1. Introduction

Due to the widespread use of fossil fuels, greenhouse gas concentrations continue to increase [

1]. After the decisions of many global summits and conventions (such as the Kyoto Protocol in 1997 and the Paris Climate Convention in 2015), mankind has become increasingly concerned about the global climate issues caused by carbon dioxide emissions caused by excessive industrialization [

2]. To address this challenge, human access to energy has started to gradually shift from traditional fossil energy sources to renewable energy sources. In this transformation process, wind energy, as a renewable energy source, is increasingly favored by human beings and has become one of the most promising renewable energy sources nowadays. In fact, wind power has been used for different purposes in ancient times, and since modern times, wind power has become a core research topic in the energy field. The source of wind energy can be traced back to solar energy, which causes temperature differences by heating the earth’s surface, leading to convection in the atmosphere and ultimately forming wind. Wind power has been proven to be one of the best sources of energy for power generation systems. Currently, global wind power systems can reduce carbon dioxide emissions by 131 million tons, with a potential reduction of up to 328.64 million tons by 2100. It is expected to slow down the global temperature rise by 0.64 degrees Celsius, which is expected to have a significant mitigating effect on global warming [

3]. Therefore, wind power generation is considered a more environmentally friendly solution to alleviate global climate issues. Because of the noise generated by the increasing number of high-power wind turbines on earth, wind farms have become a frequently raised issue regarding their impact on the environment. Various studies have shown that exposure to very high noise levels can lead to a series of discomforts, such as headache, irritability, fatigue, arterial constriction, and a weakened immune system. Noise levels above 140 dB may harm hearing organs [

4]. In fact, noise from wind power causes a higher annoyance response at lower noise levels than other noise sources in life such as aircraft, road traffic, and railroad noise. This may be due to the correlation between the intensity and annoyance of amplitude changes caused by the rotation of wind turbine blades [

5,

6]. The periodic variation in amplitude over time is called amplitude modulation, and listening tests have shown that the presence of amplitude modulation significantly increases the perceived level of annoyance for a given noise level. Thus, if a low-frequency noise is audible to the human body and still amplitude-modulated, it is likely to be more annoying [

7,

8].

Typically, the lower limit of human hearing is 20 Hz. Due to a natural distribution of auditory thresholds, some people may not hear or hear very light sounds, while others may perceive sounds as quite noisy [

9,

10]. Although the noise from wind turbines can be obscured to some extent by other background noise such as forests and buildings, the indoor low-frequency sound pressure level of residents near wind farms can be higher than that of outdoor buildings due to the low noise reduction in low frequencies by the atmosphere and building exterior walls, as well as the resonance sound mode and structural vibration inside the buildings [

11,

12,

13]. In addition, the noise generated by large wind turbines can cause vibrations in objects such as doors and windows, which are mainly related to the low-frequency noise of wind turbines [

14]. To make this article clear and understandable, the frequency range of 20 Hz to 200 Hz is called low-frequency noise.

There are two main types of noise in wind turbines. One is aerodynamic noise generated by wind blowing through blades, and the other is mechanical noise, which is generated by the vibration of internal components and the rotation of gears in the wind turbine. Mechanical noise is not considered the main noise source of wind turbines in the first stage of their lifecycle [

15,

16,

17]; therefore, the main noise source is the aerodynamic noise generated by wind turbine blades. Measuring and understanding the noise generated by wind turbines is crucial for assessing their impact on the natural environment. However, accurately measuring and analyzing the noise of wind turbines is not a simple task. This is because there are usually various other sound sources around the tested wind turbine, including road vehicles, passing trains, agricultural machinery, and other more natural sound sources, such as thunder, waves on the water surface, and the sound generated by the interaction of high-speed wind with obstacles [

18,

19].

1.1. Research Progress

Many measurement studies have been conducted on the noise generated by different wind turbines. Malec et al. compared and analyzed the infrasound noise generated by two different types of wind turbines (synchronous and asynchronous). Compared with synchronous wind turbines, asynchronous wind turbines generate lower levels of sound pressure, which is unstable over time and shows higher pressure values around the resonant frequency. Asynchronous wind turbines are more affected by wind conditions and generate higher pressure values at higher wind speeds, while synchronous wind turbines are less affected. The conclusion indicates that the type of wind turbine has a significant impact on the level of infrasound noise emitted into the environment [

20]. Legerton et al. measured the noise generated by two 450 KW wind turbines at a distance of 100 m. They reported that the sound pressure level in the one-third octave band at 20 Hz is far below the auditory threshold, while the level in the 31.5 Hz band is only slightly below the threshold [

21]. Jakobsen estimated the G-weighted levels of 10 generator units in the range of 50 kW to 4.2 MW and found that wind turbines with rotors located on the windward side produced extremely low levels of infrasound. Even when located quite close to these wind turbines, the level of infrasound is also far below relevant evaluation standards, including perceptual limits. However, wind turbines with downwind rotors generate significantly higher levels of infrasound, which may violate relevant evaluation standards within a distance of several hundred meters. But at longer distances, the infrasound level will be lower than the limits specified in the Danish low-frequency and infrasound noise guidelines [

22].

Pedersen and Møller analyzed indoor low-frequency and infrasound noise in four houses located near one or more wind turbines (0.6–2.75 MW), with distances of 90–525 m from the nearest generator set. They concluded that there are no audible harmonics through the frequency of the blades, but there is audible volume within the low-frequency range [

23]. Esther Blumendeller et al. studied the operating conditions of wind turbines (such as the impact of rotational speed, cabin position, and output power) on low-frequency and infrasound noise emissions from wind farms, as well as noise inputs in residential buildings. They found that the secondary sound tone of wind farms at the blade passing frequency is detected in wind farms and residential buildings. In residential buildings, secondary sound tones mainly appear at the maximum rotational speed of wind turbines, seemingly unrelated to wind direction [

24].

Chun Hsiang Chiu et al. estimated the

LWA of three wind farms at 20–200 Hz using the ISO 9613-2 propagation model under different weather conditions (rain, wind speed, and direction). Each wind farm had different brands of wind turbines (brands A, B, and C). The results showed that rain has a significant positive impact on noise generated in low-wind speed environments, and this impact is reduced at higher wind speeds [

25,

26]. Olof Öhlund et al. conducted noise measurements near two wind turbine sites in Sweden. Two consecutive years of data were collected to cover seasonal and daily changes in the weather. The results indicate that there are significant changes in the sound transmission of wind turbines under various refractive atmospheric conditions. The impact of weather on the sound of wind turbines increases as the distance between 400 and 1000 m from wind turbines becomes increasingly important [

27].

Tomasz Malec et al. studied the secondary signals generated by four different power wind turbines installed in different locations in Poland, and the results showed that regardless of weather, wind speed, and rated power, infrasound noise does not exceed the standards specified in relevant work laws [

28]. Lee et al. and Jung et al. measured the noise of two upwind power units of 660 kW and 1.5 MW, respectively. The comparison between measured data and hearing thresholds indicates that low-frequency noise above 30 Hz may attract complaints from ordinary adults, while infrasound at frequencies of 5–8 Hz is highly likely to cause clicking noises on house doors and windows [

29,

30]. Valtteri Hongisto et al. studied the relationship between the sound pressure level of large wind turbines (3–5 MW) and the indoor noise disturbance of surrounding residents based on a sample of 429 participants around three wind power areas. The results indicate that when the sound pressure level is below 40 dB of LAeq, the prevalence of high disturbance is less than 4% [

31].

Although extensive research has been conducted on the noise generated by wind turbines, there is relatively little comparative research on the low-frequency noise of wind turbines of different power levels. With the distribution of exploitable wind resources on land, more and more homeowners have started building large-scale wind power projects near residential areas. This raises the important question of whether the low-frequency noise generated by increasingly large wind turbines causes more interference for nearby residents. Should the relationship between the power of a single unit and the impact of noise on the environment be fully considered during the construction of a wind farm? In addition, how does the low-frequency noise of different wind turbines vary with wind speed? These issues still require more in-depth analysis and research.

