Research Progress and Future Prospects of Brake-by-Wire Technology for New Energy Vehicles

Abstract

1. Introduction

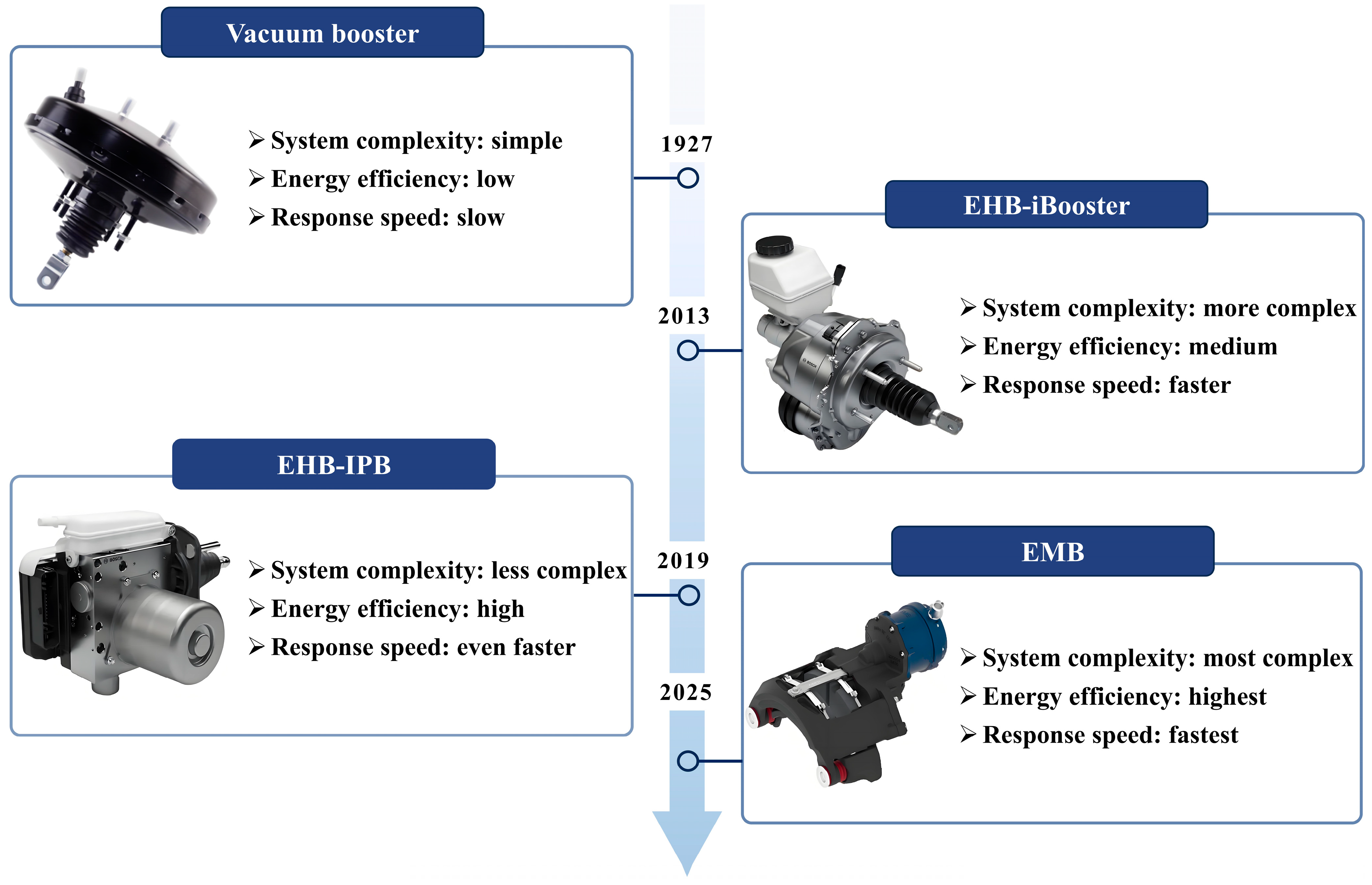

2. A Classification and Structural Analysis of the BBW System

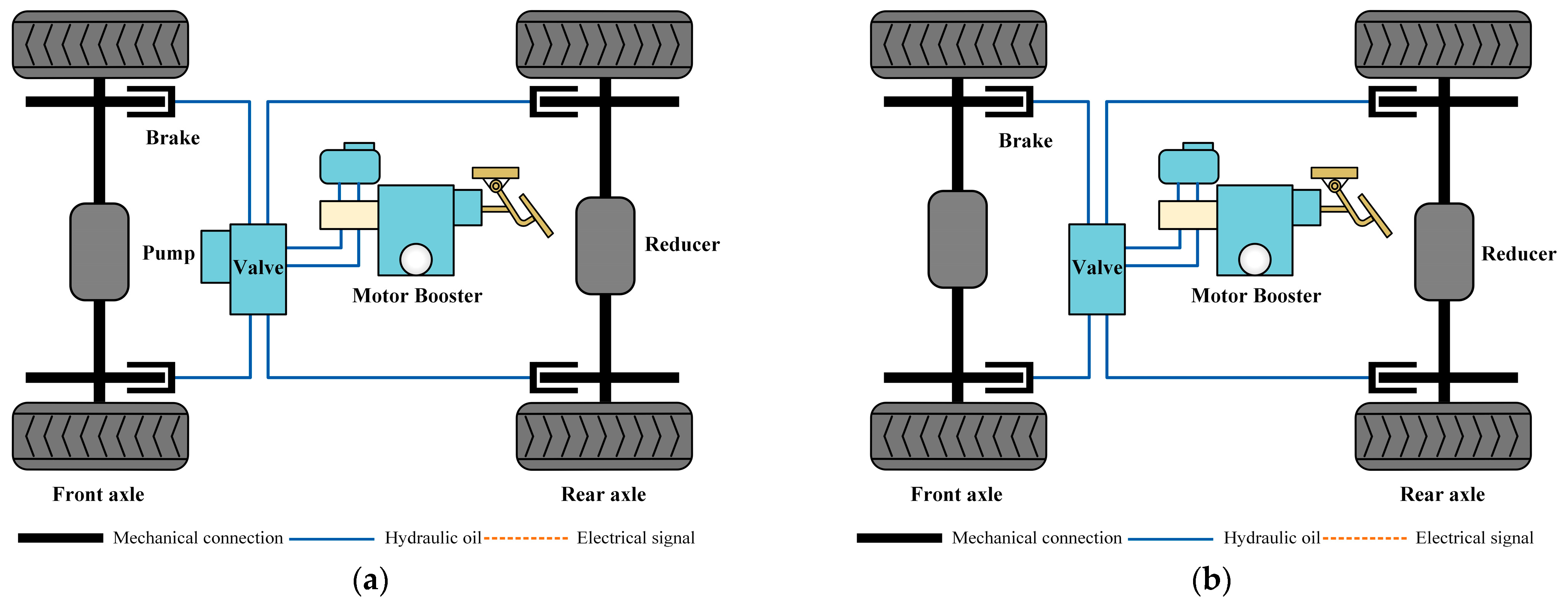

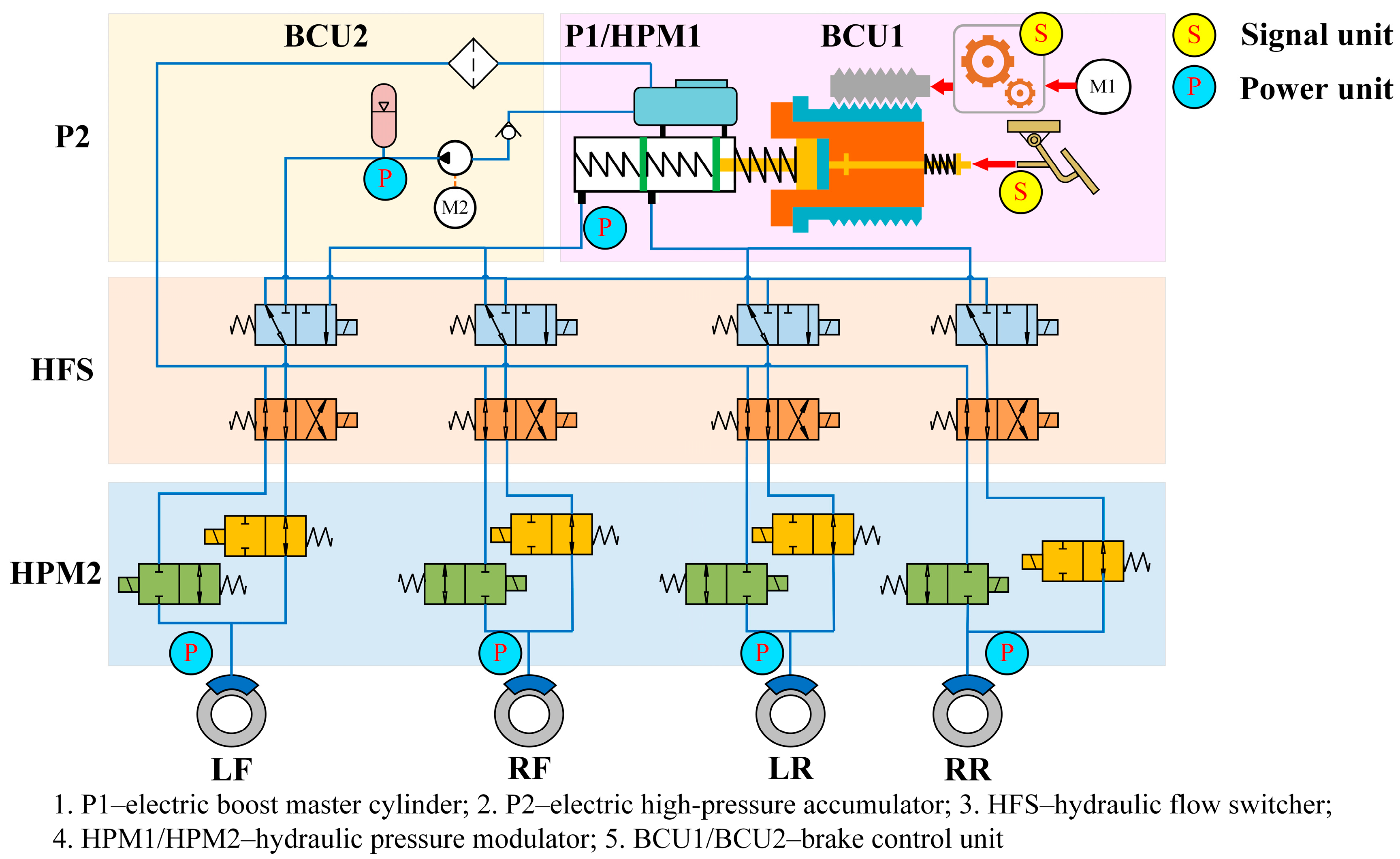

2.1. Electro-Hydraulic Braking System

2.2. Electro-Mechanical Braking System

- (1)

- The system lacks a redundancy design, resulting in reduced safety.

- (2)

- Due to spatial constraints, the motors used are relatively small, making it difficult to generate sufficient braking force.

- (3)

- The motors operate under complex conditions, requiring additional costs to improve reliability, such as an enhanced heat resistance and electromagnetic interference protection.

2.3. Regenerative Braking System

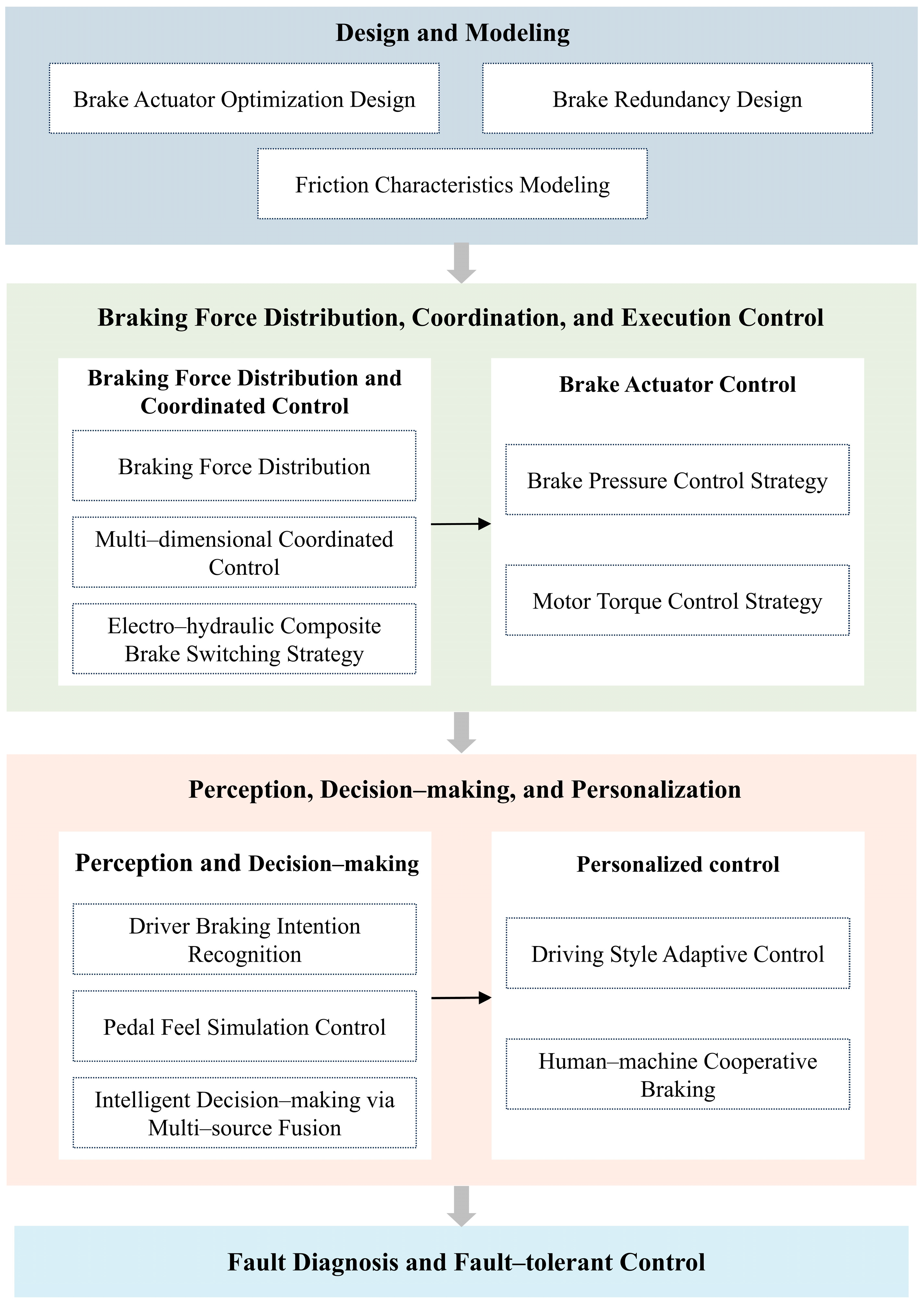

3. Key Technologies of the BBW System

3.1. The Design and Modeling of the BBW System

3.1.1. Optimal Design of the Brake Actuator

3.1.2. Brake Redundancy Design

3.1.3. Friction Characteristics Modeling

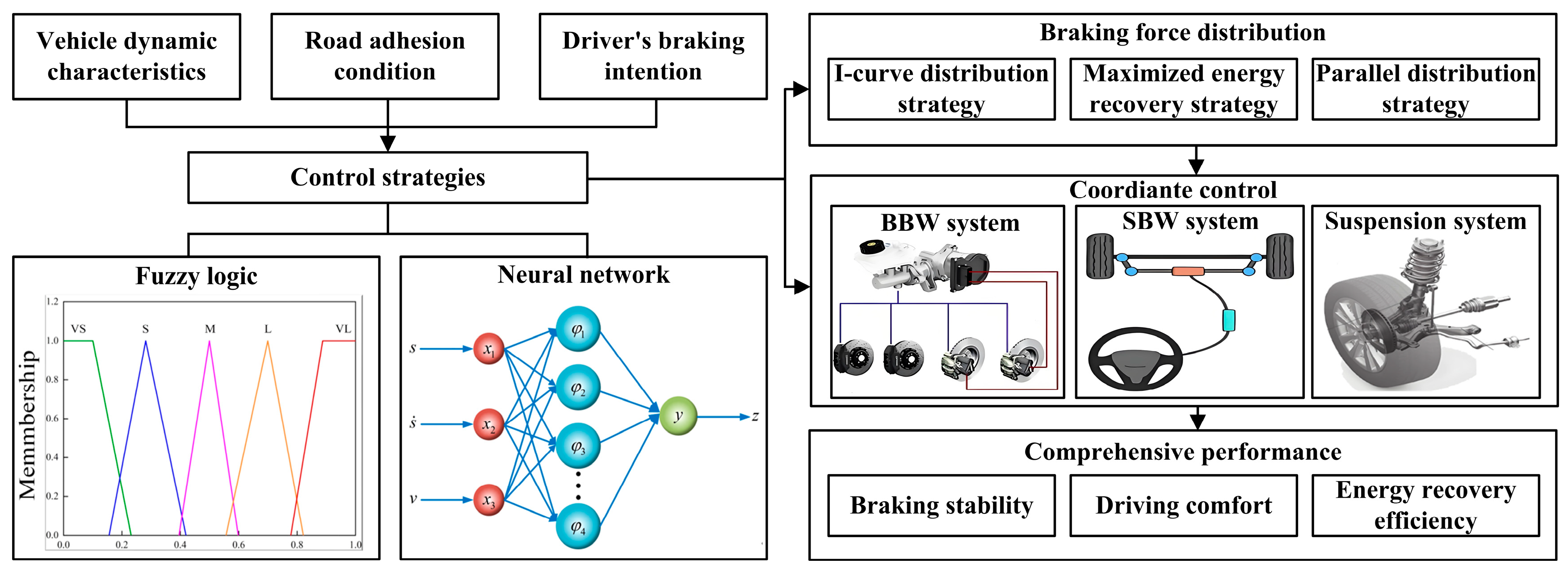

3.2. The Braking Force Distribution and the Coordinated Control of the BBW System

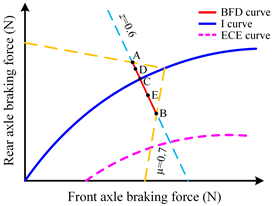

3.2.1. Braking Force Distribution

| Braking Force Distribution Strategy | Characteristic Curve | Distribution Principle |

|---|---|---|

| I-curve distribution strategy |  | If z ≤ 0.15, in the AB segment, the braking force is provided by the front axle; otherwise, in the BE segment, the braking force is distributed according to the I-line. |

| Maximized energy recovery strategy |  | If the motor’s maximum braking force is less than the front axle’s, braking force is distributed at point C; if greater, at point E; otherwise, at point B. |

| Parallel distribution strategy |  | If z < 0.1, braking force is provided by the front axle and distributed in the AB segment; if 0.1 ≤ z < 0.5, in BC; if 0.5 ≤ z < 0.7, in CD; if z ≥ 0.7, in DE. |

| Control Strategies | Energy Recovery Efficiency | Reference |

|---|---|---|

| Multi-energy recovery mode | Energy recovery efficiency improved by 15.8% compared to the baseline mode | [64] |

| Double layers multi-parameters | There is a 16.91% increase in energy recovery efficiency over the parallel RB strategy | [65] |

| Swarm intelligence-based MPC strategy | Compared to the rule-based strategy, energy recovery efficiency increased by 17% | [66] |

