Laboratory Tests of Electrical Parameters of the Start-Up Process of Single-Cylinder Diesel Engines

Abstract

1. Introduction

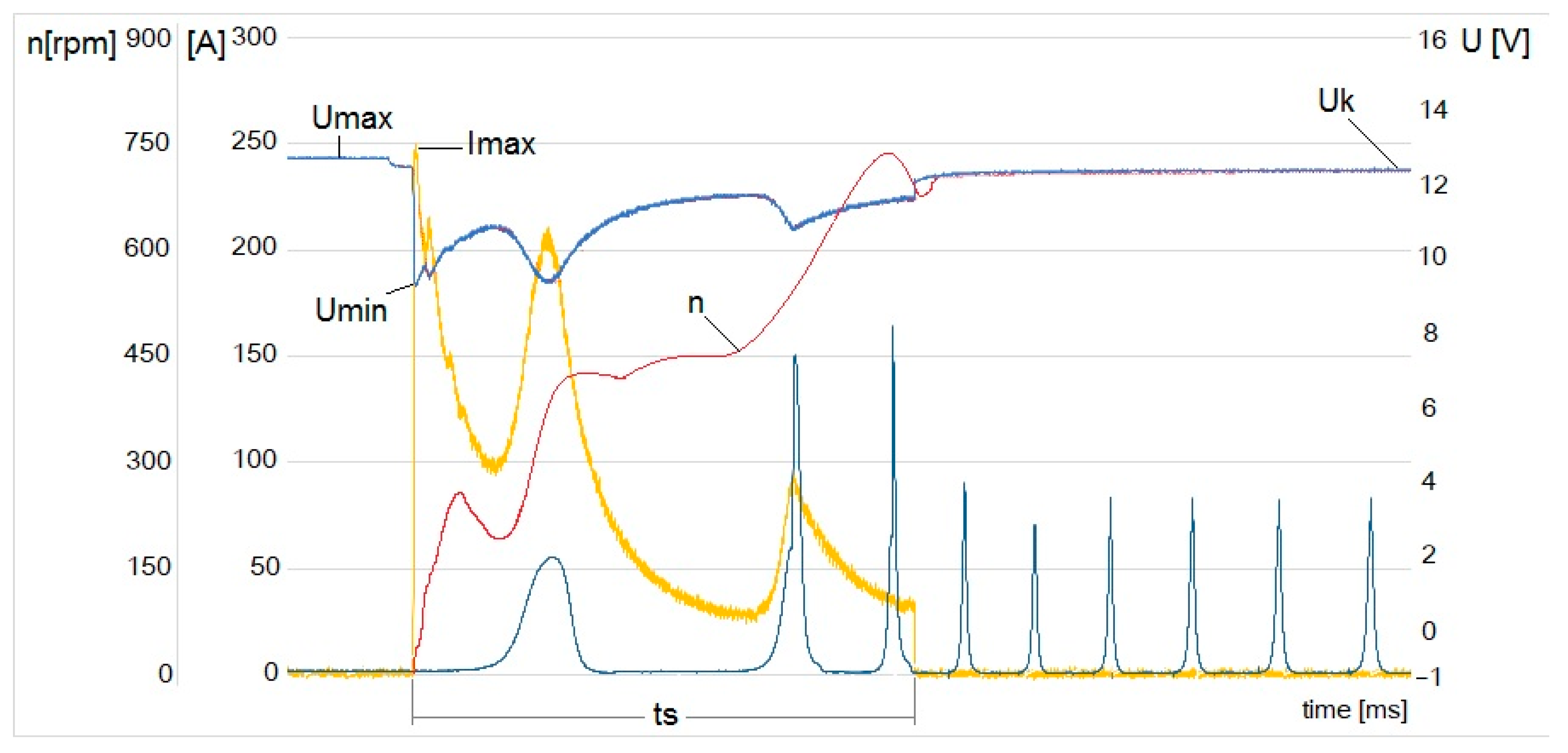

