Abstract

The growing need for sustainable biomass use has led to the development of decision support tools that investigate the implementation of biomass valorization methods. Most existing tools focus on minimizing supply chain costs and emissions, often lacking a holistic approach that integrates economic, social, and circularity principle factors. This paper introduces the Biomass Valorization Recommender tool, a decision facilitation system developed to support biomass producers, policymakers, and technology providers in selecting optimal biomass valorization pathways. The tool applies a multi-criteria analysis that incorporates biomass quality characteristics, the biomass pyramid and waste hierarchy principles, and socio-economic indicators to evaluate potential valorization pathways of the selected biomass feedstock and technology. The scoring methodology generates a ranked inventory of biomass valorization pathways, such as food ingredients, chemicals, materials, biofuels, and energy production. Additionally, the tool evaluates co-digestion feasibility for anaerobic digestion applications, as well as biogas production potential, and provides biomass roadside cost data to enhance decision-making. A theoretical example in Italy using the industrial fermentation process demonstrates its applicability in biomass valorization solutions within a circular economy framework. This tool aims to identify and assess feedstock valorization opportunities for stakeholders seeking to increase feedstock flexibility and reduce waste by promoting sustainable biomass management, circular economy, and bioeconomy principles.

1. Introduction

Biomass is a renewable resource that can be processed into valuable products, including biofuels, chemicals, and materials [1]. The valorization of biomass plays a crucial role in the circular economy (CE) and the transition to a sustainable bioeconomy. According to ISO 59004, a CE is defined as “an economic system that uses a systemic approach to maintain a circular flow of resources, by recovering, retaining, or adding to their value, while contributing to sustainable development” [2]. In 2022, the European Parliament adopted amendments to Directive (EU) 2018/2001, reinforcing the need for bioenergy policies to align with the cascading principle of biomass use. This directive emphasizes the importance of utilizing sustainable biomass resources efficiently to support the development of novel, valuable bio-based solutions in accordance with CE principles [3]. The goal is to design flexible cascading pathways that ensure almost all resources remain in the circular loop, retaining added value for as long as possible, and minimizing the need for final disposal [4,5]. Whilst CE principles are clearly defined, the literature combines these principles as a benefit to sustainability, while the connection between CE and environmental, social, and economic sustainability remains ambiguous [6,7].

To address these requirements, this study presents a Biomass Valorization Recommender tool designed to assist biomass producers (i.e., farmers, industries, etc.), policymakers, or technological providers in evaluating optimal biomass-to-product conversion pathways by maximizing resource efficiency, promoting value-added biomass applications, and supporting circular, low-waste systems [8]. This tool integrates a repository containing biomass quality characterization data, roadside cost data, and potential valorization pathways based on feedstock type and applied technology. Additionally, it includes co-digestion feasibility assessments for biomass mixtures and biogas volume calculations for cases where anaerobic digestion is applied, to evaluate the potential energy reduction of the process in case the biomass mix is appropriate for co-digestion application and biogas production.

The Biomass Valorization Recommender tool contributes to the strategic objectives of sustainable resource management and CE policies by enhancing resource efficiency, reducing waste, and optimizing biomass valorization pathways in alignment with regulatory frameworks. Through its structured decision support framework, the tool facilitates the efficient utilization of biomass feedstocks, ensuring their sustainable conversion into high-value products.

2. State of the Art

This subchapter presents the outcome of an inventory of the most advanced tools and the respective projects for supporting the analysis of the different aspects of biomass use.

2.1. Related Tools and Projects

2.1.1. S2Biom EU Project

This project supports the sustainable delivery of non-food biomass feedstock through developing datasets, strategies, and roadmaps at local, regional, national, and pan-European level for EU28, the western Balkans, Ukraine, Moldova, and Turkey [9]. Biomass potential comes from agriculture, forestry, and waste sectors [10].

Within this project, the following biomass tools have been developed:

- Biomass supply tool enables users to select a biomass type and show its available amount on a map. The user can select between NUTS0 and NUTS3 level, the year (2012, 2020, or 2030), and the different types of potentials that are technical and base potentials considering currently applied sustainability practices. In addition, the user can also choose the level entities in absolute levels (Kton dm or TJ), area weighted (Kton dm/km2 or GJ/km2), and weighted average road side cost (EUR/ton dm) [11].

- Biomass cost/supply tool enables the user to make selections of biomass types for which cost levels can be displayed in a cost–supply graph. These graphs display the total accumulated biomass (ordered from cheap to expensive) against the average roadside cost for the country or countries and scenario years chosen. Roadside cost encompasses all biomass production, collection, and pre-treatment costs up to the road where the biomass is located [11].

The road side cost data from both tools were integrated into the database to enrich the recommender solution for the user.

2.1.2. MAGIC EU Project

The MAGIC project aims to help farmers decide which industrial crops are suitable for their respective marginal locations. Using the framework of the MAGIC project, the Bio2Match tool was developed. This tool can be used to match biomass feedstocks to conversion technologies in order to support stakeholders (e.g., entrepreneurs or policymakers) in the bioeconomy to find opportunities for further exploitation of existing indigenous biomass resources. Two databases of technology and biomass characteristics were used, taking into account the value pyramid of end-use applications (materials, chemicals, fuels, and energy).

Regarding the Bio2Match tool, each conversion technology has specific biomass input requirements and is selected based on the expectation to play a key role in renewable energy and the bioeconomy in 2020 and 2030. The chosen technologies were classified into these classes: (i) thermal conversion technologies, (ii) biochemical conversion technologies, and (iii) anaerobic digestion. After that, each class was then further subdivided into main categories, subcategories, and individual process names. General information about each technology is also available in the database (i.e., TRL, conversion efficiency, labor requirements, etc.) [12,13]. For matching the technology criteria with biomass characteristics, the three main classes received various sets of specifications. Thermal processing technologies have criteria for corrosion, ash agglomeration, ash content, and NOx emissions. Chemical and biochemical processes have criteria on the ash content, lignin, hemicellulose, and cellulose. Anaerobic digestion has criteria for digestibility and biogas yield. Moreover, the bio-based products that are in line with lignocellulosic bio-based products that were expected to contribute the most to market demand in 2020 and 2030 in the EU are heat, electricity, biofuels, biomethane, sugars, hydrogen, aromatics, methanol, and ethylene. In order to be able to match the different types of biomass to the conversion technologies, various characteristics were collected for each biomass type, i.e., chlorine, ash, nitrogen, and lignin content; ash deformation temperature; carbohydrates; biogas yield; and if biomass has an application as digestate or not [13].