1.2. Research Summary

This research project conducted noise measurements on different power onshore wind turbines (1.5 MW and 4.5 MW) under normal operation and shutdown conditions, in accordance with the measurement positions of the IEC 61400-11 standard, and organized the measurement data. In this article, these measurement data are used to study the relationship between low-frequency noise emissions and wind turbine power. Specifically, this article compares and analyzes the measurement results of different power wind turbines in the time domain, the frequency domain, power spectral density (PSD), and the one-third octave range, and provides a detailed introduction to the acoustic characteristics of different power wind turbines. In particular, this article conducts a comparative analysis and research on the changes in low-frequency components in the spectrum when the power of wind turbines increases. Throughout the entire research process, the contribution of different power wind turbines to measuring low-frequency noise levels is quantified by comparing data under shutdown and operating conditions.

1.3. Article Structure

In

Section 2, the measurement process of wind turbine noise is described in detail, including on-site evaluation, measurement equipment, and specific methods for noise measurement. In

Section 3, methods for analyzing noise data are described.

Section 4 applies the obtained data to conduct time domain, frequency domain, power spectral density, and octave sound pressure level analysis to present the changes in low-frequency noise components of different power wind turbines, and also provides analysis results on their environmental impact.

Section 5 provides conclusions and recommendations.

2. Wind Turbine Noise Measurement

The noise measurement methods for wind turbines developed by the International Energy Agency (IEA) and the International Electrotechnical Commission (IEC) are developed in parallel, with some overlap in the working groups behind the methods. The IEA’s method is more like a guide, while the IEC’s method is more specific and was published as a standard. The noise measurement standards used in this study are IEC 61400-11 Edition 3.0: 2012-11 Wind turbines Part 11: Acoustic noise measurement techniques and GB/T22516-2015 “Wind turbine noise measurement methods” [

32]. This standard is currently the preferred method for wind turbine noise measurement worldwide and is applied to evaluate the noise of wind turbines within the audible range. This provides a basis for comparing noise between different brands and models, and the overall outline of the method is shown in

Figure 1. This method allows for measuring the noise of a single wind turbine and presenting the results as a function of wind speed. The method for determining wind speed follows the “Determination of the wind speed during wind turbine operation” described in IEC 61400-11 Section 8.2.1. The normalized wind speed is determined based on measurements of wind speed obtained from power curves, nacelle anemometers, and meteorological tower anemometers. The measured power curve used to determine wind speed was tested in accordance with IEC 61400-12-1:2005 [

33]. Measurements conducted according to standards can determine the sound power level within the audible frequency range (from 20 Hz to 10,000 Hz). This standard clearly defines all requirements for the measurement procedures, analysis methods of measurement results, and data uncertainty analysis. Measuring according to standards can minimize the impact of sweeping, reflection, and other sound sources, which are the main factors that may interfere with a measurement. The IEC’s method is based on the fundamental assumption that the rotor of a wind turbine can be understood as a point source. However, the International Electrical Committee (IEC) has begun work on guidelines for determining the noise characteristics of wind turbines at receiving locations, i.e., TS IEC 61400-11-2 [

34]. The focus of this guide is to measure the noise of the entire wind farm under expected low signal-to-noise ratios.

The standard process for measuring wind turbine noise includes simultaneously measuring sound signals, power output, wind direction, wind speed, temperature, rotor speed, pitch, and atmospheric pressure data. It is necessary to measure the total noise during the operation of a wind turbine and the background noise during non-operation, both of which should be conducted under different wind speed conditions. The background noise measurement should be conducted at the same location and under the same wind conditions as the total noise measurement. The data collection system collects equivalent continuous A-sound levels, as well as non-acoustic data such as wind speed and weather, every 1 s. It should be noted that during the measurement process, there may be situations where noise data are significantly affected, for example, during special time periods such as passing cars or airplanes. These time periods in the test data should be clearly indicated during testing and ignored in subsequent data processing.

2.1. Measurement of Wind Turbine Parameters and On-Site Evaluation

This study includes two wind turbines. Before measuring the noise of the wind turbines, it is necessary to understand and evaluate the parameters of the two turbines and the surrounding terrain. The wind turbine measured in this study adopts a three-blade design, with its rotor located on the windward side of the tower, and the tower types are all made of steel cones. The specific parameters are shown in

Table 1. The measurement work was conducted at the Zhangbei Experimental Base of the National Energy Large Wind Power Grid Connection System Research and Development (Experimental) Center.

The first test object is a wind turbine with a horizontal axis rated power of 1.5 MW. This typhoon generator unit is located in the north of the wind farm, surrounded by hilly terrain, approximately 850 m away from the nearest building area. Due to its distance, the acoustic interference is relatively small. In addition, the distance from adjacent wind turbines exceeds 500 m, and there are no buildings, trees, or shrubs around the microphone placement location that affect noise measurement. The testing conditions around the reflective plate comply with free field characteristics. The second test wind turbine is a wind turbine with a horizontal axis rated power of 4.5 MW. The tested wind turbine is located in the southern part of the wind farm (

Figure 2, location number 22 #). The location of the wind turbine is mostly surrounded by snow-covered grasslands, approximately 1600 m away from the nearest building area, so there is less background noise interference. During the measurement period, the test wind turbine unit operates as a single unit, and the nearby wind turbine units are in a braking and shutdown state, so the noise emitted by other wind turbine units has no impact on the measurement. There are no buildings, trees, shrubs, or other objects around the microphone that affect noise measurement. The testing conditions around the reflective plate comply with free field characteristics.

2.2. Measuring Equipment

In this experimental study, we used measurement equipment that meets standard requirements to ensure the high accuracy of the tests. The measurement system was developed in the context of a scientific project and can synchronously record acoustic signals and data such as wind speed and direction from meteorological stations. The synchronization of measurement and data transmission is achieved through wired connections. The measurement system mainly consists of the following components: a laptop with dedicated software installed. The model of the noise acquisition card is NI9234 from National Instruments. The data collector and noise acquisition card are located in a specially designed waterproof, dustproof, impact-resistant box made of aluminum and polypropylene. In addition, a 4190-type capacitive microphone with integrated preamplifier Brüel & Kjær was used, which allows for very accurate noise measurement in a free field environment. The characteristics of this microphone are its high sensitivity of 50 mV/Pa, dynamic range of 14.6 to 146 dB, and frequency range of 6.3 Hz to 20 kHz, and it can operate in a temperature range from −30 °C to +150 °C (−22 °F to +302 °F). In order to reduce the impact of wind, we took wind protection measures, including a main wind shield (with a radius of 85 mm) and a secondary hemispherical auxiliary wind shield (with a radius of 450 mm). These wind shields are made of polyurethane foam or special fabrics [

36]. The device is designed for the noise measurement of wind turbines according to standards, as shown in

Figure 3. To ensure the quality of the measurement, the microphone was calibrated using B&K’s 4231 Level 1 sound calibrator before and after each measurement item. During the calibration process, a 1 kHz signal with a 94 dB level was used, resulting in a sound level accuracy of ±0.2 dB. The sampling frequency for noise measurement was 51.2 kHz.

While measuring the sound pressure level, the measurement system also serves the function of simultaneously collecting other non-acoustic data. Equipment such as anemometers, wind vanes, barometers, thermometers, and hygrometers are installed on the meteorological mast. Meteorological stations can measure the following weather parameters: air temperature in the range from −40 °C to +65 °C with an accuracy of ±0.1 °C; atmospheric pressure in the range from 540 hPa to 1100 hPa with an accuracy of 0.1 hPa; precision in the range from 1 to 1016 mm/h with an accuracy of 0.2 mm/h; and relative air humidity from 0 to 100% with an accuracy of 1%. In addition, a container serves as the mobile control center for the data collection system and is also used to protect electronic measuring equipment from adverse weather and theft, as shown in

Figure 4.

2.3. Noise Measurement

Acoustic data are measured by acoustic sensors at different wind speeds to determine the noise radiated by the WTGs. Firstly, the sensor converts the captured sound pressure signal into an electric signal and then transmits the signal to a noise acquisition card for recording. According to standard regulations, the microphone is placed on a reflective surface with a diameter of one meter behind the wind turbine, and the distance from the wind turbine is calculated as the standard measurement position based on the height of the wheel hub and the diameter of the impeller. As shown in

Figure 1, if the hub height is

H and the rotor diameter is

D, then the distance

R 0 between the sensor position and the center of the wind turbine base should be

=

H +

D/2. In order to eliminate reflections and limit the impact of gusts, the microphone was placed directly on the ground and appropriate wind shields were used. Due to the fact that wind turbine noise is usually measured at high wind speeds, this study also used a secondary wind shield.

