Environmental Impact of Enhanced Geothermal Systems with Supercritical Carbon Dioxide: A Comparative Life Cycle Analysis of Polish and Norwegian Cases

Abstract

1. Introduction

- Lack of adequate and efficient HDR artificial fracture management technology in EGS development, which may lead to isolated, disproportionately large artificial fractures, fluid circulation short circuits, early thermal breakthrough, and, consequently, inefficient heat recovery.

- The processes of EGS formation and heat recovery are influenced by a number of variables, including water–rock interaction, seepage, heat transmission, medium deformation, and several others. It is yet unknown how multi-scale and multi-field coupling patterns and mechanisms influence geothermal reservoirs.

- Pressure drops during the lifting process in EGS producers can result in fluid flashing, which modifies the well’s flow and heat transfer properties and limits the extraction of hot fluid efficiently.

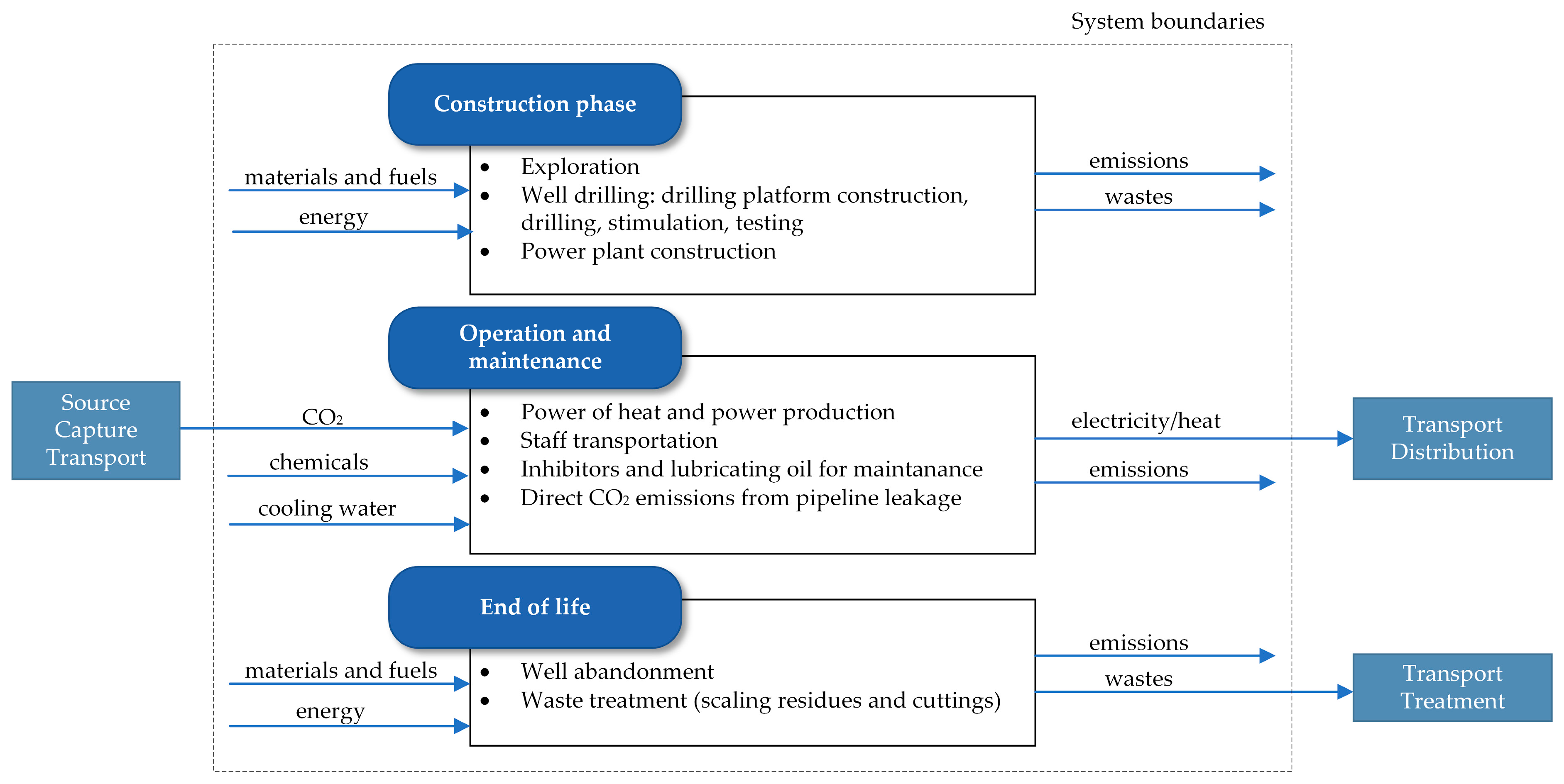

2. Life Cycle Analysis

2.1. Goal and Scope

2.2. Life Cycle Inventory

- The distance between shore and installation at Åre formation was set as 230 km, travelled by diesel freight transport.

- Transport of the materials used in the different processes is undertaken by a 16–32 metric ton lorry of category EURO4.

- Sea water cooling in Norway case.

- Well length: 4200 m for Gorzów Block and 4450 m for Åre formation.

- ORC unit modelled based on the Ecoinvent process with correction to the actual power.

- R134A as a working fluid in ORC in Polish case and butane in Norwegian case.

- Working fluid mass flow in reference variants was set as 100 kg/s for Polish cases and 200 kg/s in Norwegian case (lower mass flow for this case would be insufficient for viable unit operation).

- Testing using carbon dioxide was conducted only in Polish cases.

