Characteristics of Micro–Nano-Pores in Shallow Shale Gas Reservoirs and Their Controlling Factors on Gas Content

Abstract

1. Progress in the Study of Pore Characteristics and Gas Content in Shale Gas Reservoirs

2. Sample and Experimental Methods

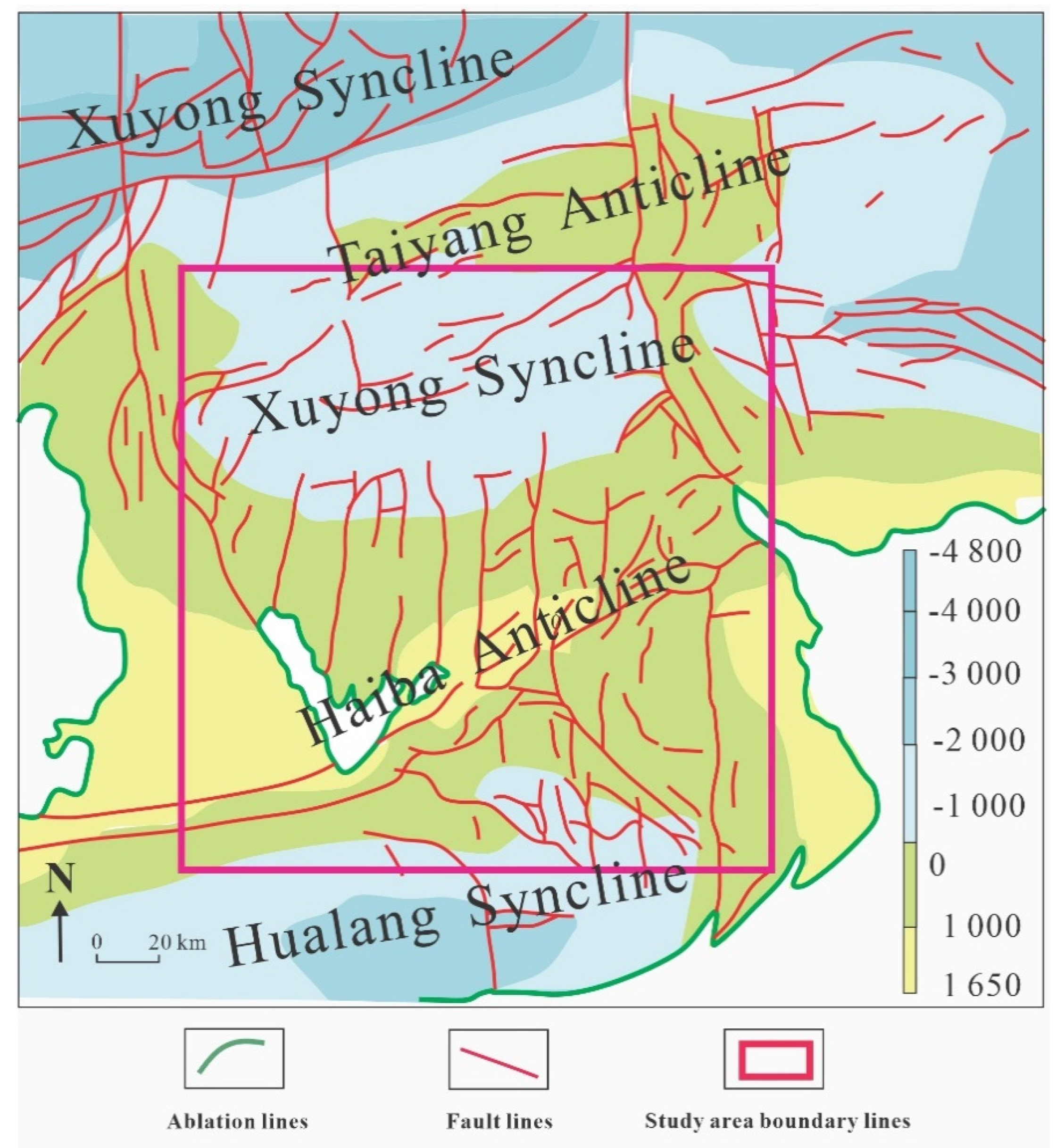

2.1. Sample Description

2.2. Experimental Methods and Procedures

2.2.1. Analysis of Microporosity Structure

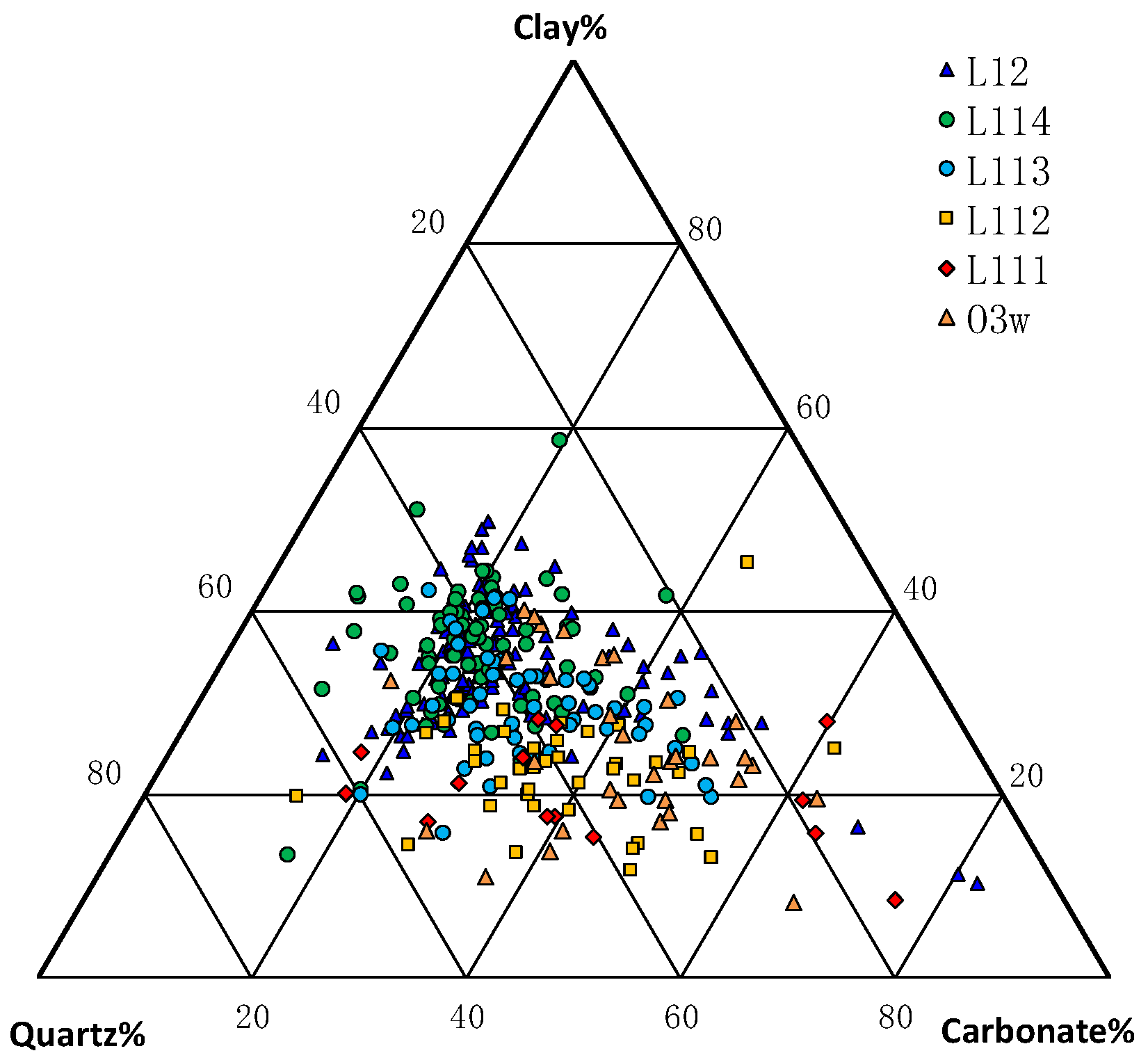

2.2.2. Analysis of Mineral Content

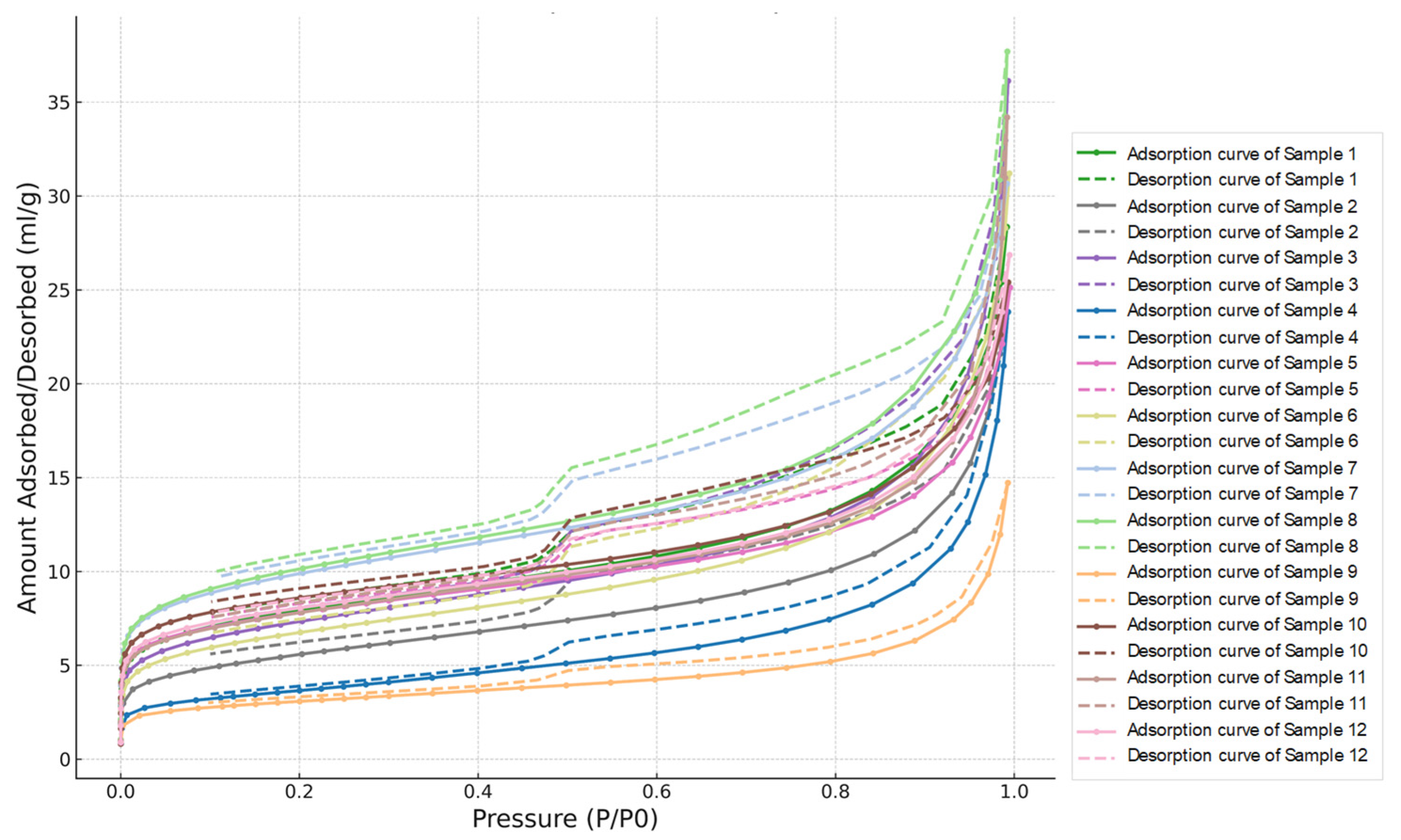

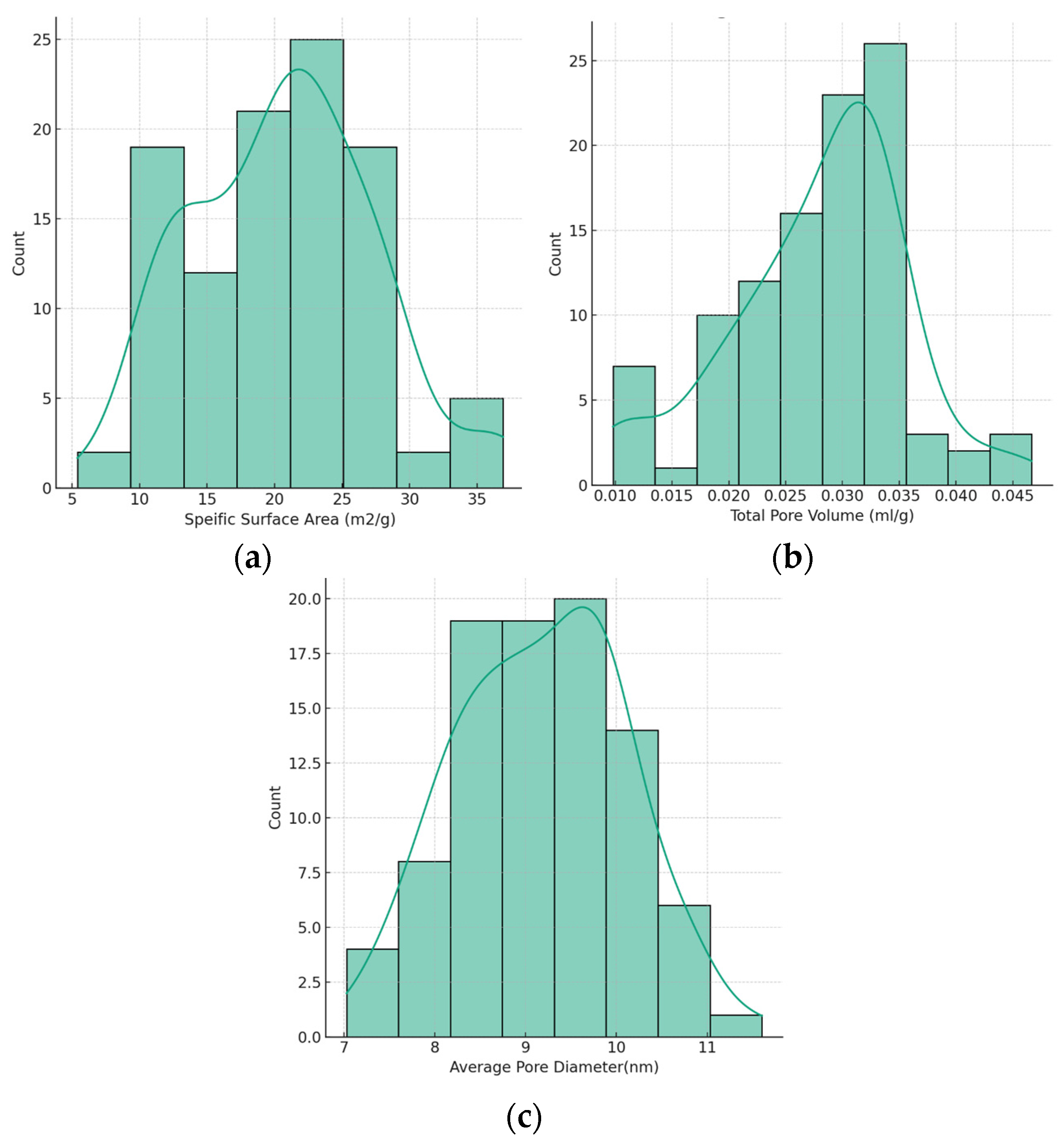

2.2.3. Low-Temperature Nitrogen Adsorption Experiment

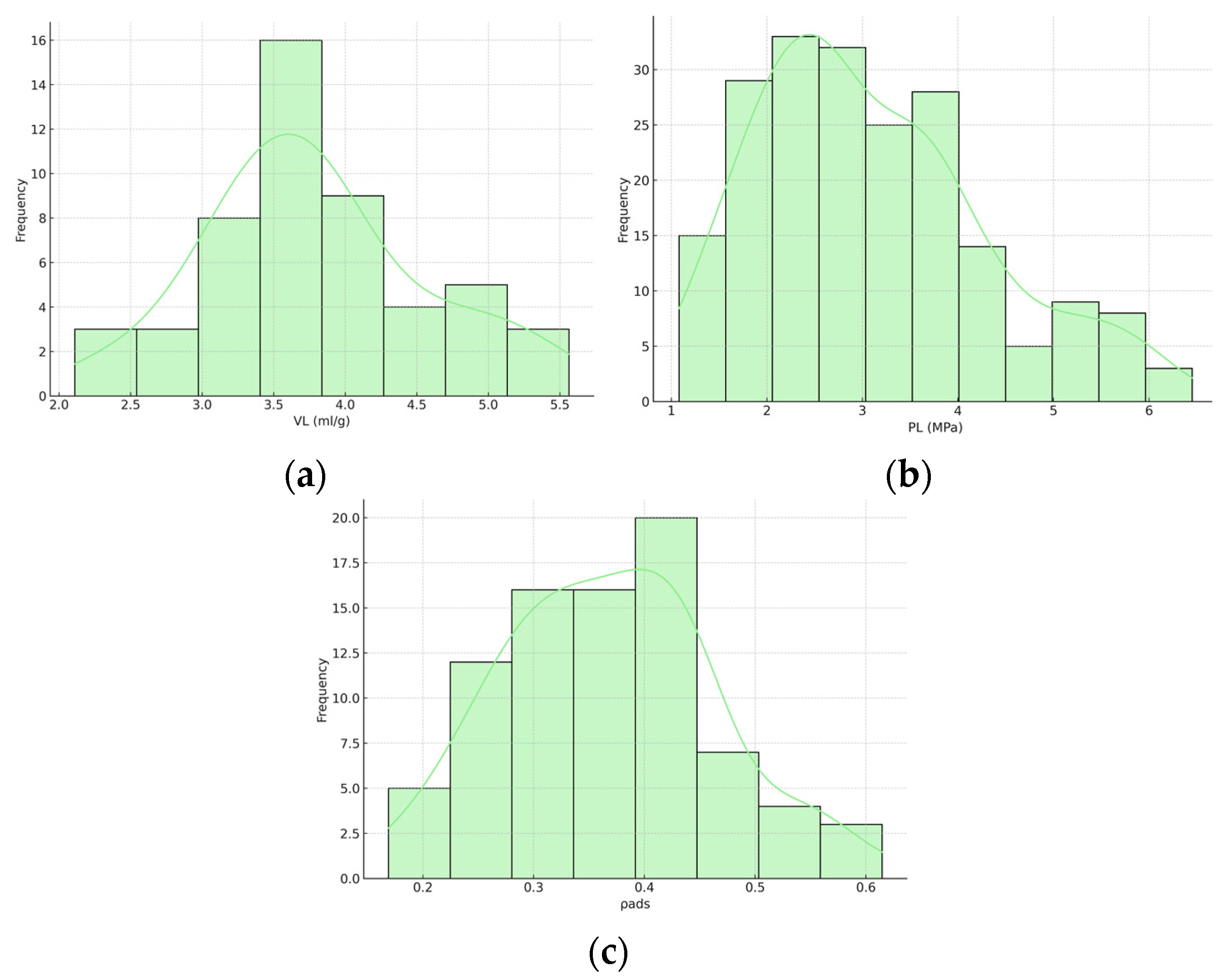