While no data were directly used from the Bio2Match tool, it was used as a benchmark for review. Specifically, we analyzed its structure—including the selection of biomass types, technologies, and final products—as well as the methodology used for matching technologies to biomass characteristics and the resulting biomass–technology–product combinations. Additionally, the selected biomass types and technologies investigated within Bio2Match tool were considered as a baseline for our analysis of lignocellulosic biomass and final product pathways.

2.1.3. Tech4Biowaste EU Project

Within this project, a database of applied technologies was developed, aiming to improve biowaste valorization. The Decision Support Tool (DST), part of the database, was designed to assist users in finding technologies for converting specific biowaste feedstocks into products like fertilizers, chemicals, fuels, and energy. It comprises a feedstock–product matrix where users can choose a feedstock and product combination, and the tool indicates applied technologies through colored dots. When users click on these dots, they are directed to a technology comparison tool, which provides detailed information about the selected technology and its providers. The database is user friendly, regularly updated, and can support users aiming to analyze and compare biowaste valorization methods [14,15].

The outcomes of the DST and the feedstock–product matrix served as a basis for developing our tool, particularly in designing the biomass–technology–final product matching logic.

2.1.4. AgriPLaCE Platform

This platform aims to promote synergies between different actors involved in the whole value chain of biowaste of fruit and vegetables, from agricultural waste production to treatment and new product facilities. It consists of a database with potential utilization methods of the investigated biowaste streams and a tool that facilitates collaborations and synergies. The database is open-access and gives information about the type of fruit or vegetable, the waste type, the processes generating waste, the economic activity from which the waste originates, the conventional methods and emerging technologies of waste management, as well as the products derived from these methods and the economic activity and industrial sectors that valorize products derived from waste.

The potential users are divided into waste suppliers, namely, farmers, the food and beverage industry, retailers, HoReCa representatives, and waste demanders like owners of waste treatment technologies and industrial partners interested in using biowaste in their processes. It is presumed that there is a mutual need between the actors, and each user needs information from the other user. Moreover, the waste suppliers need information about the valorization pathways of the waste and the waste demanders want to know which supplier could provide waste that could be used by their technology. For this reason, users are requested to submit relevant information about their waste management needs when they register on the website. This information is stored in the user data repository and used in the synergies tool that is accessible only to registered users. For matching the users, an engine calculates the priority of each user profile stored and sorts all users based on that [16,17].

Although no direct data from the AgriPLaCE Platform were used, its methodological approach to biomass and waste classification, system architecture, and matching algorithm informed the design of the decision-making framework and the system architecture of our tool.

2.2. Biomass Datasets

The most relevant biomass datasets investigated to be used on the Biomass Recommender tool are listed below:

- (i)

- The INRAE dataset presents the chemical characteristics (i.e., carbon and nitrogen contents and biochemical composition) of plant biomass and crop residues from agrosystems in Europe, gathered from the scientific literature. These data were gathered within the European project ResidueGas, which aims to improve the calculation of greenhouse gas (GHG) emissions emitted by crop residues [18].

- (ii)

- Within the S2Biom EU project, a computerized toolset that contains fully populated databases of lignocellulosic biomass at local, regional, and pan-European levels was developed. The biomass database includes an extensive characterization of lignocellulosic biomass with indicative data of density; gross and net calorific value; the content of ash, lignin, cellulose, starch, sugar, nitrogen, chlorine, sulfur, and fluorine; suitability of biogas production; biogas yield; and the applicability of the digestate as a solid [19]. These data come from the literature.

- (iii)

- The Phyllis database houses a great variety of biomasses and waste materials (biochar, char, fossil fuels, manure, grass plants, marine biomass, non-organic residue, sludge, straws, treated wood, etc.). This database contains a detailed analysis of its composition and properties (macroelements, heating value, trace elements, etc.). The data may be freely used for any purpose, and are updated and extended regularly [20].

Among the three datasets, the Phyllis database was primarily used in the development of the Biomass Recommender tool due to its detailed compositional data on various biomass types. The other datasets (INRAE and S2Biom) were used as supplementary sources to fill in data gaps where necessary, in cases where specific parameters were missing.

3. System Concept, Architecture, and Design

Despite significant technological advancements in biomass valorization over the past decades, the selection of appropriate valorization pathways based on the quality characteristics of the biomass remains a complex challenge. The decision-supporting tools presented in the previous section were developed to match biomass-to-conversion technology or to aid in determining the optimal technology and location while also assisting policymakers and entrepreneurs in assessing the feasibility of biomass-based conversions. These tools focus more on minimizing supply chain costs and emissions, yet challenges persist due to technical constraints, pre-treatment complexities, and the wide range of available conversion technologies. The Biomass Valorization Recommender tool integrates a multi-criteria decision facilitation approach that considers the biomass quality characteristics, the biomass pyramid and waste hierarchy principles, as well as socio-economic indicators to rank optimal valorization pathways. In addition, the tool evaluates biomass co-digestion applications for anaerobic digestion technologies. This holistic approach provides a more comprehensive and adaptable solution for stakeholders in biomass utilization.

An overview of the architecture of the Biomass Valorization Recommender tool is presented in this section. This tool is a digital facilitation tool developed within the TRINEFLEX project. TRINEFLEX is an innovation project, funded by the European Commission under the Horizon Europe program, designed to support the transformation of energy-intensive industrial processes by integrating energy flexibility and supply of raw materials [21]. One of the aspects TRINEFLEX focusses on is feedstock flexibility. In this context, a concept behind a Biomass Valorization Recommender, which is being developed to contribute to this facet, is presented [22].

