Research on the Accounting and Prediction of Carbon Emission from Wave Energy Convertor Based on the Whole Lifecycle

Abstract

1. Introduction

2. Research Objectives and Scope

2.1. Research Objectives

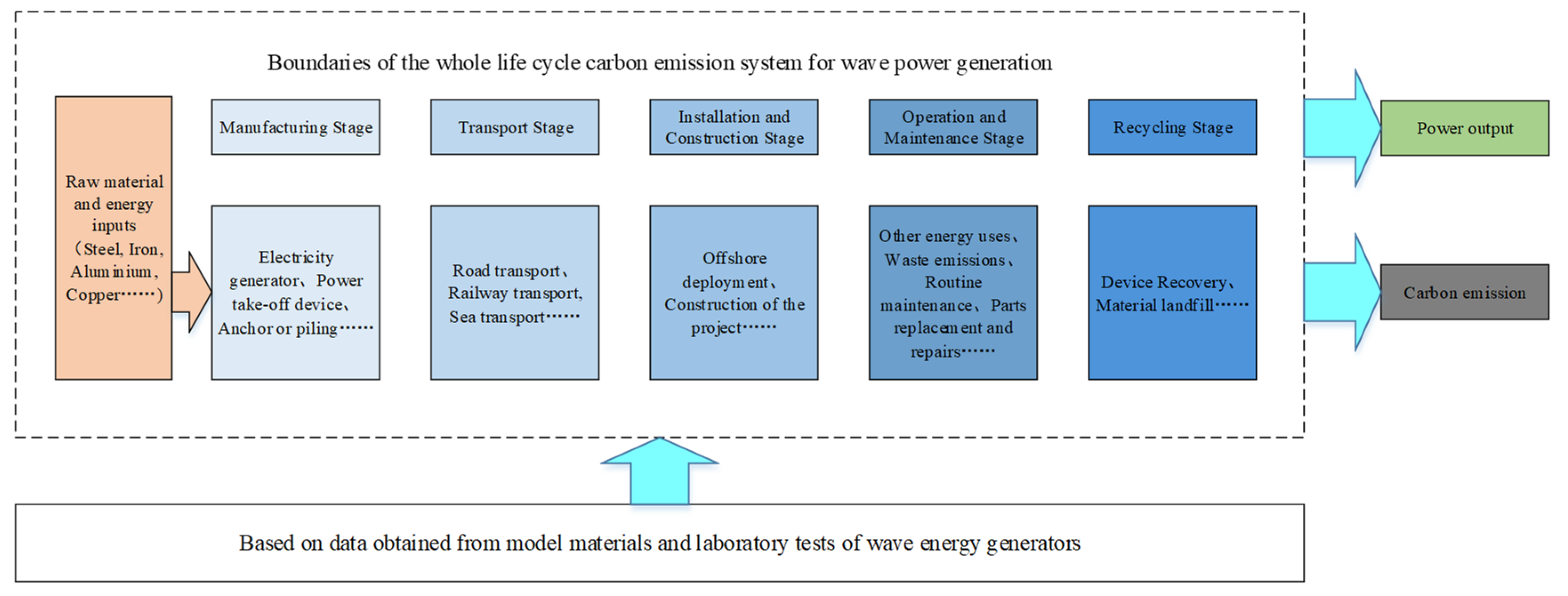

2.2. System Boundary

3. Research Methods

3.1. Similarity Criteria

3.2. Assumptions

- (1)

- A Froude similarity criteria scale factor of 3 (λ = 3).

- (2)

- Similar manufacturing materials for both the wave energy convertor model and the actual sea-deployed wave energy convertor, with both constructed from steel.

- (3)

- Consistent conversion efficiency is achieved when the wave energy convertor model is proportionally enlarged.

- (4)

- Wave energy convertor using an anchor-fixed floating method, with the anchor made of steel.

- (5)

- A 20-year lifespan for the wave energy convertor, with consistent conversion efficiency during operation.

- (6)

- According to the requirements of IEC/TS 62600-102:2016 Marine energy—Wave, tidal, and other water current converters—Part 102: Wave energy converter power performance assessment at a second location using measured assessment data, the wave energy convertor operates for 8766 h annually [24].