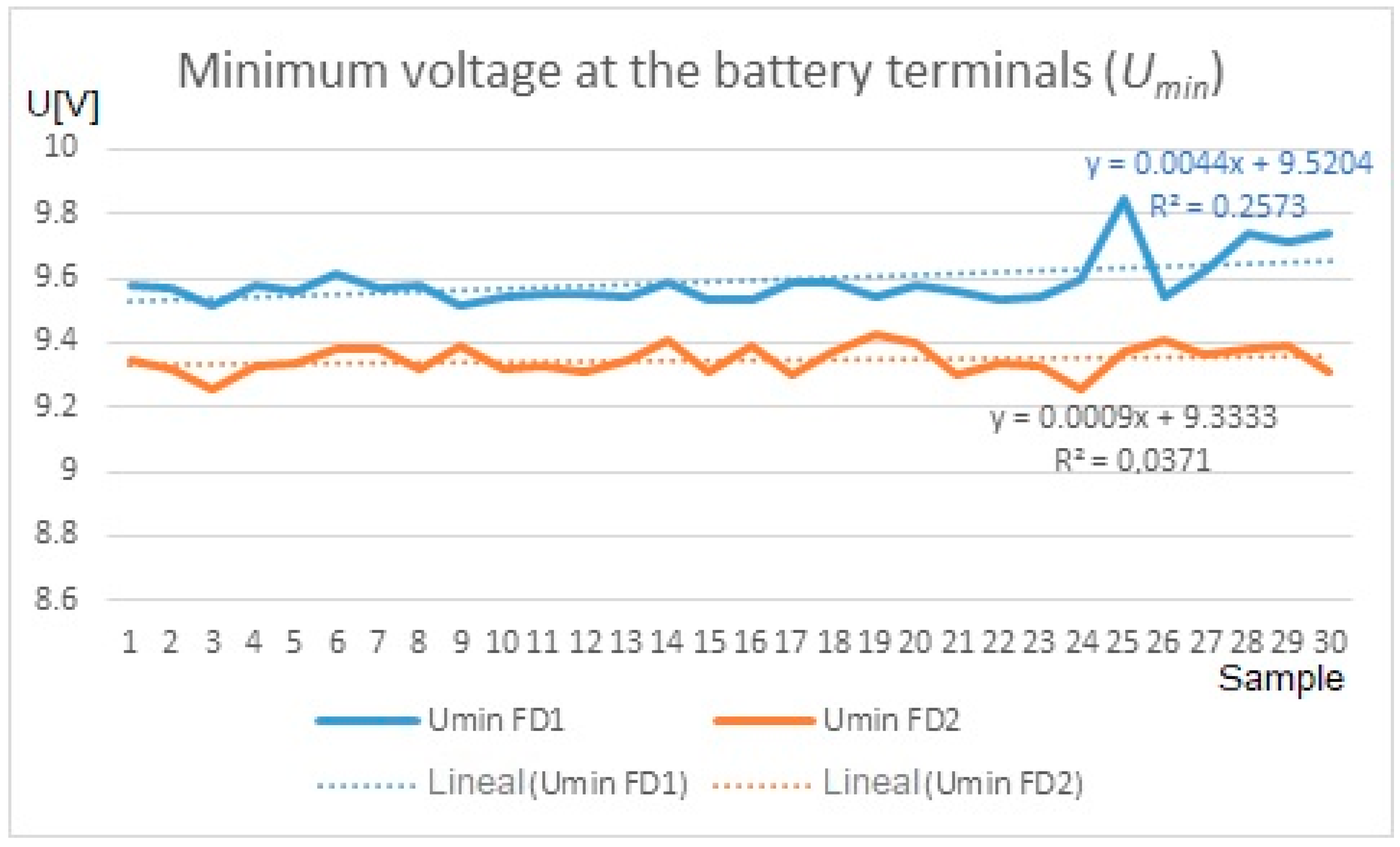

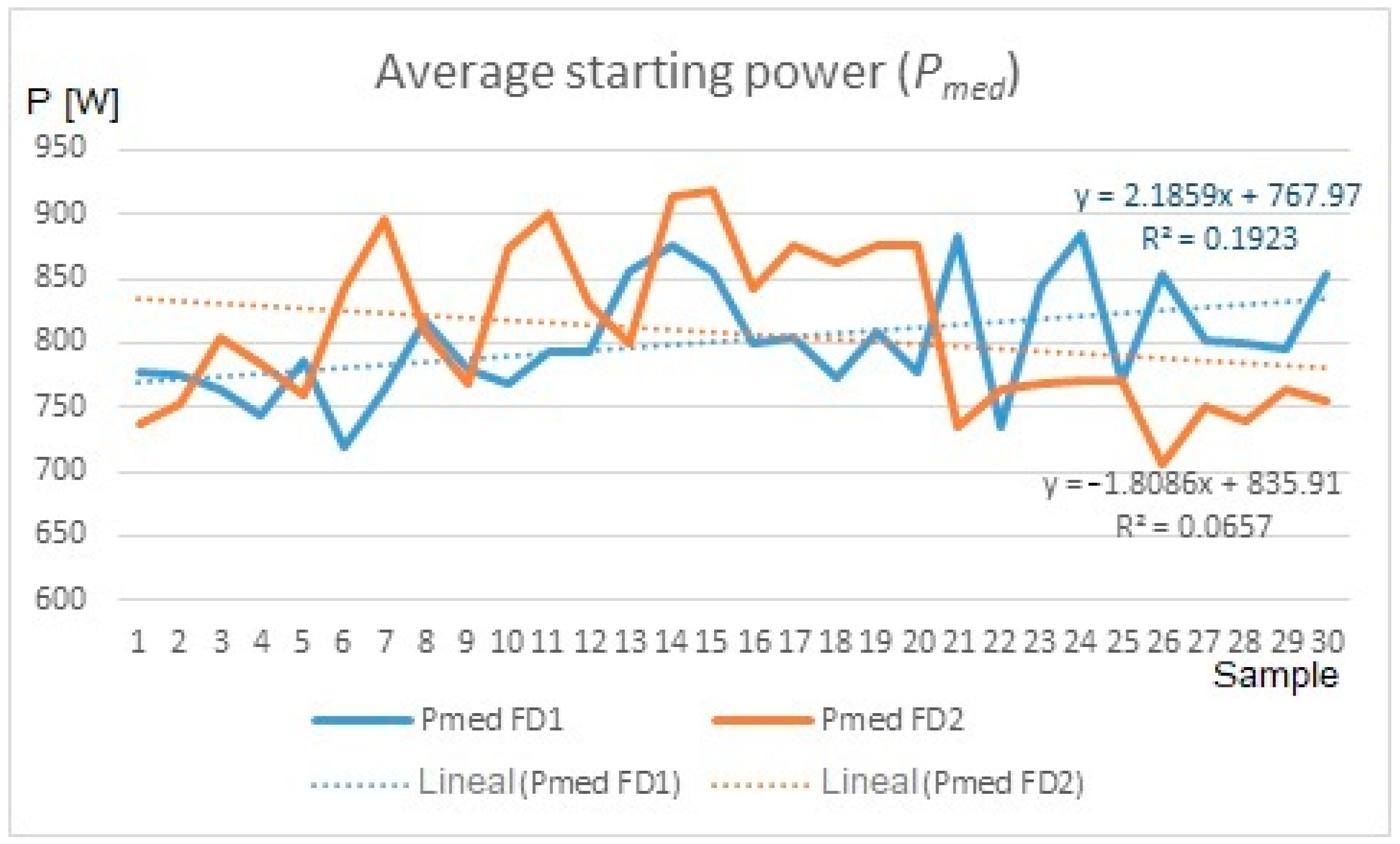

2. Materials and Methods

- Static fuel injection advance angle—17.6 °CA;

