loads and can achieve stable combustion only at a 50% load or above without external heat sources. For instance, Ma et al. [16] accomplished stable combustion in a 600 MWe boiler utilizing lean coal (Vdaf = 14.21%) at a 75% load without oil injection by modifying the combustion system, relocating fuel nozzles, reconfiguring staged air, and adding separated over-fire air. Moreover, Du et al. [17] conducted an in-depth investigation into the air flow, combustion, and NOx generation characteristics within the furnace. When combusting a blend of lean coal and anthracite (Vdaf = 13.14%), stable combustion without oil injection was accomplished at a 40% load. Presently, the swirling secondary air biased combustion technology proposed by Wang et al. [18,19] is capable of achieving stable combustion in a 300 MW anthracite-fired (Vdaf = 9.62%) boiler without oil injection at a 30% load, attaining an advanced level among the existing international reports. Notwithstanding the advancement of this technology, the duration of the stable combustion of the boiler under low loads remained comparatively short, and the NOx emission level remained relatively high, staying above 680 mg/m3, which constituted a considerable gap from the increasingly strict NOx emission standards in China. Therefore, a breakthrough in efficient and clean combustion technology for LQC boilers below a 30% load without external heat sources is urgently required to support China’s demand for efficient coal utilization.

The Institute of Engineering Thermophysics, Chinese Academy of Sciences, has proposed a fluidized fuel modification technology [20], through which pulverized coal is transformed into a binary gas–solid thermally active fuel (modified fuel) by means of fluidized preheating. Subsequently, the modified fuel enters the furnace for the judiciously organized reduction and oxidation staged combustion. The modification process takes place in a robust reducing atmosphere, where the majority of the fuel-N is liberated and reduced to N2, achieving in situ NOx control. Further still, NOx generation is multi-pathway synergistically regulated through the optimization of combustion organization within the furnace. Currently, research mainly concentrates on high-quality coal, while there are limited studies on LQC, and the capacity of the test benches is relatively diminutive, mainly concentrating on the kW level. For instance, Wang et al. [21] discovered that for anthracite, when the primary air equivalence ratio was below 0.30, the modification temperatures exceeded 800 °C, with the minimum NOx emissions being 264 mg/m3 (@6%O2) and η being 94.17%. Ouyang et al. [7] demonstrated that the modified anthracite had an increased total pore volume and specific surface area, with uniform combustion temperatures, NOx emissions of 256 mg/m3 (@6%O2), and a η of 96.50%. Zhang et al. [22] investigated the influence exerted by reaction atmospheres (O2/N2, O2/CO2, O2/CO2/H2O) on the properties of the modified fuel, finding that with a 31% O2 concentration, the reactivity of anthracite was enhanced under oxygen-rich conditions. The minimum NOx emission was 226 mg/m3 (@6%O2).

The above studies manifest that conventional pulverized coal combustion predominantly depends on the burner to orchestrate the mixture of pulverized coal and air and ignites the freshly added pulverized coal by entrapping the high-temperature hot flue gas within the furnace. The prevailing technical approaches are incapable of concurrently fulfilling the demands of the clean combustion of LQC across a wide-load spectrum. Nevertheless, the fluidized fuel modification technology exhibits considerable potential in this respect. Presently, opposed combustion is a prevalently utilized primary combustion mode, especially in large-capacity boilers [23]. However, no systematic experimental research on LQC within the wide-load range has been carried out. To further surmount the limitations of the combustion reaction performance of LQC and the challenges of low NOx emissions under wide-load scenarios, this study executed a MW-grade pilot-scale experimental study, which accomplished the safe and stable operation of LQC at a 20% load and acquired the characteristics of modification, combustion, and NOx emission, furnishing theoretical support for the study of load-change characteristics in the domain of peak shaving, and enhancing the green and low-carbon transformation of energy.

2. Experimental Section

2.1. Experimental Setup

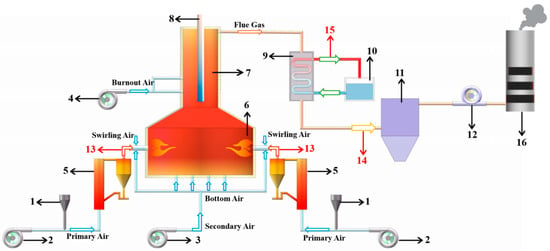

The MW-grade pilot-scale test platform comprises two fuel modification devices (FMDs), a vertical combustion chamber (VCC), a horizontal combustion chamber (HCC), and ancillary equipment, as illustrated in Figure 1. The system is designed to have a load (full load) of 2 MWth, and the configurations on both sides of the FMD are identical and symmetrically positioned on the A and B sides. Figure 2 shows the physical diagrams of the FMD and the test platform. Fabricated from 0Cr25Ni20 steel and covered with insulating rock wool on its surface, the FMD is a self-sustaining heating apparatus, formed by a circulating fluidized bed (CFB) structure that incorporates a 2100 mm high riser, a cyclone separator, and a U-shaped loop seal. Furthermore, the modification temperature is sustained through heat release within and heat dissipation to the surrounding environment.

Figure 1.

Schematic diagram of the MW-grade pilot-scale test platform for peak shaving. 1, Coal feeder; 2, primary air fan; 3, secondary air fan; 4, burnout air fan; 5, FMD; 6, HCC; 7, VCC; 8, cooling lances; 9, water cooler; 10, water tank; 11, bag filter; 12, induced draft fan; 13, modified fuel extraction point; 14, flue gas extraction point; 15, cooling water circulation; and 16, chimney.

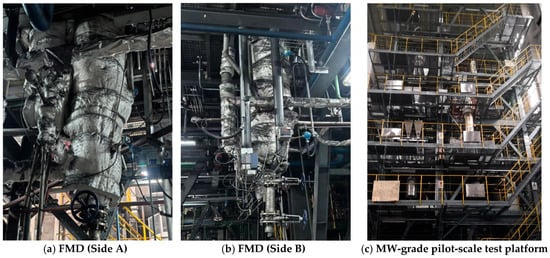

Figure 2.

Physical diagrams of the FMD (a,b) and MW-grade pilot-scale test platform (c).

Initially, the primary air characterized by a low air equivalence ratio transports the pulverized coal to the FMD, where partial combustion and gasification reactions ensue. The pulverized coal undergoes a conversion to the modified fuel within the FMD and enters the HCC via the connecting pipe, intersecting at the bottom of the VCC. The combustion reaction progresses gradually from the bottom upwards in both the VCC and HCC, whose main structures are fabricated from refractory materials. The HCC has a length of 3000 mm, and the overall height of the VCC amounts to 15,000 mm, with a water-cooling lance installed internally. The high-temperature flue gas generated during the combustion process departs from the top outlet of the VCC, passes through the cooler and the dust collector successively, and is subsequently drawn to the chimney for emission by the induced draft fan.

The ancillary equipment encompasses the pulverized coal conveying system, the air distribution system, the cooling system, and the flue gas treatment system. The air distribution system consists of the primary air, the secondary air, and the burnout air. The primary air is not merely employed for transporting the ground pulverized coal but also functions as an oxidant during the fuel modification process, entering from the bottom of the riser. Additionally, the secondary air is partitioned into swirling air and bottom air. The swirling air is injected from the outer ring of the modified fuel nozzle, while the bottom air is uniformly infused from the bottom of the HCC. The secondary air not only facilitates the ignition of combustion, but also consumes a portion of the fuel through endothermic reactions to sustain the combustion temperature. Furthermore, the burnout air is disposed in two layers along the axial direction, with the inlet positions for the lower plane of the HCC being 3632 mm and 6632 mm, respectively, in order to ensure a complete burnout.

2.2. Experimental Methods and Sampling Ports

The locations of the temperature and pressure measurement points for the FMD on both sides are consistent, and each is furnished with 5 temperature measurement points, all of which are K-type thermocouples, with an accuracy of ±0.5% FS. Among these, 3 temperature measurement points are situated in the riser, while the other 2 temperature measurement points are, respectively, positioned at the outlets of the loop seal and the cyclone separator. Pressure measurement points are also established on each temperature measurement tube. Moreover, 7 temperature measurement points are symmetrically disposed in the HCC (with 3 additional auxiliary points), and 13 temperature measurement points are arranged along the axial direction in the VCC, all of which are S-type thermocouples, with an accuracy of ±0.5% FS.