3.3. Research Objects and Data Sources

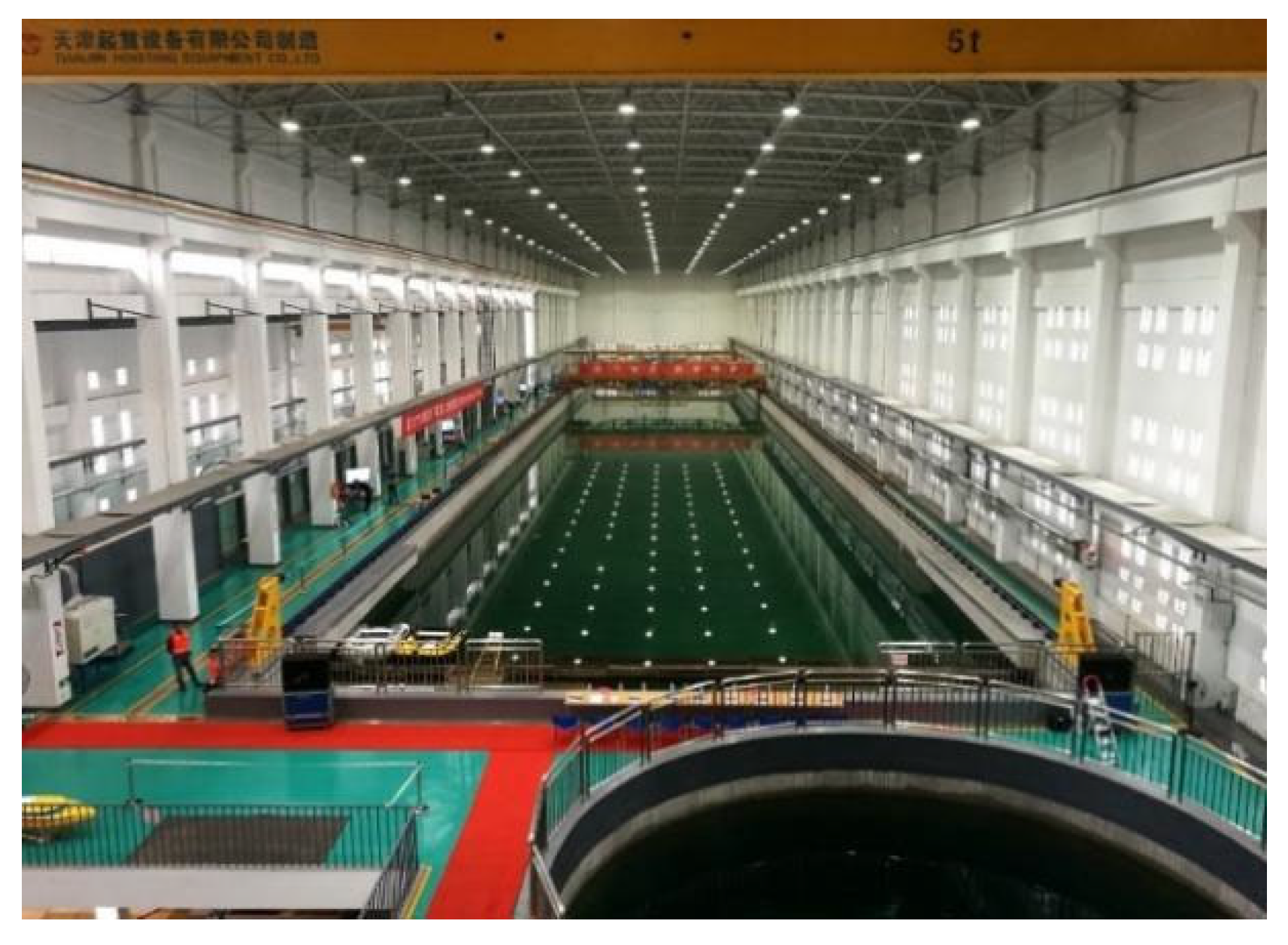

3.3.1. Research Object

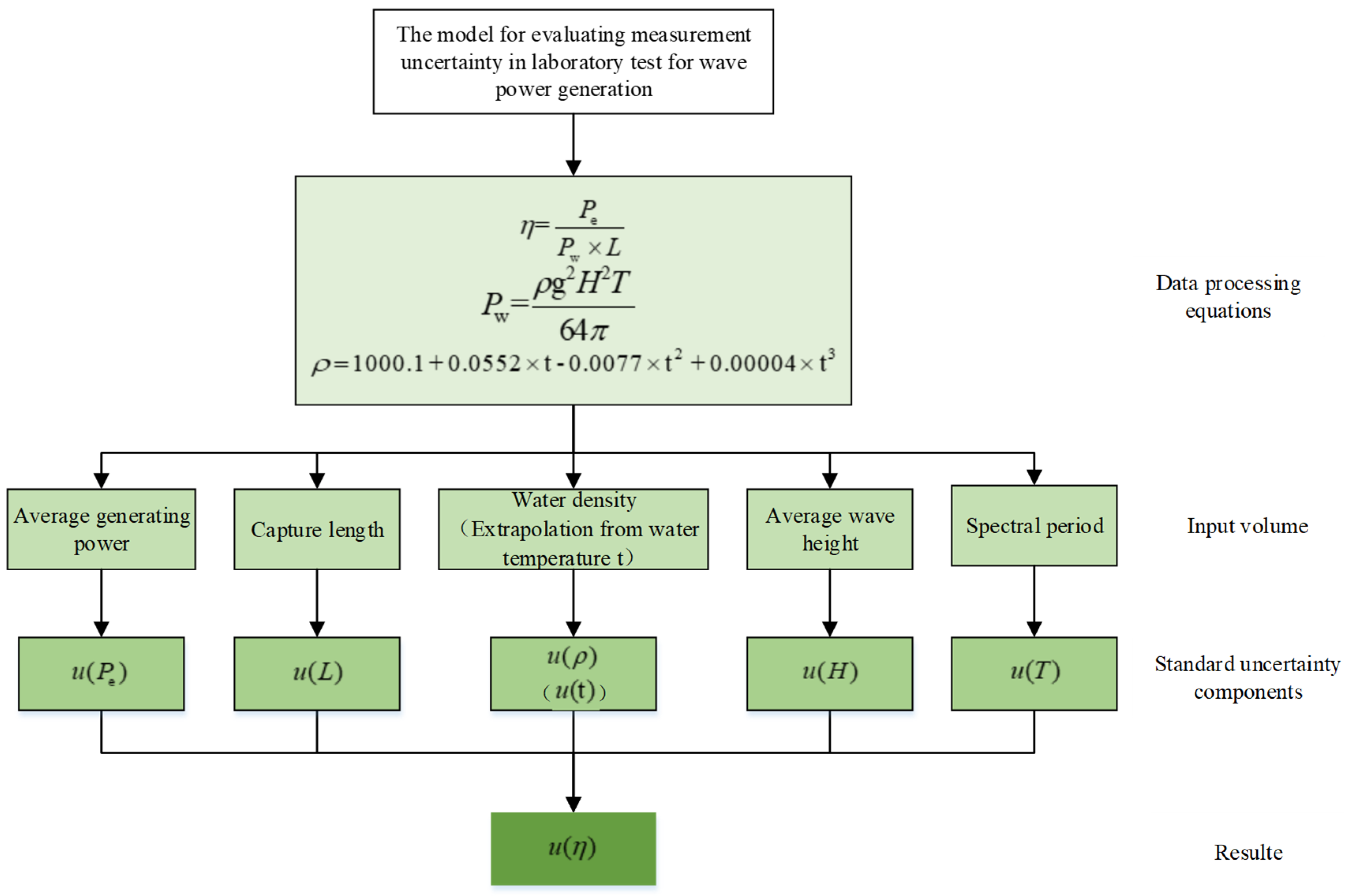

3.3.2. Measurement Uncertainty of Experimental Results

3.3.3. Data Sources

4. Life Cycle Inventory Analysis

4.1. Manufacturing Stage

4.2. Transport Stage

- (1)

- From the land-based manufacturer to the port for storage and debugging (if the device material is entirely produced within China) or from the manufacturer to the port via ship (if the device material is produced outside China);

- (2)

- From the port to the target offshore area.