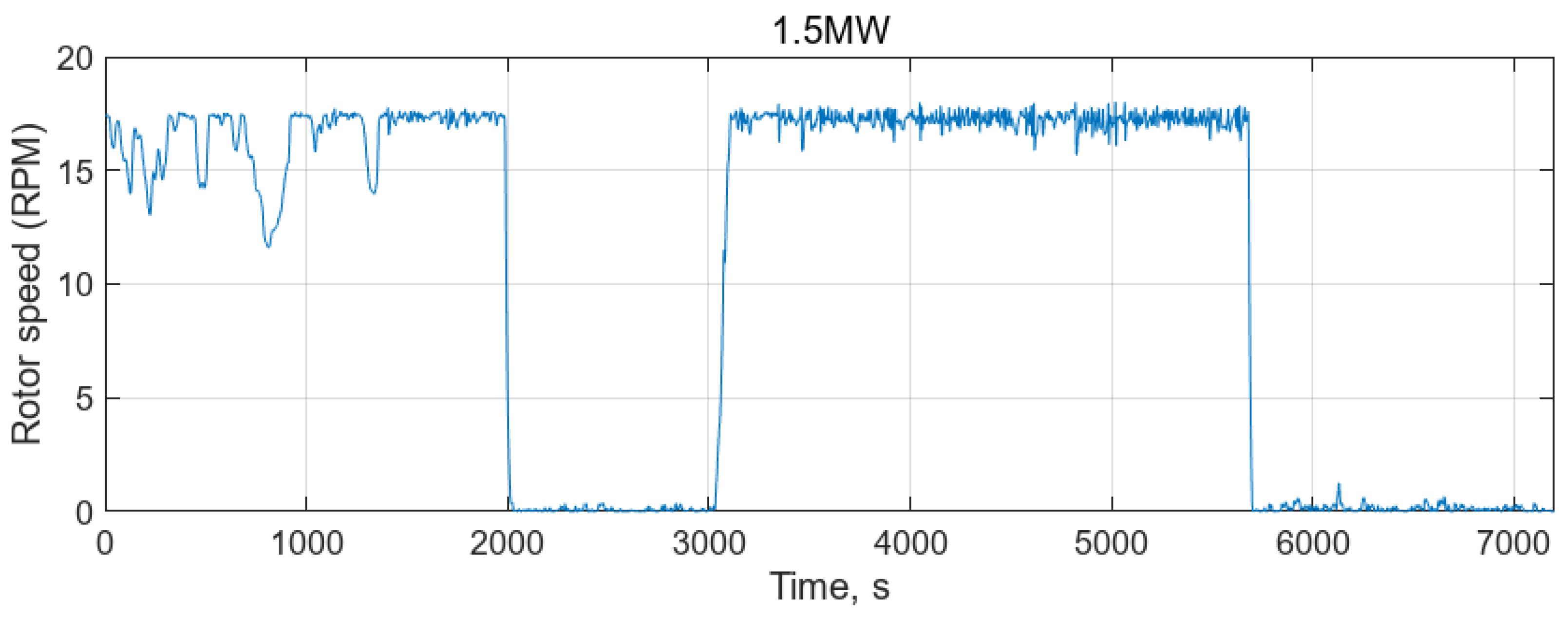

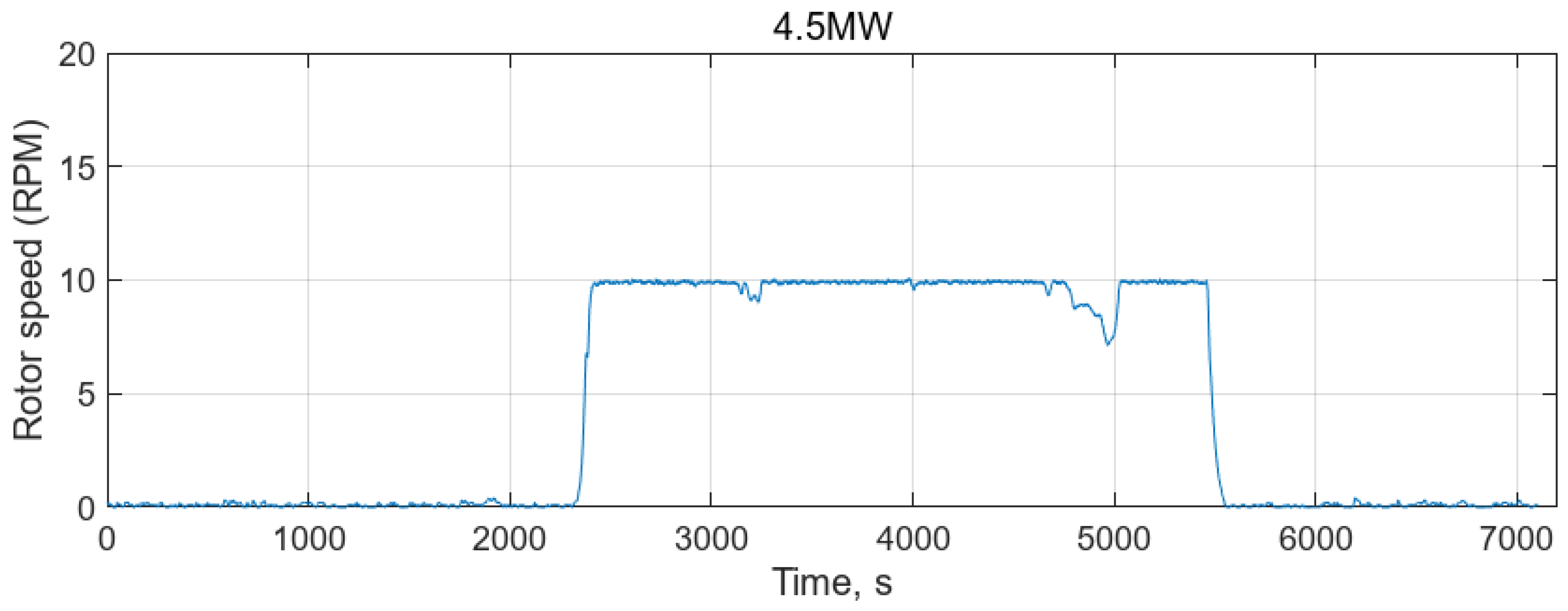

Figure 5 shows the relative position of the acoustic measurement device and the wind turbine. Due to the presence of a large number of natural and artificial sound sources from different sources in the testing environment, in order to ensure the accuracy of data analysis, abnormal interference background noise that occurs during the testing process should be carefully labeled. These interference signal sources mainly include agricultural machinery, specialized vehicles used in the timber industry, and vehicles used for wind turbine operation and maintenance. The interference noise of these labels was excluded from data analysis during data processing. The measurement of noise was continuous, and during the measurement of background noise, the wind turbine was stopped, with each wind turbine shutdown lasting at least 20 min. The data points during the operation and shutdown stages of the wind turbine correspond to the operating noise recorded by the testing system.

The measurement of non-acoustic data needs to be synchronized with the measurement of acoustic data. Meteorological parameters are mainly obtained through meteorological stations. According to standard requirements, meteorological stations should be installed in front of wind turbines at a height of 10 m above the ground. The distance from the meteorological station to the wind turbine should be at least twice the diameter of the impeller and it should be protected from being affected by the wind turbine wake. The specific installation location is shown in

Figure 6. In addition, it obtains the operating parameters of the wind turbine unit, such as power output, spindle speed, rotor speed, and pitch from the wind turbine controller. All these measurement systems need to use software clocks for synchronization before measurement, which can ensure the accurate recording of corresponding acoustic and non-acoustic data during each operation and shutdown period.

According to standard requirements, the noise measurement of wind turbines requires recording data under different wind speed conditions. Therefore, when selecting the measurement time, it is important to carefully observe the weather forecast in advance to ensure that as many different wind speed conditions as possible occur on the day of measurement. In addition, noise measurement on a WTG is a task that requires a lot of preparation and a relatively long measurement time because the weather conditions during the measurement are random and may be affected by various uncontrollable factors. In order to ensure the accuracy of measurements, this study conducted long-term noise measurements for both wind turbines based on specific weather conditions and wind turbine parameters.

Table 2 shows the meteorological conditions and wind turbine power output during the effective testing data period of this study, and the timestamps in this article are always based on Coordinated Universal Time (UTC).