2.2.4. Methane Isotherm Adsorption Experiments and Adsorption Isotherm Curve Fitting

2.3. Analysis of Experimental Results

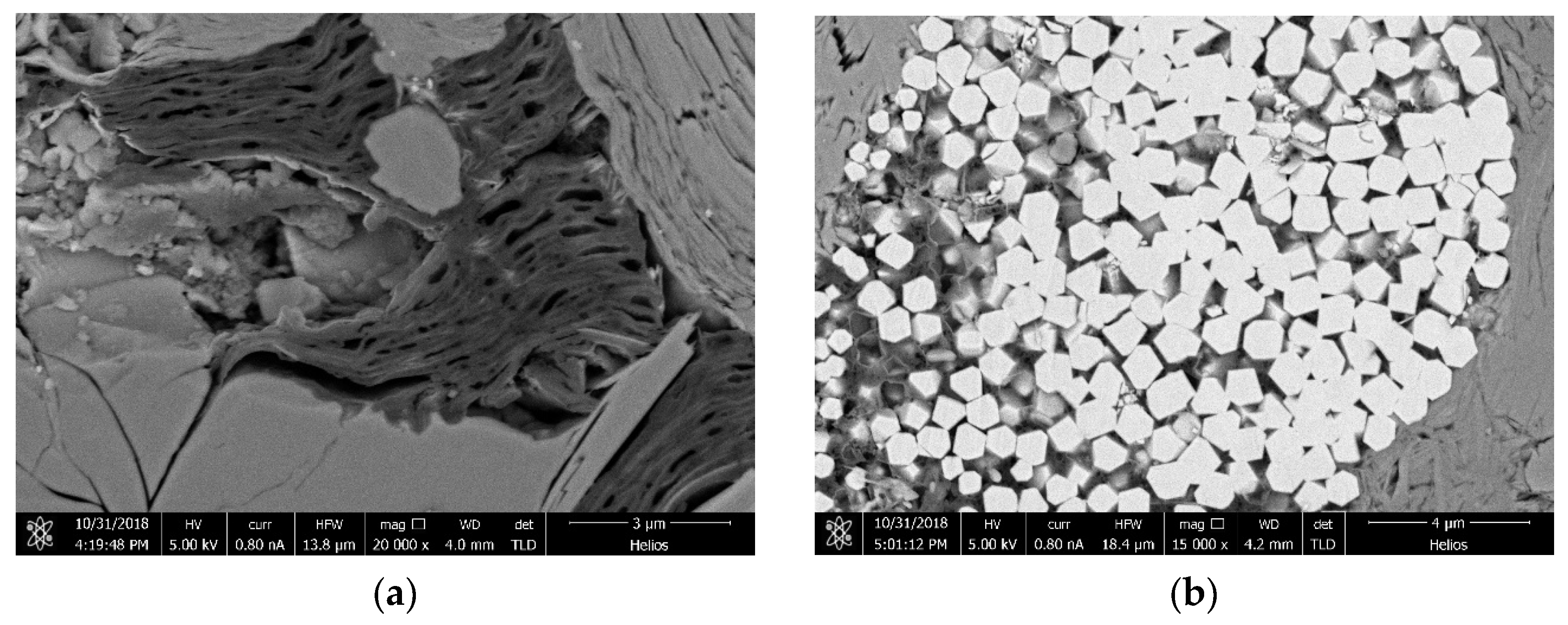

2.3.1. Electron Microscopy Analysis of Micropore Characteristics

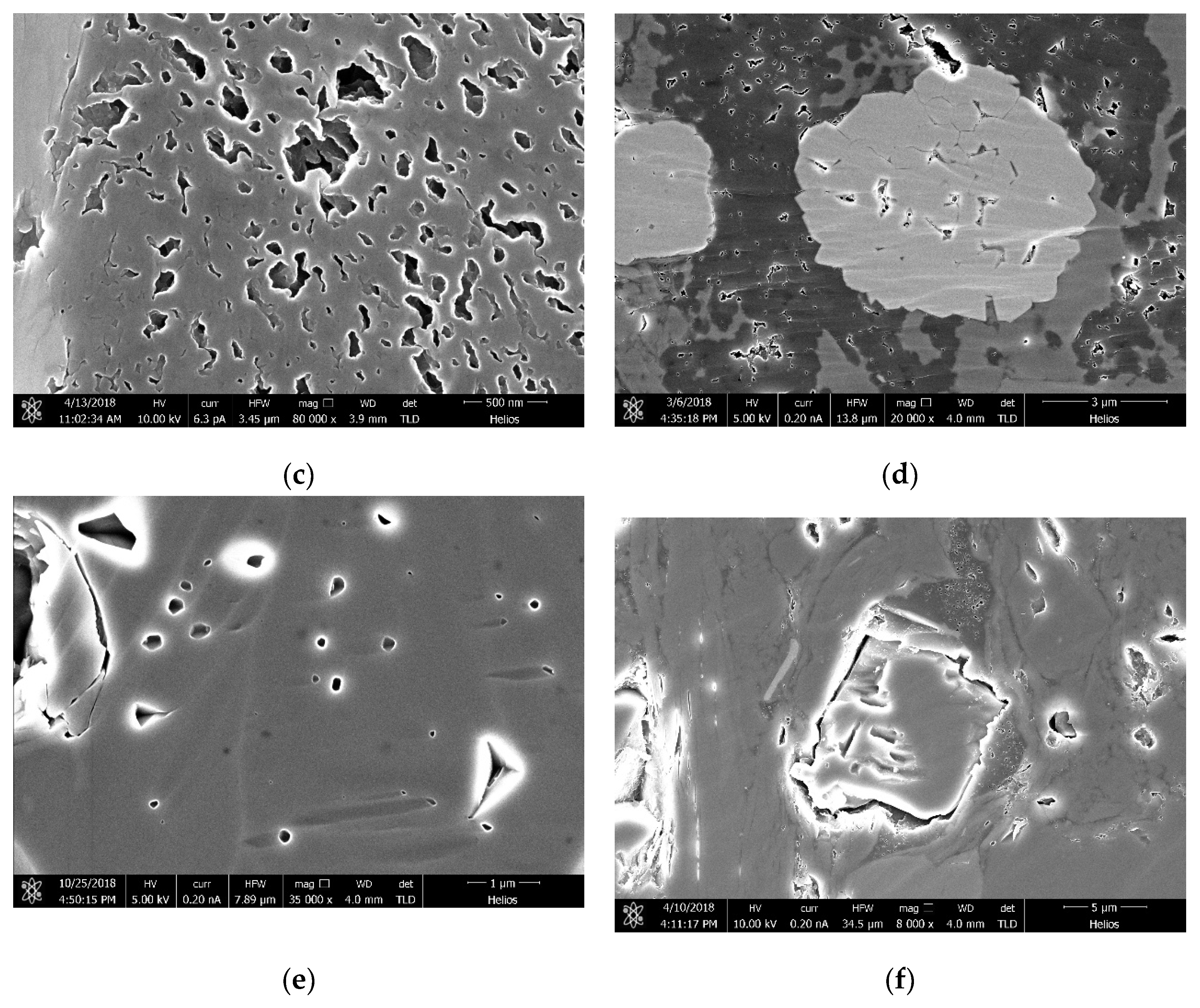

2.3.2. Total Organic Carbon and Mineral Content

2.3.3. Specific Surface Area Analysis

2.3.4. Methane Adsorption Characteristic Parameter Analysis

3. Analysis of Factors Affecting Shale Gas Content

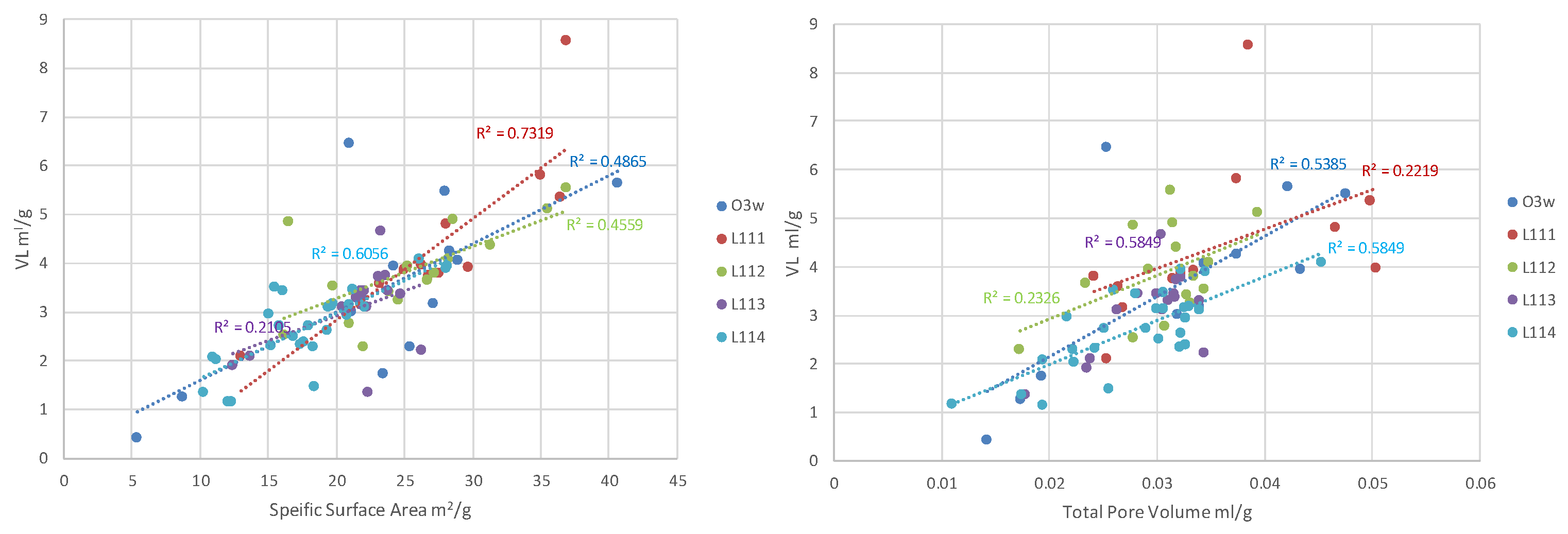

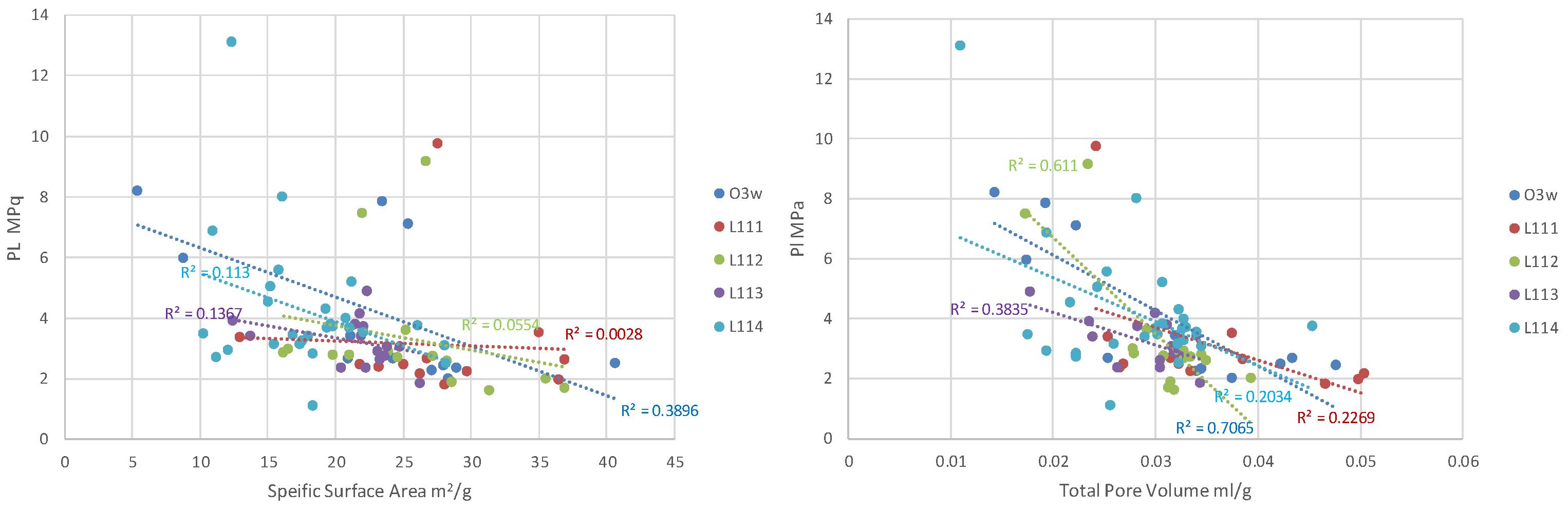

3.1. The Influence of Micropore Characteristics on Gas Content

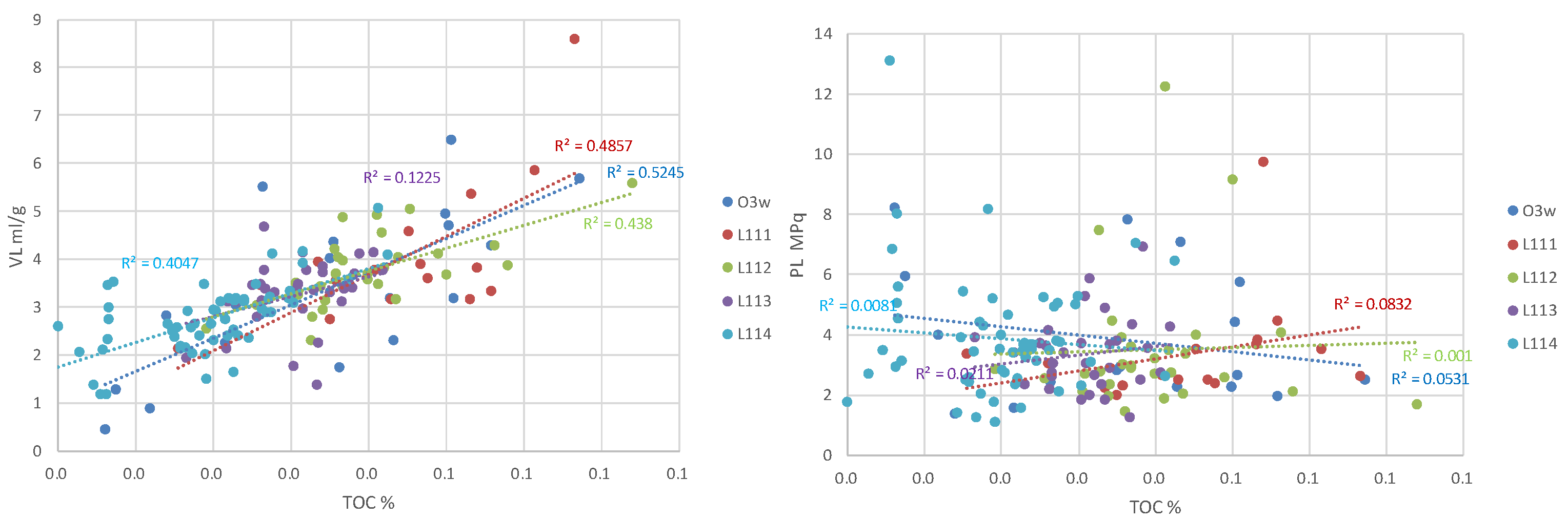