3.2.2. Multi-Dimensional Coordinated Control

3.2.3. Switching Strategy for Electro-Hydraulic Composite Braking

3.3. The Control of Brake Actuators in the BBW System

3.3.1. Brake Pressure Control Strategies

3.3.2. Motor Torque Control Strategies

3.4. Perception and Decision-Making in the BBW System

3.4.1. Driver Braking Intention Recognition

3.4.2. Pedal Feel Emulation Control

3.4.3. Intelligent Decision-Making Based on Multi-Source Information Fusion

3.5. The Personalized Control of the BBW System

3.5.1. Driving Style Adaptive Control

3.5.2. Human–Machine Cooperative Control

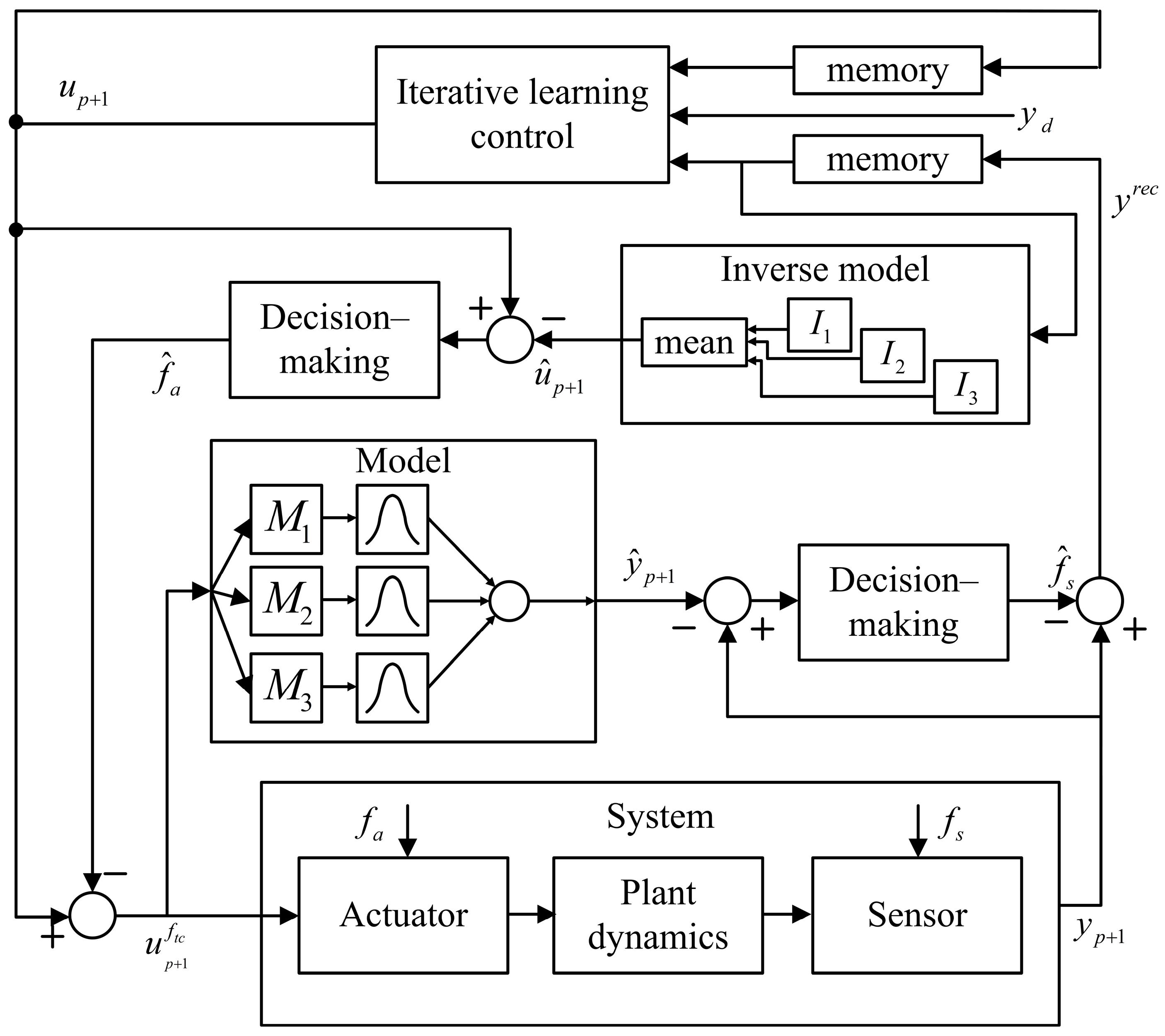

3.6. The Fault Diagnosis and Fault-Tolerant Control of the BBW System

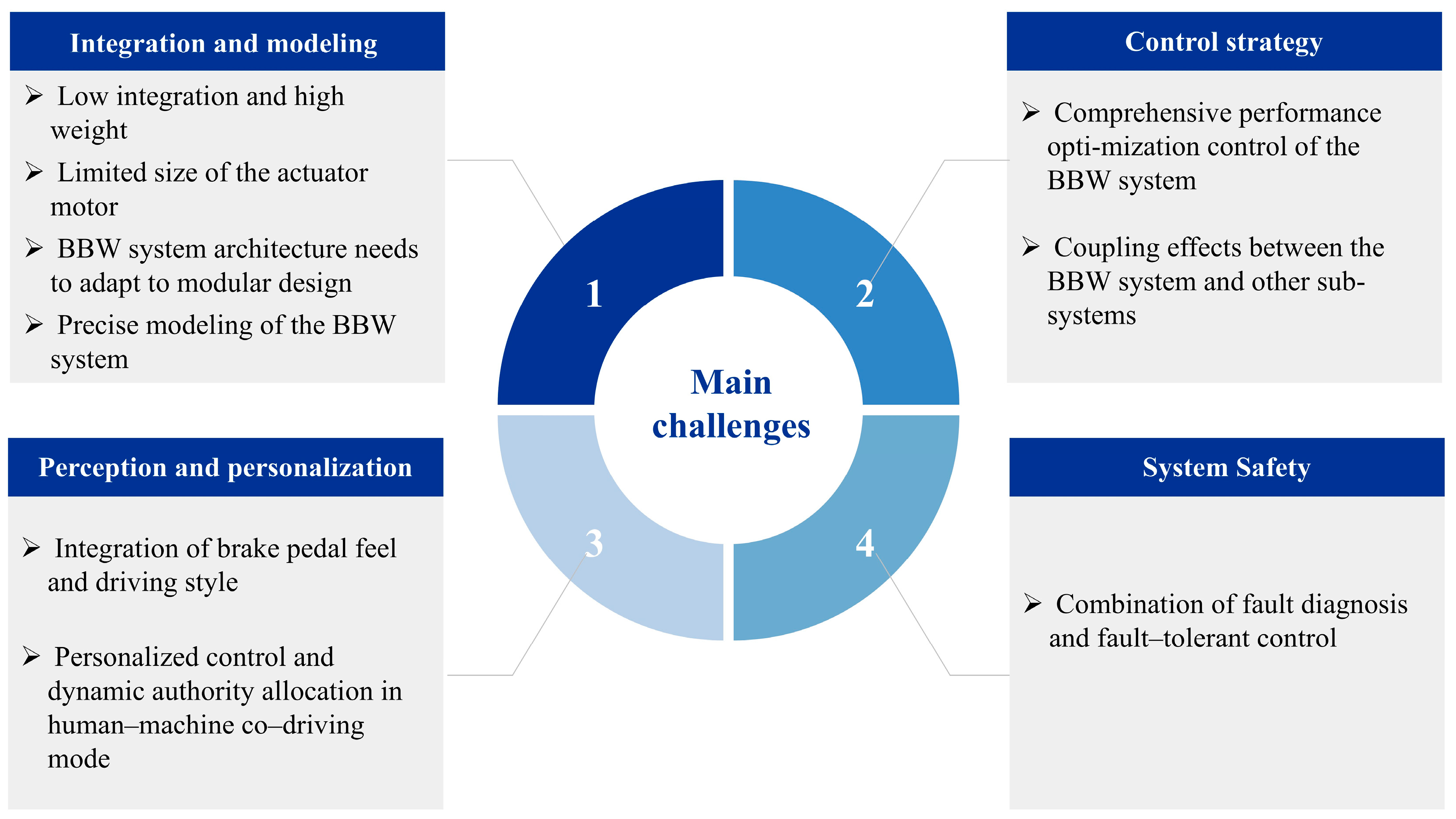

4. Challenges and Future Trends of the BBW System

- (1)