- Injector opening pressure—26 MPa;

- Fuel dose—factory default for idling—FD1, and increased—FD2;

- Idle speed—810 rpm for fuel dose FD1 and 1000 rpm for fuel dose FD2;

- Start-up temperature—in the range of 22.75–23.95 °C.

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Malik, A.; Kohli, S. Electric tractors: Survey of challenges and opportunities in India. Mater. Today Proc. 2020, 28, 2318–2324. [Google Scholar] [CrossRef]

- Stakens, J.; Mutule, A.; Lazdins, R. Agriculture Electrification, Emerging Technologies, Trends and Barriers: A Comprehensive Literature Review. Latv. J. Phys. Tech. Sci. 2023, 60, 18–32. [Google Scholar] [CrossRef]

- Vasile, I.; Tudor, E.; Sburlan, I.-C.; Matache, M.-G.; Cristea, M. Optimization of the Electronic Control Unit of Electric-Powered Agricultural Vehicles. World Electr. Veh. J. 2023, 14, 267. [Google Scholar] [CrossRef]

- Bessette, D.L.; Brainard, D.C.; Srivastava, A.K.; Lee, W.; Geurkink, S. Battery Electric Tractors: Small-Scale Organic Growers’ Preferences, Perceptions, and Concerns. Energies 2022, 15, 8648. [Google Scholar] [CrossRef]

- Gorjian, S.; Ebadi, H.; Trommsdorff, M.; Sharon, H.; Demant, M.; Schindele, S. The advent of modern solar-powered electric agricultural machinery: A solution for sustainable farm operations. J. Clean. Prod. 2021, 292, 126030. [Google Scholar] [CrossRef]

- Barta, D.; Mruzek, M.; Kendra, M.; Kordos, P.; Krzywonos, L. Using of non-conventional fuels in hybrid vehicle drives. Adv. Sci. Technol. Res. J. 2016, 10, 240–247. [Google Scholar] [CrossRef]

- Dižo, J.; Blatnický, M.; Semenov, S.; Mikhailov, E.; Kostrzewski, M.; Droździel, P.; Šťastniak, P. Electric and plug-in hybrid vehicles and their infrastructure in a particular European region. Transp. Res. Procedia 2021, 55, 629–636. [Google Scholar] [CrossRef]

- Figlus, T.; Czachor, T. Preliminary studies of the effect of travelling speed and propulsion type on the sound level in the passenger compartment of a vehicle with a hybrid propulsion system. In Proceedings of the 11th International Science and Technical Conference Automotive Safety, Častá Papiernicka, Slovakia, 18–20 April 2018; pp. 1–5. [Google Scholar]

- Vehicles in Use Europe 2023, 17 January 2023, ACEA Report. Available online: https://www.acea.auto/files/ACEA-report-vehicles-in-use-europe-2023.pdf (accessed on 5 December 2023).

- Ipci, D.; Karabulut, H. Thermodynamic and dynamic modeling of a single cylinder four stroke diesel engine. Appl. Math. Model. 2016, 40, 3925–3937. [Google Scholar] [CrossRef]

- Sakunthalai, R.A.; Xu, H.; Liu, D.; Tian, J.; Wyszynski, M.; Piaszyk, J. Impact of Cold Ambient Conditions on Cold Start and Idle Emissions from Diesel Engines. In Proceedings of the SAE 2014 International Powertrain, Fuels & Lubricants Meeting, Birmingham, UK, 20–23 October 2014. [Google Scholar]

- Baran, P.; Kukuca, P.; Barta, D.; Labuda, R.; Drozdiel, P.; Pukalskas, S. The Issue of Balancing Internal Combustion Engines with Non-Conventional Crank Mechanism. Commun. Sci. Lett. Univ. Zilina 2017, 19, 36–41. [Google Scholar] [CrossRef]

- Tarbajovský, P.; Puškár, M. The resonance expansion system for emissions reduction of internal combustion engines. Sci. J. Silesian Univ. Technol. Ser. Transp. 2023, 119, 279–289. [Google Scholar] [CrossRef]

- Figlus, T.; Liščák, Š. Assessment of the vibroactivity level of SI engines in stationary and non-stationary operating conditions. J. Vibroeng. 2014, 16, 1349–1359. [Google Scholar]

- Sejkorová, M.; Šarkan, B.; Verner, J. Efficiency Assessment of Fuel Borne Catalyst. MATEC Web Conf. 2017, 134, 00051. [Google Scholar] [CrossRef]

- Skrúcaný, T.; Šarkan, B.; Figlus, T.; Synák, F.; Vrábel, J. Measuring of noise emitted by moving vehicles. MATEC Web Conf. 2017, 107, 00072. [Google Scholar] [CrossRef]

- Figlus, T.; Szafraniec, P.; Skrúcaný, T. Methods of Measuring and Processing Signals during Tests of the Exposure of a Motorcycle Driver to Vibration and Noise. Int. J. Environ. Res. Public Health 2019, 16, 3145. [Google Scholar] [CrossRef]