4.3. Installation and Construction Stage

4.4. Operation and Maintenance Stage

4.5. Recycling Stage

5. Life Cycle Impact Assessment

5.1. Total Carbon Dioxide Emission Indicator (Econ)

5.2. Carbon Emission Factor per Unit of Power Generated ()

5.3. Carbon Payback Time (CPT)

5.4. Life Cycle Carbon Emissions Reduction (Ered)

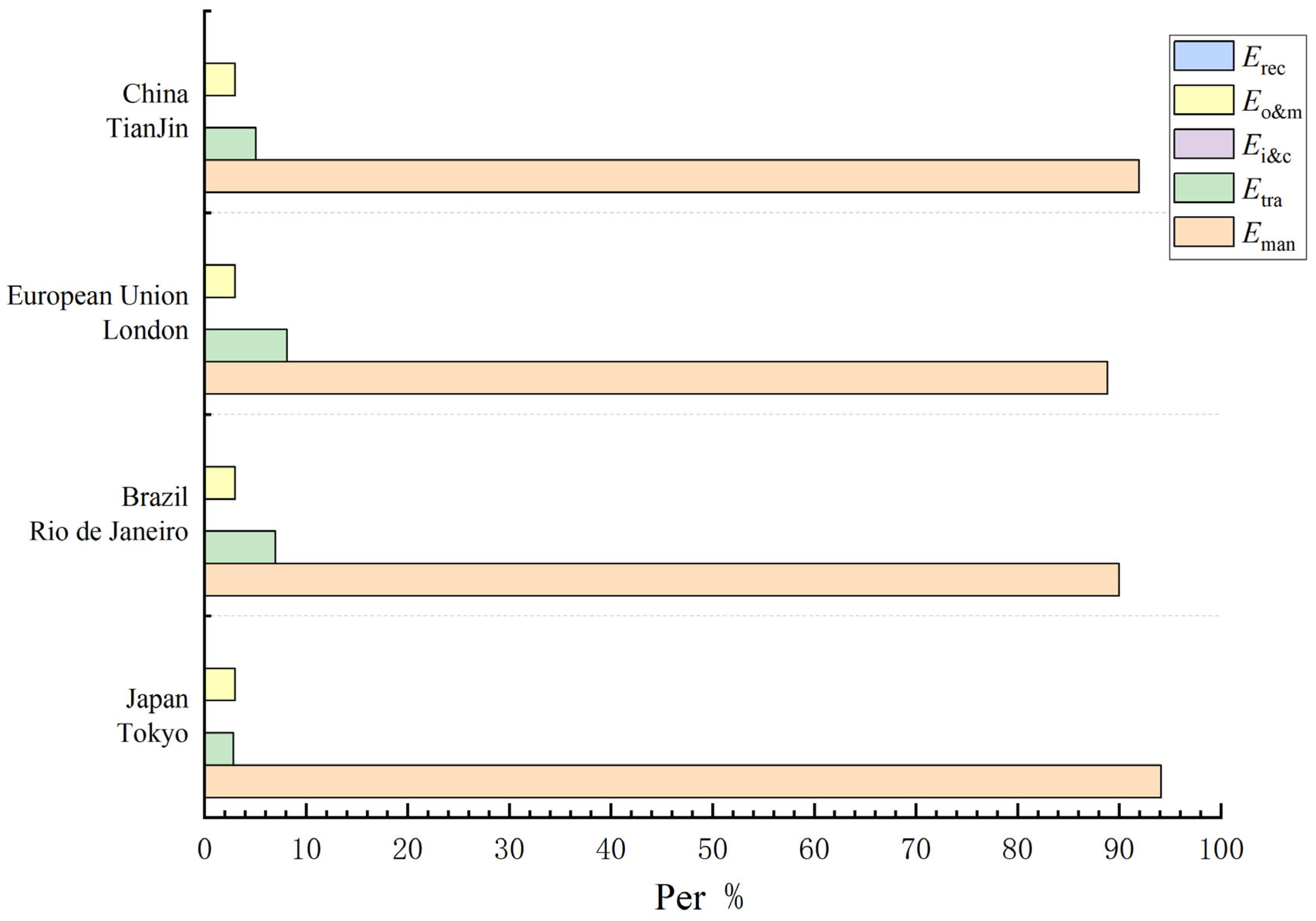

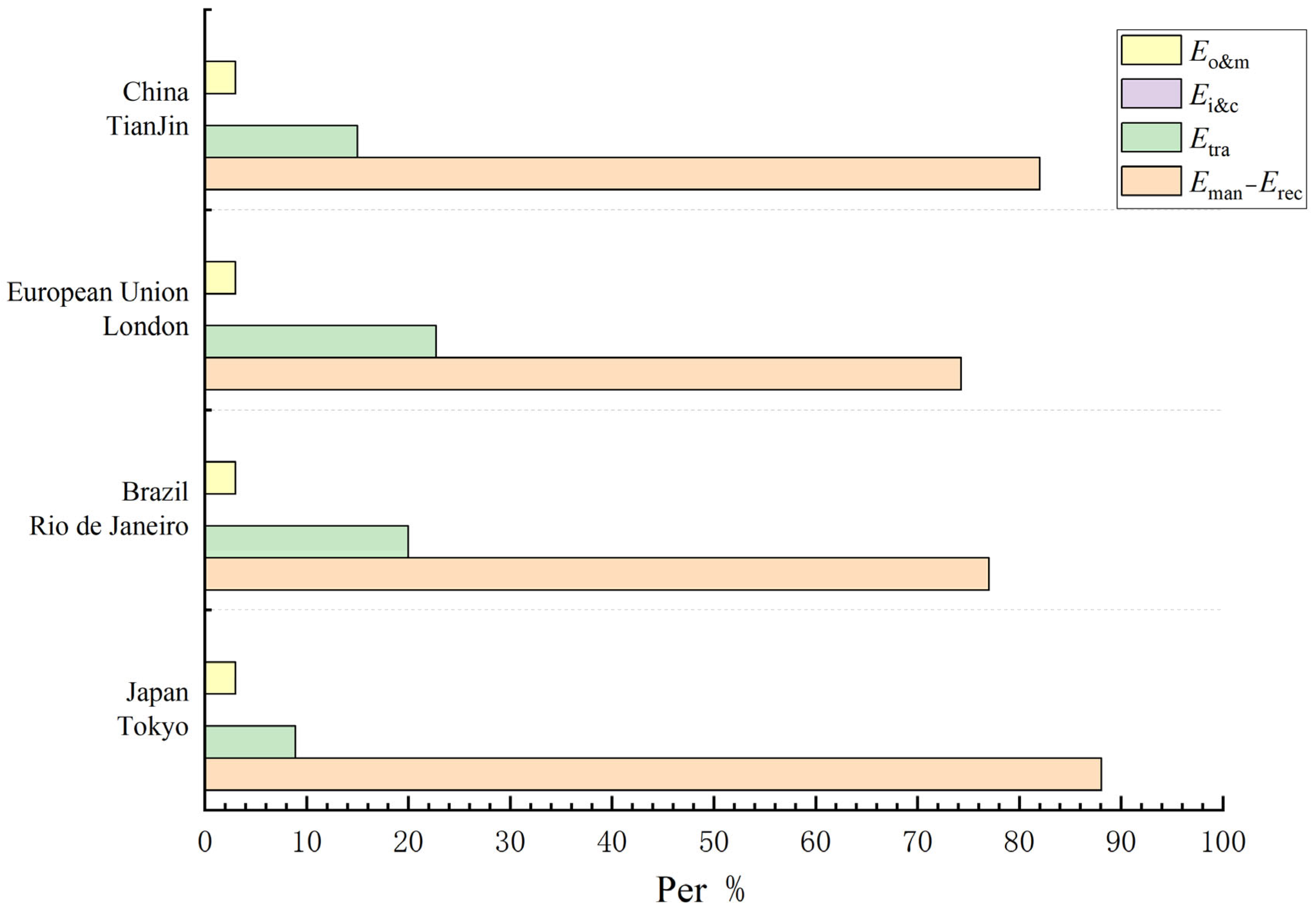

5.5. Analysis and Discussion

6. Conclusions

- (1)

- The major contributors to the carbon emissions over the full life cycle of the wave energy convertor are the manufacturing and transport stages. Without considering metal material recycling, carbon emissions predominantly arise from the manufacturing stage. While considering metal material recycling, the carbon emissions in the manufacturing stages are reduced, but they are still the main source of carbon emissions. Due to variations in steel production processes and transportation distances among different countries, there is a significant difference in total carbon emissions during the manufacturing and transport stages, ranging from 2.2 to 2.5 times between the highest and lowest emissions.