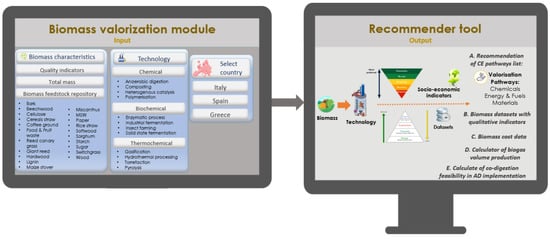

The developed tool consists of two primary modules: (1) the Biomass Valorization Module (Input data), and (2) the Valorization Recommender tool (Output/Results). These components communicate to assess biomass characteristics and applicable technology and provide users with valuable insights for optimizing biomass utilization. The envisaged users of the tool are biomass owners, for example, farmers, industries, companies, or associations of biomass producers, as well as municipalities and country- or EU-level authorities. This user group was chosen to cover all the potential stakeholders interested in accessing information on biomass quality characteristics, roadside cost data, and possible valorization pathways. In particular, industries and companies are tailored to the TRINEFLEX project, in which integrating biomass valorization into existing industrial processes is a key priority. The tool is built using Python 3.12.4 and FastAPI 0.111.0 for efficient backend processing, with PostgreSQL 16.2 as the database for managing biomass characterization data. The system processes user inputs through API endpoints, retrieving relevant information and performing feasibility assessments before generating ranked valorization pathways. The tool was internally tested and demonstrated at the pilot plants of the project to validate its functionality and practical applicability in actual scenarios.

The user is asked to define specific input data to enable tailored valorization pathways recommendations. Specifically:

- (i)

- Biomass feedstock from a predefined biomass list with its fixed quality characteristics from available datasets [20]; the biomass list comes from the state-of-the-art analysis of the related tools, specifically from the investigated biomass types of the MAGIC and Tech4Biowaste projects as well as from the corresponding datasets available in the Phyllis database.

- (ii)

- Technology (if applied): this input helps to refine the recommended valorization pathways in case of a specific technology (e.g., anaerobic digestion, gasification, pyrolysis) applied to the selected biomass feedstock; the selected technologies come from the state-of-the-art analysis of the related tools as well.

- (iii)

- Total mass (kg/year): in order to define the quantity of biomass that is used for the calculation of biogas production and co-digestion feasibility.

- (iv)

- Quality indicators of the biomass to calculate potential biogas production and co-digestion feasibility; for the biogas production calculation, the tool uses the biomass feedstock input by reading carbon, hydrogen, oxygen, and nitrogen content from the database of the respective biomass while for the co-digestion feasibility, the user either select a biomass mix from the list or define specific input values for each biomass such as Chemical Oxygen Demand (COD), Biochemical Oxygen Demand (BOD), C/N ratio, and soluble COD.

- (v)

- Country (i.e., Italy, Spain, Greece) where biomass feedstock is harvested/collected or processed: this input is used in socio-economic indicator definitions and is tailored to the location of the pilot plants of the TRINEFLEX project.

The output of the Biomass Valorization Recommender tool provides a ranking inventory list with different biomass valorization pathways based on the quality characteristics of the biomass feedstock, waste hierarchy, and biomass pyramid, as well as socio-economic indicators. The potential valorization pathways (i.e., biochemicals, biofuels, energy) are evaluated to maximize the added value of biomass utilization. These pathways are ranked from the most to the least preferable solution based on a calculated score that assesses different valorization options. This output responds to the TRINEFLEX project objective of identifying and evaluating feedstock valorization opportunities in order to increase feedstock flexibility in pilot plants. Moreover, it provides calculators for co-digestion implementation and biogas production in case of anaerobic digestion applications, as well as roadside cost data and quality characteristics for specific types of biomass. Both calculators come from the needs of pilot plants for the exploitation of co-digestion opportunities within their process and further reduction of the energy consumption, which is a key goal of the TRINEFLEX project. The collection of roadside cost data reflects the need for low-cost biomass resources. The structure of these modules is shown in Figure 1.

Figure 1.

System concept for Biomass Valorization Recommender tool.

4. System Features

4.1. Biomass Database and Roadside Cost Data Inputs

The Biomass Recommender tool incorporates a comprehensive database containing datasets derived from the Phyllis database [20], which provides quality characteristics for various biomass types. These include sugar, coffee grounds, food waste, fruit waste, potato peels, starch, vegetable waste, paper and cardboard, oils, vegetable oils, municipal solid waste (MSW), bark, beech wood, hardwood, cellulose, lignin, sorghum, miscanthus, switchgrass, giant reed, reed canary grass, rice straw, cereal straw, maize stover, sugar beet leaves, sunflower straw, and roadside verge biomass (grassy). In addition, the database integrates roadside biomass cost data (in Euros per ton) for several biomass types, including miscanthus, switchgrass, giant reed, reed canary grass, rice straw, maize stover, sugar beet leaves, sunflower straw, and roadside verge biomass (grassy). These cost data are sourced from the S2Biom project [11].

4.2. Biomass-to-Technology Mapping

The tool establishes a direct link between biomass types and applicable valorization technologies by categorizing them into three main pathways: (I) chemical processes include anaerobic digestion, composting, heterogenous catalysis, and polymerization; (II) biochemical processes include enzymatic process, industrial fermentation, insect farming, and solid-state fermentation; (III) thermochemical processes include gasification, hydrothermal processing, torrefaction, and pyrolysis. The relation between the biomass and the applicable technologies is in line with the feedstock–product matrix of the Tech4Biowaste EU project [15], which provides a structured feedstock–product matrix to facilitate the identification of appropriate biomass valorization pathways.

