Current Progress and Development Trend of Gas Injection to Enhance Gas Recovery in Gas Reservoirs

Abstract

1. Introduction

2. Gas Injection to Enhance Gas Recovery

2.1. Properties of Gas Injection Medium

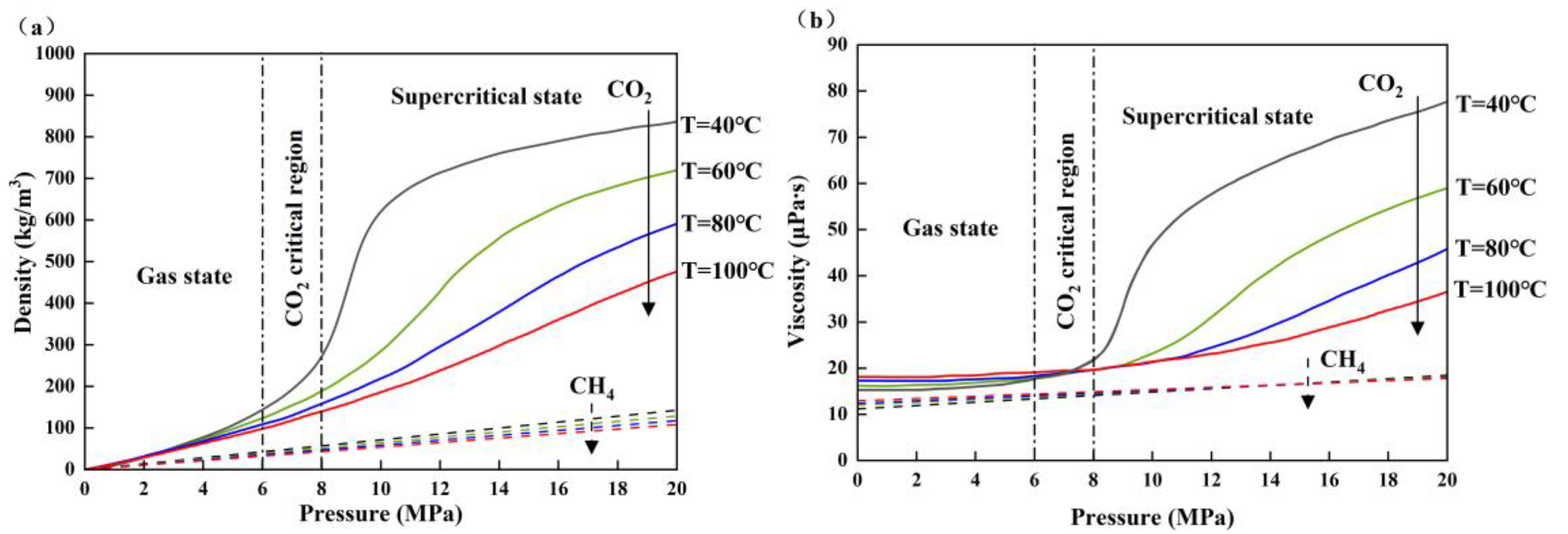

2.1.1. Physical Properties of CO2 and Natural Gas

2.1.2. Physical Properties of N2 and Natural Gas

2.2. Gas Injection Mechanism

2.2.1. Mechanism of CO2 Injection to Enhance Gas Recovery

- Cushion gas: When the temperature is greater than 31.04 °C and the pressure is greater than 7.38 MPa, CO2 reaches a supercritical state, with the viscosity of a gas and the density of a liquid, which is easier to achieve in the gas reservoir. The continuous injection of CO2 enhances the thickness of the underlying CO2 cushion and effectively isolates the aquifer. Simultaneously, the miscible displacement of CO2 and natural gas promotes the upward displacement of residual natural gas in the reservoir, thereby enhancing gas reservoir recovery [34,35], as illustrated in Figure 4.Figure 4. Schematic diagram of CO2 cushion mechanism [36].Figure 4. Schematic diagram of CO2 cushion mechanism [36].

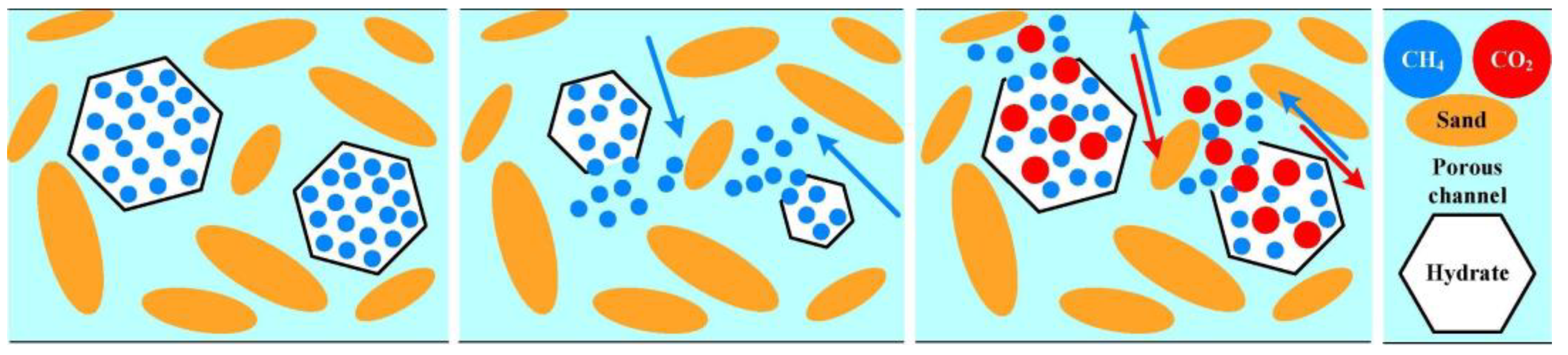

- Competitive adsorption displacement: CO2 has a stronger adsorption capacity than CH4 on the reservoir rock surface, and there is an advantage of competitive adsorption (the shale and coal seam phenomena are more significant) [37]. Therefore, CO2 can displace CH4 adsorbed on the rock surface and transform it into a free state, as shown in Figure 5. Under low temperature and high pressure, CH4 molecules combine with water molecules to form a crystal structure, constituting methane hydrate. Therefore, the stability of methane hydrate is affected by factors such as temperature, pressure and water content. Due to the stronger adsorption capacity of CO2 and its reaction with water, it is easier to promote the decomposition of methane hydrate formed by water locking, replace the CH4 molecules therein and extract them, so as to enhance gas recovery [38], as shown in Figure 6.Figure 5. Competitive adsorption of CO2 and CH4 [39].Figure 5. Competitive adsorption of CO2 and CH4 [39].

- Energy replenishment and penetration ability increase: CO2 injection into the reservoir can effectively supplement the gas reservoir energy, increase the reservoir pressure and even restore the remaining gas to the initial pressure, prolong the service life and further enhance gas recovery. In addition, the higher the abandonment pressure of the formation, the stronger the ability of the reservoir to adsorb CO2, and the higher the recovery; further, the replenishment of the reservoir energy will strengthen the adsorption and substitution mechanism [34]. At the same time, CO2 can extract reservoir rock surface water, clean water and gas flow channel in the condensate gas block area; change hydrophilic wettability; reduce gas seepage resistance; and facilitate more residual gas recovery [40].

