Abstract

Tower fatigue and strength are crucial operational concerns of floating offshore wind turbines (FOWTs) due to the escalation of the vibration phenomena observed on these structures as compared to land-based ones. FOWT towers are excited by wave and wind polyperiodic disturbances yielding continual transient states of structural vibration that are challenging for vibration mitigation systems. Thus, the paper investigates a novel implementation of nonlinear optimal-based vibration control solutions for the full-scale, tension leg platform (TLP)-based, NREL 5MW wind turbine tower-nacelle model with a 10-ton tuned vibration absorber (TVA), equipped with a magnetorheological (MR) damper, located at the nacelle. The structure is subjected to excessive wave and wind excitations, considering floating platform motions derived from model experiments in a wave tank. The MR damper operates simultaneously with an electromagnetic force actuator (forming a hybrid TVA) or independently (a semiactive TVA). The study includes both actuators’ nonlinearities and dynamics, whereby the former are embedded in the Hamilton-principle-based nonlinear control solutions. The TVA is tuned either to the NREL 5MW tower-nacelle 1st bending mode frequency (TVA-TN) or to the TLP surge frequency (TVA-TLP). The optimal control task was redeveloped concerning the TVA stroke and transient vibration minimisation, including the implementation of the protected structure’s acceleration and relative displacement terms, as well as the nonzero velocity term in the quality index. The regarded model is embedded in a MATLAB/Simulink environment. On the basis of the obtained results, the TVA-TN solution is by far superior to the TVA-TLP one. All the regarded TVA-TN solutions provide a tower deflection safety factor of ca. 2, while reference systems without any vibration reduction solutions or with a passive TVA-TLP are at risk of tower structural failure as well as the hybrid TVA-TLP system. The obtained TVA stroke reductions of 25.7%/22.0% coincide with 3.6%/10.3% maximum tower deflection reductions for the semiactive/hybrid TVA-TN case (respectively) with regard to the previously developed approaches. Moreover, these reductions are obtained due to the sole control algorithm enhancement; thus, no additional resources are necessary, while this attainment is accompanied by a reduction in the required MR damper force. The lowest obtained TVA stroke amplitude of 1.66 m is guaranteed by the newly introduced semiactive control. Its hybrid equivalent ensures 8% lower primary structure deflection amplitude and reduced nacelle acceleration levels thanks to the utilisation of the force actuator of the relatively low power (ca. 6 kW); the trade-off is an increased TVA stroke amplitude of 2.19 m, which, however, is the lowest among all the tested hybrid solutions. The analysed reference passive TVA systems, along with a modified ground-hook hybrid solution, can hardly be implemented in the nacelle (especially along the demanding side–side direction). The latter, being the well-proven hybrid solution for steady-state tower deflection minimisation, yielded unsatisfactory results. The achievements of the study may be used for an effective design of a full-scale vibration reduction system for the TLP-based floating wind turbine structure.

1. Introduction

Slender structures such as beams, plates, towers, bridges [1], tall buildings [2], and wind turbines [3,4,5] suffer from mechanical vibrations, leading to increased fatigue and reduced life span. Most of these structures are fitted with dedicated solutions for vibration attenuation and fatigue reduction, such as tuned mass dampers/tuned vibration absorbers (TMDs/TVAs), tuned inerter dampers (TIDs), tuned liquid column dampers, bracing systems [6,7,8,9,10], etc. TVAs include an additional mass connected with the protected structure, usually by a spring and a damper, and possibly an actuator connected in parallel. TVAs are widely spread vibration reduction solutions. Depending on the damper and actuator type, passive, semi-active, active, and hybrid TVAs are used. The spring, damper, or actuator parameters are tuned to the selected vibration mode [11]. Passive TVAs cope reasonably with the vibration of a single frequency but cannot adapt to a broader excitation spectrum, a structure’s frequency response variations, etc. [4]. Thus, advanced TVA solutions are used, among which TVAs utilising magnetorheological (MR) dampers (MR-TVAs) or the additional, small-scale active actuators (hybrid TVAs, H-TVAs, or hybrid MR-TVAs, H-MR-TVAs) gain an increasing interest [12,13,14,15,16]. The MR dampers are smart, semiactive actuators exhibiting wide resistance force ranges, millisecond response times, and high reliability, yet they suffer from a nonzero remanent force. Moreover, they cannot generate active forces, being semi-active devices [17,18,19]. The active force actuators of H-TVAs/H-MR-TVAs increase their vibration reduction efficiency; moreover, they provide greater robustness, eco-friendliness, and lower force/power requirements than active TVAs [20,21].

The paper focuses on the vibration control of a floating offshore wind turbine (FOWT) tower supported by a tension leg platform (TLP). The FOWT tower vibration arises due to both sea wave-induced platform motion and aerodynamic loads generated by wind, Karman vortices, variable inflow conditions for the blades, etc. Moreover, internal triggers such as imbalances in rotating machinery contribute to the tower’s structural vibration and fatigue wear. Considering the type of turbine support, bottom-founded installations are used for water depths up to ca. 40–70 m, where their installation and operation can be economically feasible. For the challenge of expanding the offshore wind sector to greater depths, many types of floating concepts have been considered, such as spar buoys, barges, semisubmersibles, and tension leg platforms. Several pertinent designs have been completed; many scaled-down prototypes have been experimentally tested, whilst pilot full-scale developments have also been reported. Until 2021, 121.4 MW of floating wind energy was installed, with the majority (110.9 MW) in Europe and the remaining (10.5 MW) in Asia. The offshore wind sector is expanding, predicting 18.9 GW of new buildings by 2030 [22].

Spars have a simple construction composed of a single vertical cylinder, which forms the basis for installing the wind turbine tower. Spars are stabilised by ballast weight at the bottom of the cylinder and thus require deep water—their conventional mooring arrangement results in a large sea bed footprint. Spars are large structures requiring special building and equipment installation docking areas. Barges and semisubmersible platforms achieve stability through the large metacentric height obtained from the extended water plane area. Their design is a mature technology since it has been used in the oil and gas sector for many years. Barges and semi-subs do not require special docks for the building and can be towed relatively easily to the installation location. Their mooring arrangement usually follows a conventional design, resulting in a large sea bed footprint. Tension leg platforms usually consist of a submerged hull connected to vertical mooring lines (tendons). The hull’s buoyancy is usually larger than the platform weight, resulting in a buoyancy surplus, which loads the tendons with a positive force (pretension). This pretension maintains the stability of the platform. The design of the buoyant part of the hull should ensure positive tendon forces in all operating and extreme conditions since compression in the tendons (which are usually made from steel pipes) results in buckling with catastrophic consequences. TLPs have a simple construction, which results in reduced manufacturing costs. Moreover, they can be installed in a wide range of water depths and exhibit a small seabed footprint due to the vertical arrangement of the tendons. If their hull is similar to semi-subs, they do not require special equipment vessels for towing and installation. However, it should be noted that the TLP mooring system comprises a critical element for the strength of the whole structure, and it is usually expensive compared to conventional mooring arrangements. Additionally, the TLP concept makes the installation difficult in water areas with large tidal ranges.

