FEM Simulation of Fault Reactivation Induced with Hydraulic Fracturing in the Shangluo Region of Sichuan Province

Abstract

1. Introduction

2. Methodology

2.1. Coupled Poroelastic Model

2.2. Strain–Permeability Model

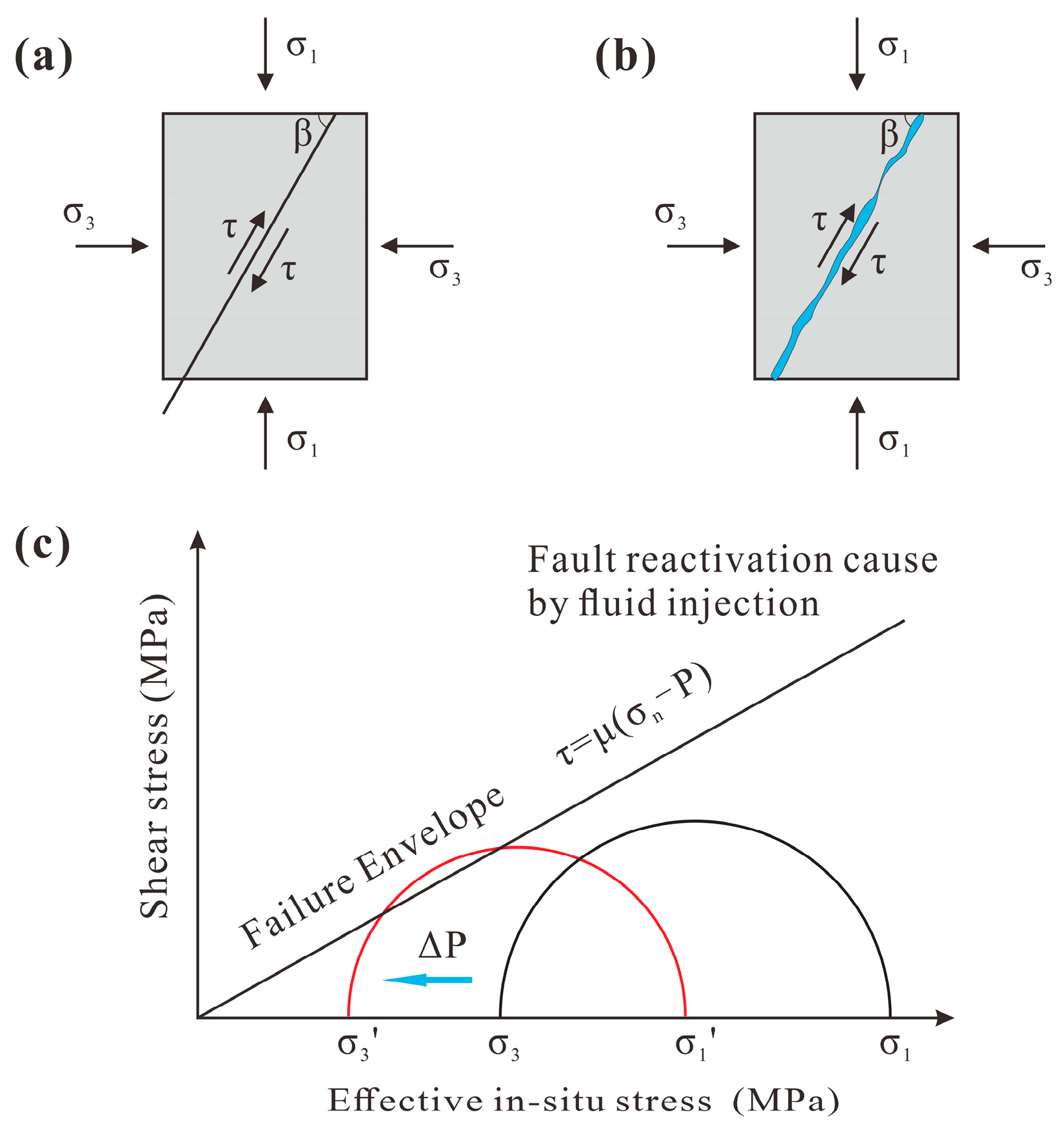

2.3. Coulomb Failure Stress Changes

3. Numerical Model

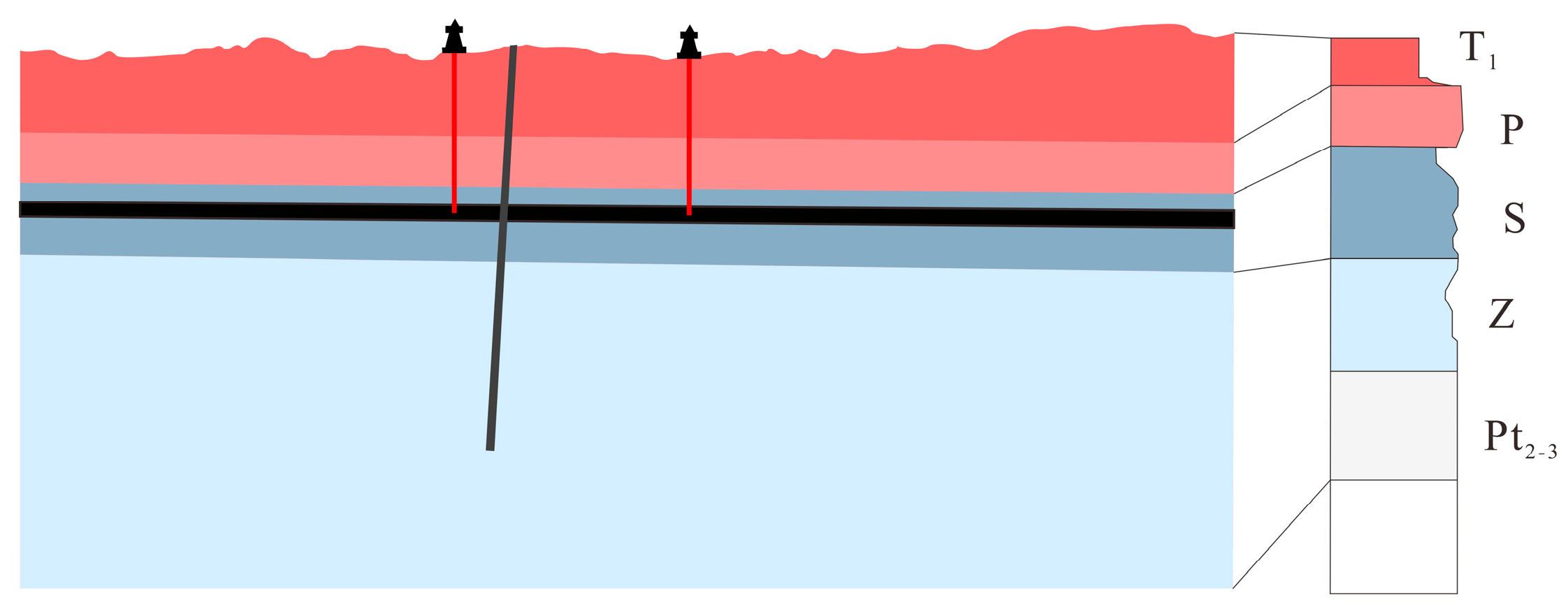

3.1. Geologic Model and Boundary Conditions

3.2. Boundary Condition and Parameter Setting

- (1)

- Effective stress initialization: The initial stress state input for the solid mechanics calculations is pore pressure, which represents pre-existing stress conditions.

- (2)

- To prevent the calculation of induced slip from being affected by settlement effects, it is necessary to apply the stress state induced by gravity settlement to the undeformed model. This can be achieved by performing two iterations of steady-state calculations, using the results from the first iteration as the starting point for the second iteration. This iterative process helps ensure convergence of the calculation and eliminates the influence of settlement displacement on simulation results.

