Techno-Economic Evaluation on Solar-Assisted Post-Combustion CO2 Capture in Hollow Fiber Membrane Contactors

Abstract

1. Introduction

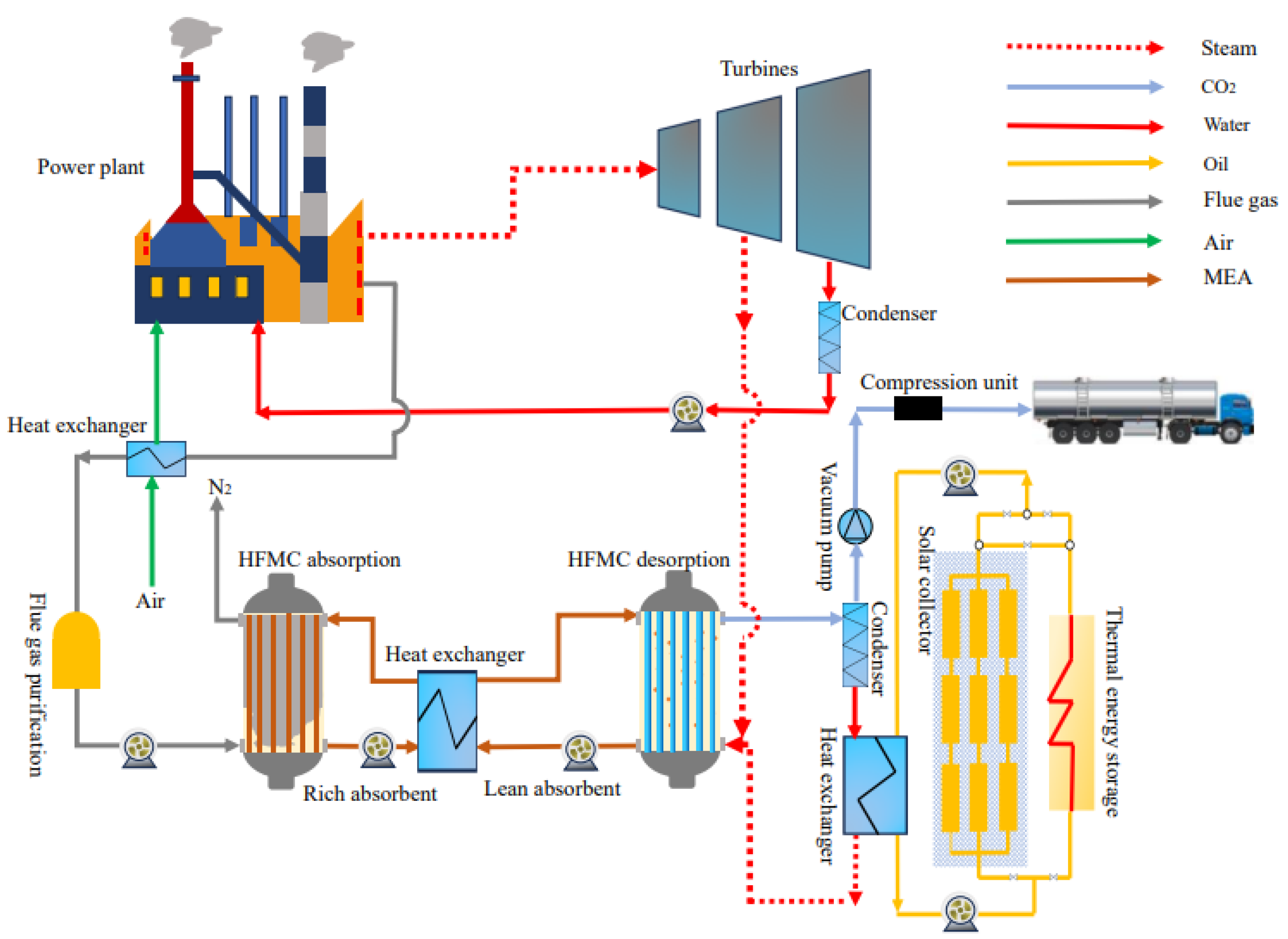

2. System Description

2.1. Membrane Contactor-Based CO2 Absorption–Desorption System