- Jacyna, M.; Wasiak, M.; Lewczuk, K.; Karoń, G. Noise and environmental pollution from transport: Decisive problems in developing ecologically efficient transport systems. J. Vibroeng. 2017, 19, 5639–5655. [Google Scholar] [CrossRef]

- Zefreh, M.M.; Torok, A. Theoretical Comparison of the Effects of Different Traffic Conditions on Urban Road Traffic Noise. J. Adv. Transp. 2018, 2018, 7949574. [Google Scholar] [CrossRef]

- Verner, J.; Sejkorova, M. Comparison of CVS and PEMS measuring devices used for stating CO2 exhaust emissions of light-duty vehicles during WLTP testing procedure. In Proceedings of the 17th International Scientific Conference Engineering for Rural Development, ERD 2018, Jelgava, Latvia, 23–25 May 2018; Engineering for Rural Development. Volume 17, pp. 2054–2059. [Google Scholar]

- Kubica, G.; Flekiewicz, M.; Marzec, P. Selected aspects of the use of gaseous fuels blends to improve efficiency and emission of SI engine. Transp. Probl. 2019, 14, 95–103. [Google Scholar] [CrossRef]

- Matijošius, J.; Orynycz, O.; Kovbasenko, S.; Simonenko, V.; Shuba, Y.; Moroz, V.; Gutarevych, S.; Wasiak, A.; Tucki, K. Testing the Indicators of Diesel Vehicles Operating on Diesel Oil and Diesel Biofuel. Energies 2022, 15, 9263. [Google Scholar] [CrossRef]

- Šarkan, B.; Hudec, J.; Sejkorova, M.; Kuranc, A.; Kiktova, M. Calculation of the production of exhaust emissions in the laboratory conditions. J. Physics Conf. Ser. 2021, 1736, 012022. [Google Scholar] [CrossRef]

- Cui, Y.; Peng, H.; Deng, K.; Shi, L. The effects of unburned hydrocarbon recirculation on ignition and combustion during diesel engine cold starts. Energy 2014, 64, 323–329. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Zardini, A.A.; Clairotte, M. Exhaust Gas Condensation during Engine Cold Start and Application of the Dry-Wet Correction Factor. Appl. Sci. 2019, 9, 2263. [Google Scholar] [CrossRef]

- Kuranc, A.; Słowik, T.; Wasilewski, J.; Szyszlak-Bargłowicz, J.; Stoma, M.; Šarkan, B. Emission of particulates and chosen gaseous exhausts components during a diesel engine starting process. In Proceedings of the 9th International Scientific Symposium on Farm Machinery and Process Management in Sustainable Agriculture, Lublin, Poland, 22–24 November 2017; pp. 210–215. [Google Scholar]

- Szpica, D.; Czaban, J.; Banaszuk, P.; Weresa, E. The Diesel and the Vegetable oil Properties Assessment in terms of Pumping Capability and Cooperation with Internal Combustion Engine Fuelling System. Acta Mech. Autom. 2015, 9, 14–18. [Google Scholar] [CrossRef]

- Ding, S.-L.; Song, E.-Z.; Yang, L.-P.; Litak, G.; Yao, C.; Ma, X.-Z. Investigation on nonlinear dynamic characteristics of combustion instability in the lean-burn premixed natural gas engine. Chaos Solitons Fractals 2016, 93, 99–110. [Google Scholar] [CrossRef]

- Longwic, R.; Sander, P. The course of combustion process under real conditions of work of a traction diesel engine supplied by mixtures of canola oil containing n-hexane. IOP Conf. Ser. Mater. Sci. Eng. 2018, 421, 042050. [Google Scholar] [CrossRef]

- Labaj, J.; Barta, D. Unsteady Flow Simulation and Combustion of Ethanol in Diesel Engines. Komunikacie 2006, 8, 27–37. [Google Scholar] [CrossRef]

- Dhande, D.Y.; Navale, S.J. Experimental investigations on the performance and emissions of compression ignition engine fueled with lower blends of neem-based biodiesel. Arch. Autom. Engineer. Archiw. Mot. 2024, 103, 57–76. [Google Scholar]

- Dzieniszewski, G.; Kuboń, M.; Pristavka, M.; Findura, P. Operating Parameters and Environmental Indicators of Diesel Engines Fed with Crop-Based Fuels. Agric. Eng. 2021, 25, 13–28. [Google Scholar] [CrossRef]

- Hawrot-Paw, M.; Koniuszy, A.; Zając, G.; Szyszlak-Bargłowicz, J. Ecotoxicity of soil contaminated with diesel fuel and biodiesel. Sci. Rep. 2020, 10, 16436. [Google Scholar] [CrossRef]

- Jayakumar, M.; Gebeyehu, K.B.; Selvakumar, K.V.; Parvathy, S.; Kim, W.; Karmegam, N. Waste Ox bone based heterogeneous catalyst synthesis, characterization, utilization and reaction kinetics of biodiesel generation from Jatropha curcas oil. Chemosphere 2022, 288, 132534. [Google Scholar] [CrossRef] [PubMed]

- Kurczyński, D.; Wcisło, G.; Leśniak, A.; Kozak, M.; Łagowski, P. Production and Testing of Butyl and Methyl Esters as New Generation Biodiesels from Fatty Wastes of the Leather Industry. Energies 2022, 15, 8744. [Google Scholar] [CrossRef]

- Imran, M.S.; Saleh, F.A. The Influence of Using Biodiesel Prepared from Cresson Oil on Emissions and Performance of CI Engines. J. Ecol. Eng. 2024, 25, 84–98. [Google Scholar] [CrossRef]