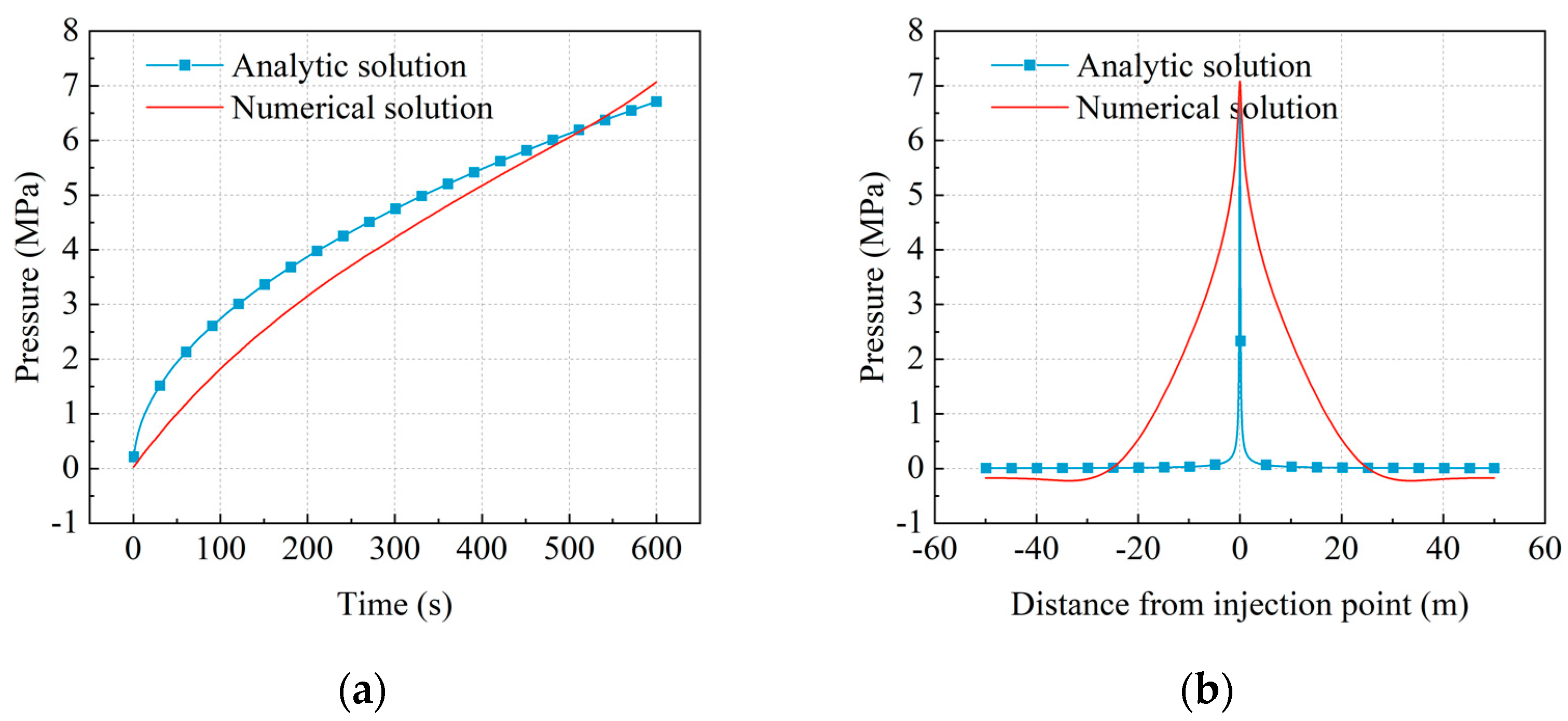

3.3. Verification

4. Results

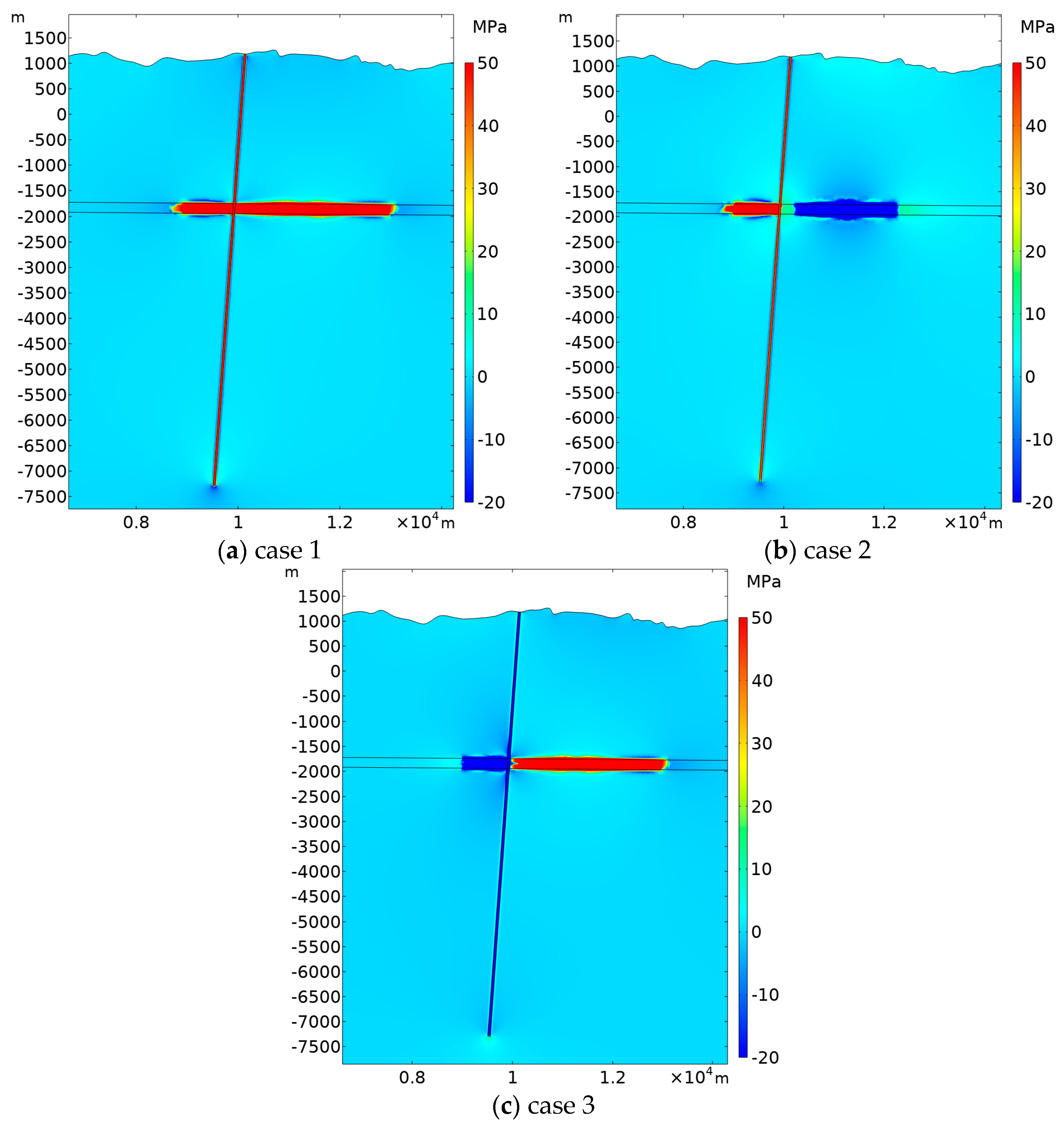

4.1. Effect of Injection on Fluid Distribution

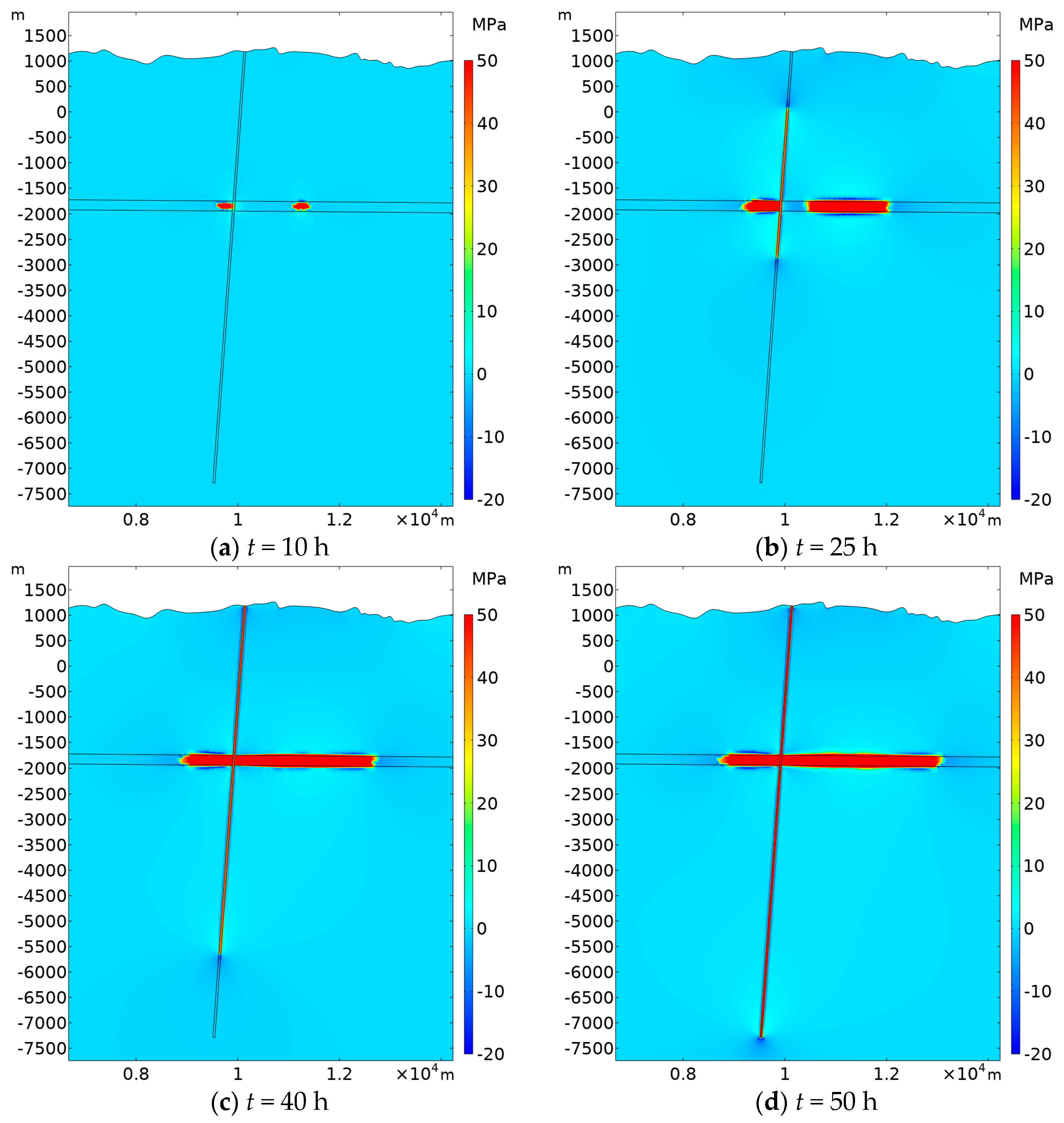

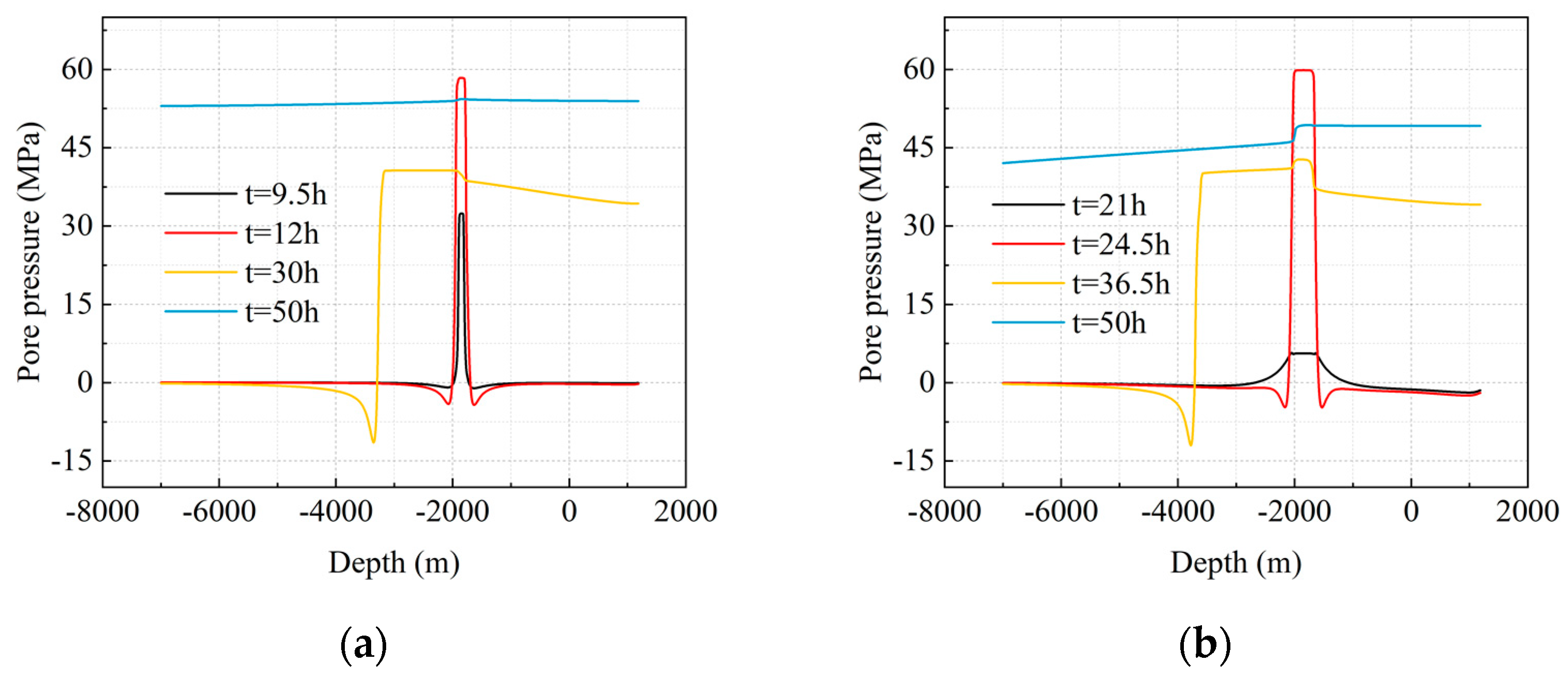

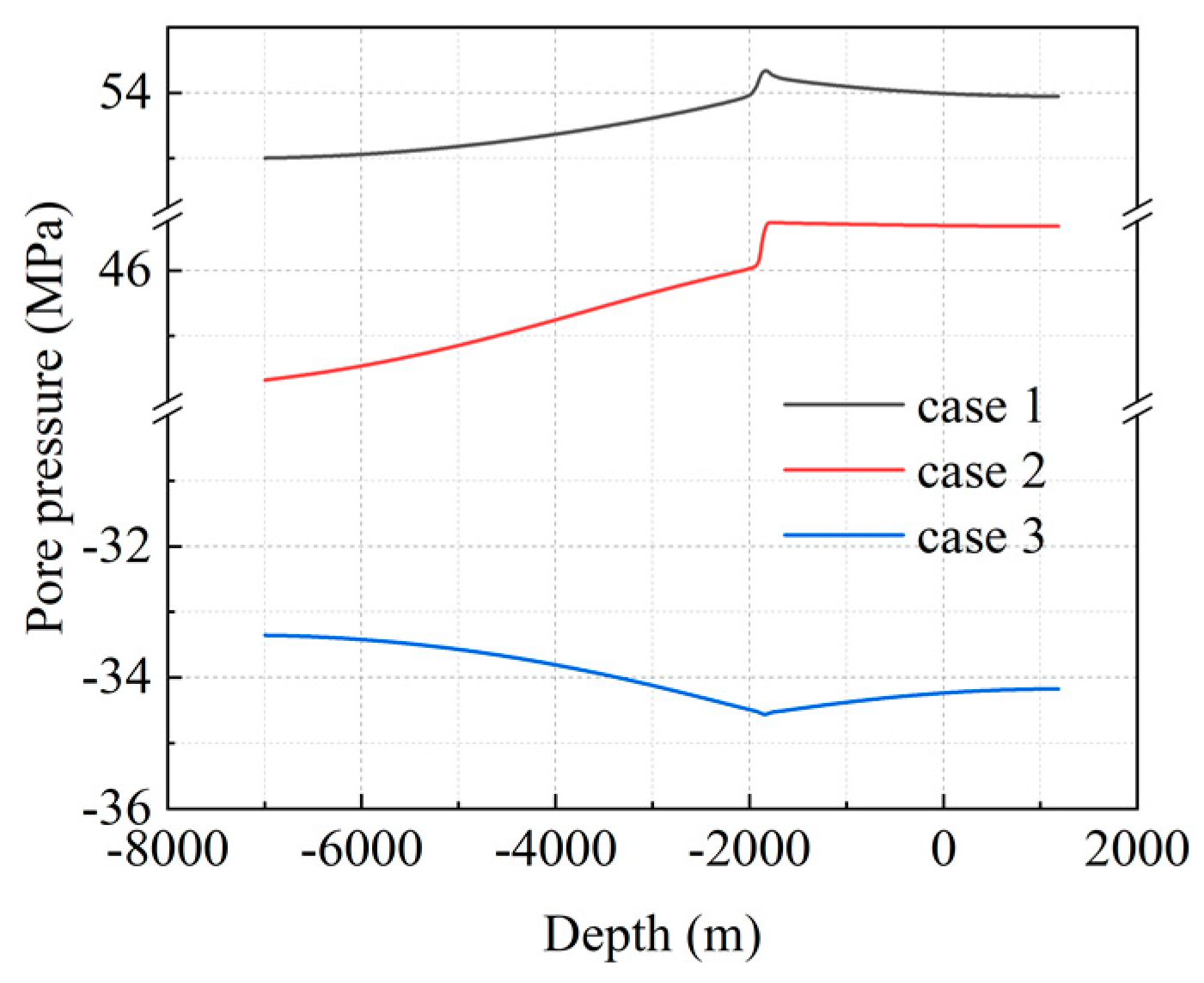

4.1.1. Pore Pressure Distribution

4.1.2. Evolution of Pore Pressure along the Fault