- Hardware integration optimization and accurate modeling: Under the limited chassis space constraints of new energy vehicles, the BBW system has put forward higher requirements for hardware integration. At present, EHB is more mature than other BBW system technologies. However, because it relies on traditional hydraulic components, such as brake lines, master cylinders, and even the pump-driven accumulator, EHB requires the additional integration of hydraulic pumps and accumulators, and the overall system integration is lower and the weight is higher. In contrast, the EMB system offers better integration. However, the size of the executing motor is constrained due to the limited installation space of the wheels, making it difficult to provide sufficient braking torque. In addition, to meet the safety requirements of autonomous driving, redundant braking designs (such as EHB backup pipelines or EMB backup motors) inevitably increase the system weight and cost, which is not conducive to the lightweight design of new energy vehicles. Therefore, future research will focus on optimizing hardware integration to improve the spatial layout efficiency of BBW systems, reduce coordination difficulties between subsystems, and decrease the system size and weight, enabling the centralized management of upper-level control strategies. A key research direction will be the development of BBW system architectures that adapt to automotive modular (corner module) designs, ensuring a high integration while maintaining the braking performance. On the other hand, as the BBW system is a typical nonlinear electro-mechanical (or electro-mechanical–hydraulic) coupled system, it exhibits complex characteristics, such as nonlinear friction and time-varying parameters, during its operation. Accurate modeling must fully account for these factors to achieve an optimal control performance. Therefore, establishing mathematical models that can accurately reflect system characteristics will be the key to future research, and it is crucial for formulating and implementing better control strategies.

- (2)

- The optimization and upgrading of control strategies: The optimization and upgrading of braking control strategies are key to improving the overall performance of new energy vehicles. As a core component for ensuring driving safety, braking strategies should not only provide a fast response and high-precision control but also enable efficient regenerative braking to extend the vehicle range. In addition, the BBW system should ensure smooth braking transitions to deliver a more comfortable experience for drivers and passengers. However, as technical requirements in the industry continue to rise, traditional control strategies, such as PID and fuzzy control, have become insufficient to meet the current diversified development demands. It is urgent to introduce more advanced intelligent control algorithms to achieve technological breakthroughs. At the same time, there is a coupling effect between the BBW system and other X-by-wire chassis subsystems. Achieving a coordinated optimization of the safety, energy recovery efficiency, and ride comfort often requires the collaboration of multiple chassis subsystems, which can lead to conflicts among control functions and compromise the overall system performance. Therefore, future research on braking control strategies for new energy vehicles will focus on introducing more intelligent control algorithms, such as deep reinforcement learning algorithms, to coordinate the BBW system with other subsystems. This method aims to deliver a superior control performance compared to standalone BBW systems, ultimately achieving an optimal balance between braking safety, energy recovery efficiency, and driving comfort.

- (3)

- Pedal perception emulation and personalized control integrating driving styles: As a key component of the perception layer of the BBW system, pedal feel emulation control is gradually evolving toward a fully decoupled design. This means that the system uses independent simulation mechanisms to dynamically replicate the characteristics of traditional brake pedals, including pedal stroke damping and force feedback gradients, to ensure that the driver’s operating experience is consistent with traditional braking systems. However, due to individual differences among drivers, braking habits vary widely, and traditional pedal characteristics do not account for different driving styles. In addition, the current control architecture of ADASs still focuses on optimizing vehicle performance. In the human–machine co-driving mode, the dynamic allocation of control authority requires the further integration of driving style recognition and personalized control strategies. Therefore, future research on BBW systems should focus on establishing brake pedal perception standards that incorporate driving style characteristics, developing quantitative evaluation methods based on human–machine interactions and driving behavior patterns, and designing personalized control systems that enable intelligent matching between control strategies and individual driver behaviors, thereby comprehensively improving the personalization of the driving experience and the intelligence level of the human–machine interaction.

- (4)

- Fault diagnosis and fault-tolerant control integration architecture for the BBW system: Although traditional hardware redundancy schemes can improve system reliability, they also increase the cost, curb weight, and energy consumption of new energy vehicles. With the continuous development of BBW technology, such redundant designs will gradually be simplified or even completely replaced. However, the increasing electrification of new energy vehicles also brings higher fault risks, making fault-tolerant control systems more critical than ever. As a prerequisite for fault-tolerant control, fault diagnosis is essential to ensuring the stability of BBW systems. Whether sensor signal anomalies or actuator failures, such issues can lead to system performance degradation or functional failure, threatening driving safety. Traditional fault diagnosis methods, such as those based on fuzzy rules or state observers, can no longer cope with the highly nonlinear characteristics of BBW systems. In contrast, fault diagnosis technologies based on intelligent algorithms can more effectively identify complex fault patterns. Therefore, the future development focus will be on the deep integration of intelligent fault diagnosis algorithms based on multi-source information fusion and efficient fault-tolerant control strategies to significantly improve the reliability and safety of the BBW system.

5. Conclusions

- (1)

- Establishing mathematical models that accurately reflect system characteristics, laying the foundation for optimizing control strategies;

- (2)

- Adopting advanced intelligent control algorithms to enable more efficient coordination between the BBW system and other components of the X-by-wire chassis, achieving the collaborative optimization of safety, braking efficiency, and ride comfort;

- (3)

- Developing pedal feel emulation and personalized control strategies that incorporate driving style characteristics, achieving intelligent matching between control systems and driver behavior patterns;

- (4)

- Integrating multi-source information fusion with intelligent fault diagnosis algorithms and efficient fault-tolerant control strategies to improve system reliability and safety.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Verma, S.; Sharma, A.; Tran, B.; Alahakoon, D. A systematic review of digital twins for electric vehicles. J. Traffic Transp. Eng. Engl. Ed. 2024, 11, 815–834. [Google Scholar] [CrossRef]

- Bei, X.R.; Yu, X.J.; Li, D.Q.; Sun, Q.L.; Yu, Y.H.; Wang, Y.Q.; Okonkwo, C.E.; Zhou, C. Heat source replacement strategy using catalytic infrared: A future for energy saving drying of fruits and vegetables. J. Food Sci. 2023, 88, 4827–4839. [Google Scholar] [CrossRef]

- Zhou, C.S.; Adeyanju, A.A.; Nwonuma, C.O.; Inyinbor, A.A.; Alejolowo, O.O.; Al-Hamayda, A.; Akinsemolu, A.; Onyeaka, H.; Olaniran, A.F. Physical field-assisted deep eutectic solvent processing: A green and water-saving extraction and separation technology. J. Food Sci. 2024, 89, 8248–8275. [Google Scholar] [CrossRef]

- Li, H.; Issaka, Z.; Jiang, Y.; Tang, P.; Chen, C. Overview of emerging technologies in sprinkler irrigation to optimize crop production. Int. J. Agric. Biol. Eng. 2019, 12, 1–9. [Google Scholar] [CrossRef]

- Tang, Q.; Yang, Y.; Luo, C.; Yang, Z.; Fu, C. A novel electro-hydraulic compound braking system coordinated control strategy for a four-wheel-drive pure electric vehicle driven by dual motors. Energy 2022, 241, 122750. [Google Scholar] [CrossRef]

- Zhu, X.Y.; Chikangaise, P.; Shi, W.D.; Chen, W.H.; Yuan, S.Q. Review of intelligent sprinkler irrigation technologies for remote autonomous system. Int. J. Agric. Biol. Eng. 2018, 11, 23–30. [Google Scholar] [CrossRef]

- Issaka, Z.; Li, H.; Jiang, Y.; Tang, P.; Chen, C.; Darko, R.O. Hydraulic performance characteristics of impact sprinkler with a fixed water dispersion device. Int. J. Agric. Biol. Eng. 2018, 11, 104–112. [Google Scholar] [CrossRef]

- Aguilar-Alvarez, P.; Valencia-Palomo, G.; Lopez-Estrada, F.-R.; Zepeda-Hernandez, J.A.; Lopez-Perez, M.-D.-J.; Santos-Ruiz, I.; Garcia-Ramos, O.-Y. Instrumentation and dynamic characterization of a commercial electric vehicle for rural public transport. IEEE Access 2023, 11, 12639–12647. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, J.; Zhang, Y.; Zhang, R.; Jin, L.; Yin, G. Key Technologies and Research Progress of Brake-by-wire System for Intelligent Electric Vehicles. J. Mech. Eng. 2024, 60, 339–365. [Google Scholar]

- Dua, R. Net-zero transport dialogue: Emerging developments and the puzzles they present. Energy Sustain. Dev. 2024, 82, 101516. [Google Scholar] [CrossRef]

- Timilsina, R.R.; Zhang, J.; Rahut, D.B.; Patradool, K.; Sonobe, T. Global drive toward net-zero emissions and sustainability via electric vehicles: An integrative critical review. Energy Ecol. Environ. 2025, 10, 125–144. [Google Scholar] [CrossRef]

- Cao, Z.; Yang, X.; Zhu, X.; Xia, Y. Optimal design and experimental study of comb-type disc magnetorheological brake. Measurement 2024, 229, 114458. [Google Scholar] [CrossRef]