3. Analytical Methods

In order to analyze the measured acoustic data and determine the low-frequency noise characteristic of wind turbines with different power levels, specific time period acoustic data with similar atmospheric conditions lasting for 2 h were selected based on atmospheric stability. The data also include non-acoustic data corresponding to acoustic data such as hub height wind speed, tower height wind speed, blade speed, temperature, wind direction, etc. One method for evaluating the correlation between atmospheric conditions and wind turbine noise is to calculate atmospheric stability using the logarithmic shear index

[

37], which is defined as follows:

where

vh is the wind speed at the hub height

h, and

vref is the wind speed at the reference height of 10 m (mast top). The relationship between the shear index and atmospheric stability was proposed by [

37,

38,

39], with Branko Zajamsek et al. linking acoustic data to atmospheric conditions [

40].

Table 3 provides the range of values for

m under different atmospheric conditions. Unstable conditions may be related to higher turbulence, so wind speed varies greatly over time and space.

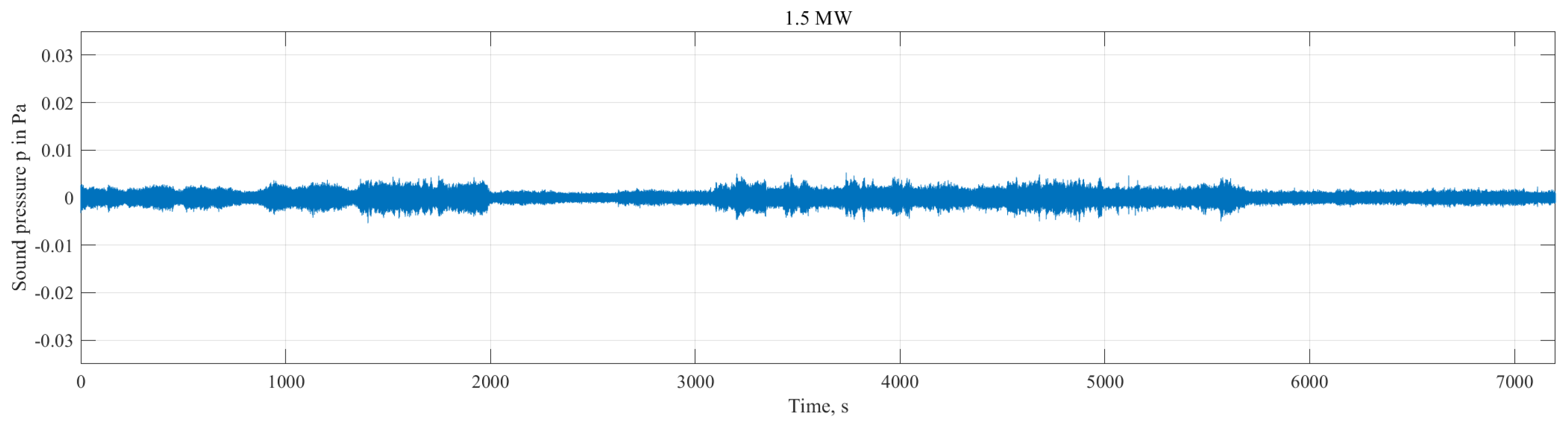

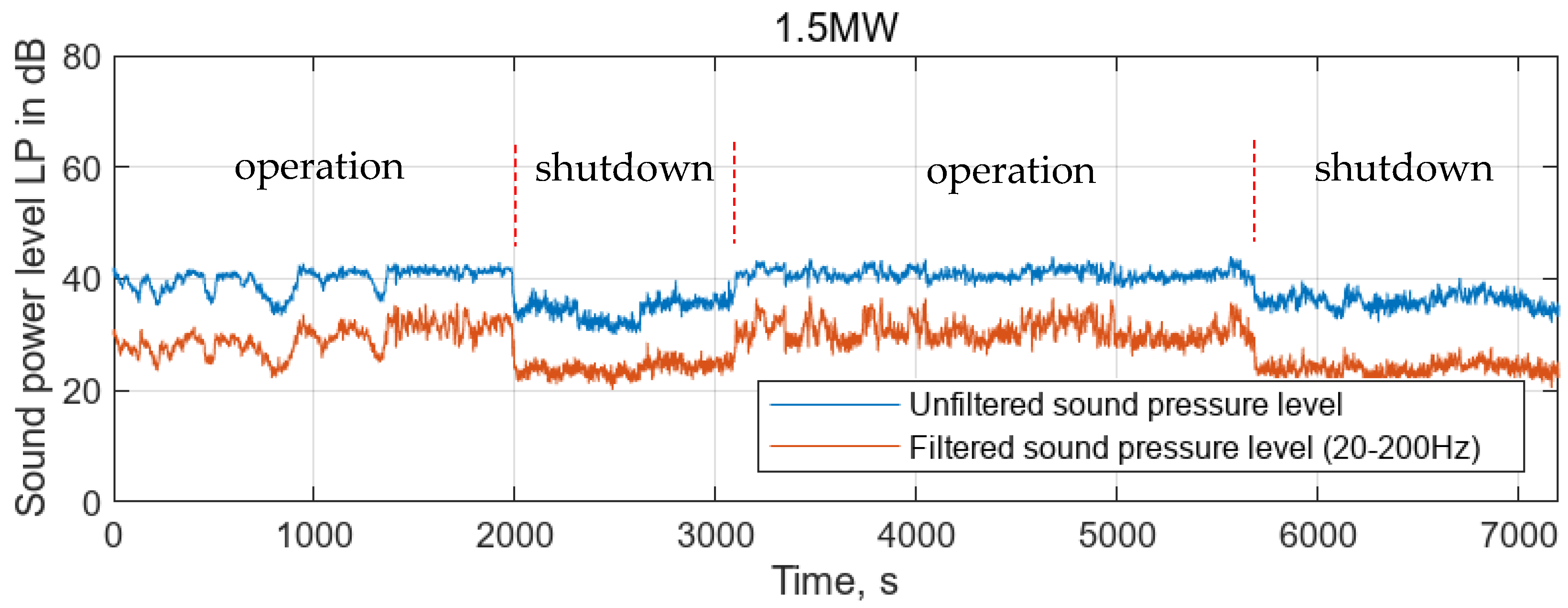

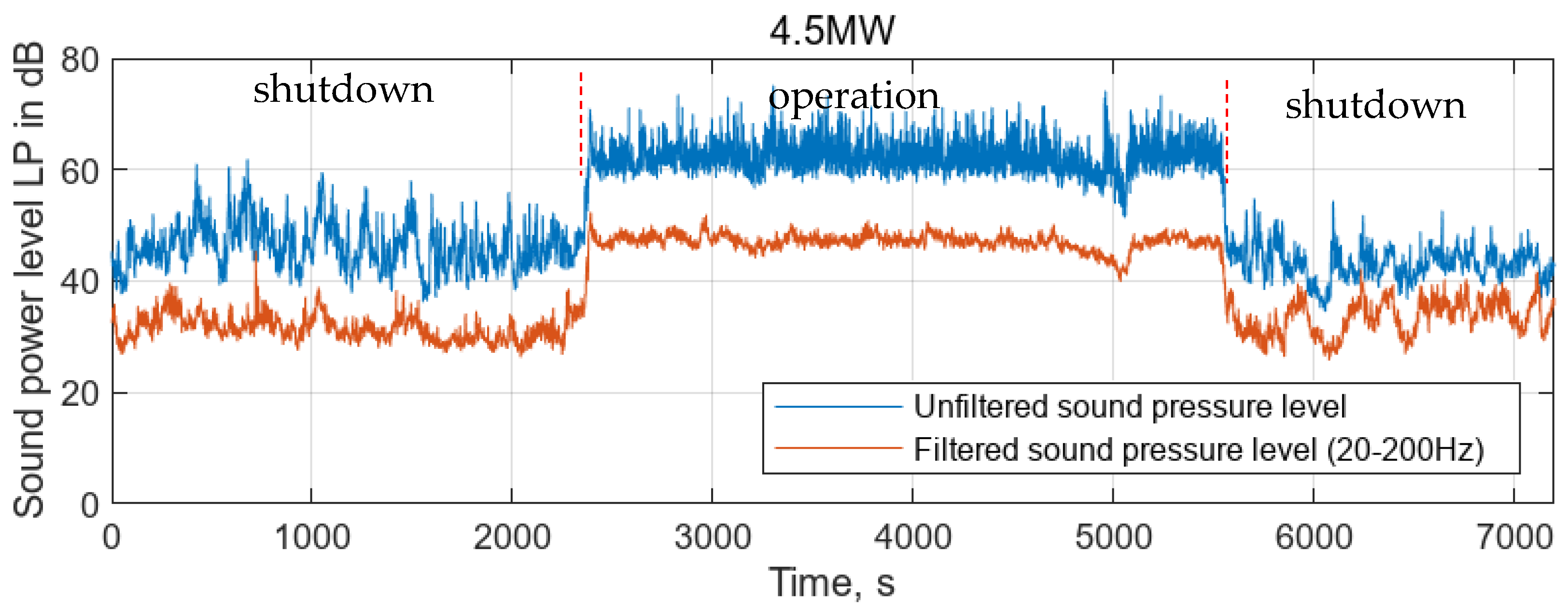