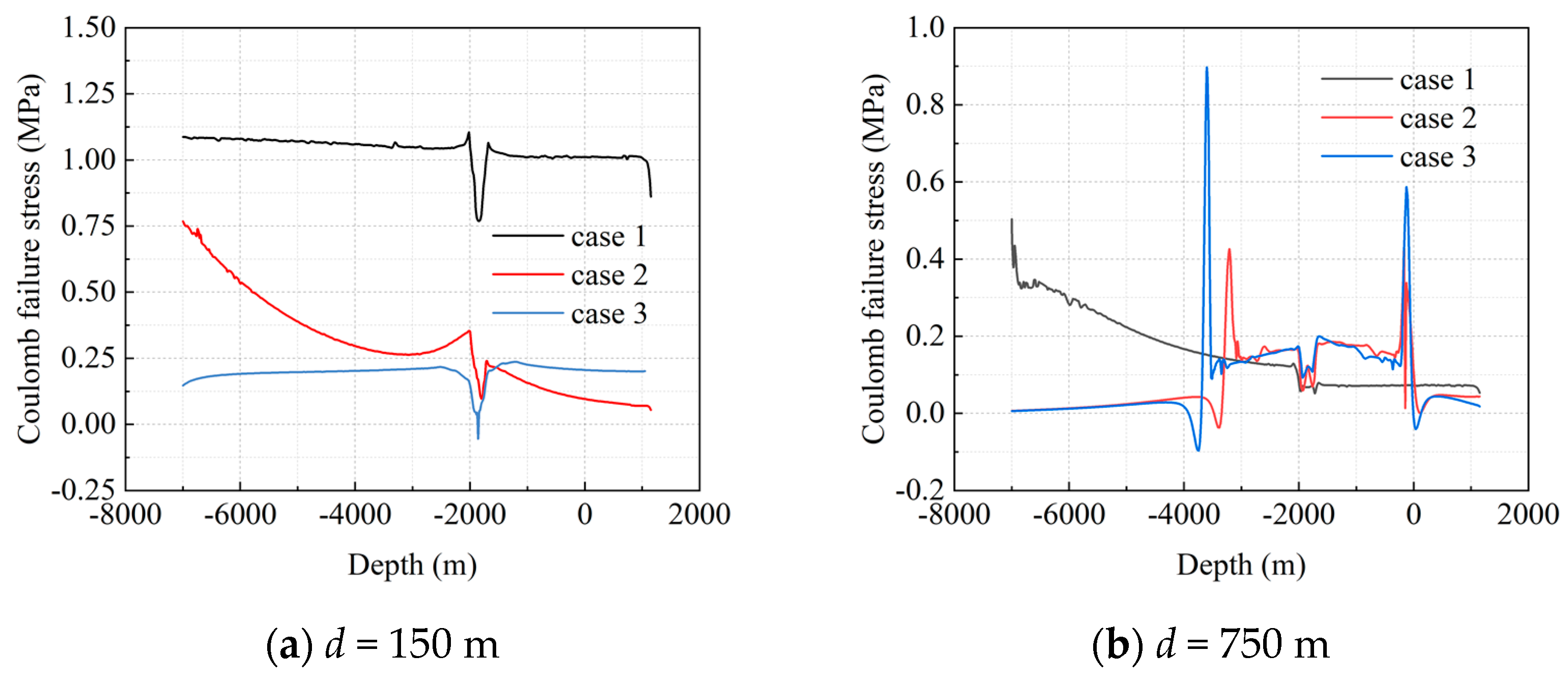

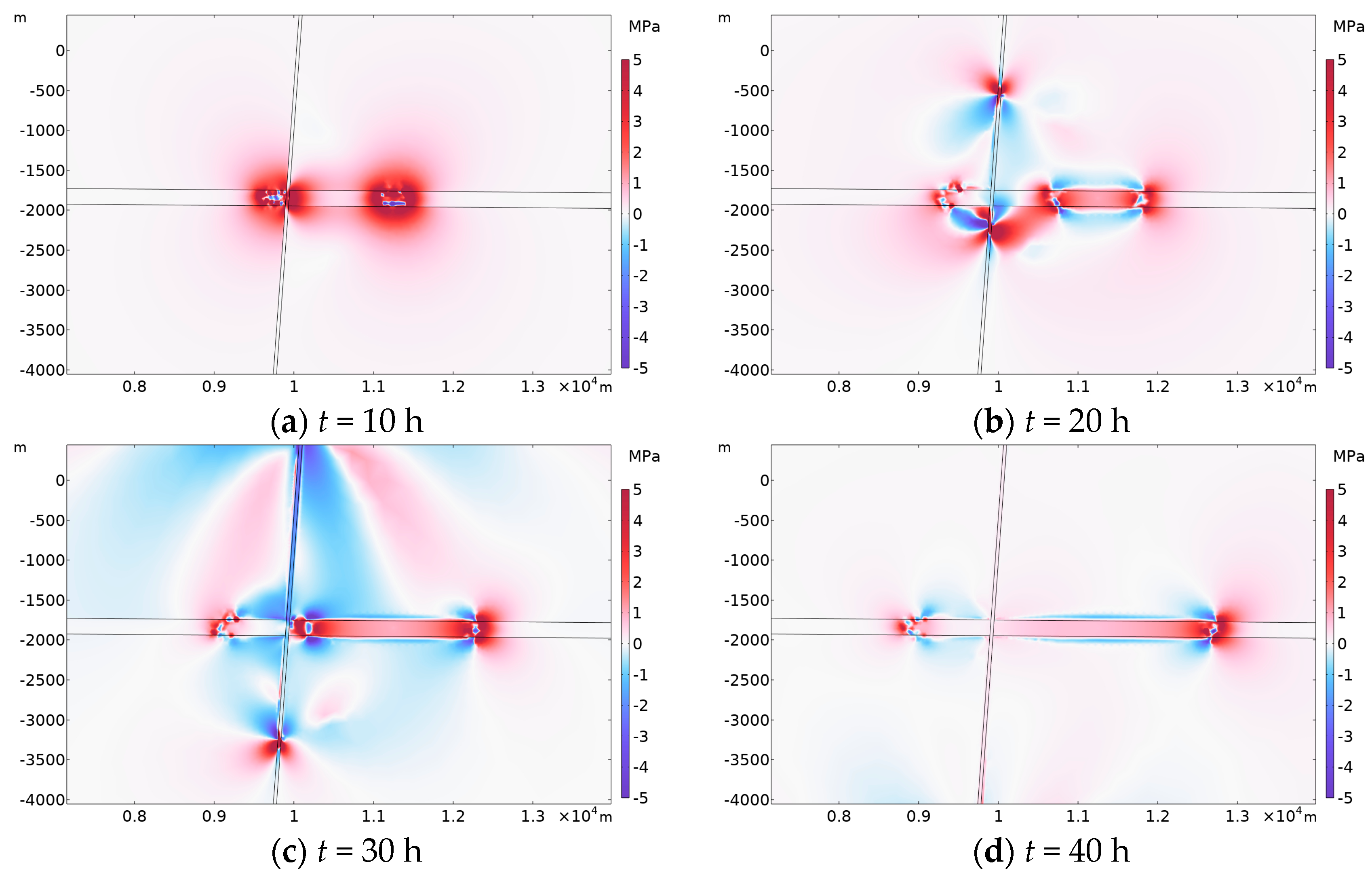

4.2. Coulomb Failure Stress (∆CFS)

4.3. Induced Seismic Events

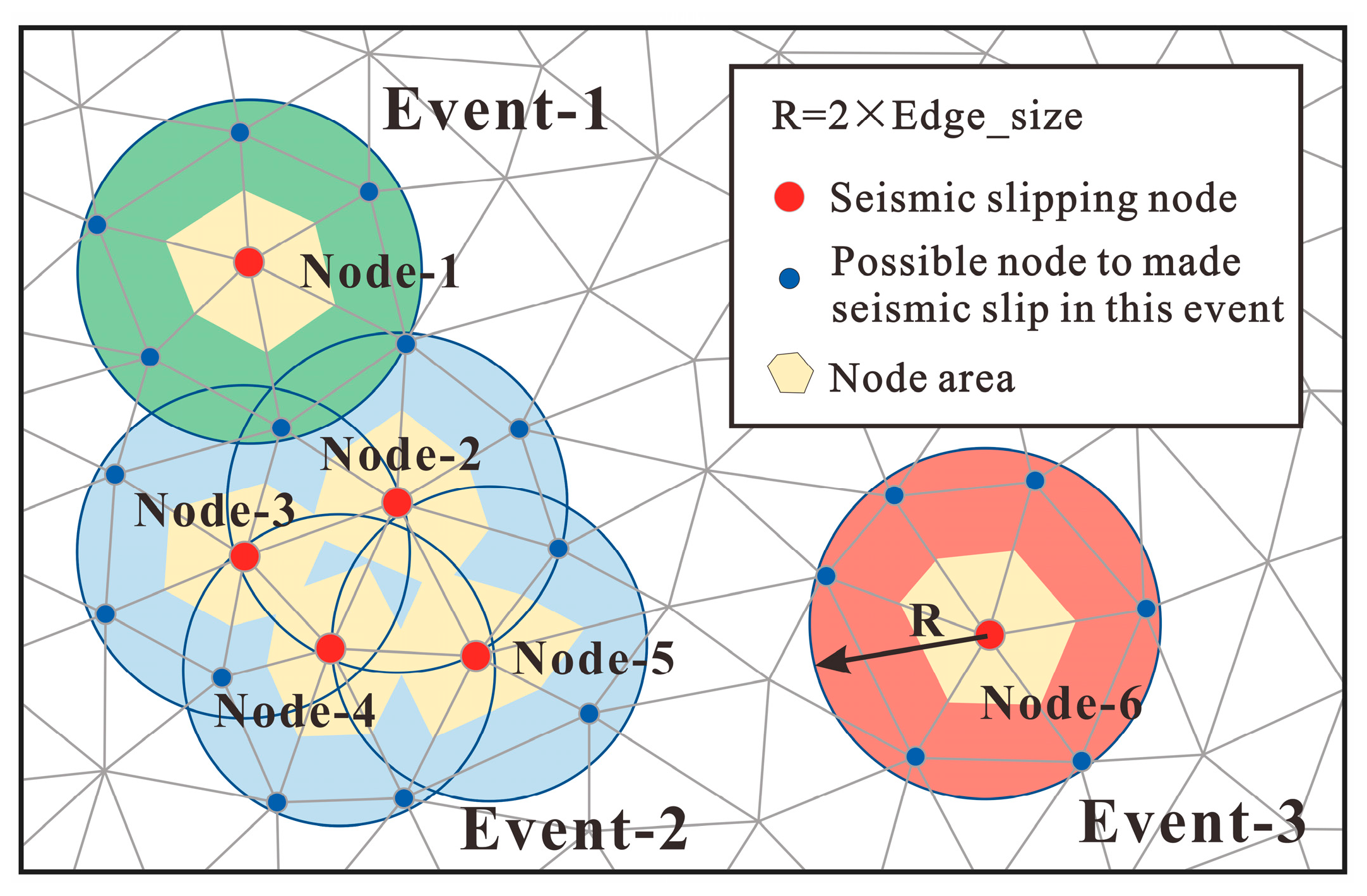

4.3.1. Calculation of Seismic Slip Events

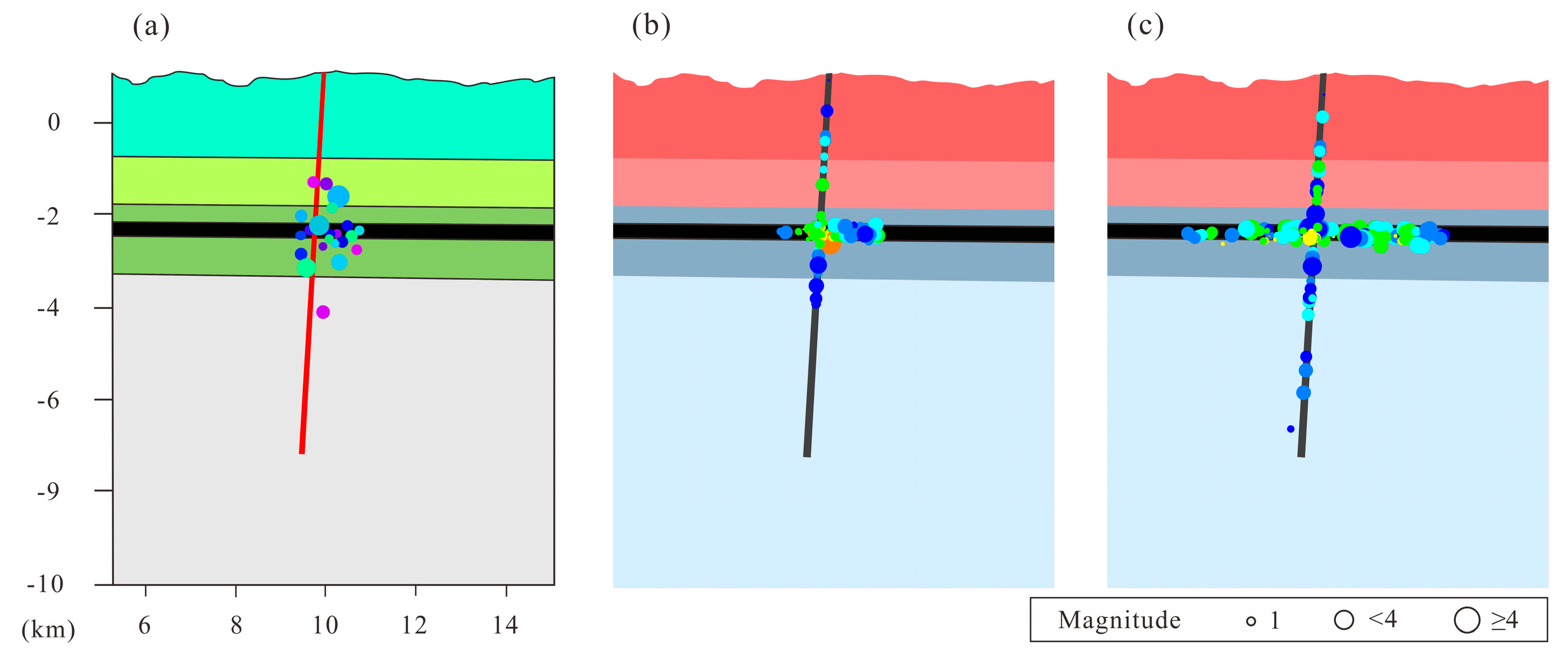

4.3.2. Distribution of Seismic Slip Events

5. Discussion