2.2. Solar Thermal Energy Collection and Storage System

3. Methodology and Study Case

3.1. Net Efficiency and Carbon Emission of Coal-Fired Power Plants

3.2. Area of Solar Thermal Collectors

3.3. Economic Evaluation Indicators

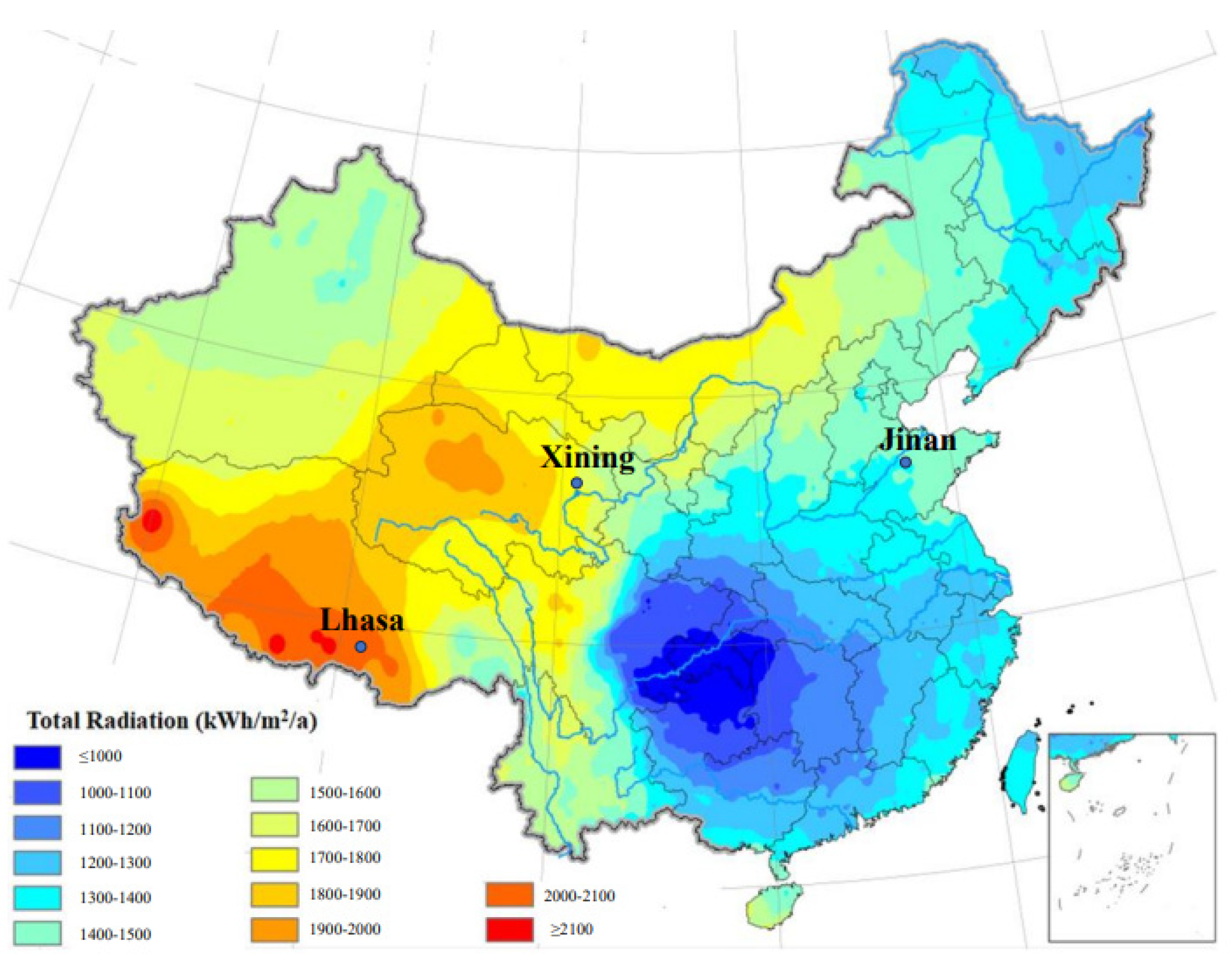

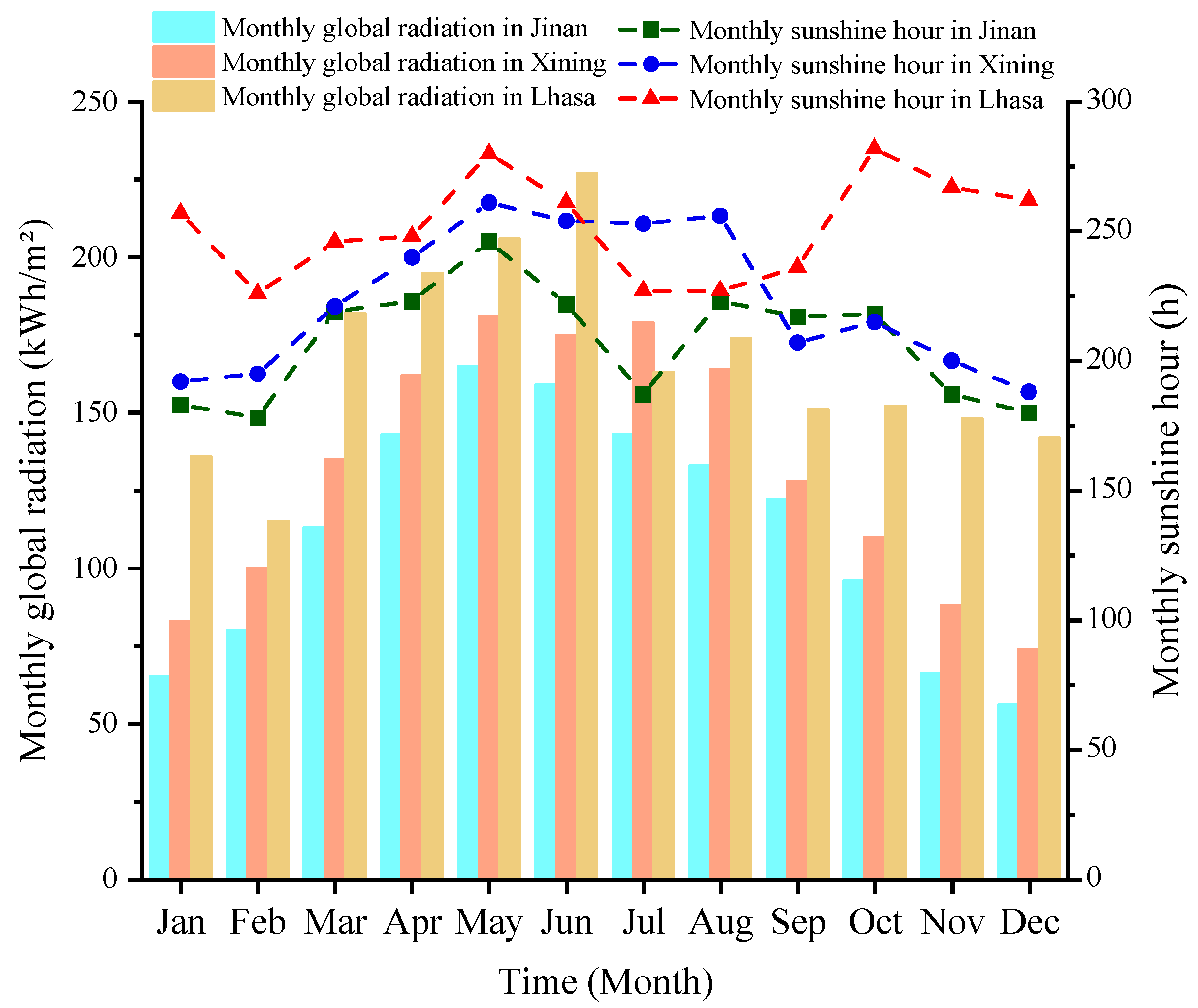

