Experimental Evaluation of a Radiant Panel System for Enhancing Sleep Thermal Comfort and Energy Efficiency

Abstract

1. Introduction

2. Materials and Methods

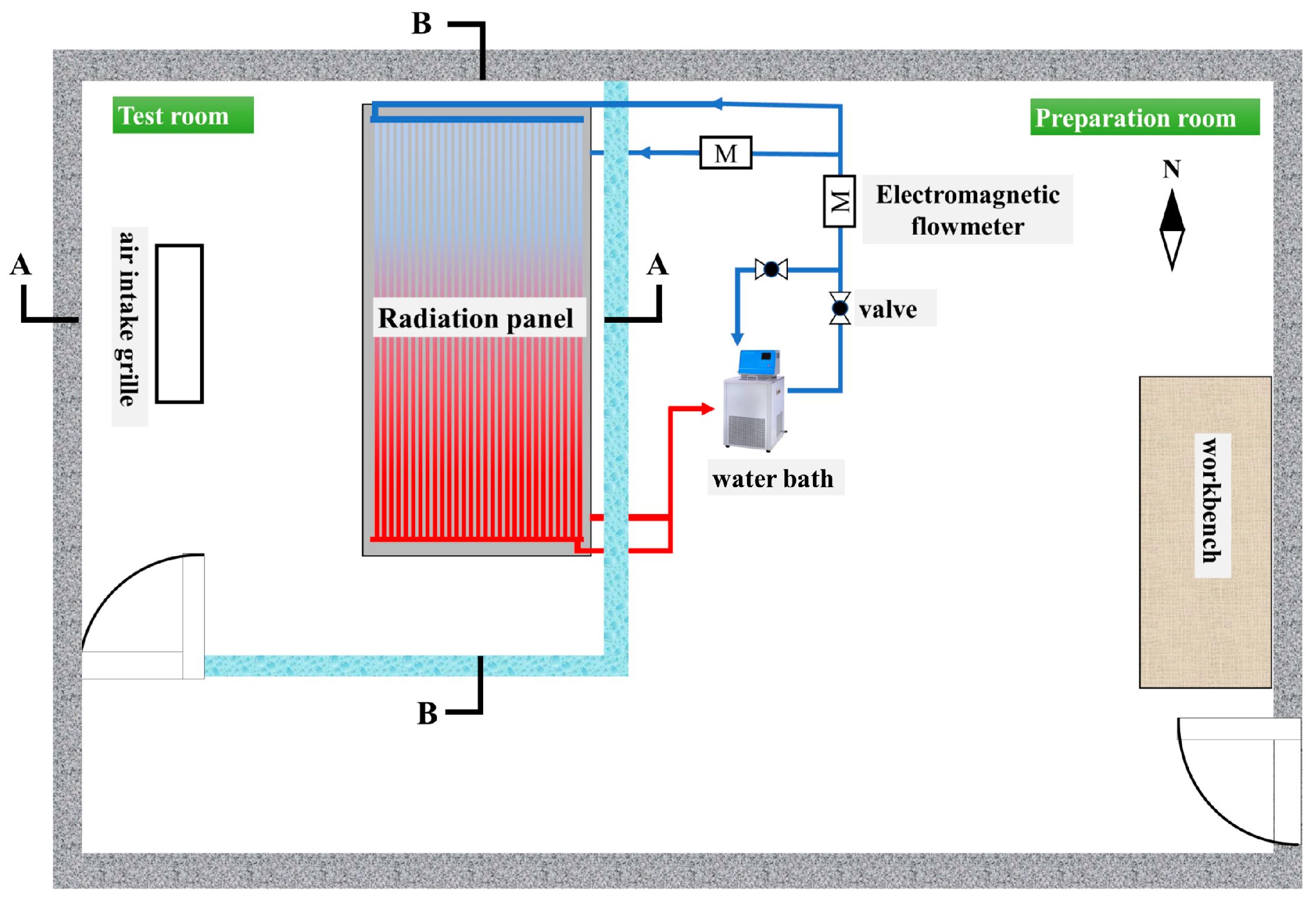

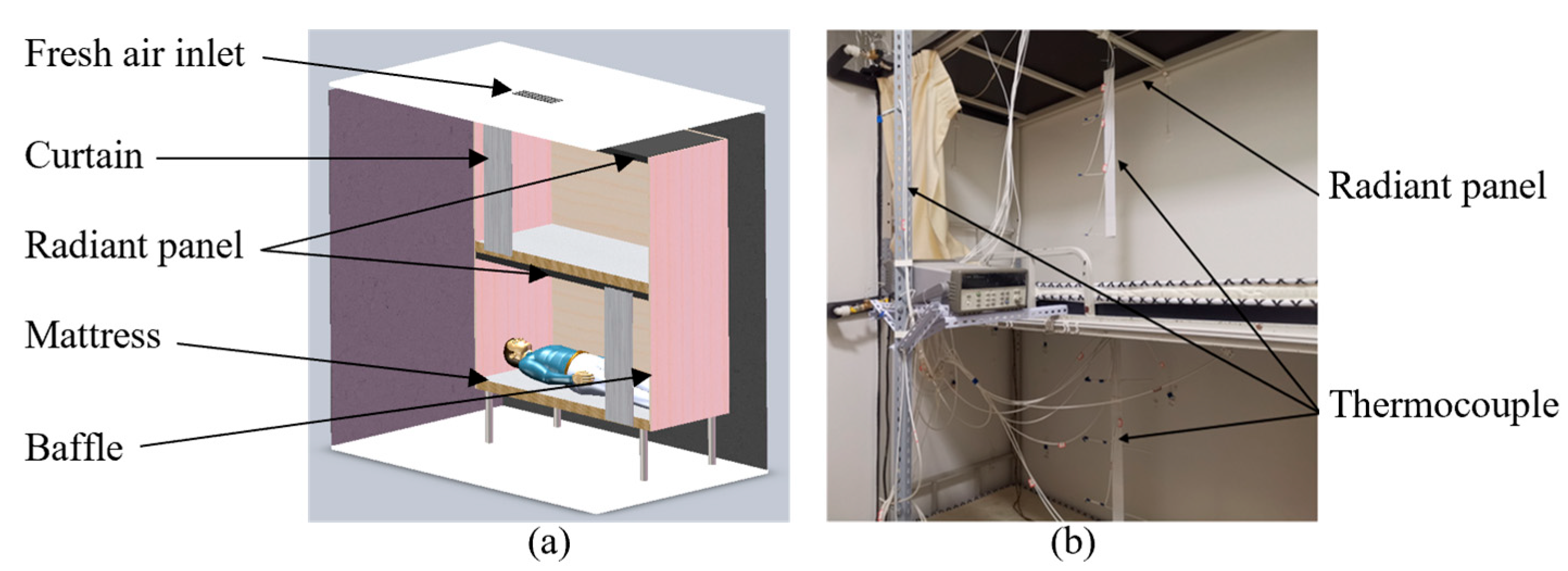

2.1. Experimental Setup

2.2. Measurements

- (1)

- Surface temperature of the envelope within the berth area: The T-thermocouple probes were attached to the surface of the envelope in the berth area using foam tape for surface temperature measurements and distributed at the center of each of the six faces in the berth area.

- (2)

- Air temperature: measurement brackets were installed in each area of the test chamber to hold T-type thermocouple probes to measure the air temperature. These points were located in the horizontal center of the area. Figure 4 shows the arrangement of air temperature measurement points from the A-A and B-B views (indicated in Figure 1), respectively. The relative humidity of the air was measured by Bluetooth Thermo hygrometers attached to the berth area and the corridor area, respectively.

- (3)

- Inlet and outlet water temperature: The inlet and outlet of the radiant panel were fitted with thermocouple sleeves in which T-type thermocouple probes were placed and filled with thermally conductive silicone grease to measure the capillary inlet and outlet temperatures.

- (4)

- Water supply flow: Electromagnetic flow meters were installed in series in the system’s water supply trunk and lower bunk water supply bypass, respectively, to monitor the water supply flow in the upper and lower bunk capillaries.

- (5)

- Human skin temperature: The local skin temperature of the individuals was measured using a Thermotron button thermometer, i.e., iButton® DS1922L. (Analog Devices, San Jose, CA, USA) A four local skin temperatures (right upper arm, left chest, right thigh front, and right calf front) method was used to identify the mean skin temperature in the tests.

- (6)

- Airflow velocity in the berth area: The hot-wire anemometer was used to measure the airflow velocity in the berth area. During the tests, the hot-wire anemometers were fixed in the center of the berth area, and the monitored data were transmitted wirelessly via Bluetooth, which could be observed and recorded by the experimenters in real time.