- Ramalingam, K.; Venkatesan, E.P.; Vellaiyan, S.; Mukhtar, A.; Sharifpur, M.; Yasir, A.S.H.M.; Saleel, C.A. Substitution of diesel fuel in conventional compression ignition engine with waste biomass-based fuel and its validation using artificial neural networks. Process. Saf. Environ. Prot. 2023, 177, 1234–1248. [Google Scholar] [CrossRef]

- Szyszlak-Bargłowicz, J.; Wasilewski, J.; Zając, G.; Kuranc, A.; Koniuszy, A.; Hawrot-Paw, M. Evaluation of Particulate Matter (PM) Emissions from Combustion of Selected Types of Rapeseed Biofuels. Energies 2023, 16, 239. [Google Scholar] [CrossRef]

- Al-Aseebee, M.D.; Ketata, A.; Gomaa, A.E.; Moussa, O.; Driss, Z.; Abid, M.S.; Naje, A.S.; Emaish, H.H. Modeling of Waste Vegetable Oil Biodiesel for Tractor Engine Utilization. J. Ecol. Eng. 2023, 24, 293–303. [Google Scholar] [CrossRef]

- Dittrich, A.; Beroun, S.; Zvolsky, T. Diesel gas dual engine with liquid LPG injection into intake manifold. Eng. Rural. Dev. 2018, 1978–1983. [Google Scholar] [CrossRef]

- Cung, K.D.; Wallace, J.; Kalaskar, V.; Smith, E.M., III; Briggs, T.; Bitsis, D.C., Jr. Experimental study on engine and emissions performance of renewable diesel methanol dual fuel (RMDF) combustion. Fuel 2024, 357, 129664. [Google Scholar] [CrossRef]

- Lebedevas, S.; Pukalskas, S.; Dauksys, V. Mathematical modelling of indicative process parameters of dual-fuel engines with conventional fuel injection system. Transport 2020, 35, 57–167. [Google Scholar] [CrossRef]

- Mikulski, M.; Hunicz, J.; Duda, K.; Kazimierski, P.; Suchocki, T.; Rybak, A. Tyre pyrolytic oil fuel blends in a modern compression ignition engine: A comprehensive combustion and emissions analysis. Fuel 2022, 320, 123869. [Google Scholar] [CrossRef]

- Buratto, W.G.; Muniz, R.N.; Nied, A.; Barros, C.F.d.O.; Cardoso, R.; Gonzalez, G.V. A Review of Automation and Sensors: Parameter Control of Thermal Treatments for Electrical Power Generation. Sensors 2024, 24, 967. [Google Scholar] [CrossRef]

- Ciupek, B.; Urbaniak, R.; Kinalska, D.; Nadolny, Z. Flue Gas Recirculation System for Biomass Heating Boilers—Research and Technical Applications for Reductions in Nitrogen Oxides (NOx) Emissions. Energies 2024, 17, 259. [Google Scholar] [CrossRef]

- Nandhini, R.; Berslin, D.; Sivaprakash, B.; Rajamohan, N.; Vo, D.-V.N. Thermochemical conversion of municipal solid waste into energy and hydrogen: A review. Environ. Chem. Lett. 2022, 20, 1645–1669. [Google Scholar] [CrossRef]

- Jia, L.; Cheng, P.; Yu, Y.; Chen, S.-H.; Wang, C.-X.; He, L.; Nie, H.-T.; Wang, J.-C.; Zhang, J.-C.; Fan, B.-G.; et al. Regeneration mechanism of a novel high-performance biochar mercury adsorbent directionally modified by multimetal multilayer loading. J. Environ. Manag. 2023, 326, 116790. [Google Scholar] [CrossRef]

- Droździel, P.; Komsta, H.; Krzywonos, L. An analysis of costs of vehicle repairs in a transportation company. Part II. Transp. Probl. 2012, 7, 5–11. [Google Scholar]

- Dzitkowski, T.; Dymarek, A.; Margielewicz, J.; Gąska, D.; Orzech, L.; Lesiak, K. Designing of Drive Systems in the Aspect of the Desired Spectrum of Operation. Energies 2021, 14, 2562. [Google Scholar] [CrossRef]

- Pulawski, G.; Szpica, D. The modelling of operation of the compression ignition engine powered with diesel fuel with LPG admixture. Mechanika 2015, 21, 500–505. [Google Scholar]

- Skrúcaný, T.; Stopková, M.; Stopka, O.; Kalašová, A.; Ovčiarik, P. User’s determination of a proper method for quantifying fuel consumption of a passenger car with compression ignition engine in specific operation conditions. Open Eng. 2021, 11, 151–160. [Google Scholar] [CrossRef]

- Aulin, D.; Klymenko, O.; Falendysh, A.; Kletska, O.; Diżo, J. Improvement of diesel injector nozzle test techniques. IOP Conf. Ser. Mater. Sci. Eng. 2020, 985, 012031. [Google Scholar] [CrossRef]

- Kamiński, M.; Budzyński, P.; Hunicz, J.; Józwik, J. Evaluation of changes in fuel delivery rate by electromagnetic injectors in a common rail system during simulated operation. Eksploat. Niezawodn. Maint. Reliab. 2021, 23, 352–358. [Google Scholar] [CrossRef]

- Osipowicz, T.; Abramek, K.F.; Matuszak, Z.; Jaskiewicz, M.; Ludwinek, K.; Łagowski, P. The concept of annular channels application on the spraying nozzle needle of modern fuel injector in the aspect of combustion process improvement. In Proceedings of the 11th International Science and Technical Conference Automotive Safety, Casta Papiernicka, Slovakia, 18–20 April 2018. Code 136991. [Google Scholar]

