Online Pre-Diagnosis of Multiple Faults in Proton Exchange Membrane Fuel Cells by Convolutional Neural Network Based Bi-Directional Long Short-Term Memory Parallel Model with Attention Mechanism

Abstract

1. Introduction

- We use existing sensors to select the input features of the required fault prediction model according to the electrochemical and thermodynamic principles of the fuel cell stack. Therefore, our method does not require installing embedded sensors in the FC stack.

- We consider the load change and simulate the working state of FC under real variable working states. By iteratively updating the input data tensor every second, the model can respond to the monitoring data online in real time, reducing data latency from minutes to 1 second compared to conventional methods.

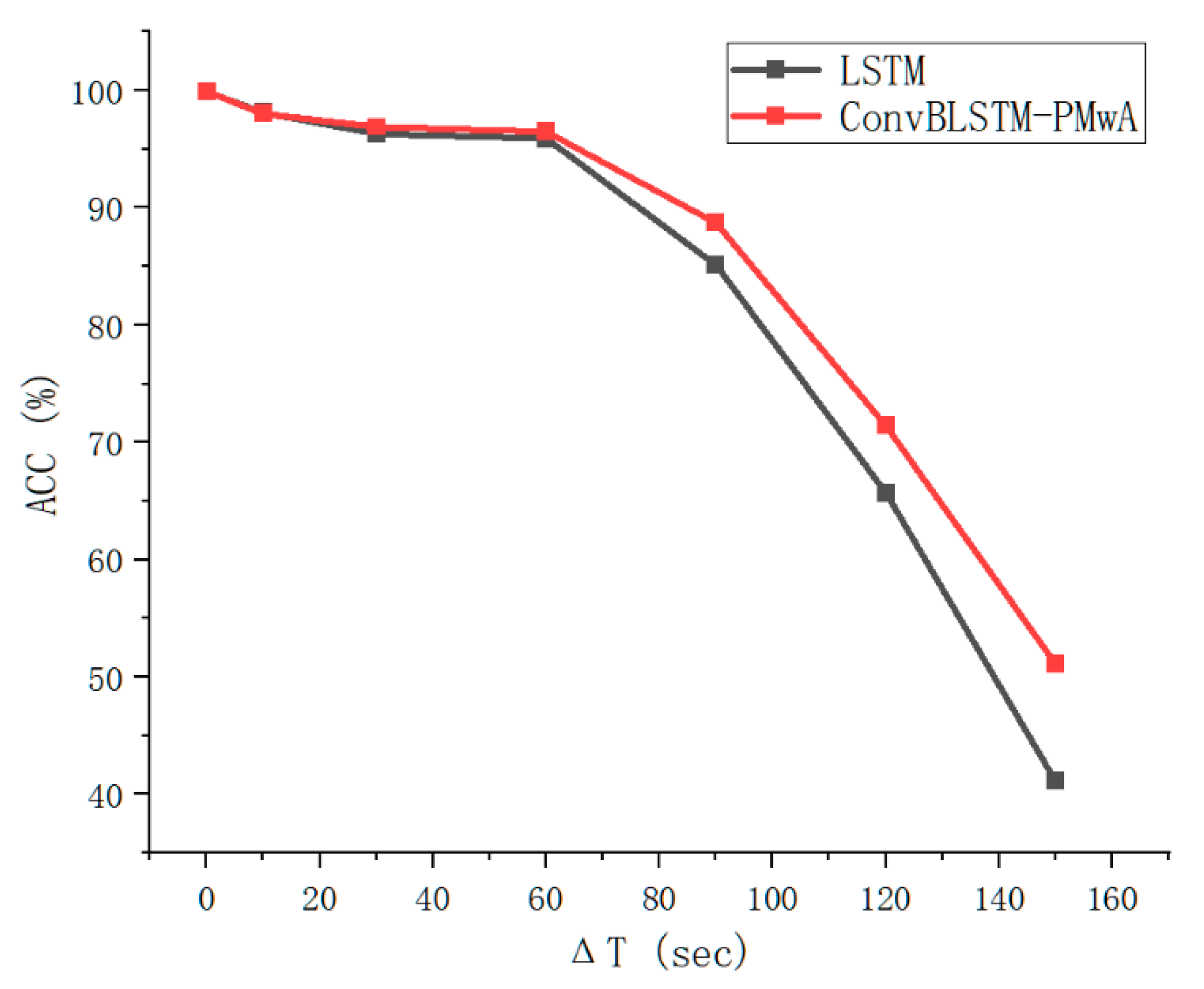

- We evaluate the performance of two different neural network models, LSTM and ConvBLSTM-PMwA, using the FC real fault dataset. We compare the impact of different network architectures, hyperparameters, and target future time on prediction performance. We also compare the prediction effects of different models by prediction times, their coefficient of variations, accuracies, and model sensitivities.

