Thermodynamic Analysis and Comparison of Power Cycles for Small Modular Reactors

Abstract

1. Introduction

1.1. Energy Supply Problems in Remote Regions

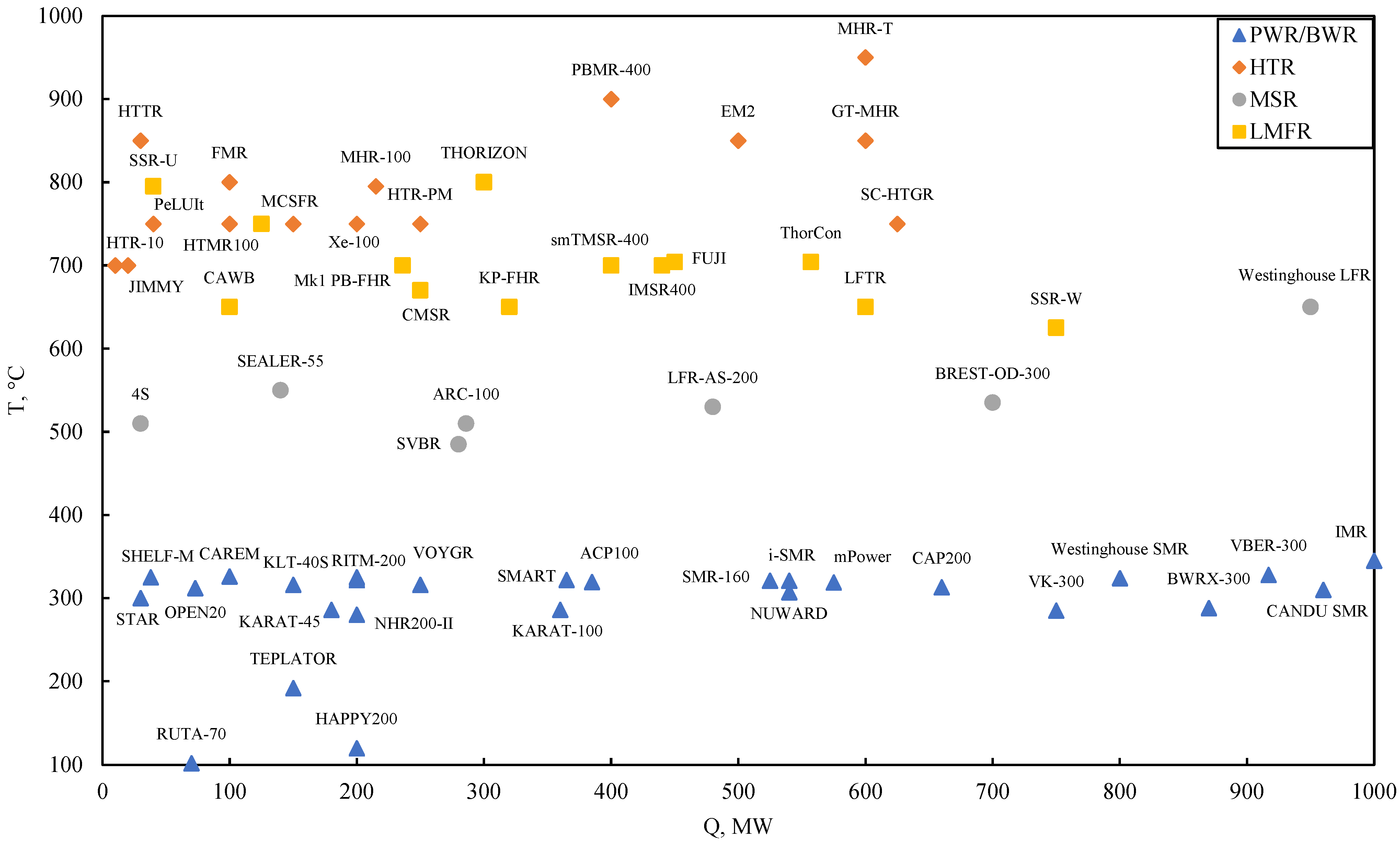

1.2. Current State of SMR Projects

1.3. Engineering Level of SMR Projects

- -

- pressurized, water-cooled reactors (PWRs) and boiling water reactors (BWRs);

- -

- high-temperature, gas-cooled reactors (HTGRs) with a helium coolant;

- -

- liquid metal fast reactors (LMFRs);

- -

- molten salt reactors (MSRs).

2. Research Object

- water-cooled small modular reactors with a coolant temperature up to 350 °C;

- liquid metal-cooled small modular reactors with a temperature up to 650 °C;

- reactors with liquid salt coolant where the temperature can reach 800 °C;

- high-temperature, gas-cooled reactors with helium coolant temperatures from 700 °C to 1000 °C.

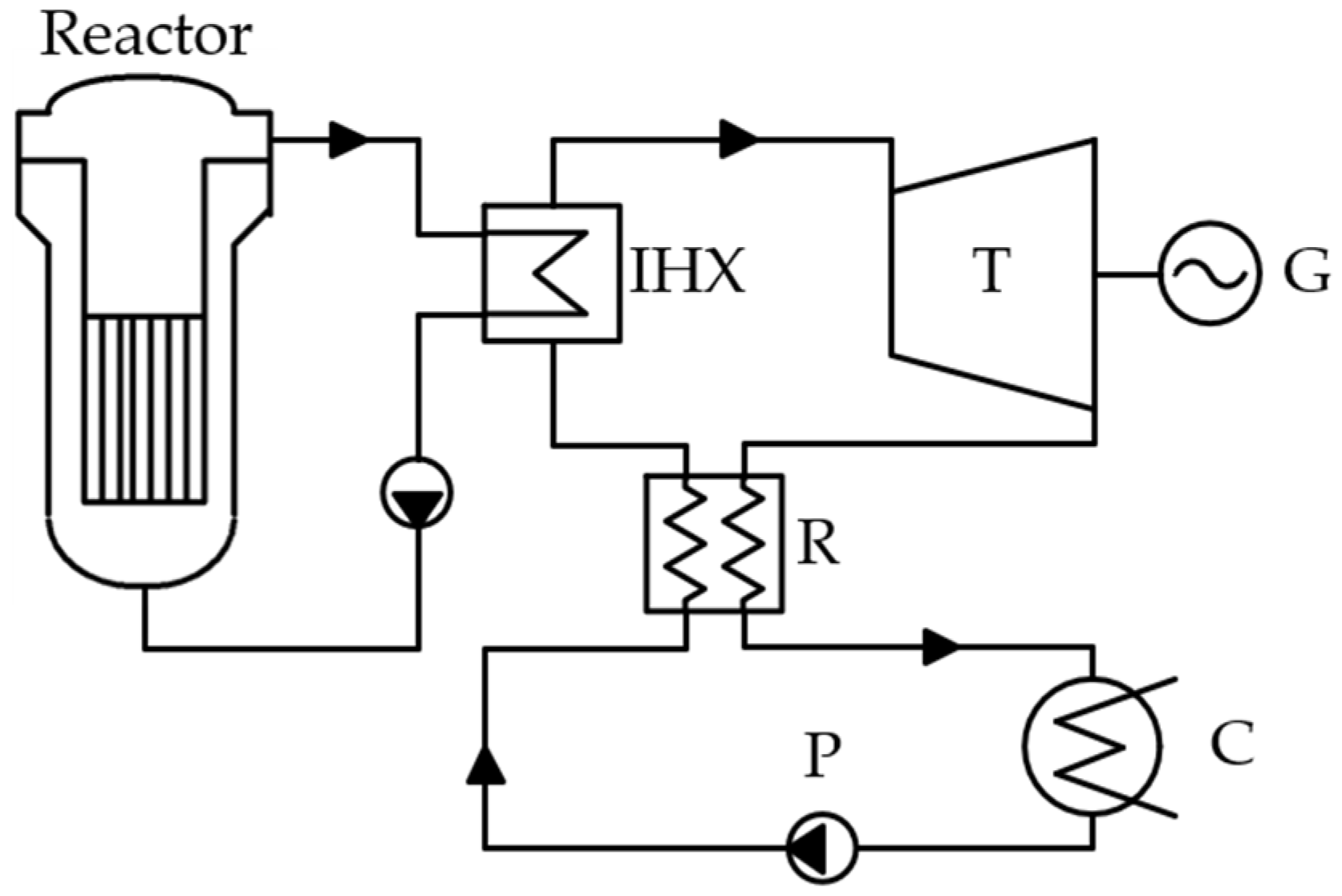

- regenerative organic Rankine cycles (ORCs) with freon coolant;