- Zhou, X.; Wu, G.; Wang, C.; Zhang, R.; Shi, S.; Zhao, W. Cooperative optimization of energy recovery and braking feel based on vehicle speed prediction under downshifting conditions. Energy 2024, 301, 131699. [Google Scholar] [CrossRef]

- Cao, W.; He, Z.; Cheng, A.; Zhao, Q.; Tan, H. Multi-bandwidth observer-based adaptive robust pressure control for electro-hydraulic brake system with uncertainties and measurement noise. Control Eng. Pract. 2024, 153, 106122. [Google Scholar] [CrossRef]

- Amin, A.A.; Mubarak, A.; Waseem, S. Application of physics-informed neural networks in fault diagnosis and fault-tolerant control design for electric vehicles: A review. Measurement 2025, 246, 116728. [Google Scholar] [CrossRef]

- Xing, C.; Zhu, Y.; Wang, J.; Lin, Y. Fault-tolerant control of in-wheel switched reluctance motor drive systems for vehicles under regenerative braking condition. J. Power Electron. 2024, 24, 1766–1777. [Google Scholar] [CrossRef]

- Li, Y.M.; Liu, Y.B.; Ji, K.Z.; Zhu, R.H. A Fault Diagnosis Method for a Differential Inverse Gearbox of a Crawler Combine Harvester Based on Order Analysis. Agriculture 2022, 12, 1300. [Google Scholar] [CrossRef]

- Hao, S.H.; Tang, Z.; Guo, S.B.; Ding, Z.; Su, Z. Model and Method of Fault Signal Diagnosis for Blockage and Slippage of Rice Threshing Drum. Agriculture 2022, 12, 1968. [Google Scholar] [CrossRef]

- Zhao, X.; Xiong, L.; Zhuo, G.; Tian, W.; Li, J.; Shu, Q.; Zhao, X.; Xu, G. A Review of One-Box Electro-Hydraulic Braking System: Architecture, Control, and Application. Sustainability 2024, 16, 1049. [Google Scholar] [CrossRef]

- Yang, C.; Sun, T.; Wang, W.; Li, Y.; Zhang, Y.; Zha, M. Regenerative braking system development and perspectives for electric vehicles: An overview. Renew. Sustain. Energy Rev. 2024, 198, 114389. [Google Scholar] [CrossRef]

- Hamada, A.T.; Orhan, M.F. An overview of regenerative braking systems. J. Energy Storage 2022, 52, 105033. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Q.; Chen, J.; Wang, Z.-P.; Li, S.-H. Brake-by-wire system for passenger cars: A review of structure, control, key technologies, and application in X-by-wire chassis. Etransportation 2023, 18, 100292. [Google Scholar] [CrossRef]

- Ji, Y.; Zhang, J.; He, C.; Ma, R.; Hou, X.; Hu, H. Constraint performance pressure tracking control with asymmetric continuous friction compensation for booster based brake-by-wire system. Mech. Syst. Signal Process. 2022, 174, 109083. [Google Scholar] [CrossRef]

- Nakamura, E.; Soga, M.; Sakai, A.; Otomo, A.; Kobayashi, T. Development of Electronically Controlled BrakeSystem for Hybrid Vehicle. In Proceedings of the SAE 2002 World Congress & Exhibition, Detroit, MI, USA, 4–7 March 2002. [Google Scholar]

- Stoll, U. Sensotronic brake control (SBC)—The electro-hydraulic brake from Mercedes-Benz. In Proceedings of the 10th International Congress on Electronic Systems for Vehicles, Baden Baden, Germany, 1 January 2003; pp. 675–685. [Google Scholar]

- Savitski, D.; Ivanov, V.; Schleinin, D.; Augsburg, L.; Pütz, T.; Lee, C.F. Advanced control functions of decoupled electro-hydraulic brake system. In Proceedings of the 2016 IEEE 14th International Workshop on Advanced Motion Control (AMC), Auckland, New Zealand, 22–24 April 2016; pp. 310–317. [Google Scholar] [CrossRef]

- Riese, C.; Gauterin, F. Evaluation of a state of the art hydraulic brake system with regard to future requirements. SAE Int. J. Passeng. Cars Mech. Syst 2016, 9, 1172–1183. [Google Scholar] [CrossRef]

- Oshima, T.; Fujiki, N.; Nakao, S.; Kimura, T.; Ohtani, Y.; Ueno, K. Development of an electrically driven intelligent brakesystem. SAE Int. J. Passeng. Cars Mech. Syst. 2011, 4, 399–405. [Google Scholar] [CrossRef]

- Bauer, U.; Brand, M.; Maucher, T. Integrated Power Brake–modular set extension for highlyautomated driving. In Proceedings of the 8th International Munich Chassis Symposium 2017, Vieweg, Wiesbaden, 21 September 2017; pp. 693–710. [Google Scholar]

- Schmid, B.; Grunwald, F.; Lehmann, S.; Acker, H. Position Sensor for Brake System Designed for Energy Recuperation. In Advanced Microsystems for Automotive Applications 2013; Springer: Berlin/Heidelberg, Germany, 2013; pp. 285–299. [Google Scholar]

- Wang, J.; Chen, R. An improved finite element model for the hydraulic analysis of drip irrigation subunits considering local emitter head loss. Irrig. Sci. 2020, 38, 147–162. [Google Scholar] [CrossRef]

- Chen, S.R.; Ding, H.T.; Tang, Z.; Hao, S.H.; Zhao, Y.F. Influence of rice straw forming factors on ring die wear and improved wear prediction model during briquetting. Biosyst. Eng. 2022, 214, 122–137. [Google Scholar] [CrossRef]

- Ma, Z.; Zhu, Y.L.; Chen, S.R.; Traore, S.N.; Li, Y.M.; Xu, L.Z.; Shi, M.; Zhang, Q. Field Investigation of the Static Friction Characteristics of High-Yielding Rice during Harvest. Agriculture 2022, 12, 327. [Google Scholar] [CrossRef]

- Wang, J.; Yang, T.; Wei, T.; Chen, R.; Yuan, S.Q. Experimental determination of local head loss of non-coaxial emitters in thin-wall lay-flat polyethylene pipes. Biosyst. Eng. 2020, 190, 71–86. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, K.; Nie, M.; Ma, C.; Tan, D.; Huang, Z. Design and Verification of a novel Synchronous Force-Increasing Disk Electro-Mechanical Brake Actuator for Pure Electric Trucks. Int. J. Automot. Technol. 2025. [Google Scholar] [CrossRef]

- Xiao, F.; Gong, X.; Lu, Z.; Qian, L.; Zhang, Y.; Wang, L. Design and Control of New Brake-by-Wire Actuator for Vehicle Based on Linear Motor and Lever Mechanism. IEEE Access 2021, 9, 95832–95842. [Google Scholar] [CrossRef]

- Durali, L.; Khajepour, A.; Jeon, S. Design and optimization of a cam-actuated electrohydraulic brake system. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2018, 232, 909–920. [Google Scholar] [CrossRef]

- Yan, Z.; Chen, X.; Yan, M.; Hang, P. Design and optimization of a novel Electronic Mechanical Brake Actuator Based on Cam. Actuators 2023, 12, 329. [Google Scholar] [CrossRef]

- Park, H.; Choi, S.B. Development of a Sensorless Control Method for a Self-Energizing Brake System Using Noncircular Gears. IEEE Trans. Control Syst. Technol. 2013, 21, 1328–1339. [Google Scholar] [CrossRef]

- Ahmad, F.; Hudha, K.; Mazlan, S.A.; Jamaluddin, H.; Zamzuri, H.; Abd Kadir, Z.; Aparow, V.R. Modelling and Control of a Fixed Calliper-Based Electronic Wedge Brake. Stroj. Vestn. J. Mech. Eng. 2017, 63, 181–190. [Google Scholar] [CrossRef]

- Li, C.; Zhang, J.; Hou, X.; Ji, Y.; Han, J.; He, C.; Hao, J. A Novel Double Redundant Brake-by-Wire System for High Automation Driving Safety: Design, Optimization and Experimental Validation. Actuators 2021, 10, 287. [Google Scholar] [CrossRef]

- Yuan, C.; He, Z.; Shen, J.; Chen, L.; Cai, Y.; He, Y.; Weng, S.; Yuan, Y.; Gong, Y. Design, modeling, and simulation of dual-source redundant braking system. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2024, 238, 18–31. [Google Scholar] [CrossRef]

- Liu, Q.; Qin, C.; Fu, Y.Q.; Lin, D.P.; Liao, K.X. Vehicle Electromechanical Brake System and Vehicle with Same. CN Patent 201910912660.X, 26 March 2021. (In Chinese). [Google Scholar]

- Lee, K.J.; Ki, Y.H.; Cheon, J.S.; Hwang, G.; Ahn, H.S. Approach to functional safety-compliant ECU design for electro-mechanical brake systems. Int. J. Automot. Technol. 2014, 15, 325–332. [Google Scholar] [CrossRef]

- Shi, X.; Krishnamurthy, M. Survivable operation of induction machine drives with smooth transition strategy for EV applications. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 609–617. [Google Scholar]

- Foshati, A.; Ejlali, A. Enhancing sensor fault tolerance in automotive systems with cost-effective cyber redundancy. IEEE Trans. Intell. Veh. 2024, 9, 4794–4803. [Google Scholar] [CrossRef]