Regarding the type of support structure, the conventional mooring arrangement of the spars, barges, and semisubmersibles permits significant linear and angular motions of the platforms due to the inherent low stiffness of the catenary-type mooring legs. In this respect, the tension leg concept offers the most stable solution, minimising the heave, pitch, and roll motions by imposing large pretension mooring forces. In this way, the platform is moving by the wave action mainly in the surge, and the wind turbine dynamics are comparatively less affected. Fatigue damage equivalent loads are lowest for TLP-based wind turbines [23]. TLP FOWT concepts combined with wave energy devices of the oscillating water column (OWC) type have been experimentally investigated in [24,25]. The surge response of a TLP FOWT combined with OWCs was measured in [24] and formed the basis for the vibration mitigation examined in the current study.

The problem of FOWT vibration control has been investigated many times within the last decade. The investigations concerned both structural fatigue and strength. The National Renewable Energy Laboratory (NREL) is one of the leading parties in this area, providing a systematic background for broader research (presented below) concerning the offshore version of NREL 5MW wind turbines [26,27]. In [28], a monopile, a barge, a spar buoy, and TLP wind turbine supports were investigated. A set of optimum passive TMDs was developed by building a limited degree-of-freedom model for each offshore wind support. The TMD parameters determined by the optimisation were applied to a series of wind turbine FAST SC simulations. A sensitivity analysis of the TMD parameters and a study on the effect of wind and wave misalignment on load reductions were also conducted. Tower fatigue damage reductions of up to 20% were achieved for the various TMD configurations. The results could have been even better if controlled vibration absorbers had been considered in this study. In [29,30], the impact of passive and semi-active pendulum-type TMD, located at the tower top, was analysed and simulated for both monopile and floating TLP-based GE Haliade 150–6MW wind turbines. Different control algorithms based on the on–off ground-hook policy were implemented, and the frequency responses were investigated. It was shown that the performance of each control policy depends on the load conditions. Fully coupled time domain analyses were conducted through the novel simulation tool integrated into the FASTv8 environment. Compared with the passive system, it was shown that the semi-active TMD results in higher load attenuation and smaller strokes under both the fatigue limit state and the ultimate limit state conditions. The ultimate loads at the tower base for the FOWT structure with semi-active TMD were increased by 3% for the shallow water depth and decreased by up to 9% for the deeper water. The clear limitation of this research was the simpleness and variable reliability of the assumed control algorithms. In [31], the nonlinear dynamic behaviour of the NREL 5MW wind turbine structure is evaluated considering various earthquake and wind intensities adopting a newly developed finite element model, which is first calibrated and verified using modal and static pushover analysis. This research shows that earthquake loads considerably inform the design and analysis of wind turbines. Moreover, the NREL 5MW tower failure conditions were established. The current work utilised these conditions to reference the obtained ultimate deflection amplitudes. One study [32] investigates a vibration control strategy for a barge-type FOWT by setting a stroke-limited H-TVA in the nacelle. The LQR active force controller is designed to reduce the vibration and loads of the wind turbine, and weighting coefficients are optimised considering the stroke of the H-TVA and the active control power. The developed controllers are deployed in high-fidelity simulations under typical wind and wave conditions. However, this approach suffers from force actuator dynamics not being included in the LQR formulation (thus, the realised control output is not the same as the calculated one), while adding the stroke-limiting springs and dampers alters the TVA frequency at higher strokes. In [33], structural vibration control of an FOWT model with barge-type support is investigated. The system is equipped with MR-damper-based TVA located in the nacelle. Tower and barge rotational amplitude frequency responses are compared, proving the quality of the adopted optimal-based solutions and their potential to minimise the pitching amplitude of the structure (yielding wind energy extraction benefits) and MR damper force and/or stroke amplitude simultaneously. All of the actuator force nonlinearities are embedded in the control solution. Thus, the utilised approach is optimal or suboptimal for the assumed actuator, respecting its constraints. However, this research is limited to steady-state vibration analysis under monoharmonic rotor excitation of a relatively low (85 kN) amplitude. In [34], the numerical predictions of a TLP wind turbine response are discussed. The numerical model is calibrated vs. the physical test measurements. Open-FAST tools are used for hydrodynamic and motion response analyses. The TLP-based NREL 5MW FOWT model’s dynamic response is compared with the physical model output concerning free-decay, regular and irregular wave tests, and analysed in time and frequency domains. This comparison addresses the uncertainties of the TLP wind turbine model, i.a., a 17% smaller natural period in surge extracted from the physical model compared to the numerical one, opening up a space for improvements. In [35], Madsen et al. covers the experimental testing of a TLP-based, pitch-regulated DTU 10 MW wind turbine at 1:60 scale in wind and waves. The responses of the floater to hydrodynamic loading are analysed and compared for two different feedback controllers: a typical onshore one tuned by a pole-placement technique and a floating wind turbine controller. Overall, the performance of the onshore controller results in a larger surge response than the offshore controller, leading to larger front mooring line tensions due to higher blade pitch angle amplitudes produced by the onshore controller. The shutdown cases of the offshore controller lead to larger surge displacement when the shutdown is initialised right before the wave impact as the aerodynamic damping is disabled. The research demonstrates the potential of physical model testing and numerical model validation. The experimental results of wind and wave alignment conditions influencing structural loads are used in this study as a reference. Larsen et al. [36] investigate an interesting use of a shunted electromagnetic transducer in a pendulum absorber to reduce tower vibration in monopile-supported wind turbines. An RCL network is designed as the supplemental shunt for the transducer’s intrinsic RL properties, resulting in an additional resonance. The optimal system calibration is derived using the pole placement method. The shunted electromagnetic transducer operates as an equivalent mechanical spring–damper–inerter system (i.e., TID). The presented standard deviation results exhibit a slight advantage in vibration mitigation (0.14%/1.57% in fore–aft/side–side directions, respectively) of the electromagnetic transducer vs. the passive damper-based pendulum absorber; however, the benefits of the implementation of this active solution with all the necessary circuitry and power supply vs. the passive absorber are questionable.