2.3. Calculation of Environment Indexes and the Mean Skin Temperature

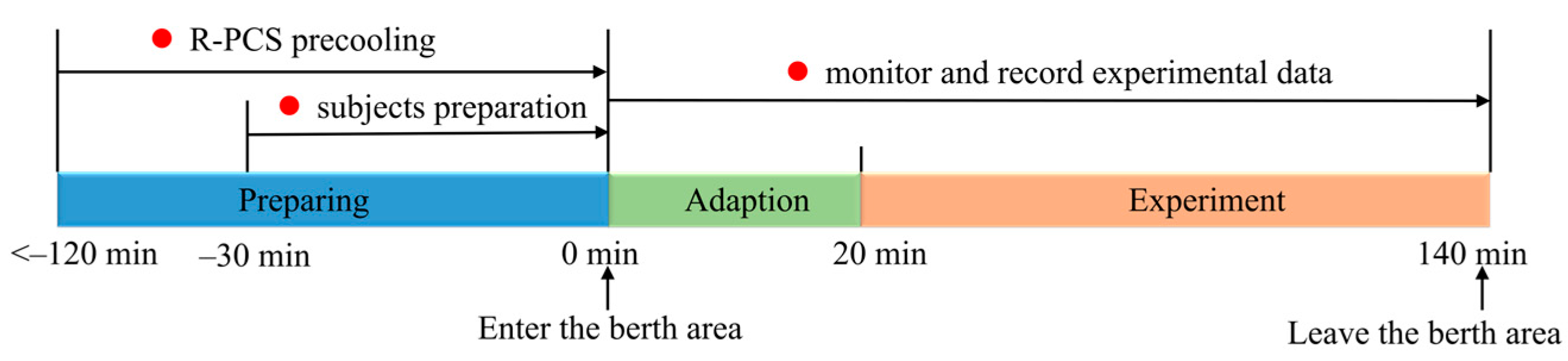

2.4. Experimental Procedure

2.5. Subjects

2.6. Experimental Cases

2.7. Statistical Analysis

3. Results

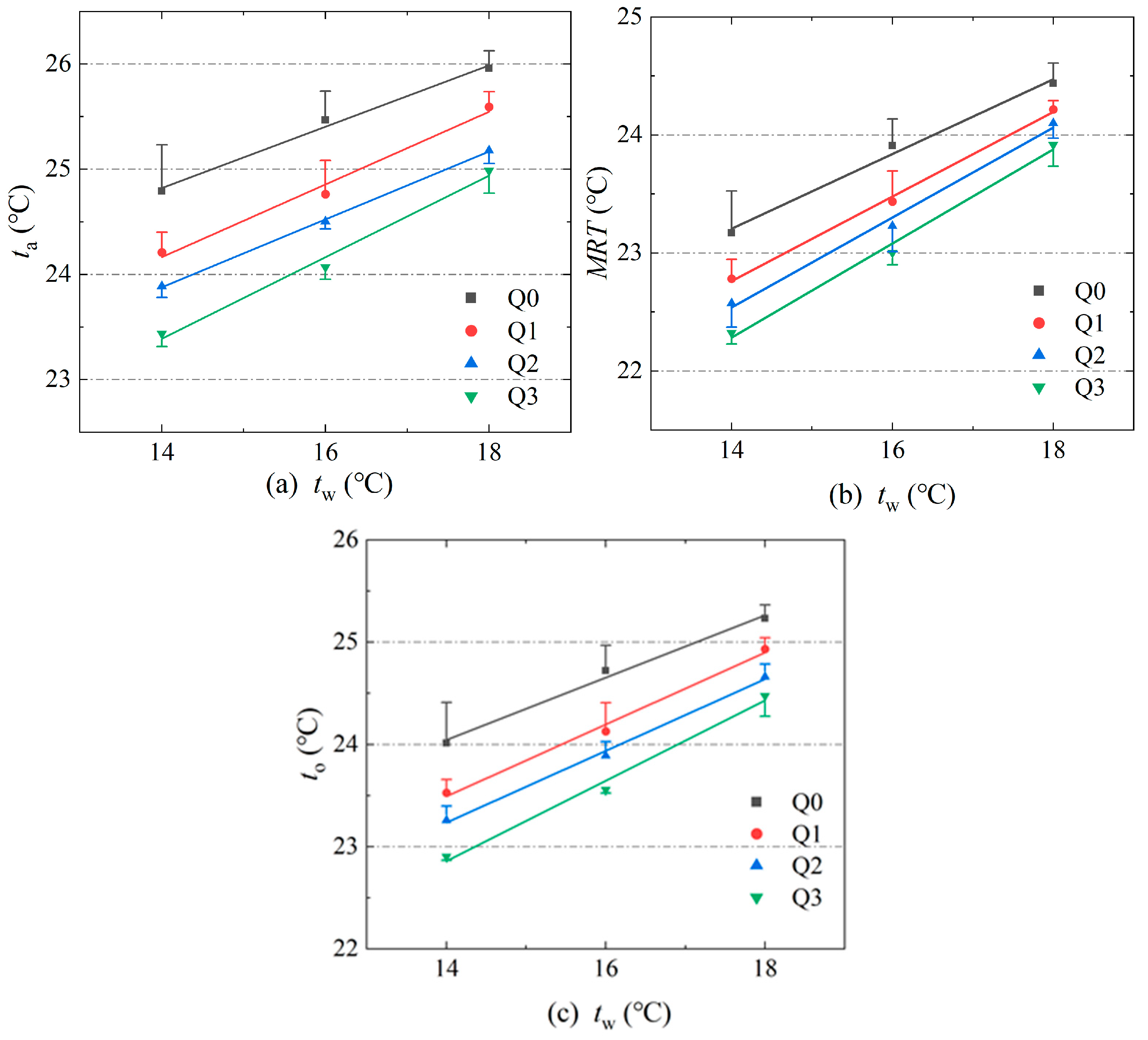

3.1. Thermal Environment Temperature Index

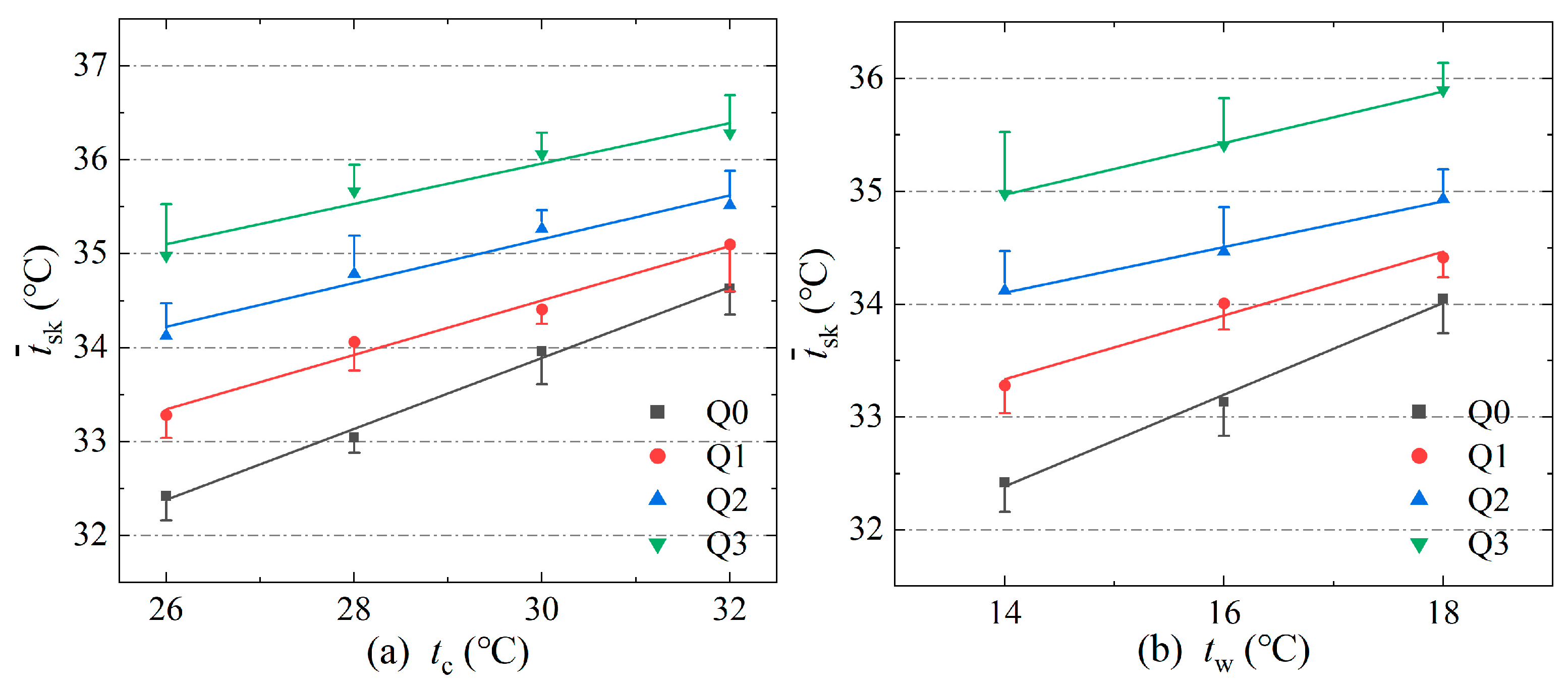

3.2. Human Skin Temperature

4. Discussion

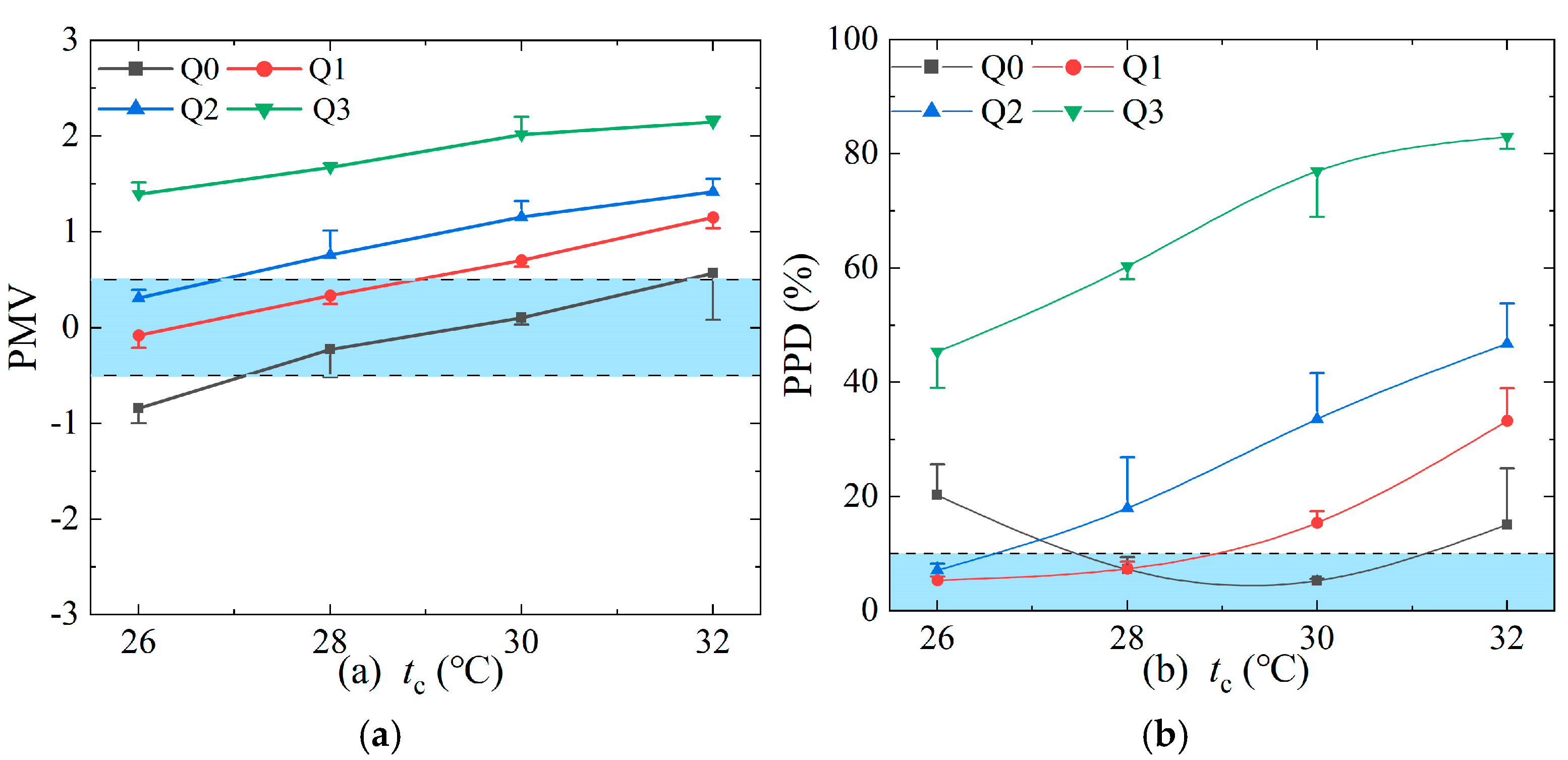

4.1. Objective Evaluation of Human Thermal Comfort

4.2. Energy-Saving Analysis

4.3. Limitations

5. Conclusions

- (1)

- Under the same covering conditions, the air temperature, radiation temperature, operating temperature in the berth area, and human skin temperature during the test are positively and linearly related to the water supply temperature and corridor area temperature, respectively.

- (2)