- Kang, W.S.; Choi, C.K.; Yoo, H.H. Stochastic modeling of friction force and vibration analysis of a mechanical system using the model. J. Mech. Sci. Technol. 2015, 29, 3645–3652. [Google Scholar] [CrossRef]

- Houhua, J.; Qinggan, L.; Mingqi, L. Friction Modeling and Control Compensation for Electromechanical Braking Systems. In Proceedings of the 2024 8th CAA International Conference on Vehicular Control and Intelligence (CVCI), Chongqing, China, 25–27 October 2024; pp. 1–6. [Google Scholar]

- Wang, Q.; Wang, Z.; Mo, J.; Zhu, S.; Gou, Q. Evaluation of the dynamic behaviors of a train braking system considering disc-block interface characteristics. Mech. Syst. Signal Process. 2023, 192, 110234. [Google Scholar] [CrossRef]

- Beerens, R.; Bisoffi, A.; Zaccarian, L.; Nijmeijer, H.; Heemels, M.; van de Wouw, N. Reset PID Design for Motion Systems With Stribeck Friction. IEEE Trans. Control Syst. Technol. 2022, 30, 294–310. [Google Scholar] [CrossRef]

- El-bakkouri, J.; Mansouri, A.; Ouadi, H.; El Aoumari, A.; El Khlifi, Y.; Giri, F. Robust Braking Pressure Control for an Electrohydraulic Brake System under Friction and Disturbance Conditions. In Proceedings of the Conference Robust Braking Pressure Control for an Electrohydraulic Brake System under Friction and Disturbance Conditions, Rabat, Morocco, 8 August 2024; Volume 58, pp. 539–544. [Google Scholar]

- Yao, J.; Deng, W.; Jiao, Z. Adaptive control of hydraulic actuators with LuGre model-based friction compensation. IEEE Trans. Ind. Electron. 2015, 62, 6469–6477. [Google Scholar] [CrossRef]

- Cao, L.; Downey, A.; Laflamme, S.; Taylor, D.; Ricles, J. Variable friction device for structural control based on duo-servo vehicle brake: Modeling and experimental validation. J. Sound Vib. 2015, 348, 41–56. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, G.; Ding, Y.; Yang, J.; Liang, C.; Fu, J. Effect of Friction Model and Tire Maneuvering on Tire-Pavement Contact Stress. Adv. Mater. Sci. Eng. 2015, 2015, 632647. [Google Scholar] [CrossRef]

- Zhao, J.; Du, J.; Zhu, B.; Chen, Z. Adaptive Dual-Loop Pressure Control for an Integrated Electro-Hydraulic Brake System Considering Uncertain Nonlinear Characteristics. IEEE Trans. Transp. Electrif. 2024, 10, 9428–9440. [Google Scholar] [CrossRef]

- Sun, P.; Trigell, A.S.; Drugge, L.; Jerrelind, J. Energy efficiency and stability of electric vehicles utilising direct yaw moment control. Veh. Syst. Dyn. 2022, 60, 930–950. [Google Scholar] [CrossRef]

- Cheng, S.; Li, L.; Liu, C.-Z.; Wu, X.; Fang, S.-N.; Yong, J.-W. Robust LMI-Based H-Infinite Controller Integrating AFS and DYC of Autonomous Vehicles With Parametric Uncertainties. IEEE Trans. Syst. Man Cybern. Syst. 2021, 51, 6901–6910. [Google Scholar] [CrossRef]

- Liu, H.; Yan, S.C.; Shen, Y.; Li, C.H.; Zhang, Y.F.; Hussain, F. Model predictive control system based on direct yaw moment control for 4WID self-steering agriculture vehicle. Int. J. Agric. Biol. Eng. 2021, 14, 175–181. [Google Scholar] [CrossRef]

- Xiong, F.; Lan, F.; Chen, J.; Yang, Y. Investigation into Improvement for Anti-Rollover Propensity of SUV. Chin. J. Mech. Eng. 2017, 30, 698–710. [Google Scholar] [CrossRef]

- Tang, M.; Zhang, X. Optimal Regenerative Braking Control Strategy for Electric Vehicles Based on Braking Intention Recognition and Load Estimation. IEEE Trans. Veh. Technol. 2024, 73, 3378–3392. [Google Scholar] [CrossRef]

- Sun, H.; Wang, H.; Zhao, X. Line Braking Torque Allocation Scheme for Minimal Braking Loss of Four-Wheel-Drive Electric Vehicles. IEEE Trans. Veh. Technol. 2019, 68, 180–192. [Google Scholar] [CrossRef]

- Hosseini Salari, A.; Mirzaeinejad, H.; Fooladi Mahani, M. A new control algorithm of regenerative braking management for energy efficiency and safety enhancement of electric vehicles. Energy Convers. Manag. 2023, 276, 116564. [Google Scholar] [CrossRef]

- Wu, J.; Liu, H.; Ren, X.; Nie, S.; Qin, Y.; Han, L. A multi-objective optimization approach for regenerative braking control in electric vehicles using MPE-SAC algorithm. Energy 2025, 318, 134586. [Google Scholar] [CrossRef]

- Ji, F.; Pan, Y.; Zhou, Y.; Du, F.; Zhang, Q.; Li, G. Energy recovery based on pedal situation for regenerative braking system of electric vehicle. Veh. Syst. Dyn. 2020, 58, 144–173. [Google Scholar] [CrossRef]

- Geng, C.; Ning, D.; Guo, L.; Xue, Q.; Mei, S. Simulation Research on Regenerative Braking Control Strategy of Hybrid Electric Vehicle. Energies 2021, 14, 2202. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Xiang, C.; Yang, C.; Peng, H.; Wei, C. A swarm intelligence-based predictive regenerative braking control strategy for hybrid electric vehicle. Veh. Syst. Dyn. 2022, 60, 973–997. [Google Scholar] [CrossRef]

- Yang, Y.; Tang, Q.; Bolin, L.; Fu, C. Dynamic Coordinated Control for Regenerative Braking System and Anti-Lock Braking System for Electrified Vehicles Under Emergency Braking Conditions. IEEE Access 2020, 8, 172664–172677. [Google Scholar] [CrossRef]

- Zhao, L.; Ye, M.; Xu, X. Intelligent optimization of EV comfort based on a cooperative braking system. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 2904–2916. [Google Scholar] [CrossRef]

- Zhang, R.; Zhao, W.; Wang, C.; Tai, K. Research on personalized control strategy of EHB system for consistent braking feeling considering driving behaviors. Energy 2024, 293, 130568. [Google Scholar] [CrossRef]

- Cui, L.F.; Mao, H.P.; Xue, X.Y.; Ding, S.M.; Qiao, B.Y. Optimized design and test for a pendulum suspension of the crop spray boom in dynamic conditions based on a six DOF motion simulator. Int. J. Agric. Biol. Eng. 2018, 11, 76–85. [Google Scholar]

- Cui, L.F.; Xue, X.Y.; Le, F.X.; Mao, H.P.; Ding, S.M. Design and experiment of electro hydraulic active suspension for controlling the rolling motion of spray boom. Int. J. Agric. Biol. Eng. 2019, 12, 72–81. [Google Scholar] [CrossRef]

- Li, J.Y.; Nie, Z.Y.; Chen, Y.F.; Ge, D.Q.; Li, M.Q. Development of Boom Posture Adjustment and Control System for Wide Spray Boom. Agriculture 2023, 13, 2162. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, W.; Liu, Z.; Zeng, M. Comfort braking control for brake-by-wire vehicles. Mech. Syst. Signal Process. 2019, 133, 106255. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, Y.; Hu, M.; Yang, Z.; Fu, C. Longitudinal–vertical comprehensive control for four-wheel drive pure electric vehicle considering energy recovery and ride comfort. Energy 2021, 236, 121417. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, Y.; Zhou, G.; Nam, K.; Ji, Z.; Yin, C. A Twisted Gaussian Risk Model Considering Target Vehicle Longitudinal-Lateral Motion States for Host Vehicle Trajectory Planning. IEEE Trans. Intell. Transp. Syst. 2023, 24, 13685–13697. [Google Scholar] [CrossRef]

- Lai, F.; Huang, C.; Ye, X. Analysis of Vehicle Driving Stability based on Longitudinal-lateral and Vertical Unified Dynamics Model. Int. J. Automot. Technol. 2022, 23, 73–87. [Google Scholar] [CrossRef]

- Zhou, H.; Jia, F.; Jing, H.; Liu, Z.; Guvenc, L. Coordinated Longitudinal and Lateral Motion Control for Four Wheel Independent Motor-Drive Electric Vehicle. IEEE Trans. Veh. Technol. 2018, 67, 3782–3790. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Q.; Wang, Z. Electro-hydraulic brake control for improved ride comfort in four-wheel-independently-actuated electric vehicles. J. Mech. Eng. 2020, 56, 125–134. [Google Scholar]

- Zhang, R.; Zhao, W.; Wang, C.; Xu, C.; Wu, G. A μ-H∞ control strategy for decreasing torque fluctuation of electro-hydraulic integrated braking system in mode switching. Asian J. Control 2023, 25, 4268–4290. [Google Scholar] [CrossRef]

- Liu, Y.; Gao, D.; Zhai, K.; Huang, Q.; Chen, Z.; Zhang, Y. Coordinated control strategy for braking and shifting for electric vehicle with two-speed automatic transmission. eTransportation 2022, 13, 100188. [Google Scholar] [CrossRef]