- (2)

- According to the carbon emission model prediction research of the wave energy convertor proposed in this study, when accounting for metal material recycling, the carbon emission coefficient for unit electricity generation () ranges from 0.008 kg CO2/kWh to 0.059 kg CO2/kWh. Because the use of electricity in steel production in Japan is higher than that in other countries, the lowest is 0.008 kg CO2/kWh. When the traditional steel production mode is adopted, the in this paper is 0.014–0.059 kg CO2/kWh. This is in close proximity to the Emission factor of CO2 for wave energy convertor provided in [38] (0.012 kg CO2/kWh to 0.050 kg CO2/kWh), validating the alignment between the proposed carbon emission model and actual operational data for wave energy convertor.

- (3)

- The lifespan of the wave energy convertor significantly impacts full life-cycle carbon emissions. Considering metal material recycling, the Carbon Payback Time ranges from 0.28 to 0.72 years, and the highest carbon reduction within its lifespan (20 years) can reach 261.80 t CO2. Without considering metal material recycling, the Carbon Payback Time ranges from 0.90 to 2.06 years, and the highest carbon reduction within its lifespan (20 years) can reach 253.72 t CO2. As the lifespan of the wave energy convertor increases, the carbon reduction potential will further rise.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Energy Agency. IEA World Energy Statistics 2018; International Energy Agency: Paris, France, 2018; ISBN 978-92-64-30126-9. [Google Scholar]

- Cascajo, R.; García, E.; Quiles, E.; Correcher, A.; Morant, F. Integration of Marine Wave Energy Converters into Seaports: A Case Study in the Port of Valencia. Energies 2019, 12, 787. [Google Scholar] [CrossRef]

- Wang, X.; Xia, H.; Guo, Y.; Duan, Y.; Wang, M.; Liu, Y.; Si, H. Research on Field Testing and Assessment Technology of Ocean Energy Converters. Ocean Eng. 2023, 285, 115539. [Google Scholar] [CrossRef]

- Sun, P.; Wang, J. Long-Term Variability Analysis of Wave Energy Resources and Its Impact on Wave Energy Converters along the Chinese Coastline. Energy 2024, 288, 129644. [Google Scholar] [CrossRef]

- Mørk, G.; Barstow, S.; Kabuth, A.; Pontes, M.T. Assessing the Global Wave Energy Potential. In Proceedings of the 29th International Conference on Ocean, Offshore and Arctic Engineering, Shanghai, China, 6–11 June 2010; ASMEDC: Shanghai, China, 2010; Volume 3, pp. 447–454. [Google Scholar]

- Liu, Y.; Huang, M.; Peng, A. Research progress on electrical conversion and control of oscillating water column wave energy converter. Acta Energiae Solaris Sin. 2023, 1–12. [Google Scholar] [CrossRef]

- Neill, S.P.; Angeloudis, A.; Robins, P.E.; Walkington, I.; Ward, S.L.; Masters, I.; Lewis, M.J.; Piano, M.; Avdis, A.; Piggott, M.D.; et al. Tidal Range Energy Resource and Optimization—Past Perspectives and Future Challenges. Renew. Energy 2018, 127, 763–778. [Google Scholar] [CrossRef]

- Kev, K.; Modi, N.; Milani, D.; Luu, M.T.; Nelson, S.; Abdul Manaf, N.; Wang, X.; Negnevitsky, M.; Abbas, A. A Comparative Life Cycle Impact Assessment for Solar Heat Integration in Post-Combustion Carbon Capture. Energy Convers. Manag. 2023, 297, 117745. [Google Scholar] [CrossRef]

- Nian, V.; Chou, S.K.; Su, B.; Bauly, J. Life Cycle Analysis on Carbon Emissions from Power Generation—The Nuclear Energy Example. Appl. Energy 2014, 118, 68–82. [Google Scholar] [CrossRef]

- Nian, V. Change Impact Analysis on the Life Cycle Carbon Emissions of Energy Systems—The Nuclear Example. Appl. Energy 2015, 143, 437–450. [Google Scholar] [CrossRef]

- Mostafaei, H.; Keshavarz, Z.; Rostampour, M.A.; Mostofinejad, D.; Wu, C. Sustainability Evaluation of a Concrete Gravity Dam: Life Cycle Assessment, Carbon Footprint Analysis, and Life Cycle Costing. Structures 2023, 53, 279–295. [Google Scholar] [CrossRef]

- Verma, S.; Paul, A.R.; Haque, N. Selected Environmental Impact Indicators Assessment of Wind Energy in India Using a Life Cycle Assessment. Energies 2022, 15, 3944. [Google Scholar] [CrossRef]

- Kaldellis, J.K.; Apostolou, D. Life Cycle Energy and Carbon Footprint of Offshore Wind Energy. Comparison with Onshore Counterpart. Renew. Energy 2017, 108, 72–84. [Google Scholar] [CrossRef]