4.3. Scoring Methodology

To evaluate potential biomass valorization pathways, the assessment considers (A) the circular economy value of the final product, according to the principles of the biomass pyramid and the waste hierarchy; and (B) socio-economic indicators, including the number of workers, turnover, and value added, differentiated by country (i.e., Italy, Greece, and Spain). The selection of these countries aligns with the locations of the pilot cases in the TRINEFLEX project. Both criteria are adapted to the key principles of the circular economy related to environmental protection and economic and social viability. Specifically, the selection of the biomass pyramid sub-criterion aims to increase the efficient use of biomass, while the waste hierarchy aims to minimize the environmental impact of the recommender valorization pathways. Moreover, the selection of the socio-economic sub-criterion aims to evaluate social equity, through job creation and enhancement of well-being through the respective sector in which the valorization path is impacted [23,24,25,26].

The scoring scheme of the recommender pathways follows the following approach:

- A.

- Circularity aspect:

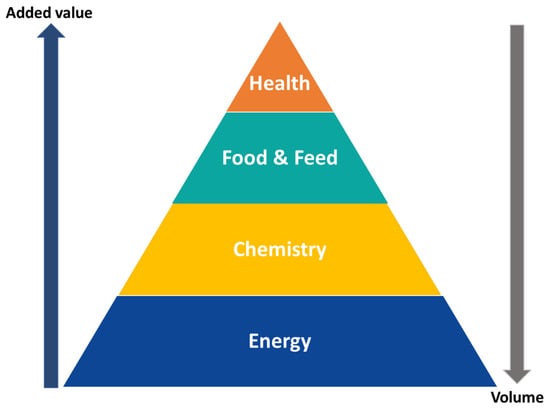

Sub-criterion 1 (Biomass pyramid): The biomass pyramid principle (see Figure 2) assumes that, firstly, biomass is applied for financially promising applications, that is, health (e.g., drugs [27,28]), food (e.g., meat alternatives [29,30], dietary supplements [31,32]), and chemistry (e.g., enzymes [33,34], materials [35,36]); following, this the residuals are used for other applications to the greatest extent, such as energy (e.g., heat and electricity) and biofuels (e.g., biodiesel, bioethanol) [37,38]. Based on these applications of biomass/waste, presented in Figure 2, the corresponding sub-scores are equal to 1 for health applications, 0.75 for food and feed production, 0.5 for chemical applications, and 0.2 for energy production.

Figure 2.

Biomass value pyramid.

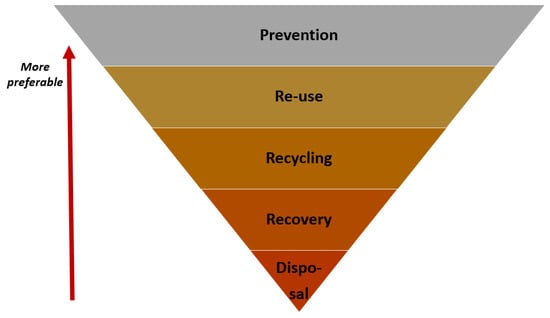

Sub-criterion 2 (Waste hierarchy): Directive 2008/98/EC [39] provides a framework for the treatment of waste within the EU called the waste hierarchy (see Figure 3). The waste hierarchy sets priorities in waste prevention and management as follows: (1) prevention, i.e., actions taken before a material or product is discarded; (2) preparing for re-use, i.e., operations (e.g., cleaning, repairing, recovery) in which products or their components are made for re-using without further pre-processing; (3) recycling, i.e., any recovery process in which waste materials are converted into new products, materials, or substances for different applications; (4) other recovery listed in Annex II of the directive, e.g., energy recovery, including fuel production, exchange of waste to be used for energy recovery, use of waste from energy recovery process or land treatment like composting; (5) disposal, i.e., any operation that is not recovery and is detailed in Annex I of the directive. Taking for granted that prevention is not investigated within the TRINEFLEX project, the corresponding scoring is equal to 1 in case of biomass re-use (i.e., fertilizers) within the process, 0.75 in case of recycling (i.e., any recommended solution not included in other cases, for example, materials, chemicals, food ingredient production), 0.4 in case of another recovery (i.e., energy, composting, fuels), and 0 in case of disposal.

Figure 3.

Waste hierarchy pyramid.

Both sub-criteria aim to prioritize the CE pathways that give the highest circular economy value to the final product. The scoring methodology of the biomass pyramid and waste hierarchy for each recommender valorization pathway, including the biomass inputs and the implemented technology per category (i.e., chemical, biochemical, and thermochemical processes), is presented in Appendix A.

- B.

- Social–economic aspect:

Based on the literature [40,41], different socio-economic indicators are investigated for each recommender pathway. Specifically, the following indicators are investigated based on NACE sectors (Table 1) considered part of the bioeconomy [40]:

Table 1.

NACE sectors considered part of the bioeconomy [40].

- The number of employees, i.e., the total number of persons who work in the plant;

- The turnover, i.e., the totals invoiced by the plant;

- The value added at factor cost, i.e., the gross income from operating activities.

Table 2, Table 3 and Table 4 present the socio-economic indicators per each NACE sector taking into account each pilot case country (i.e., Greece, Italy, Spain), as well as the EU. Workers are quantified as the number of employees, turnover and value added are measured in EUR million. The sub-scores are adapted properly to enhance the bioeconomy sector with the highest contribution to society.

Table 2.

Socio-economic parameters and sub-scores of Greece in 2020 [42].

Table 3.

Socio-economic parameters and sub-scores of Italy in 2020 [42].

Table 4.

Socio-economic parameters and sub-scores of Spain in 2020 [42].

This criterion aims to enhance the sectors in each investigated country where more people are employed and achieve high revenues and gross income.

The final ranking of valorization solutions is determined by the average score derived from the following indicators: (i) biomass pyramid, (ii) waste hierarchy, (iii) number of workers, (iv) turnover, and (v) value added.