2.2.2. Mechanism of N2 Injection to Enhance Gas Recovery

- Gravity differentiation water resistance: For the edge- and bottom-water gas reservoirs, the continuous injection of N2 can effectively form gravity differentiation slug, reduce the water invasion velocity, reduce water production and reduce the water–gas ratio of the gas well [41]. At the same time, N2 and natural gas can form complete miscible displacement and reduce the residual gas saturation of the water lock.

- Energy replenishment and penetration ability increase: N2, as the driving gas, is continuously injected, and the supplement formation energy effect is obvious. For depleted gas reservoirs, N2 injection can supplement formation energy (Nitrogen-Assisted Depletion Drive (NADD)), delay pressure reduction and maintain stable production of gas wells. In water-flooded gas reservoirs, N2 injection supplements formation energy (Nitrogen-Enhanced Residual Gas (NERG)), reduces water invasion velocity, reduces water production and improves the gas productivity of gas wells [23], as shown in Figure 7. Both of the above cases can effectively enhance gas recovery. In addition, the N2 compression coefficient is smaller than that of CO2, and the injection amount to replenish the same energy is smaller. Similarly, N2 can effectively reduce the expansion of rock clay and increase the permeability of the reservoir [42].

2.2.3. Mechanism of CO2 and N2 Mixture Injection to Enhance Gas Recovery

3. Laboratory Experiment of Gas–Gas Displacement

3.1. CO2–Natural Gas Displacement Experiment

| Research Focus | Research | Gas Type | Experimental Conditions | Observations and Conclusion |

|---|---|---|---|---|

| Technical feasibility of EGR | Mamora et al. (2002) [45] | CO2 | Carbonate core: 2.54 cm × 30.5 cm; k: 50 mD, ϕ: 23%; T: 20–60 °C; P: 3.45–20.67 MPa. | The injection of supercritical CO2 could improve displacement efficiency and re-pressurize the reservoir, effectively displacing CH4, and the recovery of CH4 was between 73% and 87%. |

| Shi et al. (2017) [46,47] | CO2 | Natural outcrop sandstone: 1 m × 2.5 cm; k: 0.652 mD, ϕ: 9.9%; T: 85 °C; P: 25 MPa. | With the increase in the injection ratio of supercritical CO2, the ultimate recovery rate increased by 17.3% on the basis of depleted production. | |

| Ding et al. (2022) [48] | CO2 | Tight sandstone core: 80 cm long; k: 0.11 mD, ϕ: 6.98%; T: 82 °C; P: 27 MPa. | Injection of supercritical CO2 after gas reservoir depletion could increase gas recovery by 18.9%. | |

| Fluid interface properties, such as contact angle, wettability, MMP, etc. | Wang et al. (2019) [40] | CO2 | Sample of tight sandstone. | CO2 can eliminate the clogging of condensate gas near the well and reduces the hydrophilic wettability of rock by pumping water, which is conducive to relieving the resistance of water to gas flow. |

| Influence of residual water | Honari et al. (2016) [50] | CO2 | Sandstone core, carbonate core: 3.75–3.80 cm × 10.04–10.47 cm; k: 460, 12, 2912, ϕ: 20%, 16%, 23%; T: 40 °C; P: 10 MPa. | Bound water occupied part of the flow channel and dissolved part of CO2, effectively reducing the adverse influence of core heterogeneity on sweep efficiency. |

| Zecca et al. (2017) [54] | CO2 | Sandstone core: 3.75–3.76 cm × 10.04–10.10 cm; k: 460, 12 mD, 20%, 15%; T: 36 °C; P: 10 MPa. | Dispersion was observed to increase significantly with water saturation in the core. | |

| Salinity effects | Abba et al. (2018 b) [55,56] | CO2 | Berea sandstone core: 2.522 cm × 7.627 cm; k: 217 mD, ϕ: 20.3%; T: 40 °C; P: 8.963 MPa. | The dispersion coefficient decreases with the increase in salinity; primary water salinity affects the mixing of CO2 and residual natural gas in the reservoir. |

3.2. N2–Natural Gas Displacement Experiment

3.3. Mixture–Natural Gas Displacement Experiment

4. Numerical Simulation of Enhanced Gas Recovery by Gas Injection

4.1. Effects of Gas Injection on Different Gas Reservoirs

4.1.1. Water Drive Gas Reservoirs

4.1.2. Condensate Gas Reservoirs

4.1.3. Depleted Gas Reservoirs

4.2. Injection Strategy Research

4.3. Research on the Influence of Reservoir Physical Properties and Injection Parameters

| Research Objective | Research | Simulator | Model Size (km) | Depth (m) | Permeability and Porosity (mD; %) | Injection Rate (m3/day) |

|---|---|---|---|---|---|---|

| Effect of permeability heterogeneity | Oldenburg et al. (2001) [28], Rebscher and Oldenburg (2005) [84] | TOUCH2 | 6.6 × 1 × 0.1 | / | kx: 1000, kz: 10; 35 | 3.58 × 105 |

| Gou et al. (2013) [82] | TOUGH2MP-FLAC3D | 4.4 × 2 × 1 | 3400 | 11; 21 | / | |

| Feather and Archer (2010) [87] | ECLIPSE | 1.524 × 1.524 × 0.03 | / | kx: 100, kz: 1–10; 20 | 1616.16–32,424.24 | |

| Effect of injected water vs. formation water | Kalra et al. (2014) [86] | CMG-GME | 2.286 × 0.02286 × 0.0915 | 3048 | 100; 20 | 1616.16 |

| Effect of inclination | Adler et al. (1983) [41] | / | / | / | 1, 50, 250, 500; 5, 10, 20 | 85,170,255 × 103 |

| Penetration layer distribution in relation to perforation location | Kalra et al. (2014) [86] | CMG-GME | 2.286 × 0.02286 × 0.0915 | 3048 | 1, 5, 10, 50, 100; 20 | 1.27 × 105 |

| Injection pressure | Narinesingh and Alexander (2014) [74] | CMG-GME | 2.43 × 0.045 × 0.045 | 3992.88 | 90–180; 22–28 | 1.42 × 105 |

| Injection gas type | Leeuwenburgh et al. (2014) [75] | / | / | / | / | A gas field: (0.3–3.2) × 105; Gas field B: (0.2–15) × 105 |

| Morsy et al. (2020) [76] | / | / | / | 0.1, 1; 20 | / | |

| Injection gas timing | Clemens (2002) [88] | / | 4 × 2 × 0.06 | / | 104–55; / | (6.07–8.28) × 105 |

| Jukic et al. (2021) [77] | / | / | 2410 | /; 2–18 | / | |

| Jikich et al. (2003) [89] | UTCOMP | 804.67 × 804.67 × 3.96 | / | 5.5; 11 | 4040.4–335,353.4 | |

| Hashami et al. (2005) [85] | / | 1.2192 × 1.2192 × 0.037 | 2133.6 | 40; 20 | 4.25 × 105 | |

| Hussen et al. (2012) [90] | tempest | 1.7 × 2.3 × 0.3 | 3650 | kx: 6–390, ky 6–390, kz: 4–370; 4–17 | 2.42 × 106 | |

| Injection rate | Seo and Mamora et al. (2005) [91] | / | 0.20119 × 0.20119 × 0.04572; 0.2845 × 0.2845 × 0.09144 | / | kx: 50, kz: 10; 35 | 202.02, 404.04 |