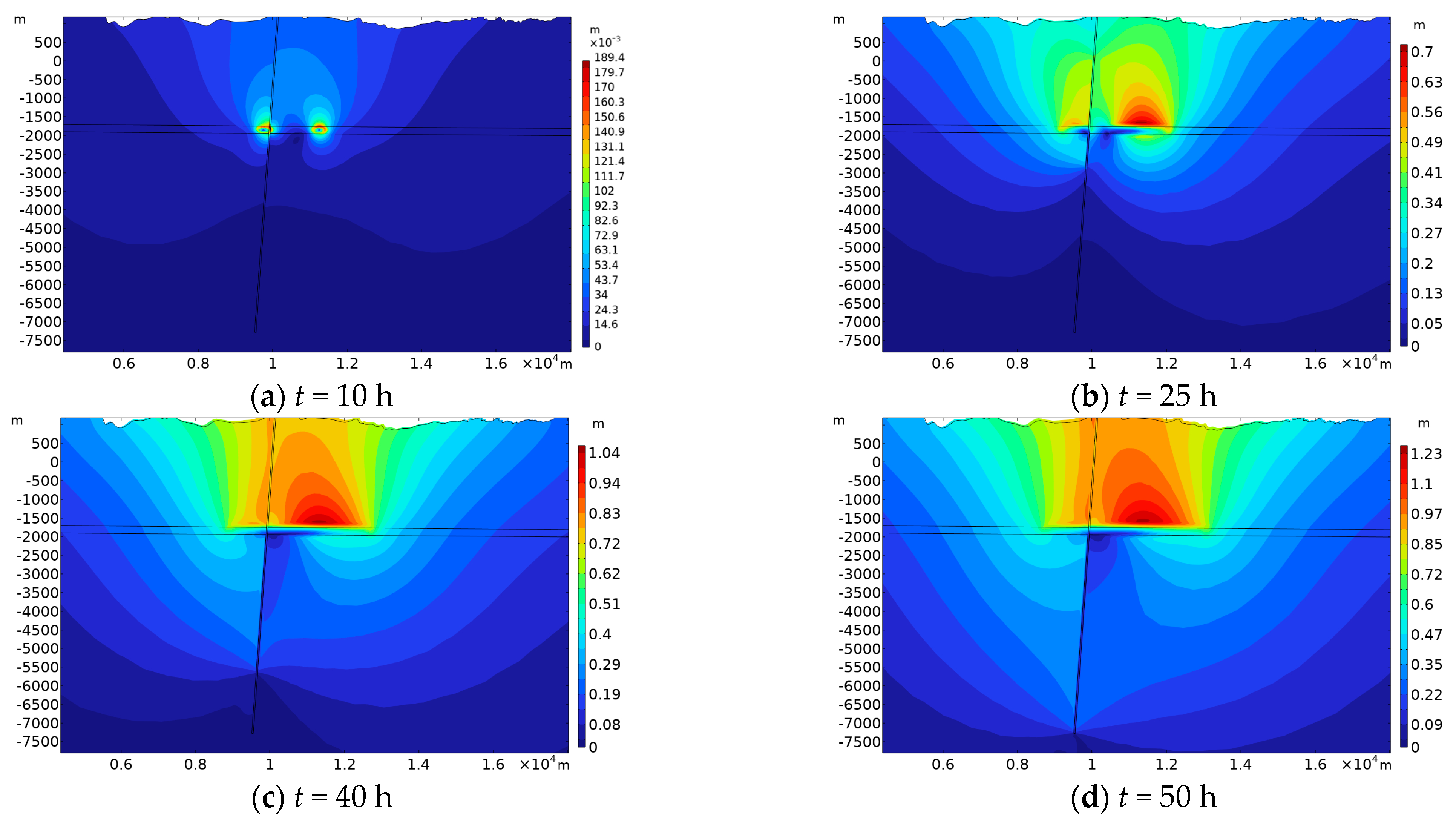

5.1. Effects of Injection on Formation Deformation

5.2. Fault Slip

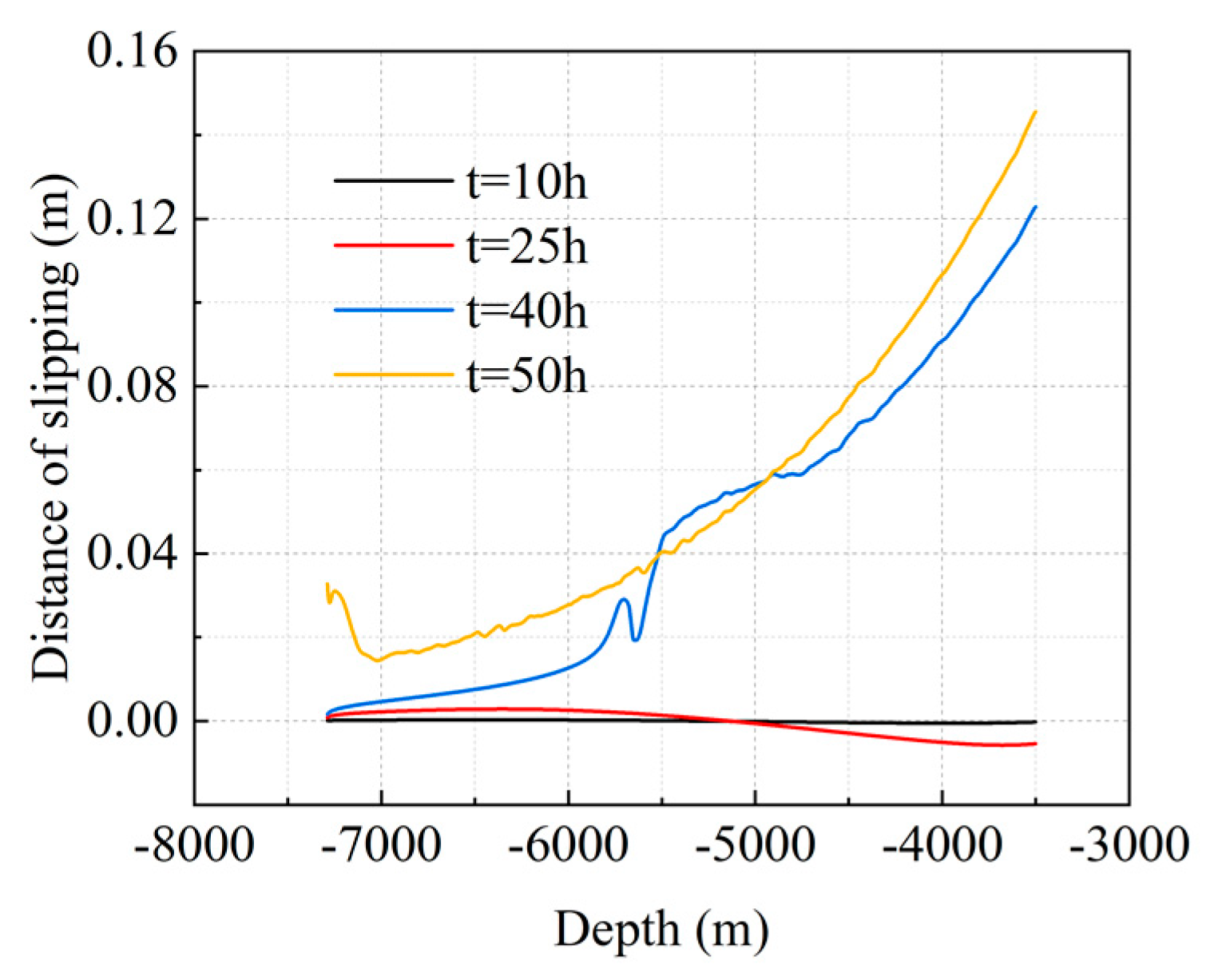

5.2.1. Effect of Injection Time

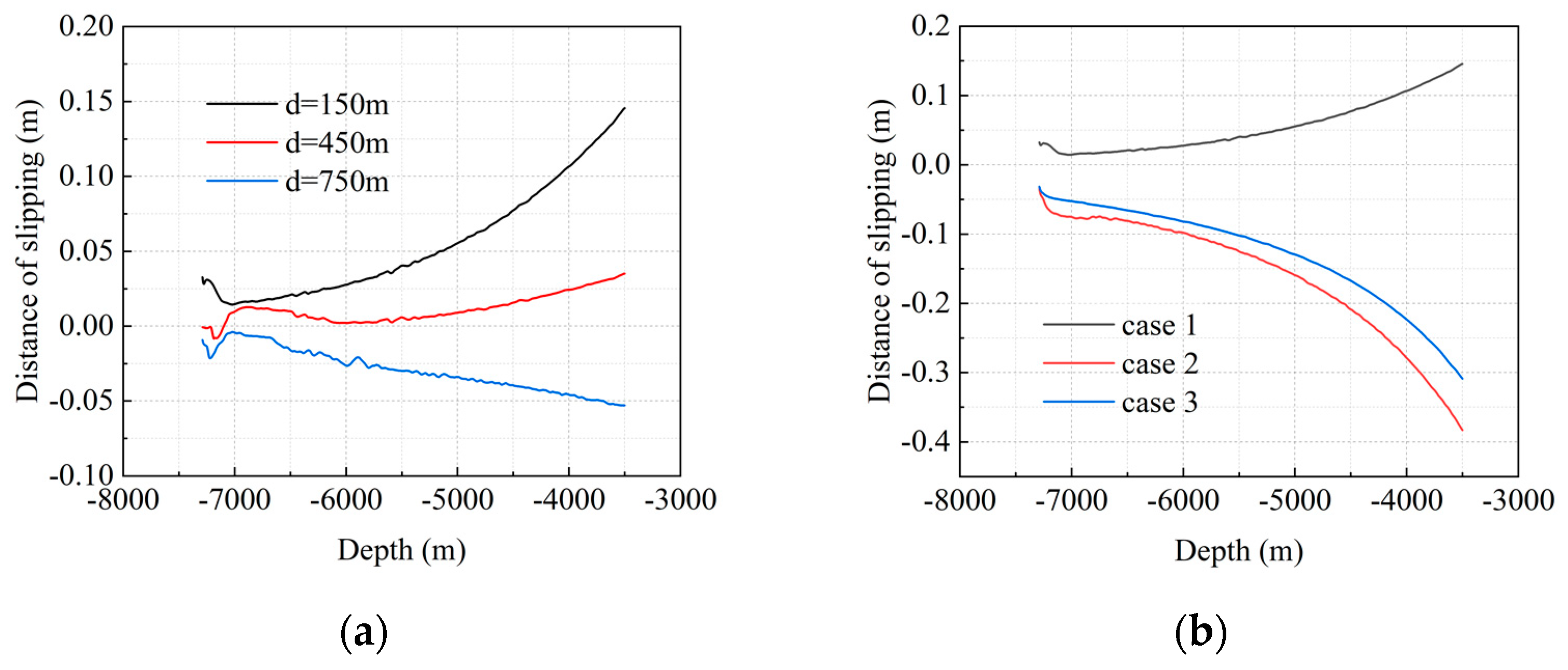

5.2.2. Effect of Injection Rate

5.2.3. Effect of Injection–Production Schemes

6. Conclusions

- (1)

- High-permeability faults display three distinct behaviors under different production schemes: barrier, fluid transport channel, and conduit channel. The faults act as conduits in the absence of producing wells. Where the production well is located far away from the fault, the fault acts as a conduit channel. If the production well is close to the fault, the fault acts as a barrier for fluid flow.

- (2)

- The migration of high-pressure fluid in the formation is closely related to the degree of rock fracturing. This leads to most of the area on the fault close to the activation state. As the fluid distribution within the fault rock mass tends to be stable, the fault can return to a relatively stable stress state.