- Schreiber, A.; Marx, J.; Zapp, P. Comparative Life Cycle Assessment of Electricity Generation by Different Wind Turbine Types. J. Clean. Prod. 2019, 233, 561–572. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; He, Y.; Li, M.; Wang, X.; Wang, B.; Zhu, Y.; Cen, K. Comparison of Onshore/Offshore Wind Power Hydrogen Production through Water Electrolysis by Life Cycle Assessment. Sustain. Energy Technol. Assess. 2023, 60, 103515. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, T. Life Cycle Assessment of CO2 Emissions from Wind Power Plants: Methodology and Case Studies. Renew. Energy 2012, 43, 30–36. [Google Scholar] [CrossRef]

- Sun, Z.; You, X. Life Cycle Carbon Footprint Accounting of an Offshore Wind Farm in Southeast China—Simplified Models and Carbon Benchmarks for Typhoons. Appl. Energy 2024, 355, 122267. [Google Scholar] [CrossRef]

- Ogunjuyigbe, A.S.O.; Ayodele, T.R.; Akinola, O.A. Optimal Allocation and Sizing of PV/Wind/Split-Diesel/Battery Hybrid Energy System for Minimizing Life Cycle Cost, Carbon Emission and Dump Energy of Remote Residential Building. Appl. Energy 2016, 171, 153–171. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, H.; Meng, J.; Long, Y.; Zhou, X.; Li, Z.; Wang, Y.; Liang, Y. Carbon Footprint in Building Distributed Energy System: An Optimization-Based Feasibility Analysis for Potential Emission Reduction. J. Clean. Prod. 2019, 239, 117990. [Google Scholar] [CrossRef]

- Liu, C.; Wang, H.; Wang, Z.; Liu, Z.; Tang, Y.; Yang, S. Research on Life Cycle Low Carbon Optimization Method of Multi-Energy Complementary Distributed Energy System: A Review. J. Clean. Prod. 2022, 336, 130380. [Google Scholar] [CrossRef]

- Liu, Y.; Feng, D.; Deng, S.; Liu, S.; Zhu, Y. Motion Similarity of an Underwater Glider Based on Scaled Model. J. Tianjin Univ. (Sci. Technol.) 2023, 56, 119–126. [Google Scholar]

- Qiao, D.; Zhi, G.; Liang, H.; Ning, D.; Yan, J.; Li, B. Scaling Orchestration in Physical Model Test of Oscillating Buoy Wave Energy Converter. Front. Mar. Sci. 2021, 8, 627453. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, S.; Wang, D.; Wang, R. Research progress of ocean wave energy converters. J. Shandong Univ. (Eng. Sci.) 2021, 51, 63–75. [Google Scholar]

- IEC/TS 62600-102:2016; Marine energy-Wave, tidal and other water current converters-Part 102: Wave energy converter power performance assessment at a second location using measured assessment data. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2016.

- Sheng, S.; Zhang, Y.; You, Y.; Jiang, J.; Wang, K.; Wang, Z. Testing and analysis of wave energy resources in Dawanshan energy demonstration field. Acta Energiae Solaris Sin. 2019, 40, 462–465. [Google Scholar]

- Wu, R.; Chen, Y.; Peng, Z.; Xue, M.; Li, M.; Wu, B. Influence of circuit on power generation performance of wave energy power generation device using oscillating water column technology. Acta Energiae Solaris Sin. 2022, 43, 410–415. [Google Scholar] [CrossRef]

- Shi, S.; Zhen, Y. Uncertainty analysis of submarine scale-mode drag test. J. Exp. Fluid Mech. 2015, 29, 65–71. [Google Scholar]

- Gao, C.; Niu, J.; Wang, F. Review of Carbon Emission Accounting Methods and Carbon Emission Factor in Steel Production. Contemp. Econ. Manag. 2021, 43, 33–38. [Google Scholar] [CrossRef]

- IPCC. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- Leão, A.S.; Medeiros, D.L.; Santiago, M.A.; Do Carmo Tavares, A.O.; Maranduba, H.L.; Almeida, E.D.S. Rigorous Environmental and Energy Life Cycle Assessment of Blast Furnace Pig Iron in Brazil: The Role of Carbon and Iron Sources, and Co-Product Utilization. Sustain. Mater. Technol. 2023, 36, e00607. [Google Scholar] [CrossRef]

- Honma, S.; Ushifusa, Y.; Okamura, S.; Vandercamme, L. Measuring Carbon Emissions Performance of Japan’s Metal Industry: Energy Inputs, Agglomeration, and the Potential for Green Recovery Reduction. Resour. Policy 2023, 82, 103519. [Google Scholar] [CrossRef]

- Peng, M.; Li, J.; Hu, H. Research on Fuel Consumption & Carbon Emission Factor of Road Freight Trucks. Automot. Technol. 2015, 4, 37–40. [Google Scholar]

- Wu, X.; Mao, B.; Zhou, Q.; Huang, J.; Tong, R. Comparative of Carbon Emission Factor Levels in Different Modes of Transportation Industry. J. East China Jiaotong Univ. 2022, 39, 41–47. [Google Scholar] [CrossRef]

- Wu, X.; Li, Z.; Tang, X.; Mi, C.; Chen, Y. Research on Technical Path of Carbon Footprint Accounting for Hydropower Projects. Environ. Impact Assess. 2023, 45, 59–63. [Google Scholar] [CrossRef]