At the outlet of the FMD, modified fuel samples are collected for comprehensive analysis. The composition of high-temperature coal gas is precisely determined using an Agilent 3000A micro gas chromatograph (Santa Clara, CA, USA), featuring a detection sensitivity of less than 10–20 ppm. Furthermore, the carbon framework of the resulting high-temperature coal char is systematically characterized via Raman spectroscopy (LabRAM HR800, HORIBA, Kyoto, Japan), while its combustion reaction kinetics are investigated using thermogravimetric analysis (STA449F3, NETZSCH, Selb, Germany). To monitor the O2 content of the system, a zirconia analyzer is equipped in the tail flue, and the NOx emission is monitored online scrupulously using a GASMET DX4000 analyzer (Vantaa, Finland), with an instrument error <±2%. Furthermore, the bottom slag and fly ash are collected deliberately at the bottom discharge valve of the HCC and the outlet of the flue gas cooler, respectively, and the unburned carbon content in fly ash (UFA) is analyzed painstakingly to calculate the η.

2.3. Fuel Characteristics

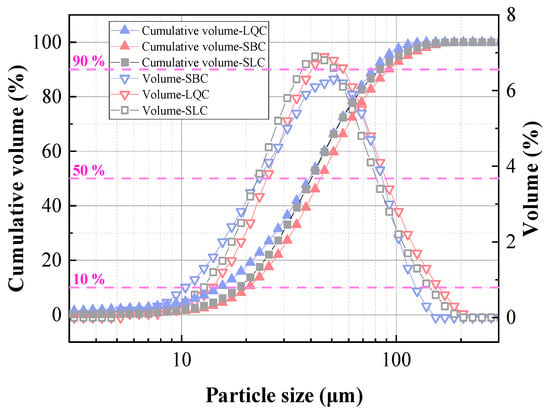

In this study, a kind of LQC, which has been combusted over an extended period in a typical 300 MW power station boiler unit from Heze City, China, was chosen as the experimental fuel (Var is only 7.66%). Due to the significant impacts of the disparities in the volatile matter content on the modification degree and the transformation traits of fuel-N, a typically Shenmu bituminous coal (SBC) featuring a relatively high volatile matter content (Var reaches 33.01%) was selected as the comparative fuel for pilot-scale experiments, while Shouyang lean coal (SLC) with an intermediate volatile content (Var reaches 13.36%) was chosen as the reference fuel for the thermogravimetric analysis (TGA). The ultimate and proximate analysis of LQC, SBC, and SLC are presented in Table 1. By means of sieving, the particle size ranges of the three kinds of coal are precisely controlled within the range of 0~0.18 mm, with R90 consistently remaining lower than 17.50%, thereby satisfactorily fulfilling the exacting requirements for pulverized coal fineness in thermal power plants. For LQC, SBC, and SLC, the particle sizes at cumulative volume fractions of 50% (d50) were 39.40 μm, 44.10 μm, and 40.37 μm, respectively, as depicted in Figure 3.

Table 1.

The ultimate and proximate analysis of LQC and SBC.

Figure 3.

Particle size distributions of LQC, SBC and SLC.

2.4. Experimental Conditions

The elaborate experimental conditions are delineated in Table 2. With regard to LQC, the load range of the text platform extends from 20% to 83%, and the input thermal power range lies within 0.40 to 1.66 MW. The selected load range is determined through the careful balancing of experimental safety, equipment constraints, and the research objective of evaluating fuel modification performance under wide-load conditions. To fulfill the requirements for a safe and stable operation under an ultra-low load, Case 1 is arranged for single-side FMD operation, with the corresponding thermal power of the FMD amounting to 0.40 MW. In Case 2 and 3, the FMD operates on both sides. The experimental conditions of SBC are comparable to those of LQC. When the FMD operates on a single side, the minimum load can attain 26%, and when it operates on both sides, the selected comparative operating conditions are a 40% load and 88% load, respectively.

Table 2.

Experimental conditions.

The ratios of the primary air flow rate, the secondary air flow rate (constituted by swirling air and bottom air, with the numerical values referring to the data from commercialized operations), and the burnout air flow rate to the theoretical air flow rate for complete combustion are, respectively, designated as the primary air equivalence ratio (λP), the secondary air equivalence ratio (λS), and the burnout air equivalence ratio (λB), and remain invariant throughout the entire experimentation. By means of regulating primary air and the coal feed, comparable primary air equivalence ratios under diverse operating cases can be attained. Subsequently, the secondary air and the burnout air are modulated in accordance with the load percentage. The identical air distribution approach is embraced for each experimental case and the operation persists stably for approximately four hours. It is necessary to ensure that λ is maintained within the range of 1.10 to 1.30 in order to guarantee the complete burnout of the fuel. During the sampling process, the temperature oscillations at each measurement point of the test platform are constrained within ±4 °C.

3. Results and Discussion

3.1. Stable Operation Characteristics of FMD

The variations in the internal temperature and bottom pressure of the FMD were primarily regarded as crucial indicators for determining the operational stability.

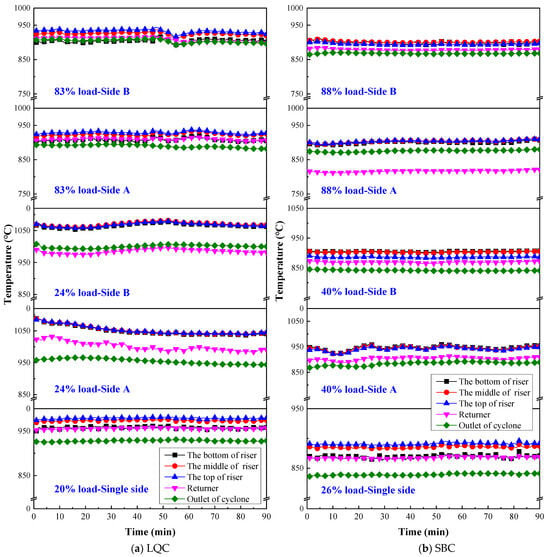

As depicted in Figure 4, the temperature distribution manifested an elevated level of stability and uniformity, featuring negligible variations over time and a maximum temperature difference of less than 50 °C. This signified that both LQC and SBC were capable of attaining stable partial gasification and partial combustion within the FMD, continuously generating gas–solid thermally active fuel above 800 °C, which notably enhanced the ignition and stable combustion characteristics. Even at low loads, the FMD sustained a uniform temperature profile. The temperature of LQC surpassed that of SBC, with a narrower temperature difference and enhanced uniformity, mainly attributed to its lower volatile content and slower yet more stable combustion rate. The higher ash content further facilitated a uniform heat transfer, leading to a more balanced heat distribution and a decreased temperature gradient. In contrast, the higher volatile matter content and faster combustion rate of SBC led to the rapid release and combustion of volatiles in the early stage of the process, making it prone to the formation of localized high- and low-temperature zones and thus more susceptible to temperature fluctuations.

Figure 4.

Temperature distributions of FMD during stable operation time.

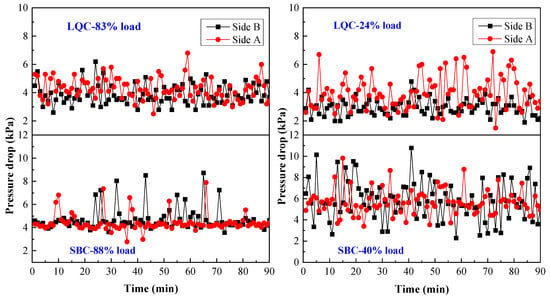

Figure 5 manifests the pressure distribution at the bottom of the FMD during the stable operation time. Taking the double-side FMD operation mode as an example, both units (denoted as sides A and B) exhibited consistently attenuated pressure oscillations, indicative of well-synchronized operating parameters and robust internal solids circulation. Such hydrodynamic uniformity fostered homogeneity in the temperature and concentration fields, promoted stable reaction kinetics, and ensured favorable gas–solid flow characteristics. This operational robustness underpinned sustained and reliable combustion within both the HCC and the VCC, underscoring the inherent merits of fluidized fuel modification in broadening coal adaptability and securing combustion stability under low-load, flexible operation regimes.