- (3)

- The results show that the displacement mainly occurs near the injection well and the fault. The production time and injection rate affect the distance of fault slip, and the fault slip near the surface is greater than in other places. The injection production scenarios could influence the fault-slip mechanism, resulting in a normal fault or reverse fault.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Foulger, G.R.; Wilson, M.P.; Gluyas, J.G.; Julian, B.R.; Davies, R.J. Global review of human-induced earthquakes. Earth-Sci. Rev. 2018, 178, 438–514. [Google Scholar] [CrossRef]

- Hui, G.; Chen, S.; Chen, Z.; Gu, F. An integrated approach to characterize hydraulic fracturing-induced seismicity in shale reservoirs. J. Pet. Sci. Eng. 2021, 196, 107624. [Google Scholar] [CrossRef]

- Wu, W.; Lu, D.; Elsworth, D. Fluid injection-induced fault slip during unconventional energy development: A review. Energy Rev. 2022, 1, 100007. [Google Scholar] [CrossRef]

- Dong, K.; Liu, N.; Chen, Z.; Huang, R.; Ding, J.; Niu, G. Geomechanical analysis on casing deformation in Longmaxi shale formation. J. Pet. Sci. Eng. 2019, 177, 724–733. [Google Scholar] [CrossRef]

- Wassing, B.B.T.; Gan, Q.; Candela, T.; Fokker, P.A. Effects of fault transmissivity on the potential of fault reactivation and induced seismicity: Implications for understanding induced seismicity at Pohang EGS. Geothermics 2021, 91, 101976. [Google Scholar] [CrossRef]

- Gan, Q.; Feng, Z.; Zhou, L.; Li, H.; Liu, J.; Elsworth, D. Down-dip circulation at the united downs deep geothermal power project maximizes heat recovery and minimizes seismicity. Geothermics 2021, 96, 102204. [Google Scholar] [CrossRef]

- Schultz, R.; Skoumal, R.J.; Brudzinski, M.R.; Eaton, D.; Baptie, B.; Ellsworth, W. Hydraulic Fracturing-Induced Seismicity. Rev. Geophys. 2020, 58, e2019RG000695. [Google Scholar] [CrossRef]

- Farghal, N.; Zoback, M. Utilizing Ant-tracking to Identify Slowly Slipping Faults in the Barnett Shale. In Proceedings of the 2nd URteC 1922263, Denver, CO, USA, 25–27 August 2014. [Google Scholar]

- Eyre, T.S.; Eaton, D.W.; Garagash, D.I.; Zecevic, M.; Venieri, M.; Weir, R.; Lawton, D.C. The role of aseismic slip in hydraulic fracturing–induced seismicity. Sci. Adv. 2019, 5, eaav7172. [Google Scholar] [CrossRef] [PubMed]

- Meng, H.; Ge, H.; Yao, Y.; Shen, Y.; Wang, J.; Bai, J.; Zhang, Z. A new insight into casing shear failure induced by natural fracture and artificial fracture slip. Eng. Fail. Anal. 2022, 137, 106287. [Google Scholar] [CrossRef]

- Xi, Y.; Li, J.; Liu, G.; Li, J.; Jiang, J. Mechanisms and Influence of Casing Shear Deformation near the Casing Shoe, Based on MFC Surveys during Multistage Fracturing in Shale Gas Wells in Canada. Energies 2019, 12, 372. [Google Scholar] [CrossRef]

- Eyre, T.S.; Samsonov, S.; Feng, W.; Kao, H.; Eaton, D.W. InSAR data reveal that the largest hydraulic fracturing-induced earthquake in Canada, to date, is a slow-slip event. Sci. Rep. 2022, 12, 2043. [Google Scholar] [CrossRef]

- Xu, B.; Hu, J.; Hu, T.; Wang, F.; Luo, K.; Wang, Q.; He, X. Quantitative assessment of seismic risk in hydraulic fracturing areas based on rough set and Bayesian network: A case analysis of Changning shale gas development block in Yibin City, Sichuan Province, China. J. Pet. Sci. Eng. 2021, 200, 108226. [Google Scholar] [CrossRef]

- Hu, J.; Xu, B.; Chen, Z.; Zhang, H.; Cao, J.; Wang, Q. Hazard and risk assessment for hydraulic fracturing induced seismicity based on the Entropy-Fuzzy-AHP method in Southern Sichuan Basin, China. J. Nat. Gas Sci. Eng. 2021, 90, 103908. [Google Scholar] [CrossRef]

- Xi, Y.; Jiang, J.; Li, J.; Li, H.; Gao, D. Research on the influence of strike-slip fault slippage on production casing and control methods and engineering application during multistage fracturing in deep shale gas wells. Energy Rep. 2021, 7, 2989–2998. [Google Scholar] [CrossRef]

- Kruszewski, M.; Montegrossi, G.; Balcewicz, M.; de Los Angeles Gonzalez de Lucio, G.; Igbokwe, O.A.; Backers, T.; Saenger, E.H. 3D in situ stress state modelling and fault reactivation risk exemplified in the Ruhr region (Germany). Geomech. Energy Environ. 2022, 32, 100386. [Google Scholar] [CrossRef]

- Huang, Y.; Lei, X.; Ma, S. Numerical study of the role of localized stress perturbations on fault slip: Insights for injection-induced fault reactivation. Tectonophysics 2021, 819, 229105. [Google Scholar] [CrossRef]

- Eyinla, D.S.; Oladunjoye, M.A.; Gan, Q.; Olayinka, A.I. Fault reactivation potential and associated permeability evolution under changing injection conditions. Petroleum 2021, 7, 282–293. [Google Scholar] [CrossRef]

- Verdon, J.P.; Rodríguez-Pradilla, G. Assessing the variability in hydraulic fracturing-induced seismicity occurrence between North American shale plays. Tectonophysics 2023, 859, 229898. [Google Scholar] [CrossRef]

- Wasantha, P.L.P.; Konietzky, H. Fault reactivation and reservoir modification during hydraulic stimulation of naturally-fractured reservoirs. J. Nat. Gas Sci. Eng. 2016, 34, 908–916. [Google Scholar] [CrossRef]

- Gan, Q.; Lei, Q. Induced fault reactivation by thermal perturbation in enhanced geothermal systems. Geothermics 2020, 86, 101814. [Google Scholar] [CrossRef]

- Lv, Y.; Yuan, C.; Zhu, X.; Gan, Q.; Li, H. THMD analysis of fluid injection-induced fault reactivation and slip in EGS. Geothermics 2022, 99, 102303. [Google Scholar] [CrossRef]

- Zhang, H.; Tong, H.; Zhang, P.; He, Y.; Liu, Z.; Huang, Y. How can casing deformation be prevented during hydraulic fracturing of shale gas?—A case study of the Weiyuan area in Sichuan, China. Geoenergy Sci. Eng. 2023, 221, 111251. [Google Scholar] [CrossRef]

- Niemeijer, A.; Marone, C.; Elsworth, D. Frictional strength and strain weakening in simulated fault gouge: Competition between geometrical weakening and chemical strengthening. J. Geophys. Res. Solid Earth 2010, 115. [Google Scholar] [CrossRef]

- An, M.; Zhang, F.; Dontsov, E.; Elsworth, D.; Zhu, H.; Zhao, L. Stress perturbation caused by multistage hydraulic fracturing: Implications for deep fault reactivation. Int. J. Rock Mech. Min. Sci. 2021, 141, 104704. [Google Scholar] [CrossRef]

- Im, K.; Elsworth, D.; Guglielmi, Y.; Mattioli, G.S. Geodetic imaging of thermal deformation in geothermal reservoirs—Production, depletion and fault reactivation. J. Volcanol. Geotherm. Res. 2017, 338, 79–91. [Google Scholar] [CrossRef]

- Yin, Z.; Huang, H.; Zhang, F.; Zhang, L.; Maxwell, S. Three-dimensional distinct element modeling of fault reactivation and induced seismicity due to hydraulic fracturing injection and backflow. J. Rock Mech. Geotech. Eng. 2020, 12, 752–767. [Google Scholar] [CrossRef]

- Zhang, F.; Cao, S.; An, M.; Zhang, C.; Elsworth, D. Friction and stability of granite faults in the Gonghe geothermal reservoir and implications for injection-induced seismicity. Geothermics 2023, 112, 102730. [Google Scholar] [CrossRef]

- Volpe, G.; Pozzi, G.; Collettini, C.; Spagnuolo, E.; Achtziger-Zupančič, P.; Zappone, A.; Aldega, L.; Meier, M.A.; Giardini, D.; Cocco, M. Laboratory simulation of fault reactivation by fluid injection and implications for induced seismicity at the BedrettoLab, Swiss Alps. Tectonophysics 2023, 862, 229987. [Google Scholar] [CrossRef]

- Liu, K.; Taleghani, A.D.; Gao, D. Calculation of hydraulic fracture induced stress and corresponding fault slippage in shale formation. Fuel 2019, 254, 115525. [Google Scholar] [CrossRef]

- Huang, N.; Liu, R.; Jiang, Y.; Cheng, Y.; Li, B. Shear-flow coupling characteristics of a three-dimensional discrete fracture network-fault model considering stress-induced aperture variations. J. Hydrol. 2019, 571, 416–424. [Google Scholar] [CrossRef]

- Wang, L.; Golfier, F.; Tinet, A.-J.; Chen, W.; Vuik, C. An efficient adaptive implicit scheme with equivalent continuum approach for two-phase flow in fractured vuggy porous media. Adv. Water Resour. 2022, 163, 104186. [Google Scholar] [CrossRef]

- Pan, W.; Zhang, Z.; Wang, S.; Lei, Q. Earthquake-induced fracture displacements and transmissivity changes in a 3D fracture network of crystalline rock for spent nuclear fuel disposal. J. Rock Mech. Geotech. Eng. 2023, 15, 2313–2329. [Google Scholar] [CrossRef]