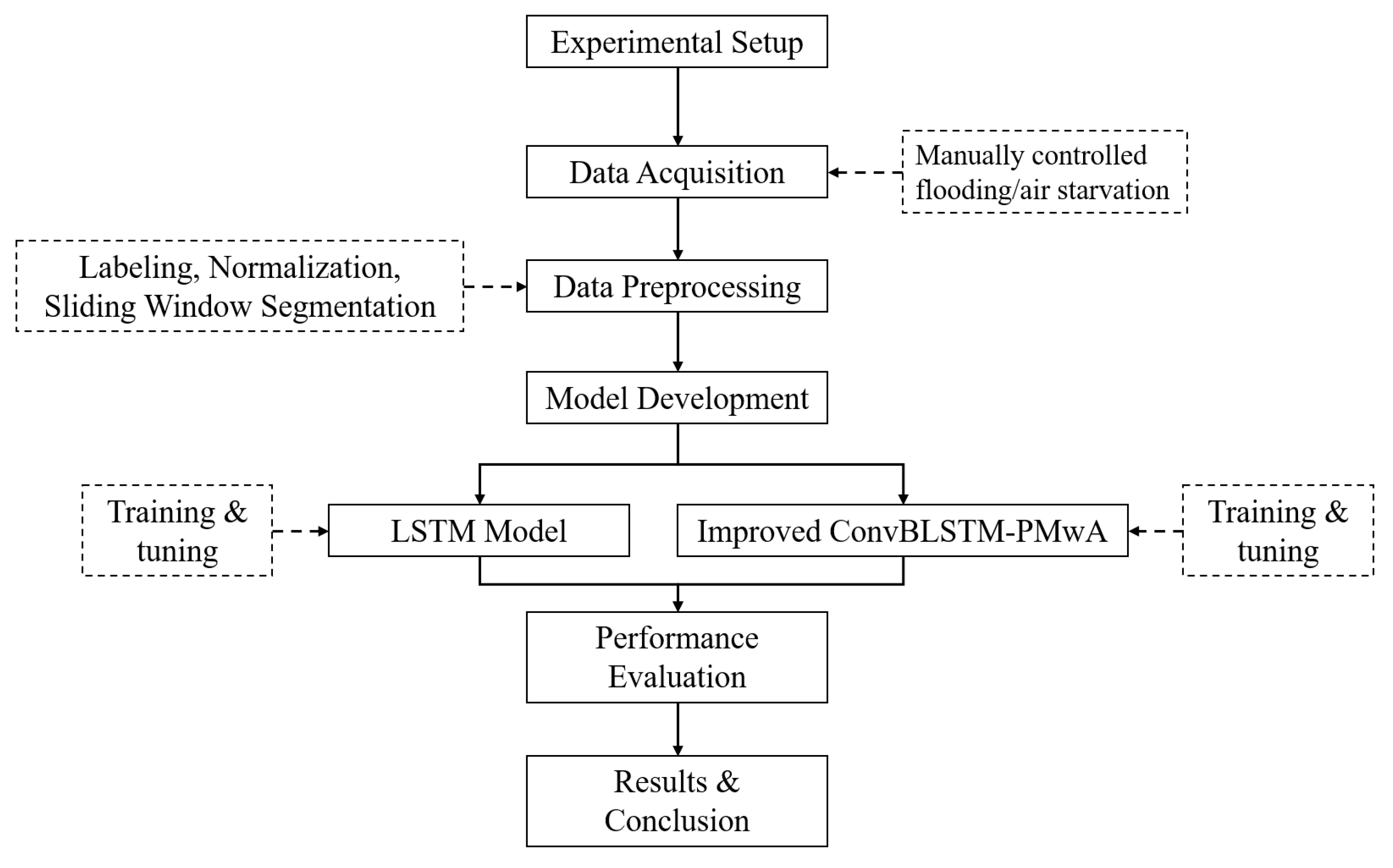

2. Method

- Collect data of PEMFC under normal working conditions and different fault conditions through experiments, and then preprocess and manually label the data;

- Build LSTM and ConvBLSTM-PMwA neural networks, use 70% of the preprocessed sensor data as input and the manually labeled fault indication data as output, and train the neural networks;

- Change the structure and hyperparameters of LSTM and ConvBLSTM-PMwA neural networks, use the remaining 30% of data for testing to select the neural network that can predict the working condition of fuel cell most accurately in the future period of time, and compare the prediction effects.

2.1. Data Marking and Processing

- Data labeling: The data labeling method is marking the training samples into the identified original data. In this study, we conduct multiple independent experiments for flooding and air starvation faults under varying load profiles (e.g., current, dynamic cycles) to generate diverse datasets. We include at least 10 repetitions for each fault type to ensure statistical validity. The data are labeled by adding two different parameters. In the flooding experiment, the normal and stable working states are taken as the standard. During the flooding process, if the output power of the fuel cell is less than 80% of the normal value standard, the marked flooding fault condition (FLC) parameter becomes FLC = 1, and FLC = 0 in other cases. In the air starvation experiment, when we take the normal stable working state as the standard and the output power of the fuel cell is less than 80% of the normal value standard, the marked air starvation condition (LAC) parameter becomes LAC = 1, and LAC = 0 in other cases.

- Data normalization: To mitigate or remove the effect of data range difference, it is often necessary to normalize the raw data, which is a method of adjusting the values of numeric variables in the example dataset to typical scales. This paper uses a relatively simple and effective maximum normalization method. The calculation formula is as follows:

- Data grouping: The data of a neural network is usually divided into two groups, namely the training dataset and the test dataset. The training dataset is used to train the model, and a portion of the data is used as a validation dataset to adjust the training parameters. The test dataset is used to verify the performance of the neural network model.