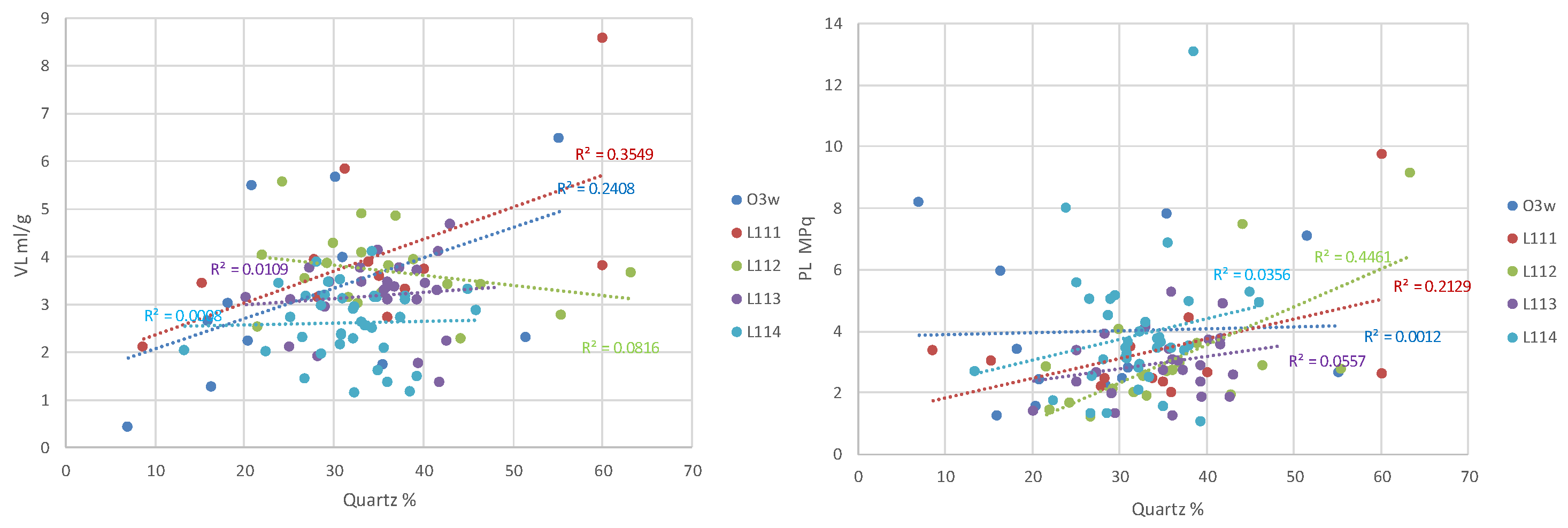

3.2. The Impact of Mineral Composition on Gas Content

3.3. The Gas Content Prediction Model

4. Conclusions

- (1)

- This research employed methods such as scanning electron microscopy imaging, analysis of shale rock mineral components, and methane adsorption experiments to study 106 shale samples from the Wufeng–Longmaxi Formations in the Sichuan Basin. The findings revealed the potential impact of shale’s mineralogy and its microporous structures on methane adsorption characteristics.

- (2)

