Properties of Forest Tree Branches as an Energy Feedstock in North-Eastern Poland

Abstract

1. Introduction

2. Materials and Methods

2.1. The Subject and Factors of the Study

2.2. Laboratory Analyses

2.3. Statistical Analysis

3. Results and Discussion

3.1. Thermophysical Properties of the Branches of the Tree Species under Study

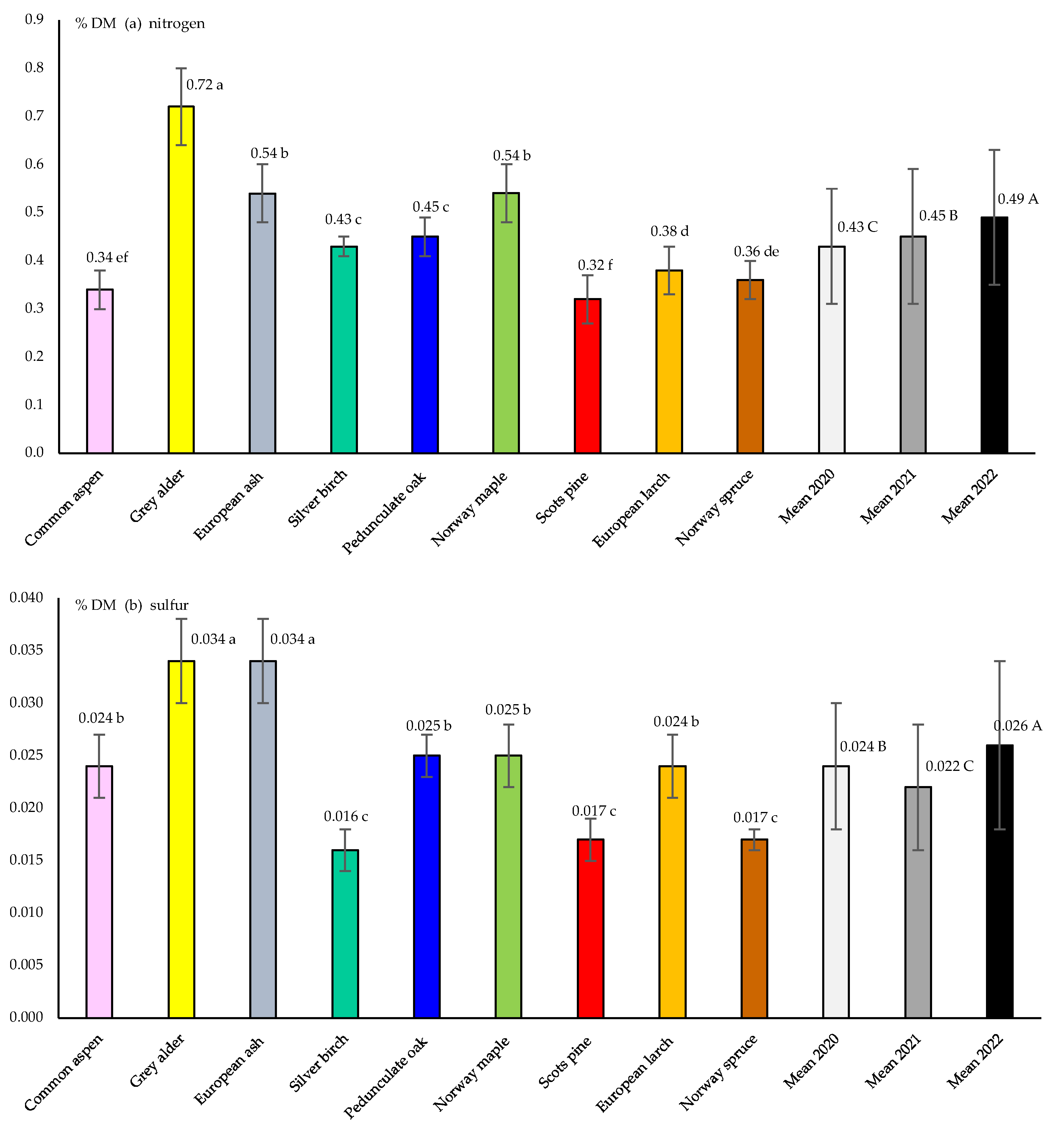

3.2. The Elemental Composition of the Branches of the Tree Species under Study

3.3. Overall Characteristics of Forest Tree Branches as a Solid Biofuel

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eurostat. Energy Imports Dependency. 2024. Available online: https://ec.europa.eu/eurostat/databrowser/view/NRG_IND_ID__custom_9437402/default/table?Lang=en (accessed on 21 January 2024).

- Eurostat. Share of Energy from Renewable Sources. 2024. Available online: https://ec.europa.eu/eurostat/databrowser/view/NRG_IND_REN__custom_9437410/default/table?Lang=en (accessed on 21 January 2024).