5. Examples of Gas Injection EGR Research

6. Conclusions

- Based on the advantages of the physical properties of CO2 and N2, from the perspective of the mechanism, effective cushion gas can be formed after injection into the reservoir to drive up natural gas recovery, and the goal of increasing pressure and supplementing energy can be reached to the maximum extent, which is the most important result and the basis for completing other mechanism effects. For water drive gas reservoirs such as edge- and bottom-water reservoirs, the advantage of gravity differentiation water resistance after gas injection is very obvious. And because of the good adsorption ability of CO2 porous medium, it is easier to complete the competitive adsorption replacement of natural gas.

- In laboratory experiments, CO2 is predominantly employed as the driving gas. However, it is more advantageous to precede CO2 injection with the injection of N2 or a mixture of CO2 and N2 in terms of both enhanced gas recovery effectiveness and cost efficiency. This approach prolongs breakthrough by facilitating CO2 dissolution in water, while the presence of N2 ensures not only efficient displacement but also mitigates the extent of CO2 corrosion.

- Numerical simulations demonstrate that water drive gas reservoirs and condensate gas reservoirs exhibit significant enhanced gas recovery, while depleted gas reservoirs have limited advantages in EGR but are more suitable for CO2 storage. Reservoir heterogeneity easily promotes the formation of high-permeability channels, which can be mitigated by the presence of formation water to stabilize displacement. Due to the absence of a mixed percolation model and conventional gas reservoir simulation, differences in gas extraction efficiency are not apparent. Injection rate and timing play crucial roles in determining EGR outcomes.

- Field case studies demonstrate that gas injection has a significant impact on enhancing gas reservoir recovery and its enforceability. Specifically, the highly representative De Wijk gas field in the Netherlands and Budafa Szinfelleti gas field in Hungary highlight the advantages of employing gas injection for water drive and depleted gas reservoirs to enhance gas recovery. Moreover, it is evident that gas injection exerts a noticeable pressurization effect, resulting in an increase in gas recovery exceeding 10%. These findings lay a solid foundation for the potential commercial application of this method.

7. Prospects

- In the mechanism of gas injection to enhance gas recovery, there are few experimental studies on the mechanism for increasing penetration ability. After different gas injection configurations, the changes in reservoir permeability and porosity are not clear enough, and the improvement degree of permeability is not specific. It is suggested to use visualization technology to measure and quantify the changes in reservoir physical properties after gas injection and to characterize and evaluate the improvement in penetration ability.

- The mixing mechanism is mainly affected by the mixing dispersion caused by diffusion and convection. In the future, the mixing mechanism, including physical and chemical action, should be further studied to understand the seepage behavior and displacement mechanism. The investigation of dispersion in gas displacement focuses on the dispersion behavior of supercritical CO2 and N2 mixtures and on the influence of residual water and salinity on dispersion, as well as the dispersion behavior and effect under water invasion and flooding. Based on the above, the mixed dispersion model should be constructed based on experiments, and numerical simulations should be applied to provide help for specific field development.

- In numerical simulations, the traditional Darcy seepage model can output the fluid flow and observe the saturation change, but it is not enough for the simulation of gas injection for enhanced gas recovery. It is very important to characterize the gas flow path in gas injection, which can be used to analyze the injection strategy and observe the sweep and breakthrough characteristics. Therefore, a flow path characterization model should be constructed and incorporated into reservoir simulation.

- For deep, high-temperature gas reservoirs, it is very promising to use supercritical CO2 storage to enhance gas recovery and exploit geothermal energy at the same time, which is worthy of further study.

Author Contributions

Funding

Conflicts of Interest

References

- Li, L. Development of natural gas industry in China: Review and prospect. Nat. Gas Ind. B 2022, 9, 187–196. [Google Scholar] [CrossRef]

- Wang, Z.; Fan, Z.; Zhang, X.; Liu, B.; Chen, X. Status, Trends and Enlightenment of Global Oil and Gas Development in 2021. Pet. Explor. Dev. 2022, 49, 1210–1228. [Google Scholar] [CrossRef]

- Hassan Shetol, M.; Moklesur Rahman, M.; Sarder, R.; Ismail Hossain, M.; Kabir Riday, F. Present Status of Bangladesh Gas Fields and Future Development: A Review. J. Nat. Gas Geosci. 2019, 4, 347–354. [Google Scholar] [CrossRef]

- Yong, R.; Hu, Y.; Peng, X.; Mei, Q.Y.; Qi, T.; Yang, J.; Zhang, L. Progress and prospect of enhanced gas recovery technology in the Sichuan Basin. J. Nat. Gas Ind. 2023, 43, 23–35. [Google Scholar] [CrossRef]

- Ma, X.; He, D.; Wei, Y.; Guo, J.; Jia, C. Enhanced gas recovery: Theory, technology and prospect. J. Nat. Gas Ind. 2023, 10, 393–405. [Google Scholar] [CrossRef]

- Ping, G.; Shasha, J.; Caizhen, P. Technologies and Countermeasures for Gas Recovery Enhancement. Nat. Gas Ind. B 2014, 1, 96–102. [Google Scholar] [CrossRef]

- Hongjun, X.; Lei, S. CO2 injection to improve recovery facter of gas reservoir. J. Nat. Gas Explor. Dev. 2006. [Google Scholar]

- Lin, J.; Ren, T.; Cheng, Y.; Nemcik, J.; Wang, G. Cyclic N2 Injection for Enhanced Coal Seam Gas Recovery: A Laboratory Study. Energy 2019, 188, 116115. [Google Scholar] [CrossRef]

- Iddphonce, R.; Wang, J.; Zhao, L. Review of CO2 Injection Techniques for Enhanced Shale Gas Recovery: Prospect and Challenges. J. Nat. Gas Sci. Eng. 2020, 77, 103240. [Google Scholar] [CrossRef]

- Guoting, W.; Ailin, J.; Zhi, G. Effect evaluation and adjustment countermeasures of tight gas development well patterns in the Sulige Gas Field. J. Nat. Gas Ind. 2023, 43, 66–79. [Google Scholar] [CrossRef]

- Yunsheng, W. A new way of evaluation productivity of staged fracturing horizontal well in tight gas reservoir. J. Nat. Gas Ind. 2012, 35, 32–34. [Google Scholar] [CrossRef]