2.2.1. Construction Phase

2.2.2. Operation and Maintenance Phase

2.2.3. End-of-Life Phase

2.3. Life Cycle Impact Assessment

3. Results

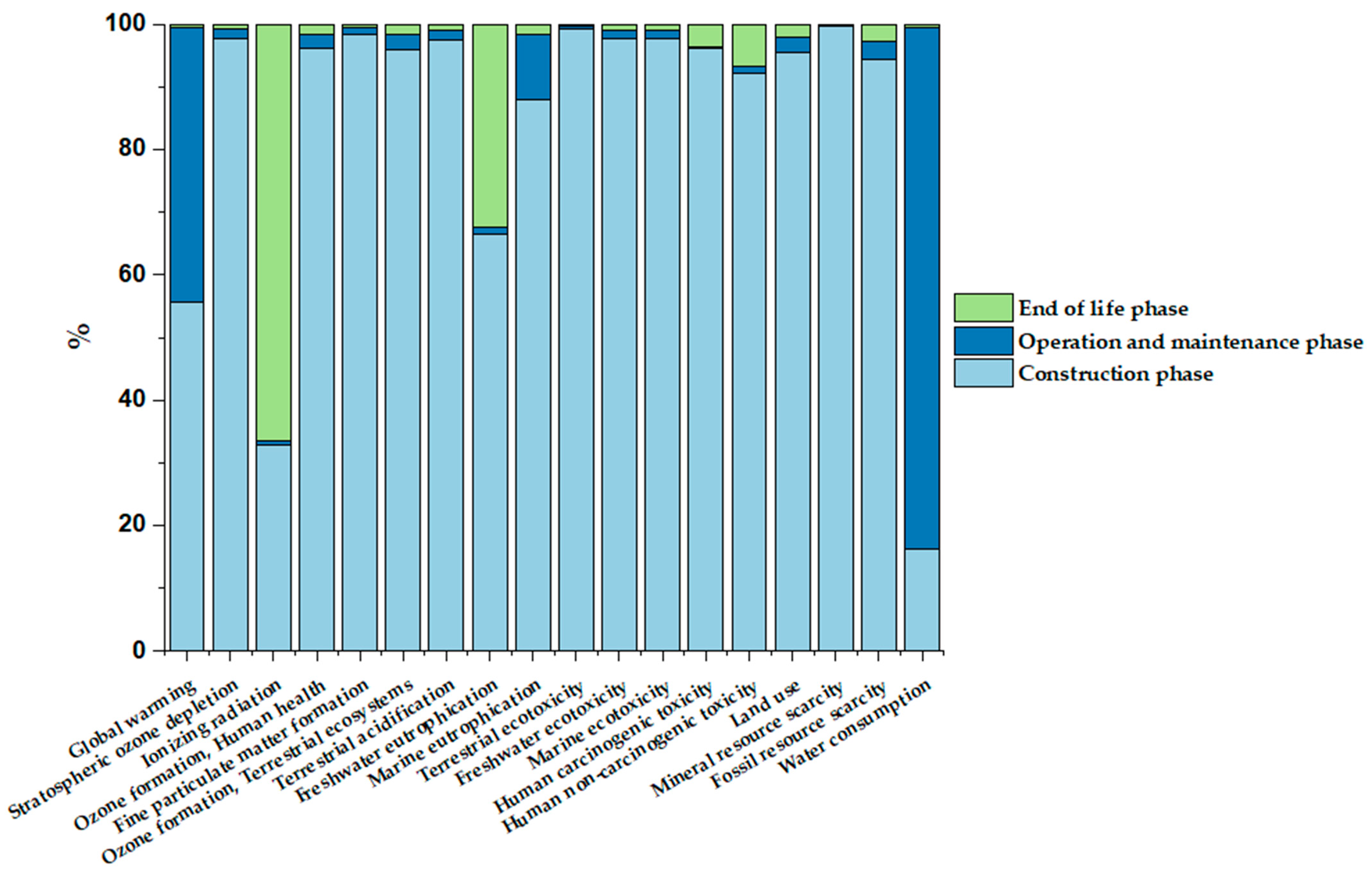

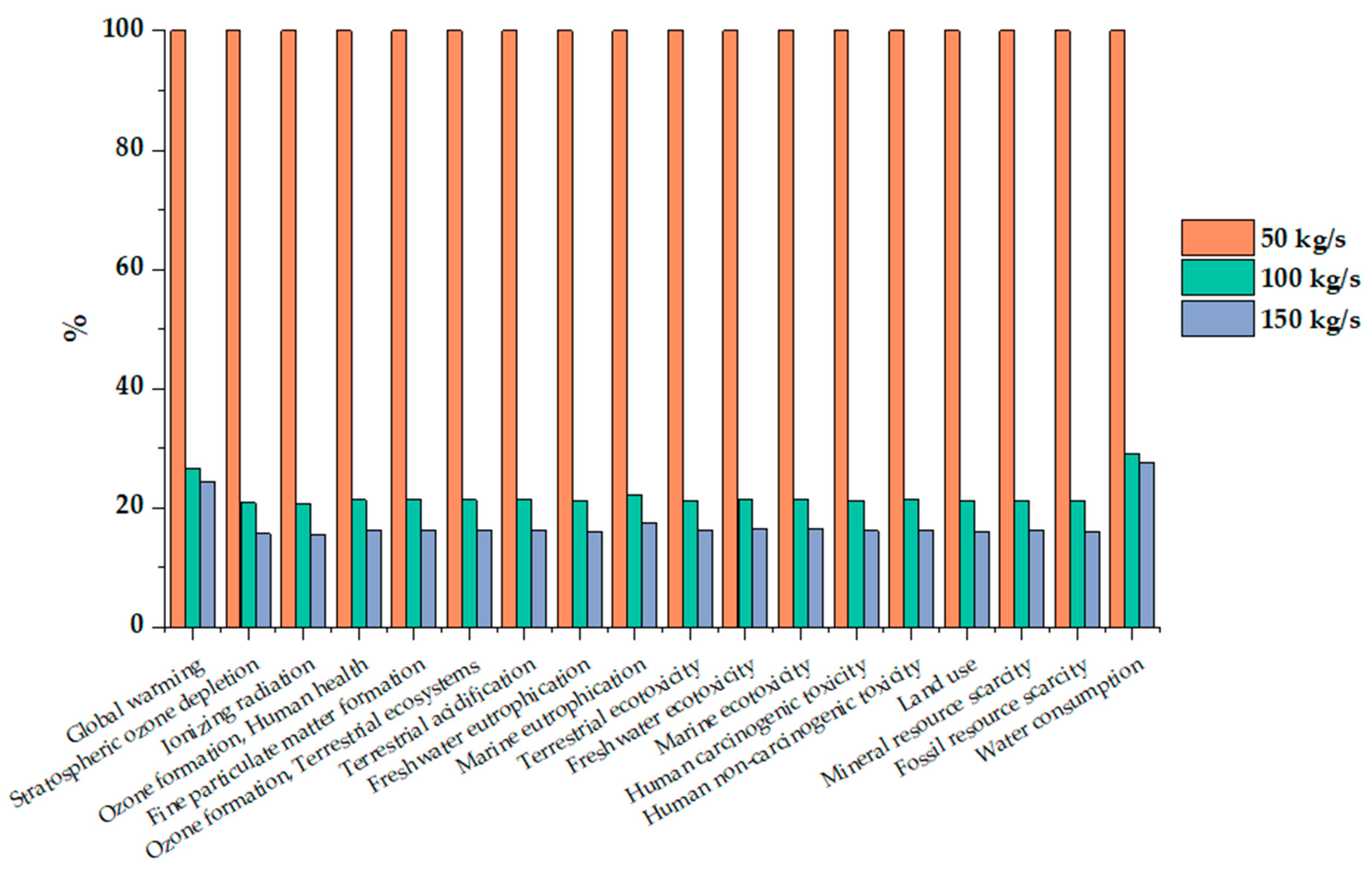

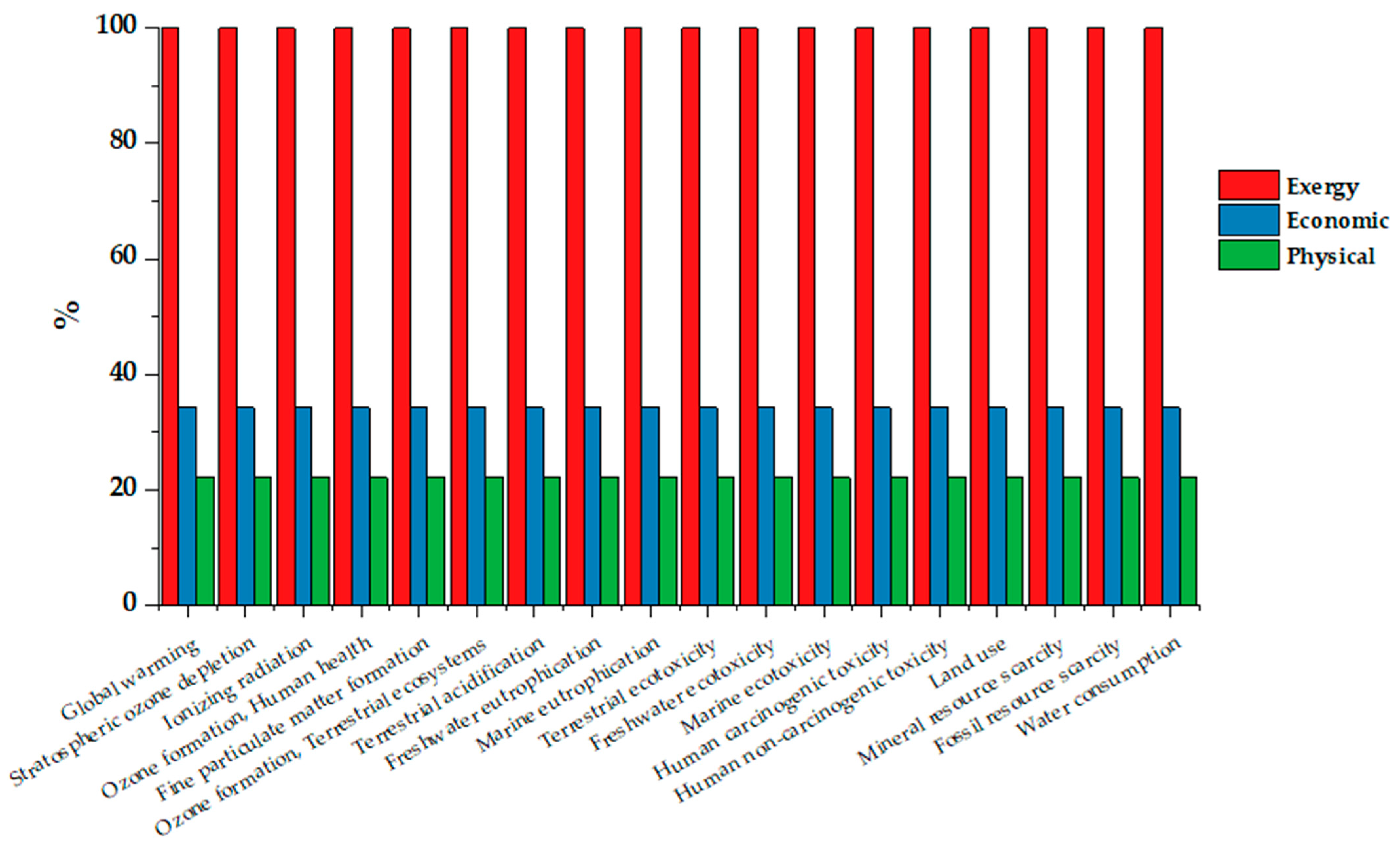

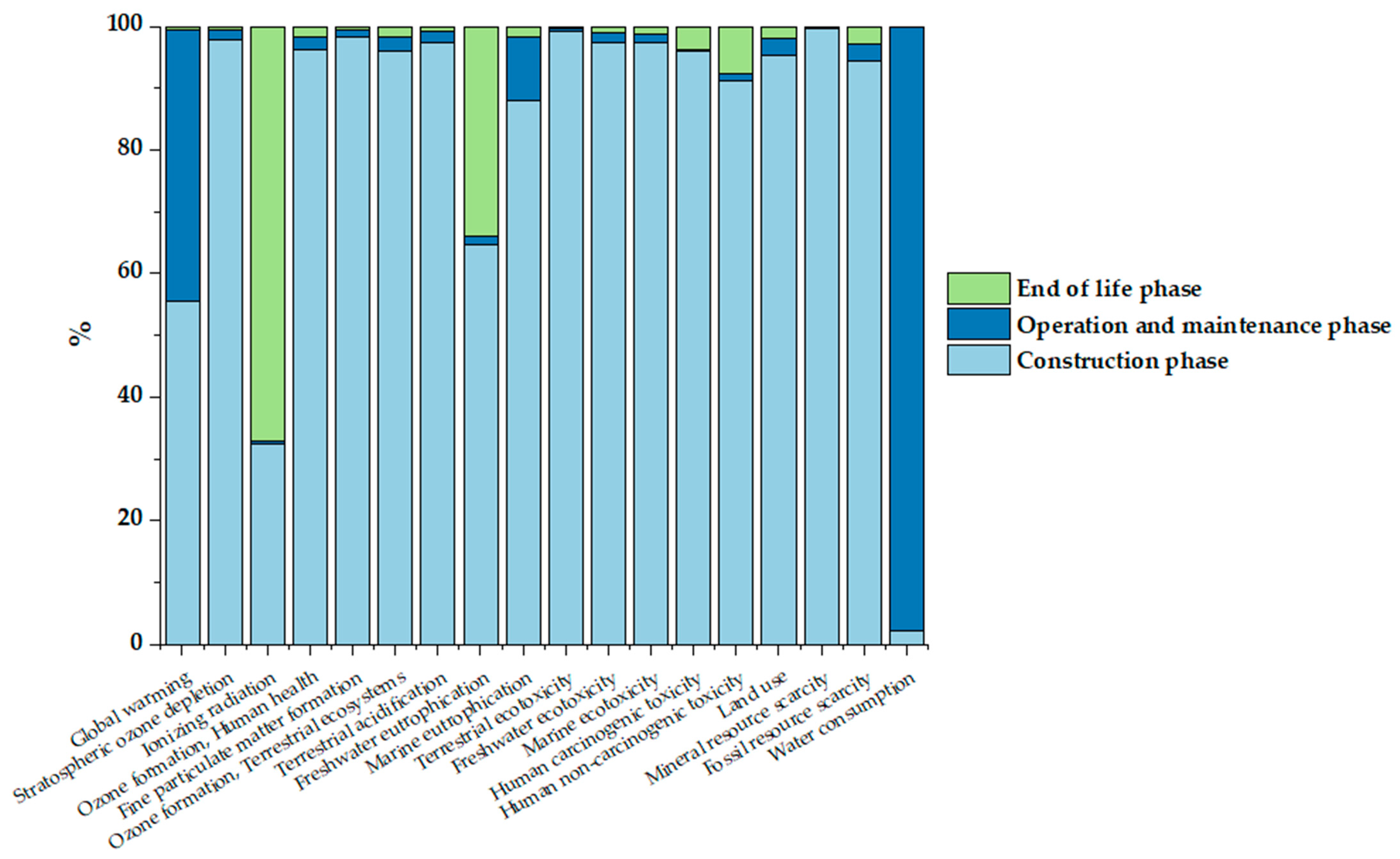

3.1. Case 1—Combined Heat and Power with Direct sCO2 Cycle

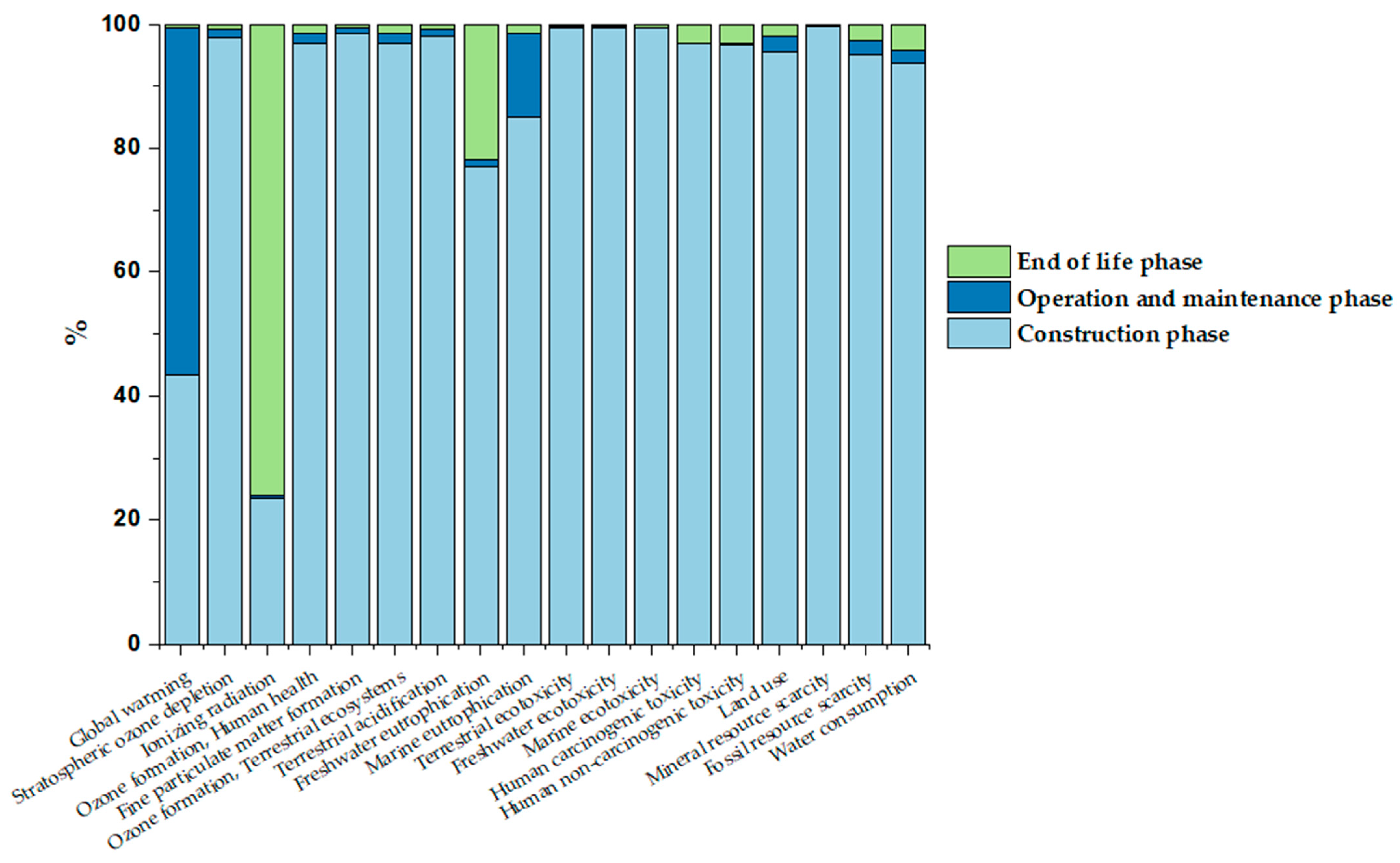

3.2. Case 2—Power Generation Only with Indirect sCO2 Cycle with ORC