- Punov, P.; Gechev, T.; Mihalkov, S.; Podevin, P.; Barta, D. Experimental study of multiple pilot injection strategy in an automotive direct injection diesel engine. MATEC Web Conf. 2018, 234, 03007. [Google Scholar] [CrossRef][Green Version]

- Pawlak, G.; Skrzek, T. Combustion of raw Camelina sativa oil in CI engine equipped with common rail system. Sci. Rep. 2023, 13, 19731. [Google Scholar] [CrossRef]

- Stoeck, T. Analytical methodology for testing Common Rail fuel injectors in problematic cases. Diagnostyka 2021, 22, 47–52. [Google Scholar] [CrossRef]

- Figlus, T.; Konieczny, Ł.; Burdzik, R.; Czech, P. Assessment of diagnostic usefulness of vibration of the common rail system in the diesel engine. Vibroengineering Procedia 2015, 6, 185–189. [Google Scholar]

- Figlus, T.; Konieczny, Ł.; Burdzik, R.; Czech, P. The effect of damage to the fuel injector on changes of the vibroactivity of the diesel engine during its starting. Vibroengineering Procedia 2015, 6, 180–184. [Google Scholar]

- Szpica, D.; Czaban, J. Investigating of the combustion process in a diesel engine fueled with conventional and alternative fuels. In Proceedings of the 23rd International Scientific Conference, Transport Means 2019, Palanga, Lithuania, 2–4 October 2019; pp. 176–181. [Google Scholar]

- Balyts’kyi, O.I.; Abramek, K.F. Diagnostic parameter of wear of a piston-bush-cylinder system. Mater. Sci. 2013, 49, 234–236. [Google Scholar] [CrossRef]

- Droździel, P. Cylinder liner wear during starting of an internal combustion engine. J. Frict. Wear 2001, 22, 65–71. [Google Scholar]

- Czech, P.; Madej, H. Application of cepstrum and spectrum histograms of vibration engine body for setting up the clearance model of the piston-cylinder assembly for rbf neutral classifier. Eksploat. Niezawodn. Maint. Reliab. 2011, 52, 15–20. [Google Scholar]

- Kowalski, S.; Cieślikowski, B.; Barta, D.; Dižo, J.; Dittrich, A. Analysis of the Operational Wear of the Combustion Engine Piston Pin. Lubricants 2023, 11, 100. [Google Scholar] [CrossRef]

- Siemiątkowski, Z.; Szumiata, T.; Gzik-Szumiata, M.; Martynowski, R.; Rucki, M. Application of the microscopic and Mössbauer studies to the analysis of a marine diesel engine crankshaft. J. Mar. Eng. Technol. 2018, 17, 160–167. [Google Scholar] [CrossRef]

- Jermak, C.J.; Dereżyński, J.; Rucki, M. Measurement system for assesment of motor cylinder tolerances and roundness. Metrol. Meas. Syst. 2018, 25, 103–114. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, L.; Wu, D.; Shen, B.; Li, Q. Measurement Uncertainty Analysis of the Stitching Linear-Scan Method for the Measurable Dimension of Small Cylinders. Appl. Sci. 2023, 13, 9091. [Google Scholar] [CrossRef]

- Abramek, K.F. Phenomenon of load losses at the engine start-up stage. Teka Kom. Motoryz. Energetyki Rol. 2008, 8a, 7–11. [Google Scholar]

- Andrych-Zalewska, M.; Chlopek, Z.; Merkisz, J.; Pielecha, J. Impact of the Internal Combustion Engine Thermal State during Start-Up on the Exhaust Emissions in the Homologation Test. Energies 2023, 16, 1937. [Google Scholar] [CrossRef]

- Van, T.C.; Zare, A.; Jafari, M.; Bodisco, T.A.; Surawski, N.; Verma, P.; Suara, K.; Ristovski, Z.; Rainey, T.; Stevanovic, S.; et al. Effect of cold start on engine performance and emissions from diesel engines using IMO-Compliant distillate fuels. Environ. Pollut. 2019, 255, 113260. [Google Scholar] [CrossRef]

- Deng, Y.; Liu, H.; Zhao, X.; Jiaqiang, E.; Chen, J. Effects of cold start control strategy on cold start performance of the diesel engine based on a comprehensive preheat diesel engine model. Appl. Energy 2018, 210, 279–287. [Google Scholar] [CrossRef]

- García-Oliver, J.; Pastor, J.; Ramírez-Hernández, J. Ignition and combustion development for high speed direct injection diesel engines under low temperature cold start conditions. Fuel 2011, 90, 1556–1566. [Google Scholar] [CrossRef]

- Roberts, A.; Brooks, R.; Shipway, P. Internal combustion engine cold-start efficiency: A review of the problem, causes and potential solutions. Energy Convers. Manag. 2014, 82, 327–350. [Google Scholar] [CrossRef]

- Jaworski, A.; Kuszewski, H.; Ustrzycki, A.; Balawender, K.; Lejda, K.; Woś, P. Analysis of the repeatability of the exhaust pollutants emission research results for cold and hot starts under controlled driving cycle conditions. Environ. Sci. Pollut. Res. 2018, 25, 17862–17877. [Google Scholar] [CrossRef]

- Lodi, F.; Zare, A.; Arora, P.; Stevanovic, S.; Jafari, M.; Ristovski, Z.; Brown, R.J.; Bodisco, T. Engine Performance and Emissions Analysis in a Cold, Intermediate and Hot Start Diesel Engine. Appl. Sci. 2020, 10, 3839. [Google Scholar] [CrossRef]