- Jo, C.; Ko, J.; Yeo, H.; Yeo, T.; Hwang, S.; Kim, H. Cooperative regenerative braking control algorithm for an automatic-transmission-based hybrid electric vehicle during a downshift. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2012, 226, 457–467. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, C.; Zhang, Q.; He, X. Torque Coordination Control during Braking Mode Switch for a Plug-in Hybrid Electric Vehicle. Energies 2017, 10, 1684. [Google Scholar] [CrossRef]

- Wu, D.M.; Ding, H.T.; Guo, K.H.; Wang, Z.Q. Experiment Reasearch on the PressureFollowing Control of Electro-Hydraulic Braking System. SAE Tech. Pap. 2014. [Google Scholar] [CrossRef]

- Li, C.Q.; Wu, J.G.; Pan, X.Y.; Dou, H.J.; Zhao, X.G.; Gao, Y.Y.; Yang, S.; Zhai, C. Design and Experiment of a Breakpoint Continuous Spraying System for Automatic-Guidance Boom Sprayers. Agriculture 2023, 13, 2203. [Google Scholar] [CrossRef]

- Zhu, Y.Y.; Cui, B.B.; Yu, Z.L.; Gao, Y.Y.; Wei, X.H. Tillage Depth Detection and Control Based on Attitude Estimation and Online Calibration of Model Parameters. Agriculture 2024, 14, 2130. [Google Scholar] [CrossRef]

- Yang, Y.; Li, G.; Zhang, Q. A Pressure-Coordinated Control for Vehicle Electro-Hydraulic Braking Systems. Energies 2018, 11, 2336. [Google Scholar] [CrossRef]

- Wang, W.; Wu, Y.; Shi, J.; Li, L. Electronic hydraulic brake power system control strategy based on driver intention recognition. J. Jilin Univ. Eng. Technol. Ed. 2021, 51, 406–413. [Google Scholar]

- Song, X.H.; Li, H.; Chen, C.; Xia, H.M.; Zhang, Z.Y.; Tang, P. Design and Experimental Testing of a Control System for a Solid-Fertilizer-Dissolving Device Based on Fuzzy PID. Agriculture 2022, 12, 1382. [Google Scholar] [CrossRef]

- Chen, Y.X.; Chen, L.; Wang, R.C.; Xu, X.; Shen, Y.J.; Liu, Y.L. Modeling and test on height adjustment system of electrically-controlled air suspension for agricultural vehicles. Int. J. Agric. Biol. Eng. 2016, 9, 40–47. [Google Scholar]

- Wei, L.; Liu, Y.; Wang, X.; Liu, Z.; Li, L. Pressure Control Strategy for Brake by Wire Systems Based on Hierarchical Structure. J. Mech. Eng. 2024, 60, 487–496. [Google Scholar]

- Sun, J.L.; Wang, Z.; Ding, S.H.; Xia, J.; Xing, G.Y. Adaptive disturbance observer-based fixed time nonsingular terminal sliding mode control for path-tracking of unmanned agricultural tractors. Biosyst. Eng. 2024, 246, 96–109. [Google Scholar] [CrossRef]

- Li, J.Y.; Shang, Z.J.; Li, R.F.; Cui, B.B. Adaptive Sliding Mode Path Tracking Control of Unmanned Rice Transplanter. Agriculture 2022, 12, 1225. [Google Scholar] [CrossRef]

- Wang, R.C.; Zhang, K.Q.; Ding, R.K.; Jiang, Y.; Jiang, Y.Y. A Novel Hydraulic Interconnection Design and Sliding Mode Synchronization Control of Leveling System for Crawler Work Machine. Agriculture 2025, 15, 137. [Google Scholar] [CrossRef]

- Shi, Q.; He, L. A Model Predictive Control Approach for Electro-Hydraulic Braking by Wire. IEEE Trans. Ind. Inform. 2023, 19, 1380–1388. [Google Scholar] [CrossRef]

- Lu, E.; Xue, J.L.; Chen, T.T.; Jiang, S. Robust Trajectory Tracking Control of an Autonomous Tractor-Trailer Considering Model Parameter Uncertainties and Disturbances. Agriculture 2023, 13, 869. [Google Scholar] [CrossRef]

- Shan, T.; Li, L.; Wu, X.; Cheng, S. Pressure control based on reinforcement learning strategy of the pneumatic relays for an electric-pneumatic braking system. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023, 237, 2664–2675. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, Y.; Wu, X.; Tao, X. Research on accurate modeling and control for pneumatic electric braking system of commercial vehicle based on multi-dynamic parameters measurement. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023, 237, 803–815. [Google Scholar] [CrossRef]

- Zhu, B.; Zheng, Y.; Zhao, J.; Du, J.; Chen, Z.; Chen, Z.; Li, J.; Hao, W. Wheel Cylinder Pressure Control Strategy for Integrated Brake-by-wire System Based on Motor-solenoid Valve Coordinated Fluid Replenishment Logic. China J. Highw. Transp. 2024, 37, 289–300. [Google Scholar]

- Ma, C.; Wang, X.; Xu, T.; Wang, J.; Feng, P. Research on a novel electro-hydraulic brake system and pedal feel control strategy. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023, 237, 1681–1694. [Google Scholar] [CrossRef]

- Feng, L.; Sun, X.; Tian, X.; Diao, K. Direct Torque Control With Variable Flux for an SRM Based on Hybrid Optimization Algorithm. IEEE Trans. Power Electron. 2022, 37, 6688–6697. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, Z.; Ding, K.; He, G. Transfer Mechanism Analysis of Injected Voltage Harmonic and its Effect on Current Harmonic Regulation in FOC PMSM. IEEE Trans. Power Electron. 2022, 37, 820–829. [Google Scholar] [CrossRef]

- Elgbaily, M.; Anayi, F.; Alshbib, M.M. A Combined Control Scheme of Direct Torque Control and Field-Oriented Control Algorithms for Three-Phase Induction Motor: Experimental Validation. Mathematics 2022, 10, 3842. [Google Scholar] [CrossRef]

- Hazem, H.; Fernando, S. Performance Comparison of Field-oriented Control, Direct Torque Control, and Model-predictive Control for SynRMs. Chin. J. Electr. Eng. 2022, 8, 24–37. [Google Scholar]

- Ali, M.M.; Xu, W.; Junejo, A.K.; Elmorshedy, M.F.; Tang, Y. One New Super-Twisting Sliding Mode Direct Thrust Control for Linear Induction Machine Based on Linear Metro. IEEE Trans. Power Electron. 2022, 37, 795–805. [Google Scholar] [CrossRef]

- Gillmeier, K.; Schuettke, T.; Diederichs, F.; Miteva, G.; Spath, D. Combined Driver Distraction and Intention Algorithm for Maneuver Prediction and Collision Avoidance. In Proceedings of the 2018 IEEE International Conference on Vehicular Electronics and Safety (ICVES), Madrid, Spain, 12–14 September 2018; pp. 1–6. [Google Scholar]

- Cui, B.B.; Cui, X.Y.; Wei, X.H.; Zhu, Y.Y.; Ma, Z.; Zhao, Y.; Liu, Y. Design and Testing of a Tractor Automatic Navigation System Based on Dynamic Path Search and a Fuzzy Stanley Model. Agriculture 2024, 14, 2136. [Google Scholar] [CrossRef]

- Chandio, F.A.; Li, Y.M.; Xu, L.Z.; Ma, Z.; Ahmad, F.; Cuong, D.M.; Lakhiar, I.A. Predicting 3D forces of disc tool and soil disturbance area using fuzzy logic model under sensor based soil-bin. Int. J. Agric. Biol. Eng. 2020, 13, 77–84. [Google Scholar] [CrossRef]

- Chang, X.H.; Huang, X.Y.; Xu, W.D.; Tian, X.Y.; Wang, C.Q.; Wang, L.; Yu, S. Monitoring of dough fermentation during Chinese steamed bread processing by near-infrared spectroscopy combined with spectra selection and supervised learning algorithm. J. Food Process Eng. 2021, 44, e13783. [Google Scholar] [CrossRef]

- Chen, Y.; Lin, M.W.; Yu, Z.; Sun, W.H.; Fu, W.G.; He, L. Enhancing cotton irrigation with distributional actor-critic reinforcement learning. Agric. Water Manag. 2025, 307, 109194. [Google Scholar] [CrossRef]

- Zhou, X.; Jun, S.; Yan, T.; Bing, L.; Hang, Y.Y.; Quansheng, C. Hyperspectral technique combined with deep learning algorithm for detection of compound heavy metals in lettuce. Food Chem. 2020, 321, 126503. [Google Scholar] [CrossRef]

- Li, X.; Zhang, X. Recognition Method of Braking Intention of Electric Vehicles Based on ABC-SVM Algorithm. China Mech. Eng. 2021, 32, 2125–2135. [Google Scholar]

- Zheng, H.; Ma, S.; Fang, L.; Zhao, W.; Zhu, T. Braking intention recognition algorithm based on electronic braking system in commercial vehicles. Int. J. Heavy Veh. Syst. 2019, 26, 268–290. [Google Scholar] [CrossRef]

- Yang, W.; Liu, J.; Zhou, K.; Zhang, Z.; Qu, X. An Automatic Emergency Braking Model considering Driver’s Intention Recognition of the Front Vehicle. J. Adv. Transp. 2020, 2020, 5172305. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, X.; Yu, Q.; Yuan, T. Identification of Driver Braking Intention Based on Long Short-Term Memory (LSTM) Network. IEEE Access 2020, 8, 180422–180432. [Google Scholar] [CrossRef]