Figure 5.

Pressure distribution at the bottom of the FMD during stable operation time.

3.2. Fuel Modification Characteristics

3.2.1. The High-Temperature Coal Gas Composition

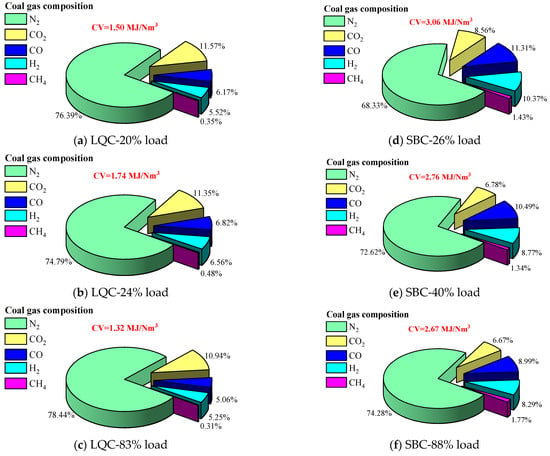

Given the near-identical composition and calorific value (CV) of the high-temperature coal gas observed between the A and B sides, the analysis focused on the representative data obtained under single-side FMD operation for each case, as shown in Figure 6. A strongly reducing atmosphere dominated within the FMD, with CO, H2, and CH4 as the main effective components. Additionally, owing to the low volatile matter and high ash content of the LQC, a lesser amount of combustible gas was produced, leading to a lower CV range of 1.32~1.74 MJ/m3, whereas the CV of the SBC coal gas was 2.67~3.06 MJ/m3, roughly twice that of the LQC. As the load diminished, the CV escalated, which was attributed to a reduction in gas flow and material circulation rates. This resulted in an extended particle residence time, the enhancement of volatile release, and the promotion of reactions such as the water–gas reaction (C + H2O → CO + H2), Boudouard reaction (C + CO2 → 2CO), and the hydrogenative methanation (C + 2H2 → CH4) during fluidized modification. The higher CV empowered the gas–solid thermally active fuel to ignite the high-temperature coal char in the HCC more promptly, thereby significantly enhancing the combustion stability, which was also a prominent advantage of the fluidized fuel modification.

Figure 6.

Principal components and CVs of the high-temperature coal gas.

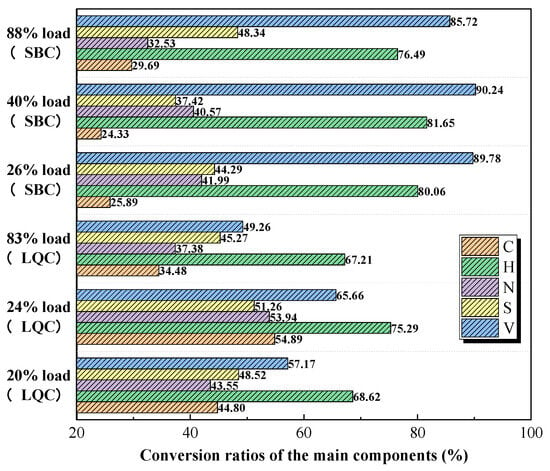

Based on the supposition of ash balance [7], the calculation outcomes of the conversion ratios of the main components during fuel modification are illustrated in Figure 7. In the instance of LQC, due to the highest modification temperature at a 24% load (Figure 4), the conversion ratios of all components were conspicuously superior to those in other cases and corresponded to the highest coal gas CV (Figure 6). Although LQC demonstrated lower H and volatile matter conversion ratios than SBC, it exhibited enhanced C, N, and S—a phenomenon directly correlated with LQC’s high fixed carbon content, coupled with the thermal oxidation propensity of N/S elements. Conversely, its reduced volatile content and dense structural configuration constrained H and volatile release, indicating that the modification process exerted a greater influence on LQC’s component release than SBC. Particularly, the N conversion ratio of the LQC ranged from 37.38% to 53.94%, while that of the SBC ranged from 32.53% to 41.99%. In a strongly reductive atmosphere, the majority of the liberated N elements would be directed to transform into N2, thereby reducing the likelihood of the char-N converting into NOx during the subsequent combustion. Consequently, LQC exhibited a more pronounced pre-removal effect of fuel-N during the modification process.

Figure 7.

Conversion ratios of the main components during fuel modification.

3.2.2. The High-Temperature Coal Char Reactivity

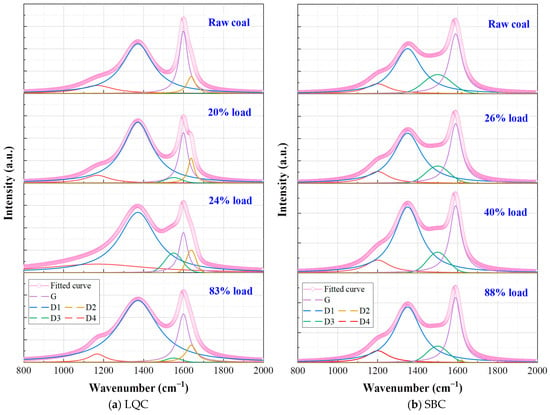

Figure 8 presents spectra intensity and peak fitting curves before and after fuel modification. The laser scanning range was set between 800 and 2000 cm−1. Due to the presence of second-order vibrational modes in the Raman spectra of coal and considering that the ordered and defect-related bands in carbonaceous materials were more distinctly observed within the first-order region, the analysis focused primarily on the variations in spectral parameters in this region [24]. The first-order region consisted of one Gaussian peak (D3 band at 1530 cm−1) and four Lorentzian peaks: the G band at 1580 cm−1, the D1 band at 1350 cm−1, the D2 band at 1620 cm−1, and the D4 band at 1150 cm−1 [25].

Figure 8.

Spectra intensity and peak fitting curves before and after fuel modification.

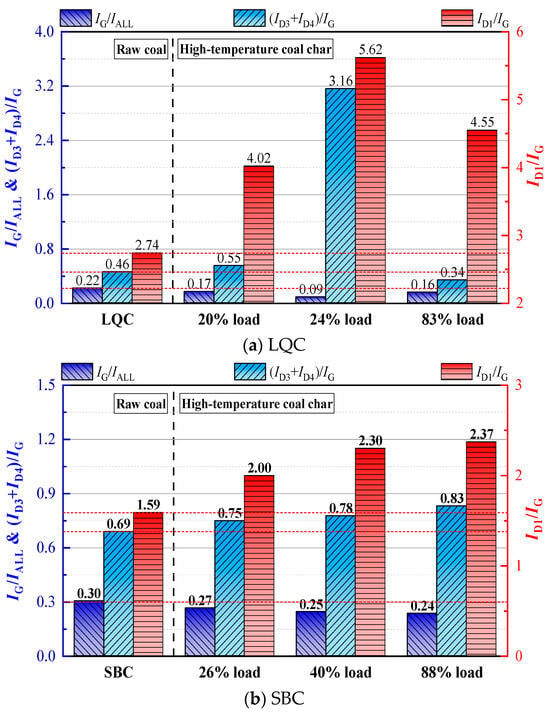

Figure 9 depicts the relative area ratio of the Raman spectral curves of raw coal and high-temperature coal char. The ratio IG/IAll reflects the degree of graphitization, ID1/IG represents the defect density within the carbon matrix, while (ID3 + ID4)/IG quantifies the relative abundance of reactive sites in the carbon framework [26].

Figure 9.

Relative area ratio of Raman spectral curves of raw coal and high-temperature coal char.

Under various load cases, the relative band area ratios on both sides of A and B exhibited high consistency, thereby confirming the uniformity of operational conditions within the FMD. During fuel modification, collisions between oxygen atoms and polycyclic aromatic hydrocarbons induced molecular bond cleavage, facilitating the formation of lighter aromatic compounds. The increased proportion of light aromatics significantly elevated the density of reactive surface sites on char particles. Concurrently, the relative content of amorphous carbon increased, while the overall graphitization degree diminished, leading to a pronounced decline in the IG/IAll ratio. Moreover, the cleavage of large carbon chains promoted the transformation of stable graphitic structures into disordered, defect-rich configurations [27]. This structural transition was evidenced by the elevated ID1/IG ratio, indicating reduced graphitic stability and enhanced porosity development, along with a substantial rise in (ID3 + ID4)/IG, reflective of increased active defect sites.