2.2. Neural Network Models

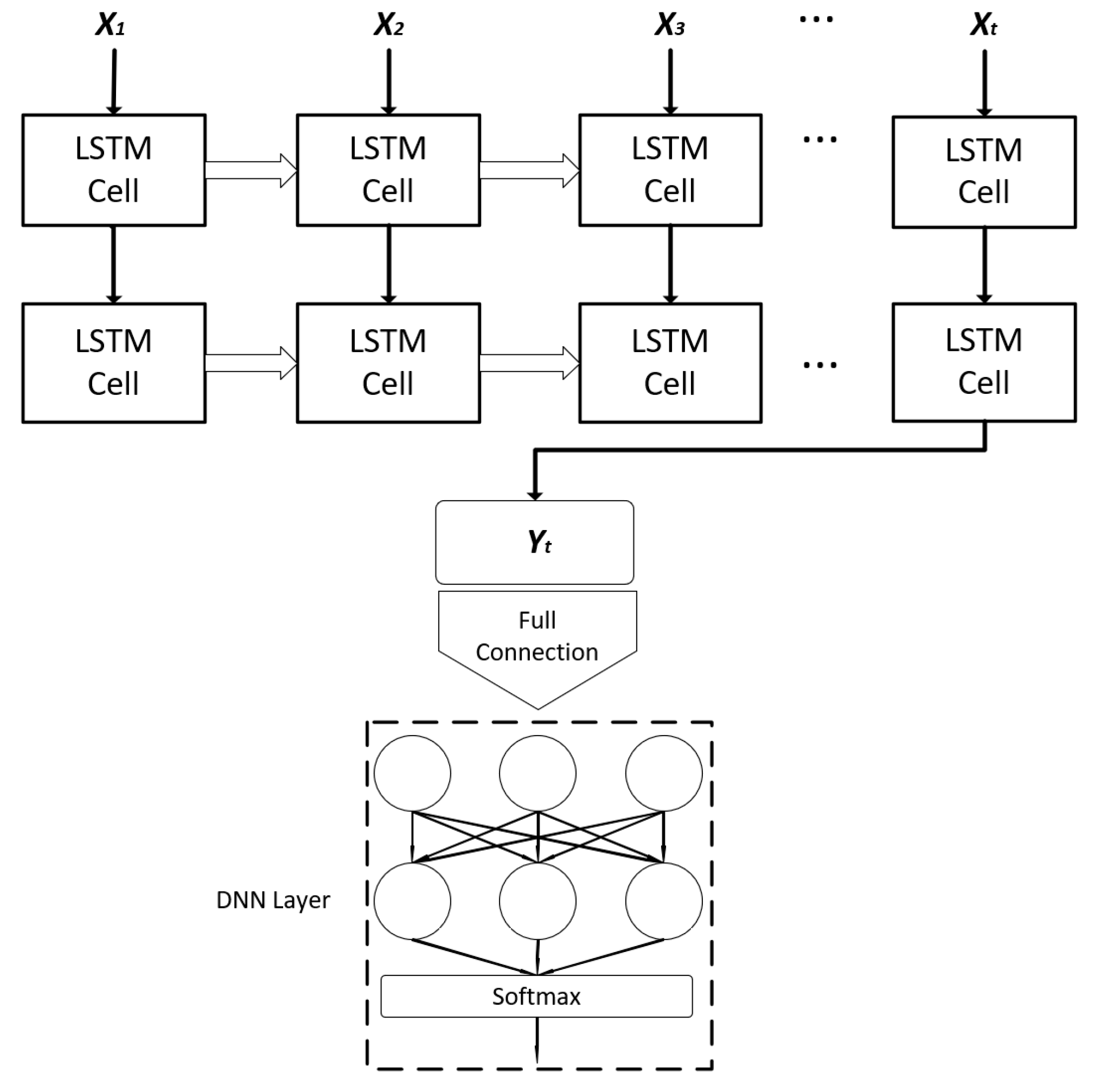

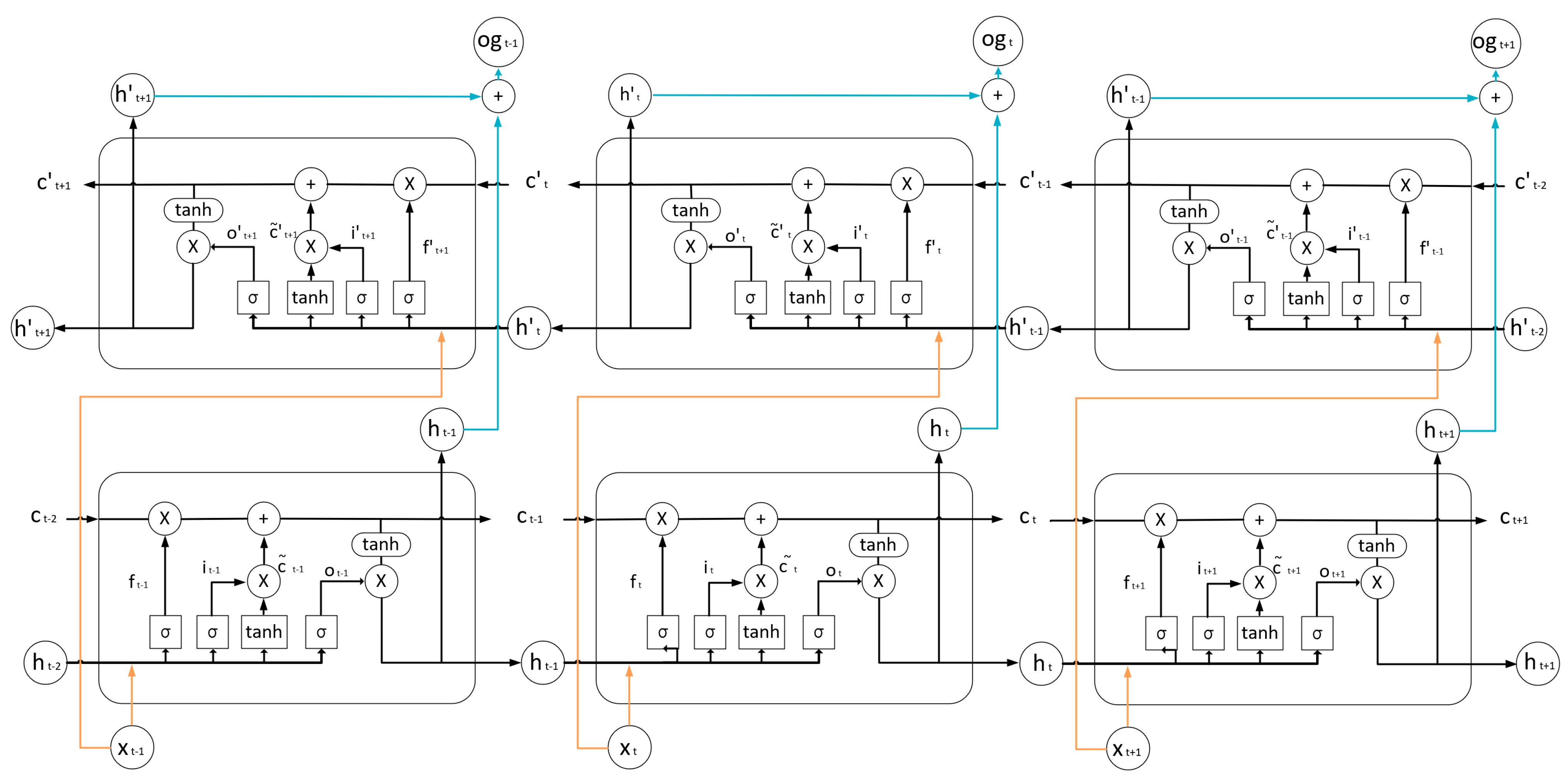

2.2.1. LSTM Neural Network Model

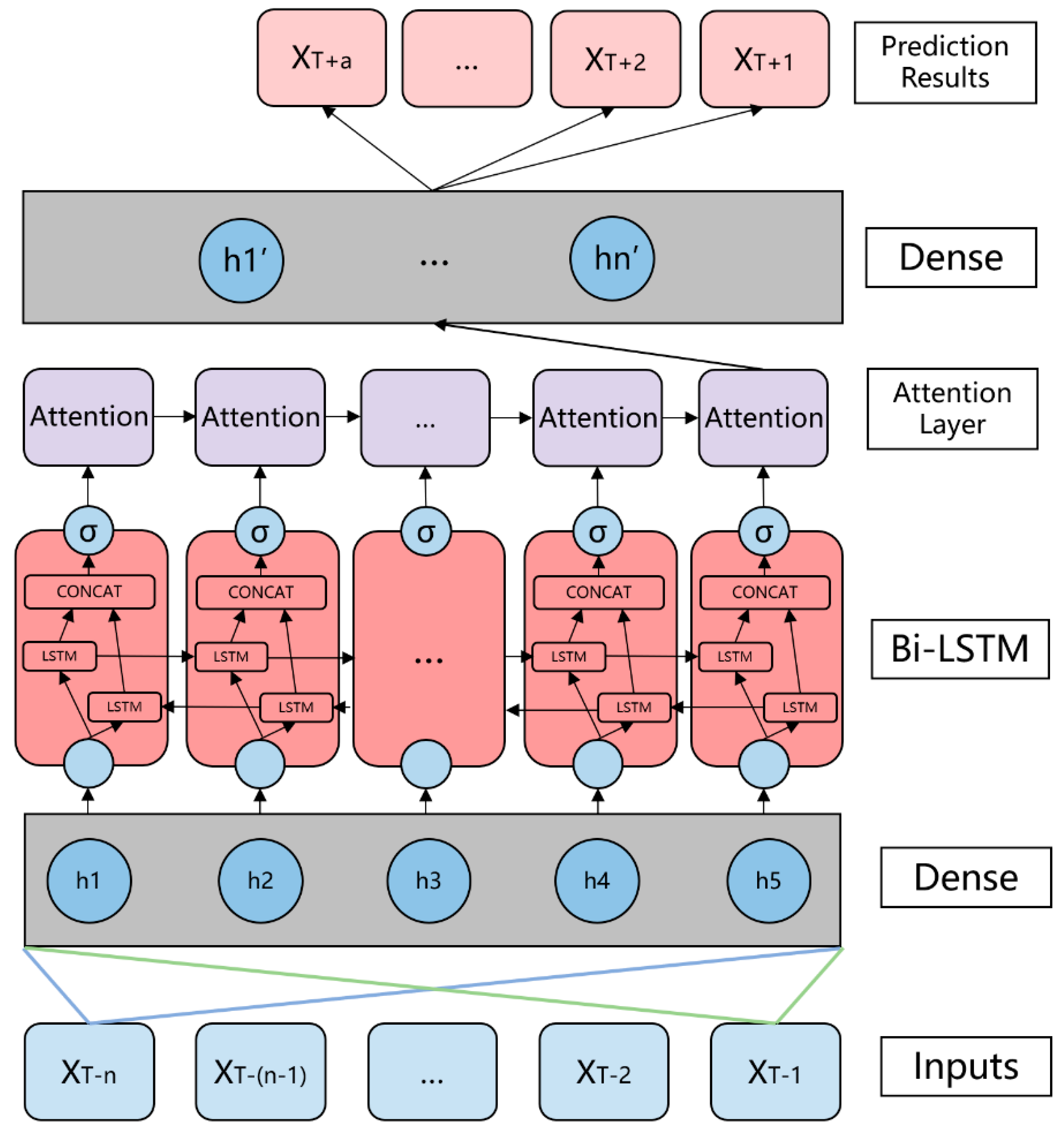

2.2.2. ConvBLSTM-PMwA Neural Network Model

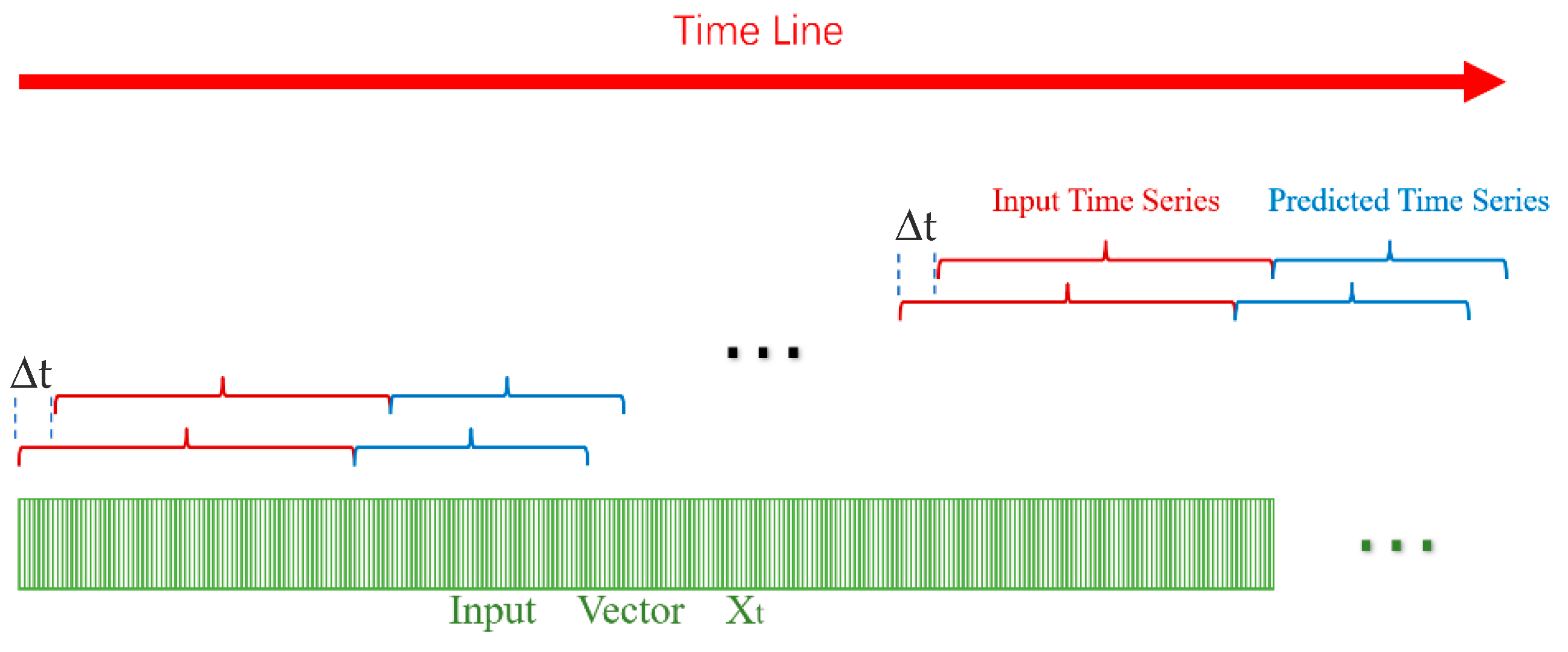

2.3. Input Data for Online Calculation

2.4. Hyperparameter Selection and Tuning

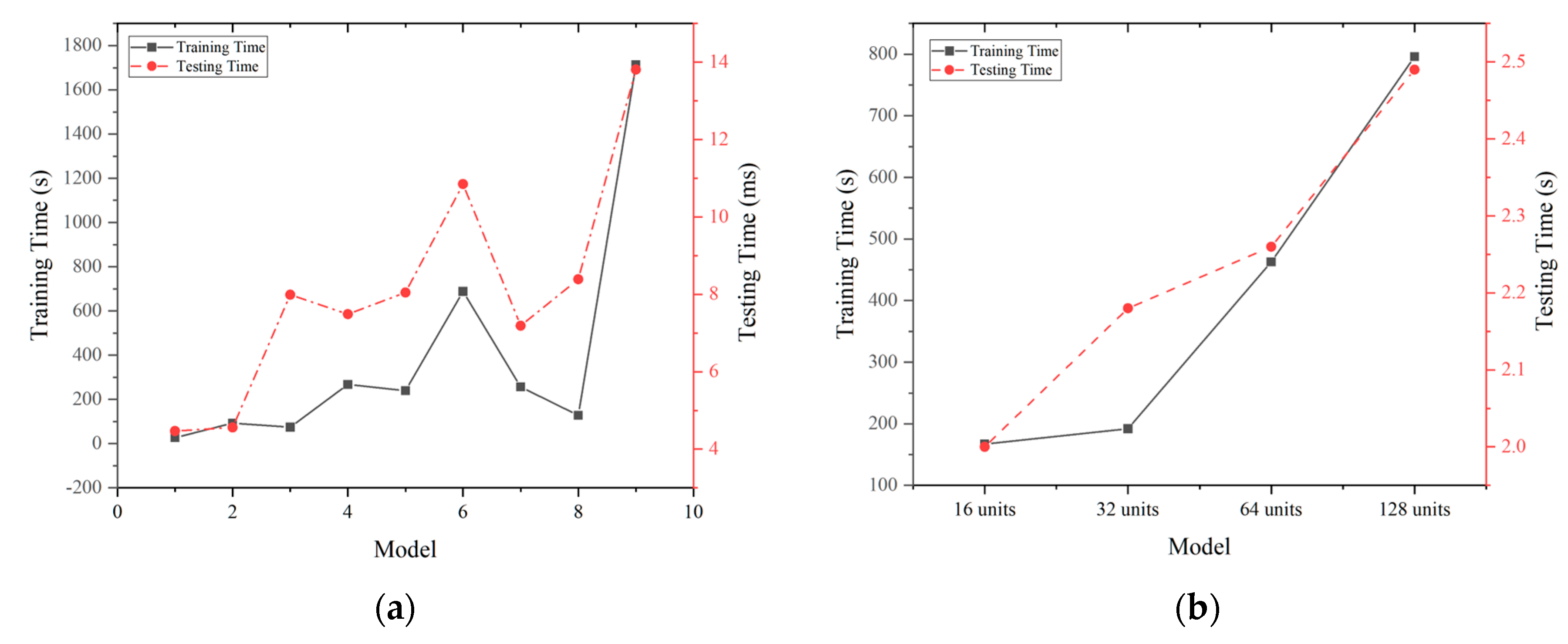

2.4.1. LSTM Model Hyperparameter Tuning

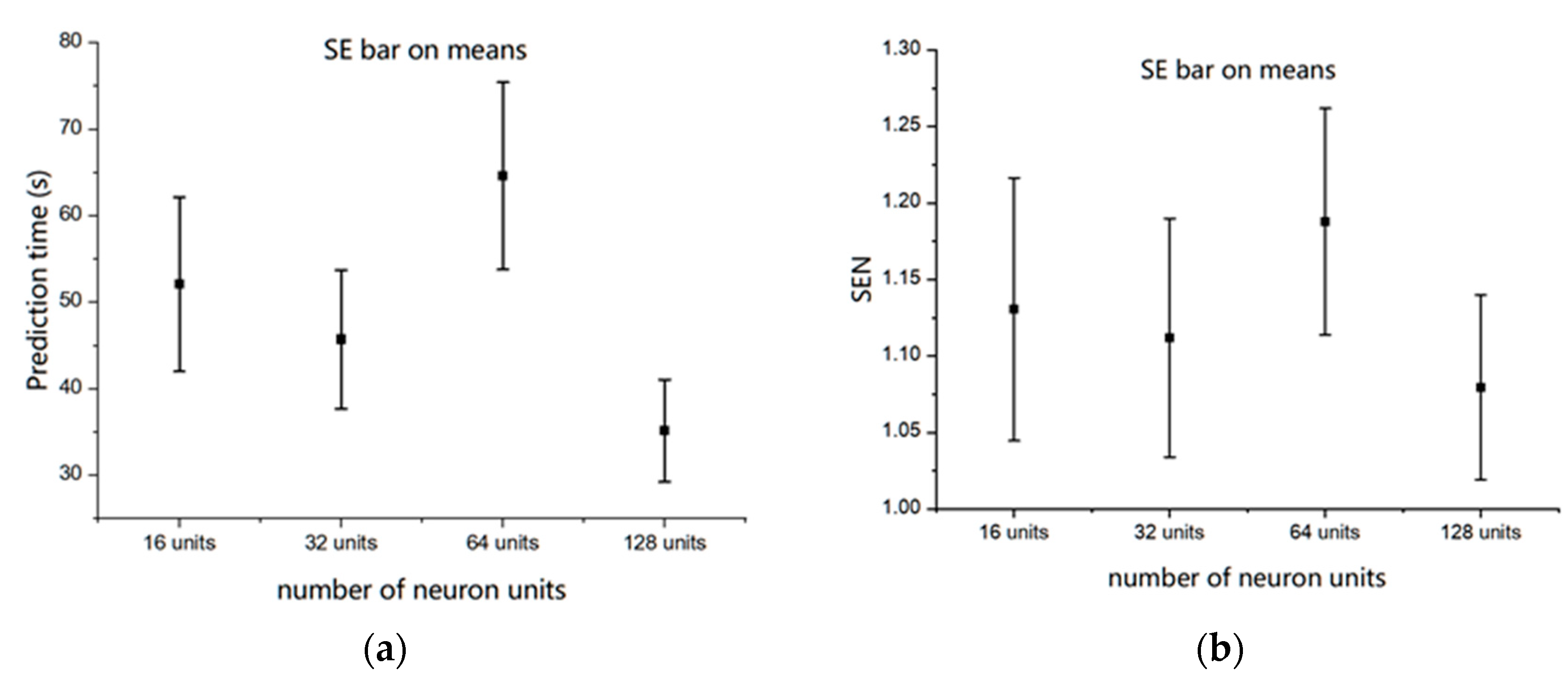

2.4.2. ConvBLSTM-PMwA Model Hyperparameter Tuning

2.5. Post Processing

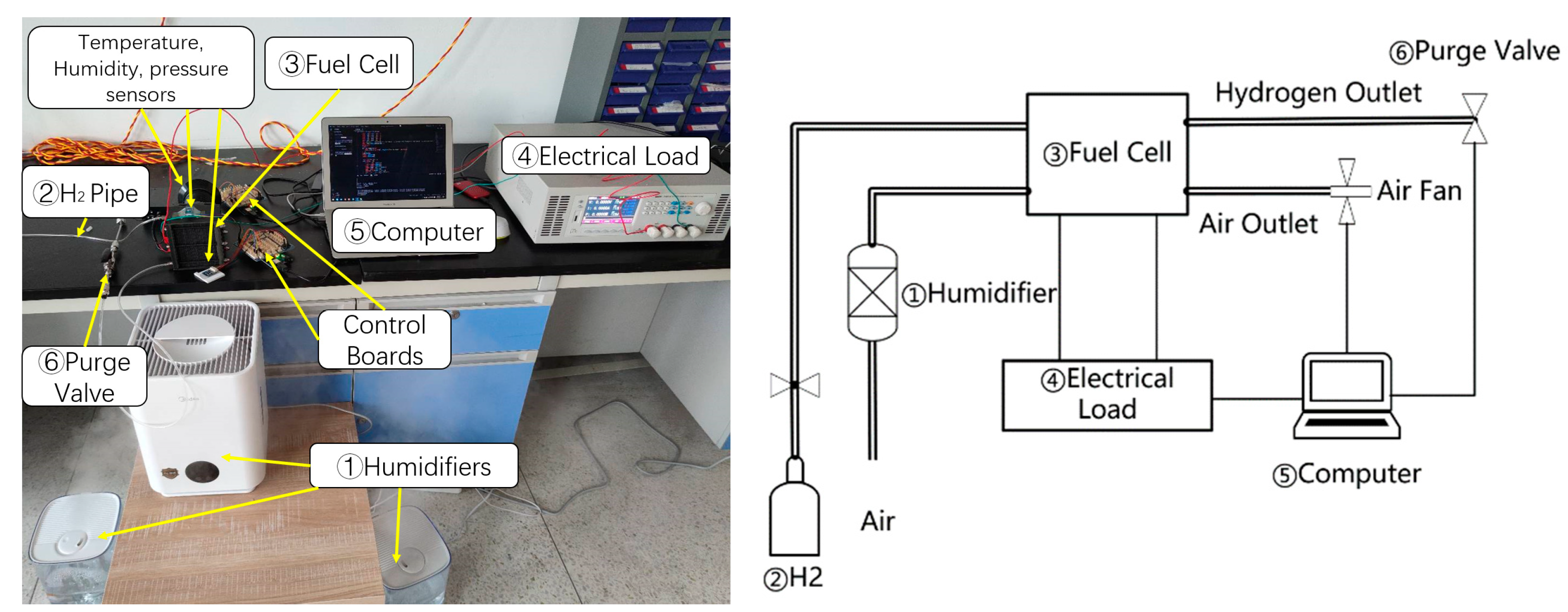

3. Experiment

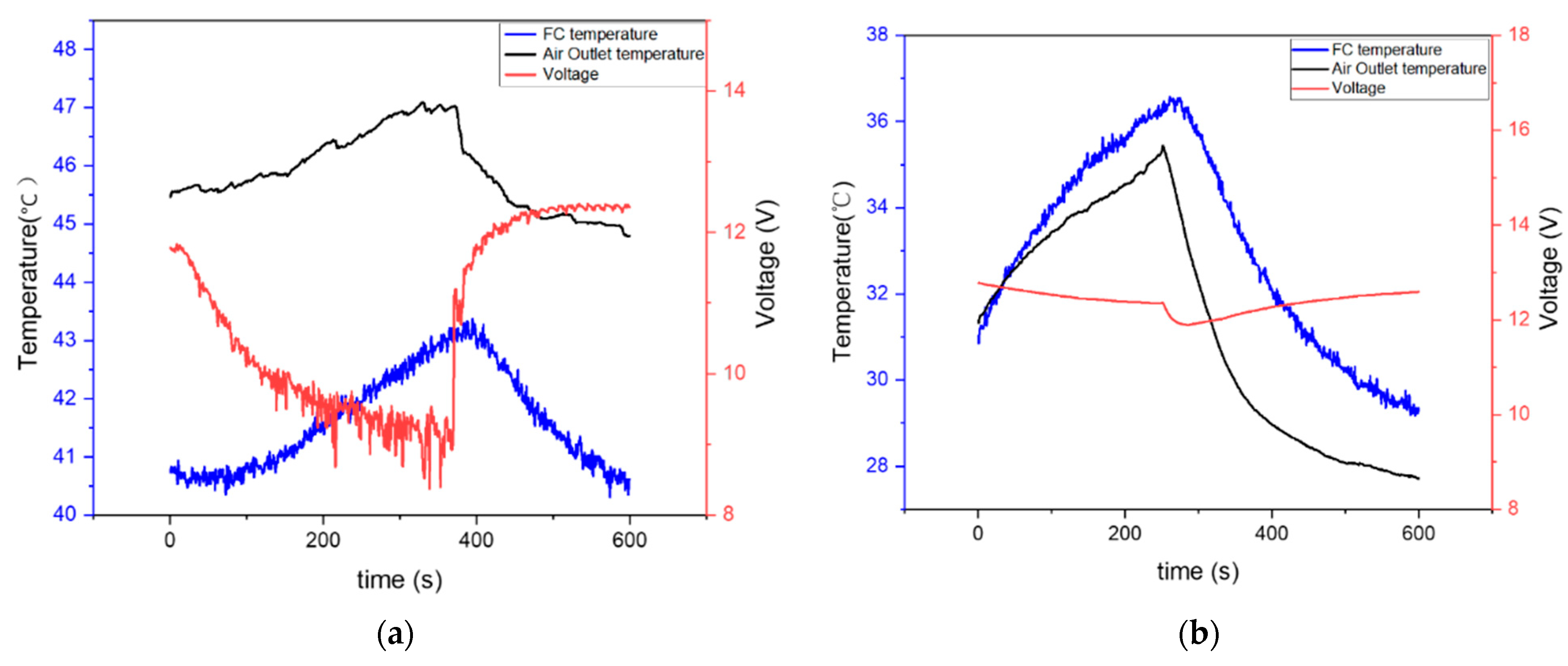

3.1. Flooding Experiment

3.2. Air Starvation Experiment

4. Results and Discussion

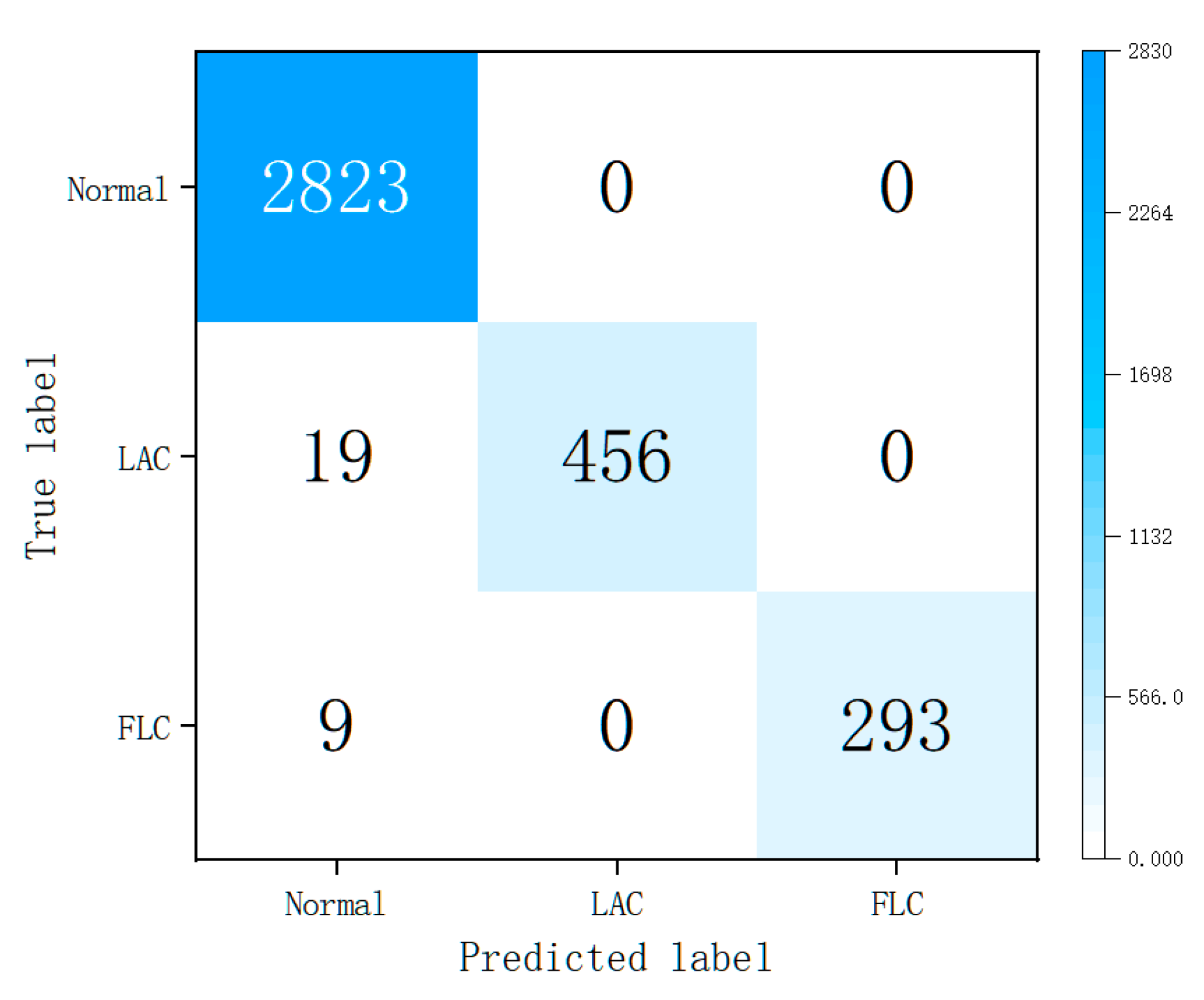

4.1. Experiment Results

4.2. Neural Network Results

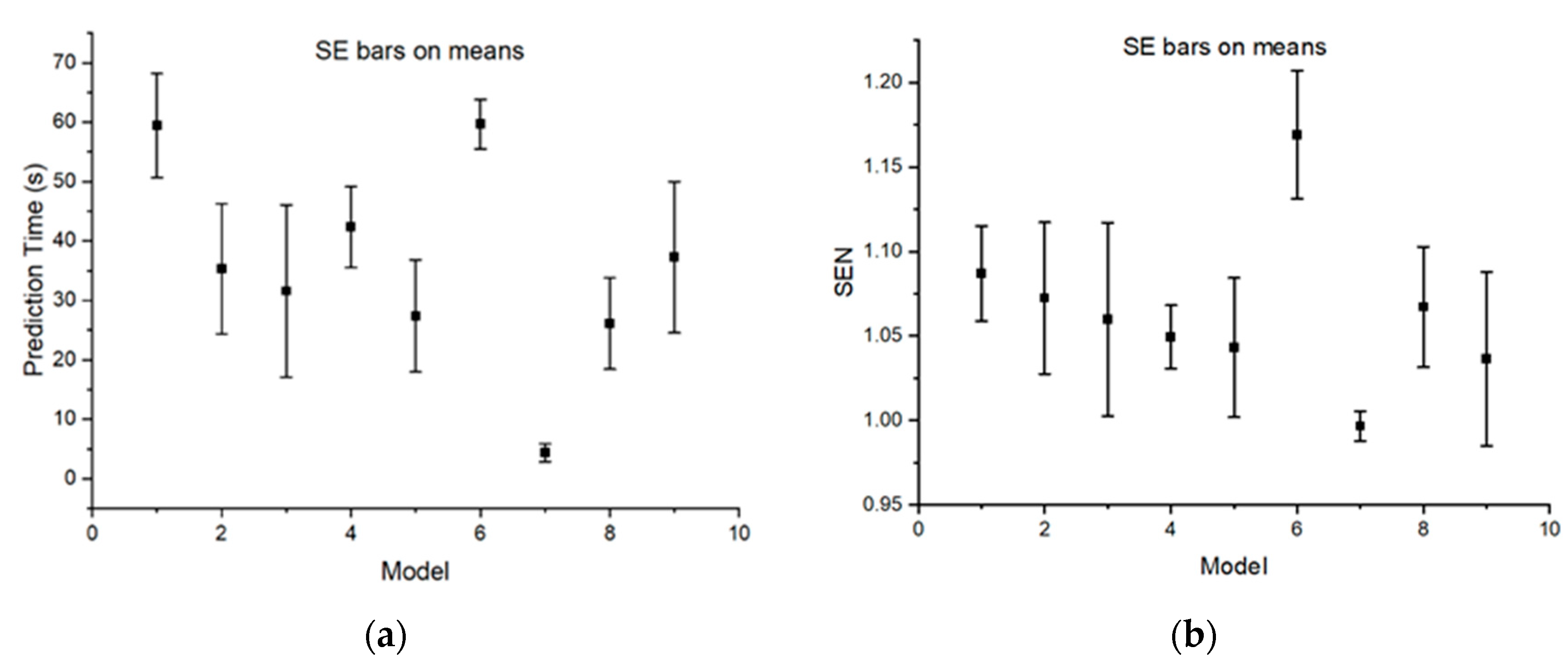

4.2.1. LSTM Model Results

4.2.2. ConvBLSTM-PMwA Model Results

4.3. Performance of Different Prediction Times

4.4. Performance of Prediction on Different Faults

4.5. Training and Testing Time

5. Conclusions

- The best model for fault prediction in PEMFC systems is the 64-unit ConvBLSTM−PMwA model, which achieves an accuracy of 96.49% and a prediction time of 64.63 s before the fault occurs.