- Yongqiang, F.; Ye, H. Reservoir stimulation techniques and their application to the Longwangmiao Fm gas resevoirs in the Sichuan Basin. J. Nat. Gas Ind. 2014, 34, 93–96. [Google Scholar] [CrossRef]

- Yong, H.; Yingli, C. The formation development and theoretical connotations of “overall water control of gas reservoir” technology in gas field development. J. Nat. Gas Ind. 2022, 42, 10–20. [Google Scholar] [CrossRef]

- Gao, S.; Zhang, J.; Liu, H.; Ye, L.; Zhu, W.; Xiong, W. Water-Gas Ratio Characteristics and Development Concepts for Water-Producing Gas Reservoirs. Heliyon 2023, 9, e19201. [Google Scholar] [CrossRef]

- Clemens, T.; Secklehner, S.; Mantatzis, K.; Jacobs, B. Enhanced Gas Recovery, Challenges Shown at the Example of Three Gas Fields. In Proceedings of the SPE EUROPEC/EAGE Annual Conference, Barcelona, Spain, 14–17 June 2010; p. SPE 130151. [Google Scholar]

- Vandeweijer, V.; Hofstee, C. CO2 Injection at K12-B, the Final Story. In Proceedings of the 15th International Conference on Greenhouse Gas Control Technologies, Abu Dhabi, United Arab Emirates, 5–8 October 2021; Available online: https://ssrn.com/abstract=3820865 (accessed on 29 April 2023).

- Vandeweijer, V.; Van Der Meer, B.; Hofstee, C.; Mulders, F.; D’Hoore, D.; Graven, H. Monitoring the CO2 Injection Site: K12-B. Energy Procedia 2011, 4, 5471–5478. [Google Scholar] [CrossRef]

- Audigane, P.; Oldenburg, C.; van der Meer, B.; Geel, K.; Lions, J.; Gaus, I.; Robelin, C.; Durst, P.; Xu, T. Hydrodynamics and Geochemical Modelling of CO2 Injection at the K12B Gas Field. In Proceedings of the 69th EAGE Conference and Exhibition incorporating SPE EUROPEC 2007, London, UK, 11–14 June 2007; p. cp-27-00174. [Google Scholar] [CrossRef]

- Kreft, E.; Brouwer, G.K.; Hofstee, C.; Wildenborg, A.F.B.; Audigane, P.; Gozalpour, F.; D‘Hoore, D.; Hartman, J.; van der Meer, L.G.H.; Geel, C.R. Results of the Second Test Program in K12-B, a Site for CO2 Storage and Enhanced Gas Recovery. In Proceedings of the 68th EAGE Conference and Exhibition incorporating SPE EUROPEC 2006, Vienna, Austria, 12–15 June 2006; p. cp-2-00288. [Google Scholar] [CrossRef]

- Underschultz, J.; Boreham, C.; Dance, T.; Stalker, L.; Freifeld, B.; Kirste, D.; Ennis-King, J. CO2 Storage in a Depleted Gas Field: An Overview of the CO2CRC Otway Project and Initial Results. Int. J. Greenh. Gas Control 2011, 5, 922–932. [Google Scholar] [CrossRef]

- Jenkins, C.R.; Cook, P.J.; Ennis-King, J.; Undershultz, J.; Boreham, C.; Dance, T.; De Caritat, P.; Etheridge, D.M.; Freifeld, B.M.; Hortle, A.; et al. Safe Storage and Effective Monitoring of CO2 in Depleted Gas Fields. Proc. Natl. Acad. Sci. USA 2012, 109, E35–E41. [Google Scholar] [CrossRef] [PubMed]

- Kühn, M.; Förster, A.; Großmann, J.; Lillie, J.; Pilz, P.; Reinicke, K.M.; Schäfer, D.; Tesmer, M. The Altmark Natural Gas Field Is Prepared for the Enhanced Gas Recovery Pilot Test with CO2. Energy Procedia 2013, 37, 6777–6785. [Google Scholar] [CrossRef]

- Goswami, R.; Seeberger, F.C.; Bosman, G. Enhanced Gas Recovery of an Ageing Field Utilizing N2 Displacement: De Wijk Field, The Netherlands. Geol. Soc. Lond. Spec. Publ. 2018, 469, 237–251. [Google Scholar] [CrossRef]

- Mohammed, N.; Abubakar, A.J.; Enyi, G.C.; Ghavami, G.N. Flow Characteristics Through Gas Alternating Gas Injection During Enhanced Gas Recovery. In Proceedings of the SPE Gas & Oil Technology Showcase and Conference, Dubai, United Arab Emirates, 21–23 October 2019; p. SPE-198658-MS. [Google Scholar]

- Fan, C.; Elsworth, D.; Li, S.; Chen, Z.; Luo, M.; Song, Y.; Zhang, H. Modelling and Optimization of Enhanced Coalbed Methane Recovery Using CO2/N2 Mixtures. Fuel 2019, 253, 1114–1129. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, S.; Chen, M.; Xu, S. Experimental Study on Dispersion Characteristics and CH4 Recovery Efficiency of CO2, N2 and Their Mixtures for Enhancing Gas Recovery. J. Pet. Sci. Eng. 2022, 216, 110756. [Google Scholar] [CrossRef]

- Ramachandran, H.; Pope, G.A.; Srinivasan, S. Effect of Thermodynamic Phase Changes on CO2 Leakage. Energy Procedia 2014, 63, 3735–3745. [Google Scholar] [CrossRef]

- Oldenburg, C.M.; Benson, S.M. Carbon Sequestration with Enhanced Gas Recovery: Identifying Candidate Sites for Pilot Study. Lawrence Berkeley National Laboratory: Alameda County, CA, USA, 2001; Available online: http://escholarship.org/uc/item/2qn563v5 (accessed on 29 April 2023).

- Liao, H.; Pan, W.; He, Y.; Fang, X.; Zhang, Y. Study on the Mechanism of CO2 Injection to Improve Tight Sandstone Gas Recovery. Energy Rep. 2023, 9, 645–656. [Google Scholar] [CrossRef]

- Biagi, J.; Agarwal, R.; Zhang, Z. Simulation and Optimization of Enhanced Gas Recovery Utilizing CO2. Energy 2016, 94, 78–86. [Google Scholar] [CrossRef]

- Liu, S.-Y.; Ren, B.; Li, H.-Y.; Yang, Y.-Z.; Wang, Z.-Q.; Wang, B.; Xu, J.-C.; Agarwal, R. CO2 Storage with Enhanced Gas Recovery (CSEGR): A Review of Experimental and Numerical Studies. Pet. Sci. 2022, 19, 594–607. [Google Scholar] [CrossRef]

- Shoushtari, S.; NamDar, H.; Jafari, A. Utilization of CO2 and N2 as Cushion Gas in Underground Gas Storage Process: A Review. J. Energy Storage 2023, 67, 107596. [Google Scholar] [CrossRef]

- Ran, W. A Numerical Simulation Study of Underground Gas Storage in Depleted Gas Reservoirs with N2 as Cushion Gas. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2020. [Google Scholar]