- This study analyzed the correlation between experimental data—like microporous structures (specific surface area and total pore volume), geochemical properties (e.g., total organic carbon TOC content), and mineral composition (e.g., clay and quartz content)—and the volume of adsorbed methane. A gas content model, developed based on nonlinear regression analysis, enhanced prediction accuracy, thereby providing a reliable computational tool for reserve estimation.

- (3)

- This research further elaborated on the variability in contributions to methane adsorption, offering new insights into the evaluation and development of shale gas reservoirs. The proposed component-based adsorption model successfully described shale’s excess adsorption isotherms, reflecting the weighted average effect of organic matter and clay composition in adsorption.

- (4)

- The outcomes not only improved the accuracy of shale gas reserve estimates under limited core sampling conditions but also advanced our understanding of methane adsorption mechanisms within shale. These findings have substantial implications for guiding exploration and production activities in the Sichuan Basin and other shale gas regions globally, providing a scientific basis and technical support for the effective development of future shale gas resources.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hill, R.J.; Zhang, E.; Katz, B.J.; Tang, Y. Modeling of gas generation from the Barnett shale, Fort Worth Basin, Texas. AAPG Bull. 2007, 91, 501–521. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Jarvie, D.M. Morphology, genesis, and distribution of nanometer-scale pores in siliceous mudstones of the Mississippian Barnett Shale. J. Sediment. Res. 2009, 79, 848–861. [Google Scholar] [CrossRef]

- Chen, S.; Yao, S.; Wang, Y.; Liu, S.; Wang, X.; Zhang, Y.; Wang, H. Investigation of pore evolution and variation with magma intrusion on Permian Gufeng shale formation and their implications on gas enrichment. J. Nat. Gas Sci. Eng. 2021, 96, 104277. [Google Scholar] [CrossRef]