5. Decision Facilitation and Outputs

The Biomass Valorization Recommender tool provides five key outputs: First, it identifies potential biomass valorization pathways, showing final products such as agricultural and industrial chemicals, enzymes, polymers, monomers, building blocks, materials, food ingredients, biogas, fuel additives, liquid fuels, heat, and electricity. These pathways are assessed to increase the value added of biomass utilization, and the ranking is based on a calculated total score, presenting the most preferable solution first, followed by the least preferable ones.

Second, the tool evaluates the suitability of specific biomasses for co-digestion, based on their carbon-to-nitrogen (C/N) ratio. It retrieves biomass data from the database and requires mass input (kg) per biomass flow. The system calculates the total carbon and nitrogen content of the selected biomass mix and determines the C/N ratio suitability for co-digestion. If the biomass mix is unsuitable, the tool recommends adjustments by adding carbon-rich or nitrogen-rich biomass, depending on whether the C/N ratio is too low or too high, respectively.

Third, the tool assesses whether a biomass mix is suitable for co-digestion based on chemical parameters, requiring input values such as COD, BOD, C/N ratio, soluble COD, and biomass mass. Additionally, the user defines weight metrics (α, β, and γ) to account for the impact of BOD/COD ratio, C/N ratio, and soluble COD on the digestion process. The tool processes these inputs and determines the suitability of the biomass mix, providing computed COD, BOD, C/N ratio, and soluble COD values as outputs.

Finally, the tool estimates biogas production potential based on the elemental composition (carbon, hydrogen, oxygen, and nitrogen content) of the available biomass in the database. The system requires the biomass name and mass (grams) as inputs, then calculates and outputs the moles and volumes (m3) of CH4 (methane) and CO2 (carbon dioxide) produced, along with the total potential biogas production (m3) for the given biomass mix. In addition, the tool shows the range of roadside costs (in euros per ton) of specific biomass types by selecting the country where the biomass is collected or harvested.

Table 5 summarizes the inputs from the user and the respective outputs generated from the tool using the biomass datasets and functionalities.

Table 5.

Overview of inputs and outputs of Biomass Valorization Recommender tool.

6. Implementation and Use Case Example

To demonstrate the applicability of the Biomass Valorization Recommender tool, a theoretical use case was conducted, assuming an industrial site in Italy using the industrial fermentation process. The use case focused on evaluating optimal biomass valorization pathways.

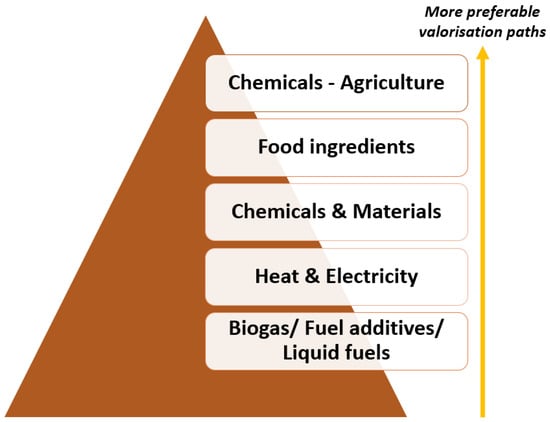

According to Table 6 and the scores considering CE principles (i.e., biomass pyramid and waste hierarchy) and socio-economic impact (i.e., workers, turnover, value added), the most optimal valorization pathway identified was the production of agricultural chemicals, such as fertilizers. This outcome is attributed to the high socio-economic indicators of the agricultural sector in Italy, combined with the fact that biomass re-use in agricultural fields is considered a high-priority option according to the waste hierarchy pyramid. The second-ranked option was the production of food ingredients, as it holds a high priority in both the biomass pyramid and waste hierarchy while also being supported by strong socio-economic indicators. The potential biomass feedstocks suitable for both pathways include sugar, coffee grounds, food and fruit waste, potato peels, starch, vegetable waste, paper and cardboard, vegetable oils, MSW, bark, cellulose, and lignin. Additionally, for food ingredient production, beech wood and hardwood can also be used as feedstocks.

Table 6.

Overview of use case scoring data and results.

The third-ranked valorization pathway was the production of industrial chemicals and materials, utilizing biomass feedstocks such as sugar, coffee grounds, food and fruit waste, potato peels, starch, vegetable waste, paper and cardboard, vegetable oils, MSW, bark, beech wood, hardwood, cellulose, and lignin.

The fourth-ranked option was heat and electricity production, which was preferred over biogas, fuel additives, and liquid fuels, as the heat and electricity sector in Italy has better socio-economic indicators than the latter pathways. The least favorable options were biogas, fuel additives, and liquid fuel production, which ranked lower due to weaker socio-economic performance in the evaluated indicators. For these valorization paths, the potential biomass types are sugar, coffee grounds, food and fruit waste, potato peels, starch, vegetable waste, paper and cardboard, vegetable oils, MSW, bark, cellulose, and lignin.

Table 7 presents the potential biomass type for each valorization pathway. As shown, there are no significant differences in the types of biomass inputs for the various valorization pathways. All categories—including agricultural chemicals, food ingredients, industrial chemicals and materials, and energy-related applications—utilize similar feedstocks, indicating the broad applicability of these biomass types through the industrial fermentation process.

Table 7.

Overview of biomass input for each valorization path.

These results are summarized in Figure 4, showing the ranking of biomass valorization pathways based on the CE and socio-economic criteria.

Figure 4.

Recommended biomass valorization pathways of the use case example.

7. Conclusions and Future Work

Overall, the Biomass Valorization Recommender tool is a decision facilitation system developed to help stakeholders, such as biomass producers, policymakers, and technology providers, select more efficient and sustainable biomass valorization pathways. While existing tools primarily focus on minimizing supply chain costs and emissions, the Biomass Valorization Recommender tool applies a multi-criteria approach that investigates biomass quality data, socio-economic indicators, and CE principles. This tool aims to improve resource efficiency, reduce waste, and promote high-value biomass applications. Considering the circular economy value of the final products and assessing the socio-economic impact, such as employment and value-added metrics, the tool prioritizes biomass valorization solutions that are in line with sustainability goals. Furthermore, for anaerobic digestion applications, the tool evaluates the feasibility of co-digestion for biomass mixtures, estimates biogas production potential, and provides biomass roadside cost data. At this point, it is worth mentioning that any recommended valorization pathway, even if promising from environmental or social aspects, may present technological challenges and economic risks during its implementation. These barriers should be identified and managed prior to implementing a solution in a real business case. Regulatory incentives and a well-designed business model for the recommended solution can help mitigate these risks [7].