- Statistics Poland. Energy from Renewable Sources in 2022; Statistics Poland: Warsaw/Rzeszow, Poland, 2023. [Google Scholar]

- Gradziuk, P. The Economic Importance and Possibilities of Using Straw for Energy Purposes in Poland; Institute of Soil Science and Plant Cultivation State Research Institute: Puławy, Poland, 2015. [Google Scholar]

- Scordia, D.; Papazoglou, E.G.; Kotoula, D.; Sanz, M.; Ciria, C.S.; Pérez, J.; Maliarenko, O.; Prysiazhniuk, O.; von Cossel, M.; Greiner, B.E.; et al. Towards Identifying Industrial Crop Types and Associated Agronomies to Improve Biomass Production from Marginal Lands in Europe. GCB Bioenergy 2022, 14, 710–734. [Google Scholar] [CrossRef]

- Matyka, M.; Radzikowski, P. Productivity and Biometric Characteristics of 11 Varieties of Willow Cultivated on Marginal Soil. Agriculture 2020, 10, 616. [Google Scholar] [CrossRef]

- Amaducci, S.; Facciotto, G.; Bergante, S.; Perego, A.; Serra, P.; Ferrarini, A.; Chimento, C. Biomass Production and Energy Balance of Herbaceous and Woody Crops on Marginal Soils in the Po Valley. GCB Bioenergy 2017, 9, 31–45. [Google Scholar] [CrossRef]

- Jankowski, K.J.; Dubis, B.; Sokólski, M.M.; Załuski, D.; Bórawski, P.; Szempliński, W. Biomass Yield and Energy Balance of Virginia Fanpetals in Different Production Technologies in North-Eastern Poland. Energy 2019, 185, 612–623. [Google Scholar] [CrossRef]

- Jankowski, K.J.; Dubis, B.; Kozak, M. Sewage Sludge and the Energy Balance of Jerusalem Artichoke Production—A Case Study in North-Eastern Poland. Energy 2021, 236, 121545. [Google Scholar] [CrossRef]

- Picchio, R.; Latterini, F.; Venanzi, R.; Stefanoni, W.; Suardi, A.; Tocci, D.; Pari, L. Pellet Production from Woody and Non-Woody Feedstocks: A Review on Biomass Quality Evaluation. Energies 2020, 13, 2937. [Google Scholar] [CrossRef]

- Enström, J.; Eriksson, A.; Eliasson, L.; Larsson, A.; Olsson, L. Wood Chip Supply from Forest to Port of Loading—A Simulation Study. Biomass Bioenergy 2021, 152, 106182. [Google Scholar] [CrossRef]

- Stolarski, J.; Wierzbicki, S.; Nitkiewicz, S.; Stolarski, M.J. Wood Chip Production Efficiency Depending on Chipper Type. Energies 2023, 16, 4894. [Google Scholar] [CrossRef]

- The State Forests National Forest Holding, Technical Conditions—Wood Residues, Annex 12 to Regulation No. 51 of DGLP of 30/09/2019. Available online: http://drewno.zilp.lasy.gov.pl/drewno/Normy/12._pozostaosci_drzewne.pdf (accessed on 21 January 2024).

- Stolarski, M.J.; Krzyżaniak, M.; Olba-Zięty, E.; Stolarski, J. Changes in Commercial Dendromass Properties Depending on Type and Acquisition Time. Energies 2023, 16, 7973. [Google Scholar] [CrossRef]

- Lauri, P.; Havlík, P.; Kindermann, G.; Forsell, N.; Böttcher, H.; Obersteiner, M. Woody Biomass Energy Potential in 2050. Energy Policy 2014, 66, 19–31. [Google Scholar] [CrossRef]

- Verkerk, P.J.; Anttila, P.; Eggers, J.; Lindner, M.; Asikainen, A. The Realisable Potential Supply of Woody Biomass from Forests in the European Union. For. Ecol. Manag. 2011, 261, 2007–2015. [Google Scholar] [CrossRef]

- Statistics Poland. Forestry in 2022; Signal Information; Statistics Poland: Warsaw, Poland, 2023; p. 5. [Google Scholar]

- Statistics Poland. Statistical Yearbook of Forestry 2022; Statistical Publishing Establishment; Statistics Poland: Warsaw, Poland, 2022; p. 360. [Google Scholar]

- Roszyk, E.; Mania, P.; Iwańska, E.; Kusiak, W.; Broda, M. Mechanical Performance of Scots Pine Wood from Northwestern Poland—A Case Study. Bioresources 2020, 15, 6781–6794. [Google Scholar] [CrossRef]

- Kozakiewicz, P.; Jankowska, A.; Mamiński, M.; Marciszewska, K.; Ciurzycki, W.; Tulik, M. The Wood of Scots Pine (Pinus sylvestris L.) from Post-Agricultural Lands Has Suitable Properties for the Timber Industry. Forests 2020, 11, 1033. [Google Scholar] [CrossRef]