- The optimal prediction target time is 60 s, as shorter times reduce the repair time and longer times decrease prediction accuracy.

- The ConvBLSTM-PMwA model outperforms the LSTM model in long-term prediction accuracy, as it can extract more hidden features from the sensor data.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PEMFC | Proton exchange membrane fuel cell |

| LSTM | Long short-term memory |

| ConvBLSTM-PMwA | CNN-based Bi-LSTM parallel model with attention mechanism |

| FLC | Flooding fault condition parameter |

| LAC | Air starvation condition parameter |

References

- Zhao, Y.; Setzler, B.P.; Wang, J.; Nash, J.; Wang, T.; Xu, B.; Yan, Y. An Efficient Direct Ammonia Fuel Cell for Affordable Carbon-Neutral Transportation. Joule 2019, 3, 2472–2484. [Google Scholar] [CrossRef]

- 2019 Fuel Cell Technologies Market Report. U.S. Department of Energy. Available online: https://publications.anl.gov/anlpubs/2021/08/166534.pdf (accessed on 6 June 2022).

- Wang, Y.; Pang, Y.; Xu, H.; Martinez, A.; Chen, K.S. PEM Fuel cell and electrolysis cell technologies and hydrogen infrastructure development—A review. Energy Environ. Sci. 2022, 15, 2288–2328. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, X.; Zhang, T.; Pei, P. The reactant starvation of the proton exchange membrane fuel cells for vehicular applications: A review. Energy Convers. Manag. 2019, 182, 282–298. [Google Scholar] [CrossRef]