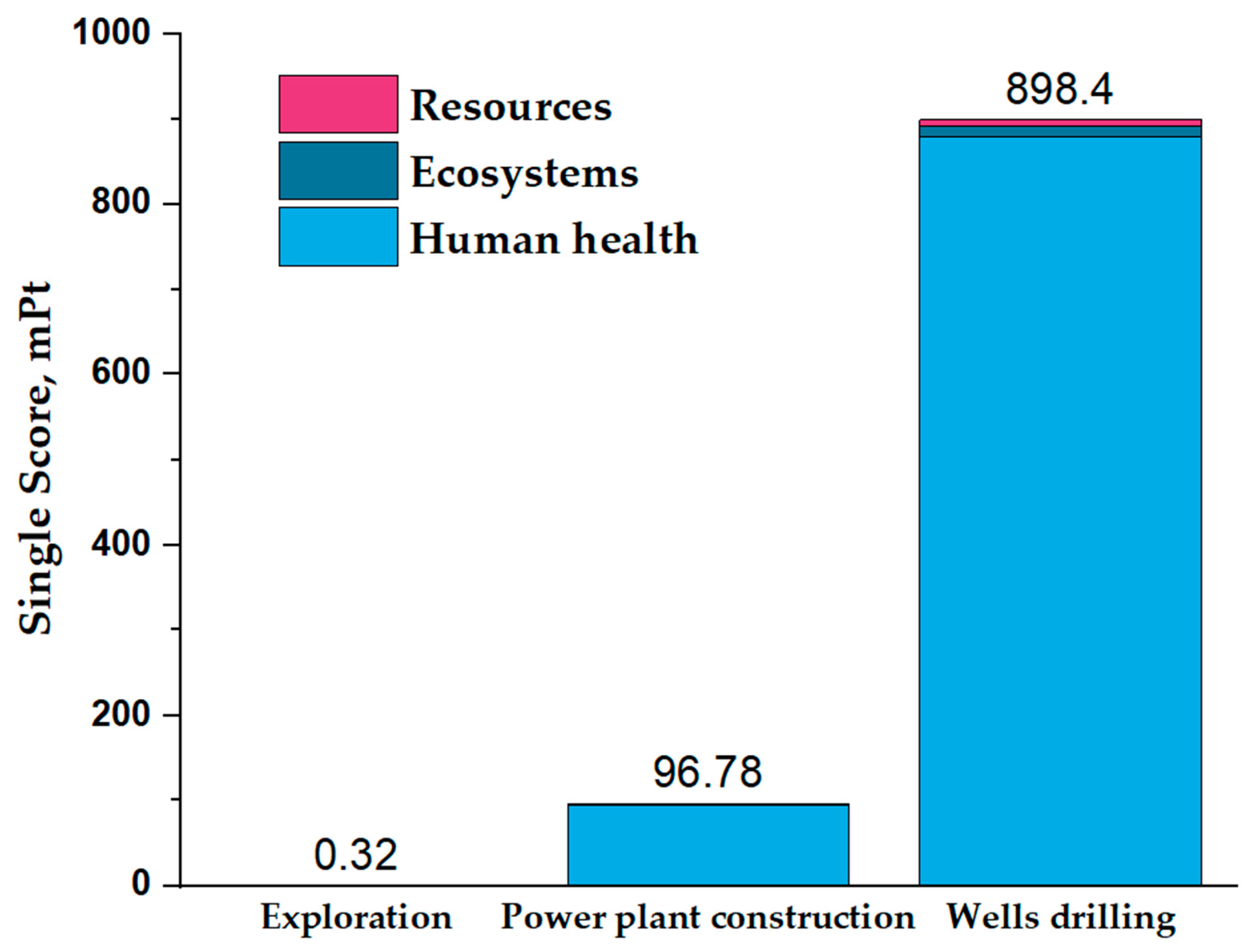

3.3. Case 3—Power Generation Only with Indirect sCO2 Cycle with ORC

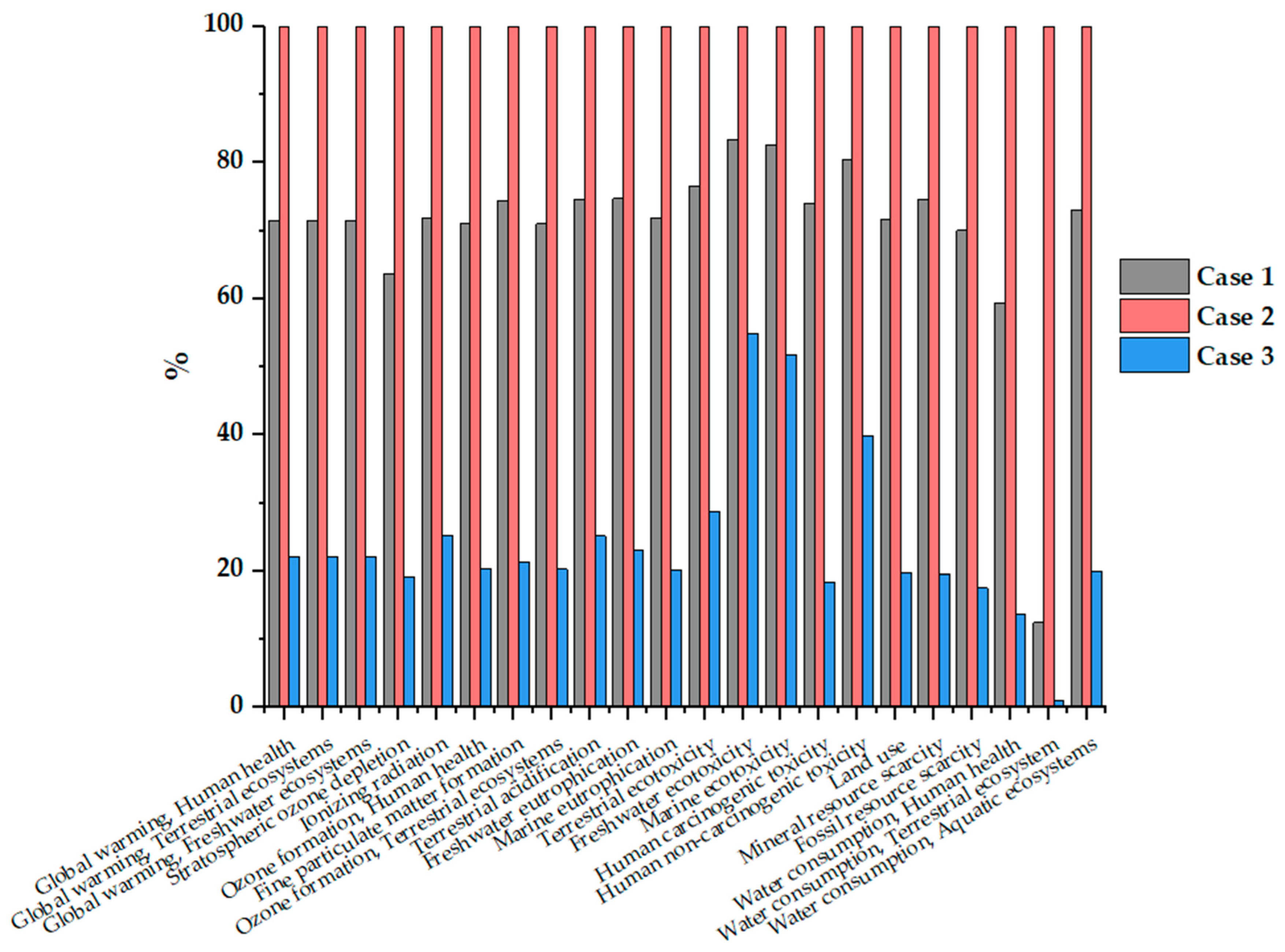

3.4. Comparison between Polish and Norwegian Cases

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| CCUS | carbon capture, utilization and storage |

| CO2 | carbon dioxide |

| DHS | district heating system |

| EGS | Enhanced Geothermal System |

| GWP | global warming potential |

| HDR | hot, dry rock |