- Demirbas, A. Reuse of Wood Wastes for Energy Generation. Energy Sources Part A Recovery Util. Environ. Eff. 2009, 31, 1687–1693. [Google Scholar] [CrossRef]

- Pedišius, N.; Praspaliauskas, M.; Pedišius, J.; Dzenajavičienė, E.F. Analysis of Wood Chip Characteristics for Energy Production in Lithuania. Energies 2021, 14, 3931. [Google Scholar] [CrossRef]

- Moriana, R.; Vilaplana, F.; Ek, M. Forest Residues as Renewable Resources for Bio-Based Polymeric Materials and Bioenergy: Chemical Composition, Structure and Thermal Properties. Cellulose 2015, 22, 3409–3423. [Google Scholar] [CrossRef]

- Vusić, D.; Vujanić, F.; Pešić, K.; Šafran, B.; Jurišić, V.; Zečić, Ž. Variability of Normative Properties of Wood Chips and Implications to Quality Control. Energies 2021, 14, 3789. [Google Scholar] [CrossRef]

- Irdla, M.; Padari, A.; Kurvits, V.; Muiste, P. The Chipping Cost of Wood Raw Material for Fuel in Estonian Conditions. For. Stud. 2017, 66, 65–74. [Google Scholar] [CrossRef]

- Wojciechowska, N. Evaluation of Properties of Selected Forest Solid Biofuels on the Background of Fossil Fuels. Master’s Thesis, University of Warmia and Mazury in Olsztyn, Olsztyn, Poland, 2021; p. 47. [Google Scholar]

- Seliwiak, M. Assessment of Energy Properties of Selected Solid Biofuels of Forest Origin against the Background of Coal Fuels. Master’s Thesis, University of Warmia and Mazury in Olsztyn, Olsztyn, Poland, 2022; p. 33. [Google Scholar]

- Dobrzański, T.K. Forest-Based Solid Biofuels as an Energy Feedstock. Master’s Thesis, University of Warmia and Mazury in Olsztyn, Olsztyn, Poland, 2023; p. 52. [Google Scholar]

- PN-EN ISO 18134-2; Solid Biofuels–Determination of Moisture Content–Dryer Method–Part 2: Total Moisture–Simplified Method. Polish Standardization Committee: Warsaw, Poland, 2014.

- PN-EN ISO 18122:2016-01; Solid Biofuels—Determination of Ash Content. Polish Standardization Committee: Warsaw, Poland, 2016.

- PN-EN ISO 18123:2016-01; Solid Biofuels—Determination of Volatile Matter Content. Polish Standardization Committee: Warsaw, Poland, 2016.

- PN-EN ISO 16948:2015-07; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. Polish Standardization Committee: Warsaw, Poland, 2015.

- PN-EN ISO 16994:2016-10; Solid Biofuels—Determination of Total Content of Sulfur and Chlorine. Polish Standardization Committee: Warsaw, Poland, 2016.

- PN-ISO 587:2000; Solid Fuels—Determination of Chlorine Using Eschka Mixture. Polish Standardization Committee: Warsaw, Poland, 2000.

- PN-EN ISO 18125:2017-07; Solid Biofuels—Determination of Calorific Value. Polish Standardization Committee: Warsaw, Poland, 2017.

- Kask, Ü.; Vares, V.; Saareoks, M. Wood Fuel User Manual, 1st ed.; Tartu Regional Energy Agency: Tartu, Estonia, 2020; pp. 14–43. [Google Scholar]

- Anerud, E.; Jirjis, R.; Larsson, G.; Eliasson, L. Fuel Quality of Stored Wood Chips—Influence of Semi-Permeable Covering Material. Appl. Energy 2018, 231, 628–634. [Google Scholar] [CrossRef]

- Deboni, T.L.; Simioni, F.J.; Brand, M.A.; Lopes, G.P. Evolution of the Quality of Forest Biomass for Energy Generation in a Cogeneration Plant. Renew. Energy 2019, 135, 1291–1302. [Google Scholar] [CrossRef]

- Sabatti, M.; Fabbrini, F.; Harfouche, A.; Beritognolo, I.; Mareschi, L.; Carlini, M.; Paris, P.; Scarascia-Mugnozza, G. Evaluation of Biomass Production Potential and Heating Value of Hybrid Poplar Genotypes in a Short-Rotation Culture in Italy. Ind. Crops Prod. 2014, 61, 62–73. [Google Scholar] [CrossRef]

- Monedero, E.; Hernández, J.; Collado, R. Combustion-Related Properties of Poplar, Willow and Black Locust to Be Used as Fuels in Power Plants. Energies 2017, 10, 997. [Google Scholar] [CrossRef]

- Stachowicz, P.; Stolarski, M.J. Thermophysical Properties and Elemental Composition of Black Locust, Poplar and Willow Biomass. Energies 2022, 16, 305. [Google Scholar] [CrossRef]