- Huo, W.; Li, W.; Zhang, Z.; Sun, C.; Zhou, F.; Gong, G. Performance prediction of proton-exchange membrane fuel cell based on convolutional neural network and random forest feature selection. Energy Convers. Manag. 2021, 243, 114367. [Google Scholar] [CrossRef]

- Wang, J. System integration, durability and reliability of fuel cells: Challenges and solutions. Appl. Energy 2017, 189, 460–479. [Google Scholar] [CrossRef]

- Gu, X.; Hou, Z.; Cai, J. Data-based flooding fault diagnosis of proton exchange membrane fuel cell systems using LSTM networks. Energy AI 2021, 4, 100056. [Google Scholar] [CrossRef]

- Kim, S.-G.; Lee, S.-J. A review on experimental evaluation of water management in a polymer electrolyte fuel cell using X-ray imaging technique. J. Power Sources 2013, 230, 101–108. [Google Scholar] [CrossRef]

- Bodner, M.; Schenk, A.; Salaberger, D.; Rami, M.; Hochenauer, C.; Hacker, V. Air Starvation Induced Degradation in Polymer Electrolyte Fuel Cells. Fuel Cells 2017, 17, 18–26. [Google Scholar] [CrossRef]

- Laribi, S.; Mammar, K.; Sahli, Y.; Koussa, K. Analysis and diagnosis of PEM fuel cell failure modes (flooding & drying) across the physical parameters of electrochemical impedance model: Using neural networks method. Sustain. Energy Technol. Assess. 2019, 34, 35–42. [Google Scholar]