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| ORC | Organic Rankine Cycle |

| RES | renewable energy sources |

| sCO2 | supercritical carbon dioxide |

| TRL | technology readiness level |

References

- Milewski, J.; Lis, P.; Szczęśniak, A.; Szabłowski, Ł.; Dybinski, O.; Futyma, K. Prospects for the Use of Supercritical CO2 Cycles. J. Power Technol. 2021, 101, 173–189. [Google Scholar]

- Uusitalo, A.; Turunen-Saaresti, T.; Grönman, A. Design and Loss Analysis of Radial Turbines for Supercritical CO2 Brayton Cycles. Energy 2021, 230, 120878. [Google Scholar] [CrossRef]

- Xu, J.; Liu, C.; Sun, E.; Xie, J.; Li, M.; Yang, Y.; Liu, J. Perspective of S−CO2 Power Cycles. Energy 2019, 186, 115831. [Google Scholar] [CrossRef]

- Olasolo, P.; Juárez, M.C.; Morales, M.P.; Damico, S.; Liarte, I.A. Enhanced Geothermal Systems (EGS): A Review. Renew. Sustain. Energy Rev. 2016, 56, 133–144. [Google Scholar] [CrossRef]

- Gong, L.; Han, D.; Chen, Z.; Wang, D.; Jiao, K.; Zhang, X.; Yu, B. Research Status and Development Trend of Key Technologies for Enhanced Geothermal Systems. Nat. Gas Ind. B 2023, 10, 140–164. [Google Scholar] [CrossRef]

- Brown, D.W. A hot day rock geothermal energy concept utilizing super-critical CO2 instead of water. In Proceedings of the Twenty-Fifth Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 24–26 January 2000; Available online: https://pangea.stanford.edu/ERE/pdf/IGAstandard/SGW/2000/Brown.pdf (accessed on 14 March 2024).