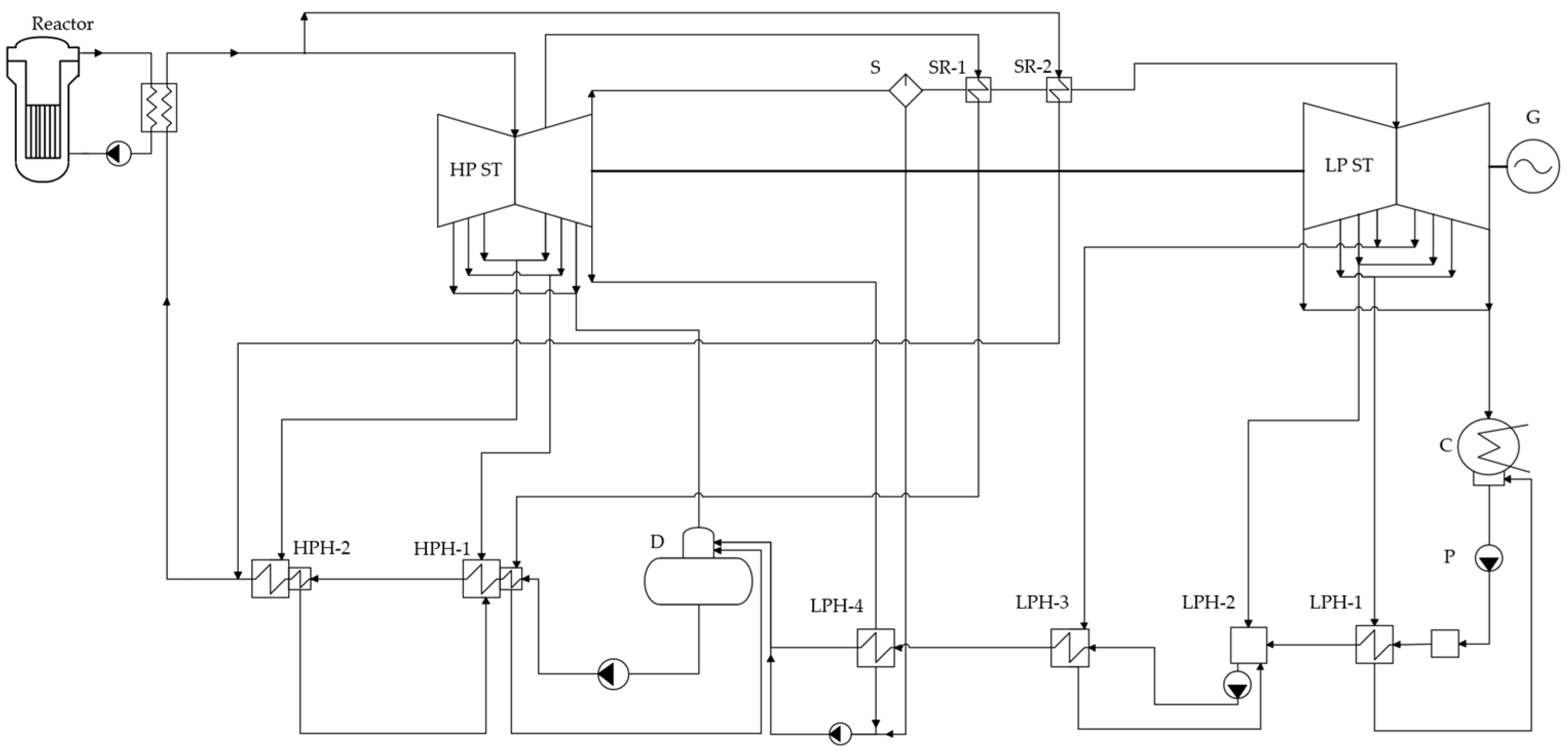

- steam turbine Rankine cycles with an intermediate steam separator and reheater;

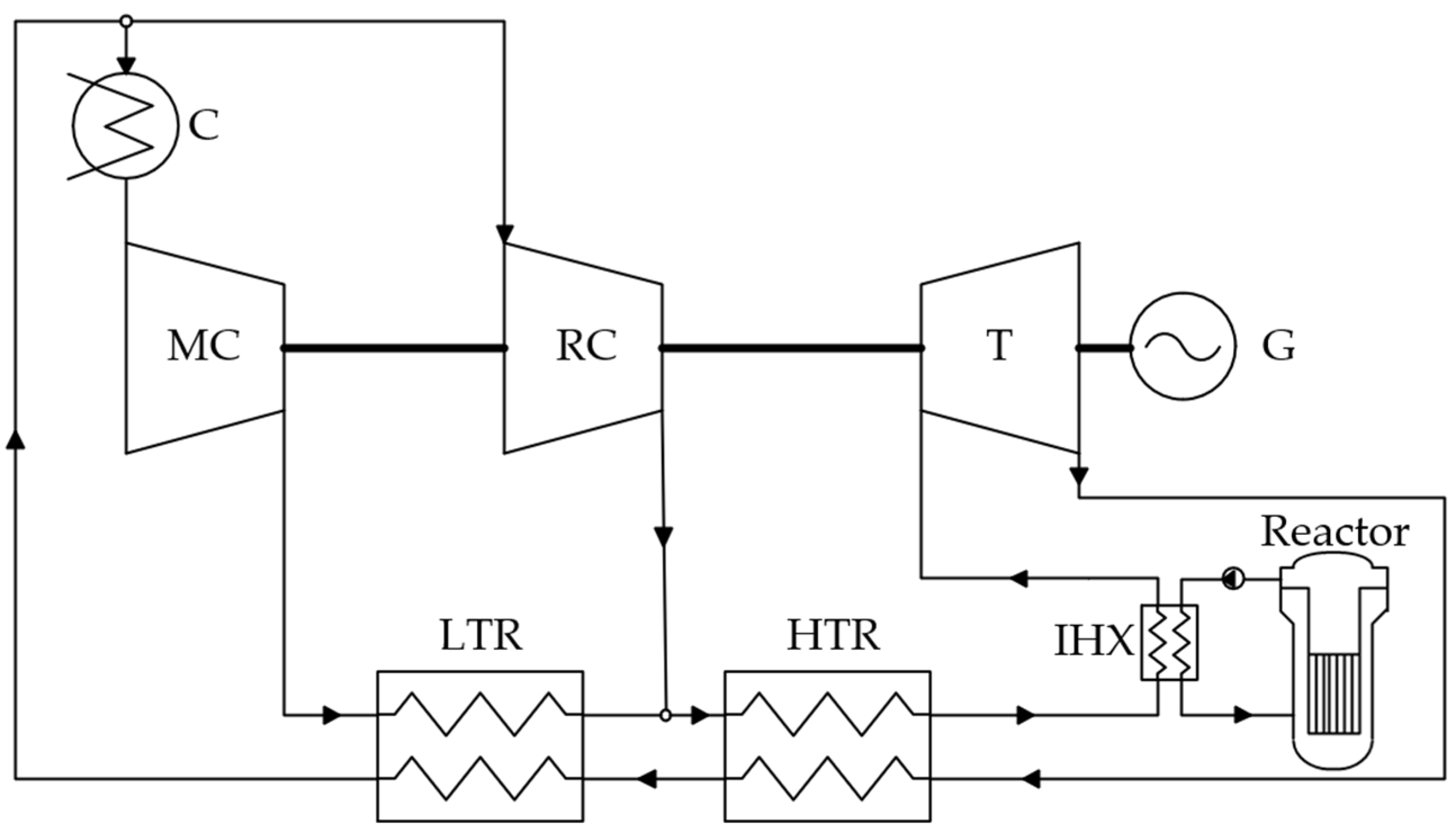

- carbon dioxide Brayton cycles with recompression;

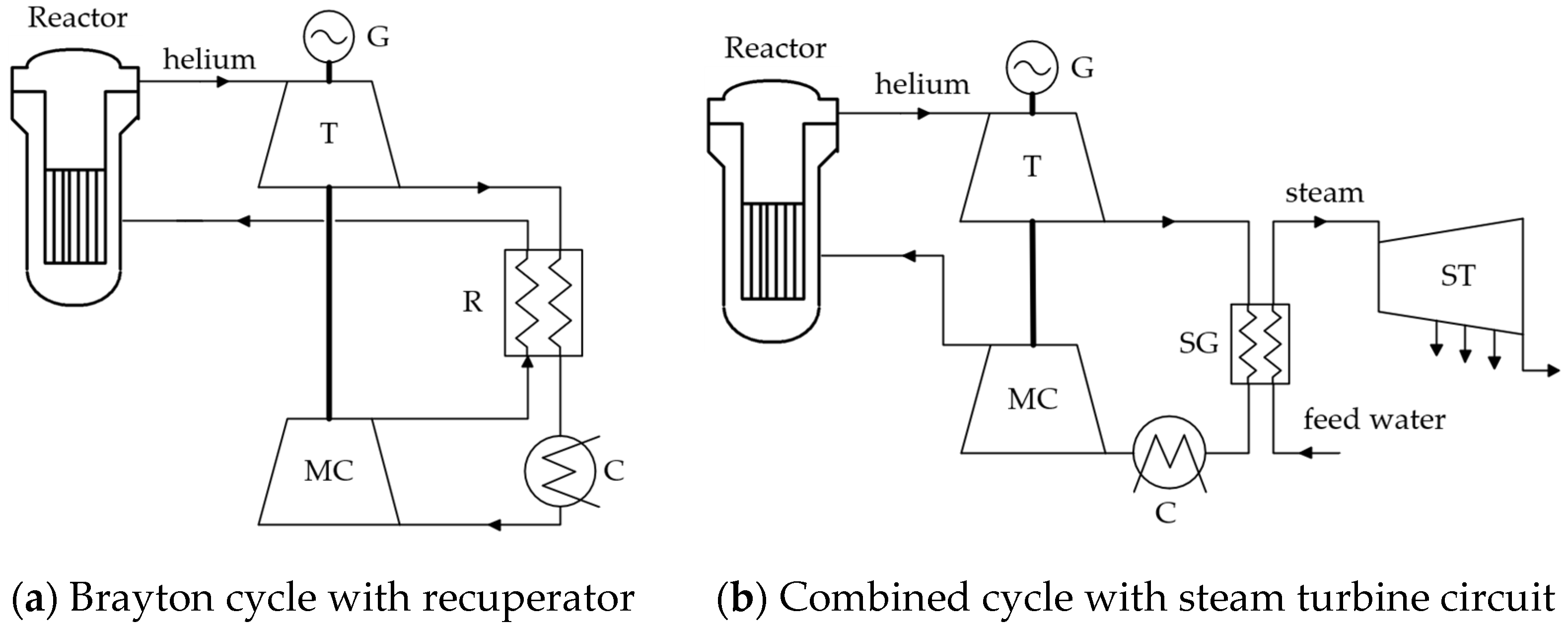

- helium Brayton cycles with regeneration;

- helium Brayton cycles with an additional steam turbine circuit.