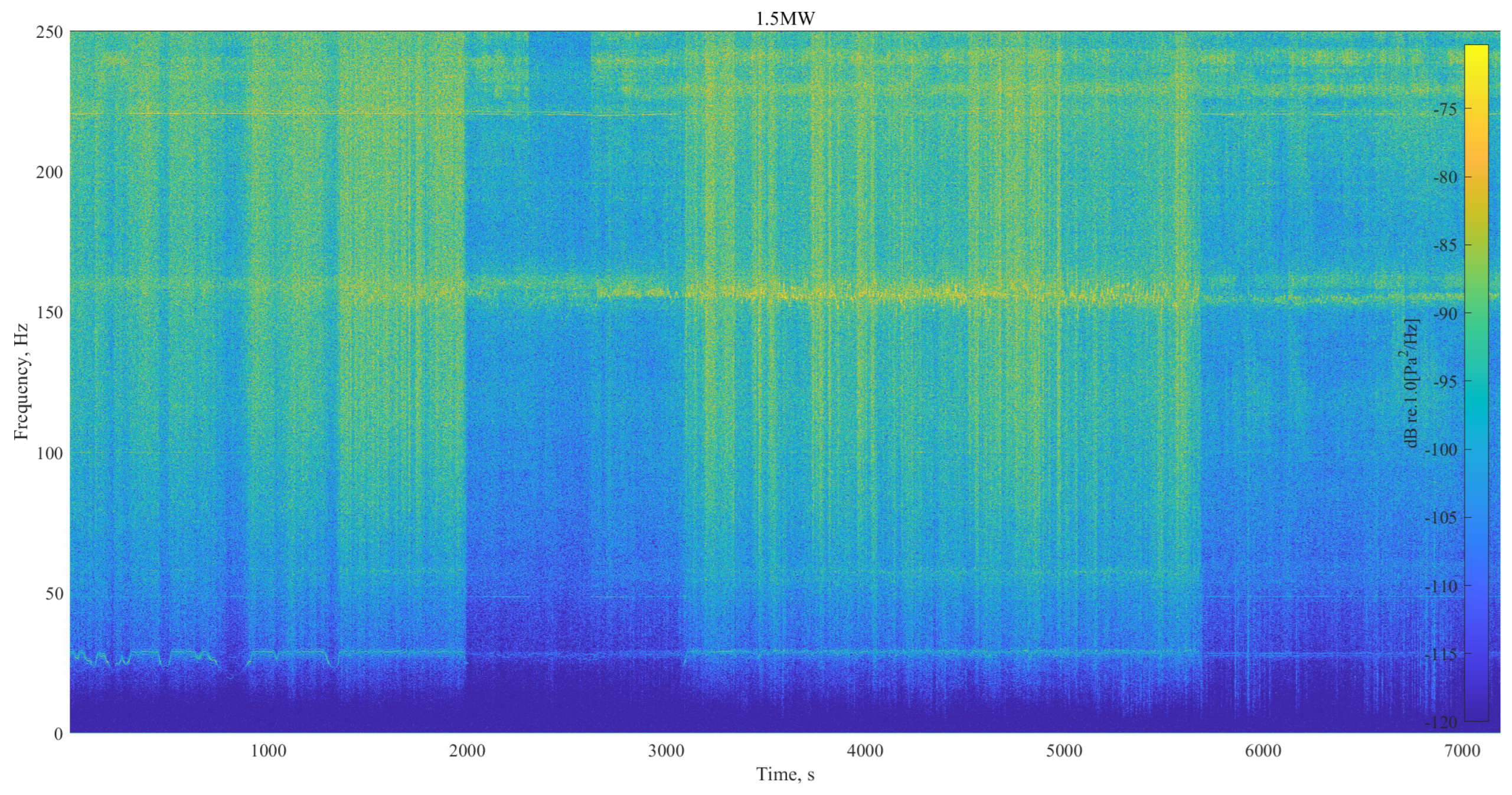

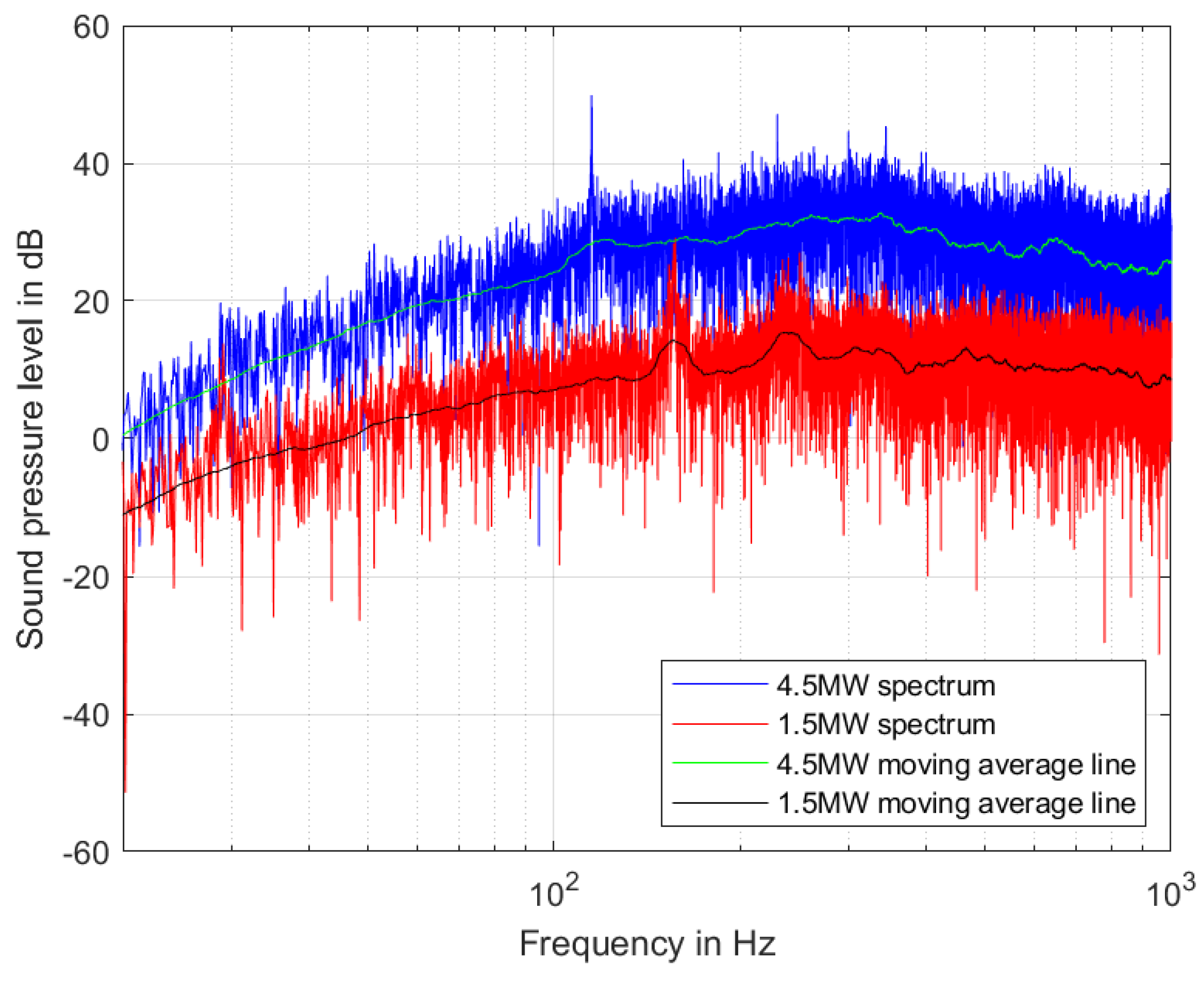

During a specific two-hour time period selected for different power wind turbines, band-pass filtering was performed on sound pressure data with a sampling rate of 51,200 HZ, and resampling was performed at a sampling rate of 500 Hz to simplify data processing. The sound pressure time series after the band-pass filtering of wind turbines with different power levels is shown in

Section 4.2. In order to maintain the identification of small amplitudes in the time series diagram, the vertical axis was intentionally restricted. The A-weighted sound pressure level was calculated for each second based on Formula (2) for the band-pass filtered noise data and unfiltered noise data. Then, the operating time and downtime were classified, and the average sound pressure level for both operating and down time was calculated based on Formula (3). For the spectrogram (see also

Section 4.3), an estimate of the power spectral density (PSD) of the acoustic data was calculated using MATLAB R2022b function “spectrogram”.

where

T is the measurement time (s),

p is the registered variations in acoustic pressure (Pa),

p0 is the reference pressure (2 × 10

−5 Pa—hearing threshold for 1 kHz), and

N is the number of measurements during operation and shutdown.