- Liu, Y.; Wang, G.; Yue, G.; Zhang, W.; Zhu, X.; Zhang, Q. Comparison of Enhanced Geothermal System with Water and CO2 as Working Fluid: A Case Study in Zhacanggou, Northeastern Tibet, China. Energy Explor. Exploit. 2019, 37, 736–755. [Google Scholar] [CrossRef]

- Wang, C.L.; Cheng, W.L.; Nian, Y.L.; Yang, L.; Han, B.B.; Liu, M.H. Simulation of Heat Extraction from CO2-Based Enhanced Geothermal Systems Considering CO2 Sequestration. Energy 2018, 142, 157–167. [Google Scholar] [CrossRef]

- Kaieda, H.; Ito, H.; Kiho, K.; Suzuki, K.; Suenaga, H.; Shin, K. Review of the Ogachi HDR Project in Japan. In Proceedings of the Proceedings World Geothermal Congress, Antalya, Turkey, 24–29 April 2005. [Google Scholar]

- Sowiżdżał, A.; Starczewska, M.; Papiernik, B. Future Technology Mix—Enhanced Geothermal System (EGS) and Carbon Capture, Utilization, and Storage (CCUS)—An Overview of Selected Projects as an Example for Future Investments in Poland. Energies 2022, 15, 3505. [Google Scholar] [CrossRef]

- Gładysz, P.; Sowiżdżał, A.; Miecznik, M.; Pająk, L. Carbon Dioxide-Enhanced Geothermal Systems for Heat and Electricity Production: Energy and Economic Analyses for Central Poland. Energy Convers. Manag. 2020, 220, 113142. [Google Scholar] [CrossRef]

- Gladysz, P.; Sowizdzal, A.; Miecznik, M.; Hacaga, M.; Pajak, L. Techno-Economic Assessment of a Combined Heat and Power Plant Integrated with Carbon Dioxide Removal Technology: A Case Study for Central Poland. Energies 2020, 13, 2841. [Google Scholar] [CrossRef]

- Tagliaferri, M.; Gładysz, P.; Ungar, P.; Strojny, M.; Talluri, L.; Fiaschi, D.; Manfrida, G.; Andresen, T.; Sowiżdżał, A. Techno-Economic Assessment of the Supercritical Carbon Dioxide Enhanced Geothermal Systems. Sustainability 2022, 14, 16580. [Google Scholar] [CrossRef]

- Colucci, V.; Manfrida, G.; Mendecka, B.; Talluri, L.; Zuffi, C. LCA and Exergo-Environmental Evaluation of a Combined Heat and Power Double-Flash Geothermal Power Plant. Sustainability 2021, 13, 1935. [Google Scholar] [CrossRef]

- Blanc, I.; Damen, L.; Douziech, M.; Fiaschi, D.; Manfrida, G.; Parisi, M.L.; Lopez, P.P.; Ravier, G.; Tosti, L.; Mendecka, B. First Version of Harmonized Guidelines to Perform Environmental Assessment for Geothermal Systems Based on LCA and Non LCA Impact Indicators: LCA Guidelines for Geothermal Installations; Deliverable 3.2, GEOENVI EU H2020 Project. 2020. Available online: https://www.geoenvi.eu/wp-content/uploads/2020/07/D3.2_Environmental-impact-and-LCA-Guidelines-for-Geothermal-Installations-v2.pdf (accessed on 5 March 2024).

- Frank, E.D.; Sullivan, J.L.; Wang, M.Q. Life Cycle Analysis of Geothermal Power Generation with Supercritical Carbon Dioxide. Environ. Res. Lett. 2012, 7, 034030. [Google Scholar] [CrossRef]

- Frick, S.; Kaltschmitt, M.; Schröder, G. Life Cycle Assessment of Geothermal Binary Power Plants Using Enhanced Low-Temperature Reservoirs. Energy 2010, 35, 2281–2294. [Google Scholar] [CrossRef]

- Lacirignola, M.; Blanc, I. Environmental Analysis of Practical Design Options for Enhanced Geothermal Systems (EGS) through Life-Cycle Assessment. Renew. Energy 2013, 50, 901–914. [Google Scholar] [CrossRef]

- Parisi, M.L.; Douziech, M.; Tosti, L.; Pérez-López, P.; Mendecka, B.; Ulgiati, S.; Fiaschi, D.; Manfrida, G.; Blanc, I. Definition of LCA Guidelines in the Geothermal Sector to Enhance Result Comparability. Energies 2020, 13, 3534. [Google Scholar] [CrossRef]

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Douziech, M.; Blanc, I.; Damen, L.; Dillman, K.; Eggertsson, V.; Ferrara, N.; Guðjónsdóttir, S.R.; Harcouët-Menou, V.; Parisi, M.L.; Pérez-López, P.; et al. Generation of Simplified Parametrised Models for a Selection of GEOENVI Geothermal Installations Categories; Deliverable 3.4, GEOENVI EU H2020 Project; 2020. Available online: https://www.geoenvi.eu/wp-content/uploads/2021/02/D3.4-Simplified-parameterized-models.pdf (accessed on 5 March 2024).

- Karnkowski, P.H. Budowa Geologiczna Oraz Geneza i Ewolucja Bloku Gorzowa. Przegląd Geol. 2010, 58, 8. [Google Scholar]

- Szynkaruk, E. 3D Geological Model of Gorzów Block. Available online: https://geo3d.pgi.gov.pl/en/3d-geological-model-gorzow-block (accessed on 23 February 2024).

- Ali, A. Basin Modelling: HC Generation Modelling of the Åre, Melke and Spekk Formations, Haltenbanken Area; 2012. Available online: https://www.semanticscholar.org/paper/Basin-Modelling%3A-HC-Generation-Modelling-of-the-and-Ali/f587deaaff6207b486d28f6586e18a8d2defff43 (accessed on 20 March 2024).

- Sullivan, J.L.; Frank, E.D.; Han, J.; Elgowainy, A.; Wang, M.Q. Geothermal Life Cycle Assessment—Part 3; ANL/ESD/12-15; 2012. Available online: https://www.osti.gov/biblio/1118131 (accessed on 13 March 2024).

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Guide to Floating Offshore Wind—Export Cables. Available online: https://guidetofloatingoffshorewind.com/guide/b-balance-of-plant/b-1-cables/b-1-2-export-cable/ (accessed on 25 March 2024).