In the next phase, the tool will integrate real-time data on biomass quality characteristics from industries that use biomass as feedstock. This aims to improve the accuracy of the decision-making process and will also demonstrate the tool’s applicability in real industrial scenarios. The tool will also explore more biomass types and countries, expanding the current biomass database. In addition, more socio-economic indicators will be included, which will enhance its adaptability and make it relevant to more users located outside Italy, Greece, and Spain. The tool will also explore industrial symbiosis (IS) opportunities, enhancing collaboration between industries and exploring more efficient biomass valorization solutions. An additional key point that needs to be considered in a future version of the tool is the cost of setting up a biomass processing facility. This could be achieved by incorporating an additional module in the tool that will conduct a techno-economic assessment of biomass processing [43,44,45]. Moreover, incorporating biomass availability data for each investigated country could significantly improve the tool. This could be achieved by integrating biomass availability data from the Biomass supply tool of the S2Biom project, as presented in Section 2.1 [11]. These developments are expected to significantly improve the capabilities of the tool and enhance its impact on sustainable and circular biomass valorization solutions.

Author Contributions

Conceptualization, V.T., L.L.-A., K.C., T.T. and G.T.; methodology, V.T., L.L.-A., K.C., T.T. and G.T.; software, V.T. and T.T.; validation, V.T. and T.T.; investigation, V.T. and L.L.-A.; resources, V.T. and L.L.-A.; data curation, V.T. and T.T.; writing—original draft preparation, V.T.; writing—review and editing, L.L.-A., K.C., T.T., G.T. and A.A.; supervision, L.L.-A., K.C., T.T., G.T. and A.A.; project administration, G.T. and A.A.; funding acquisition, G.T. and A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Union through the Horizon Europe Research and Innovation Program, under Grant Agreement No. 101058174 for the project “Transformation of energy intensive process industries through integration of energy, process, and feedstock flexibility” (TRINEFLEX). The project is part of the HORIZON-CL4-2021-TWIN-TRANSITION-01 call, under the Innovation Actions type of action, and is managed by the European Health and Digital Executive Agency.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

The scores for the biomass pyramid (BP) and waste hierarchy (WH) indicators for each valorization path are presented in the following tables, including the applied technologies and the respective biomass inputs.

Table A1.

An overview of food ingredients valorization path.

Table A1.

An overview of food ingredients valorization path.

| Food ingredients, e.g., sugar monomers, proteins, peptides [46] |

| Scores: BP: 0.75|WH: 0.75 |

Biochemical process:

|

Chemical process:

|

Table A2.

An overview of food agriculture chemicals valorization path.

Table A2.

An overview of food agriculture chemicals valorization path.

| Chemicals used in agriculture, e.g., fertilizers, pesticides [46] |

| Scores: BP: 0.5|WH: 1 |

Biochemical process:

|

Chemical process:

|

Thermochemical process:

|

Table A3.

An overview of bulk chemicals valorization path.

Table A3.

An overview of bulk chemicals valorization path.

| Bulk chemicals, e.g., alcohols, butanediol, lactic acid [46] |

| Scores: BP: 0.5|WH: 0.75 |

Biochemical process:

|

Chemical process:

|

Thermochemical process:

|

Table A4.

An overview of enzymes valorization path.

Table A4.

An overview of enzymes valorization path.

| Enzymes |

| Scores: BP: 0.5|WH: 0.75 |

Biochemical process:

|

Table A5.

An overview of chemicals for personal and home care valorization path.

Table A5.

An overview of chemicals for personal and home care valorization path.

| Chemicals for personal and home care, e.g., biomedical applications, detergents, cosmetic ingredients [46] |

| Scores: BP: 1|WH: 0.75 |

Biochemical process:

|

Chemical process:

|

Table A6.

An overview of polymer, monomer, and building block valorization paths.

Table A6.

An overview of polymer, monomer, and building block valorization paths.

| Polymers, monomers, and building blocks, e.g., xylan, butadiene [46] |

| Scores: BP: 1|WH: 0.75 |

Biochemical process:

|

Chemical process:

|

Table A7.

An overview of specialty chemicals valorization path.

Table A7.

An overview of specialty chemicals valorization path.

| Specialty chemicals, e.g., antifouling compounds, formic acid, lubricants [46] |

| Scores: BP: 0.5|WH: 0.75 |

Biochemical process:

|

Chemical process:

|

Thermochemical process:

|

Table A8.

An overview of materials valorization path.

Table A8.

An overview of materials valorization path.

| Materials |

| Scores: BP: 0.5|WH: 0.75 |

Biochemical process:

|

Chemical process:

|

Thermochemical process:

|

Table A9.

An overview of biogas valorization path.

Table A9.

An overview of biogas valorization path.

| Biogas |

| Scores: BP: 0.2|WH: 0.4 |

Biochemical process:

|

Chemical process:

|

Table A10.

An overview of fuel additives valorization path.

Table A10.

An overview of fuel additives valorization path.

| Fuel additives |

| Scores: BP: 0.2|WH: 0.4 |

Biochemical process:

|

Thermochemical process:

|

Table A11.

An overview of liquid fuels valorization path.

Table A11.

An overview of liquid fuels valorization path.

| Liquid fuels |

| Scores: BP: 0.2|WH: 0.4 |

Biochemical process:

|

Chemical process:

|

Thermochemical process:

|

Table A12.

An overview of heat and electricity valorization path.

Table A12.