3.4. Study Case

4. Results and Discussion

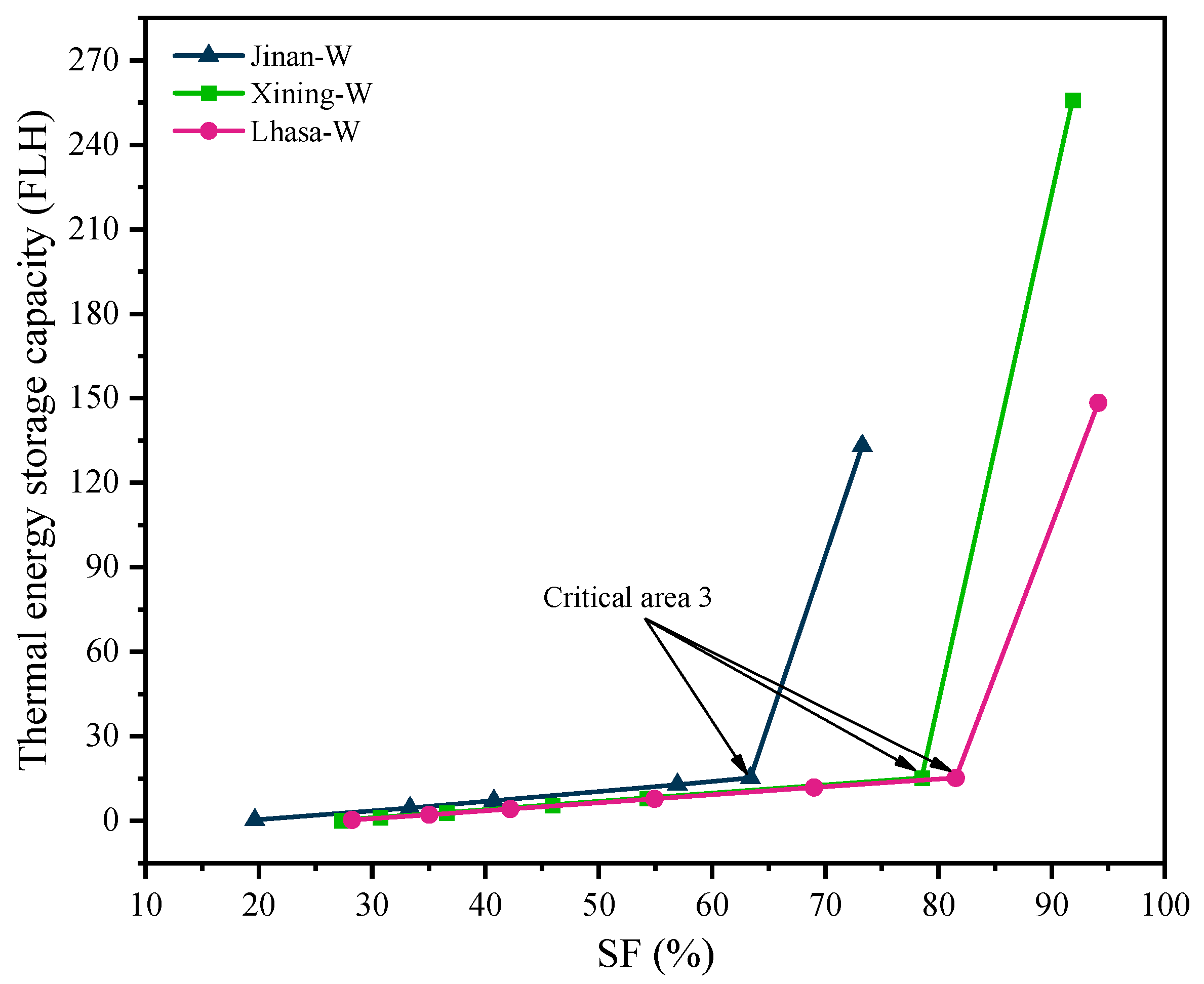

4.1. Technical Feasibility Evaluation

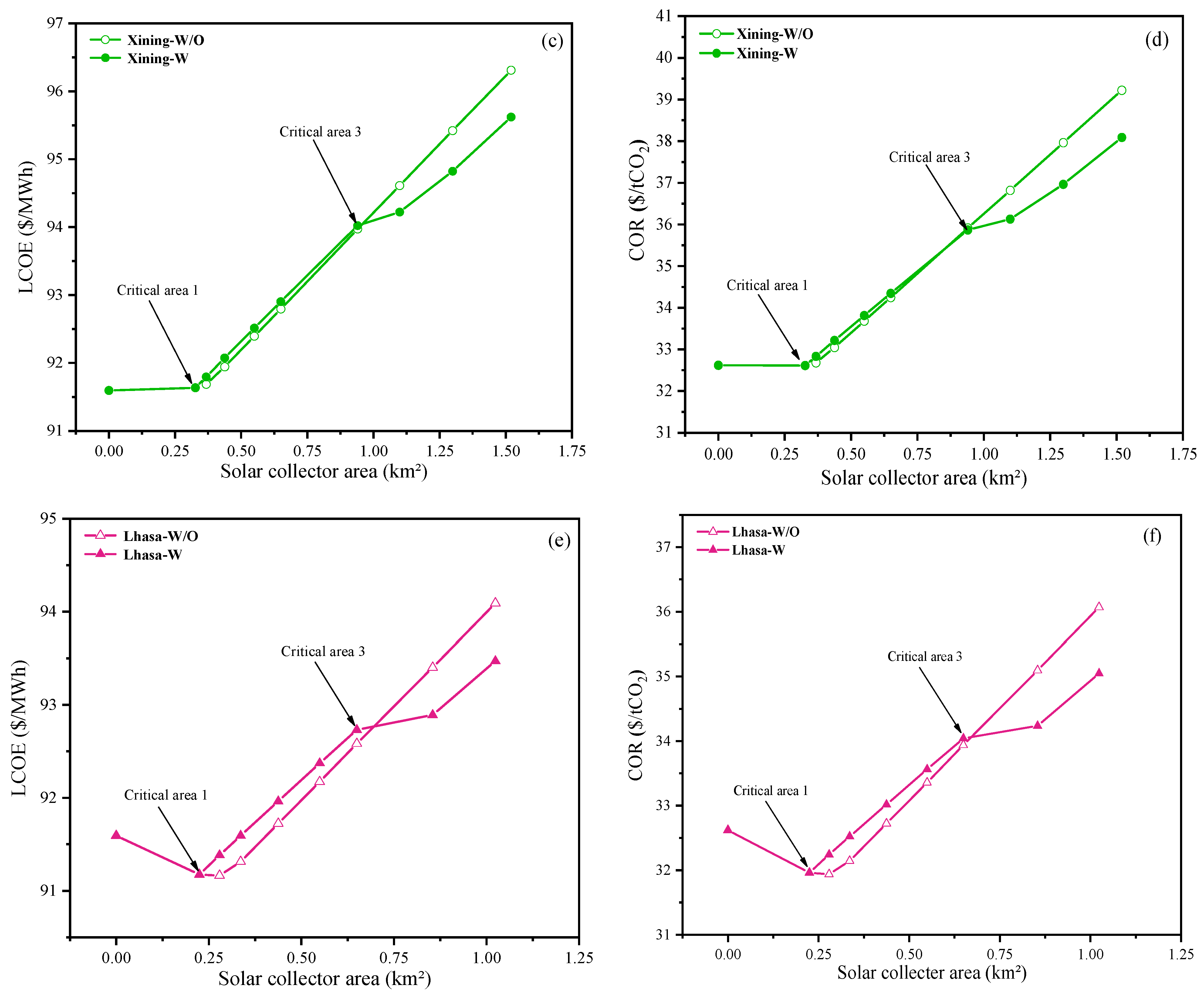

4.2. Economic Performance Evaluation

5. Sensitivity Analysis

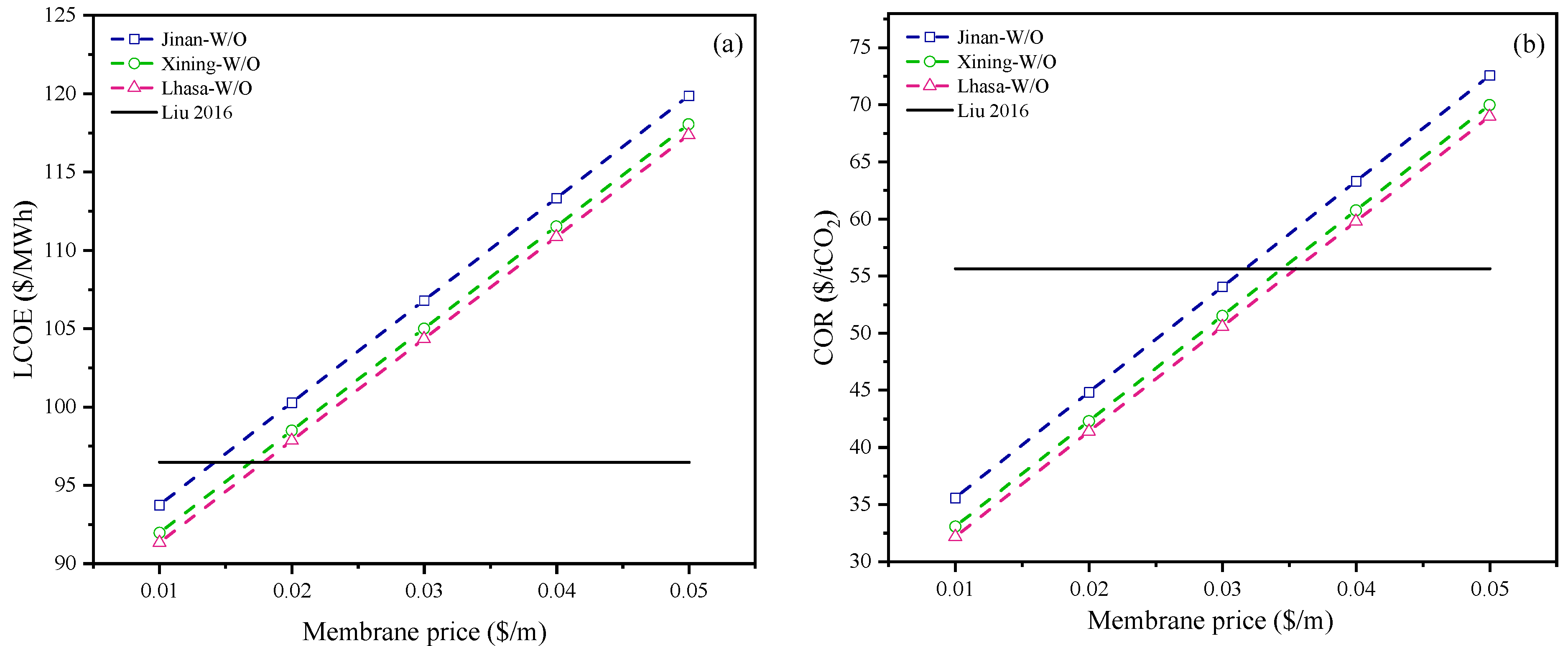