Most of the vibration control solutions are based on the bang-bang control (ground-hook, sky-hook, sliding mode, etc.) [37,38], fuzzy logic, or two-stage approaches [1,17], which suffer from the inability to generate the force calculated in the first stage by the second-stage algorithm due to the actuator limitations, including force and stroke constraints, the inability to produce active forces, etc. The stroke constraints of the real-world vibration reduction system/TVA are frequently addressed by the use of end-stop collision bumpers or spring-damper buffer systems with stroke-dependent stiffness restoring force [32], which prevent the impact with the protected structure but, at the same time, deteriorate the vibration attenuation quality. Moreover, many first-stage algorithms require real-time vibration frequency determination, which is problematic for transient, polyperiodic, and multi-mode vibrations, for which these systems switch to the passive mode.

To address all the limitations mentioned above, a concept was devised to embed actuators’ constraints into the control problem formulation [18,19,20,21] to avoid efficiency and robustness problems of the calculated control function being imprecisely mapped or beyond the actuator output/TVA stroke limits. This involved the use of nonlinear control methods, which may be grouped generally as maximum-principle-based [39], Lyapunov-function-based [16,38], and linearisation-based methods utilising linear optimal control theory (LQR/LQG/H2/H∞) [7,32,40,41]. The main implementation issues regarding these methods are the high computational load of the real-time operation or control quality degradation due to dynamics/disturbances that were unmodelled during offline pre-calculations. Thus, the concept of the maximum-principle-based nonlinear optimal-based vibration control was previously developed [18,19,21], eliminating all of the above computational or control authority problems.

The idea of simultaneous operation of the MR damper and the active force actuator was seldom investigated. Recently, it was literature-reviewed and implemented in a scaled laboratory model of an onshore wind turbine tower-nacelle structure with H-MR-TVA [21]. The developed concurrent MR damper–electric drive quasi-optimal and modified ground-hook control solutions provided significant attenuation of the steady-state monoharmonic vibration with regard to a passive system. The quasi-optimal control solution offered a significant energy efficiency advantage over the modified ground-hook law thanks to its various optimisation fields covered by the quality index; moreover, the MR damper and force actuator constraints were embedded in the optimal control task of the former, so they did not compromise the vibration control quality. No offline calculations nor disturbance assumptions were required for proper controller operation. The obtained results may be transferred to a full-scale real-world wind turbine structure thanks to the dynamical similarity [42].

Based on these results, the current research addresses the utilisation of the optimal-based, concurrent control algorithm for the TLP–NREL 5MW full-scale FOWT structure under excessive wave/wind conditions (characterised by polyperiodic excitations and continual transient vibration states), along with the design and tuning of the H-MR-TVA located in the nacelle; the optimal control task is enhanced with regard to the TVA stroke amplitude minimisation, including the implementation of the nacelle’s acceleration and relative displacement terms, as well as nonzero velocity term in the quality index, yielding the redeveloped optimal-based control propositions for both the MR damper current and the actuator force, being the main contributions of the paper. As a reference, the optimal-based, modified ground-hook law with the sole objective of the primary structure deflection minimisation is used along with the passive TVA system.

The paper is organised as follows. The succeeding section presents a regarded system. Next, the Pontryagin maximum-principle-based nonlinear optimal vibration control problem is stated and solved. Then, the numerical tests’ conditions, simulation model setup, and control implementation procedure are described. This is followed by the vibration control results and discussion. The paper is summed up with several conclusions.

2. A Regarded System

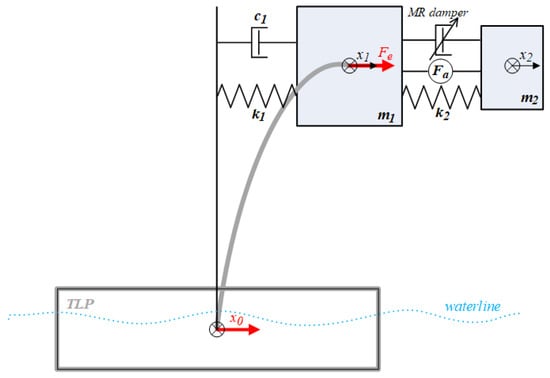

An NREL 5MW wind turbine (Table 1) tower-nacelle system, supported by a TLP [23] (Table 2), is regarded as a protected structure [26,27]. The NREL 5MW tower-nacelle system’s 1st bending mode corresponds to the dominant modal mass and vibration energy participation, especially for the low-frequency range associated with wave, wind and rotor excitations. Therefore, the current study takes into account the structure’s 1st bending mode modal parameters, such as mass m1, stiffness k1, and damping c1 (Table 3). Previous studies confirm minor discrepancies of the 1 DOF tower-nacelle model vs. FAST code responses to tower base horizontal excitations [5,28], being the case regarded in the current research. An H-MR-TVA of the absorber mass m2 and spring stiffness k2 embedded in the nacelle is considered (Figure 1) based on [28]. The movement of both m1 and m2 is assumed to be linear displacement x1 and x2, accordingly (small bending angles assumed), along the common, horizontal axis of an external force (representing the resultant load applied to the nacelle i.a. through rotor) and the supporting TLP platform surge motion (Figure 1). An MR damper and a small-scale electromagnetic actuator [21] of an output force are both built-in parallel to the spring k2 in the TVA system. The absorber stiffness k2 (and damping c2 for passive TVA tests) was tuned either to the NREL 5MW tower-nacelle 1st bending mode frequency of 0.30 Hz (from now on referred to as TVA-TN) or to the TLP surge frequency of 0.10 Hz (from now on referred to as TVA-TLP). For structural vibration control purposes, the MR damper was used, working in cooperation with the force actuator or independently.

Table 1.

NREL 5MW baseline wind turbine parameters [26,28].

Table 2.

TLP platform main particulars [24].

Table 3.

TLP–NREL 5MW with TVA-TN/TVA-TLP simulation model parameters.

Figure 1.

Diagram of a regarded system with an H-MR-TVA.

Table 1 and Table 2 present the main particulars of the regarded FOWT structure. The values of the adopted simulation model parameters are given in Table 3 and Table 4. The values of the m1, k1, and c1 parameters were calculated on the basis of the 1st bending mode modal properties of the NREL 5MW tower-nacelle structure regarded as an Euler–Bernoulli cantilever beam with a tip mass [5], assuming m1 to be the mass of the nacelle-rotor assembly enlarged by the 22.68% of the tower mass, based on the structural data given in [26,27,28,33]. The k2 and c2 values were selected using the Den Hartog principle [11] on the basis of the assumed tuning frequency and absorber mass m2 = 10 t.

Table 4.

MR damper simulation model parameters.