- Mitchell, B.J.; Zare, A.; Bodisco, T.A.; Nabi, N.; Hossain, F.M.; Ristovski, Z.D.; Brown, R.J. Engine blow-by with oxygenated fuels: A comparative study into cold and hot start operation. Energy 2017, 140, 612–624. [Google Scholar] [CrossRef]

- Zare, A.; Bodisco, T.A.; Nabi, M.N.; Hossain, F.M.; Ristovski, Z.D.; Brown, R.J. A comparative investigation into cold-start and hot-start operation of diesel engine performance with oxygenated fuels during transient and steady-state operation. Fuel 2018, 228, 390–404. [Google Scholar] [CrossRef]

- Caban, J. Influence of Fuel Injection Parameters on the Course of the Diesel Engine Starting Process. Ph.D. Thesis, Lublin University of Technology, Lublin, Poland, 2018; p. 165. (In Polish). [Google Scholar]

- Droździel, P. The influence of the vehicle work organization conditions on the engine start-up parameters. Eksploat. Niezawodn. Maint. Reliab. 2008, 37, 72–74. [Google Scholar]

- Drozdziel, P. The Influence of Vehicle Maintenance Conditions on Chosen Electric Parameters of Starter During Combustion Engine Start-Up. Commun. Sci. Lett. Univ. Zilina 2006, 8, 53–58. [Google Scholar] [CrossRef]

- Desantes, J.; García-Oliver, J.; Pastor, J.; Ramírez-Hernández, J. Influence of nozzle geometry on ignition and combustion for high-speed direct injection diesel engines under cold start conditions. Fuel 2011, 90, 3359–3368. [Google Scholar] [CrossRef][Green Version]

- Payri, F.; Broatch, A.; Salavert, J.; Martín, J. Investigation of Diesel combustion using multiple injection strategies for idling after cold start of passenger-car engines. Exp. Therm. Fluid Sci. 2010, 34, 857–865. [Google Scholar] [CrossRef]

- Dziubiński, M.; Litak, G.; Drozd, A.; Szydło, K.; Longwic, R.; Wolszczak, P. Using the Hall Effect for Monitoring the Starter Condition in Motor Vehicles. Appl. Sci. 2018, 8, 747. [Google Scholar] [CrossRef]

- Dziubiński, M.; Siemionek, E.; Plich, M.; Drozd, A.; Toborek, K. Simulation of Automotive Starter Faults. J. Konbin 2017, 44, 141–158. [Google Scholar] [CrossRef][Green Version]

- Plizga, K. Metody diagnozowania rozruszników samochodowych. Motrol. Motoryz. Energetyka Rol. 2008, 10, 102–109. [Google Scholar]

- Bohdanowicz, Z.; Kowalski, J.; Biele, C. Intentions to Charge Electric Vehicles Using Vehicle-to-Grid Technology among People with Different Motivations to Save Energy. Sustainability 2022, 14, 12681. [Google Scholar] [CrossRef]

- König, A.; Mayer, S.; Nicoletti, L.; Tumphart, S.; Lienkamp, M. The Impact of HVAC on the Development of Autonomous and Electric Vehicle Concepts. Energies 2022, 15, 441. [Google Scholar] [CrossRef]

- Skuza, A.; Jurecki, R.; Szumska, E. Influence of Traffic Conditions on the Energy Consumption of an Electric Vehicle. Commun. Sci. Lett. Univ. Zilina 2023, 25, B22–B33. [Google Scholar] [CrossRef]

- Stoma, M.; Dudziak, A. Future Challenges of the Electric Vehicle Market Perceived by Individual Drivers from Eastern Poland. Energies 2023, 16, 7212. [Google Scholar] [CrossRef]

- Turoń, K.; Kubik, A.; Folęga, P.; Chen, F. Perception of Shared Electric Scooters: A Case Study from Poland. Sustainability 2023, 15, 12596. [Google Scholar] [CrossRef]

- Burdzik, R.; Konieczny, Ł.; Jaworski, R.; Laskowski, D.; Polak, R. Comparison of Energy Consumption of Short and Long City Buses in Terms of Assessing the Needs for e-Mobility. Adv. Intell. Syst. Comput. 2020, 1032, 74–83. [Google Scholar]

- Čulík, K.; Hrudkay, K.; Štefancová, V. Vplyv teploty prostredia na spotrebu elektrických autobusov. Perner’s Contacts 2021, 16. [Google Scholar] [CrossRef]

- Almohaimeed, S.A. Electric Vehicle Deployment and Integration in the Saudi Electric Power System. World Electr. Veh. J. 2022, 13, 84. [Google Scholar] [CrossRef]

- Čulík, K.; Hrudkay, K.; Štefancová, V. Possibilities of Legislative and Economic Support for Electromobility in Slovakia. Lect. Notes Intell. Transp. Infrastruct. 2023, Part F1379, 125–134. [Google Scholar]

- Balitskii, A.I.; Abramek, K.F.; Osipowicz, T.K.; Eliasz, J.J.; Balitska, V.O.; Kochmański, P.; Prajwowski, K.; Mozga, Ł.S. Hydrogen-Containing “Green” Fuels Influence on the Thermal Protection and Formation of Wear Processes Components in Compression-Ignition Engines Modern Injection System. Energies 2023, 16, 3374. [Google Scholar] [CrossRef]

- Capurso, T.; Stefanizzi, M.; Torresi, M.; Camporeale, S. Perspective of the role of hydrogen in the 21st century energy transition. Energy Convers. Manag. 2021, 251, 114898. [Google Scholar] [CrossRef]