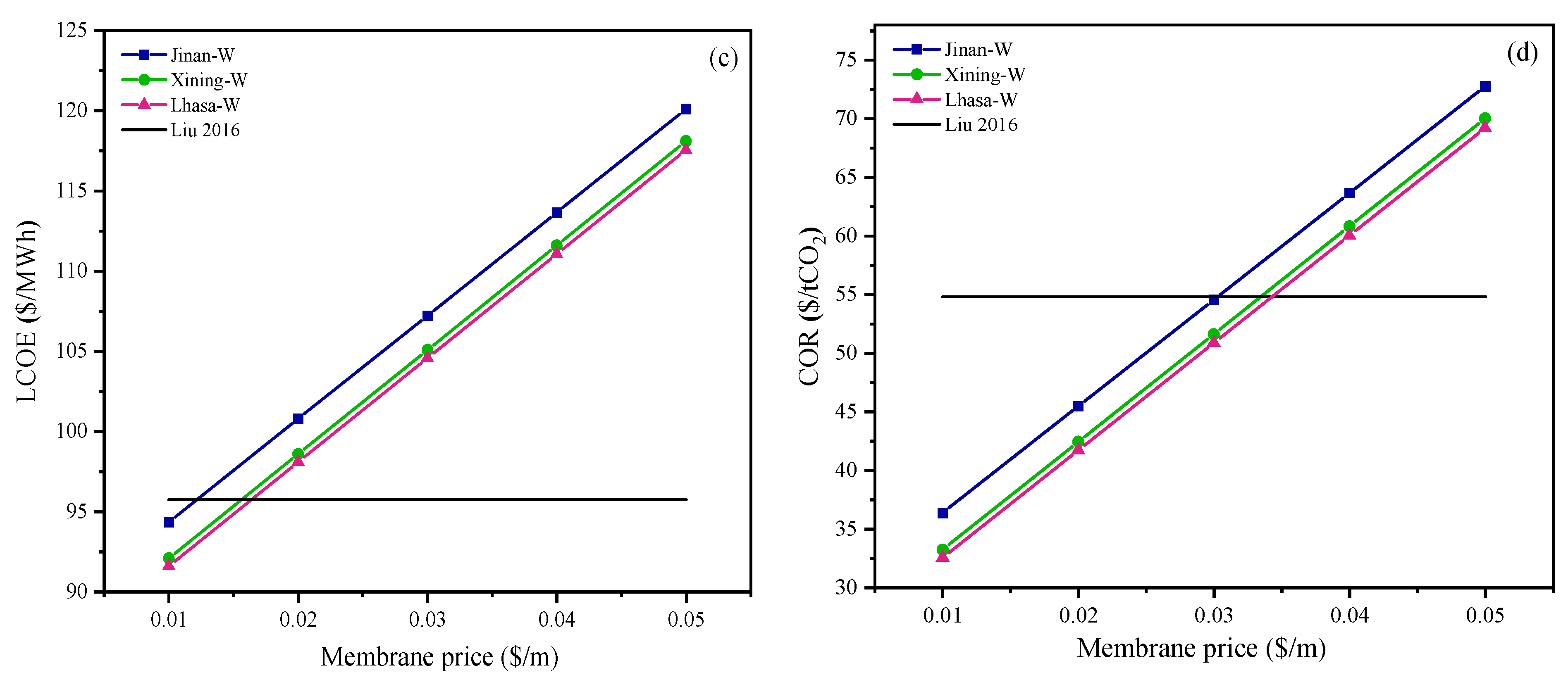

5.1. Sensitivity Study on Membrane Prices

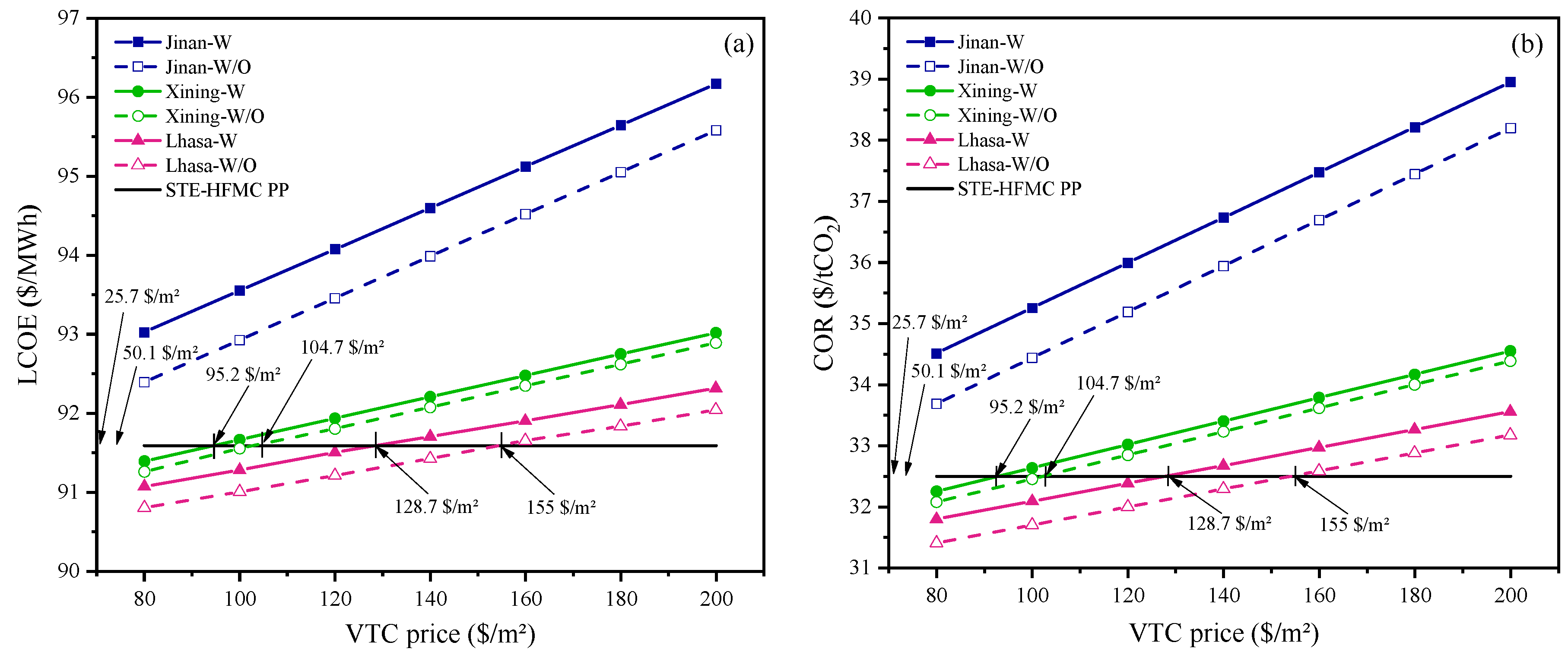

5.2. Sensitivity Study on Solar Collector Prices

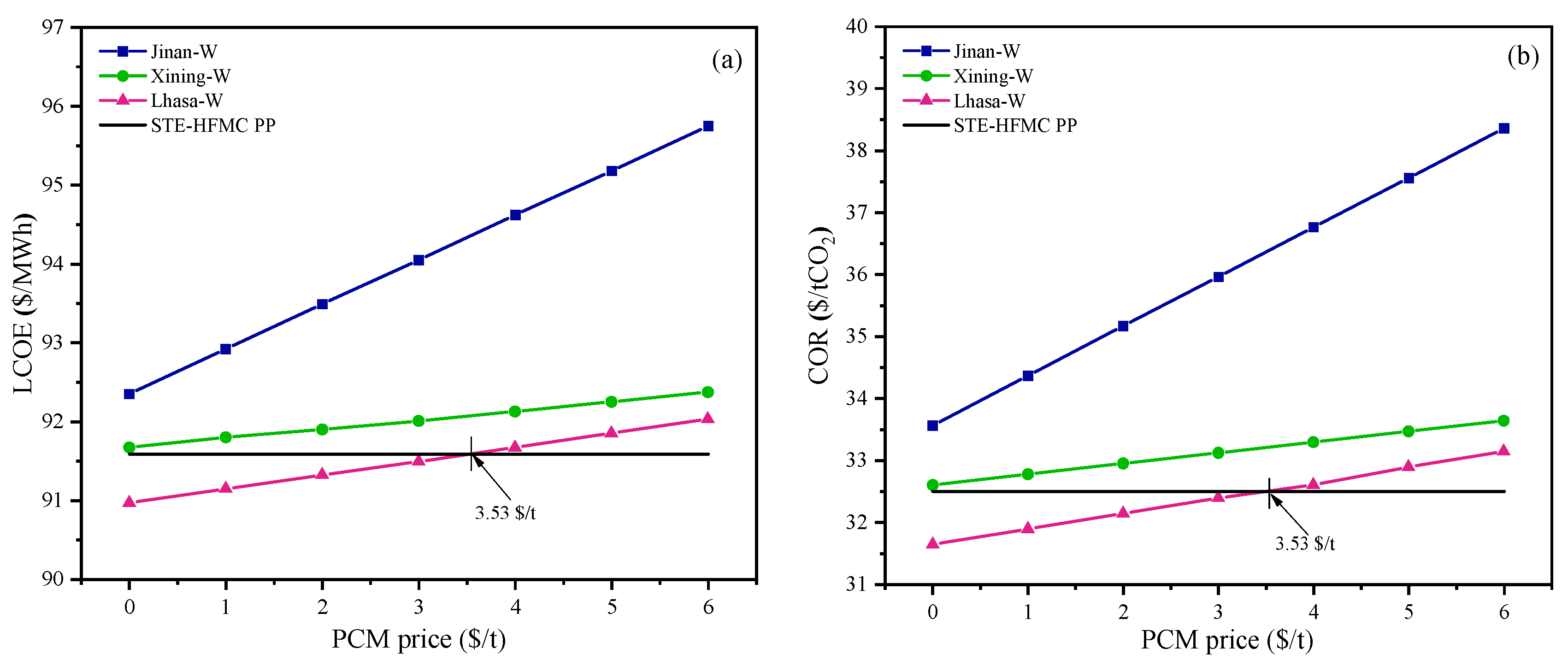

5.3. Sensitivity Study on PCM Prices

6. Conclusions

- (1)