- Through the PMV–PPD index of the human body under different experimental operating conditions, it was revealed that the higher water supply temperature, corridor area temperature, and insulation of quilts could lead to a higher human thermal sensation. The experimental conditions that are close to thermal neutrality are (1) Rt = 0.28 (m2·K)/W, tw = 14 °C, tc = 26 °C; (2) Rt = 0.28 (m2·K)/W, tw = 16 °C, tc = 26 °C.

- (3)

- The experimental condition (Rt = 0.28 (m2·°C)/W, tw = 14 °C, tc = 26 °C) that reached the specification-recommended thermal neutrality was analyzed for its energy efficiency. It was found that the R-PCS can save 20.6% of energy compared with conventional air conditioning systems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Boor, B.E.; Spilak, M.P.; Laverge, J.; Novoselac, A.; Xu, Y. Human exposure to indoor air pollutants in sleep microenvironments: A literature review. Build. Environ. 2017, 125, 528–555. [Google Scholar] [CrossRef]

- Cui, Y.; Wang, Y.P.; Zhu, L. Performance analysis on a building–integrated solar heating and cooling panel. Renew. Energy 2015, 74, 627–632. [Google Scholar] [CrossRef]

- Wang, Z.H.; Cao, B.; Zhu, Y.X. Questionnaire survey and field investigation on sleep thermal comfort and behavioral adjustments in bedrooms of Chinese residents. Energy Build. 2021, 253, 111462. [Google Scholar] [CrossRef]

- Ismail, O.A.; Kassem, M.A.; Hassan, M.A. Sleeping pods with radiant cooling panels: A first assessment of thermal comfort and cooling capacity. Energy Build. 2021, 250, 111282. [Google Scholar] [CrossRef]

- Aryal, A.; Chaiwiwatworakul, P.; Chirarattananon, S. An experimental study of thermal performance of the radiant ceiling cooling in office building in Thailand. Energy Build. 2023, 283, 112849. [Google Scholar] [CrossRef]