- Wang, K.; Qiao, P.; Wang, Z.; Liu, X.; Li, Y. Multiple scale pore size characterization of coal based on carbon dioxide and liquid nitrogen adsorption, high-pressure mercury intrusion and low field nuclear magnetic resonance. China Min. Mag. 2017, 26, 146–152. [Google Scholar]

- Li, X.; Wang, M.; Zhang, S.; Yan, W.; Xu, D.; Li, Y.; Fu, Y.; Yang, C.; Xie, L.; Lu, W. Study on nanopore structure of soil and quantitative characterization based on mercury intrusion, liquid nitrogen adsorption, CO2 adsorption, and SEM. Arab. J. Geosci. 2022, 15, 210. [Google Scholar] [CrossRef]

- Lu, F.; Zhou, Y.; Wang, P.; Jia, K.; Han, G. Pore Characteristics of Oil Shales in Jilin Province, Northeast China: Investigations Using Gas Adsorption, Mercury Intrusion, and NMR Cryoporometry. Energy Fuels 2023, 37, 11914–11927. [Google Scholar] [CrossRef]

- Xi, Z.; Tang, S.; Wang, J.; Yang, G.; Li, L. Formation and development of pore structure in marine-continental transitional shale from northern China across a maturation gradient: Insights from gas adsorption and mercury intrusion. Int. J. Coal Geol. 2018, 200, 87–102. [Google Scholar] [CrossRef]

- Mi, H.; Guo, Y.; Yu, X. Study on Pore Structure of Shale Reservoir by Low Temperature Nitrogen Adsorption Method. Geofluids 2022, 2022, 9355020. [Google Scholar] [CrossRef]

- Ma, R.; Yao, Y.; Wang, M.; Dai, X.; Li, A. CH4 and CO2 adsorption characteristics of low-rank coals containing water: An experimental and comparative study. Nat. Resour. Res. 2022, 31, 993–1009. [Google Scholar] [CrossRef]

- Han, H.; Dai, J.; Guo, C.; Zhong, N.; Pang, P.; Ding, Z.; Chen, J.; Huang, Z.; Gao, Y.; Luo, J.; et al. Pore Characteristics and Factors Controlling Lacustrine Shales from the Upper Cretaceous Qingshankou Formation of the Songliao Basin, Northeast China: A Study Combining SEM, Low-temperature Gas Adsorption and MICP Experiments. Acta Geol. Sin. Engl. Ed. 2021, 95, 585–601. [Google Scholar] [CrossRef]

- Wang, Z.; Cheng, Y.; Wang, G.; Ni, G.; Wang, L. Comparative analysis of pore structure parameters of coal by using low pressure argon and nitrogen adsorption. Fuel 2022, 309, 122120. [Google Scholar] [CrossRef]

- Cao, T.; Song, Z.; Wang, S.; Xia, J. Characterization of pore structure and fractal dimension of Paleozoic shales from the northeastern Sichuan Basin, China. J. Nat. Gas Sci. Eng. 2016, 35, 882–895. [Google Scholar] [CrossRef]

- Zhu, W.; Zhang, X.; Zhou, D.; Fang, C.; Li, J.; Huang, Z. New cognition on pore structure characteristics of Permian marine shale in the Lower Yangtze region and its implications for shale gas exploration. Nat. Gas Ind. B 2021, 8, 562–575. [Google Scholar] [CrossRef]

- Zou, X.; Li, X.; Zhang, J.; Li, H.; Guo, M.; Zhao, P. Characteristics of Pore Structure and Gas Content of the Lower Paleozoic Shale from the Upper Yangtze Plate, South China. Energies 2021, 14, 7603. [Google Scholar] [CrossRef]

- Kelly, S.; El-Sobky, H.; Torres-Verdín, C.; Balhoff, M.T. Assessing the utility of FIB-SEM images for shale digital rock physics. Adv. Water Resour. 2016, 95, 302–316. [Google Scholar] [CrossRef]

- Ma, R.; Wang, M.; Xie, W.; Wang, H. Micro-pore reservoir spaces and gas-bearing characteristics of the shale reservoirs of the coal measure strata in the Qinshui Basin. J. Nanosci. Nanotechnol. 2021, 21, 371–381. [Google Scholar] [CrossRef] [PubMed]

- Aji, A.Q.M.; Mohshim, D.F.; Maulianda, B.; Elraeis, K.A. Supercritical methane adsorption measurement on shale using the isotherm modelling aspect. RSC Adv. 2022, 12, 20530–20543. [Google Scholar]

- Fu, Y.; Zhang, R.; Jiang, Y.; Fan, X.; Gu, Y. Experimental Studies on Pore Structure and the Gas Content Evolution Mechanisms of Shale Gas Reservoirs at Different Burial Depths in the Longmaxi Formation, Southern Sichuan Basin. Appl. Sci. 2023, 13, 13194. [Google Scholar] [CrossRef]

- Harlow, F.J.; Willows, R.S. A simple method of deriving the Gibbs adsorption formula. Trans. Faraday Soc. 1915, 11, 53–54. [Google Scholar] [CrossRef][Green Version]

- Langmuir, I. The Adsorption of Gases on Plane Surfaces of Glass, Mica and Platinum. J. Am. Chem. Soc. 1918, 40, 1361–1403. [Google Scholar] [CrossRef]

- Boudaizt, M.; Mikhail, I. Temkin, 1908–1991. In Advances in Catalysis; Elsevier: New York, NY, USA, 1993; Volume xiii–xv. [Google Scholar]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Pursell, C.J.; Chandler, B.D.; Manzoli, M.; Boccuzzi, F. CO adsorption on supported gold nanoparticle catalysts: Application of the Temkin model. J. Phys. Chem. C 2012, 116, 11117–11125. [Google Scholar] [CrossRef]

- Yang, F.; Ning, Z.F.; Kong, D.T.; Peng, P.; Zhao, H.W. Comparison analysis on model of methane adsorption isotherms in shales. Coal Sci. Technol. 2013, 41, 86–89. [Google Scholar]

- Tianyi, Z.; Zhengfu, N.; Yan, Z. Comparative analysis of isothermal adsorption models for shales and coals. Xinjiang Pet. Geol. 2014, 35, 1. [Google Scholar]

- Sandoval, D.; Yan, W.; Michelsen, M.; Stenby, E. Model Comparison for High-pressure Adsorption in Shale and its Influence on Phase Equilibria. In Proceedings of the ECMOR XV—15th European Conference on the Mathematics of Oil Recovery, Amsterdam, The Netherlands, 29 August–1 September 2016. [Google Scholar]

- Bashir, H. Methane Adsorption into Sandstones and Its Role in Gas Recovery from Depleted Reservoirs. University of Salford, Salford, UK, 2018. [Google Scholar]