3. Methods

4. Results and Discussion

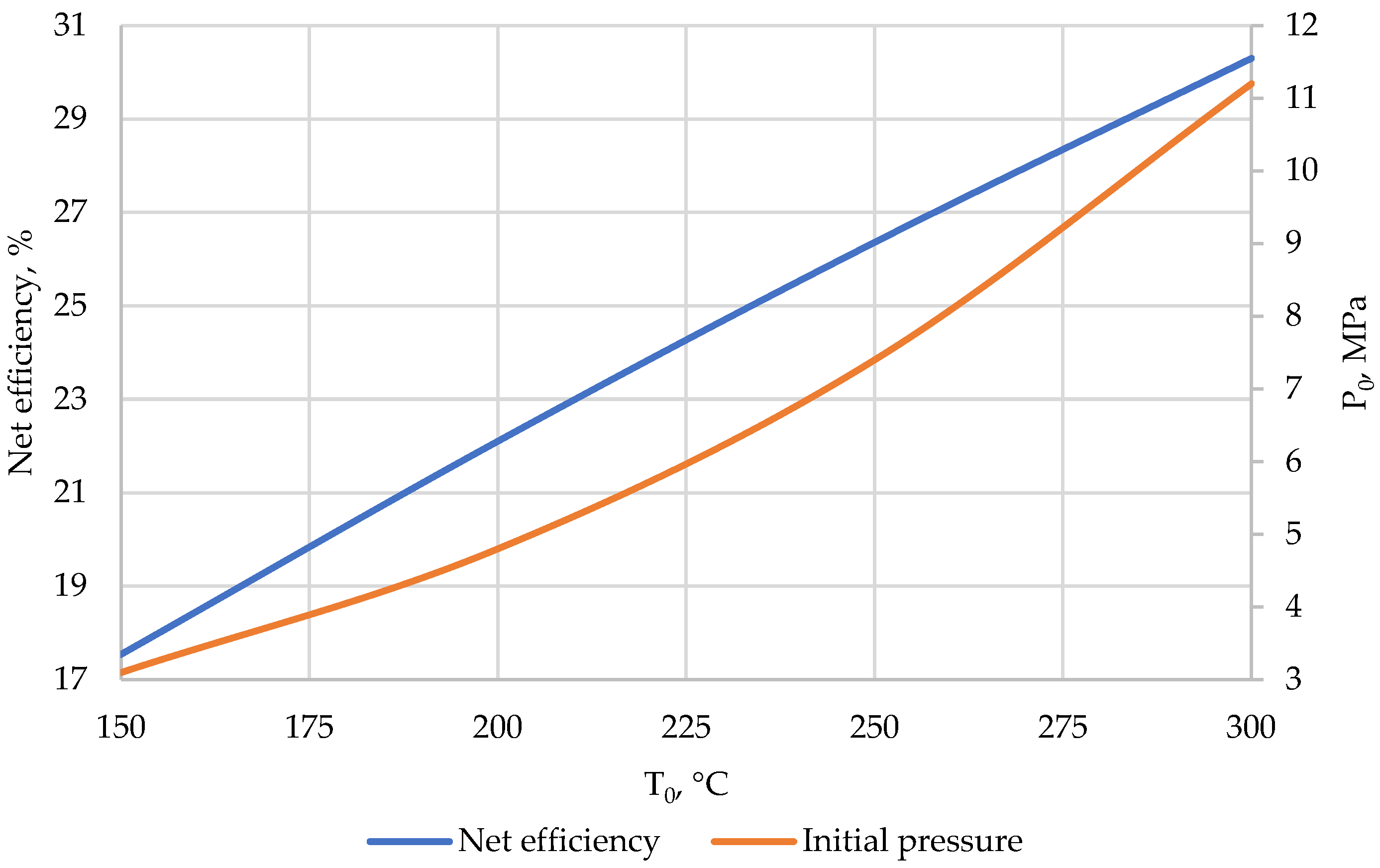

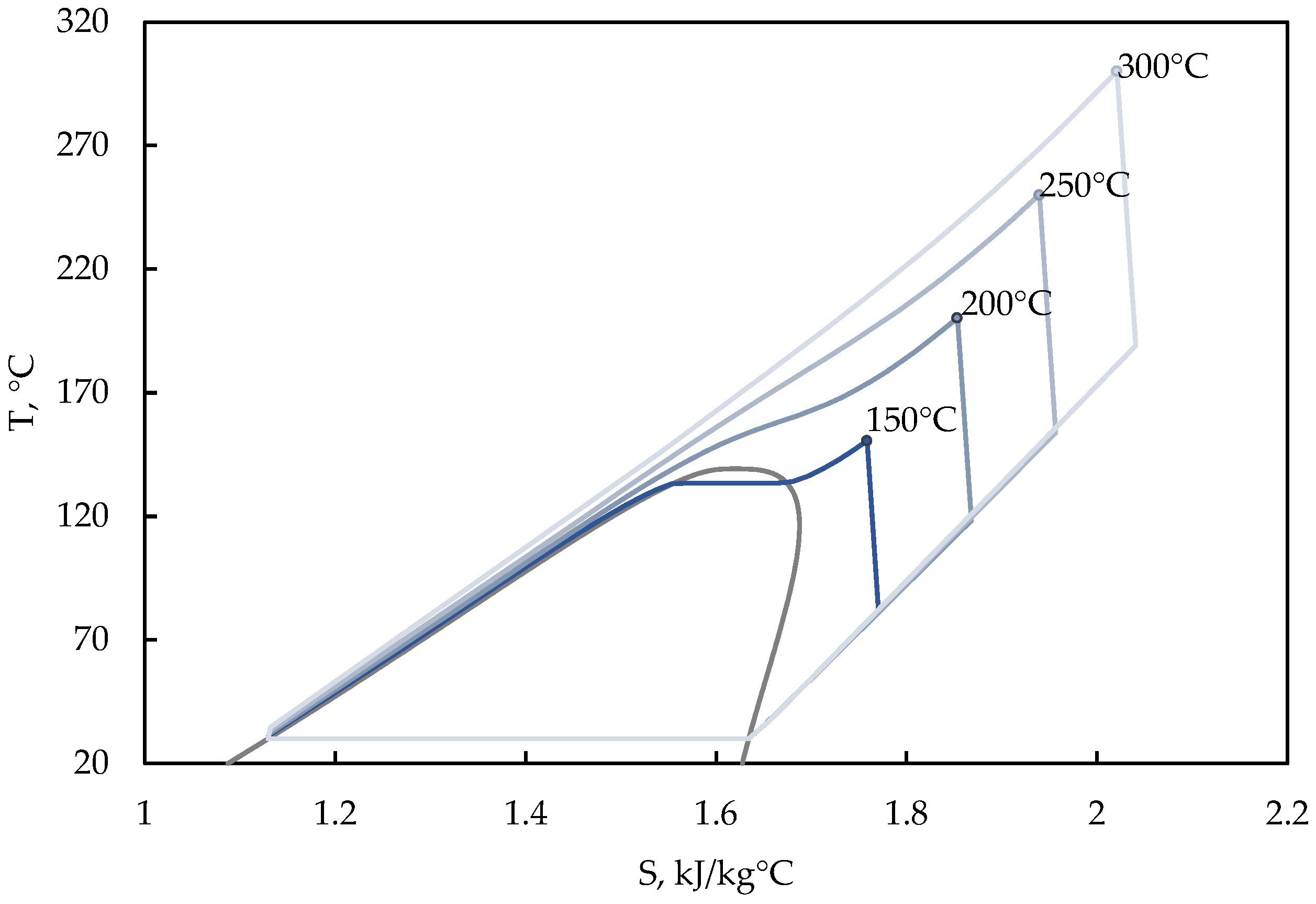

4.1. Power Cycles for Water-Cooled Small Modular Reactors

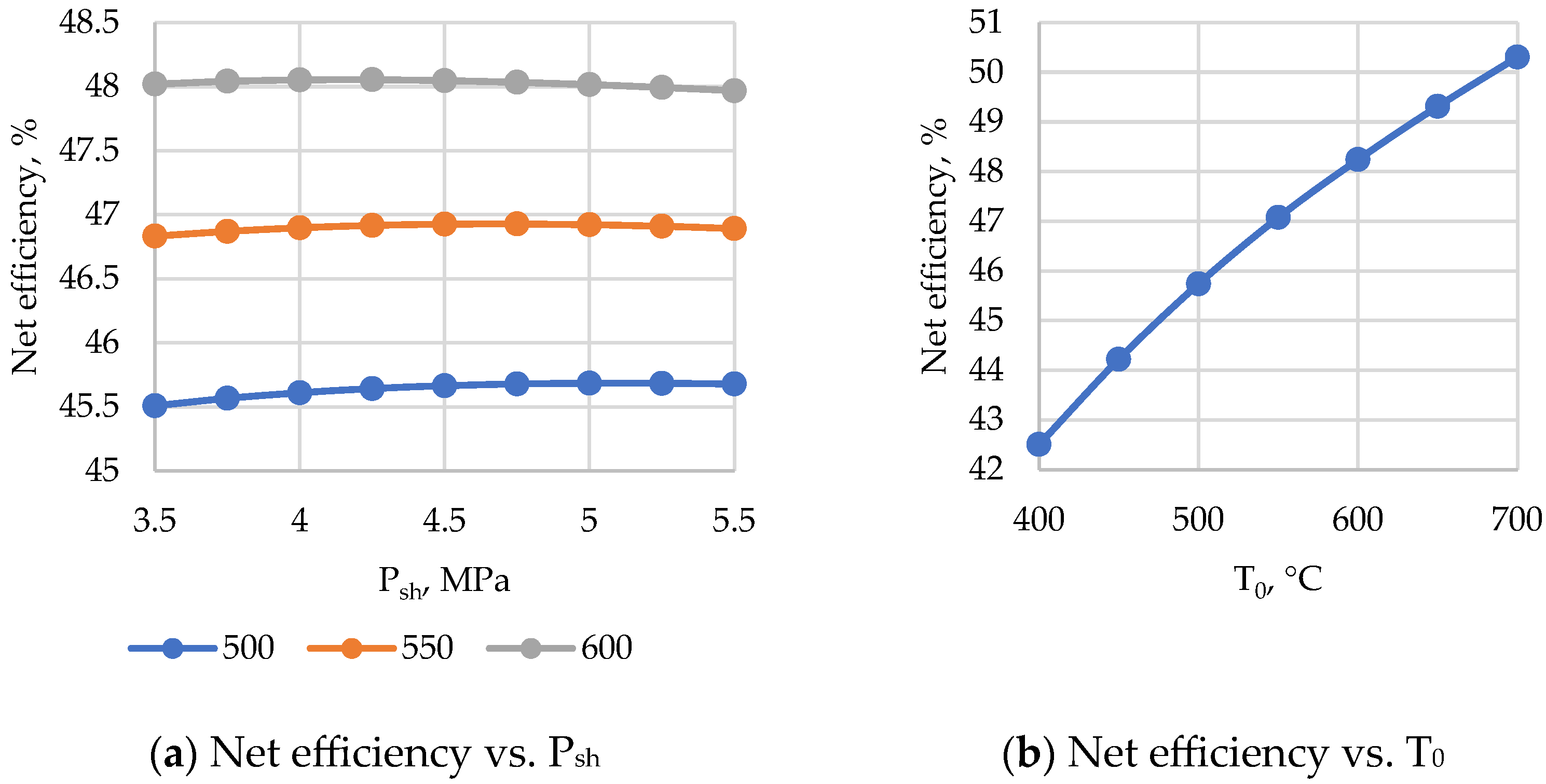

4.2. Power Cycles for Small Modular Reactors with Liquid Metal and Liquid Salt Coolants

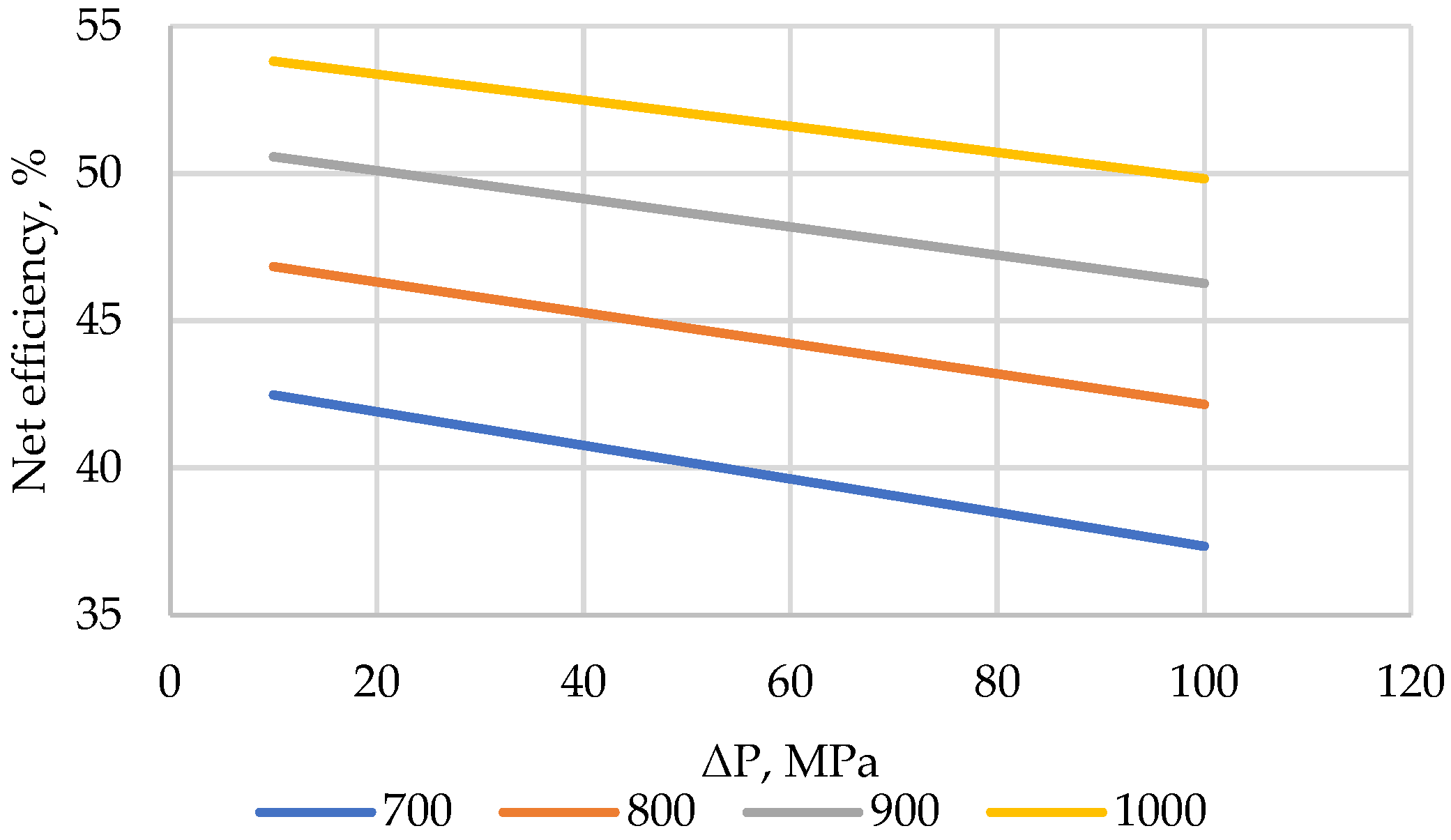

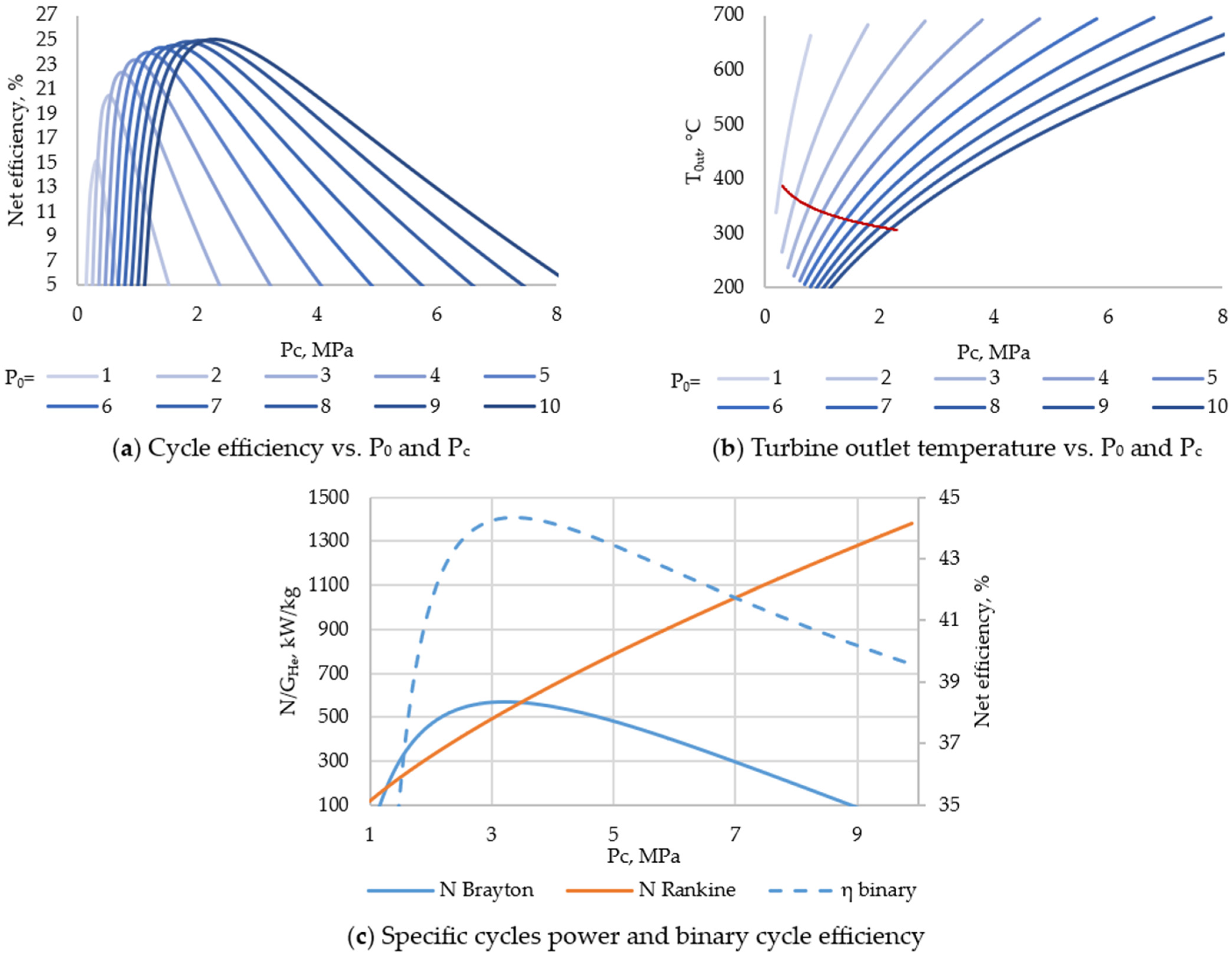

4.3. Helium Cycles for High-Temperature, Gas-Cooled SMRs