- Chen, J.B.; Yu, H.Z.; Liu, G. The Comparison of Cooling Performance Between New-type Capillary Radiant Panel and Traditional Radiant Panel. In Proceedings of the 8th International Symposium on Heating, Ventilation and Air Conditioning, Xi’an, China, 19–21 October 2013; Volume 262, pp. 317–325. [Google Scholar] [CrossRef]

- Guo, Y.L.; Wu, H.J.; Du, K.; Huang, G.S.; Xu, X.H. Experimental study on radiant cooling with double-skin infrared-transparent membranes. Energy Build. 2023, 278, 112654. [Google Scholar] [CrossRef]

- Shin, M.S.; Rhee, K.N.; Park, S.H.; Yeo, M.S.; Kim, K.W. Enhancement of cooling capacity through open-type installation of cooling radiant ceiling panel systems. Build. Environ. 2019, 148, 417–432. [Google Scholar] [CrossRef]

- Choi, J.S.; Jung, G.J.; Rhee, K.N. Cooling performance evaluation of a fan–assisted ceiling radiant cooling panel system. Energy Build. 2023, 281, 112760. [Google Scholar] [CrossRef]

- Liang, Y.Y.; Zhang, N.; Wu, H.J.; Xu, X.H.; Du, K.; Yang, J.M.; Sun, Q.; Dong, K.J.; Huang, G.S. Thermal environment and thermal comfort built by decoupled radiant cooling units with low radiant cooling temperature. Build. Environ. 2021, 206, 108342. [Google Scholar] [CrossRef]

- Jia, H.Y.; Pang, X.F.; Haves, P. Experimentally-determined characteristics of radiant systems for office buildings. Appl. Energy 2018, 221, 41–54. [Google Scholar] [CrossRef]

- Wang, D.J.; Chen, P.H.; Liu, Y.F.; Wu, C.J.; Liu, J.P. Heat transfer characteristics of a novel sleeping bed with an integrated hot water heating system. Appl. Therm. Eng. 2017, 113, 79–86. [Google Scholar] [CrossRef]

- Kim, B.Y.; Ham, Y. Personal thermal comfort modeling based on facial expression. J. Build. Eng. 2023, 75, 106956. [Google Scholar] [CrossRef]

- Song, W.F.; Zhang, C.J.; Lai, D.D.; Wang, F.M.; Kuklane, K. Use of a novel smart heating sleeping bag to improve wearers’ local thermal comfort in the feet. Sci. Rep. 2016, 6, 19326. [Google Scholar] [CrossRef]

- Xue, W.P.; Zhang, G.F.; Chen, L.; Li, K.J. Developing a novel personal thermoelectric comfort system for improving indoor occupant’s thermal comfort. J. Build. Eng. 2024, 84, 108561. [Google Scholar] [CrossRef]

- Zhang, H.; Arens, E.; Zhai, Y.C. A review of the corrective power of personal comfort systems in non–neutral ambient environments. Build. Environ. 2015, 91, 15–41. [Google Scholar] [CrossRef]

- Ismail, N.; Ouahrani, D. Modelling of cooling radiant cubicle for an office room to test cooling performance, thermal comfort and energy savings in hot climates. Energy 2022, 244, 123185. [Google Scholar] [CrossRef]

- Pan, D.M.; Chan, M.Y.; Xia, L.; Xu, X.G.; Deng, S.M. Performance evaluation of a novel bed-based task/ambient conditioning (TAC) system. Energy Build. 2012, 44, 54–62. [Google Scholar] [CrossRef]

- Mao, N.; Pan, D.M.; Chan, M.Y.; Deng, S.M. Experimental and numerical studies on the performance evaluation of a bed-based task/ambient air conditioning (TAC) system. Appl. Energy 2014, 136, 956–967. [Google Scholar] [CrossRef]

- Du, J.; Chan, M.Y.; Deng, S.M. An experimental study on the performances of a radiation–based task/ambient air conditioning system applied to sleeping environments. Energy Build. 2017, 139, 291–301. [Google Scholar] [CrossRef]

- Cao, T.; Lian, Z.W.; Ma, S.; Bao, J.K. Thermal comfort and sleep quality under temperature, relative humidity and illuminance in sleep environment. J. Build. Eng. 2021, 43, 102575. [Google Scholar] [CrossRef]

- Cao, T.; Lian, Z.W.; Zhu, J.W.; Xu, X.B.; Du, H.; Zhao, Q.T. Parametric study on the sleep thermal environment. Build. Simulat. 2021, 15, 885–898. [Google Scholar] [CrossRef]

- Lan, L.; Pan, L.; Lian, Z.W.; Huang, H.Y.; Lin, Y.B. Experimental study on thermal comfort of sleeping people at different air temperatures. Build. Environ. 2014, 73, 24–31. [Google Scholar] [CrossRef]