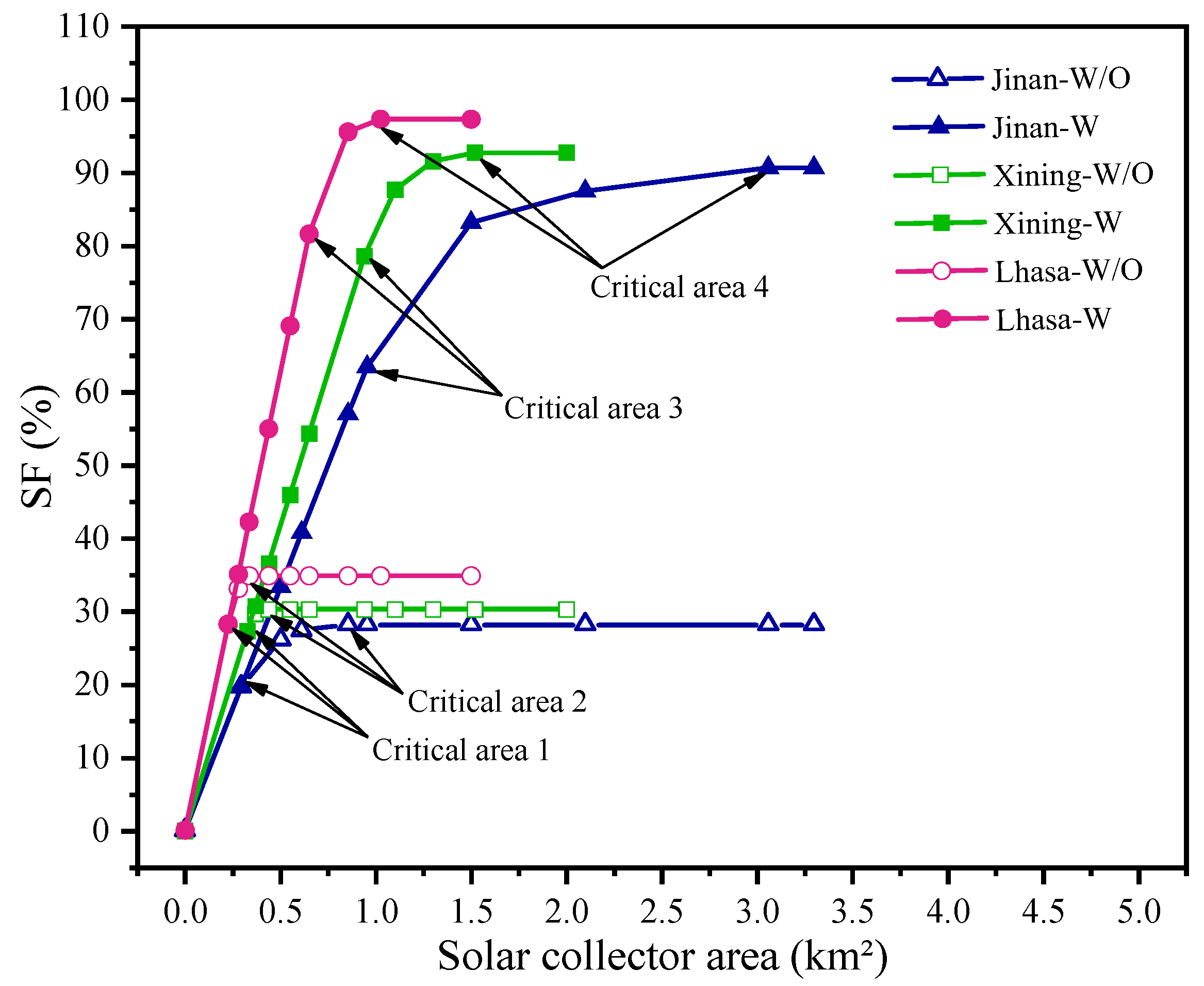

- Specific to the SF of the SOL-HFMC power plant without a TES system, the SF reaches its maximum value of 28.19%, 30.26%, and 34.84% when the solar collector area reaches Critical Area 2 in Jinan, Xining, and Lhasa cities, respectively; if the TES system is applied, the SF can reach its maximum value of 90.7%, 92.76%, and 97.34% for Jinan, Xining, and Lhasa, respectively; in this study, the SF value could not reach 100% due to the TES capacity limitation of 15 FLH;

- (2)

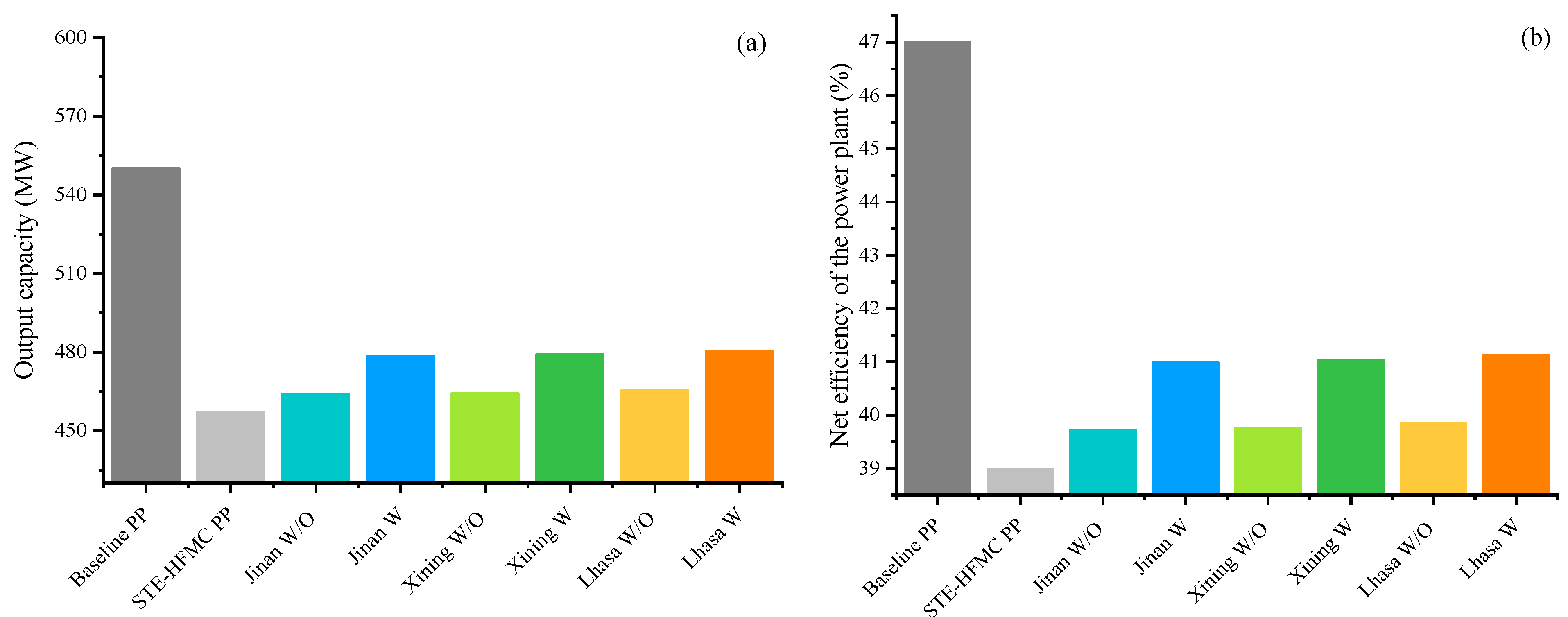

- From the perspective of technical potential, the output capacity and net efficiency of the SOL-HFMC power plant are both significantly improved in comparison with the STE-HFMC power plant, regardless of whether the TES system is equipped or not; the performance of the SOL-HFMC power plant equipped with the TES system is superior to that of the SOL-HFMC power plant without the TES system, with the net efficiency increased by 2.00%, 2.04%, and 2.13% in Jinan, Xining, and Lhasa, respectively;