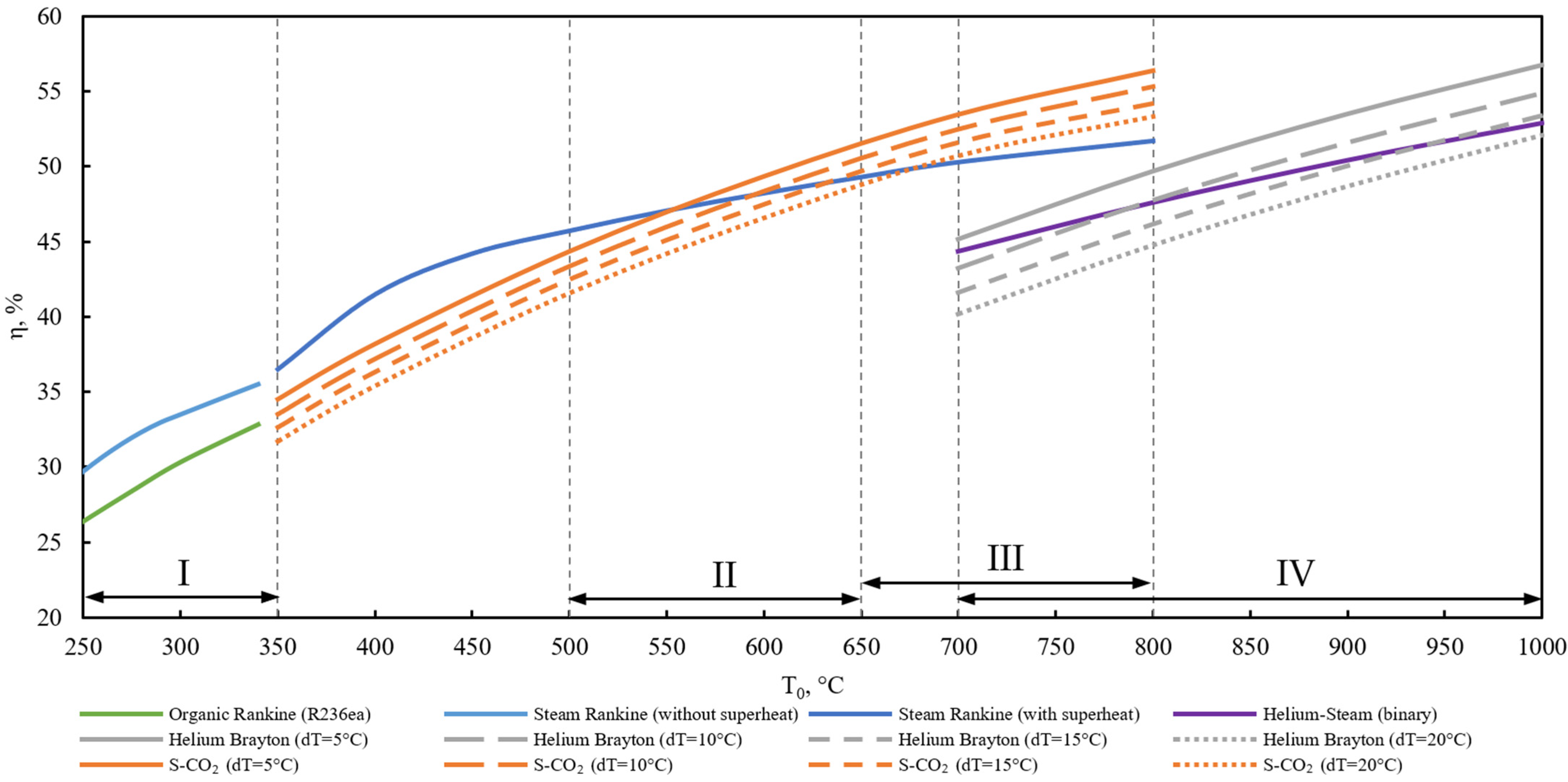

4.4. Comparative Analysis of Power Cycle Efficiencies for SNPPs

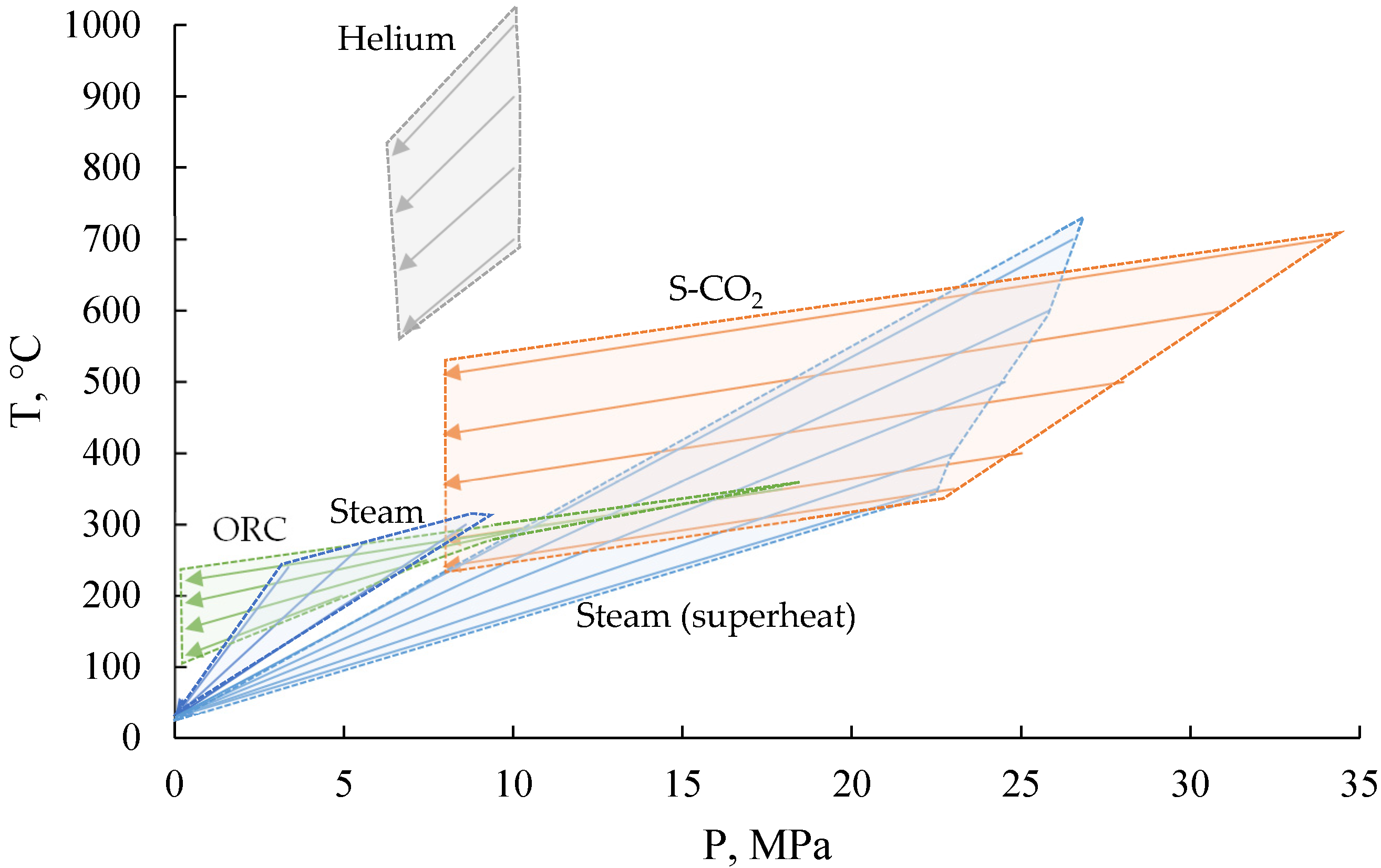

4.5. Comparative Analysis of the Operating Conditions of Power Cycles Equipment for SNPP

5. Conclusions

- For PWR-type reactor plants, in which the coolant temperature does not exceed 350 °C, the highest efficiency of electricity production is achieved when using steam power cycles. Thus, net efficiency at 300 °C can reach 33.5%. The use of cycles using organic coolants provides an efficiency of 30.3%, and, to achieve parameters comparable to the steam power cycle, it is necessary to increase the initial temperature by more than 50 °C. Thus, when using R236ea freon in an organic Rankine cycle with a recuperator, an efficiency of 33.9% is achieved at a temperature of 350 °C.