- Mitsui, Y.; Seto, S.; Nishio, M.; Minato, K.; Ishizawa, K.; Satoh, S. Willow Clones with High Biomass Yield in Short Rotation Coppice in the Southern Region of Tohoku District (Japan). Biomass Bioenergy 2010, 34, 467–473. [Google Scholar] [CrossRef]

- Kurvits, V.; Ots, K.; Kangur, A.; Korjus, H.; Muiste, P. Assessment of Load and Quality of Logging Residues from Clear-Felling Areas in Järvselja: A Case Study from Southeast Estonia. Cent. Eur. For. J. 2020, 66, 3–11. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Stachowicz, P.; Sieniawski, W.; Krzyżaniak, M.; Olba-Zięty, E. Quality and Delivery Costs of Wood Chips by Railway vs. Road Transport. Energies 2021, 14, 6877. [Google Scholar] [CrossRef]

- Dibdiakova, J.; Wang, L.; Li, H. Characterization of Ashes from Pinus sylvestris Forest Biomass. Energy Procedia 2015, 75, 186–191. [Google Scholar] [CrossRef][Green Version]

- Palacka, M.; Vician, P.; Holubčík, M.; Jandačka, J. The Energy Characteristics of Different Parts of the Tree. Procedia Eng. 2017, 192, 654–658. [Google Scholar] [CrossRef]

- Neiva, D.M.; Araújo, S.; Gominho, J.; Carneiro, A.d.C.; Pereira, H. An Integrated Characterization of Picea abies Industrial Bark Regarding Chemical Composition, Thermal Properties and Polar Extracts Activity. PLoS ONE 2018, 13, e0208270. [Google Scholar] [CrossRef]

- Nosek, R.; Holubcik, M.; Jandacka, J. The Impact of Bark Content of Wood Biomass on Biofuel Properties. Bioresources 2015, 11, 44–53. [Google Scholar] [CrossRef]

- Ninikas, K.; Ntalos, G.; Mitani, A.; Koutsianitis, D. Calorific Values from Greek Spruce Residues and Bioenergy Potentials via Pellet Production. Pro Ligno 2019, 15, 300–305. [Google Scholar]

- Telmo, C.; Lousada, J.; Moreira, N. Proximate Analysis, Backwards Stepwise Regression between Gross Calorific Value, Ultimate and Chemical Analysis of Wood. Bioresour. Technol. 2010, 101, 3808–3815. [Google Scholar] [CrossRef] [PubMed]

- Pretzsch, H. Forest Dynamics, Growth and Yield from Measurement to Model, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 90–93. [Google Scholar]

- Feng, S.; Cheng, S.; Yuan, Z.; Leitch, M.; Xu, C. Valorization of Bark for Chemicals and Materials: A Review. Renew. Sustain. Energy Rev. 2013, 26, 560–578. [Google Scholar] [CrossRef]

- Dudziec, P.; Stachowicz, P.; Stolarski, M.J. Diversity of Properties of Sawmill Residues Used as Feedstock for Energy Generation. Renew. Energy 2023, 202, 822–833. [Google Scholar] [CrossRef]

- Stachowicz, P.; Stolarski, M.J. Short Rotation Woody Crops and Forest Biomass Sawdust Mixture Pellet Quality. Ind. Crops Prod. 2023, 197, 116604. [Google Scholar] [CrossRef]

- Chen, T.; Deng, C.; Liu, R. Effect of Selective Condensation on the Characterization of Bio-Oil from Pine Sawdust Fast Pyrolysis Using a Fluidized-Bed Reactor. Energy Fuels 2010, 24, 6616–6623. [Google Scholar] [CrossRef]

- Ali, L.; Ahmed Baloch, K.; Palamanit, A.; Raza, S.A.; Laohaprapanon, S.; Techato, K. Physicochemical Characterisation and the Prospects of Biofuel Production from Rubberwood Sawdust and Sewage Sludge. Sustainability 2021, 13, 5942. [Google Scholar] [CrossRef]

- Sarker, S.; Nielsen, H.K. Preliminary Fixed-Bed Downdraft Gasification of Birch Woodchips. Int. J. Environ. Sci. Technol. 2015, 12, 2119–2126. [Google Scholar] [CrossRef]

- Rosas, J.G.; Gómez, N.; Cara-Jiménez, J.; González-Arias, J.; Olego, M.Á.; Sánchez, M.E. Evaluation of Joint Management of Pine Wood Waste and Residual Microalgae for Agricultural Application. Sustainability 2020, 13, 53. [Google Scholar] [CrossRef]

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Spanish Biofuels Heating Value Estimation. Part I: Ultimate Analysis Data. Fuel 2014, 117, 1130–1138. [Google Scholar] [CrossRef]