- Park, J.-W.; Guglielmi, Y.; Graupner, B.; Rutqvist, J.; Kim, T.; Park, E.-S.; Lee, C. Modeling of fluid injection-induced fault reactivation using coupled fluid flow and mechanical interface model. Int. J. Rock Mech. Min. Sci. 2020, 132, 104373. [Google Scholar] [CrossRef]

- Eyinla, D.S. Modelling of fault reactivation mechanisms and associated induced seismicity in rocks with different elastic materials. Pet. Res. 2022, 7, 91–105. [Google Scholar] [CrossRef]

- Zhou, S.; Zhuang, X.; Rabczuk, T. Phase-field modeling of fluid-driven dynamic cracking in porous media. Comput. Methods Appl. Mech. Eng. 2019, 350, 169–198. [Google Scholar] [CrossRef]

- Santillán, D.; Juanes, R.; Cueto-Felgueroso, L. Phase Field Model of Hydraulic Fracturing in Poroelastic Media: Fracture Propagation, Arrest, and Branching Under Fluid Injection and Extraction. J. Geophys. Res. Solid Earth 2018, 123, 2127–2155. [Google Scholar] [CrossRef]

- Segall, P.; Lu, S. Injection-induced seismicity: Poroelastic and earthquake nucleation effects. J. Geophys. Res. Solid Earth 2015, 120, 5082–5103. [Google Scholar] [CrossRef]

- Wang, L.; Yin, Z.-Y.; Han, G.; Yu, M. Toward temporal evolution of consolidation in fluid-saturated poroelastic media with various permeable conditions. Comput. Geotech. 2023, 156, 105273. [Google Scholar] [CrossRef]

- Biot, M.A. General Theory of Three—Dimensional Consolidation. J. Appl. Phys. 2004, 12, 155–164. [Google Scholar] [CrossRef]

- Wang, L.; Chen, W.; Vuik, C. Hybrid-dimensional modeling for fluid flow in heterogeneous porous media using dual fracture-pore model with flux interaction of fracture–cavity network. J. Nat. Gas Sci. Eng. 2022, 100, 104450. [Google Scholar] [CrossRef]

- Rutqvist, J.; Noorishad, J.; Tsang, C.F.; Stephansson, O. Determination of fracture storativity in hard rocks using high-pressure injection testing. Water Resour. Res. 1998, 34, 2551–2560. [Google Scholar] [CrossRef]

- Cappa, F.; Rutqvist, J. Modeling of coupled deformation and permeability evolution during fault reactivation induced by deep underground injection of CO2. Int. J. Greenh. Gas Control 2011, 5, 336–346. [Google Scholar] [CrossRef]

- Rutqvist, J.; Rinaldi, A.P.; Cappa, F.; Moridis, G.J. Modeling of fault reactivation and induced seismicity during hydraulic fracturing of shale-gas reservoirs. J. Pet. Sci. Eng. 2013, 107, 31–44. [Google Scholar] [CrossRef]

- Kim, S.; Hosseini, S.A. Geological CO2 storage: Incorporation of pore-pressure/stress coupling and thermal effects to determine maximum sustainable pressure limit. Energy Procedia 2014, 63, 3339–3346. [Google Scholar] [CrossRef]

- Cappa, F.; Guglielmi, Y.; Nussbaum, C.; Birkholzer, J. On the Relationship Between Fault Permeability Increases, Induced Stress Perturbation, and the Growth of Aseismic Slip During Fluid Injection. Geophys. Res. Lett. 2018, 45, 11012–11020. [Google Scholar] [CrossRef]

- Rutqvist, J.; Stephansson, O. The role of hydromechanical coupling in fractured rock engineering. Hydrogeol. J. 2003, 11, 7–40. [Google Scholar] [CrossRef]

- Catalli, F.; Meier, M.A.; Wiemer, S. The role of Coulomb stress changes for injection—Induced seismicity: The Basel enhanced geothermal system. Geophys. Res. Lett. 2013, 40, 72–77. [Google Scholar] [CrossRef]

- Zhan, Z.Y. Study on Controlling Factors of Marine Shale Gas Dispersion in South China: A Case Study of Southern Margin of Sichuan Basin; China University of Petroleum: Beijing, China, 2019. [Google Scholar]

- Pereira, L.C.; Guimarães, L.J.N.; Horowitz, B.; Sánchez, M. Coupled hydro-mechanical fault reactivation analysis incorporating evidence theory for uncertainty quantification. Comput. Geotech. 2014, 56, 202–215. [Google Scholar] [CrossRef]

- Sun, C.; Shen, F.; Wen, Z.; Zhang, Y.; Scarselli, N.; Li, S.; Yu, Y.; Wu, G. Seismic analysis of fault damage zones in the northern Tarim Basin (NW China): Implications for growth of ultra-deep fractured reservoirs. J. Asian Earth Sci. 2023, 255, 105778. [Google Scholar] [CrossRef]

- Mortezaei, K.; Vahedifard, F. Multi-scale simulation of thermal pressurization of fault fluid under CO2 injection for storage and utilization purposes. Int. J. Rock Mech. Min. Sci. 2017, 98, 111–120. [Google Scholar] [CrossRef]

- Jia, Y.; Wu, W.; Kong, X.-Z. Injection-induced slip heterogeneity on faults in shale reservoirs. Int. J. Rock Mech. Min. Sci. 2020, 131, 104363. [Google Scholar] [CrossRef]

- Fasola, S.L.; Brudzinski, M.R.; Skoumal, R.J.; Langenkamp, T.; Currie, B.S.; Smart, K.J. Hydraulic Fracture Injection Strategy Influences the Probability of Earthquakes in the Eagle Ford Shale Play of South Texas. Geophys. Res. Lett. 2019, 46, 12958–12967. [Google Scholar] [CrossRef]

- Hui, G.; Chen, Z.; Schultz, R.; Chen, S.; Song, Z.; Zhang, Z.; Song, Y.; Wang, H.; Wang, M.; Gu, F. Intricate unconventional fracture networks provide fluid diffusion pathways to reactivate pre-existing faults in unconventional reservoirs. Energy 2023, 282, 128803. [Google Scholar] [CrossRef]

- Zhang, F.; Mack, M. Integrating fully coupled geomechanical modeling with microsesmicity for the analysis of refracturing treatment. J. Nat. Gas Sci. Eng. 2017, 46, 16–25. [Google Scholar] [CrossRef]

- Lei, X.; Huang, D.; Su, J.; Jiang, G.; Wang, X.; Wang, H.; Guo, X.; Fu, H. Fault reactivation and earthquakes with magnitudes of up to Mw4.7 induced by shale-gas hydraulic fracturing in Sichuan Basin, China. Sci. Rep. 2017, 7, 7971. [Google Scholar] [CrossRef]

- Rutqvist, J. Status of the TOUGH-FLAC simulator and recent applications related to coupled fluid flow and crustal deformations. Comput. Geosci. 2011, 37, 739–750. [Google Scholar] [CrossRef]

- Jun, S.; Song, Y.; Wang, J.; Weijermars, R. Formation uplift analysis during geological CO2-Storage using the Gaussian pressure transient method: Krechba (Algeria) validation and South Korean case studies. Geoenergy Sci. Eng. 2023, 221, 211404. [Google Scholar] [CrossRef]

- Siriwardane, H.J.; Gondle, R.K.; Varre, S.B.; Bromhal, G.S.; Wilson, T.H. Geomechanical response of overburden caused by CO2 injection into a depleted oil reservoir. J. Rock Mech. Geotech. Eng. 2016, 8, 860–872. [Google Scholar] [CrossRef]

| Category | Limestone | Shale | Fault |

|---|---|---|---|

| 47.1 | 26.2 | 5 | |

| 0.12 | 0.2 | 0.25 | |

| 0.015 | 0.025 | 0.04 | |

| 1.00 × 10−19 | 3.00 × 10−17 | 2.35 × 10−14 | |

| 30.4 | 16.2 | 0 | |

| 46.2 | 36.2 | 31 | |

| 2700 | 2700 | 2700 | |

| 1050 | 1050 | 1050 | |

| 0.8 | 0.8 | 0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Li, Y. FEM Simulation of Fault Reactivation Induced with Hydraulic Fracturing in the Shangluo Region of Sichuan Province. Energies 2024, 17, 1614. https://doi.org/10.3390/en17071614

He Y, Li Y. FEM Simulation of Fault Reactivation Induced with Hydraulic Fracturing in the Shangluo Region of Sichuan Province. Energies. 2024; 17(7):1614. https://doi.org/10.3390/en17071614

Chicago/Turabian StyleHe, Yujie, and Yanyan Li. 2024. "FEM Simulation of Fault Reactivation Induced with Hydraulic Fracturing in the Shangluo Region of Sichuan Province" Energies 17, no. 7: 1614. https://doi.org/10.3390/en17071614

APA StyleHe, Y., & Li, Y. (2024). FEM Simulation of Fault Reactivation Induced with Hydraulic Fracturing in the Shangluo Region of Sichuan Province. Energies, 17(7), 1614. https://doi.org/10.3390/en17071614