- Nicholson, S.; Heath, G. Life Cycle Greenhouse Gas Emissions from Electricity Generation: Update; NREL: Golden, CO, USA, 2021. [Google Scholar]

- Pratiwi, A.; Ravier, G.; Genter, A. Life-Cycle Climate-Change Impact Assessment of Enhanced Geothermal System Plants in the Upper Rhine Valley. Geothermics 2018, 75, 26–39. [Google Scholar] [CrossRef]

| Case | Localization | Description |

|---|---|---|

| Case 1 | Poland, Gorzów Block | Combined heat and power with direct sCO2 cycle |

| Case 2 | Poland, Gorzów Block | Power generation only with indirect sCO2 cycle with ORC |

| Case 3 | Norway, Åre formation (at sea floor) | Power generation only with indirect sCO2 cycle with ORC |

| Parameter | Case 1, Poland Direct sCO2 Cycle | Case 2, Poland Indirect sCO2 Cycle with ORC | Case 3, Norway Indirect sCO2 Cycle with ORC |

|---|---|---|---|

| Gross power, MWe | 0.8 | 2.1 | 13.0 |

| Gross electricity production, MWhe | 175,844.3 | 451,058.1 | 2,877,695.7 |

| Electricity own consumption, MWhe | 55,609.1 | 81,818.0 | 299,708.7 |

| Net electricity production, MWhe | 120,235.1 | 369,240.1 | 2,577,987.0 |

| Heat production, MWhth | 2,219,119.1 | n/a | n/a |

| Heat exergy supply, MWhex | 396,692.8 | n/a | n/a |

| Parameter | Unit | Value |

|---|---|---|

| Number of injection wells | - | 1 |

| Number of production wells | - | 1 |

| Drilling platform size | m3 | 20,000 |

| Operating hours | hours | 7884 (90% of year) |

| Average distance for material transportation | km | 300 |

| Average distance for staff transportation onshore | km | 50 |

| Staff working days | days | 250 |

| Fraction of CO2 released from pipeline leakage | % | 0.01 |

| Allocation Scheme | Heat Product | Electricity Product |

|---|---|---|

| Exergy | 76.8% | 23.2% |

| Physical energy | 94.9% | 5.1% |

| Economic | 92.1% | 7.9% |

| Damage Category | Variant A (Local Electricity Consumption) | Variant B (Electricity Transmission to Land) |

|---|---|---|

| Total, Pt | 0.678 | 19.876 |

| Human health, Pt | 0.660 | 19.511 |

| Ecosystems, Pt | 0.013 | 0.320 |

| Resources, Pt | 0.004 | 0.045 |

| Impact Category | Unit | Case 1 | Case 2 | Case 3 |

|---|---|---|---|---|

| Poland, Direct sCO2 Cycle | Poland, Indirect sCO2 Cycle | Norway, Indirect sCO2 Cycle | ||

| Global warming | kg CO2 eq | 38.682 | 54.148 | 11.929 |

| Stratospheric ozone depletion | kg CFC11 eq | 0.000 | 0.000 | 0.000 |

| Ionizing radiation | kBq Co-60 eq | 2.871 | 3.996 | 1.009 |

| Ozone formation, Human health | kg NOx eq | 0.051 | 0.072 | 0.015 |

| Fine particulate matter formation | kg PM2.5 eq | 0.052 | 0.069 | 0.015 |

| Ozone formation, Terrestrial ecosystems | kg NOx eq | 0.054 | 0.076 | 0.015 |

| Terrestrial acidification | kg SO2 eq | 0.084 | 0.112 | 0.028 |

| Freshwater eutrophication | kg P eq | 0.012 | 0.016 | 0.004 |

| Marine eutrophication | kg N eq | 0.001 | 0.001 | 0.000 |

| Terrestrial ecotoxicity | kg 1,4-DCB | 415.091 | 542.357 | 156.104 |

| Freshwater ecotoxicity | kg 1,4-DCB | 2.314 | 2.773 | 1.523 |

| Marine ecotoxicity | kg 1,4-DCB | 3.137 | 3.794 | 1.968 |

| Human carcinogenic toxicity | kg 1,4-DCB | 17.772 | 24.013 | 4.419 |

| Human non-carcinogenic toxicity | kg 1,4-DCB | 39.411 | 48.943 | 19.529 |

| Land use | m2a crop eq | 0.843 | 1.177 | 0.234 |

| Mineral resource scarcity | kg Cu eq | 1.028 | 1.377 | 0.270 |

| Fossil resource scarcity | kg oil eq | 6.173 | 8.681 | 1.573 |

| Water consumption | m3 | 1.702 | 17.114 | 0.070 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Strojny, M.; Gładysz, P.; Andresen, T.; Pająk, L.; Starczewska, M.; Sowiżdżał, A. Environmental Impact of Enhanced Geothermal Systems with Supercritical Carbon Dioxide: A Comparative Life Cycle Analysis of Polish and Norwegian Cases. Energies 2024, 17, 2077. https://doi.org/10.3390/en17092077

Strojny M, Gładysz P, Andresen T, Pająk L, Starczewska M, Sowiżdżał A. Environmental Impact of Enhanced Geothermal Systems with Supercritical Carbon Dioxide: A Comparative Life Cycle Analysis of Polish and Norwegian Cases. Energies. 2024; 17(9):2077. https://doi.org/10.3390/en17092077

Chicago/Turabian StyleStrojny, Magdalena, Paweł Gładysz, Trond Andresen, Leszek Pająk, Magdalena Starczewska, and Anna Sowiżdżał. 2024. "Environmental Impact of Enhanced Geothermal Systems with Supercritical Carbon Dioxide: A Comparative Life Cycle Analysis of Polish and Norwegian Cases" Energies 17, no. 9: 2077. https://doi.org/10.3390/en17092077

APA StyleStrojny, M., Gładysz, P., Andresen, T., Pająk, L., Starczewska, M., & Sowiżdżał, A. (2024). Environmental Impact of Enhanced Geothermal Systems with Supercritical Carbon Dioxide: A Comparative Life Cycle Analysis of Polish and Norwegian Cases. Energies, 17(9), 2077. https://doi.org/10.3390/en17092077