- Davidsson, S.; Höök, M.; Wall, G. A Review of Life Cycle Assessments on Wind Energy Systems. Int. J. Life Cycle Assess. 2012, 17, 729–742. [Google Scholar] [CrossRef]

- Kabir, M.R.; Rooke, B.; Dassanayake, G.D.M.; Fleck, B.A. Comparative Life Cycle Energy, Emission, and Economic Analysis of 100 kW Nameplate Wind Power Generation. Renew. Energy 2012, 37, 133–141. [Google Scholar] [CrossRef]

- Brussa, G.; Grosso, M.; Rigamonti, L. Life Cycle Assessment of a Floating Offshore Wind Farm in Italy. Sustain. Prod. Consum. 2023, 39, 134–144. [Google Scholar] [CrossRef]

- Nassar, Y.F.; El-Khozondar, H.J.; El-Osta, W.; Mohammed, S.; Elnaggar, M.; Khaleel, M.; Ahmed, A.; Alsharif, A. Carbon Footprint and Energy Life Cycle Assessment of Wind Energy Industry in Libya. Energy Convers. Manag. 2024, 300, 117846. [Google Scholar] [CrossRef]

- Bonou, A.; Laurent, A.; Olsen, S.I. Life Cycle Assessment of Onshore and Offshore Wind Energy-from Theory to Application. Appl. Energy 2016, 180, 327–337. [Google Scholar] [CrossRef]

- Xiang, N.; Wang, L.; Qu, Q.; Xiong, C.; Wang, B. Comparison of emissions from offshore and onshore wind power systems based on life cycle assessment. Resour. Sci. 2021, 43, 745–755. [Google Scholar]

- Ministry of Ecology and Environment of the People’s Republic of China. The Notice on Doing a Good Job in the Management of Greenhouse Gas Emission Reports for Enterprises in the Power Generation Industry from 2023 to 2025; Ministry of Ecology and Environment of the People’s Republic of China: Beijing, China, 2023. [Google Scholar]

- Ocean Harvesting. WECHULL+ Project to Develop Novel Floating Structures Based on High-Performance Concrete and Ocean Harvesting’s Buoy Design. Ocean Harvest. Technol. 2023. Available online: https://oceanharvesting.com/2023/12/19/wechull-project-to-develop-novel-floating-structures-based-on-high-performance-concrete-and-ocean-harvestings-buoy-design/ (accessed on 15 February 2024).

- Yu, X.; Ai, T.; Wang, K. Application of Nanogenerators in Acoustics Based on Artificial Intelligence and Machine Learning. APL Mater. 2024, 12, 020602. [Google Scholar] [CrossRef]

- Yu, X.; Shang, Y.; Zheng, L.; Wang, K. Application of Nanogenerators in the Field of Acoustics. ACS Appl. Electron. Mater. 2023, 5, 5240–5248. [Google Scholar] [CrossRef]

- Gao, J.; Yang, D.; Wang, S.; Li, Z.; Wang, L.; Wang, K. State of Health Estimation of Lithium-Ion Batteries Based on Mixers-Bidirectional Temporal Convolutional Neural Network. J. Energy Storage 2023, 73, 109248. [Google Scholar] [CrossRef]

| Parameter | Scale Factor |

|---|---|

| Length | λ |

| Area | λ2 |

| Volume | λ3 |

| Time | λ0.5 |

| Scale Factor | Wave Energy Convertor Model Parameters | Intended Sea-Deployed Wave Energy Convertor Parameters | |

|---|---|---|---|

| Device Size | λ = 3 | 4.0 m × 1.8 m × 1.8 m | 12 m × 5.4 m × 5.4 m |

| Wave-Facing Width | λ = 3 | 1.83 m | 5.49 m |

| Device Weight | λ3 = 8 | 1300 kg | 10,400 kg |

| No. | Wave Energy Convertor Indoor Experiment Parameters | Intended Deployment Area Wave Parameters | Conversion Efficiency (%) | ||

|---|---|---|---|---|---|

| Effective Wave Height (m) | Significant Wave Period (s) | Effective Wave Height λ = 3 | Significant Wave Period λ0.5 = 1.732 | ||

| 1 | 0.217 | 2.30 | 0.651 | 3.9836 | 20.02 |

| 2 | 0.220 | 2.30 | 0.660 | 3.9836 | 19.34 |

| 3 | 0.219 | 2.40 | 0.657 | 4.1568 | 22.80 |

| 4 | 0.220 | 2.40 | 0.660 | 4.1568 | 23.34 |

| 5 | 0.226 | 2.45 | 0.678 | 4.2434 | 25.16 |

| 6 | 0.227 | 2.45 | 0.681 | 4.2434 | 25.79 |

| 7 | 0.218 | 2.50 | 0.654 | 4.3300 | 21.93 |

| 8 | 0.219 | 2.50 | 0.657 | 4.3300 | 21.72 |

| 9 | 0.227 | 2.70 | 0.681 | 4.6764 | 19.00 |

| Country or Region | Carbon Emission Factor for Steel Production (tCO2/t) | Weight of the Wave Energy Convertor (t) | CO2 Emissions (t) |