For LQC, low-load cases favored a prolonged and uniform volatile release process, which facilitated extensive carbon chain fragmentation and the formation of amorphous carbon structures. Consequently, the number of reactive sites on the particle surface increased significantly, accompanied by a higher proportion of amorphous carbon and a markedly lower graphitization degree. In contrast, under high-load cases, although the volatiles were rapidly released, the shortened residence time inhibited the full development of carbon chain scission and amorphous structure formation [28]. As a result, the surface reactivity was comparatively limited, and the overall reactivity enhancement was less pronounced than under a low-load operation. In comparison, SBC exhibited a minimal variation in modification performance between high and low loads. This suggested that the release of volatiles and the fragmentation of carbon chains proceeded sufficiently under both conditions, enabling the formation of a stable porous architecture and a moderate quantity of amorphous carbon. Even under high-load cases with shortened residence times, the rapid evolution of volatiles and the efficient cleavage of carbon chains ensured that the modification effect remained comparable to that observed under low-load cases.

In summary, LQC demonstrated a substantially greater enhancement in reactivity following modification compared to SBC. This could be attributed to the inherently lower reactivity and more ordered structure of raw LQC, rendering it more susceptible to structural disruption and activation during modification. Conversely, SBC possessed higher native volatility and reactivity, resulting in comparatively minor structural alterations and, thus, a limited improvement in overall fuel performance. These distinctions provided critical theoretical insights and practical guidance for tailoring fuel modification strategies to different coal types.

3.2.3. Combustion Reaction Kinetics

TGA was conducted to quantitatively assess the combustion kinetics of the three coal types. Each experiment utilized a 20 mg sample. The testing protocol consisted of an initial isothermal stage at ambient temperature for 30 min to stabilize the system, followed by a temperature ramp from room temperature to 1200 °C at a constant heating rate of 10 °C/min under an air atmosphere. Upon reaching the target temperature, samples were held isothermally at 1200 °C for an additional 30 min to ensure complete combustion.

Combustion behavior was comprehensively evaluated in terms of both ignition and burnout characteristics. The ignition performance was characterized by the ignition temperature (Ti), determined using the tangent intersection method, and the flammability index (Fith), calculated as described in Ref. [29]. Burnout characteristics were assessed using the burnout index (Cb), following the methodology outlined in Ref. [30], and the burnout performance indicator (Hj), as defined in Ref. [31]. To provide a holistic measure of combustion reactivity, the comprehensive combustion index (S) was employed, which integrates both ignition and burnout properties, with its calculation method detailed in Ref. [32]. The activation energy (Ea) was determined using the integral form of the Coats–Redfern method [33] under the single heating rate approach.

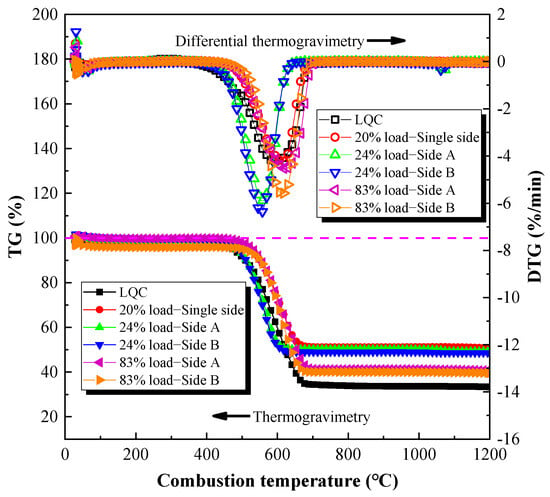

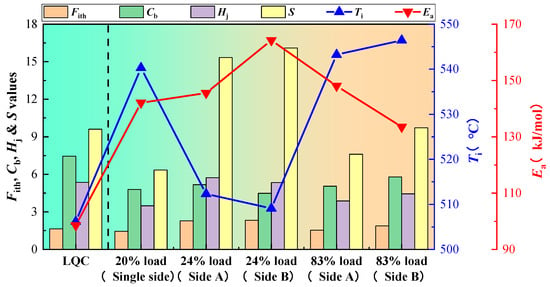

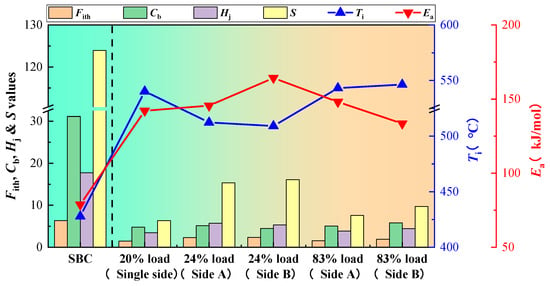

The TG-DTG curves of LQC and its high-temperature coal char are manifested in Figure 10, with the corresponding combustion characteristic parameters compared in Figure 11. Due to its inherently low volatile content, LQC exhibited a negligible devolatilization below 400 °C. The ignition temperature of LQC was approximately 506.18 °C, accompanied by a steep TG slope and a sharp DTG peak, indicating the maximum mass loss rate. Burnout was achieved at 658.91 °C, beyond which mass loss stabilized. Among the high-temperature coal char samples produced under different cases, the one generated at a 24% load exhibited the most favorable combustion performance (Figure 9). This sample showed the lowest DTG peak temperature and the highest maximum mass loss rate, suggesting markedly enhanced combustion reactivity. Notably, its Ti was the lowest among all tested samples, and its Fith, Cb, Hj, and S were all significantly improved compared to LQC. These findings suggest that substantial structural modifications occurred under this case, promoting fuel reactivity. In contrast, high-temperature coal char produced under the other cases exhibited that the Ti was approximately 40 °C higher than that of LQC. The corresponding Fith and Cb showed only a slight improvement, while Hj and S remained comparable to the raw coal, indicating limited enhancement in combustion behavior. These results highlighted that significant improvements in combustion characteristics at a low load required moderate increases in the λp and a modification temperature exceeding 980 °C, as corroborated by the results shown in Figure 4 and Figure 8.

Figure 10.

TG-DTG curves of LQC and its high-temperature coal char.

Figure 11.

Comparison of combustion parameters of LQC and its high-temperature coal char.

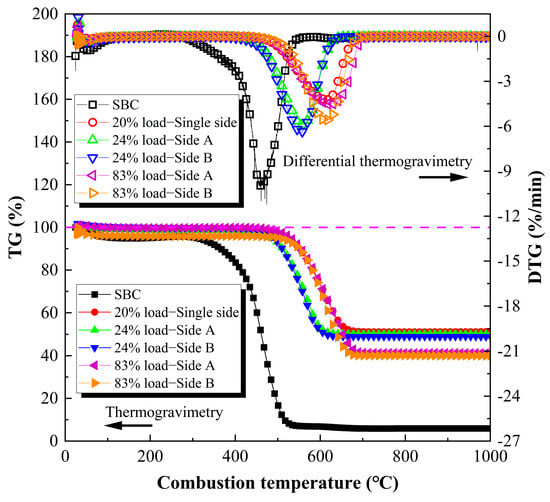

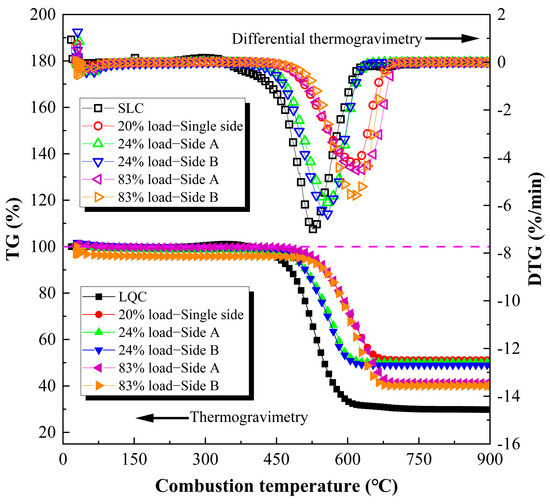

To further evaluate the combustion performance of high-temperature coal char derived from LQC, a comparative analysis was conducted using SBC as a reference, as illustrated in Figure 12 and Figure 13. SBC began to lose mass at approximately 300 °C, primarily attributed to the release and subsequent oxidation of moisture and light volatiles. The principal combustion stage occurred between 400 °C and 550 °C, with ignition and burnout temperatures of 427.86 °C and 530.45 °C, respectively. The comparative results clearly revealed the superior combustion performance of SBC relative to the LQC high-temperature coal char. Specifically, SBC exhibited a Ti 80~120 °C lower, a Fith that was 2.5~4.5 times higher, and a Cb, Hj, and S that exceeded those of LQC high-temperature coal char by factors of 5~7, 3~5, and 7~20, respectively. These differences highlighted significant disparities in combustion reactivity and efficiency between the two fuels.