- Xin, Y.L.; Cui, W.Z.; Zeng, J.K. Experimental study on thermal comfort in a confined sleeping environment heating with capillary radiation panel. Energy Build. 2019, 205, 109540. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, N.; Cao, B.; Zhu, Y.X. Thermal sensation and sleep quality in different combinations of indoor air temperature and bedding system conditions. Build. Environ. 2023, 243, 110729. [Google Scholar] [CrossRef]

- Pan, D.M.; Lin, Z.P.; Mao, N.; Song, M.J. A study on the effects of different bedding systems on thermal comfort—Quantifying the sensitivity coefficient used for calculating Predicted Mean Vote (PMV) in sleeping environments. Energy Procedia 2017, 142, 1939–1946. [Google Scholar] [CrossRef]

- Lin, Z.P.; Deng, S.M. A study on the thermal comfort in sleeping environments in the subtropics—Measuring the total insulation values for the bedding systems commonly used in the subtropics. Build. Environ. 2008, 43, 905–916. [Google Scholar] [CrossRef]

- Yan, F.Y.; Zheng, Q.; Ke, Y. Effect of quilt thermal resistance on bedding system and sleep thermal comfort. J. Therm. Biol. 2023, 117, 103713. [Google Scholar] [CrossRef]

- Zhang, N.; Cao, B.; Wang, Z.H.; Zhu, Y.X. Effects of bedding insulation and indoor temperature on bed microclimate and thermal comfort. Energy Build. 2020, 233, 110097. [Google Scholar] [CrossRef]

- Horikoshi, T.; Kobayashi, Y. Configuration factors between a rectangular solid as a model of the human body and rectangular planes, for evaluation of the influence of thermal radiation on the human body: I. calculation of configuration factors for the rectangular solids. Trans. Archit. Inst. Jpn. 1977, 253, 91–102. [Google Scholar] [CrossRef]

- Nagano, K.; Mochida, T. Experiments on thermal environmental design of ceiling radiant cooling for supine human subjects. Build. Environ. 2004, 39, 267–275. [Google Scholar] [CrossRef]

- ASHRAE. ASHRAE Handbook of Fundamentals (SI); ASHRAE: Atalanta, GA, USA, 2021. [Google Scholar]

- Colin, J.; Houdas, Y. Experimental determination of coefficient of heat exchanges by convection of human body. J. Appl. Physiol. 1967, 22, 31–38. [Google Scholar] [CrossRef] [PubMed]

- Nadel, E.R.; Mitchell, J.W.; Stolwijk, J.A. Differential thermal sensitivity in human skin. Pflug. Arch. 1973, 340, 71–76. [Google Scholar] [CrossRef]

- Liu, W.W.; Lian, Z.W.; Deng, Q.H.; Liu, Y.M. Evaluation of calculation methods of mean skin temperature for use in thermal comfort study. Build. Environ. 2011, 46, 478–488. [Google Scholar] [CrossRef]

- Lan, L.; Lian, Z.W.; Qian, X.L.; Dai, C.Z. The effects of programmed air temperature changes on sleep quality and energy saving in bedroom. Energy Build. 2016, 129, 207–214. [Google Scholar] [CrossRef]

- Pan, D.M.; Lin, Z.P.; Deng, S.M. A mathematical model for predicting the total insulation value of a bedding system. Build. Environ. 2010, 45, 1866–1872. [Google Scholar] [CrossRef]

- ISO 7730:2005; Ergonomics of the Thermal Environment–Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. International Organization for Standardization: Geneva, Switzerland, 2005.

- Lin, Z.P.; Deng, S.M. A study on the thermal comfort in sleeping environments in the subtropics—Developing a thermal comfort model for sleeping environments. Build. Environ. 2008, 43, 70–81. [Google Scholar] [CrossRef]

- Liu, W.W.; Lian, Z.W.; Deng, Q.H. Use of mean skin temperature in evaluation of individual thermal comfort for a person in a sleeping posture under steady thermal environment. Indoor Built Environ. 2015, 24, 489–499. [Google Scholar] [CrossRef]

- Lan, L.; Xia, L.L.; Tang, J.Y.; Wyon, D.P.; Liu, H. Mean skin temperature estimated from 3 measuring points can predict sleeping thermal sensation. Build. Environ. 2019, 162, 106292. [Google Scholar] [CrossRef]

- Song, C.; Zhao, T.T.; Song, Z.Y.; Liu, Y.F. Effects of phased sleeping thermal environment regulation on human thermal comfort and sleep quality. Build. Environ. 2020, 181, 107108. [Google Scholar] [CrossRef]

- Fanger, P.O. Thermal Comfort; Danish Technical Press: Copenhagen, Denmark, 1970. [Google Scholar]

- Lu, Y.Q. Practical Heating, Ventilation, and Air Conditioning Design Manual; China Architecture & Building Press: Beijing, China, 2008. (In Chinese) [Google Scholar]