- Jiao, K.; Li, X. Water transport in polymer electrolyte membrane fuel cells. Prog. Energy Combust. Sci. 2011, 37, 221–291. [Google Scholar] [CrossRef]

- Pang, Y.; Wang, Y. Water spatial distribution in polymer electrolyte membrane fuel cell: Convolutional neural network analysis of neutron radiography. Energy AI 2023, 14, 100265. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Z.; Guan, C.; Gao, H. Optimization of sizing and frequency control in battery/supercapacitor hybrid energy storage system for fuel cell ship. Energy 2020, 197, 117285. [Google Scholar] [CrossRef]

- Xu, J.-H.; Yan, H.-Z.; Zhang, B.-X.; Ding, Q.; Zhu, K.-Q.; Yang, Y.-R.; Wan, Z.-M.; Lee, D.-J.; Wang, X.-D.; Tu, Z.-K. Multi-criteria evaluation and optimization of PEM fuel cell degradation system. Appl. Therm. Eng. 2023, 227, 120389. [Google Scholar] [CrossRef]

- Dhimish, M.; Vieira, R.G.; Badran, G. Investigating the stability and degradation of hydrogen PEM fuel cell. Int. J. Hydrogen Energy 2021, 46, 37017–37028. [Google Scholar] [CrossRef]

- Yang, Y.; Gao, Y.; Liu, Z.; Zhang, X.; Meng, F.; Wang, J.; Zhang, J.; Zhao, P.; Li, P.; He, X. Simultaneous measurement of local current and temperature distributions in proton exchange membrane fuel cells with dead-ended anode. Appl. Therm. Eng. 2023, 230, 120728. [Google Scholar] [CrossRef]