- Ciupek, B.J.; Brodzik, Ł.; Semkło, Ł.; Prokopowicz, W.; Sielicki, P.W. Analysis of the Environmental Parameters of the GTM 400 Turbojet Engine During the Co-Combustion of JET A-1 Jet Oil with Hydrogen. J. Ecol. Eng. 2024, 25, 205–211. [Google Scholar] [CrossRef]

- Małek, A.; Karowiec, R.; Jóżwik, K. A review of technologies in the area of production, storage and use of hydrogen in the automotive industry. Arch. Automot. Eng. Arch. Mot. 2023, 102, 41–67. [Google Scholar] [CrossRef]

- Okafor, E.C.; Kurata, O.; Yamashita, H.; Inoue, T.; Tsujimura, T.; Iki, N.; Hayakawa, A.; Ito, S.; Uchida, M.; Kobayashi, H. Liquid ammonia spray combustion in two-stage micro gas turbine combustors at 0.25 MPa; Relevance of combustion enhancement to flame stability and NOx control. Appl. Energy Combust. Sci. 2021, 7, 100038. [Google Scholar] [CrossRef]

- Tornatore, C.; Marchitto, L.; Sabia, P.; De Joannon, M. Ammonia as Green Fuel in Internal Combustion Engines: State-of-the-Art and Future Perspectives. Front. Mech. Eng. 2022, 8, 944201. [Google Scholar] [CrossRef]

- Samociuk, W.; Krzysiak, Z.; Szmigielski, M.; Zarajczyk, J.; Stropek, Z.; Gołacki, K.; Bartnik, G.; Skic, A.; Nieoczym, A. Modernization of the control system to reduce a risk of severe accidents during non-pressurized ammonia storage. Przem. Chem. 2016, 95, 1032–1035. [Google Scholar]

- Warguła, L.; Waluś, K.J.; Krawiec, P. Small engines spark ignited (SI) for non-road mobile machinery-Review. In Proceedings of the 22nd International Scientific Conference Transport Means 2018, Trakai, Lithuania, 3–5 October 2018; pp. 585–591. [Google Scholar]

- Work Shop Manual RY125 Series Engines, 1st ed.; Lombardini: Reggio Emilia, Italy, 2004; p. 1-5302-633.

- Reiter, M.S.; Kockelman, K.M. The problem of cold starts: A closer look at mobile source emissions levels. Transp. Res. Part D Transp. Environ. 2016, 43, 123–132. [Google Scholar] [CrossRef]

- BN-84/1301-08; Silniki o Zapłonie Samoczynnym. Wtryskiwacze. Wymagania i Badania. [Diesel Engines. Injectors. Requirements and Tests]. Wydawnictwa Normalizacyjne: Warszawa, Poland, 1982. (In Polish)

- Kurtyka, K.; Pielecha, J. Cold start emissions from a gasoline engine in RDE tests at different ambient temperatures. Combust. Engines 2020, 181, 24–30. [Google Scholar] [CrossRef]

- Broatch, A.; Ruiz, S.; Margot, X.; Gil, A. Methodology to estimate the threshold in-cylinder temperature for self-ignition of fuel during cold start of Diesel engines. Energy 2010, 35, 2251–2260. [Google Scholar] [CrossRef]

- Pszczółkowski, J.P. The model for cylinder charge parameters during engine starting. Combust. Engines 2021, 188, 60–66. [Google Scholar] [CrossRef]

- Czech, P. Determination of the course of pressure in an internal combustion engine cylinder with the use of vibration effects and radial basis function–Preliminary research. Commun. Comput. Inf. Sci. 2012, 329, 175–182. [Google Scholar]

- Coronado, M.; Kadoch, B.; Contreras, J.; Kristjanpoller, F. Reliability and availability modelling of a retrofitted Diesel-based cogeneration system for heat and hot water demand of an isolated Antarctic base. Eksploat. Niezawodn. Maint. Reliab. 2023, 25. [Google Scholar] [CrossRef]

| Parameter | Type/Value |

|---|---|

| Type of cooling | Air |

| Displacement | 505 cm3 |

| Power | 8.8 kW at 3600 rpm |

| Maximum torque | 31 Nm at 2000 rpm |

| Number of valves | 2 |

| Compression ratio | 20:1 |

| Cylinder diameter | 87 mm |

| Piston stroke | 85 mm |

| Number of injector holes | 5 |

| Starter voltage | 12 V (Bosch 0 001 107 090) |

| Rated power of starter | 1.1 kW |

| Maximum rotational speed | 300 rpm |

| Direction of rotation | Right |

| Number of pinion teeth | 11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caban, J.; Seńko, J.; Ignaciuk, P. Laboratory Tests of Electrical Parameters of the Start-Up Process of Single-Cylinder Diesel Engines. Energies 2024, 17, 2155. https://doi.org/10.3390/en17092155

Caban J, Seńko J, Ignaciuk P. Laboratory Tests of Electrical Parameters of the Start-Up Process of Single-Cylinder Diesel Engines. Energies. 2024; 17(9):2155. https://doi.org/10.3390/en17092155

Chicago/Turabian StyleCaban, Jacek, Jarosław Seńko, and Piotr Ignaciuk. 2024. "Laboratory Tests of Electrical Parameters of the Start-Up Process of Single-Cylinder Diesel Engines" Energies 17, no. 9: 2155. https://doi.org/10.3390/en17092155

APA StyleCaban, J., Seńko, J., & Ignaciuk, P. (2024). Laboratory Tests of Electrical Parameters of the Start-Up Process of Single-Cylinder Diesel Engines. Energies, 17(9), 2155. https://doi.org/10.3390/en17092155