- Jiang, K.; Yang, W.; Huang, S. LaTAS-F: Locality-aware transformer architecture search with multi-source fusion for driver continuous braking intention inference. Expert Syst. Appl. 2024, 242, 122719. [Google Scholar] [CrossRef]

- Diederichs, F.; Schuettke, T.; Spath, D. IEEE Driver Intention Algorithm for Pedestrian Protection and Automated Emergency Braking Systems. In Proceedings of the Conference Driver Intention Algorithm for Pedestrian Protection and Automated Emergency Braking Systems, Gran Canaria, Spain, 15–18 September 2015; pp. 1049–1054. [Google Scholar]

- Ju, J.; Bi, L.; Feleke, A.G. Noninvasive neural signal-based detection of soft and emergency braking intentions of drivers. Biomed. Signal Process. Control 2022, 72, 103330. [Google Scholar] [CrossRef]

- Liu, Y.; Liang, X.; Yu, Y.; Sun, J.; Hu, J.; Liu, Y.; Zeng, L.-L.; Zhou, Z.; Hu, D. Recognizing drivers’ turning intentions with EEG and eye movement. Biomed. Signal Process. Control 2025, 101, 107218. [Google Scholar] [CrossRef]

- Qu, X.; Zhang, J.; Qu, L. Structure design and optimization of a disc-drum hybrid magnetorheological device for pedal force control. J. Automot. Saf. Energy 2023, 14, 698–706. [Google Scholar]

- Caliskan, U.; Apaydin, A.; Otaran, A.; Patoglu, V. A Series Elastic Brake Pedal to Preserve Conventional Pedal Feel under Regenerative Braking. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 1367–1373. [Google Scholar]

- Wang, D.; Wang, B.; Zi, B.; Bai, X.; Chen, W. Development and Control of a Magnetorheological Damper-Based Brake Pedal Simulator for Vehicle Brake-by-Wire Systems. Chin. J. Mech. Eng. 2022, 35, 136. [Google Scholar] [CrossRef]

- Huang, X.Y.; Pan, S.H.; Sun, Z.Y.; Ye, W.T.; Aheto, J.H. Evaluating quality of tomato during storage using fusion information of computer vision and electronic nose. J. Food Process Eng. 2018, 41, e12832. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, Z.; Han, Z.X.; Sun, W.H.; He, L. A Decision-Making System for Cotton Irrigation Based on Reinforcement Learning Strategy. Agronomy 2024, 14, 11. [Google Scholar] [CrossRef]

- Cheng, J.H.; Sun, J.; Yao, K.S.; Xu, M.; Tian, Y.; Dai, C.X. A decision fusion method based on hyperspectral imaging and electronic nose techniques for moisture content prediction in frozen-thawed pork. Lwt Food Sci. Technol. 2022, 165, 113778. [Google Scholar] [CrossRef]

- Yang, W.; Liu, J.; Liu, J. Active Anti-collision Warning Model Considering the Driver’s Intention of the Vehicle Ahead under Internet of Vehicles. J. Mech. Eng. 2021, 57, 284–295. [Google Scholar]

- Zhu, B.; Wu, D.; Zhang, N.; Zheng, M. Decision-making research of V2I electric vehicle based on rolling optimization and energy recovery. Control Decis. 2020, 35, 956–964. [Google Scholar]

- Shang, Y.; Ma, C.; Yang, K.; Tan, D. Regenerative Braking Control Strategy Based on Multi-source Information Fusion under Environment Perception. Int. J. Automot. Technol. 2022, 23, 805–815. [Google Scholar] [CrossRef]

- Fountas, G.; Pantangi, S.S.; Hulme, K.F.; Anastasopoulos, P.C. The effects of driver fatigue, gender, and distracted driving on perceived and observed aggressive driving behavior: A correlated grouped random parameters bivariate probit approach. Anal. Methods Accid. Res. 2019, 22, 100091. [Google Scholar] [CrossRef]

- Chengqun, Q.; Wan, X.; Wang, N.; Cao, S.; Ji, X.; Wu, K.; Hu, Y.; Meng, M. A novel regenerative braking energy recuperation system for electric vehicles based on driving style. Energy 2023, 283, 129055. [Google Scholar] [CrossRef]

- Sun, T.; Gao, Z.; Gao, F.; Zhang, T.; Ji, D.; Chen, S. Intelligent Vehicle Automatic Stop-and-Go Task Based on Humanized Learning Control Model. Adv. Civ. Eng. 2021, 2021, 1–11. [Google Scholar] [CrossRef]

- Baek, S.E.; Kim, H.S.; Han, M. Personalized Speed Planning Algorithm Using a Statistical Driver Model in Car-following Situations. Int. J. Automot. Technol. 2022, 23, 829–840. [Google Scholar] [CrossRef]

- Mei, P.; Karimi, H.R.; Ou, L.; Xie, H.; Zhan, C.; Li, G.; Yang, S. Driving style classification and recognition methods for connected vehicle control in intelligent transportation systems: A review. ISA Trans. 2025, 158, 167–183. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Cheng, W.; Ma, C. Man-machine cooperative control strategy of the longitudinal collision avoidances based on the factors of driver, vehicle and road. J. Automot. Saf. Energy 2023, 14, 46–54. [Google Scholar]

- Wang, H.; Wang, Q.; Chen, W.; Tan, D.; Zhao, L. Multi-mode human-machine cooperative control for lane departure prevention based on steering assistance and differential braking. IET Intell. Transp. Syst. 2020, 14, 578–588. [Google Scholar] [CrossRef]

- Wang, X.; Cheng, Y. Lane departure avoidance by man-machine cooperative control based on EPS and ESP systems. J. Mech. Sci. Technol. 2019, 33, 2929–2940. [Google Scholar] [CrossRef]

- Matute, J.; Khaleghi, M.; Karimoddini, A. Decentralized most permissive observer architecture for brake leakage diagnosis in automotive systems. IEEE Access 2024, 12, 110457–110468. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, Z.; Wei, L.; Wang, X.; Li, L. Braking sensor and actuator fault diagnosis with combined model-based and data-driven pressure estimation methods. IEEE Trans. Ind. Electron. 2023, 70, 11639–11648. [Google Scholar] [CrossRef]

- Yin, Y.; Cao, J.; Bao, J.; Zhang, J.; Zhang, H.; Su, W. Frictional signal processing and fault diagnosis and forecasting methods for mechanical brake. Mech. Syst. Signal Process. 2025, 226, 112349. [Google Scholar] [CrossRef]

- Zhang, B.; Lu, S.; Wu, W.; Li, C.; Lu, J. Robust fault-tolerant control for four-wheel individually actuated electric vehicle considering driver steering characteristics. J. Frankl. Inst. 2021, 358, 5883–5908. [Google Scholar] [CrossRef]

- Huang, X.; Zha, Y.; Lv, X.; Quan, X. Torque Fault-Tolerant Hierarchical Control of 4WID Electric Vehicles Based on Improved MPC and SMC. IEEE Access 2023, 11, 132718–132734. [Google Scholar] [CrossRef]

- Huang, S.; Zhou, C.; Yang, L.; Qin, Y.; Huang, X.; Hu, B. Transient fault tolerant control for vehicle brake-by-wire systems. Reliab. Eng. Syst. Saf. 2016, 149, 148–163. [Google Scholar] [CrossRef]

- Patan, K.; Patan, M. Fault-tolerant design of non-linear iterative learning control using neural networks. Eng. Appl. Artif. Intell. 2023, 124, 106501. [Google Scholar] [CrossRef]

- Patan, K.; Patan, M. Actuator fault-tolerant iterative learning control of the magnetic brake system. IFAC Pap. 2022, 55, 266–271. [Google Scholar] [CrossRef]

| Performance Parameters | Two-Box | One-Box |

|---|---|---|

| Integration level | ECU and HCU separated, larger space required | Highly integrated, compact |

| Cost | More components, higher cost | Fewer components, lower cost |

| Response time | 150 ms | 80 ms |

| Control logic | Complex control logic | Simpler control logic |

| Coordination | Less efficient coordination | Efficient coordination |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Wang, R.; Ding, R.; Liu, B.; Liu, W.; Sun, D.; Guo, Z. Research Progress and Future Prospects of Brake-by-Wire Technology for New Energy Vehicles. Energies 2025, 18, 2702. https://doi.org/10.3390/en18112702

Chen Z, Wang R, Ding R, Liu B, Liu W, Sun D, Guo Z. Research Progress and Future Prospects of Brake-by-Wire Technology for New Energy Vehicles. Energies. 2025; 18(11):2702. https://doi.org/10.3390/en18112702

Chicago/Turabian StyleChen, Zhengrong, Ruochen Wang, Renkai Ding, Bin Liu, Wei Liu, Dong Sun, and Zhongyang Guo. 2025. "Research Progress and Future Prospects of Brake-by-Wire Technology for New Energy Vehicles" Energies 18, no. 11: 2702. https://doi.org/10.3390/en18112702

APA StyleChen, Z., Wang, R., Ding, R., Liu, B., Liu, W., Sun, D., & Guo, Z. (2025). Research Progress and Future Prospects of Brake-by-Wire Technology for New Energy Vehicles. Energies, 18(11), 2702. https://doi.org/10.3390/en18112702