- Wang, W.; Wen, J.; Wang, C.; Gomari, S.R.; Xu, X.; Zheng, S.; Su, Y.; Li, L.; Hao, Y.; Li, D. Current Status and Development Trends of CO2 Storage with Enhanced Natural Gas Recovery (CS-EGR). Fuel 2023, 349, 128555. [Google Scholar] [CrossRef]

- Ogolo, N.A.; Isebor, J.O.; Onyekonwu, M.O. Feasibility Study of Improved Gas Recovery by Water Influx Control in Water Drive Gas Reservoirs. In Proceedings of the SPE Nigeria Annual International Conference, Lagos, Nigeria, 5–7 August 2014; p. SPE-172364-MS. [Google Scholar]

- Yang, S.; Zhimin, D. Phase behavior of CO2 sequestration and the enhanced natural gas recovery. J. Nat. Gas Ind. 2012, 32, 39–42. [Google Scholar] [CrossRef]

- Wolf, J.; Maaref, S.; Esmaeili, S.; Tutolo, B.; Kantzas, A. An Experimental Study on the Effects of Competitive Adsorption During Huff-N-Puff Enhanced Gas Recovery. In Proceedings of the SPE Canadian Energy Technology Conference, Calgary, AB, Canada, 15–16 March 2023. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, Y.; Zhao, Y.; Chen, L.; Dong, C.; Sun, B. Experimental Investigation of Different Factors Influencing the Replacement Efficiency of CO2 for Methane Hydrate. Appl. Energy 2018, 228, 309–316. [Google Scholar] [CrossRef]

- Godec, M.; Koperna, G.; Petrusak, R.; Oudinot, A. Enhanced Gas Recovery and CO2 Storage in Gas Shales: A Summary Review of Its Status and Potential. Energy Procedia 2014, 63, 5849–5857. [Google Scholar] [CrossRef]

- Wang, J.; Ryan, D.; Szabries, M.; Jaeger, P. A Study for Using CO2 To Enhance Natural Gas Recovery from Tight Reservoirs. Energy Fuels 2019, 33, 3821–3827. [Google Scholar] [CrossRef]

- Adler, A.B. Nitrogen Injection Into Water-Driven Natural Gas or Condensate Reservoirs Increases Recovery. In Proceedings of the 58th Annual Technical Conference, San Francisco, CA, USA, 5–8 October 1983; p. SPE 12046. [Google Scholar]

- Omari, A.; Wang, C.; Li, Y.; Xu, X. The Progress of Enhanced Gas Recovery (EGR) in Shale Gas Reservoirs: A Review of Theory, Experiments, and Simulations. J. Pet. Sci. Eng. 2022, 213, 110461. [Google Scholar] [CrossRef]

- Carchini, G.; Hussein, I.; Al-Marri, M.J.; Shawabkeh, R.; Mahmoud, M.; Aparicio, S. A Theoretical Study of Gas Adsorption on α-Quartz (0 0 1) for CO2 Enhanced Natural Gas Recovery. Appl. Surf. Sci. 2020, 525, 146472. [Google Scholar] [CrossRef]

- Lu, Y.; Ao, X.; Tang, J.; Jia, Y.; Zhang, X.; Chen, Y. Swelling of Shale in Supercritical Carbon Dioxide. J. Nat. Gas Sci. Eng. 2016, 30, 268–275. [Google Scholar] [CrossRef]

- Mamora, D.D.; Seo, J.G. Enhanced Gas Recovery by Carbon Dioxide Sequestration in Depleted Gas Reservoirs. In Proceedings of the SPE Annual Technical Conference, San Antonio, TX, USA, 29 September–2 October 2002; p. SPE 77347. [Google Scholar]

- Yunqing, S.; Ying, J. Selection and numerical simulation of CO2 injection in tight and low-permeability gas reservoirs in Daniu area. In Proceedings of the 2016 National Gas Academic Annual Conference, Sichuan, China, 2 May 2016. [Google Scholar]

- Yunqing, S.; Ying, J. Mechanism of supercritical CO2 flooding in low- permeability tight gas reservoirs. J. Oil Gas Geol. 2017, 38, 610–616. [Google Scholar] [CrossRef]

- Ding, J.; Cao, T.; Wu, J. Experimental Investigation of Supercritical CO2 Injection for Enhanced Gas Recovery in Tight Gas Reservoir. In Proceedings of the Carbon Management Technology Conference, Houston, TX, USA, 15–18 June 2019; p. CMTC-558535-MS. [Google Scholar]

- Honari, A.; Hughes, T.J.; Fridjonsson, E.O.; Johns, M.L.; May, E.F. Dispersion of Supercritical CO2 and CH4 in Consolidated Porous Media for Enhanced Gas Recovery Simulations. Int. J. Greenh. Gas Control 2013, 19, 234–242. [Google Scholar] [CrossRef]

- Honari, A.; Bijeljic, B.; Johns, M.L.; May, E.F. Enhanced Gas Recovery with CO2 Sequestration: The Effect of Medium Heterogeneity on the Dispersion of Supercritical CO2–CH4. Int. J. Greenh. Gas Control 2015, 39, 39–50. [Google Scholar] [CrossRef]

- Liu, S.; Yuan, L.; Zhao, C.; Zhang, Y.; Song, Y. A Review of Research on the Dispersion Process and CO2 Enhanced Natural Gas Recovery in Depleted Gas Reservoir. J. Pet. Sci. Eng. 2022, 208, 109682. [Google Scholar] [CrossRef]

- Enick, R.M.; Klara, S.M.; Jones, J. The Dispersion of a Nonuniform Slug Flowing in a Porous Medium. J. Pet. Sci. Eng. 1993, 8, 293–301. [Google Scholar] [CrossRef]

- Honari, A.; Zecca, M.; Vogt, S.J.; Iglauer, S.; Bijeljic, B.; Johns, M.L.; May, E.F. The Impact of Residual Water on CH4-CO2 Dispersion in Consolidated Rock Cores. Int. J. Greenh. Gas Control 2016, 50, 100–111. [Google Scholar] [CrossRef]

- Zecca, M.; Vogt, S.J.; Honari, A.; Xiao, G.; Fridjonsson, E.O.; May, E.F.; Johns, M.L. Quantitative Dependence of CH4-CO2 Dispersion on Immobile Water Fraction. AIChE J. 2017, 63, 5159–5168. [Google Scholar] [CrossRef]

- Abba, M.K.; Al-Othaibi, A.; Abbas, A.J.; Nasr, G.G.; Mukhtar, A. Experimental Investigation on the Impact of Connate Water Salinity on Dispersion Coefficient in Consolidated Rocks Cores during Enhanced Gas Recovery by CO2 Injection. J. Nat. Gas Sci. Eng. 2018, 60, 190–201. [Google Scholar] [CrossRef]

- Abba, M.K.; Al-Otaibi, A.; Abbas, A.J.; Nasr, G.G.; Burby, M. Influence of Permeability and Injection Orientation Variations on Dispersion Coefficient during Enhanced Gas Recovery by CO2 Injection. Energies 2019, 12, 2328. [Google Scholar] [CrossRef]