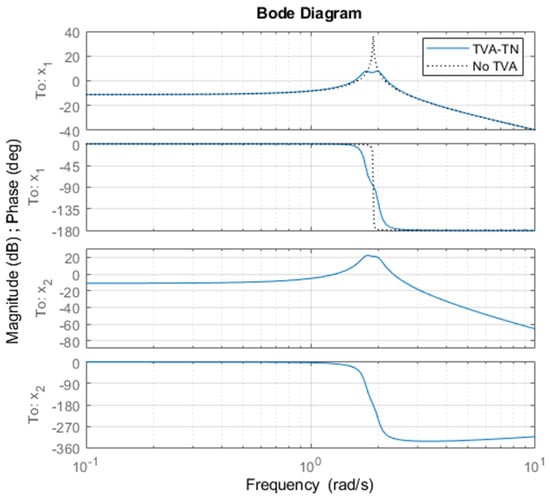

Figure 2 presents bode diagrams of the regarded simulation model without TVA (No TVA legend) and with passive TVA tuned to the NREL 5MW tower-nacelle 1st bending mode (TVA-TN legend) concerning input. The magnitude of the x1 steady-state resonance vibration due to the passive TVA-TN implementation is reduced by 28.3 dB; however, the efficiency of the passive TVA along with MR-TVA, and H-MR-TVA will be investigated using random sea and wind state excitation patterns, enforcing continual transient vibration states, as described in Section 5.

Figure 2.

Bode diagram of a regarded simulation model with and without TVA.

3. Control Problem Formulation and Solution

The regarded system dynamics is described in a form of Equation (1):

where is a state vector:

while () is a piecewise-continuous control vector. A quality function to be minimised is:

According to Figure 1, Section 2, let us assume: , , , , thus:

where:

is the MR damper force as described in [18,33] with parameters tuned to the present application as given in Table 4; is the MR damper control current, is the actuator force [21], is the nacelle horizontal excitation force, and is the TLP surge that is assumed to be independent of the wind turbine tower-nacelle system bending in this research, as the NREL 5.0MW 1st tower bending modal mass is small in relation to the TLP structural mass plus an added mass due to the outgoing waves created by the floater motion [34]. The force produced by the MR damper includes electric current dependent friction force, viscous damping and stiffness components with a scaling parameter .

The MR damper current limitation to range () and the actuator output nominal force limitation to range were assumed as in [21]:

The regarded quality function (8) is:

to account for the protected structure relative displacement (i.e., tower deflection) and relative velocity (tower deflection rate) minimisation, the protected structure (nacelle) acceleration minimisation, the TVA stroke and relative velocity minimisation, the MR damper coil current and force minimisation, and the actuator force and power minimisation, where:

The newly introduced term implementation, the original contribution of current research, is intended to minimise the protected structure’s (i.e., nacelle/rotor with its sensitive instrumentation) acceleration. As the structure acceleration increases with the square of the frequency (for the constant oscillation displacement amplitude), this term is aimed to minimise predominantly higher frequency content of the displacement (thus minimising the acceleration ). At these higher frequencies TVA mass vibrates at a close antiphase to the protected structure’s mass—see x1 vs. x2 phase diagrams (Figure 2). Thus, the minimisation of the high-frequency content of with the use of appropriate weight consequently reduces moving away the protected structure and the TVA (due to the close antiphase). This, in turn, reduces the TVA stroke amplitude and MR damper force amplitude, which will be proven in Section 7.

Let us consider he Hamiltonian in a form (10):

If pair is an optimal control process, there exists an adjoint vector function satisfying:

with a transversality condition:

so that maximises the Hamiltonian over the set for almost all (see details in [43]). For the regarded system, the adjoint (co-state) vector is:

whereas:

and:

with:

The Hamiltonian therefore takes the form (16):

The Hamiltonian maximisation conditions [43] are:

with the appropriate sign change conditions, where:

Fixing an attention on range of , Equation (17) results in ():

or:

Analogically to [19]:

where is the right-hand side of Equation (20).

From condition (18) we obtain ():

Fixing an attention on range of , Equation (22) results in proposition (23)–(25), analogically to [21]:

- (22) is fulfilled and exhibits sign change (Hamiltonian maximisation) for: only; thus:

- (22) is fulfilled and exhibits sign change for: only; thus:

- (2) is fulfilled and exhibits sign change for:only; thus:

4. Test Conditions

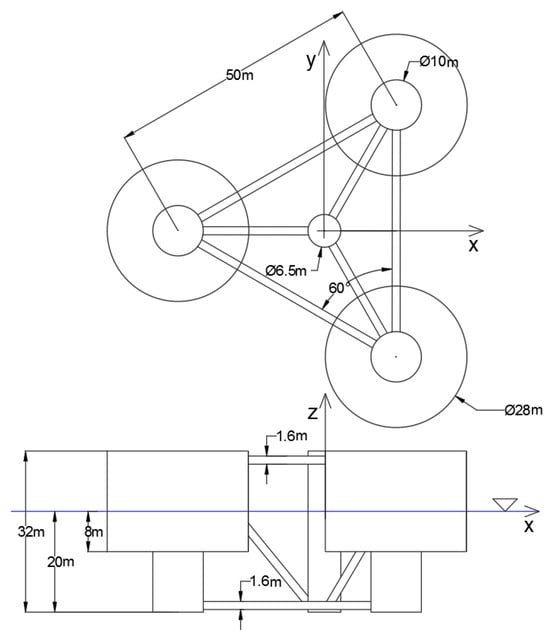

The TLP surge realisations used in this research correspond to the platform’s response under the action of an ocean wave spectrum of the Bretschneider type. The examined TLP platform is shown in Figure 3 and Figure 4. It has a triangular arrangement and is composed of vertical buoyant cylinders interconnected with cylindrical bracing members. Three of the vertical cylinders are placed at the vertices of the triangle providing the major part of the buoyancy. A 5MW NREL offshore wind turbine is installed on a cylinder at the centre of the triangle. The concept includes also devices for parallel wave energy extraction of the oscillating water column type (OWC). Their air chambers are formed by a concentric skirt and a dome, which surround each cylinder at the vertices of the triangle.

Figure 3.

TLP platform dimensions.

Figure 4.

TLP with NREL 5MW model in the experimental facilities.

The platform is moored to the sea bed using tensioned legs, placed vertically between the corner cylinders and the sea bottom. The floating cylinders provide a substantial buoyancy surplus, generating the necessary pretension in the mooring tendons for platform stabilisation and station keeping.

A breakdown of the platform weight groups is presented in Table 2, together with the tendon loads. The experimental investigation of the dynamic behaviour of the floating platform was carried out in the wave basin of the National Technical University of Athens (NTUA) using the scaled-down instrumented model (scale 1:40) shown in Figure 4.