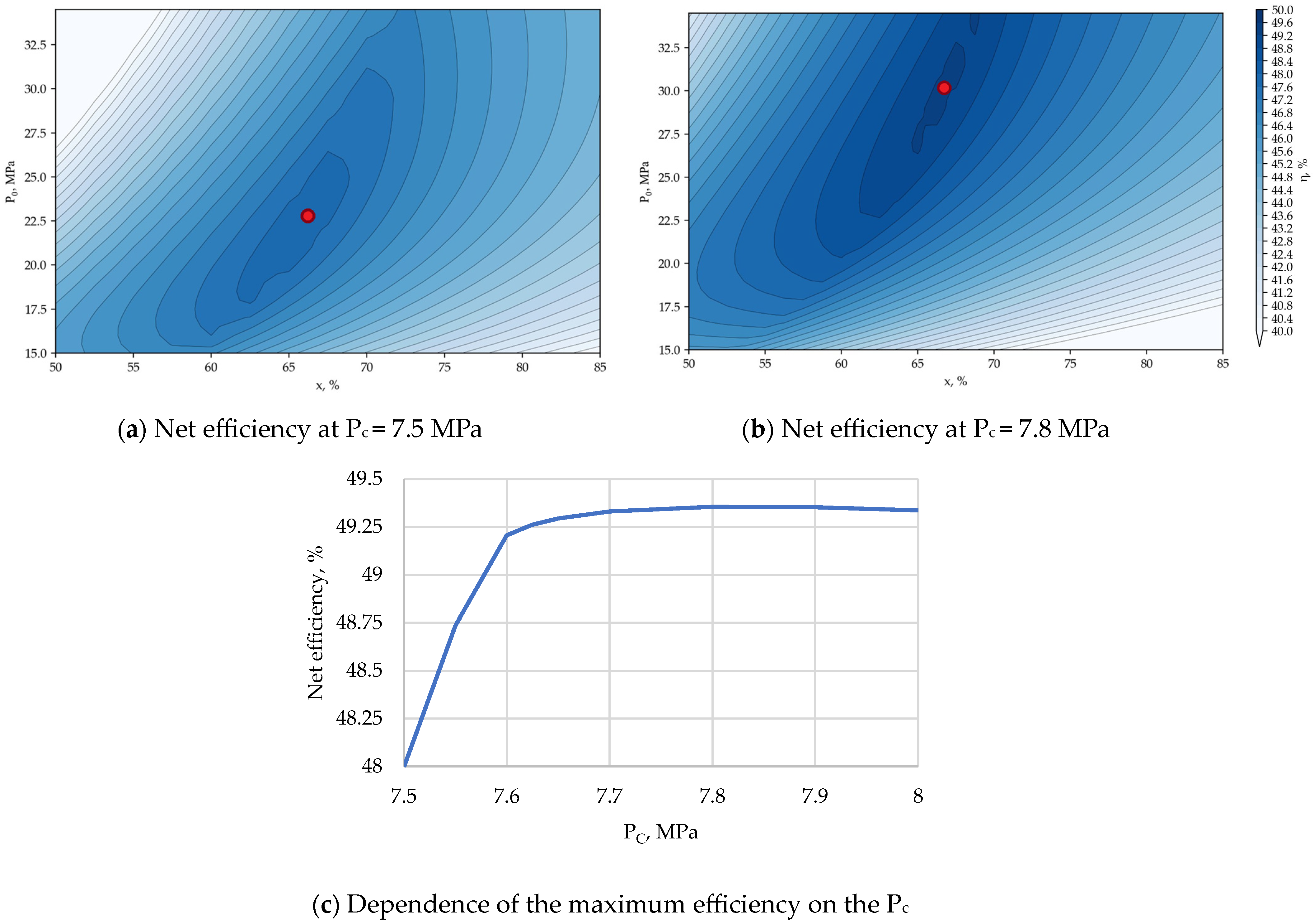

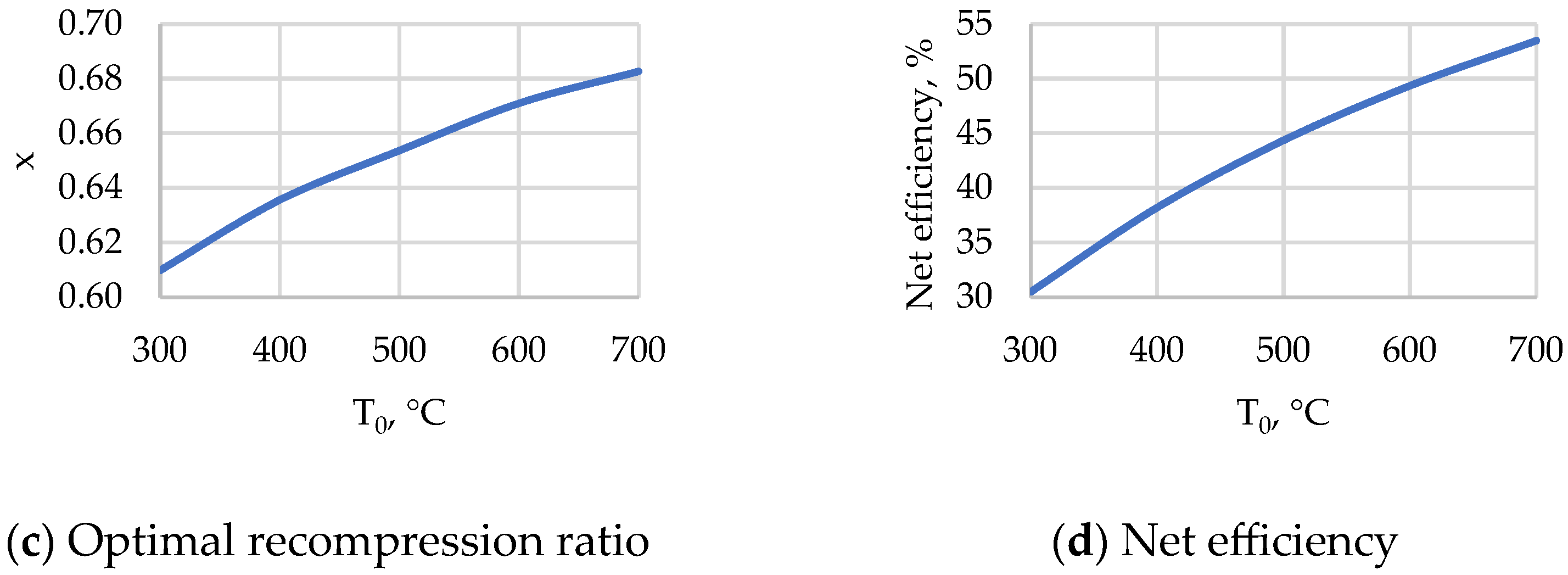

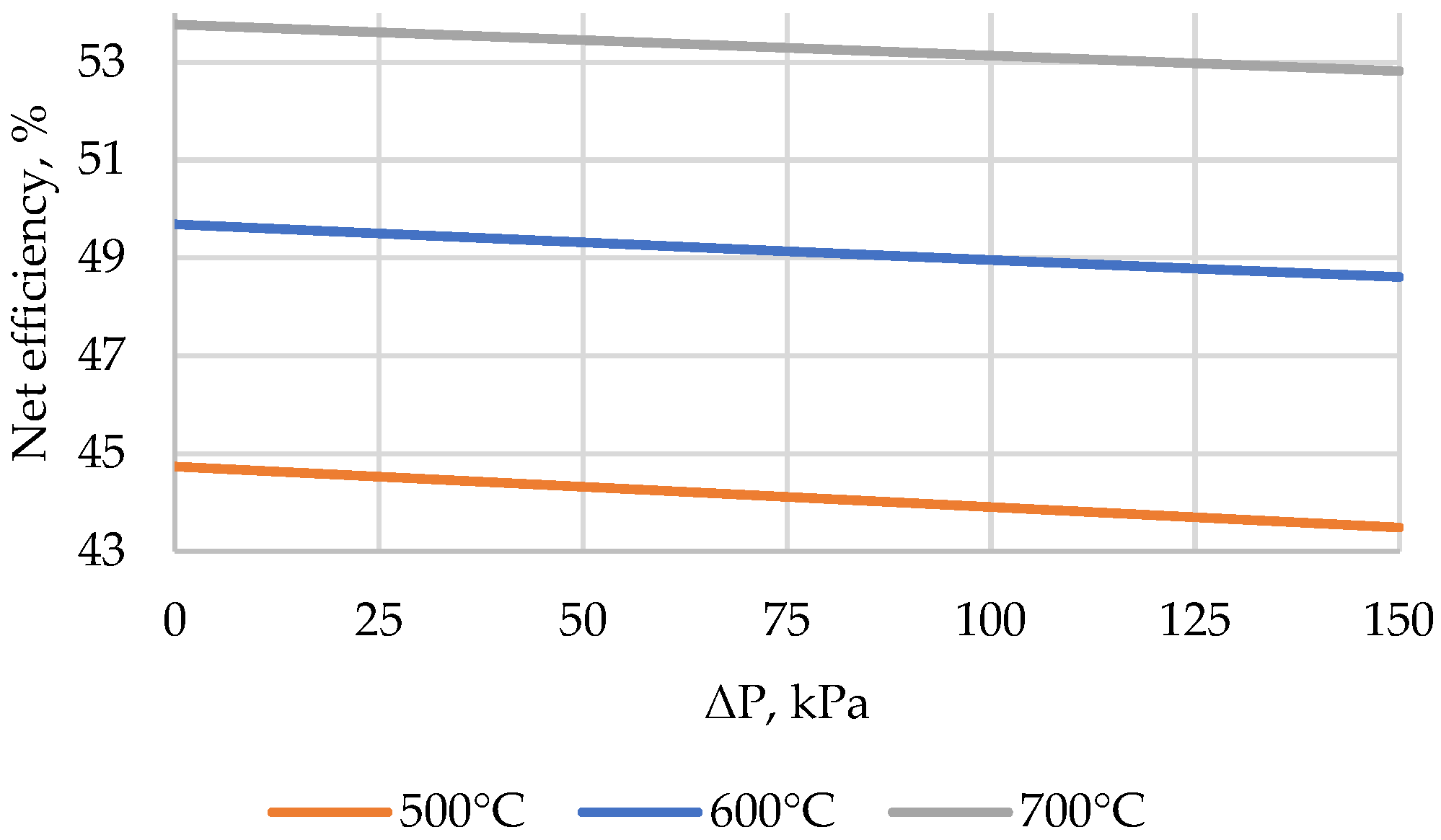

- For reactor plants with liquid metal and liquid salt coolants in the temperature range up to 550 °C, the highest net efficiency is achieved when using power cycles with a steam–water coolant. The level of initial parameters makes it possible to implement in such a cycle the superheating of live steam in front of the turbine as well as intermediate superheating between the high- and low-pressure cylinders. This ensures the net efficiency of such a cycle at the level of 41.5% at an initial temperature of 400 °C, 45.7% at 500 °C, and 48.2% at 600 °C. In this case, in the temperature range of 550–700 °C, the cycle using a carbon dioxide coolant can have the greatest efficiency. When using the Brayton recompression cycle with CO2, the efficiency of net electricity production reaches values from 46.6% (with a minimum temperature difference in heat exchangers of 20 °C) to 49.4% (with a difference of 5 °C) at 600 °C and 50.7–53.48% at 700 °C. Thus, at an initial temperature above 550 °C, it is promising to use carbon dioxide as a coolant for the power cycle. At the same time, these cycles have a high potential for increasing efficiency due to the utilization of low-temperature heat supplied to the cold source using organic Rankine cycles.

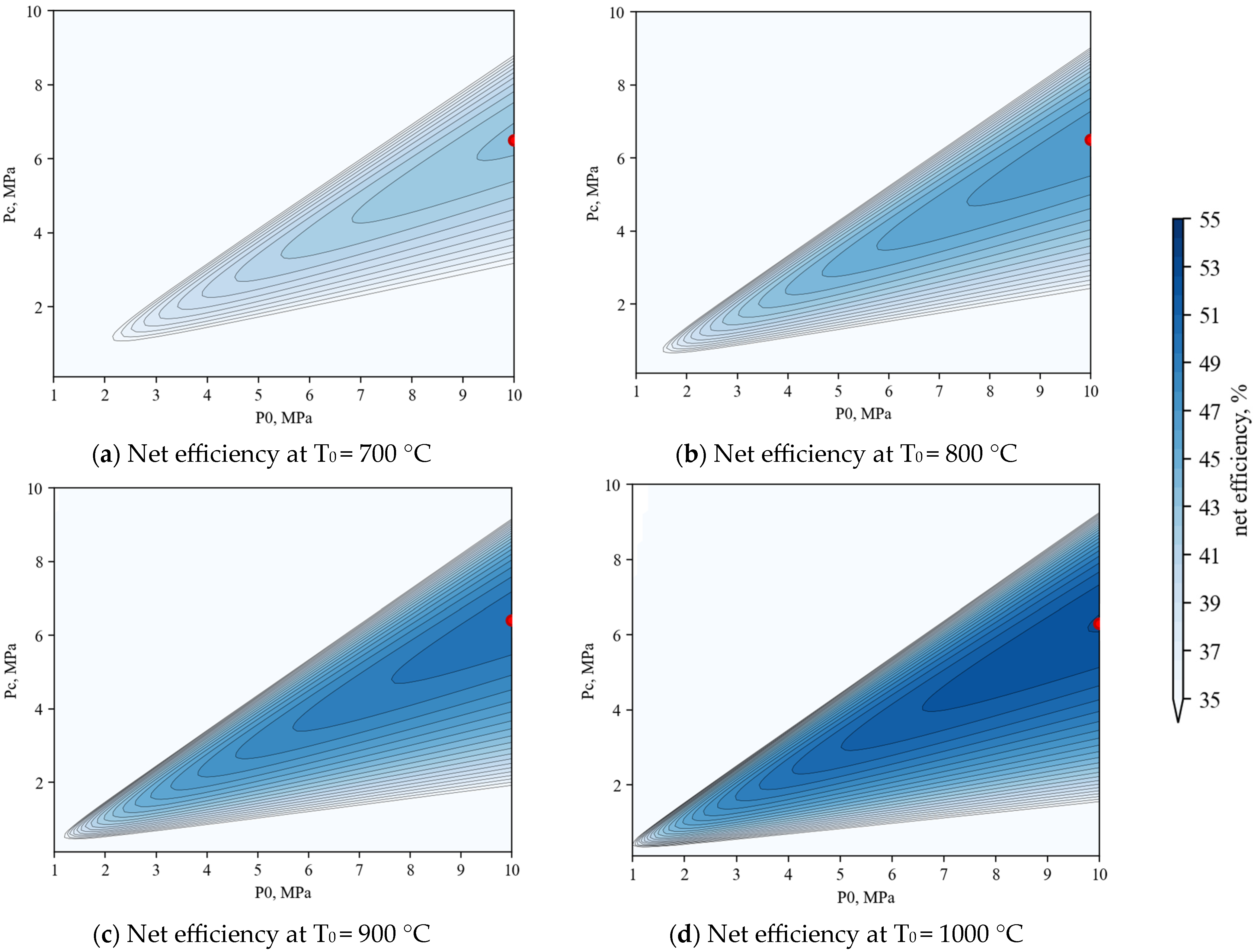

- For high-temperature, gas-cooled reactor plants, the use of a binary cycle consisting of a helium Brayton cycle and a steam–water Rankine cycle achieves a net efficiency of 44.3% at an initial helium temperature of 700 °C and 52.9% at 1000 °C. This is higher than in the Brayton cycle with a recuperator with a minimum temperature difference in the heat exchanger of 20 °C: the efficiency is 40.2% and 52%, respectively (the efficiency can be increased by reducing the temperature difference, but this will significantly increase the weight and dimensions of the heat exchanger).