Figure 12.

TG-DTG curves of SBC and LQC high-temperature coal char.

Figure 13.

Comparison of combustion parameters of SBC and LQC high-temperature coal char.

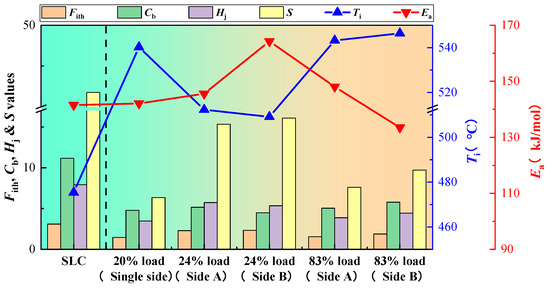

A comparative analysis using SLC as a reference was further conducted, as presented in Figure 14 and Figure 15. The ignition and burnout temperatures of SLC were determined to be 475.39 °C and 589.47 °C, respectively. In terms of combustion indices, SLC demonstrated superior performance compared to the LQC high-temperature coal char, with a Ti that was 30~70 °C lower, and a Fith, Cb, and Hj that were elevated by factors of 1.3~2.5. Additionally, S was enhanced by a factor of 2.5~6.5. Although SLC exhibited relatively superior ignition, combustion, and burnout characteristics, the differences were not particularly pronounced—especially when compared to the high-temperature coal char derived from LQC under a 24% load, which demonstrated comparable overall combustion performance (Figure 9). With the further optimization of modification parameters, the combustion behavior of LQC high-temperature coal char could approach, or even surpass, that of SLC. It is important to highlight that, under actual operating conditions, the high-temperature coal char was not extracted or cooled but instead proceeded directly into the combustion chamber, which enabled a synergistic interaction between the high-calorific-value volatiles and the reactive high-temperature coal char during the modification, which conferred a distinct advantage over the conventional lean coal pulverized fuel alone. This process exemplified a “dimensionality-reduction utilization” strategy for high-rank coals with a low quality.

Figure 14.

TG-DTG curves of SLC and LQC high-temperature coal char.

Figure 15.

Comparison of combustion parameters of SLC and LQC high-temperature coal char.

Although correlations existed between Ea and combustion characteristic parameters, the two were not strictly equivalent [32,33]. Among the tested samples, LQC exhibited the highest Ea, primarily due to its dense molecular structure and strong covalent bonding, which required a greater energy input to disrupt during combustion. In contrast, SBC demonstrated the lowest Ea, attributed to its higher volatile content and more porous, loosely bound structure, which facilitated easier ignition and combustion. SLC showed an intermediate Ea, falling between those of LQC and SBC. Although the thermal modification significantly enhanced the porosity and increased the number of reactive sites, thereby improving the apparent combustion reactivity of the fuel, the resulting char typically exhibited a higher activation energy than the raw coal. This was primarily attributed to the increased structural ordering and aromaticity of the carbon matrix induced by devolatilization, leading to a predominance of more stable chemical bonds. Consequently, while the reaction rate might be enhanced due to greater surface accessibility, the energy barrier required to initiate combustion reactions became higher, reflecting a fundamental trade-off between microstructural stabilization and ignition energetics.

3.3. Combustion Characteristics and NOx Emission

3.3.1. Combustion Temperature Distribution

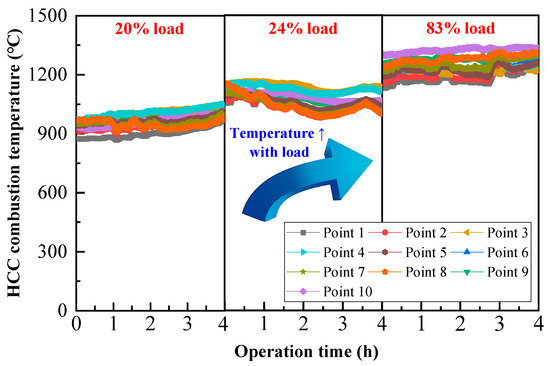

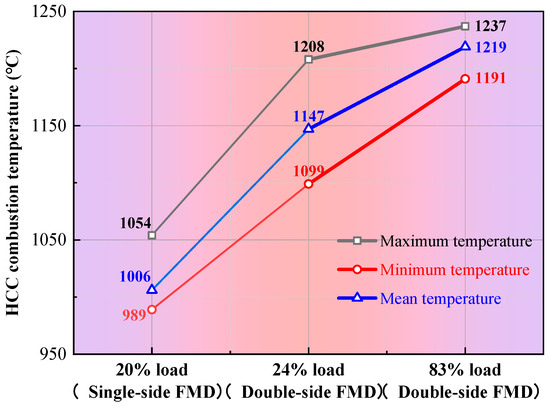

Figure 16 depicts the combustion temperature distribution of HCC when burning LQC, while Figure 17 shows the comparison of average combustion temperatures under different loads. The temperature profiles remained generally stable across the load range, with only minor fluctuations attributed to slight variations in coal feeding uniformity. These fluctuations exerted a negligible influence on overall combustion performance, indicating the excellent combustion stability of the modified fuel. Notably, under ultra-low-load conditions of 20% and 24%, stable ignition and sustained combustion were achieved regardless of whether the FMD operated on a single side or in a symmetrical opposing mode. This demonstrated the significant enhancement of combustion characteristics by FMD (Figure 15).

Figure 16.

Combustion temperature distribution (LQC high-temperature coal char).

Figure 17.

Comparison of average combustion temperatures (LQC high-temperature coal char).

With an increasing load, the overall combustion temperature exhibited a rising trend. This was attributed to the increased supply of LQC and combustion air, leading to enhanced mixing, the expansion of the combustion zone, and reduced unburned carbon and heat losses. Consequently, the combustion temperature became not only higher but also more uniformly distributed. The symmetric operation of double-side FMD further contributed to a balanced thermal input and stable flame structure. In contrast, under a 20% load with single-side FMD operation, the asymmetric heat input resulted in an uneven thermal distribution, leading to the lowest observed maximum, minimum, and average combustion temperatures. Importantly, the peak combustion temperature remained below 1250 °C, effectively suppressing the formation of thermal NOx and achieving an intrinsic NOx reduction during the combustion process. Overall, the double-side FMD operation mode not only ensured the stable combustion of LQC under low-load conditions but also reduced the vibration, thermal stress, and potential equipment damage. This provides a technically feasible and economically promising solution for the clean and efficient combustion of LQC in power plant boilers.