- Mohammed, N.; Abbas, A.J.; Enyi, G.C.; Edem, D.E.; Suleiman, S.M. Enhanced Gas Recovery by Nitrogen Injection: The Effects of Injection Velocity during Natural Gas Displacement in Consolidated Rocks. J. Nat. Gas Sci. Eng. 2020, 83, 103513. [Google Scholar] [CrossRef]

- Mohammed, N.; Abbas, A.J.; Enyi, G.C. The Role of N2 as Booster Gas during Enhanced Gas Recovery by CO2 Flooding in Porous Medium. J. Nat. Gas Sci. Eng. 2021, 93, 104051. [Google Scholar] [CrossRef]

- Turtata, A.T.; Sim, S.S.K.; Singhal, A.K.; Hawkins, B.F. Basic Investigations on Enhanced Gas Recovery by Gas-Gas Displacement. J. Can. Pet. Technol. 2008, 47, 39–44. [Google Scholar]

- Sim, S.S.K.; Brunelle, P.; Turta, A.T.; Singhal, A.K. Enhanced Gas Recovery and CO2 Sequestration by Injection of Exhaust Gases from Combustion of Bitumen. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 24–28 April 2008; p. SPE-113468-MS. [Google Scholar]

- Sim, S.S.K.; Turta, A.T.; Singhal, A.K.; Hawkins, B.F. Enhanced Gas Recovery: Factors Affecting Gas-Gas Displacement Efficiency. J. Can. Pet. Technol. 2009, 48, 393–405. [Google Scholar] [CrossRef]

- van der Burgt, M.J.; Cantle, J.; Boutkan, V.K. Carbon Dioxide Disposal from Coal-Based IGCC’s in Depleted Gas Fields. Energy Convers. Manag. 1992, 33, 603–610. [Google Scholar] [CrossRef]

- Oldenburg, C.M.; Pruess, K.; Benson, S.M. Process Modeling of CO2 Injection into Natural Gas Reservoirs for Carbon Sequestration and Enhanced Gas Recovery. Energy Fuels 2001, 15, 293–298. [Google Scholar] [CrossRef]

- Khan, C.; Amin, R.; Madden, G. Carbon Dioxide Injection for Enhanced Gas Recovery and Storage (Reservoir Simulation). Egypt. J. Pet. 2013, 22, 225–240. [Google Scholar] [CrossRef]

- Oldenburg, C.M.; Stevens, S.H.; Benson, S.M. Economic Feasibility of Carbon Sequestration with Enhanced Gas Recovery (CSEGR). Energy 2004, 29, 1413–1422. [Google Scholar] [CrossRef]

- Givens, J.W. A Practical Two-Dimensional Model for Simulating Dry Gas Reservoirs with Bottom Water Drive. J. Pet. Technol. 1968, 20, 1229–1233. [Google Scholar] [CrossRef]

- Smith, C.; Tracy, G.; Farrar, R. Applied Reservoir Engineering; OSTI.GOV: Oak Ridge, TN, USA, 1992.

- Shugang, Y.; Qingji, W. Key challenges and countermeasures for treatment and disposal of gas field produced water in China. J. Iudustrial Water Treat. 2023, 11, 1–16. [Google Scholar] [CrossRef]

- Zangeneh, H.; Safarzadeh, M.A. Enhanced Gas Recovery with Carbon Dioxide Sequestration in a Water- Drive Gas Condensate Reservoir: A Case Study in a Real Gas Field. Sci. Technol. 2017, 7, 3–11. [Google Scholar]

- Ahmed, T.; Evans, J.; Kwan, R.; Vivian, T. Wellbore Liquid Blockage in Gas-Condensate. In Proceedings of the 1998 SPE Easten Regional Meeting, Pittsburgh, PA, USA, 9–11 November 1998; p. SPE 51050. [Google Scholar]

- Kamath, J. Deliverability of Gas-Condensate Reservoirs—Field Experiences and Prediction Techniques. J. Pet. Technol. 2007, 59, 94–99. [Google Scholar] [CrossRef]

- Ayyalasomayajula, P.; Silpngarmlers, N.; Kamath, J. Well Deliverability Predictions for a Low-Permeability Gas/Condensate Reservoir. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005; p. SPE-95529. [Google Scholar]

- Wilkins, A.J.; Morrison, G.R. Numerical Analysis of Production Impairment by Condensate Banking in Gas Condensate Fields. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth, Australia, 25–27 October 2016; p. SPE-182428-MS. [Google Scholar]

- Narinesingh, J.; Alexander, D. CO2 Enhanced Gas Recovery and Geologic Sequestration in Condensate Reservoir: A Simulation Study of the Effects of Injection Pressure on Condensate Recovery from Reservoir and CO2 Storage Efficiency. Energy Procedia 2014, 63, 3107–3115. [Google Scholar] [CrossRef]

- Leeuwenburgh, O.; Neele, F.; Hofstee, C.; Weijermans, P.-J.; De Boer, H.; Oosthoek, P.; Lefebvre, A.; Godderij, R.; Gutierrez-Neri, M. Enhanced Gas Recovery–a Potential ‘U’ for CCUS in The Netherlands. Energy Procedia 2014, 63, 7809–7820. [Google Scholar] [CrossRef]

- El Morsy, M.; Ali, S.; Giddins, M.A.; Fitch, P. CO2 Injection for Improved Recovery in Tight Gas Condensate Reservoirs. In Proceedings of the SPE Asia Pacific Oil & Gas Conference and Exhibition, Virtually, 12 November 2020; p. SPE-202363-MS. [Google Scholar]

- Jukić, L.; Vulin, D.; Kružić, V.; Arnaut, M. Carbon-Negative Scenarios in High CO2 Gas Condensate Reservoirs. Energies 2021, 14, 5898. [Google Scholar] [CrossRef]

- Hamza, A.; Hussein, I.A.; Al-Marri, M.J.; Mahmoud, M.; Shawabkeh, R.; Aparicio, S. CO2 Enhanced Gas Recovery and Sequestration in Depleted Gas Reservoirs: A Review. J. Pet. Sci. Eng. 2021, 196, 107685. [Google Scholar] [CrossRef]

- Amer, M.A.; Ghazi, S.; Ali, S.; Zafar, T.; Riaz, M. Enhanced Gas Recovery by CO2 Injection Method in Depleted Gas Reservoirs. Arch. Pet. Environ. Biotechnol. 2018, 10, 2574–7614. [Google Scholar] [CrossRef]

- Raza, A.; Gholami, R.; Rezaee, R.; Bing, C.H.; Nagarajan, R.; Hamid, M.A. CO2 Storage in Depleted Gas Reservoirs: A Study on the Effect of Residual Gas Saturation. Petroleum 2018, 4, 95–107. [Google Scholar] [CrossRef]

- Ezekiel, J.; Kumbhat, D.; Ebigbo, A.; Adams, B.M.; Saar, M.O. Sensitivity of Reservoir and Operational Parameters on the Energy Extraction Performance of Combined CO2-EGR–CPG Systems. Energies 2021, 14, 6122. [Google Scholar] [CrossRef]

- Gou, Y.; Hou, Z.; Liu, H.; Zhou, L.; Were, P. Numerical Simulation of Carbon Dioxide Injection for Enhanced Gas Recovery (CO2-EGR) in Altmark Natural Gas Field. Acta Geotech. 2014, 9, 49–58. [Google Scholar] [CrossRef]

- Oldenburg, C.M. Carbon Dioxide as Cushion Gas for Natural Gas Storage. Energy Fuels 2003, 17, 240–246. [Google Scholar] [CrossRef]

- Rebscher, D.; Oldenburg, C.M. Sequestration of Carbon Dioxide with Enhanced Gas Recovery-Case Study Altmark, North German Basin. 2005. Available online: https://escholarship.org/uc/item/7sj2g8mc (accessed on 29 April 2023).