- (3)

- Specific to the CEI value, the minimum CEI value of the proposed SOL-HFMC power plant with the TES system can be stabilized at 92.14 kg CO2/MWh, 92.05 kg CO2/MWh and 91.84 CO2/MWh in Jinan, Xining, and Lhasa, respectively; for the SOL-HFMC power plant without the TES system, the CEI value is decreased by 1.40 kg CO2/MWh, 1.50 kg CO2/MWh, and 1.73 kg CO2/MWh in Jinan, Xining, and Lhasa, respectively, compared to 96.50 kg CO2/MWh in the STE-HFMC power plant;

- (4)

- To achieve better economic performance compared to the STE-HFMC power plant, if the TES system is not applied, the critical VTC price is 50.1 $/m2 for Jinan, 104.7 $/m2 for Xining, and 155.1$/m2 for Lhasa, respectively; when TES system is applied, the corresponding VTC prices shall be reduced to be lower than 25.7 $/m2 for Jinan, 95.2 $/m2 for Xining, and 128.7 $/m2 for Lhasa, respectively; for Lhasa city with rich solar resources, the SOL-HFMC power plant is more competitive than the STE-HFMC power plant when the PCM price is lower than 3.53 $/t;

- (5)

- The membrane price is also critical for the economic performance of the SOL-HFMC power plant; in comparison with the reference point, for the SOL-HFMC power plant with the TES system, the LCOE is reduced by 1.5%, 3.9%, and 4.4%, and COR is reduced by 33.7%, 39.4%, and 40.7% at a given membrane price of 0.01 $/m in Lhasa, Xining, and Jinan, respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Available online: https://www.ipcc.ch/sr15/ (accessed on 13 October 2023).

- Available online: https://net0.com/blog/net-zero-countries (accessed on 8 March 2024).

- Available online: https://www.irena.org/publications/2022/Jul/Chinas-Route-to-Carbon-Neutrality (accessed on 26 October 2023).

- Ghoniem, A.F. Needs, resources and climate change: Clean and efficient conversion technologies. Prog. Energy Combust. 2011, 37, 15–51. [Google Scholar] [CrossRef]

- Goto, K.; Yogo, K.; Higashii, T. A review of efficiency penalty in a coal-fired power plant with post-combustion CO2 capture. Appl. Energy 2013, 111, 710–720. [Google Scholar] [CrossRef]

- Zahedi, R.; Ayazi, M.; Aslani, A. Comparison of amine adsorbents and strong hydroxides soluble for direct air CO2 capture by life cycle assessment method. Environ. Technol. Innov. 2022, 28, 102854. [Google Scholar] [CrossRef]

- Li, X.L.; Zhou, X.B.; Wei, J.W.; Fan, Y.M.; Liao, L.; Wang, H.Q. Reducing the energy penalty and corrosion of carbon dioxide capture using a novel nonaqueous monoethanolamine-based biphasic solvent. Sep. Purif. Technol. 2021, 265, 118481. [Google Scholar] [CrossRef]

- Aghel, B.; Janati, S.; Wongwises, S.; Shadloo, M.S. Review on CO2 capture by blended amine solutions. Int. J. Greenh. Gas Control 2022, 119, 103715. [Google Scholar] [CrossRef]

- Bravo, J.; Drapanauskaite, D.; Sarunac, N.; Romero, C.; Jesikiewicz, T.; Baltrusaitis, J. Optimization of energy requirements for CO2 post-combustion capture process through advanced thermal integration. Fuel 2021, 283, 118940. [Google Scholar] [CrossRef]

- Lv, Y.X.; Yu, X.H.; Tu, S.T.; Yan, J.Y.; Dahlquist, E. Experimental studies on simultaneous removal of CO2 and SO2 in a polypropylene hollow fiber membrane contactor. Appl. Energy 2012, 97, 283–288. [Google Scholar] [CrossRef]

- Belaissaoui, B.; Favre, E. Novel dense skin hollow fiber membrane contactor based process for CO2 removal from raw biogas using water as absorbent. Sep. Purif. Technol. 2018, 193, 112–126. [Google Scholar] [CrossRef]

- Nguyen, K.; Iliuta, I.; Bougie, F. Techno-economic assessment of enzymatic CO2 capture in hollow fiber membrane contactors with immobilized carbonic anhydrase. Sep. Purif. Technol. 2023, 307, 122702. [Google Scholar] [CrossRef]

- Jang, M.G.; Yun, S.; Kim, J.K. Process design and economic analysis of membrane-integrated absorption processes for CO2 capture. J. Clean. Prod. 2022, 368, 133180. [Google Scholar] [CrossRef]

- Scholes, C.A. Membrane contactors modelled for process intensification post combustion solvent regeneration. Int. J. Greenh. Gas Control 2019, 87, 203–210. [Google Scholar] [CrossRef]

- Kumar, A.; Tiwari, A.K. Solar-assisted post-combustion carbon-capturing system retrofitted with coal-fired power plant towards net-zero future: A review. J. CO2 Util. 2022, 65, 102241. [Google Scholar] [CrossRef]

- Alzhrani, A.; Romero, C.E.; Baltrusaitis, J. Sustainability Assessment of a Solar Energy-Assisted Flue Gas Amine-Based CO2 Capture Process Using Fully Dynamic Process Models. ACS Sustain. Chem. Eng. 2023, 11, 11385–11398. [Google Scholar] [CrossRef]

- Quang, D.V.; Milani, D.; Zahra, M.A. A review of potential routes to zero and negative emission technologies via the integration of renewable energies with CO2 capture processes. Int. J. Greenh. Gas Control 2023, 124, 103862. [Google Scholar] [CrossRef]

- Mokhtar, M.; Ali, M.T.; Khalilpour, R.; Abbas, A.; Shah, N.; Hajaj, A.A.; Armstrong, P.; Chiesa, M.; Sgouridis, S. Solar-assisted Post-combustion Carbon Capture feasibility study. Appl. Energy 2012, 92, 668–676. [Google Scholar] [CrossRef]

- Liu, L.X.; Zhao, J.; Deng, S.; An, Q.S. A technical and economic study on solar-assisted ammonia-based post-combustion CO2 capture of power plant. Appl. Therm. Eng. 2016, 102, 412–422. [Google Scholar] [CrossRef]

- Khalilpour, R.; Milani, D.; Qadir, A.; Chiesa, M.; Abbas, A. A novel process for direct solvent regeneration via solar thermal energy for carbon capture. Renew. Energy 2017, 104, 60–75. [Google Scholar] [CrossRef]

- Kev, K.; Modi, N.; Milani, D.; Luu, M.T.; Nelson, S.; Manaf, N.A.; Wang, X.L.; Negnevitsky, M.; Abbas, A. A comparative life cycle impact assessment for solar heat integration in post-combustion carbon capture. Energy Convers. Manag. 2023, 297, 117745. [Google Scholar] [CrossRef]

- Cost NETL. Performance Baseline for Fossil Energy Plants, Volume 1: Bituminous Coal and Natural Gas to Electricity, Revision 2; DOE/NETL-2010/1397; National Energy Technology Laboratory: Albany, OR, USA, 2010. [Google Scholar]

- Vinjarapu, S.H.B.; Regueira, T.; Neerup, R.; Solms, N.V.; Fosbøl, P.L. Heat of absorption of CO2 in 30 wt% MEA with monoethyleneglycol and urea as vapour reduction additives. Energy 2024, 294, 130609. [Google Scholar] [CrossRef]

- Kim, K.; Lee, H.; Park, H.S.; Song, H.; Kim, S. Surface modification of polypropylene hollow fiber membranes using fluorosilane for CO2 absorption in a gas-liquid membrane contactor. Heliyon 2023, 9, e19829. [Google Scholar] [CrossRef]