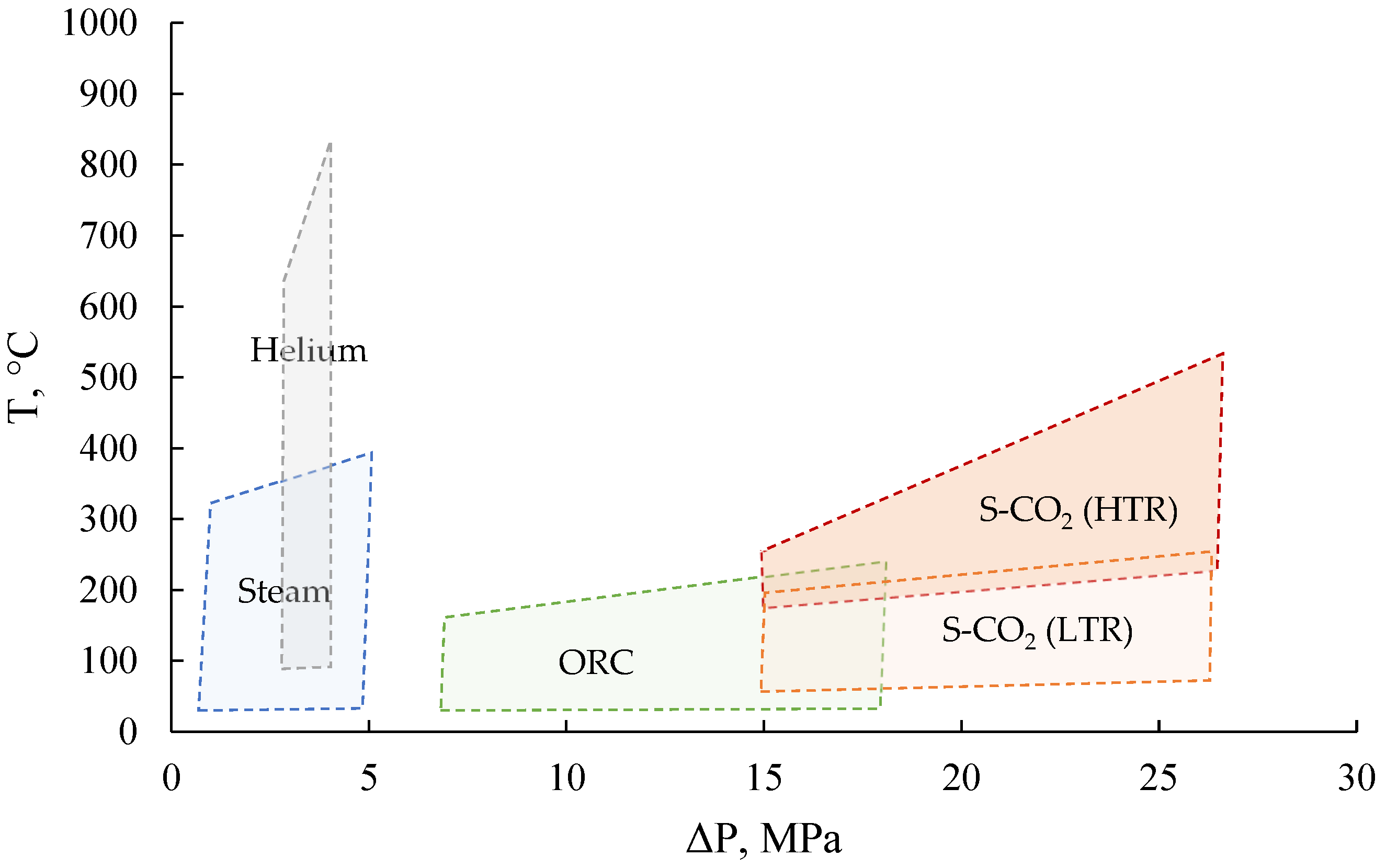

- Despite the thermodynamic efficiency of power cycles using non-traditional coolants, one of the key issues standing in the way of the implementation of such projects is the development of basic equipment (primarily turbomachines and heat exchangers). Thus, helium and carbon dioxide turbines, unlike steam turbines, operate with a lower degree of expansion of the working medium, due to which their dimensions are significantly smaller. In turn, heat exchange equipment operates at a significantly higher pressure difference between coolants (>7 MPa for ORC and >15 MPa for carbon dioxide cycle recuperators), and the requirements for the reliability of the heat recovery system in such cycles increase significantly.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kaundinya, D.P.; Balachandra, P.; Ravindranath, N.H. Grid-Connected versus Stand-Alone Energy Systems for Decentralized Power—A Review of Literature. Renew. Sustain. Energy Rev. 2009, 13, 2041–2050. [Google Scholar] [CrossRef]

- Alqahtani, B.J.; Patino-Echeverri, D. Identifying Economic and Clean Strategies to Provide Electricity in Remote Rural Areas: Main-Grid Extension vs. Distributed Electricity Generation. Energies 2023, 16, 958. [Google Scholar] [CrossRef]

- Arriaga, M.; Cañizares, C.A.; Kazerani, M. Northern Lights: Access to Electricity in Canada’s Northern and Remote Communi-ties. IEEE Power Energy Mag. 2014, 12, 50–59. [Google Scholar] [CrossRef]

- Boute, A. Off-Grid Renewable Energy in Remote Arctic Areas: An Analysis of the Russian Far East. Renew. Sustain. Energy Rev. 2016, 59, 1029–1037. [Google Scholar] [CrossRef]

- Rogalev, N.; Rogalev, A.; Kindra, V.; Zlyvko, O.; Osipov, S. An Overview of Small Nuclear Power Plants for Clean Energy Pro-duction: Comparative Analysis of Distributed Generation Technologies and Future Perspectives. Energies 2023, 16, 4899. [Google Scholar] [CrossRef]

- Petrunin, V.V. Reactor Units for Small Nuclear Power Plants. Her. Russ. Acad. Sci. 2021, 91, 335–346. [Google Scholar] [CrossRef]

- Ingersoll, D.T.; Carelli, M.D. Handbook of Small Modular Nuclear Reactors, 2nd ed.; Woodhead Publishing: Sawston, UK, 2020; ISBN 978-0-12-823917-9. [Google Scholar]

- Belyaev, V.M.; Bolshukhin, M.A.; Pakhomov, A.N.; Khizbullin, A.M.; Lepekhin, A.N.; Polunichev, V.I.; Veshnyakov, K.B.; Sokolov, A.N.; Turusov, A.Y. The Worlds First Floating NPP: Origination and Direction of Future Development. At. Energy 2020, 129, 27–34. [Google Scholar] [CrossRef]

- Wu, Z.; Lin, D.; Zhong, D. The Design Features of the HTR-10. Nucl. Eng. Des. 2002, 218, 25–32. [Google Scholar] [CrossRef]

- China’s Demonstration HTR-PM Enters Commercial Operation: New Nuclear—World Nuclear News. Available online: https://www.world-nuclear-news.org/Articles/Chinese-HTR-PM-Demo-begins-commercial-operation (accessed on 17 January 2024).

- Mitsubishi Heavy Industries, Ltd. Global Website|JAEA and MHI Commence Demonstration Program for Hydrogen Production Using a High Temperature Engineering Test Reactor—Project for Achieving Carbon Neutrality. Available online: https://www.mhi.com/news/220427.html (accessed on 5 September 2023).

- CAREM-25 (National Atomic Energy Commission Argentina). Passive Safety Systems in Advanced Small Modular Reactors; International Atomic Energy Agency (IAEA): Vienna, Austria, 2014; pp. 190–192. [Google Scholar]

- Penn, I.; Plumer, B. Nuclear Energy Project in Idaho Is Canceled. The New York Times 2023.

- Advances in Small Modular Reactor Technology Developments. 2022. Available online: https://aris.iaea.org/publications/smr_booklet_2022.pdf (accessed on 20 January 2024).

- Dostal, V.; Hejzlar, P.; Driscoll, M.J. The Supercritical Carbon Dioxide Power Cycle: Comparison to Other Advanced Power Cy-cles. Nucl. Technol. 2006, 154, 283–301. [Google Scholar] [CrossRef]

- Rogalev, N.; Rogalev, A.; Kindra, V.; Komarov, I.; Zlyvko, O. Structural and Parametric Optimization of S–CO2 Nuclear Power Plants. Entropy 2021, 23, 1079. [Google Scholar] [CrossRef] [PubMed]

- Ahn, Y.; Bae, S.J.; Kim, M.; Cho, S.K.; Baik, S.; Lee, J.I.; Cha, J.E. Review of Supercritical CO2 Power Cycle Technology and Current Status of Research and Development. Nucl. Eng. Technol. 2015, 47, 647–661. [Google Scholar] [CrossRef]

- Kissick, S.M.; Wang, H. A Comparative Study of Alternative Power Cycles for Small Modular Reactors. Energy Convers. Manag. 2021, 247, 114734. [Google Scholar] [CrossRef]

- Dostal, V.; Driscoll, M.J.; Hejzlar, P.; Todreas, N.E. A Supercritical CO2 Gas Turbine Power Cycle for Next-Generation Nuclear Reactors. In Proceedings of the International Conference on Nuclear Engineering, Arlington, VA, USA, 14–18 April 2002; pp. 567–574. [Google Scholar]

- Kindra, V.; Rogalev, N.; Rogalev, A.; Naumov, V.; Sabanova, E. Thermodynamic Optimization of Low-Temperature Cycles for the Power Industry. Energies 2022, 15, 2979. [Google Scholar] [CrossRef]

| Reactor | Type | Country | Status | Q, MW | N, MW | T0, °C |

|---|---|---|---|---|---|---|

| CAREM | PWR | Argentina | Under construction | 100 | 30 | 326 |

| ACP100 | PWR | China | Under construction | 385 | 125 | 319.5 |

| VOYGR | PWR | USA | Licensed (canceled) | 250 | 77 | 316 |

| KLT-40S | PWR | Russia | In operation | 150 | 35 | 316 |

| RITM-200N | PWR | Russia | Under construction | 175 | 50 | 318 |

| HTR-PM | HTGR | China | In operation | 250 | 105 | 750 |

| HTR-10 | HTGR | China | In operation | 10 | 2.5 | 700 |

| HTTR | HTGR | Japan | In operation | 30 | 0 | 850 |

| BREST-OD-300 | LMFR | Russia | Under construction | 700 | 300 | 535 |

| MARVEL | LMFR | USA | Final design | 0.1 | 0.027 | 548 |

| Parameter | Value |

|---|---|

| Minimum temperature difference in heat exchangers | 5 °C |

| Heat losses in heat exchangers | 1% |

| Mechanical, electric generator, and electric drive efficiencies | 99% |

| Isentropic efficiency of turbo machines and compressors | 90% |

| Isentropic efficiency of pumps | 85% |

| Minimum steam dryness factor at turbine outlet | 90% |

| Pressure loss at the gas side of heat exchangers | 50 kPa |

| Temperature at the cold source of the cycle | 30 °C (32 °C for S-CO2) |

| Type | Coolant | Temperature Range | Power Cycles |

|---|---|---|---|

| PWR | Water | up to 350 °C | ORC Steam Rankine (without superheat) |

| LMFR | Liquid metals (Na/Pb) | 500–650 °C | Steam Rankine (with superheat) S-CO2 recomp. |

| MSR | Molten salts | 650–800 °C | Steam Rankine (with superheat) S-CO2 recomp. |

| HTGR | Helium | 700–1000 °C | Helium Brayton Helium–steam binary cycle |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kindra, V.; Maksimov, I.; Zlyvko, O.; Rogalev, A.; Rogalev, N. Thermodynamic Analysis and Comparison of Power Cycles for Small Modular Reactors. Energies 2024, 17, 1650. https://doi.org/10.3390/en17071650

Kindra V, Maksimov I, Zlyvko O, Rogalev A, Rogalev N. Thermodynamic Analysis and Comparison of Power Cycles for Small Modular Reactors. Energies. 2024; 17(7):1650. https://doi.org/10.3390/en17071650

Chicago/Turabian StyleKindra, Vladimir, Igor Maksimov, Olga Zlyvko, Andrey Rogalev, and Nikolay Rogalev. 2024. "Thermodynamic Analysis and Comparison of Power Cycles for Small Modular Reactors" Energies 17, no. 7: 1650. https://doi.org/10.3390/en17071650

APA StyleKindra, V., Maksimov, I., Zlyvko, O., Rogalev, A., & Rogalev, N. (2024). Thermodynamic Analysis and Comparison of Power Cycles for Small Modular Reactors. Energies, 17(7), 1650. https://doi.org/10.3390/en17071650