- Rahimi-Esbo, M.; Ramiar, A.; Ranjbar, A.A.; Alizadeh, E. Design, manufacturing, assembling and testing of a transparent PEM fuel cell for investigation of water management and contact resistance at dead-end mode. Int. J. Hydrogen Energy 2017, 42, 11673–11688. [Google Scholar] [CrossRef]

- Banerjee, R.; Ge, N.; Han, C.; Lee, J.; George, M.G.; Liu, H.; Muirhead, D.; Shrestha, P.; Bazylak, A. Identifying in operando changes in membrane hydration in polymer electrolyte membrane fuel cells using synchrotron X-ray radiography. Int. J. Hydrogen Energy 2018, 43, 9757–9769. [Google Scholar] [CrossRef]

- Sinha, P.K.; Halleck, P.; Wang, C.-Y. Quantification of Liquid Water Saturation in a PEM Fuel Cell Diffusion Medium Using X-ray Microtomography. Electrochem. Solid-State Lett. 2006, 9, A344. [Google Scholar] [CrossRef]

- Iranzo, A.; Gregorio, J.M.; Boillat, P.; Rosa, F. Bipolar plate research using Computational Fluid Dynamics and neutron radiography for proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2020, 45, 12432–12442. [Google Scholar] [CrossRef]

- Mishler, J.; Wang, Y.; Mukundan, R.; Spendelow, J.; Hussey, D.S.; Jacobson, D.L.; Borup, R.L. Probing the water content in polymer electrolyte fuel cells using neutron radiography. Electrochim. Acta 2012, 75, 1–10. [Google Scholar] [CrossRef]