An overview of heat and electricity valorization path.

| Heat and Electricity |

| Scores: BP: 0.2|WH: 0.4 |

Biochemical process:

|

Chemical process:

|

Thermochemical process:

|

References

- Ning, P.; Yang, G.; Hu, L.; Sun, J.; Shi, L.; Zhou, Y.; Wang, Z.; Yang, J. Recent Advances in the Valorization of Plant Biomass. Biotechnol. Biofuels 2021, 14, 102. [Google Scholar] [CrossRef] [PubMed]

- ISO/DIS 59004; Circular Economy—Terminology, Principles and Guidance for Implementation. ISO: Geneva, Switzerland. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:59004:dis:ed-1:v1:en (accessed on 7 April 2025).

- European Parliament. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Amended by Directive (EU) 2018/2001). EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L2001 (accessed on 7 April 2025).

- Kalverkamp, M.; Pehlken, A.; Wuest, T. Cascade Use and the Management of Product Lifecycles. Sustainability 2017, 9, 1540. [Google Scholar] [CrossRef]

- Campbell-Johnston, K.; Vermeulen, W.J.V.; Reike, D.; Brullot, S. The Circular Economy and Cascading: Towards a Framework. Resour. Conserv. Recycl. X 2020, 7, 100038. [Google Scholar] [CrossRef]

- Jarre, M.; Petit-Boix, A.; Priefer, C.; Meyer, R.; Leipold, S. Transforming the Bio-Based Sector towards a Circular Economy—What Can We Learn from Wood Cascading? For. Policy Econ. 2020, 110, 101872. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Tzelepi, V.; Lekawska-Andrinopoulou, L.; Chatziioannou, K.; Tsimiklis, G.; Amditis, A. Development of Conceptual Framework for Biomass Valorization Recommender. In Proceedings of the 32nd European Biomass Conference and Exhibition Proceedings, Marseille, France, 26 June 2024; pp. 482–484. [Google Scholar]

- S2Biom. D4.10 S2Biom Technical Description Toolset (Final Version). S2Biom Project. Available online: https://www.s2biom.eu/images/Publications/D4.10_S2Biom_Technical_description_toolset_Final2.pdf (accessed on 7 April 2025).

- Dees, M.; Datta, P.; Fitzgerald, J.; Verkerk, H.; Lindner, M.; Elbersen, B.; Schrijver, R.; Staritsky, I.; Diepen, K.; Ramirez-Almeyda, J.; et al. Roadmap for Regional End-Users on How to Collect, Process, Store and Maintain Biomass Supply Data; Chair of Remote Sensing and Landscape Information Systems, Institute of Forest Sciences, University of Freiburg: Freiburg, Germany, 2017; p. 78. [Google Scholar]

- S2Biom. Deliverable D1.6: Final Report on Biomass Resources (Version 1.2). S2Biom Project. Available online: https://s2biom.wenr.wur.nl/doc/S2Biom_D1_6_v1_2_FINAL_20_04_2017_CP.pdf (accessed on 7 April 2025).

- S2Biom. Deliverable D4.5: Tool for Matching Biomass and Conversion Technologies. S2Biom Project. Available online: https://s2biom.wenr.wur.nl/doc/S2Biom%20D4.5%20-%20Tool%20for%20Matching%20Biomass%20and%20Conversion%20Technologies.pdf (accessed on 7 April 2025).

- Lammens, T.M.; Vis, M.; de Groot, H.; Vanmeulebrouk, B.; Staritsky, I.; Elbersen, B.; Annevelink, E.; Elbersen, W.; Alakangas, E.; van den Berg, D. Bio2match: A Tool for Optimising the Match between Lignocellulosic Biomass and Conversion Technologies. Eur. Biomass Conf. Exhib. Proc. 2016, 2016, 1381–1386. [Google Scholar]

- Circular Bio-Based Europe Joint Undertaking Tech4Biowaste/Project Details. Available online: https://www.cbe.europa.eu/projects/tech4biowaste (accessed on 19 February 2025).

- BTG Tech4Biowaste Project. Available online: https://tech4biowaste.eu/ (accessed on 19 February 2025).

- Varvaringos, I.; Skourtanioti, E.; Letsos, G.; Rizoudi, E.; Makras, E.; Panagiotopoulou, M.; Papadaki, S.; Valta, K. Promoting Sustainable Fruit and Vegetable Biowaste Management and Industrial Symbiosis through an Innovative Web Platform. Waste 2023, 1, 532–548. [Google Scholar] [CrossRef]

- DRAXIS Environmental. AgriPLaCE: Valorisation of Agricultural Waste for the Production of Innovative Plastic Materials in Line with the Circular Economy. Available online: https://draxis.gr/project/agriplace/ (accessed on 7 April 2025).

- Thiébeau, P.; Jensen, L.S.; Ferchaud, F.; Recous, S. Dataset of Biomass and Chemical Quality of Crop Residues from European Areas. Data Brief 2021, 37, 107227. [Google Scholar] [CrossRef]

- S2Biom. Deliverable D2.4: Database for Standardized Biomass Characterization (Final Version). S2Biom Project. Available online: https://www.s2biom.eu/images/Publications/D2.4_S2Biom_Database_for_standardized_biomass_characterisation_Final.pdf (accessed on 7 April 2025).

- TNO Biobased and Circular Technologies Phyllis2, Database for (Treated) Biomass, Algae, Feedstocks for Biogas Production and Biochar. Available online: https://phyllis.nl/ (accessed on 7 April 2025).

- AIMEN TRINEFLEX Website. Available online: https://trineflex.eu/ (accessed on 30 August 2024).