- Filbakk, T.; Jirjis, R.; Nurmi, J.; Høibø, O. The Effect of Bark Content on Quality Parameters of Scots Pine (Pinus sylvestris L.) Pellets. Biomass Bioenergy 2011, 35, 3342–3349. [Google Scholar] [CrossRef]

- Kraszkiewicz, A. Chemical Composition and Selected Energy Properties of Black Locust Bark (Robinia Pseudoacacia L.). Agric. Eng. 2016, 20, 117–124. [Google Scholar] [CrossRef]

- He, Y.; Zhao, Y.; Chai, M.; Zhou, Z.; Sarker, M.; Li, C.; Liu, R.; Cai, J.; Liu, X. Comparative Study of Fast Pyrolysis, Hydropyrolysis and Catalytic Hydropyrolysis of Poplar Sawdust and Rice Husk in a Modified Py-GC/MS Microreactor System: Insights into Product Distribution, Quantum Description and Reaction Mechanism. Renew. Sustain. Energy Rev. 2020, 119, 109604. [Google Scholar] [CrossRef]

- Alakangas, E.; Hurskainen, M.; Laatikainen-Luntama, J.; Korhonen, J. Properties of Indigenous Fuels in Finland, 1st ed.; VTT Technical Research Centre of Finland Ltd.: Jyväskylä, Finland, 2016. [Google Scholar]

- Fiala, M.; Nonini, L. Biomass and Biofuels. EPJ Web Conf. 2018, 189, 00006. [Google Scholar] [CrossRef]

- Han, K.; Gao, J.; Qi, J. The Study of Sulphur Retention Characteristics of Biomass Briquettes during Combustion. Energy 2019, 186, 115788. [Google Scholar] [CrossRef]

- Warguła, Ł.; Kukla, M.; Wieczorek, B.; Krawiec, P. Energy Consumption of the Wood Size Reduction Processes with Employment of a Low-Power Machines with Various Cutting Mechanisms. Renew. Energy 2022, 181, 630–639. [Google Scholar] [CrossRef]

| Source of Variation | MC | Ash | HHV | LHV | Cl | For the Other Characteristics 1 |

|---|---|---|---|---|---|---|

| Species (A) | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * |

| Year of harvesting (B) | <0.001 * | 0.001 * | <0.001 * | <0.001 * | 0.137 | <0.001 * |

| A × B | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * |

| Species and the Year of Harvesting | MC (%) | Ash (% DM) | FC (% DM) | VM (% DM) | HHV (GJ Mg−1 DM) | LHV (GJ Mg−1) |

|---|---|---|---|---|---|---|

| Common aspen, 2020 | 52.54 ± 0.72 a | 2.63 ± 0.01 a | 18.17 ± 0.05 i | 79.19 ± 0.04 b | 19.30 ± 0.01 e | 7.36 ± 0.14 f |

| Common aspen, 2021 | 51.63 ± 0.14 a | 2.48 ± 0.47 a | 18.35 ± 0.47 i | 79.18 ± 0.02 b | 19.30 ± 0.02 e | 7.53 ± 0.02 f |

| Common aspen, 2022 | 49.77 ± 0.19 b | 2.12 ± 0.17 a | 19.02 ± 0.30 h | 78.87 ± 0.13 c | 19.23 ± 0.01 f | 7.89 ± 0.05 e |

| Grey alder, 2020 | 49.63 ± 0.31 b | 1.39 ± 0.03 c | 21.22 ± 0.20 d | 77.39 ± 0.23 e | 20.05 ± 0.03 c | 8.34 ± 0.06 d |

| Grey alder, 2021 | 45.59 ± 0.12 c | 1.62 ± 0.01 b | 19.89 ± 0.09 e | 78.50 ± 0.09 d | 19.94 ± 0.01 c | 9.10 ± 0.04 c |

| Grey alder, 2022 | 45.52 ± 0.41 c | 1.34 ± 0.08 c | 20.67 ± 0.68 e | 77.99 ± 0.63 d | 19.83 ± 0.02 d | 9.07 ± 0.08 c |

| European ash, 2020 | 39.05 ± 2.71 e | 1.86 ± 0.06 b | 20.28 ± 0.02 e | 77.86 ± 0.04 d | 19.40 ± 0.03 e | 10.15 ± 0.55 ab |

| European ash, 2021 | 35.38 ± 0.41 f | 1.57 ± 0.03 b | 19.67 ± 0.05 f | 78.77 ± 0.05 c | 19.46 ± 0.11 e | 10.90 ± 0.13 a |

| European ash, 2022 | 37.13 ± 0.45 e | 2.32 ± 0.09 a | 20.71 ± 0.15 e | 76.98 ± 0.23 e | 19.23 ± 0.05 f | 10.45 ± 0.12 a |

| Silver birch, 2020 | 46.26 ± 1.03 c | 0.78 ± 0.01 e | 19.09 ± 0.14 g | 80.12 ± 0.15 a | 19.84 ± 0.06 d | 8.91 ± 0.25 |