- Al-Hashami, A.; Ren, S.R.; Tohidi, B. CO2 Injection for Enhanced Gas Recovery and Geo-Storage: Reservoir Simulation and Economics. In Proceedings of the SPE Europec/EAEA Annual Conference, Barcelona, Spain, 21–24 September 2005; p. SPE 94129. [Google Scholar]

- Kalra, S.; Wu, X. CO2 Injection for Enhanced Gas Recovery. In Proceedings of the SPE Western Regional Meeting, Denver, CO, USA, 17 April 2014; p. SPE-169578-MS. [Google Scholar]

- Feather, B.; Archer, R.A. Enhanced Natural Gas Recovery by Carbon Dioxide Injection for Storage Purposes. In Proceedings of the 17th Australasian Fluid Mechanics Conference, Auckland, New Zealand, 5–9 December 2010. [Google Scholar]

- Clemens, T.; Wit, K. CO2 Enhanced Gas Recovery Studied for an Example Gas Reservoir. In Proceedings of the 2002 SPE Annual Technical Conference, San Antonio, TX, USA, 29 September–2 October 2002; p. SPE 77348. [Google Scholar]

- Jikich, S.A.; Smith, D.H.; Sams, W.N.; Bromhal, G.S. Enhanced Gas Recovery (EGR) with Carbon Dioxide Sequestration: A Simulation Study of Effects of Injection Strategy and Operational Parameters. In Proceedings of the SPE Easten Regional/AAPG Eastern Section Joint Meeting, Long Beach, CA, USA, 19–24 May 2003; p. SPE 84813. [Google Scholar]

- Hussen, C.; Amin, R.; Madden, G.; Evans, B. Reservoir Simulation for Enhanced Gas Recovery: An Economic Evaluation. J. Nat. Gas Sci. Eng. 2012, 5, 42–50. [Google Scholar] [CrossRef]

- Seo, J.G.; Mamora, D.D. Experimental and Simulation Studies of Sequestration of Supercritical Carbon Dioxide in Depleted Gas Reservoirs. In Proceedings of the SPE/EPA/DOE Exploration and Production Environmental Conference, San Antonio, TX, USA, 10–12 March 2003; p. SPE 81200. [Google Scholar]

- Caizhen, P.; Ping, G. Technology and Case Analysis of Enhancing Gas Recovery in Edge and Bottom Water Gas Reservoirs; Petroleum Iudustry Press: Bejing, China, 2015. [Google Scholar]

- Papay, J. Improved Recovery of Conventional Natural Gas Part 2: Results of a Piolt Test. Reserv. Eng. 1999, 115, 354–355. [Google Scholar]

- Secklehner, S.; Arzmüller, G.; Clemens, T. Tight Ultra-Deep Gas Field Production Optimisation–Development Optimisation and CO2 Enhanced Gas Recovery Potential of the Schoenkirchen Uebertief Gas Field, Austria. In Proceedings of the SPE Deep Gas Conference and Exhibition, Manama, Bahrain, 24 January 2010; p. SPE-130154-MS. [Google Scholar]

| Critical Temperature | Critical Pressure | |

|---|---|---|

| N2 | 126.1 K (147.05) °C | 3.4 MPa |

| CH4 | 190.55 K (82.6) °C | 4.6 MPa |

| Gas Types | Pressurization and Energy Replenishment | Gravity Differentiation Water Resistance | High Miscible Displacement Efficiency | Competitive Adsorption Displacement | Gas Phase Permeability Increase | Contamination Corrosion Side Effects |

|---|---|---|---|---|---|---|

| CO2 | ★★★ | ★★ | ★ | ★★ | ★ | ★★ |

| N2 | ★★★ | ★ | ★ | / | ★ | / |

| N2 + CO2 | ★★★ | ★★ | ★ | ★ | ★ | ★ |

| Remarks | Requires large injection | The larger the angle of the edge-water gas reservoir, the better the effect | / | The longer the breakthrough time, the better | / | / |

| Research Focus | Research | Gas Type | Experimental Conditions | Observations and Conclusion |

|---|---|---|---|---|

| Effect of different injection rates on recovery efficiency | Mohammed et al. (2020) [57] | N2 | Bandera core: 7.602 cm × 2.531 cm; k: 32 mD, ϕ: 19.68%; T: 40 °C; P: 10.3 MPa. Berea core: 7.607 cm × 2.549 cm; k: 214 mD, ϕ: 20.53%; T: 40 °C; P: 10.3 MPa. | A medium Peclet number indicated the best injection rate, which is conducive to displacement. |

| Method of CO2 injection to enhance gas recovery with appropriate N2 injection first | Mohammed and Abbas et al. (2021) [58] | CO2 and N2 | Bandera core: 7.602 cm × 2.531 cm; k: 32 mD, ϕ: 19.68%; T: 40 °C; P: 10.3 MPa. | Compared with conventional CO2 injection, the recovery rate of CH4 storage and CO2 storage were increased by 10.64% and 24.84%, respectively. |

| Research Focus | Research | Gas Types | Experimental Conditions | Observations and Conclusion |

|---|---|---|---|---|

| Mixed gas injection for enhanced gas recovery | TurTA et al. (2008) [59] | CO2, N2, their mixtures | Berea core: 3.81 cm × 30.48 cm; k: 500 mD, ϕ: 25%; T: 70 °C; P: 6.2 MPa. | Mixed gas displacement is better than pure CO2 or N2 displacement. CO2 dissolves in water to delay breakthrough, and the presence of N2 ensures efficient displacement and replacement. |

| Enhance gas recovery with flue gas and acid gas | Sim and Brunelle et al. (2008) [60] | First mixture: 90%CO2, 5%N2 and 5%SO2; second mixture: 60%SO2, 40%CO2 | Berea sandstone core: 30.48 cm × 3.8 cm; k: 500 mD, ϕ: 25%; T: 70 °C; P: 6.2 MPa. Silica sand filling: 2 m × 5 cm; k: 2000 mD, ϕ: 43%; T: 22 °C; P: 0.69 MPa, 3.45 MPa. Fractured carbonate filling: 2 m × 5 cm; k: 48,000 mD, ϕ: 36.9%; T: 22 °C; P: 0.69 MPa, 3.45 MPa | Chemical reactions within the porous media appeared to result in an increased mixing of displacement and replacement gases. |