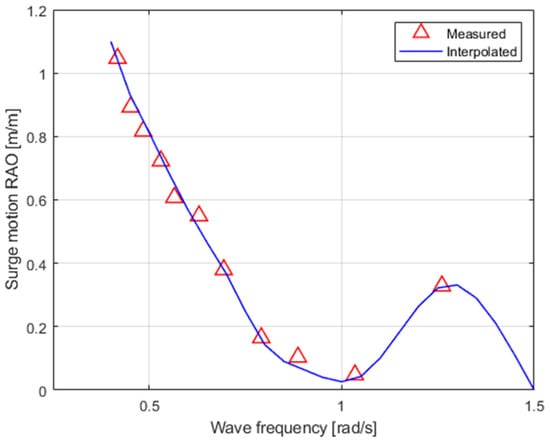

The sea wave actions were simulated following the Froude law of scaling, which ensures the dynamic similarity to the prototype by preserving the ratio of the inertial to the gravitational forces. The experiments included both monochromatic waves and random sea states. Their parameters (periods and amplitudes) were selected from a wide range, corresponding to the wave climates prevailing in the candidate installation location (Aegean Sea). Figure 5 depicts the measured surge response amplitude operators, RAOs (i.e., motion amplitude in the surge due to a harmonic wave of unit amplitude).

Figure 5.

Surge motion RAOs for the TLP FOWT.

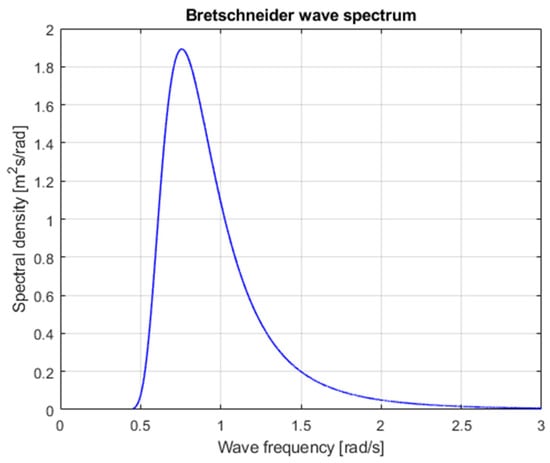

For the installation location considered in the Aegean Sea, the most probable severe wave state can be described by a Bretschneider wave spectrum S(ω) (Figure 6) having a significant wave height of 4 m and a peak period of 8.3 s. The corresponding spectrum of the surge response (26) can be found through the combination of the sea wave spectrum and the surge motion RAOs:

Figure 6.

Wave spectrum considered.

Based on the experimentally derived platform surge spectrum, ten random realizations (numbered 0 through 9) of surge motion were produced by combining the spectral density and random phases for individual motion components.

The external excitation applied on the tower-nacelle structure through the rotor is mainly due to changeable aerodynamic loads. The wind realisations at 90 m above the open sea level were generated using the Weibull distribution with a scale parameter of 10 and shape parameter of 2.0, resulting in 8.86 m/s mean wind speed and 4.63 m/s standard deviation. The horizontal nacelle excitation force was then calculated using the rotor thrust data from the characteristics of ‘Steady-state responses as a function of wind speed’ [26], which is generally consistent with [44].

The most severe vibration excitation case of coaxial wind and wave loads was assumed. Ten Bredsneider spectrum ocean wave realisations 0 ÷ 9 were paired with ten Weibull distribution wind patterns 0 ÷ 9, 2500 s in length each, 1 ms of time resolution, as described above. Due to a continual thrust asymmetry for all the 360° rotor angular positions but six ones (i.e., 0°, 60°, 120°, 180°, 240°, 300°) corresponding to one of the blades being aligned with the tower, both tower fore–aft and side–side bending mode is excited. Moreover, TLP horizontal excitation directions (surge/sway) may vary, too. Current analyses assume (H-)MR-TVA operation direction as the excitation direction. In a practical implementation, two (H-)MR-TVAs operating along mutually perpendicular directions (side–side/fore–aft) may be installed, or a single (H-)MR-TVA operating along the side–side direction (fore–aft vibrations attenuated by the rotor aerodynamic damping and collective pitch control of the blades). The assumed here excitation combinations, including their alignment, are not necessarily frequent in real-world conditions. The analyses of the wave/wind misalignment [28] suggest that side–side TVA installation is necessary due to side–side loads being a large contributor to the overall fatigue wear and ultimate fracture risk. The work [35] indicates that the aerodynamic damping is strongest on the surge motion for unidirectional conditions; thus, a fore–aft TVA may also be essential for wave/wind misalignment.

5. Simulation Setup

The NREL 5MW tower-nacelle 1st bending mode model equipped with passive TVA/MR-TVA/H-MR-TVA located in the nacelle, excited horizontally by the supporting TLP platform surge and resultant load applied to the nacelle , was embedded in MATLAB/Simulink environment, adopting the fixed ms sampling step. A relatively low TVA mass m2 of 10 tons (0.35% of the total structure’s mass) was assumed, yielding a 2.33% m2/m1 mass ratio, regarding 1st bending mode mass m1 of 428.8 tons. As discussed earlier [21], an increased TVA mass ratio does not yield a proportional efficiency gain, not to mention the spatial and structural support requirements; however, it contributes to lower TVA sensitivity to detuning [45] and more limited TVA stroke. The selection of the 10-ton absorber mass is consistent with [28]. Therefore, the current study discusses the benefits of implementing an MR damper (and possibly a small-scale force actuator) to address all the regarded efficiency, stroke/space/structural support limitations and detuning issues, using a smaller absorber mass.

In addition to the MR damper’s and actuator’s static non-linearities discussed above (5)–(7), their linear dynamics (27) and (28) are also included in the current study:

where and are Laplace transforms of actual MR damper and electromagnetic actuator outputs, respectively. However, as the MR damper dynamics (27) may be modelled with a 2nd order inertia, while the electromagnetic actuator time-delayed transfer function (28) [21] may be modelled with a 2nd order oscillatory dynamics with a 1st order inertia, the corresponding optimal control task would be of the 9th order. This would yield a computational load that was real-time tested to be unrealisable. Thus, the dynamics of the MR damper and the electromagnetic actuator are both embedded in the simulation model of the NREL 5MW tower-nacelle system equipped with a TVA, supported by the TLP; the actual values of are fed as into Equations (4), (8), (11), (21) and (23)–(25) (in this way, the modelled MR damper and force actuator responses inertia and delays influence state and co-state variables’ values as well as and control patterns), but they do not augment optimal problem order. This guarantees the simplicity of the real-time implementation, while not impairing the overall system performance (partially due to the frequency spectrum of the regarded vibration problem being low in relation to actuators’ dynamics).