| Silver birch, 2021 | 40.11 ± 0.14 d | 0.83 ± 00.2 e | 19.44 ± 0.01 f | 79.73 ± 0.01 a | 19.89 ± 0.27 d | 10.23 ± 0.16 ab |

| Silver birch, 2022 | 44.27 ± 0.43 c | 0.72 ± 0.10 e | 19.04 ± 0.06 g | 80.24 ± 0.13 a | 19.75 ± 0.02 d | 9.25 ± 0.10 c |

| Pedunculate oak, 2020 | 43.34 ± 0.28 d | 1.37 ± 0.02 c | 19.84 ± 0.19 f | 78.79 ± 0.18 c | 19.22 ± 0.02 f | 9.19 ± 0.06 c |

| Pedunculate oak, 2021 | 42.06 ± 0.56 d | 1.70 ± 0.03 b | 19.65 ± 0.06 f | 78.66 ± 0.09 c | 19.07 ± 0.06 f | 9.34 ± 0.08 c |

| Pedunculate oak, 2022 | 41.10 ± 0.32 d | 1.47 ± 0.06 c | 20.00 ± 0.17 e | 78.54 ± 0.23 c | 19.05 ± 0.05 f | 9.54 ± 0.06 c |

| Norway maple, 2020 | 39.89 ± 0.15 e | 2.13 ± 0.02 a | 19.26 ± 0.25 g | 78.61 ± 0.23 c | 18.99 ± 0.04 g | 9.77 ± 0.02 b |

| Norway maple, 2021 | 39.71 ± 1.00 e | 2.92 ± 0.09 a | 19.29 ± 0.17 g | 77.80 ± 0.26 d | 18.81 ± 0.06 g | 9.65 ± 0.17 b |

| Norway maple, 2022 | 38.39 ± 0.39 e | 2.27 ± 0.04 a | 19.72 ± 0.03 f | 78.02 ± 0.02 d | 18.55 ± 0.01 h | 9.78 ± 0.07 b |

| Scots pine, 2020 | 48.63 ± 0.55 b | 0.55 ± 0.01 f | 22.36 ± 0.16 d | 77.09 ± 0.17 e | 20.74 ± 0.03 a | 8.89 ± 0.13 d |

| Scots pine, 2021 | 48.12 ± 1.07 b | 0.65 ± 0.01 f | 21.88 ± 0.16 d | 77.48 ± 0.17 e | 20.95 ± 0.05 a | 9.10 ± 0.26 c |

| Scots pine, 2022 | 49.97 ± 0.51 b | 0.60 ± 0.01 f | 22.32 ± 0.20 d | 77.08 ± 0.21 e | 20.51 ± 0.07 b | 8.47 ± 0.08 d |

| European larch, 2020 | 52.67 ± 0.51 a | 1.03 ± 0.01 d | 23.65 ± 0.07 b | 75.32 ± 0.07 g | 20.36 ± 0.07 b | 7.87 ± 0.10 e |

| European larch, 2021 | 48.84 ± 0.56 b | 1.00 ± 0.01 d | 22.93 ± 0.22 b | 76.08 ± 0.23 f | 20.40 ± 0.06 b | 8.65 ± 0.10 d |

| European larch, 2022 | 49.16 ± 0.56 b | 0.92 ± 0.02 d | 24.62 ± 0.26 a | 74.47 ± 0.29 h | 20.13 ± 0.04 b | 8.47 ± 0.10 d |

| Norway spruce, 2020 | 47.09 ± 0.99 b | 1.07 ± 0.02 d | 22.43 ± 0.02 c | 76.51 ± 0.01 f | 20.43 ± 0.03 b | 9.07 ± 0.19 c |

| Norway spruce, 2021 | 44.78 ± 1.57 c | 0.84 ± 0001 e | 22.65 ± 0.17 c | 76.51 ± 0.17 f | 20.32 ± 0.02 b | 9.49 ± 0.32 c |

| Norway spruce, 2022 | 44.44 ± 0.78 c | 0.88 ± 0.03 e | 22.99 ± 0.16 b | 76.14 ± 0.19 f | 20.13 ± 0.06 b | 9.45 ± 0.18 c |

| Characteristic | MC (%) | FC (% DM) | VM (% DM) | Ash (% DM) | HHV (GJ Mg−1 DM) | LHV (GJ Mg−1) | C (% DM) | H (% DM) | N (% DM) | S (% DM) | Cl (% DM) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MC (%) | 1.00 | ||||||||||