- Hoyt, T.; Arens, E.; Zhang, H. Extending air temperature setpoints: Simulated energy savings and design considerations for new and retrofit buildings. Build. Environ. 2015, 88, 89–96. [Google Scholar] [CrossRef]

- Tsang, T.W.; Mui, K.W.; Wong, L.T. Investigation of thermal comfort in sleeping environment and its association with sleep quality. Build. Environ. 2021, 187, 107406. [Google Scholar] [CrossRef]

- Pan, L.; Lian, Z.W.; Lan, L. Investigation of Gender Differences in Sleeping Comfort at Different Environmental Temperatures. Indoor Built Environ. 2012, 21, 811–820. [Google Scholar] [CrossRef]

- Tang, Y.; Yu, H.; Mao, H.; Zhang, K.; Wang, M. Indoor thermal comfort and ageing: A systematic review. J. Build. Eng. 2025, 100, 111714. [Google Scholar] [CrossRef]

- Wakamura, T.; Tokura, H. Circadian rhythm of rectal temperature in humans under different ambient temperature cycles. J. Therm. Biol. 2002, 27, 439–447. [Google Scholar] [CrossRef]

- Candas, V.; Libert, J.P.; Muzet, A. Heating and cooling stimulations during SWS and REM sleep in man. J. Therm. Biol. 1982, 7, 155–158. [Google Scholar] [CrossRef]

- Jennings, J.R.; Reynolds, C.F.; Bryant, D.S.; Berman, S.R.; Buysse, D.J.; Dahl, R.E.; Hoch, C.C.; Monk, T.H. Peripheral thermal responsivity to facial cooling during sleep. Psychophysiology 1993, 30, 374–382. [Google Scholar] [CrossRef]

- Lan, L.; Qian, X.L.; Lian, Z.W.; Lin, Y.B. Local body cooling to improve sleep quality and thermal comfort in a hot environment. Indoor Air 2017, 28, 135–145. [Google Scholar] [CrossRef]

- Zhao, K.; Liu, X.H.; Jiang, Y. Application of radiant floor cooling in large space buildings—A review. Renewable Sustainable Energy Rev. 2016, 55, 1083–1096. [Google Scholar] [CrossRef]

- Imanari, T.; Omori, T.; Bogaki, K. Thermal comfort and energy consumption of the radiant ceiling panel system: Comparison with the conventional all–air system. Energy Build. 1999, 30, 167–175. [Google Scholar] [CrossRef]

- Antonopoulos, K.A.; Vrachopoulos, M.; Tzivanidis, C. Experimental evaluation of energy savings in air-conditioning using metal ceiling panels. Appl. Therm. Eng. 1988, 18, 1129–1138. [Google Scholar] [CrossRef]

| Instruments | Instrument Model | Measuring Range | Precision |

|---|---|---|---|

| Thermocouple | TT–T–30–SLE | −200~150 °C | ±0.1 °C |

| Button thermometer | iButton DS1922L | −40~85 °C | ±0.5 °C |

| Electromagnetic flowmeter | CKLDG–D20–W | 0.1~15 m/s | ±0.5% |

| Hot-wire anemometer | Testo–405i | 0~30 m/s | ±(0.1 m/s + 5%rdg) (0–2 m/s) ±(0.3 m/s + 5%rdg) (2–15 m/s) |

| Hygrometer | COS–03–5 | −40~80 °C 0~100% RH | ±0.1 °C ±1.5% RH |

| Type of Air Conditioner | Area | COP | Cooling Load/W | Energy Consumption /W | Energy Saving/% |

|---|---|---|---|---|---|

| Conventional | Entire space | 2.50 | 386.4 | 154.6 | 20.6% |

| R-PCS | Corridor area | 2.50 | 274.4 | 98.8 | |

| Berth area | 3.20 | 76.6 | 23.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, W.; Cui, W.; Li, Y.; Wu, X. Experimental Evaluation of a Radiant Panel System for Enhancing Sleep Thermal Comfort and Energy Efficiency. Energies 2025, 18, 2724. https://doi.org/10.3390/en18112724

Xiang W, Cui W, Li Y, Wu X. Experimental Evaluation of a Radiant Panel System for Enhancing Sleep Thermal Comfort and Energy Efficiency. Energies. 2025; 18(11):2724. https://doi.org/10.3390/en18112724

Chicago/Turabian StyleXiang, Wanfu, Wenzhi Cui, Yongwei Li, and Xiang Wu. 2025. "Experimental Evaluation of a Radiant Panel System for Enhancing Sleep Thermal Comfort and Energy Efficiency" Energies 18, no. 11: 2724. https://doi.org/10.3390/en18112724

APA StyleXiang, W., Cui, W., Li, Y., & Wu, X. (2025). Experimental Evaluation of a Radiant Panel System for Enhancing Sleep Thermal Comfort and Energy Efficiency. Energies, 18(11), 2724. https://doi.org/10.3390/en18112724