All the structural model parameters, as in Table 3, along with the MR damper model parameters (Table 4) were assumed for the simulations. The value of A yielding respective ranges and nominal actuator output force kN were tuned to the current application. As previously proven [21], the MR damper responds faster than the electromagnetic actuator. In contrast, the actuator may cancel the MR damper undesirable (i.e., of improper sign due to its dissipative nature) force. The resultant maximum MR damper force was ca. 50 kN (excluding the more demanding Mod.GH and Mod.GH-H solutions), whereas the mean actuator power was up to 6.27 kW for TVA-TN hybrid solutions; however, less force/power demanding solutions were investigated as well.

6. Control Implementation

For the vibration control of the FOWT 1st bending mode, the approach described in Section 3 and Section 5 was implemented using the MR damper control Formula (21) and the force actuator control Formula (23)–(25). Regarding the considerations presented in [18,19,20,21], the control propositions (21) and (23)–(25) were implemented using the optimisation horizon equal to one integration step [18,21]; as it was proven in [18,19,20], the computationally excessive iteration procedure could be omitted using a relatively short (with regard to system’s time constants) sample step and zero initial conditions for adjoint variables, yielding an optimal-based (suboptimal) control solution that is negligibly different from the optimal one. The control solution incorporates either two simultaneous control outputs: (i.e., ) and (i.e., ) (H-MR-TVA system), or a single control output (MR-TVA system).

The baseline weighting factors for the optimal-based control quality index (8) are assumed as follows: , , , , . The remaining weight values are given for each control case regarded below if they are nonzero (the omitted weights are assumed zero all over this section). A significant value with regard to the previous research [21] is used to address transient states during simulated wave/wind realisations–incorporation of the protected structure velocity significant weight value corresponds to a derivative term of a displacement controller, which is known to be efficient during transients. A negligible but nonzero value was selected to eliminate zero-division errors for in (23)–(25). The detailed weights of the quality function (8) were assumed as follows (control cases I, II, III, I-H, II-H, III-H):

- I

- and –minimise the tower deflection and deflection rate as a sole objective (being the primary objective for all the control cases), MR-TVA used;

- II

- (the TVA stroke weight) assumed in addition to control case I weights, MR-TVA used;

- III

- (the nacelle/tower tip acceleration weight) assumed in addition to control case I weights, MR-TVA used;

- I-H

- as for control case I, H-MR-TVA used;

- II-H

- as for control case II, H-MR-TVA used;

- III-H

- as for control case III, H-MR-TVA used.

As a reference, an optimal-based, modified ground-hook law (Mod.GH using MR-TVA, and Mod.GH-H using H-MR-TVA) with the sole objective of the primary structure deflection minimisation is used [21], along with the passive TVA systems (TVA-TN and TVA-TLP).