- Damour, C.; Benne, M.; Grondin-Perez, B.; Bessafi, M.; Hissel, D.; Chabriat, J.-P. Polymer electrolyte membrane fuel cell fault diagnosis based on empirical mode decomposition. J. Power Sources 2015, 299, 596–603. [Google Scholar] [CrossRef]

- Debenjak, A.; Gašperin, M.; Pregelj, B.; Atanasijević-Kunc, M.; Petrovčič, J.; Jovan, V. Detection of flooding and drying inside a PEM fuel cell stack. J. Mech. Eng. 2013, 59, 56–64. [Google Scholar] [CrossRef]

- Ren, P.; Pei, P.; Li, Y.; Wu, Z.; Chen, D.; Huang, S.; Jia, X. Diagnosis of water failures in proton exchange membrane fuel cell with zero-phase ohmic resistance and fixed-low-frequency impedance. Appl. Energy 2019, 239, 785–792. [Google Scholar] [CrossRef]

- Mammar, K.; Saadaoui, F.; Laribi, S. Design of a PEM fuel cell model for flooding and drying diagnosis using fuzzy logic clustering. Renew. Energy Focus 2019, 30, 123–130. [Google Scholar] [CrossRef]

- Chen, X.; Xu, J.; Fang, Y.; Li, W.; Ding, Y.; Wan, Z.; Wang, X.; Tu, Z. Temperature and humidity management of PEM fuel cell power system using multi-input and multi-output fuzzy method. Appl. Therm. Eng. 2022, 203, 117865. [Google Scholar] [CrossRef]

- Pan, T.; Shen, J.; Sun, L.; Lee, K.Y. Thermodynamic modelling and intelligent control of fuel cell anode purge. Appl. Therm. Eng. 2019, 154, 196–207. [Google Scholar] [CrossRef]

- Chen, K.; Laghrouche, S.; Djerdir, A. Aging prognosis model of proton exchange membrane fuel cell in different operating conditions. Int. J. Hydrogen Energy 2020, 45, 11761–11772. [Google Scholar] [CrossRef]

- Yuan, H.-B.; Zou, W.-J.; Jung, S.; Kim, Y.-B. Optimized rule-based energy management for a polymer electrolyte membrane fuel cell/battery hybrid power system using a genetic algorithm. Int. J. Hydrogen Energy 2022, 47, 7932–7948. [Google Scholar] [CrossRef]

- Ma, T.; Zhang, Z.; Lin, W.; Yang, Y.; Yao, N. A Review on Water Fault Diagnosis of a Proton Exchange Membrane Fuel Cell System. J. Electrochem. Energy Convers. Storage 2021, 18, 030801. [Google Scholar] [CrossRef]

- Yousfi Steiner, N.; Hissel, D.; Moçotéguy, P.; Candusso, D. Diagnosis of polymer electrolyte fuel cells failure modes (flooding & drying out) by neural networks modeling. Int. J. Hydrogen Energy 2011, 36, 3067–3075. [Google Scholar]

- Zuo, B.; Zhang, Z.; Cheng, J.; Huo, W.; Zhong, Z.; Wang, M. Data-driven flooding fault diagnosis method for proton-exchange membrane fuel cells using deep learning technologies. Energy Convers. Manag. 2022, 251, 115004. [Google Scholar] [CrossRef]

- Yu, X.; Pingwen, M.; Ming, H.; Baolian, Y.; Shao, Z.-G. The critical pressure drop for the purge process in the anode of a fuel cell. J. Power Sources 2009, 188, 163–169. [Google Scholar] [CrossRef]

- Mao, L.; Jackson, L.; Davies, B. Investigation of PEMFC fault diagnosis with consideration of sensor reliability. Int. J. Hydrogen Energy 2018, 43, 16941–16948. [Google Scholar] [CrossRef]

- Kim, K.; Kim, J.; Choi, H.; Kwon, O.; Jang, Y.; Ryu, S.; Lee, H.; Shim, K.; Park, T.; Cha, S.W. Pre-diagnosis of flooding and drying in proton exchange membrane fuel cells by bagging ensemble deep learning models using long short-term memory and convolutional neural networks. Energy 2023, 266, 126441. [Google Scholar] [CrossRef]

- Yin, X.; Liu, Z.; Liu, D.; Ren, X. A Novel CNN-based Bi-LSTM parallel model with attention mechanism for human activity recognition with noisy data. Sci. Rep. 2022, 12, 7878. [Google Scholar] [CrossRef]

| Model | No. of LSTM Layers | Nodes of Each Layer |

|---|---|---|

| 1 | 1 | 16 |

| 2 | 1 | 32 |

| 3 | 1 | 64 |

| 4 | 2 | 16 |

| 5 | 2 | 32 |

| 6 | 2 | 64 |

| 7 | 3 | 16 |

| 8 | 3 | 32 |

| 9 | 3 | 64 |

| Model | No. of Neuron Units | No. of Parameters |

|---|---|---|

| 1 | 16 | 23,587 |

| 2 | 32 | 52,675 |

| 3 | 64 | 129,283 |

| 4 | 128 | 356,227 |

| Model | Overall Accuracy (%) | Prediction Time (s) | CV (%) |

|---|---|---|---|

| 1 | 96.03 | 59.43 | 36.01 |

| 2 | 95.61 | 35.31 | 75.84 |

| 3 | 96.15 | 31.58 | 112.45 |

| 4 | 97.94 | 42.32 | 39.54 |

| 5 | 95.99 | 27.41 | 84.48 |

| 6 | 95.90 | 59.65 | 17.07 |

| 7 | 95.06 | 4.39 | 86.26 |

| 8 | 96.67 | 26.10 | 72.18 |

| 9 | 96.18 | 37.28 | 83.60 |

| Model | Overall Accuracy (%) | Prediction Time (s) | CV (%) |

|---|---|---|---|

| 16 units | 95.91 | 52.08 | 19.36 |

| 32 units | 97.28 | 45.72 | 17.52 |

| 64 units | 96.49 | 64.63 | 16.73 |

| 128 units | 94.68 | 35.16 | 16.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Ran, H.; Chen, Z.; Kwan, T.H.; Yao, Q. Online Pre-Diagnosis of Multiple Faults in Proton Exchange Membrane Fuel Cells by Convolutional Neural Network Based Bi-Directional Long Short-Term Memory Parallel Model with Attention Mechanism. Energies 2025, 18, 2669. https://doi.org/10.3390/en18102669

Chen J, Ran H, Chen Z, Kwan TH, Yao Q. Online Pre-Diagnosis of Multiple Faults in Proton Exchange Membrane Fuel Cells by Convolutional Neural Network Based Bi-Directional Long Short-Term Memory Parallel Model with Attention Mechanism. Energies. 2025; 18(10):2669. https://doi.org/10.3390/en18102669

Chicago/Turabian StyleChen, Junyi, Huijun Ran, Ziyang Chen, Trevor Hocksun Kwan, and Qinghe Yao. 2025. "Online Pre-Diagnosis of Multiple Faults in Proton Exchange Membrane Fuel Cells by Convolutional Neural Network Based Bi-Directional Long Short-Term Memory Parallel Model with Attention Mechanism" Energies 18, no. 10: 2669. https://doi.org/10.3390/en18102669

APA StyleChen, J., Ran, H., Chen, Z., Kwan, T. H., & Yao, Q. (2025). Online Pre-Diagnosis of Multiple Faults in Proton Exchange Membrane Fuel Cells by Convolutional Neural Network Based Bi-Directional Long Short-Term Memory Parallel Model with Attention Mechanism. Energies, 18(10), 2669. https://doi.org/10.3390/en18102669