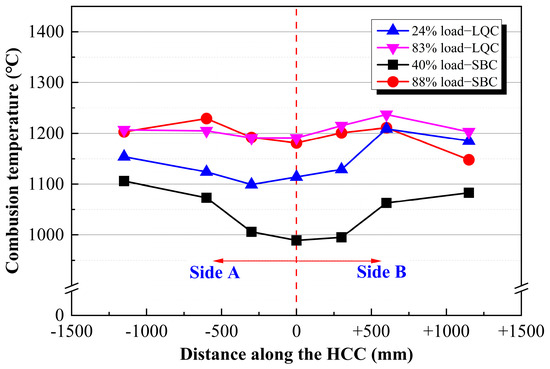

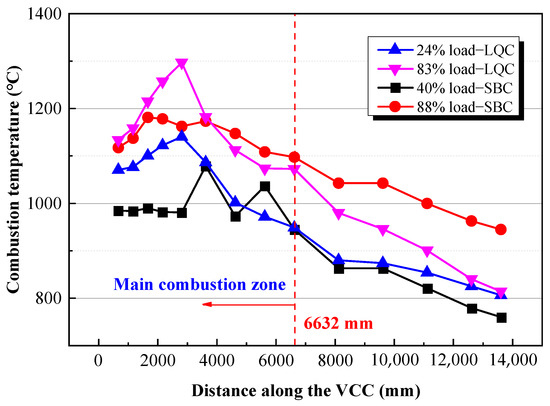

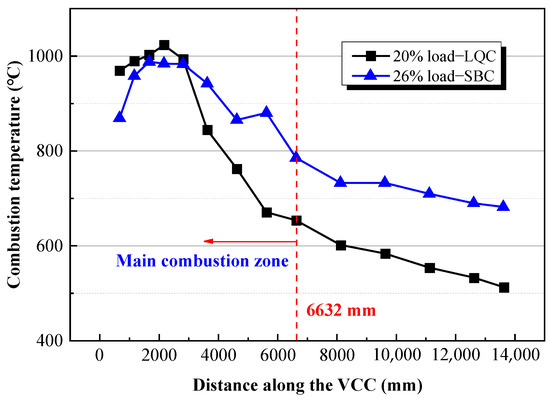

Figure 18 and Figure 19 manifest the HCC and VCC temperature distributions of LQC and SBC-modified fuels under double-side FMD operation. As burnout air was introduced at 3632 mm and 6632 mm from the bottom, the region below 6632 mm was defined as the main combustion zone. The combustion temperature profiles on both sides of the HCC exhibited good axisymmetry, owing to the symmetric operation of the FMDs on both sides of A and B, which promoted a uniform thermal and concentration field, effectively preventing localized high-temperature or oxidation zones and reducing the slagging risk. Along the horizontal axis, the high-temperature coal gas—rich in combustibles—ignited rapidly upon mixing with secondary air, with no observable ignition delay. Under high-load cases, combustion temperatures on both sides of HCC were nearly equal. In contrast, at low loads, a noticeable temperature drop occurred in the central furnace region. This decline was primarily attributed to the reduced jet momentum of the fuel streams, which limited the flame penetration and combustion intensity in the core zone. As a result, unburned fuel was more readily entrained and transported upward by the secondary air flow before complete combustion could take place. For LQC, the combustion temperature remained higher than that of SBC under low-load cases. This was attributed to the higher fixed carbon content and lower volatile release of LQC during thermal modification, resulting in a more concentrated heat release from solid-phase combustion (Figure 6). In the vertical direction, for SBC, the combustion at low loads was strongest near the furnace bottom, where the introduction of burnout air enhanced combustion and led to local peak temperatures. For LQC, peak combustion occurred in the flame convergence zone at the mid-furnace height, indicating the dominance of fixed carbon combustion. As the load increased, SBC presented improved temperature uniformity due to intensified and balanced gas–solid combustion. In contrast, LQC benefited from reduced loads, which alleviated local overheating caused by concentrated fixed carbon combustion at higher loads, thereby improving temperature uniformity.

Figure 18.

HCC temperature distributions under double-side FMD operation.

Figure 19.

VCC temperature distributions under double-side FMD operation.

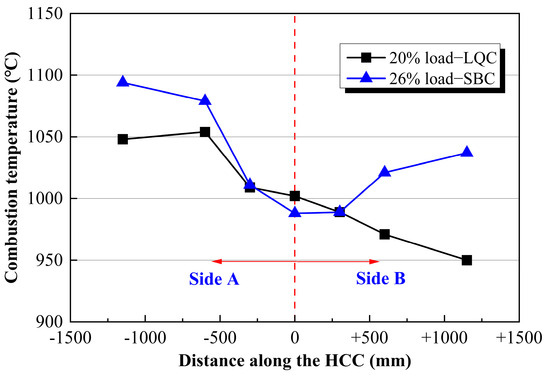

Figure 20 and Figure 21 illustrate the combustion temperature profiles of SBC and LQC-modified fuels under single-side FMD operation. Both fuels exhibited a higher combustion temperature on the FMD operating side. Relative to double-side FMD operation, the single-side mode led to reduced uniformity in both temperature and concentration fields within the HCC. Peak combustion temperatures were primarily located at the bottom of the VCC and the flame interaction zone within the HCC. For LQC, a notably higher combustion temperature was observed at the bottom of the VCC compared to SBC. This was mainly attributed to the concentrated heat release from fixed carbon, driven by carbon chain cleavage and subsequent reformation [34]. Although LQC exhibited a slower combustion rate, the localized energy release resulted in higher peak temperatures in this region. In contrast, SBC presented elevated combustion temperatures across a broader spatial range, owing to its more vigorous gas–solid phase reactions. Despite the asymmetric FMD operation, SBC maintained a relatively uniform heat distribution, suggesting a limited impact on overall combustion uniformity. Furthermore, the introduction of burnout air led to a pronounced axial decrease in combustion temperature for LQC, highlighting the adverse effect of a nonuniform temperature and concentration field on its combustion behavior. Although LQC retained a degree of flame stability, its η was significantly compromised under single-side FMD operation.

Figure 20.

HCC temperature distributions under single-side FMD operation.

Figure 21.

VCC temperature distributions under single-side FMD operation.

3.3.2. Combustion Efficiency and NOx Emission

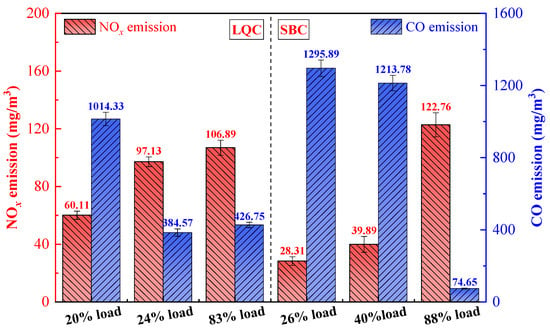

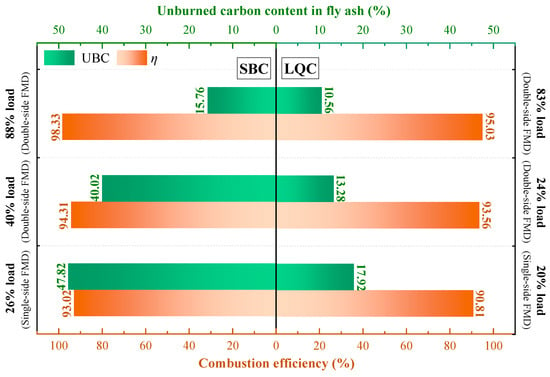

Figure 22 depicts the NOx and CO emissions of SBC and LQC modified fuels under different loads, normalized to 6% O2. As the load reduced, the CO emissions of SBC increased due to the decrease in combustion temperature and insufficient air flow. These factors weakened the fuel–air mixing uniformity and exacerbated the incomplete combustion of high-temperature coal char. In contrast, LQC maintained relatively stable CO emissions as the load decreased to a 24% load, demonstrating the stability and load adaptability of LQC under double-side FMD operation. However, under the single-side FMD operation, the system imbalance disrupted this stability. The uneven mixing of reactants and existence of local retention zones together worsened the incomplete combustion of coal char, leading to an increase in CO emissions. Overall, NOx emissions decreased with a reduced load. This reduction could be attributed to two primary factors: first, the lower fuel input under a low load led to a decrease in fuel-N sources; second, the extended gas residence time under such conditions promoted reductive reactions that suppressed NOx formation. Compared with single-side FMD operation, the double-side mode provided more symmetric thermal conditions that enhanced combustion uniformity and stability, which was particularly beneficial at low loads. However, the more complete combustion under this mode also promoted the release and oxidation of fuel-N, leading to higher NOx emissions. Therefore, a balanced strategy would be considered in practical applications to simultaneously control CO and NOx emissions and achieve optimal overall performance.

Figure 22.

NOx and CO emissions (@6%O2) under different loads.