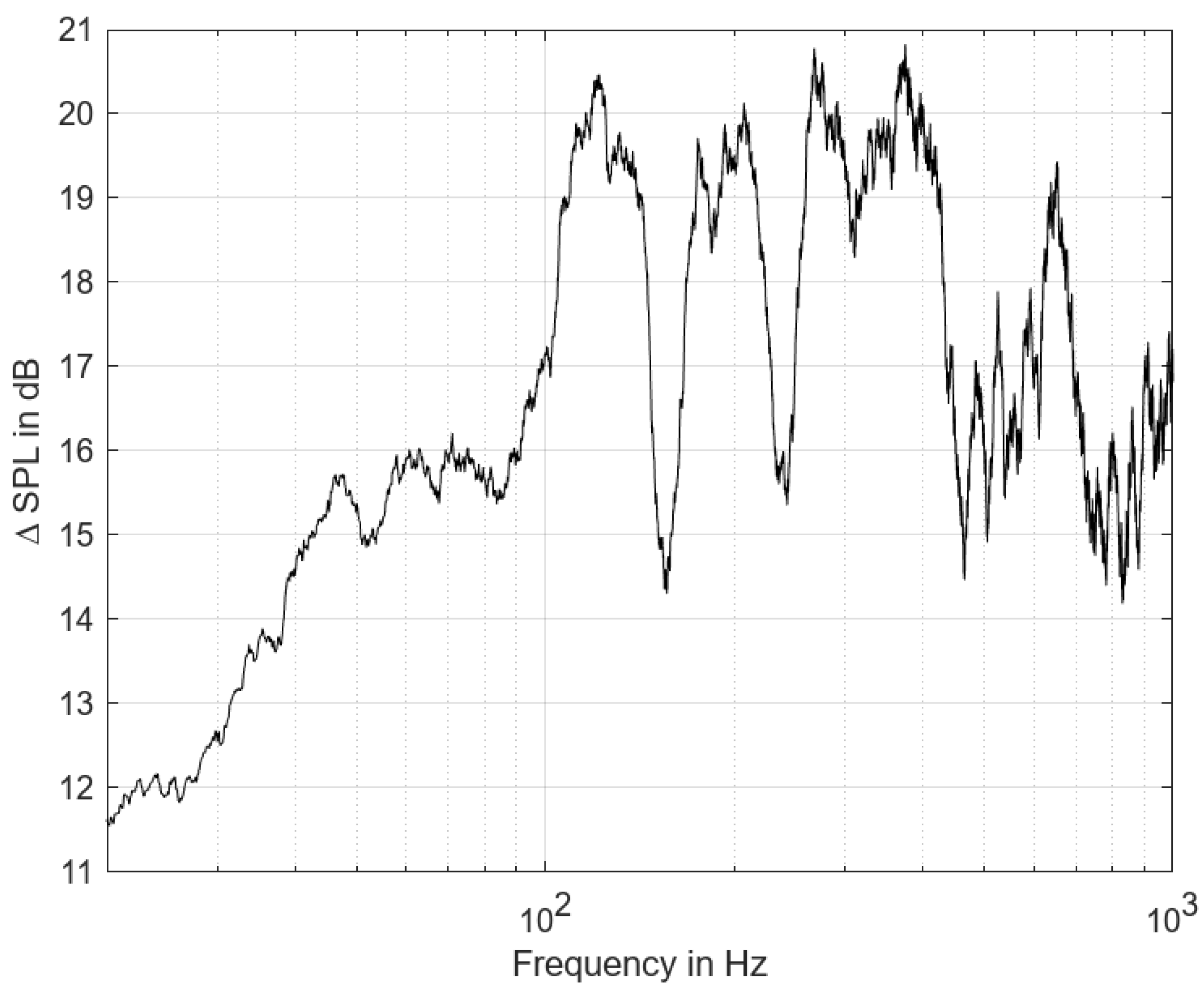

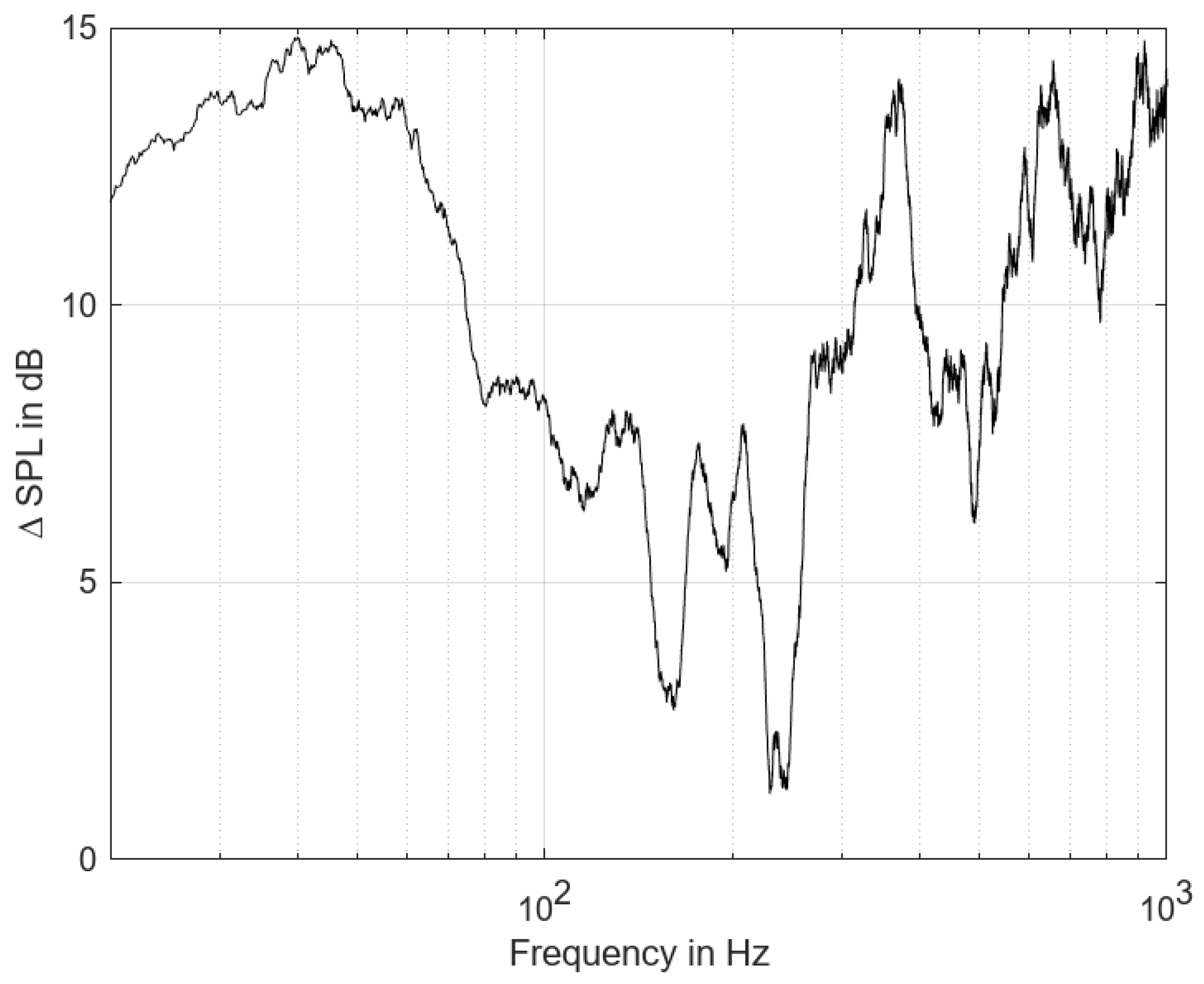

By selecting 10 s of noise data with identical atmospheric conditions during specific operating and shutdown time periods to evaluate the narrowband spectrum, more detailed information about the frequency and sound pressure level of the measured noise signal can be obtained. Therefore, the narrowband spectrum of 10 s measurement noise was calculated using MATLAB functions, the spectrum was smoothed using a moving average filter with a window length of 200, thus showing the overall trend in the spectrum more clearly. The difference analysis was conducted on the operation and shutdown moving average lines of different power wind turbines at the same wind speed (see

Section 4.4).