- TRINEFLEX consortium. D3.1 TRINEFLEX Platform; 2025. Internal Report, Confidential. 2025. [Google Scholar]

- Vural Gursel, I.; Elbersen, B.; Meesters, K.P.H.; van Leeuwen, M. Defining Circular Economy Principles for Biobased Products. Sustainability 2022, 14, 12780. [Google Scholar] [CrossRef]

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Carus, M.; Dammer, L. The “Circular Bioeconomy”-Concepts, Opportunities and Limitations Www.Bio-Based.Eu/Nova-Papers. Ind. Biotechnol. 2018, 14, 83–91. [Google Scholar] [CrossRef]

- Meyer, R. Bioeconomy Strategies: Contexts, Visions, Guiding Implementation Principles and Resulting Debates. Sustainability 2017, 9, 1031. [Google Scholar] [CrossRef]

- Chaachouay, N.; Zidane, L. Plant-Derived Natural Products: A Source for Drug Discovery and Development. Drugs Drug Candidates 2024, 3, 184–207. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, L.; Cai, H.; Qu, X.; Chang, J.; Waterhouse, G.I.N.; Lu, S. Biomass-Derived Carbon Dots with Pharmacological Activity for Biomedicine: Recent Advances and Future Perspectives. Sci. Bull. 2024, 69, 3127–3149. [Google Scholar] [CrossRef]

- Controlled Mold QuornTM: A Story About Single Cell Protein. Controlled Mold. Available online: https://controlledmold.com/quorn-a-story-about-single-cell-protein/ (accessed on 9 April 2025).

- Hubalek, S.; Post, M.J.; Moutsatsou, P. Towards Resource-Efficient and Cost-Efficient Cultured Meat. Curr. Opin. Food Sci. 2022, 47, 100885. [Google Scholar] [CrossRef]

- Lafarga, T.; Fernández-Sevilla, J.M.; González-López, C.; Acién-Fernández, F.G. Spirulina for the Food and Functional Food Industries. Food Res. Int. 2020, 137, 109356. [Google Scholar] [CrossRef]

- Méndez-Carmona, J.Y.; Ascacio-Valdes, J.A.; Alvarez-Perez, O.B.; Hernández-Almanza, A.Y.; Ramírez-Guzman, N.; Sepúlveda, L.; Aguilar-González, M.A.; Ventura-Sobrevilla, J.M.; Aguilar, C.N. Tomato Waste as a Bioresource for Lycopene Extraction Using Emerging Technologies. Food Biosci. 2022, 49, 101966. [Google Scholar] [CrossRef]

- Raina, D.; Kumar, V.; Saran, S. A Critical Review on Exploitation of Agro-Industrial Biomass as Substrates for the Therapeutic Microbial Enzymes Production and Implemented Protein Purification Techniques. Chemosphere 2022, 294, 133712. [Google Scholar] [CrossRef]

- Kukreti, N.; Kumar, P.; Kataria, R. Sustainable Biotransformation of Lignocellulosic Biomass to Microbial Enzymes: An Overview and Update. Ind. Crops Prod. 2024, 222, 119432. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, H.; Wu, S.; Pan, S.; Cui, D.; Wu, D.; Xu, F.; Wang, Z. Production of Biomass-Based Carbon Materials in Hydrothermal Media: A Review of Process Parameters, Activation Treatments and Practical Applications. J. Energy Inst. 2023, 110, 101357. [Google Scholar] [CrossRef]

- Kong, Z.; Zhang, H.; Zhou, T.; Xie, L.; Wang, B.; Jiang, X. Biomass-Derived Functional Materials: Preparation, Functionalization, and Applications in Adsorption and Catalytic Separation of Carbon Dioxide and Other Atmospheric Pollutants. Sep. Purif. Technol. 2025, 354, 129099. [Google Scholar] [CrossRef]

- Márquez Luzardo, N.M.; Venselaar, J. Bio-Based Targeted Chemical Engineering Education; Role and Impact of Bio-Based Energy and Resource Development Projects. Procedia Eng. 2012, 42, 214–225. [Google Scholar] [CrossRef]

- Asveld, L.; van Est, R., S. D. From Biobased 0.0 to Biobased 3.0: Some Propositions; Rathenau Institute: Hague, The Netherlands, 2010. [Google Scholar]

- European Parliament. Directive 2008/98/EC of the European Parliament and of the Council on Waste (Amended by Directive 2018/851/EU). EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32008L0098 (accessed on 7 April 2025).

- Ronzon, T.; M’Barek, R. Socioeconomic Indicators to Monitor the EU’s Bioeconomy in Transition. Sustainability 2018, 10, 1745. [Google Scholar] [CrossRef]

- D’Adamo, I.; Falcone, P.M.; Morone, P. A New Socio-Economic Indicator to Measure the Performance of Bioeconomy Sectors in Europe. Ecol. Econ. 2020, 176, 106724. [Google Scholar] [CrossRef]

- Tamošiunas, S.; Ronzon, T.; Piotrowski, S.; M’barek, R.; Carus, M. Jobs and Wealth in the EU Bioeconomy/JRC—Bioeconomics. Available online: http://data.europa.eu/89h/7d7d5481-2d02-4b36-8e79-697b04fa4278 (accessed on 26 September 2023).

- IEA Bioenergy Task 43. Biohub: IEA Bioenergy Task 43 Final Report. IEA Bioenergy, 2022. Available online: https://www.ieabioenergy.com/wp-content/uploads/2022/12/Biohub-IEA-Bioenergy-Task-43-Final-Report.pdf (accessed on 7 April 2025).

- E4Tech (UK) Ltd., PSE, CMCL, Imperial College London, Black & Veatch, University of Sheffield, University of Leeds & TEABPP Consortium Techno-Economic Assessment of Biomass Pre-Processing (TEABPP)—Initial Techno-Economic Results—Spreadsheet Tool [Data Set]. Available online: https://ukerc.rl.ac.uk/cgi-bin/dataDiscover.pl?Action=detail&dataid=9a076260-32b4-452f-bba5-c74496d9cd1b&utm_source (accessed on 3 April 2025).

- Aspen Technology Inc Aspen Plus®. Available online: https://www.aspentech.com/en/products/engineering/aspen-plus (accessed on 3 April 2025).

- Tech4Biowaste Chemicals. Available online: https://www.tech4biowaste.eu/wiki/Chemicals (accessed on 10 April 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).