- Gurin, O.V.; Degtyarev, A.V.; Dubinin, M.M.; Maslov, V.A. Focusing of modes for metallic resonator of a terahertz laser with nonuniform spatial polarization. In Proceedings of the 2018 IEEE 17th International Conference on Mathematical Methods in Electromagnetic Theory (MMET), Kyiv, Ukraine, 2–5 July 2018. [Google Scholar]

- Wang, S.; Feng, Q.; Javadpour, F.; Zha, M.; Cui, R. Multiscale modeling of gas transport in shale matrix: An integrated study of molecular dynamics and rigid-pore-network model. SPE J. 2020, 25, 1416–1442. [Google Scholar] [CrossRef]

- Xing, X.; Fu, D.; Wang, Z.; Tian, Y.; Sun, L. Influence of Organic-Inorganic Composition on the Adsorption of Niutitang Formation Shale in Huijunba Syncline. Geofluids 2022, 2022, 3292399. [Google Scholar] [CrossRef]

- Zhang, C.; Cheng, S.; Zhou, W. Considering the Modified BET Adsorption, the Material Balance Calculation Method for Abnormally High-Pressure Shale Gas Reservoirs. Spec. Oil Gas Reserv. 2022, 29, 77–82. [Google Scholar]

- Acevedo-Reyes, D.; Perez, M.; Verdu, C.; Bogner, A.; Epicier, T. Characterisation of precipitates size distribution: A comparative study of SEM and TEM potentialities. J. Microsc. 2008, 232, 112–122. [Google Scholar] [PubMed]

- Joos, J.; Carraro, T.; Weber, A.; Ivers-Tiffée, E. Reconstruction of porous electrodes by FIB/SEM for detailed microstructure modeling. J. Power Sources 2011, 196, 7302–7307. [Google Scholar] [CrossRef]

- Jiang, W.; Lin, M. Molecular dynamics investigation of conversion methods for excess adsorption amount of shale gas. J. Nat. Gas Sci. Eng. 2018, 49, 241–249. [Google Scholar] [CrossRef]

- Thomas, K.M. Perspectives of gas adsorption and storage in kerogens and shales. Energy Fuels 2023, 37, 2569–2585. [Google Scholar] [CrossRef]

- Qian, C.; Li, X.; Zhang, Q.; Shen, W.; Guo, W.; Lin, W.; Han, L.; Cui, Y.; Huang, Y.; Pei, X.; et al. Reservoir characteristics of different shale lithofacies and their effects on the gas content of Wufeng-Longmaxi Formation, southern Sichuan Basin, China. Geoenergy Sci. Eng. 2023, 225, 211701. [Google Scholar] [CrossRef]

- Guo, H.; Jia, W.; Lei, Y.; Luo, X.; Cheng, M.; Wang, X.; Zhang, L.; Jiang, C. The composition and its impact on the methane sorption of lacustrine shales from the Upper Triassic Yanchang Formation, Ordos Basin China. Mar. Pet. Geol. 2014, 57, 509–520. [Google Scholar] [CrossRef]

- Jiang, W.; Cao, G.; Luo, C.; Lin, M.; Ji, L.; Zhou, J. A composition-based model for methane adsorption of overmature shales in Wufeng and Longmaxi Formation, Sichuan Basin. Chem. Eng. J. 2022, 429, 130766. [Google Scholar] [CrossRef]

- Rexer, T.F.; Mathia, E.J.; Aplin, A.C.; Thomas, K.M. High-pressure methane adsorption and characterization of pores in Posidonia shales and isolated kerogens. Energy Fuels 2014, 28, 2886–2901. [Google Scholar] [CrossRef]

- Gasparik, M.; Ghanizadeh, A.; Bertier, P.; Gensterblum, Y.; Bouw, S.; Krooss, B.M. High-pressure methane sorption isotherms of black shales from the Netherlands. Energy Fuels 2012, 26, 4995–5004. [Google Scholar] [CrossRef]

| R2 | SSA vs. VL | TPV vs. VL |

|---|---|---|

| Q3w | 0.732 | 0.524 |

| L111 | 0.486 | 0.855 |

| L112 | 0.606 | 0.624 |

| L113 | 0.263 | 0.233 |

| L114 | 0.454 | 0.722 |

| R2 | SSA vs. PL | TPV vs. PL |

|---|---|---|

| Q3w | 0.174 | 0.562 |

| L111 | 0.366 | 0.337 |

| L112 | 0.054 | 0.202 |

| L113 | 0.003 | 0.027 |

| L114 | 0.339 | 0.707 |

| R2 | TOC vs. VL | TOC vs. PL |

|---|---|---|

| Q3w | 0.486 | 0.008 |

| L111 | 0.123 | 0.030 |

| L112 | 0.405 | 0.001 |

| L113 | 0.525 | 0.003 |

| L114 | 0.438 | 0.053 |

| R2 | Quartz vs. VL | Quartz vs. PL |

|---|---|---|

| Q3w | 0.011 | 0.446 |

| L111 | 0.241 | 0.036 |

| L112 | 0.011 | 0.001 |

| L113 | 0.031 | 0.006 |

| L114 | 0.355 | 0.122 |

| R2 | TClay vs. VL | TClay vs. PL |

|---|---|---|

| Q3w | 0.216 | 0.006 |

| L111 | 0.045 | 0.133 |

| L112 | 0.030 | 0.000 |

| L113 | 0.049 | 0.011 |

| L114 | 0.034 | 0.325 |

| Parameter | VLorg | PLorg | ρadsorg | VLTPV | PLTPV | ΡadsTPV | VLSSA | PLSSA | ΡadsSSA | R2 |

|---|---|---|---|---|---|---|---|---|---|---|

| Value | 16.547 | 0.371 | 0.087 | 0.008 | 4.733 | 0.08 | 0.141 | 5.114 | 20.1 | 0.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Xian, C.; Huang, X. Characteristics of Micro–Nano-Pores in Shallow Shale Gas Reservoirs and Their Controlling Factors on Gas Content. Energies 2024, 17, 1682. https://doi.org/10.3390/en17071682

Liu Y, Xian C, Huang X. Characteristics of Micro–Nano-Pores in Shallow Shale Gas Reservoirs and Their Controlling Factors on Gas Content. Energies. 2024; 17(7):1682. https://doi.org/10.3390/en17071682

Chicago/Turabian StyleLiu, Yang, Chenggang Xian, and Xiaoqing Huang. 2024. "Characteristics of Micro–Nano-Pores in Shallow Shale Gas Reservoirs and Their Controlling Factors on Gas Content" Energies 17, no. 7: 1682. https://doi.org/10.3390/en17071682

APA StyleLiu, Y., Xian, C., & Huang, X. (2024). Characteristics of Micro–Nano-Pores in Shallow Shale Gas Reservoirs and Their Controlling Factors on Gas Content. Energies, 17(7), 1682. https://doi.org/10.3390/en17071682