| Mixture-enhanced gas recovery | Sim et al. (2009) [61] | CO2, N2, their mixtures | Silica sand filling: 2 m × 4.14 cm; k: 2000 mD, ϕ: 43%; T: 25 °C; P: 0.69 MPa, 1.38 MPa, 3.45 MPa. | In mixed gas displacement, the breakthrough is delayed, and the displacement energy can be guaranteed, which is conducive to enhancing the recovery of CH4 and reducing the cost of corrosion treatment. |

| Research | Simulator | Depth (m) | Permeability (mD) | Porosity (%) | Pressure (MPa) | Injection Rate (m3/day) |

|---|---|---|---|---|---|---|

| Adler et al. (1983) [41] | / | / | 1, 50, 250, 500 | 5, 10, 20 | / | 85, 170, 255 × 103 |

| Khan et al. (2012) [64] | Tempest | 3650 | kx: 6–390; ky: 6–390; kz: 4–370 | 4–17% | 40.6 | 2.4225/1.275 × 106 |

| Ogolo et al. (2014) [35] | / | / | / | / | / | / |

| Zangeneh and Safarzadeh (2017) [69] | / | 2486 | kx: 4.98, kz: 0.5726 | 10.63% | 27.08 | 4 × 106 |

| Research | Simulator | Depth (m) | Permeability (mD) | Porosity (%) | Pressure (MPa) | Injection Rate (m3/day) |

|---|---|---|---|---|---|---|

| Narinesingh and Alexander (2014) [74] | CMG-GEM | 3992.88 | 90–180 | 22–28 | 44.13 | 1.41 × 105 |

| Leeuwenburgh et al. (2014) A gas field [75] | \ | \ | \ | \ | \ | (0.3–3.2) × 105 |

| El Morsy et al. (2020) [76] | \ | \ | 0.1, 1 | 20 | 31.66 | \ |

| Jukic et al. (2021) [77] | \ | 2410 | \ | 2–18 | 39.6 | \ |

| Research | Simulator | Depth (m) | Permeability (mD) | Porosity (%) | Pressure (MPa) | Injection Rate (m3/day) |

|---|---|---|---|---|---|---|

| Amer et al. (2018) [79] | CMG-GEM | 1651.781 | 1713 | 21 | \ | 1.37 × 106 |

| Leeuwenburgh et al. (2014) [75] | \ | \ | \ | \ | \ | (0.2–15) × 105 |

| Raza et al. (2018) [80] | Eclipse | 840 | 100 | 20 | 19.96 | 7.079 × 106 |

| Ezekiel et al. (2021) [81] | \ | 3000 | Kh: 100; Kv: 50 | 20 | 30 | 3.05 × 105 |

| Objective | Research | Well Configuration Relationship | Simulator | Model Size (km) | Depth (m) | Permeability and Porosity (mD; %) |

|---|---|---|---|---|---|---|

| Water drive gas reservoir for water control gas production | Zangeneh and Safarzadeh (2017) [69] | Two horizontal injection wells are located on either side, and four vertical production wells are located in the middle. | \ | 8.7 × 7.8 × 1.9 | 2486 | kx: 4.98, kz: 0.5726; 10.63 |

| Water drive gas reservoir for water control and gas production | Ogolo et al. (2014) [35] | Of the ten wells, seven injected CO2 in the periphery at the gas–water contact and in the middle. | \ | \ | \ | \ |

| Enhanced gas recovery from depleted gas reservoirs | Amer et al. (2018) [79] | Eight wells: two injection wells and six production wells. The injection wells are placed on the very end wing of the gas–water contact. The production wells are located on top of the anticlinal structure of the reservoir. | CMG-GEM | \ | 1651.781 | 1713; 21 |

| CO2 storage | Raza et al. (2018) [80] | Six upper reservoir production wells (P1-6), approximately 1 km from injection well I1. This injection well is located at 2386 m. | Eclipse | \ | 840 | 100; 20 |

| Reservoir original flow field and deformation | Gou et al. (2013) [82] | One injection well, two observation wells, and one production well are distributed according to faults. | TOUGH2MP-FLAC3D | 4.4 × 2 × 1 | 3400 | 11; 21 |

| Combined CO2-EGR-CPG system | Ezekiel et al. (2021) [81] | \ | \ | 4.5 × 4.5 × 0.1 | 3000 | Kh: 100, Kv: 50; 20 |

| Name of Gas Field | Gas Reservoir Type | Gas Injection Type | Reservoir Parameters | Enhanced Gas Recovery |

|---|---|---|---|---|

| Medvedevich gas field in Russia | Bottom-water gas reservoir | N2 content of 0.08–12% | ϕ: 27%; k: 0.5–3500 mD | 3.90% |

| De Wijk gas field in the Netherlands | Local edge-water gas reservoir | N2 content of 5–11% with associated N2 | ϕ: 20–27%; k: 300–700 mD | 10% |

| Budafa gas field, Hungary | Weak water drive sandstone gas reservoir | Adjacent CO2 gas reservoir | ϕ: 21%; k: 5–40 mD | 11.60% |

| Sawan gas field, Pakistan | - | 8.39% CO2 content with associated CO2 | ϕ: 14–24%; k: 0.07–507 mD | - |

| Schoenkirchen ultra-deep gas field in Austria | - | CO2 content of 11.72%, associated with CO2 | ϕ: 3–4%; k: 1–10 mD | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, B.; Wei, Y.; Gao, S.; Ye, L.; Liu, H.; Zhu, W.; Zhang, J.; Han, D. Current Progress and Development Trend of Gas Injection to Enhance Gas Recovery in Gas Reservoirs. Energies 2024, 17, 1595. https://doi.org/10.3390/en17071595

Lin B, Wei Y, Gao S, Ye L, Liu H, Zhu W, Zhang J, Han D. Current Progress and Development Trend of Gas Injection to Enhance Gas Recovery in Gas Reservoirs. Energies. 2024; 17(7):1595. https://doi.org/10.3390/en17071595

Chicago/Turabian StyleLin, Baicen, Yunsheng Wei, Shusheng Gao, Liyou Ye, Huaxun Liu, Wenqing Zhu, Jianzhong Zhang, and Donghuan Han. 2024. "Current Progress and Development Trend of Gas Injection to Enhance Gas Recovery in Gas Reservoirs" Energies 17, no. 7: 1595. https://doi.org/10.3390/en17071595

APA StyleLin, B., Wei, Y., Gao, S., Ye, L., Liu, H., Zhu, W., Zhang, J., & Han, D. (2024). Current Progress and Development Trend of Gas Injection to Enhance Gas Recovery in Gas Reservoirs. Energies, 17(7), 1595. https://doi.org/10.3390/en17071595