7. Control Results

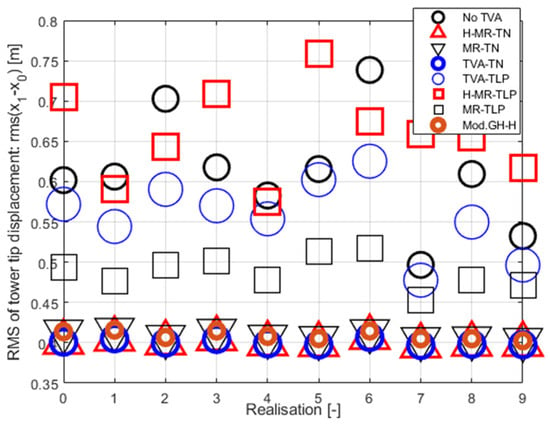

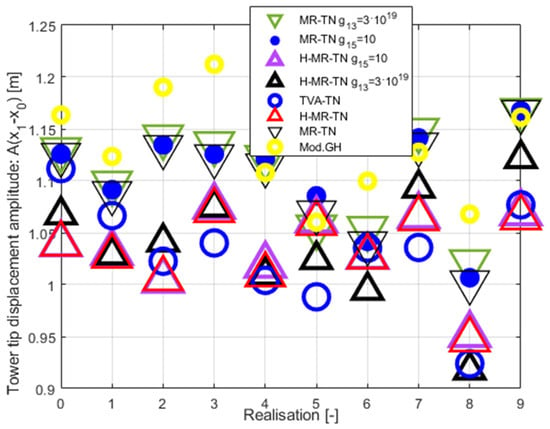

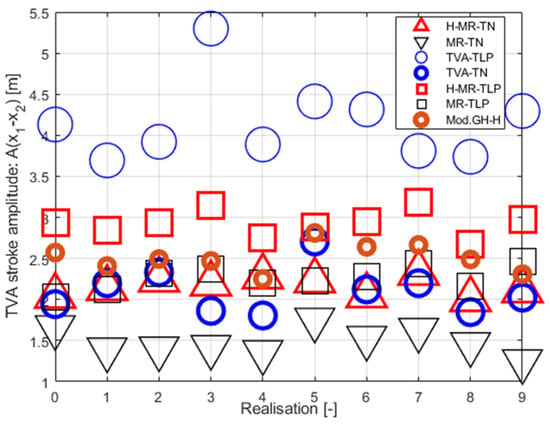

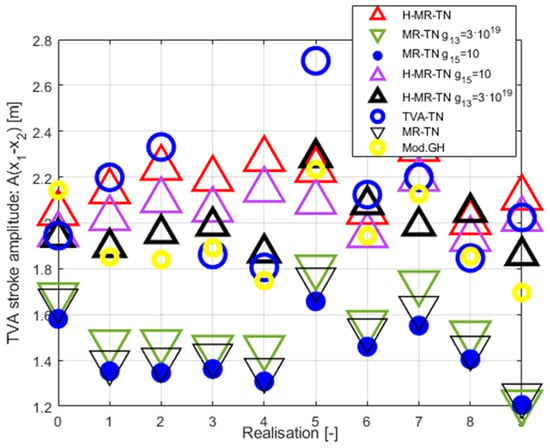

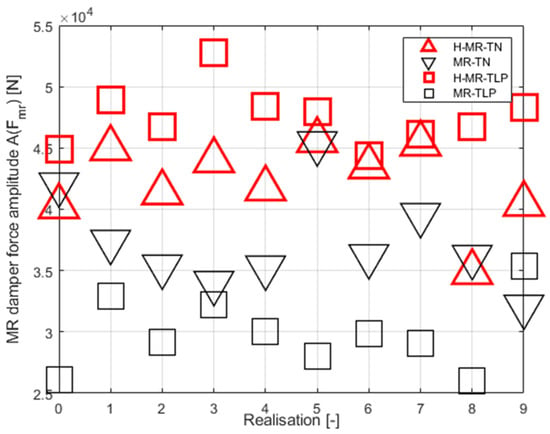

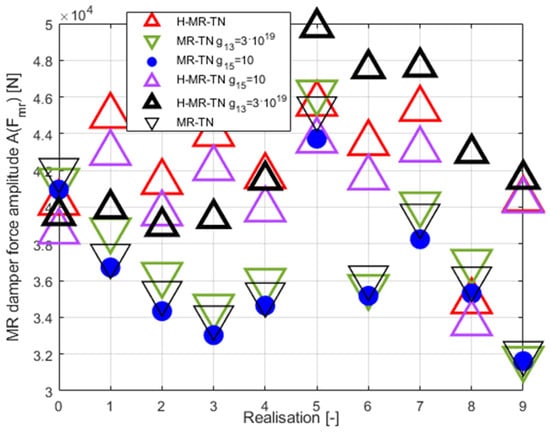

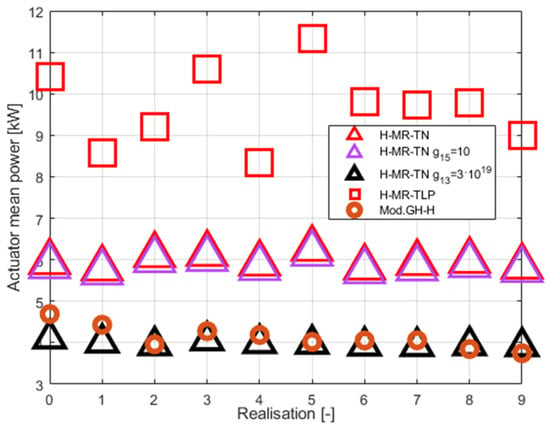

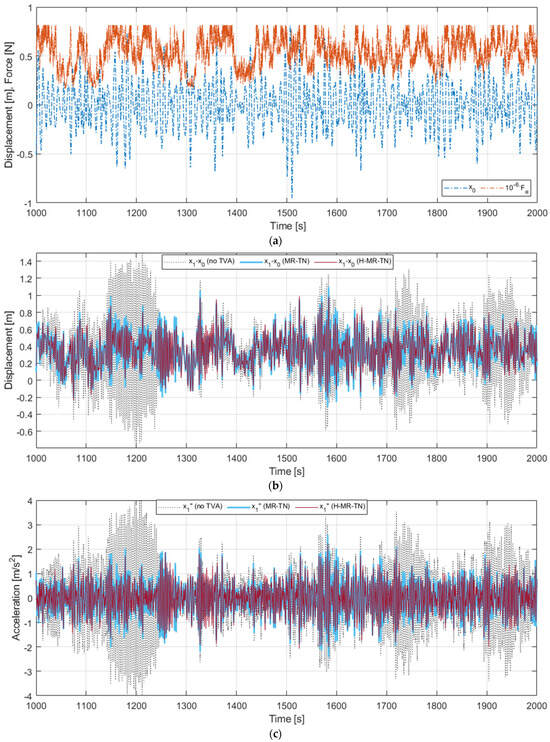

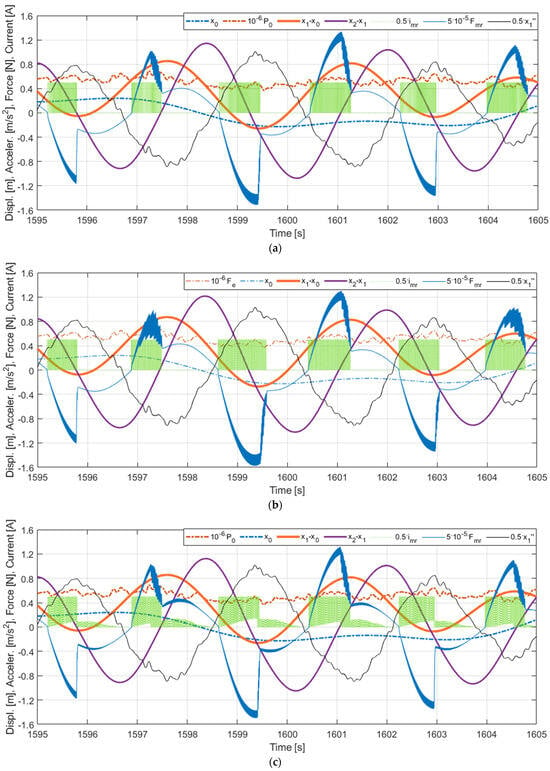

The efficiency of the considered solutions was analysed using the following quality indexes: tower tip relative displacement (i.e., tower deflection) root-mean-square (RMS) ) (Figure 7 and Figure 8), tower tip relative displacement (tower deflection) amplitude ) (Figure 9 and Figure 10), TVA stroke amplitude ) (Figure 11 and Figure 12), the MR damper force amplitude (Figure 13 and Figure 14; Mod.GH and Mod.GH-H results excluded due to seriously outlying values–see Table 5), and mean actuator power (Figure 15), along with the time patterns of , , , , and (Figure 16, Figure 17 and Figure 18) and Table 5 ( states for the amplitude, i.e., the maximum deviation from the equilibrium state). The ) (equal to the standard deviation for zero mean value) value indicates the tower structure operational fatigue, the tower deflection amplitude indicates the maximum structural stress, whereas the TVA stroke amplitude determines the spatial and structural applicability of the vibration control solution; the required MR damper force , associated with the particular solution, conditions its efficiency. In Table 5, the most favourable results are marked in green boldface, the worst results are marked in red boldface, whereas the runner-up solutions are marked in green/red (respectively) regular face.

Figure 7.

RMS of tower tip relative displacement ) for and . Results summary.

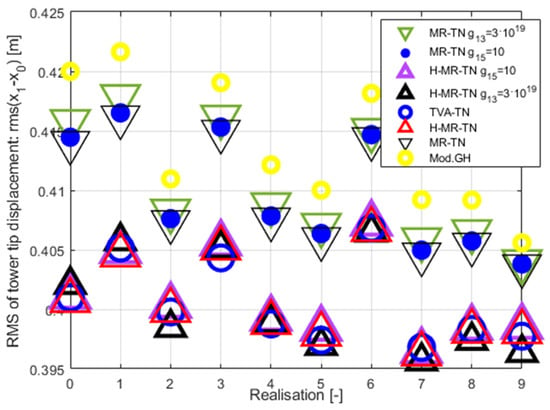

Figure 8.

RMS of tower tip relative displacement ) for and . TVA tuned to the NREL 5MW tower-nacelle 1st bending mode.