| FC (% DM) | 0.32 * | 1.00 | |||||||||

| VM (% DM) | −0.26 * | −0.93 * | 1.00 | ||||||||

| Ash (% DM) | −0.27 * | −0.62 * | 0.27 * | 1.00 | |||||||

| HHV (GJ Mg−1 DM) | 0.54 * | 0.71 * | −0.48 * | −0.81 * | 1.00 | ||||||

| LHV (GJ Mg−1) | −0.95 * | −0.10 | 0.12 | 0.00 | −0.24 * | 1.00 | |||||

| C (% DM) | 0.09 | 0.57 * | −0.31 * | −0.81 * | 0.68 * | 0.15 | 1.00 | ||||

| H (% DM) | −0.24 * | −0.25 * | 0.36 * | −0.12 | 0.04 | 0.28 * | 0.08 | 1.00 | |||

| N (% DM) | −0.42 * | −0.24 * | 0.13 | 0.33 * | −0.36 * | 0.35 * | −0.39 * | 0.02 | 1.00 | ||

| S (% DM) | −0.27 * | −0.13 | −0.07 | 0.48 * | −0.42 * | 0.15 | −0.54 * | −0.23 * | 0.70 * | 1.00 | |

| Cl (% DM) | −0.25 * | −0.33 * | 0.42 * | −0.04 | −0.19 | 0.22 | 0.12 | 0.17 | 0.26 * | −0.11 | 1.00 |

| Species and the Year of Harvesting | C (% DM) | H (% DM) | N (% DM) | S (% DM) | Cl (% DM) |

|---|---|---|---|---|---|

| Common aspen, 2020 | 50.50 ± 0.08 f | 6.07 ± 0.01 b | 0.35 ± 0.01 d | 0.021 ± 0.002 b | 0.011 ± 0.001 d |

| Common aspen, 2021 | 49.02 ± 0.26 g | 6.21 ± 0.10 a | 0.30 ± 0.01 f | 0.023 ± 0.002 b | 0.010 ± 0.001 d |

| Common aspen, 2022 | 50.45 ± 0.03 f | 6.03 ± 0.01 b | 0.38 ± 0.04 d | 0.028 ± 0.002 b | 0.011 ± 0.002 d |

| Grey alder, 2020 | 52.96 ± 0.35 c | 5.90 ± 0.09 b | 0.64 ± 0.02 a | 0.035 ± 0.001 a | 0.025 ± 0.001 b |

| Grey alder, 2021 | 50.13 ± 0.12 f | 6.24 ± 0.20 a | 0.72 ± 0.05 a | 0.029 ± 0.003 a | 0.022 ± 0.001 c |

| Grey alder, 2022 | 51.55 ± 0.23 e | 6.15 ± 0.01 b | 0.81 ± 0.03 a | 0.036 ± 0.001 a | 0.012 ± 0.002 d |

| European ash, 2020 | 53.33 ± 0.45 c | 6.17 ± 0.02 a | 0.58 ± 0.01 b | 0.032 ± 0.001 a | 0.011 ± 0.003 d |

| European ash, 2021 | 51.90 ± 0.11 d | 6.46 ± 0.22 a | 0.47 ± 0.01 b | 0.030 ± 0.003 a | 0.010 ± 0.001 d |

| European ash, 2022 | 51.58 ± 0.24 e | 6.07 ± 0.04 b | 0.56 ± 0.06 b | 0.039 ± 0.001 a | 0.014 ± 0.002 d |

| Silver birch, 2020 | 54.46 ± 0.43 b | 6.27 ± 0.03 a | 0.41 ± 0.01 c | 0.017 ± 0.001 c | 0.030 ± 0.013 a |

| Silver birch, 2021 | 55.04 ± 0.20 a | 6.19 ± 0.06 a | 0.46 ± 0.01 c | 0.015 ± 0.004 c | 0.030 ± 0.005 a |

| Silver birch, 2022 | 54.62 ± 0.14 a | 6.47 ± 0.01 a | 0.41 ± 0.01 c | 0.017 ± 0.001 c | 0.035 ± 0.002 a |

| Pedunculate oak, 2020 | 52.50 ± 0.12 c | 6.02 ± 0.04 b | 0.41 ± 0.01 c | 0.024 ± 0.001 b | 0.011 ± 0.002 d |

| Pedunculate oak, 2021 | 52.51 ± 0.34 c | 6.19 ± 0.05 a | 0.46 ± 0.03 c | 0.023 ± 0.003 b | 0.011 ± 0.002 d |

| Pedunculate oak, 2022 | 51.46 ± 0.30 e | 6.05 ± 0.10 b | 0.49 ± 0.03 b | 0.027 ± 0.002 b | 0.011 ± 0.003 d |

| Norway maple, 2020 | 51.44 ± 0.11 e | 5.90 ± 0.06 b | 0.50 ± 0.02 b | 0.022 ± 0.002 b | 0.024 ± 0.003 b |

| Norway maple, 2021 | 52.05 ± 0.22 d | 6.26 ± 0.16 a | 0.61 ± 0.04 b | 0.023 ± 0.003 b | 0.022 ± 0.002 b |

| Norway maple, 2022 | 51.35 ± 0.23 e | 6.02 ± 0.08 b | 0.52 ± 0.02 b | 0.028 ± 0.001 b | 0.033 ± 0.003 a |