- Wang, Z.; Fang, M.X.; Ma, Q.H.; Zhao, Z.; Wang, T.; Luo, Z.Y. Membrane Stripping Technology for CO2 Desorption from CO2-rich Absorbents with Low Energy Consumption. Energy Procedia 2014, 63, 765–772. [Google Scholar] [CrossRef]

- Yan, Q.; Yang, Y.; Nishimura, A.; Kouzani, A.; Hu, E. Multi-point and multi-level solar integration into a conventional coal-fired power plant. Energy Fuels 2010, 24, 3733–3738. [Google Scholar] [CrossRef]

- Sweet, M.L.; McLeskey, J.T., Jr. Numerical simulation of underground Seasonal Solar Thermal Energy Storage (SSTES) for a single-family dwelling using TRNSYS. Sol. Energy 2012, 86, 289–300. [Google Scholar] [CrossRef]

- Chen, J.F.; Dai, Y.J.; Wang, R.Z. Experimental and analytical study on an air-cooled single effect LiBr-H2O absorption chiller driven by evacuated glass tube solar collector for cooling application in residential buildings. Sol. Energy 2017, 151, 110–118. [Google Scholar] [CrossRef]

- Zhao, R.K.; Liu, L.C.; Zhao, L.; Deng, S.; Li, S.J.; Zhang, Y.; Li, H.L. Techno-economic analysis of carbon capture from a coal-fired power plant integrating solar-assisted pressure-temperature swing adsorption (PTSA). J. Clean. Prod. 2019, 214, 440–451. [Google Scholar] [CrossRef]

- Li, K.; Leigh, W.; Feron, P.; Yu, H.; Tade, M. Systematic study of aqueous monoethanolamine (MEA)-based CO2 capture process: Techno-economic assessment of the MEA process and its improvements. Appl. Energy 2016, 165, 648–659. [Google Scholar] [CrossRef]

- Rubin, E.S.; Short, C.; Booras, G.; Davsion, J.; Ekstrom, C.; Matuszewski, M.; McCoy, S. A proposed methodology for CO2 capture and storage cost estimates. Int. J. Greenh. Gas Control 2013, 17, 488–503. [Google Scholar] [CrossRef]

- Theis, J. Quality Guidelines for Energy Systems Studies: Cost Estimation Methodology for NETL Assessments of Power Plant Performance; National Energy Technology Laboratory (NETL): Albany, OR, USA, 2021. [Google Scholar]

- Meteotest, J.R.; Kunz, S. MeteonormData (Worldwide). Available online: https://meteonorm.com/en/ (accessed on 11 December 2023).

- Li, H.; Yan, J.; Campana, P.E. Feasibility of integrating solar energy into a power plant with amine-based chemical absorption for CO2 capture. Int. J. Greenh. Gas Control 2012, 9, 272–280. [Google Scholar] [CrossRef]

- Cau, G.; Cocco, D.; Tola, V. Performance assessment of USC power plants integrated with CCS and concentrating solar collectors. Energy Convers. Manag. 2014, 88, 973–984. [Google Scholar] [CrossRef]

- Wang, F.; Li, H.; Zhao, J.; Deng, S.; Yan, J.Y. Technical and economic analysis of integrating low-medium temperature solar energy into power plant. Energy Convers. Manag. 2016, 112, 459–469. [Google Scholar] [CrossRef]

| Technical Parameters | Value | References |

|---|---|---|

| Baseline power plant without CCS | ||

| Auxiliary load (MWe) | 30 | [22] |

| Net output power (MWe) | 550 | [22] |

| Coal consumption (kg/h) | 185,759 | [22] |

| CO2 emission (t/h) | 441 | [22] |

| CO2 concentration of flue gas (% mol) | 13.53 | [22] |

| STE-HFMC power plant | ||

| Number of HFMC | 200 | [12] |

| HFMC diameter (m) | 2.8 | [12] |

| HFMC effective height (m) | 4.0 | [12] |

| HFMC total height (m) | 4.2 | [12] |

| Chemical absorbent | MEA | |

| Absorbent mass fraction (wt %) | 20 | |

| Regeneration energy consumption (MJth/kg CO2) | 1.25 | [25] |

| CO2 capture rate (%) | 90 | |

| Gas velocity (m/s) Purity of desorbed CO2 (%) | 1.0 98 | [12] |

| Absorption temperature (K) | 300 | |

| Regeneration temperature (K) | 353 | |

| Liquid velocity (m/s) | 0.07 | [12] |

| Blower and pump power (MWe) | 5 | [12] |

| Vacuum pump power (MWe) | 26 | [12] |

| Compression power (MWe) | 38 | [12] |

| Capacity reduction due to steam extraction (MWe) | 24 | |

| Power output after CO2 capture (MWe) | 457 |

| Economic Parameters | Value | References |

|---|---|---|

| Service lifespan of the project (years) | 30 | |

| Discount rate (%) | 7 | [29] |

| Power plant total equipment cost (M$) | 444.7 | [22] |

| Membrane contactor cost (M$) | 76.2 | [12] |

| Heat Exchanger (M$) | 8.3 | [12] |

| Pumps, blowers, coolers (M$) | 10.7 | [12] |

| Compression unit (M$) | 50.1 | [12] |

| Fuel cost (M$/year) | 58.2 | [22] |

| MEA replenishment (kg/t CO2) | 1.5 | [30] |

| MEA cost ($/kg) | 2.5 | [12] |

| Vacuum tube collector price (USD/m2) | 130 | [19] |

| Energy storage material density (kJ/kg) | 339.8 | [19] |

| Energy storage material price ($/kg) | 3.5 | [19] |

| Capital Cost Items | Quantification |

|---|---|

| Process equipment cost | 444.7 M$ for power plant without CCS [22] 145.3 M$ for HFMC capture unit [12] |

| Supporting facilities cost | 10% of process equipment cost |

| Direct and indirect labor cost | 50% of process equipment cost |

| Bare Erected Cost (BEC) | The sum of the above items |

| Engineering services cost | 18% of BEC |

| Process contingencies | 5% of BEC for power plant without CCS 40% of BEC for HFMC capture unit |