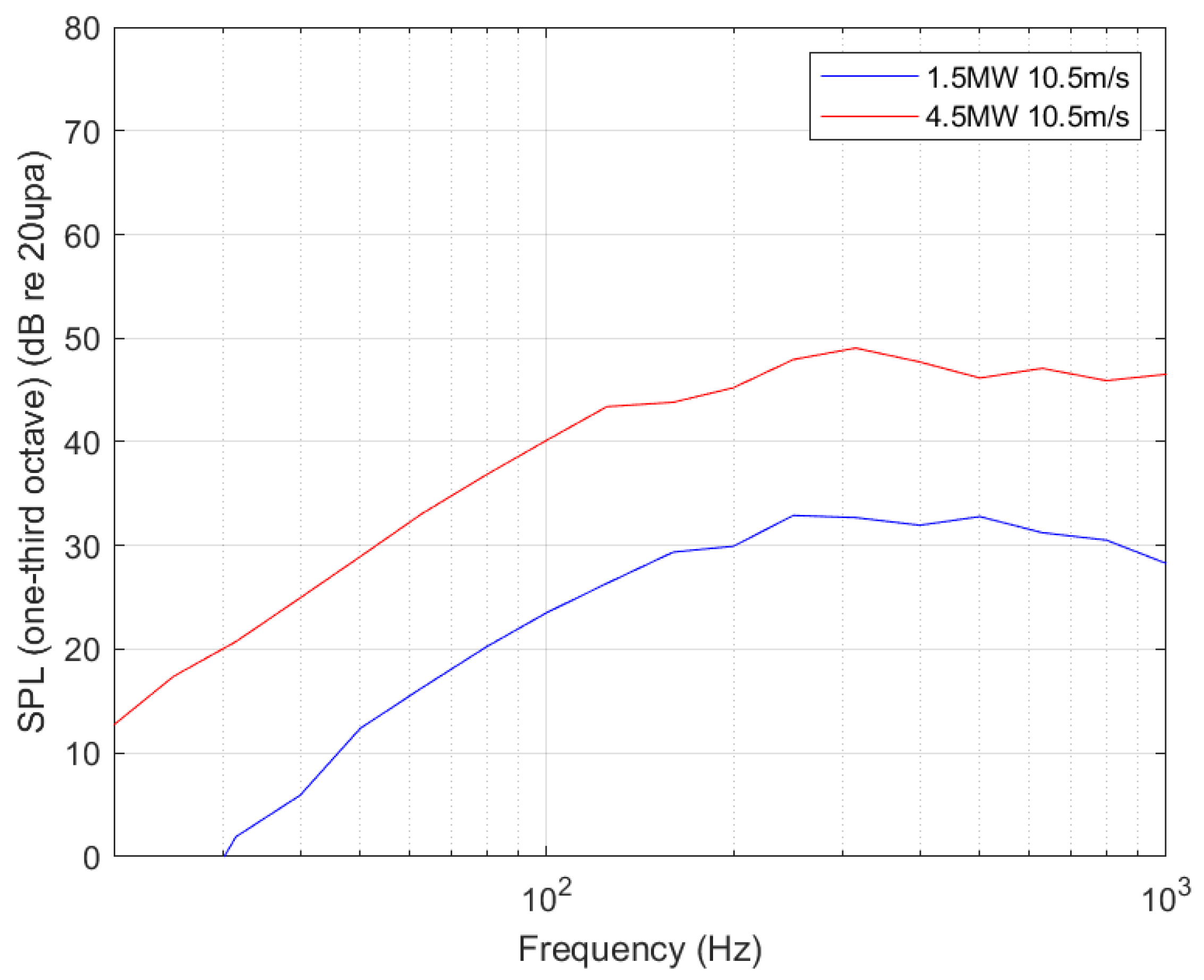

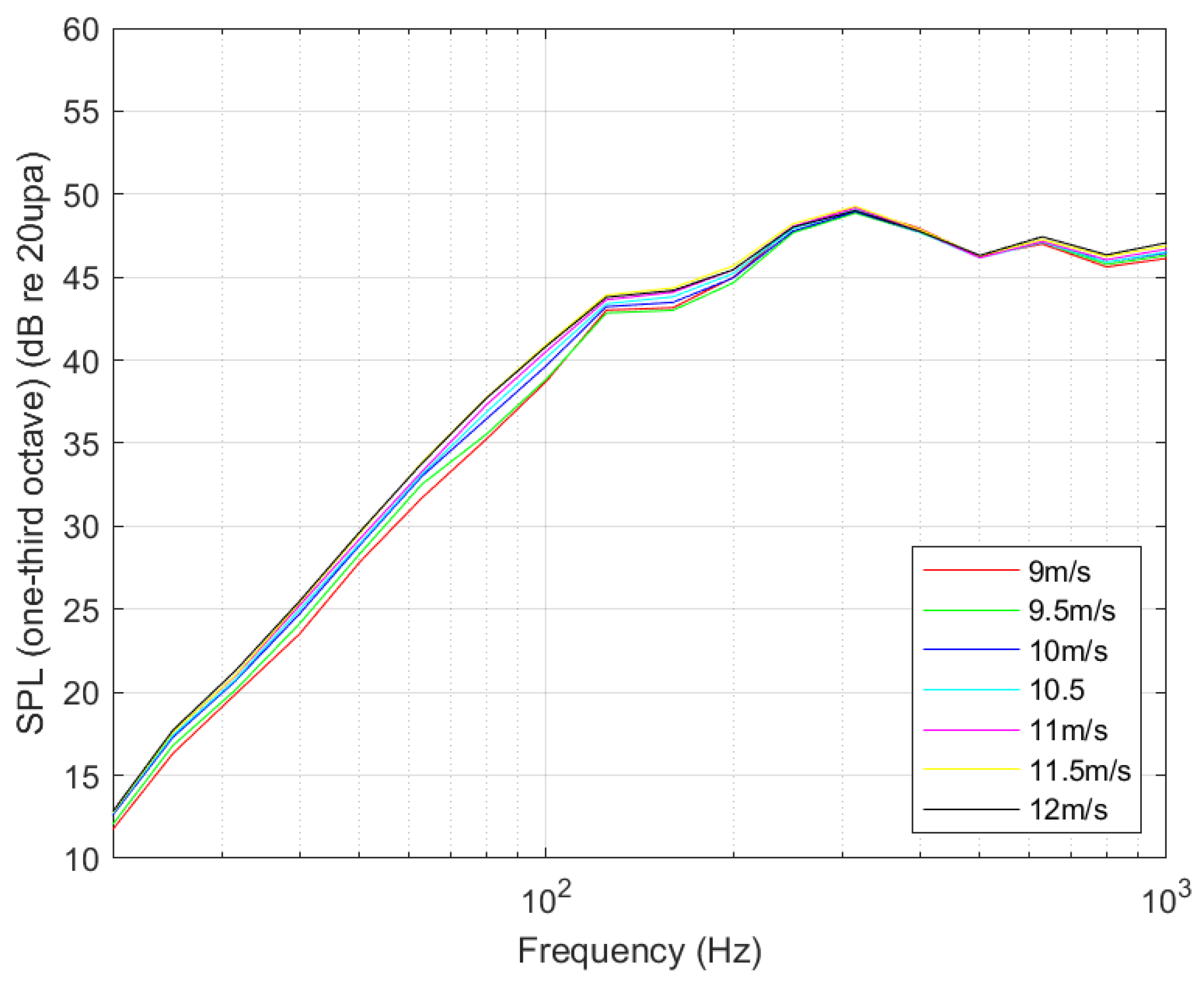

The detailed data processing method for correcting the one-third octave sound pressure level of wind turbine background noise is detailed in Standard 61400-11 [

41]. In this data analysis and processing, two averaging methods are used as follows: arithmetic averaging for non-acoustic data and energy averaging for acoustic data. The measured data points were divided into 0.5 m/s wind speed intervals, centered around integer or semi-integer wind speed values, with left opening and right closing. At the center of each wind speed interval, the corresponding one-third octave spectrum of the background noise calculated at the center of the same wind speed interval was used to correct the total operating noise spectrum according to Formula (4), and the one-third octave spectrum of the wind turbine operating noise without background noise correction was obtained. The total sound pressure level of wind turbines with different power levels in the corrected 10.5 m/s wind speed range and the low frequency range of 20–200 Hz were calculated using Formula (5).