| Scots pine, 2020 | 55.20 ± 0.04 a | 6.09 ± 0.08 b | 0.26 ± 0.01 g | 0.017 ± 0.001 c | 0.013 ± 0.001 d |

| Scots pine, 2021 | 54.67 ± 0.23 a | 6.19 ± 0.02 a | 0.34 ± 0.01 e | 0.015 ± 0.002 c | 0.012 ± 0.001 d |

| Scots pine, 2022 | 55.22 ± 0.25 a | 6.27 ± 0.02 a | 0.35 ± 0.01 d | 0.019 ± 0.001 c | 0.016 ± 0.002 d |

| European larch, 2020 | 54.50 ± 0.40 b | 5.70 ± 0.04 c | 0.35 ± 0.02 d | 0.026 ± 0.001 b | 0.010 ± 0.001 d |

| European larch, 2021 | 53.54 ± 0.06 b | 6.32 ± 0.16 a | 0.35 ± 0.01 d | 0.020 ± 0.003 b | 0.014 ± 0.001 d |

| European larch, 2022 | 53.16 ± 0.65 c | 6.04 ± 0.04 b | 0.45 ± 0.01 c | 0.025 ± 0.001 b | 0.013 ± 0.001 d |

| Norway spruce, 2020 | 54.00 ± 0.37 b | 5.96 ± 0.05 b | 0.36 ± 0.01 d | 0.018 ± 0.001 c | 0.011 ± 0.001 d |

| Norway spruce, 2021 | 55.47 ± 0.19 a | 6.16 ± 0.20 b | 0.31 ± 0.01 e | 0.017 ± 0.002 c | 0.011 ± 0.001 d |

| Norway spruce, 2022 | 53.85 ± 0.09 b | 6.19 ± 0.01 a | 0.40 ± 0.01 c | 0.016 ± 0.001 c | 0.013 ± 0.001 d |

| Characteristic | Mean | Median | Minimum Value | Maximum Value | Lower Quartile | Upper Quartile | Standard Deviation | Coefficient of variation (%) |

|---|---|---|---|---|---|---|---|---|

| MC (%) | 45.00 | 45.59 | 34.96 | 53.37 | 40.81 | 49.29 | 4.90 | 10.90 |

| FC (% DM) | 20.71 | 20.00 | 17.88 | 24.88 | 19.44 | 22.36 | 1.73 | 8.36 |

| VM (% DM) | 77.85 | 78.00 | 74.18 | 80.34 | 76.92 | 78.79 | 1.42 | 1.82 |

| Ash (% DM) | 1.44 | 1.37 | 0.54 | 3.00 | 0.84 | 1.93 | 0.68 | 47.30 |

| HHV (GJ Mg−1 DM) | 19.74 | 19.78 | 18.54 | 21.01 | 19.22 | 20.28 | 0.62 | 3.17 |

| LHV (GJ Mg−1) | 9.11 | 9.14 | 7.19 | 11.03 | 8.54 | 9.61 | 0.86 | 9.48 |

| C (% DM) | 52.83 | 52.85 | 48.76 | 55.66 | 51.55 | 54.46 | 1.77 | 3.35 |

| H (% DM) | 6.13 | 6.13 | 5.65 | 6.68 | 6.02 | 6.24 | 0.18 | 2.98 |

| N (% DM) | 0.45 | 0.42 | 0.25 | 0.85 | 0.35 | 0.52 | 0.13 | 29.07 |

| S (% DM) | 0.024 | 0.023 | 0.012 | 0.040 | 0.018 | 0.028 | 0.007 | 28.47 |

| Cl (% DM) | 0.017 | 0.013 | 0.008 | 0.043 | 0.011 | 0.022 | 0.008 | 49.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stolarski, M.J.; Wojciechowska, N.; Seliwiak, M.; Dobrzański, T.K. Properties of Forest Tree Branches as an Energy Feedstock in North-Eastern Poland. Energies 2024, 17, 1975. https://doi.org/10.3390/en17081975

Stolarski MJ, Wojciechowska N, Seliwiak M, Dobrzański TK. Properties of Forest Tree Branches as an Energy Feedstock in North-Eastern Poland. Energies. 2024; 17(8):1975. https://doi.org/10.3390/en17081975

Chicago/Turabian StyleStolarski, Mariusz Jerzy, Natalia Wojciechowska, Mateusz Seliwiak, and Tomasz Krzysztof Dobrzański. 2024. "Properties of Forest Tree Branches as an Energy Feedstock in North-Eastern Poland" Energies 17, no. 8: 1975. https://doi.org/10.3390/en17081975

APA StyleStolarski, M. J., Wojciechowska, N., Seliwiak, M., & Dobrzański, T. K. (2024). Properties of Forest Tree Branches as an Energy Feedstock in North-Eastern Poland. Energies, 17(8), 1975. https://doi.org/10.3390/en17081975