| Project contingencies | 15% of all above |

| Total Plant Cost (TPC) | BEC + Engineering services + Contingencies |

| Owner’s costs | 15% of TPC |

| Total Overnight cost (TOC) | TPC + Owner’s costs |

| Total Capital Requirement |

| Critical Area 1 | Critical Area 2 | Critical Area 3 | Critical Area 4 | ||

|---|---|---|---|---|---|

| Jinan | Collector area (km2) | 0.29 | 0.86 | 0.96 | 3.06 |

| SF (%) | 19.65 | 57.00 | 63.45 | 90.69 | |

| Xining | Collector area (km2) | 0.33 | 0.44 | 0.94 | 1.52 |

| SF (%) | 27.34 | 36.58 | 78.59 | 92.76 | |

| Lhasa | Collector area (km2) | 0.22 | 0.34 | 0.65 | 1.02 |

| SF (%) | 28.24 | 42.22 | 81.63 | 97.34 |

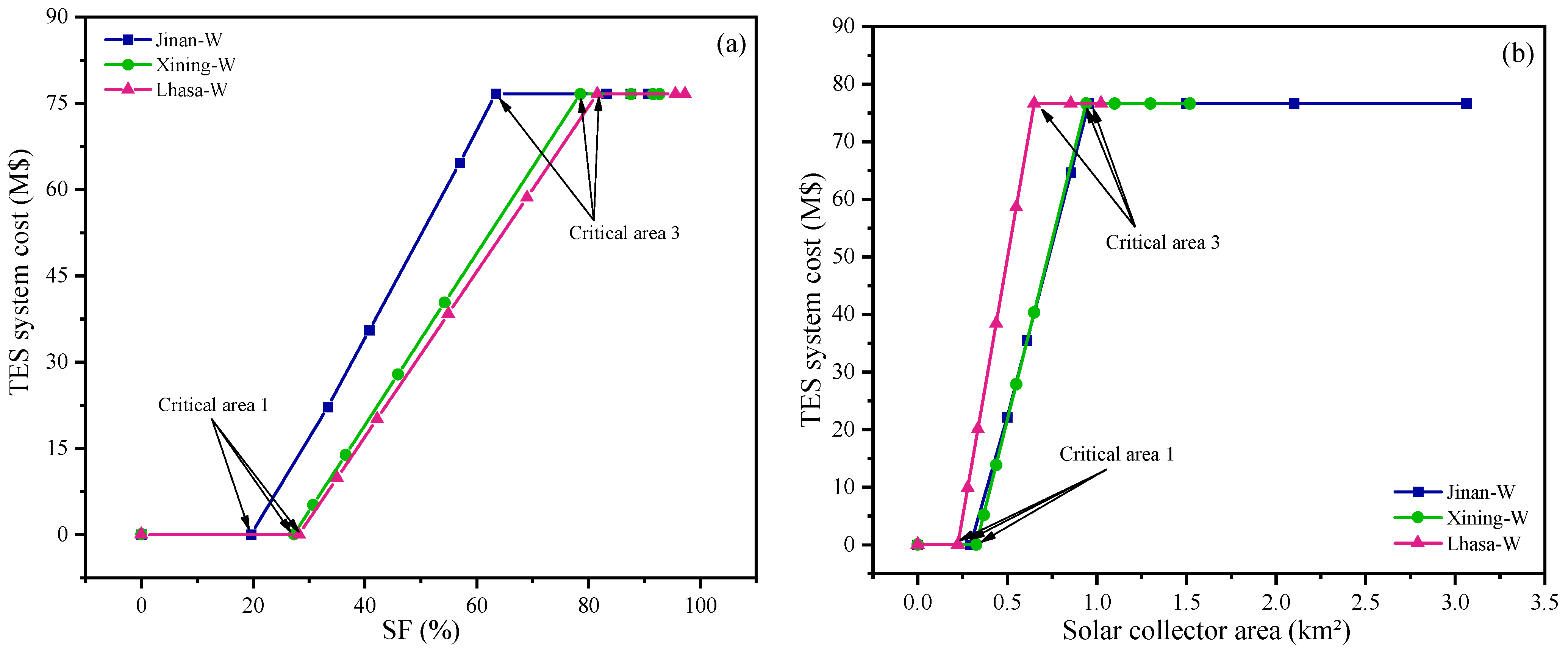

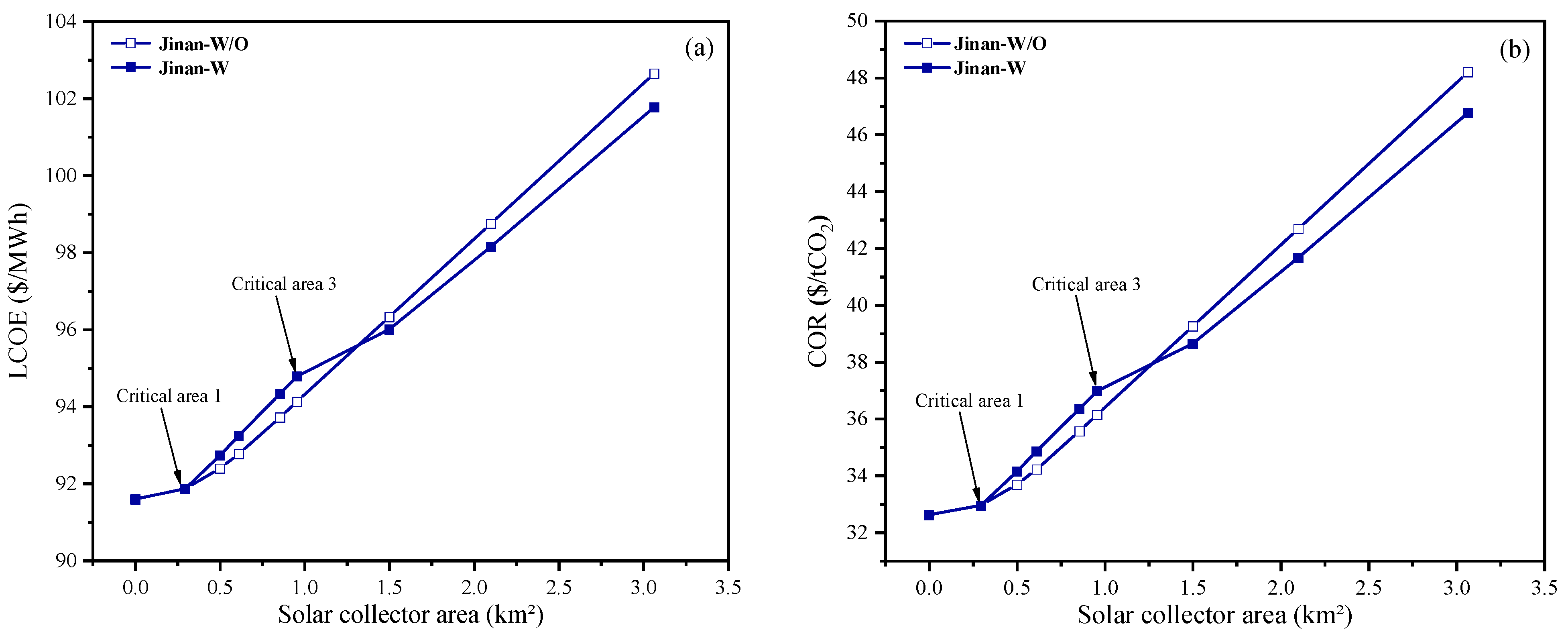

| LCOE ($/MWh) | COR ($/t CO2) | TES System Cost (M$) | ||||

|---|---|---|---|---|---|---|

| Critical Area 1 | Critical Area 3 | Critical Area 1 | Critical Area 3 | Critical Area 1 | Critical Area 3 | |

| Jinan-W | 91.86 | 94.78 | 32.95 | 36.97 | 0 | 76.65 |

| Jinan-W/O | 91.86 | 94.13 | 32.95 | 36.14 | 0 | 76.65 |

| Xining-W | 91.63 | 94.02 | 32.61 | 35.87 | 0 | 76.65 |

| Xining-W/O | 91.63 | 93.97 | 32.61 | 35.91 | 0 | 76.65 |

| Lhasa-W | 91.17 | 92.73 | 31.95 | 34.04 | 0 | 76.65 |

| Lhasa-W/O | 91.17 | 92.58 | 31.95 | 33.93 | 0 | 76.65 |

| Reference | Capture System | CEI (kg CO2/MWh) | LCOE ($/MWh) | COR ($/t CO2) |

|---|---|---|---|---|

| Present | Membrane gas absorption | 91.84–95.52 | 91.17–102.65 | 31.95–48.20 |

| [19] | Chemical absorption | - | 95–105 | 47–65 |

| [34] | Chemical absorption | 70–114 | 46–117 | |

| [35] | Chemical absorption | 103.5 | 216 | - |

| [36] | Chemical absorption | - | 117 | 62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mu, J.; Bi, J.; Lv, Y.; Su, Y.; Zhao, W.; Zhang, H.; Du, T.; Li, F.; Zhou, H. Techno-Economic Evaluation on Solar-Assisted Post-Combustion CO2 Capture in Hollow Fiber Membrane Contactors. Energies 2024, 17, 2139. https://doi.org/10.3390/en17092139

Mu J, Bi J, Lv Y, Su Y, Zhao W, Zhang H, Du T, Li F, Zhou H. Techno-Economic Evaluation on Solar-Assisted Post-Combustion CO2 Capture in Hollow Fiber Membrane Contactors. Energies. 2024; 17(9):2139. https://doi.org/10.3390/en17092139

Chicago/Turabian StyleMu, Junkun, Jinpeng Bi, Yuexia Lv, Yancai Su, Wei Zhao, Hui Zhang, Tingting Du, Fuzhao Li, and Hongyang Zhou. 2024. "Techno-Economic Evaluation on Solar-Assisted Post-Combustion CO2 Capture in Hollow Fiber Membrane Contactors" Energies 17, no. 9: 2139. https://doi.org/10.3390/en17092139

APA StyleMu, J., Bi, J., Lv, Y., Su, Y., Zhao, W., Zhang, H., Du, T., Li, F., & Zhou, H. (2024). Techno-Economic Evaluation on Solar-Assisted Post-Combustion CO2 Capture in Hollow Fiber Membrane Contactors. Energies, 17(9), 2139. https://doi.org/10.3390/en17092139