The η and UBC are summarized in Figure 23. Under a 40% load, although SBC achieved ultra-low NOx emissions, the CO concentration exceeded 1200 mg/m3 (@6%O2), with η dropping to 94.30%. This poor performance was attributed to the insufficient mixing of fuel and air due to low furnace temperatures and inadequate air flow velocity. As the load increased to 88%, both the furnace temperature and air volume improved significantly, raising SBC’s η above 98%. In comparison, for LQC, both NOx and CO emissions remained at moderate levels, with η consistently above 93% and less sensitivity to load variations, highlighting the greater robustness of LQC combustion under double-side FMD operation. Nonetheless, under single-side FMD operation, the system became relatively unbalanced, contributing to incomplete gas–solid mixing and localized stagnation zones, where a portion of the combustion products would accumulate within the furnace, further impairing combustion stability and efficiency. At a 20% load, LQC recorded a NOx emission of 60.11 mg/m3, while SBC emitted 28.33 mg/m3 (@6%O2) at a 26% load. Despite the low NOx values, both fuels experienced high CO emissions and reduced η. Therefore, the further optimization of the fuel modification condition to enhance mixing intensity and combustion uniformity was essential for improving combustion performance and NOx emission characteristics under low-load, single-side FMD operation.

Figure 23.

η and UBC under different loads.

As the load reduced, the CO emissions of SBC increased due to the decrease in combustion temperature and insufficient air flow. These factors weakened the fuel–air mixing uniformity and exacerbated the incomplete combustion of high-temperature coal char. In contrast, LQC maintained relatively stable CO emissions as the load decreased to a 24% load, demonstrating the stability and load adaptability of LQC under double-side FMD operation. However, under the single-side FMD operation, the system imbalance disrupted this stability. The uneven mixing of reactants and existence of local retention zones together worsened the incomplete combustion of coal char, leading to an increase in CO emissions.

Although this study primarily focused on the technical feasibility and combustion performance of the proposed fuel modification strategy under wide-load conditions, the economic viability of industrial implementation was equally important. Preliminary engineering evaluations indicated that the FMD system could essentially be designed in different capacity grades and was modifiable, without the need for major renovations to the boiler or combustion system. The associated capital and operational costs were relatively low, particularly when offset by gains in operational flexibility, combustion efficiency, and emission reductions. These benefits enabled enhanced participation in peak-shaving compensation, frequency regulation, and capacity pricing mechanisms, while also reducing startup fuel consumption and NOx control costs. Comprehensive techno-economic analyses are ongoing to support future deployment.

4. Conclusions

To address the intrinsically low reactivity of LQC and achieve wide-load adaptability, high η, and low NOx emissions, this study employed a fuel modification strategy that fundamentally redefined the conventional combustion pathway for such coals. Peak-shaving performance and combustion behavior were systematically investigated on an MW-grade pilot-scale test platform. Key evaluations included the operational stability of FMD, fuel modification characteristics, and combustion behavior and NOx emissions under variable load cases. The main conclusions are summarized as follows:

1. Stable fuel modification was successfully achieved without any auxiliary energy for LQC across a load range of 20%~83% and for SBC from 26% to 88%. Both double-side and single-side FMD operation modes demonstrated reliable combustion system stability under low-load cases. Compared to raw coal, the reactivity of the high-temperature coal char was significantly enhanced. Under equivalent load cases, the fluidized fuel modification process had a stronger effect on the release characteristics of volatile and nitrogenous components in LQC, demonstrating superior performance in fuel-N pre-removal and a substantially greater enhancement in char reactivity compared to SBC.

2. The ignition, combustion, and burnout characteristics of the LQC high-temperature coal char were comparable to those of SLC, exemplifying a “dimensionality-reduction utilization” strategy for high-rank coals. Under double-side FMD operation, the HCC exhibited an axially symmetric temperature field (<1250 °C), while the peak temperature in the VCC (<1300 °C) was concentrated near the bottom and the flame intersection zone. In contrast, under single-side FMD operation, the HCC showed a temperature asymmetry, with higher temperatures on the FMD operating side (<1200 °C), reflecting nonuniform combustion and thermal fields. The advance mixing of burnout air and modified fuel proved beneficial to the burnout of LQC.

3. Excellent NOx control performance was observed under different FMD operation modes. For SBC, ultra-low original NOx emissions were achieved at loads below 40%, and emissions remained below 130 mg/m3 (@6%O2) in the 40~88% load range. For LQC, original NOx emissions were maintained below 110 mg/m3 (@6%O2) across the 20~83% load range, indicating that the fuel modification strategy enabled compliance with strict NOx emission standards for coal-fired power generation.

4. Coal-type-specific advantages were observed under different load cases. For SBC, fuel modification enhanced combustion temperature uniformity at high loads and reduced NOx emissions at low loads. Conversely, for LQC, fuel modification led to lower NOx emissions at high loads and better combustion uniformity at low loads. These trends suggested that a coal-type selection and FMD operational strategy should be tailored to the plant’s load profile to maximize efficiency and environmental performance.

5. This study provided both theoretical and empirical support for the low emission retrofit and flexibility enhancement of coal-fired power units, particularly under deep peak-shaving scenarios. The fuel modification approach effectively mitigated ignition challenges associated with LQC, reducing reliance on auxiliary ignition systems and related infrastructure. Double-side FMD operation was recommended to promote temperature uniformity, and the further optimization of the premixing between burnout air and modified fuel was advised to improve η and environmental outcomes.

Author Contributions

Methodology, H.D.; Validation, S.L.; Formal analysis, S.L.; Investigation, S.L., S.Z., X.Z., H.W., K.S. and Z.L.; Data curation, H.D.; Writing—original draft, H.D.; Writing—review & editing, Z.O.; Supervision, Z.O.; Project administration, H.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Postdoctoral Fellowship Program of CPSF [GZC20232672] and Strategic Priority Research Program of the CAS [XDA29010200], and the APC was funded by [GZC20232672].

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Symbols | |

| MP | Primary Air Flow Rate, Nm3/h |

| MS | Secondary Air Flow Rate, Nm3/h |

| MB | Burnout Air Flow Rate, Nm3/h |

| M | Total Air Flow Rate, Nm3/h |

| Qnet,ar | Lower Heating Value, MJ/kg |

| UFV | Fluidized Air Velocity, m/s |

| Greek letters | |

| λp | Primary Air Equivalence Ratio, % |

| λS | Secondary Air Equivalence Ratio, % |

| λB | Burnout Air Equivalence Ratio, % |

| λ | Total Air Equivalence Ratio, % |

| η | Combustion Efficiency, % |

| Abbreviations | |

| CFB | Circulating Fluidized Bed |

| CV | Calorific Value, MJ/Nm3 |

| FMD | Fuel Modification Device |

| HCC | Horizontal Combustion Chamber |

| LQC | Low-quality Coal |

| SBC | Shenmu Bituminous Coal |

| SLC | Shouyang Lean Coal |

| TGA | Thermogravimetric analysis |

| UFA | Unburned Carbon Content in Fly Ash, % |

| VCC | Vertical Combustion Chamber |

References

- Rousseau, P.; Laubscher, R. A thermofluid network-based model for heat transfer in membrane walls of pulverized coal boiler furnaces. Therm. Sci. Eng. Prog. 2021, 18, 100547. [Google Scholar] [CrossRef]

- Ming, H.; Lin, M.; Gao, C.; Zhang, N.; Xie, L.; Mou, Y. Towards the prospect of carbon-neutral power system 2060: A Power-Meteorology-Society systematic view. Heliyon 2024, 10, e27970. [Google Scholar] [CrossRef] [PubMed]

- Yuan, R.; Liu, M.; Chen, W.; Yan, J. CO2 emission characteristics modeling and low-carbon scheduling of thermal power units under peak shaving conditions. Fuel 2024, 373, 132339. [Google Scholar] [CrossRef]

- Li, L.; Meng, Y.; Yuan, X.; Li, J. Peak shaving strategy optimization based on load forecasting: Evidence from Anhui Provence, China. J. Energy Storage 2024, 90, 111818. [Google Scholar] [CrossRef]

- Kanca, A. Investigation on pyrolysis and combustion characteristics of low quality lignite, cotton waste, and their blends by TGA-FTIR. Fuel 2020, 263, 116517. [Google Scholar] [CrossRef]

- Wang, J.; Kuang, M.; Zhao, X.; Wu, H.; Ti, S.; Chen, C.; Jiao, L. Trends of the low-NOx and high-burnout combustion characteristics in a cascade-arch, W-shaped flame furnace regarding with the staged-air angle. Energy 2020, 212, 118768. [Google Scholar] [CrossRef]