Among them, under the reference atmospheric conditions of LVTik, the A-weighted sound pressure level on the one-third octave band of the total operating noise, and under the reference atmospheric conditions of LVBik, at the interval wind speed k, the A-weighted sound pressure level on the one-third octave band of the background noise is measured.

Within each wind speed range, the apparent sound power level

LWAik on each one-third octave band

Lck is calculated from the corresponding background-corrected sound pressure level

LVcik on the same one-third octave band

Lck according to Formula (6).

where

R1 is the straight-line distance from the center of the wind turbine to the microphone in

Figure 4, in meters (m), and

S0 is the reference area,

S0 = 1 m

2. The constant 6 dB in Formula (6) indicates that due to the use of a measuring plate, the measured sound pressure is approximately twice the actual sound pressure.

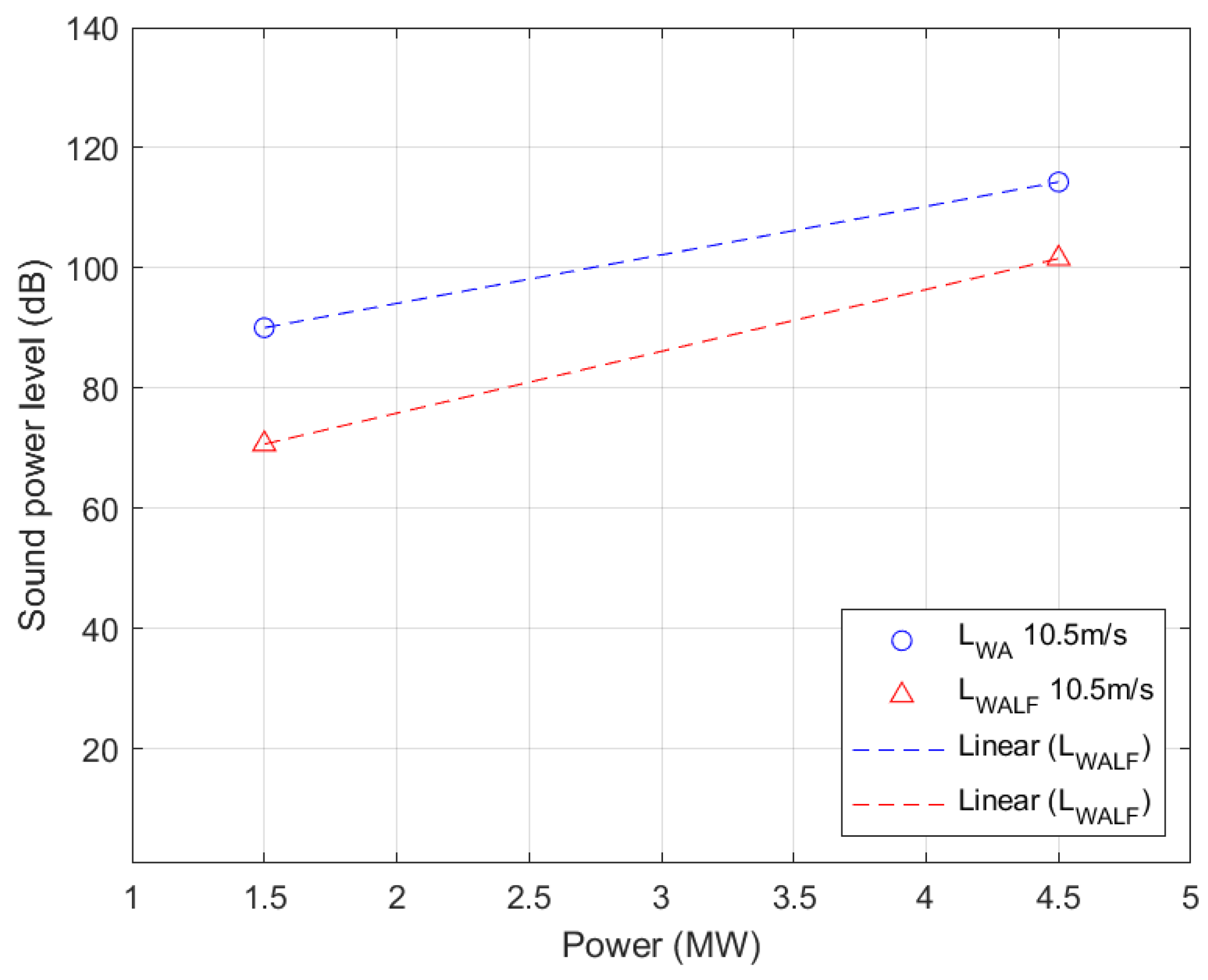

The A-weighted apparent sound power level within the wind speed range

k is calculated by summing the energy of all sound power values in the one-third octave band, as shown in Equation (7). The A-weighted sound power level

LWALFk in the low-frequency range of 20–200 Hz was calculated using Formula (8).

The above are the calculation methods mainly involved in this study, and a more detailed analysis of the apparent sound power level can be found in

Figure 6 of IEC 61400-11 (which shows the flowchart of the data processing process).

5. Conclusions

The IEC 61400-11 standard provides a reliable method for determining the acoustic emissions of a single wind turbine. Based on the measurement results of this method, different sizes and types of wind turbines can be compared. This study conducted long-term acoustic measurements and analysis of 1.5 MW and 4.5 MW wind turbines and concluded that the research results indicate that regardless of the power of the wind turbine, noise containing low-frequency components is generated. Compared with small wind turbines, large wind turbines generate more noise at the same wind speed, and the low-frequency portion of these noises increases more. Through the study of the narrowband spectrum over a 10-s time period, it was shown that the increased low-frequency noise mainly ranges from approximately 60 Hz to 300 Hz. Through the analysis of the corrected one-third octave sound pressure level, it was found that the low-frequency noise of large wind turbines does not change as significantly with wind speed as small wind turbines, and the amplitude variation in large wind turbines is mainly at lower frequencies. The possible reason for these results is that at the same wind speed, the speed of large wind turbines is lower than that of small wind turbines, and the speed of large wind turbines is not as sensitive to changes in wind speed as small wind turbines. In addition, 4.5 MW wind turbines have larger blades and larger loads, which can lead to higher levels of low-frequency noise, and longer blades will decrease stiffness and increase flexibility, which is also the reason why large wind turbines generate more low-frequency noise. Due to the weak propagation and attenuation of low-frequency noise in the air, the same attenuation level of low-frequency noise at the same wind speed means that low-frequency noise generated by large wind turbines can be heard further away. Therefore, the low-frequency portion of the spectrum of large wind turbines is more likely to have an impact on residents living near wind farms.

The novelty of this research results lies in providing guidance and recommendations for planning onshore wind energy projects. The potential impact of noise on residents needs to be carefully considered when better wind resources are available near residential areas, and it is necessary to build wind farms near residential areas as a last resort. To reduce this impact, when planning wind farm projects with the same power capacity, selecting relatively small power wind turbines can reduce the impact of noise on nearby residents. In addition, when building a wind farm with large wind turbines, it should be planned to be installed as far away from residential areas as possible in the early stages to reduce potential noise disturbance. The current national standards have not yet incorporated the level of low-frequency noise from wind turbines into standards and regulations. This research emphasizes the need to pay attention to the low-frequency noise generated by large wind turbines and suggests measures that may need to be taken to mitigate their potential impact on surrounding residents. In future research, the results of this research can serve as a reference for the study of the relationship between wind turbine noise and power balance, providing strong cases to reduce the impact of wind turbine noise on the environment and also playing a very important role in the orderly and comprehensive transformation of high-power wind turbines.