|---|---|---|---|

| China | 1.970 | 12.4 | 24.43 |

| European Union | 1.328 | 12.4 | 16.47 |

| Brazil | 1.980 | 12.4 | 24.56 |

| Japan | 0.903 | 12.4 | 11.20 |

| Port of Loading | Port of Destination (Qianshan/Zhuhai) | Deployment Sea Area (Dawanshan) | The Total of CO2 Emissions (t) | ||||

|---|---|---|---|---|---|---|---|

| Distance (km) | CO2 Emissions (t) | Water Transport Carbon Emission Factor (kg/t·km) | Distance of Water Transport (km) | Weight (t) | CO2 Emissions (t) | ||

| China, Tianjin | 2230 | 1.33 | 0.008 | 50 | 12.4 | 0.01 | 1.34 |

| European Union, London | 17,941 | 1.50 | 0.008 | 50 | 12.4 | 0.01 | 1.51 |

| Brazil, Rio de Janeiro | 18,673 | 1.90 | 0.008 | 50 | 12.4 | 0.01 | 1.91 |

| Japan, Tokyo | 2975 | 0.33 | 0.008 | 50 | 12.4 | 0.01 | 0.34 |

| Country and Region | Eman (tCO2) | Etra (tCO2) | Ei&c (tCO2) | Eo&m (tCO2) | Erec (tCO2) | Econ (tCO2) | Epow (kWh) | (kg CO2/kWh) | CPT (year) | Ered (tCO2) |

|---|---|---|---|---|---|---|---|---|---|---|

| China, TianJin | 24.43 | 1.34 | 0 | Econ × 3% | 0 | 26.56 | 4.66 × 105 | 0.057 | 2.00 | 239.05 |

| European Union, London | 16.47 | 1.51 | 0 | Econ × 3% | 0 | 18.53 | 4.66 × 105 | 0.040 | 1.40 | 247.08 |

| Brazil, Rio de Janeiro | 24.56 | 1.91 | 0 | Econ × 3% | 0 | 27.29 | 4.66 × 105 | 0.059 | 2.06 | 238.33 |

| Japan, Tokyo | 11.20 | 0.34 | 0 | Econ × 3% | 0 | 11.90 | 4.66 × 105 | 0.026 | 0.90 | 253.72 |

| Country and Region | Eman (tCO2) | Etra (tCO2) | Ei&c (tCO2) | Eo&m (tCO2) | Erec (30%Eman) | Econ (tCO2) | Epow (kWh) | (kg CO2/kWh) | CPT (year) | Ered (tCO2) |

|---|---|---|---|---|---|---|---|---|---|---|

| China, TianJin | 24.43 | 1.34 | 0 | Econ × 3% | −17.10 | 8.94 | 4.66 × 105 | 0.019 | 0.67 | 256.68 |

| European Union, London | 16.47 | 1.51 | 0 | Econ × 3% | −11.53 | 6.65 | 4.66 × 105 | 0.014 | 0.50 | 258.97 |

| Brazil, Rio de Janeiro | 24.56 | 1.91 | 0 | Econ × 3% | −17.20 | 9.56 | 4.66 × 105 | 0.020 | 0.72 | 256.06 |

| Japan, Tokyo | 11.20 | 0.34 | 0 | Econ × 3% | −7.84 | 3.81 | 4.66 × 105 | 0.008 | 0.28 | 261.80 |

| Energy Generation Technology | Emission Factor (g CO2/kWh) |

|---|---|

| Thermal power plant | 800–1500 |

| Biomass energy | 100–1000 |

| Biogas energy | 25–600 |

| Thermal solar energy | 15–150 |

| Photovoltaic solar energy | 20–200 |

| Geothermal energy | 10–80 |

| Tidal energy | 10–80 |

| Wave energy (This paper) | 19–57 |

| Wave energy | 12–50 |

| Hydropower | 2–60 |

| Off-shore wind energy | 5–70 |

| Onshore wind energy | 5–70 |

| Nuclear energy | 10–20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Wang, X.; Wang, H.; Zhang, Y.; Zhang, C.; Xu, H.; Wu, B. Research on the Accounting and Prediction of Carbon Emission from Wave Energy Convertor Based on the Whole Lifecycle. Energies 2024, 17, 1626. https://doi.org/10.3390/en17071626

Li J, Wang X, Wang H, Zhang Y, Zhang C, Xu H, Wu B. Research on the Accounting and Prediction of Carbon Emission from Wave Energy Convertor Based on the Whole Lifecycle. Energies. 2024; 17(7):1626. https://doi.org/10.3390/en17071626

Chicago/Turabian StyleLi, Jian, Xiangnan Wang, Huamei Wang, Yuanfei Zhang, Cailin Zhang, Hongrui Xu, and Bijun Wu. 2024. "Research on the Accounting and Prediction of Carbon Emission from Wave Energy Convertor Based on the Whole Lifecycle" Energies 17, no. 7: 1626. https://doi.org/10.3390/en17071626

APA StyleLi, J., Wang, X., Wang, H., Zhang, Y., Zhang, C., Xu, H., & Wu, B. (2024). Research on the Accounting and Prediction of Carbon Emission from Wave Energy Convertor Based on the Whole Lifecycle. Energies, 17(7), 1626. https://doi.org/10.3390/en17071626