- Ouyang, Z.; Zhu, J.; Lyu, Q. Experimental study on preheating and combustion characteristics of pulverized anthracite coal. Fuel 2013, 113, 122–127. [Google Scholar] [CrossRef]

- Orszulik, E.; Sliwinska, A. Combustion of hard coal and alternative fuels in a boiler with an innovative retort burner. Combust. Sci. Technol. 2019, 191, 555–569. [Google Scholar] [CrossRef]

- Bielowicz, B. Petrographic characteristics of coal gasification and combustion by-products from high volatile bituminous coa. Energies 2020, 13, 4374. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Z.; Zhang, M.; Zeng, L.; Li, Z. Combustion stability, burnout and NOx emissions of the 300 MW down-fired boiler with bituminous coal: Load variation and low-load comparison with anthracite. Fuel 2021, 295, 120641. [Google Scholar] [CrossRef]

- Tuttle, J.; Vesel, R.; Alagarsamy, S.; Blackburn, L.; Powell, K. Sustainable NOx emission reduction at a coal-fired power station through the use of online neural network modeling and particle swarm optimization. Control Eng. Pract. 2019, 93, 104167. [Google Scholar] [CrossRef]

- Ibrahimoglu, B.; Yilmazoglu, M.; Cucen, A. Numerical modelling of repowering of a thermal power plant boiler using plasma combustion systems. Energy 2016, 103, 38–48. [Google Scholar] [CrossRef]

- Zhao, F.; Li, S.; Ren, Y.; Yao, Q.; Yuan, Y. Investigation of mechanisms in plasma-assisted ignition of dispersed coal particle streams. Fuel 2016, 186, 518–524. [Google Scholar] [CrossRef]

- Messerle, V.; Karpenko, E.; Ustimenko, A. Plasma assisted power coal combustion in the furnace of utility boiler: Numerical modeling and full-scale test. Fuel 2014, 126, 294–300. [Google Scholar] [CrossRef]

- Chen, Y.; Kuang, M.; Ge, Z.; Zhao, Y.; Chen, J. Establishing essentially symmetrical combustion plus apparent improvement in burnout and NOx emissions within a down-fired furnace by rearranging its W-shaped flame into a sidewall-dominated pattern. Fuel 2023, 340, 127544. [Google Scholar] [CrossRef]

- Ma, L.; Fang, Q.; Lyu, D.; Zhang, C.; Chen, Y.; Chen, G.; Duan, X.; Wang, X. Reducing NOx emissions for a 600 MWe down-fired pulverized-coal utility boiler by applying a novel combustion system. Environ. Sci. Technol. 2015, 49, 13040–13049. [Google Scholar] [CrossRef]

- Du, H.; Li, Z.; Liu, Z.; Zhang, M.; Huang, C.; Jiang, G.; Chen, Z.; Song, J.; Fang, F.; Su, J.; et al. Industrial measurement of combustion and NOx formation characteristics on a low-grade coal-fired 600 MWe FW down-fired boiler retrofitted with novel low-load stable combustion technology. Fuel 2022, 321, 123926. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Z.; Li, L.; Zeng, L.; Li, Z. Achievement in ultra-low-load combustion stability for an anthracite and down-fired boiler after applying novel swirl burners: From laboratory experiments to industrial applications. Energy 2020, 192, 116623. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Q.; Wang, B.; Zeng, L.; Che, M.; Zhang, X.; Li, Z. Anthracite combustion characteristics and NOx formation of a 300 MWe Cross Markdown-fired boiler with swirl burners at different loads after the implementation of a new combustion system. Appl. Energy 2017, 189, 133–141. [Google Scholar] [CrossRef]

- Lyu, Q.; Zhu, J.; Niu, T.; Song, G.; Na, Y. Pulverized coal combustion and NOx emissions in high temperature air from circulating fluidized bed. Fuel Process. Technol. 2008, 89, 1186–1192. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, J.; Lyu, Q. Experimental study on the combustion characteristics and NOx emissions of pulverized anthracite preheated by circulating fluidized bed. J. Therm. Sci. 2011, 20, 355–361. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, S.; Zhu, J.; Liu, Y.; Zhang, J.; Hui, J.; Ding, H.; Cao, X.; Lyu, Q. Preheating and combustion characteristics of anthracite under O2/N2, O2/CO2 and O2/CO2/H2O atmospheres. Energy 2023, 274, 127419. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Y. Numerical optimization of the influence of multiple deep air-staged combustion on the NOx emission in an opposed firing utility boiler using lean coal. Fuel 2020, 269, 116996. [Google Scholar] [CrossRef]

- Guedes, A.; Valentim, B.; Prieto, A. Raman spectroscopy of coal macerals and fluidized bed char morphotypes. Fuel 2012, 97, 443–449. [Google Scholar] [CrossRef]

- Gao, F.; Jia, Z.; Cui, Z.; Li, Y.; Jiang, H. Evolution of macromolecular structure during coal oxidation via FTIR, XRD and Raman. Fuel Process. Technol. 2024, 262, 108114. [Google Scholar] [CrossRef]

- Cheng, C.; Yu, J.; Wang, J.; Ding, L.; Yu, G. In-situ Raman spectroscopy study on coal pyrolysis and subsequent char low temperature oxidation and gasification. Chem. Eng. Sci. 2024, 285, 119619. [Google Scholar] [CrossRef]

- He, Q.; Jiang, X.; Xu, J.; Wang, C.; Jiang, M.; Wang, G.; Jiang, L.; Xu, K.; Wang, Y.; Su, S.; et al. Heterogeneous chemical structures of single pulverized coal particles and their evolution during pyrolysis: Insight from micro-Raman mapping technique. Powder Technol. 2023, 420, 118385. [Google Scholar] [CrossRef]

- Matlala, I.; Moroeng, O.; Kalaitzidis, S.; Wagner, N. Raman Spectroscopy for the characterization of the macromolecular structure of Highveld coals (South Africa). Int. J. Coal Geol. 2024, 288, 104531. [Google Scholar] [CrossRef]

- Wu, X.; Bourbigot, S.; Li, K.; Zou, Y. Co-pyrolysis characteristics and flammability of polylactic acid and acrylonitrile-butadiene-styrene plastic blend using TG, temperature-dependent FTIR, Py-GC/MS and cone calorimeter analyses. Fire Saf. J. 2022, 128, 103543. [Google Scholar] [CrossRef]

- Wang, L.; Ye, T.; Ma, X.; Lin, Y.; Chen, J.; Wang, F.; Ma, P.; Liu, J. Kinetics and products distribution study on the catalytic effect of Zn/HZSM-5 over pyrolysis of chlorella through TG-FTIR and Py-GC/MS. J. Therm. Sci. 2023, 32, 1635–1643. [Google Scholar] [CrossRef]

- Ahmad, M.B.; Su, G.; Li, L.; Ma, J.; Li, X.; Embaye, T.M.; Hu, Z.; Deng, S.; Guo, H.; Wang, X. Co-combustion behaviour of municipal waste and food waste using TG-FTIR and Py-GC/MS: Thermo-kinetic behaviour and gaseous pollutants emission. Fuel 2025, 398, 135552. [Google Scholar] [CrossRef]

- Guo, S.; Deng, X.; Liu, L.; Ge, L.; Lisak, G. Comprehensive analysis of combustion behavior, kinetics, and gas emissions of fungus bran biofuel through torrefaction pretreatment and polypropylene addition. Fuel 2024, 364, 131014. [Google Scholar] [CrossRef]

- Wu, L.; Jiang, X.; Lyu, G.; Li, X.; Yan, J. Analysis of the pyrolysis of solid recovered fuel and its sorted components by using TG-FTIR and DAEM. J. Therm. Sci. 2023, 32, 1671–1683. [Google Scholar] [CrossRef]

- Zhang, T.; Feng, W.; Bai, Z.; Zheng, H.; Dou, H.; Guo, Z.; Kong, L.; Bai, J.; Li, W. Interpretation of interactions between low rank coal and polyethylene during co-pyrolysis from the bond cleavage perspective. J. Energy Inst. 2024, 113, 101529. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).