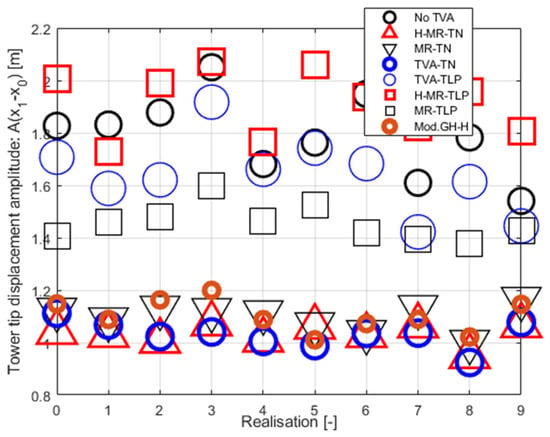

Figure 9.

Tower tip relative displacement amplitude ) for and . Results summary.

Figure 10.

Tower tip relative displacement amplitude ) for and . TVA tuned to the NREL 5MW tower-nacelle 1st bending mode.

Figure 11.

TVA stroke amplitude ) for and . Results summary.

Figure 12.

TVA stroke amplitude ) for and TVA tuned to the NREL 5MW tower-nacelle 1st bending mode.

Figure 13.

MR damper force amplitude ) for and . Results summary.

Figure 14.

MR damper force amplitude ) for and . TVA tuned to the NREL 5MW tower-nacelle 1st bending mode.

Table 5.

The test cases’ cumulative results over realisations 0 ÷ 9 (baseline weights: , , , , assumed for control cases I, II, III, I-H, II-H, III-H).

Figure 15.

Mean actuator power .

Figure 16.

Time patterns for exemplary Realisation 7: (a) TLP surge combined with the nacelle horizontal load , (b) tower tip relative displacement (tower deflection), (c) nacelle acceleration.

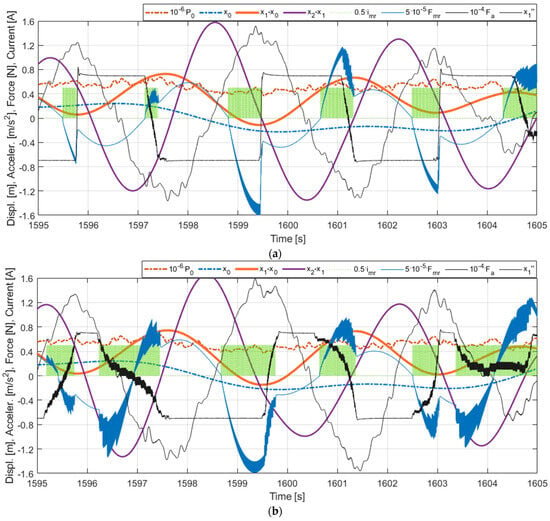

Figure 17.

Time responses for MR-TVA tuned to the NREL 5MW tower-nacelle 1st bending mode: (a) Control case I, (b) Control case II, (c) Control case III (Realisation 7).

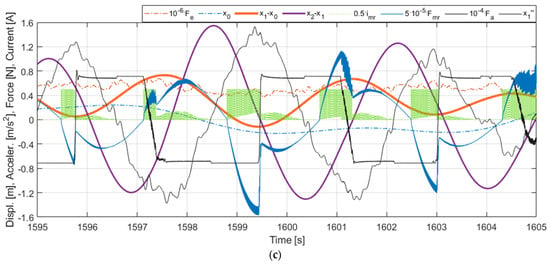

Figure 18.

Time responses for H-MR-TVA tuned to the NREL 5MW tower-nacelle 1st bending mode: (a) Control case I-H, (b) Control case II-H, (c) Control case III-H (Realisation 7).

Figure 7 and Figure 8 present tower tip relative displacement RMS values obtained for the 0 ÷ 9 Bredsneider spectrum ocean wave realisations paired with Weibull distribution wind patterns. The TVA was tuned either to the NREL 5MW tower-nacelle first bending mode case (H-MR-TN legend for H-MR-TVA case; MR-TN legend for MR-TVA case), or to the TLP surge frequency case (H-MR-TLP legend for H-MR-TVA case; MR-TLP legend for MR-TVA case). Figure 9 and Figure 10 present tower tip relative displacement amplitudes for the same set of ten ocean wave/wind realisations for the TVA tuned to the tower-nacelle first bending mode or the TLP surge frequency. Similarly, Figure 11 and Figure 12/Figure 13 and Figure 14 present the TVA stroke amplitudes/MR damper force amplitudes (respectively), whereas Figure 15 presents the mean actuator power values obtained for TVA-TN cases. The regarded control solutions comparison, covering the vibration attenuation results cumulated over all 0 ÷ 9 wave/wind realisations, is presented in Table 5, including the mean of RMSs of tower tip relative displacements (tower deflections) , tower tip relative displacements (tower deflections) maximum amplitudes , TVA stroke maximum amplitudes , and MR damper force maximum amplitudes .

Based on the obtained results, the general conclusion regarding the TVA tuning frequency is consistent with the previous work [33], i.e., the TVA-TN solution is by far superior to the TVA-TLP one regarding tower deflection RMS/amplitude and TVA stroke values. Thus, only the TVA-TN case was selected for the more thorough analyses described below. The obtained values of the maximum tower tip relative displacement (tower deflection) amplitude indicate that under the assumed extreme wave/wind conditions, the regarded TLP–NREL 5MW structures without a TVA (or any other vibration attenuation solution) or with a TVA tuned to the TLP surge frequency (especially passive and hybrid TVA-TLPs) are at risk of tower structural failure, which starts to occur when the tower deflection reaches 2.2 m according to the research [31]. All the regarded TVA-TN solutions provide a tower structural deflection safety factor of ca. 2 following [31], which is a quite conservative estimate as the TLP surge motion is assumed uninfluenced by the wind turbine tower bending; in fact, tower-reaction-driven TLP motion contributes to lowering the tower deflection.

The results shown in Figure 7, Figure 8, Figure 9 and Figure 10 and Table 5 indicate mixed benefits of the force actuator utilisation in the TVA system. Up to a 2.5% cumulative (i.e., across all ten ocean wave/wind realisations, see Table 5) minimisation in the RMS tower deflection, along with up to an 8.8% tower deflection amplitude minimisation in the TVA-TN case, at the cost of up to 32.5% increased TVA stroke, is the result of the implementation of this active machinery along with the control circuity and computation resources for the H-MR-TVA system vs. the MR-TVA one (BTW, a significant increase in the tower deflection RMSs/amplitudes, TVA strokes, and MR damper force amplitudes may be observed for the active actuator utilisation in the TVA-TLP case). The MR damper is a semi-active, dissipative device, which force attenuates the relative travel of the protected structure and the absorber. In contrast, the active actuator repetitively generates the force of the opposite sign, leading to the primary structure deflection and acceleration minimisation through the TVA stroke extension (see Figure 18 vs. Figure 17), as observed for all the regarded H-MR-TVA systems vs. MR-TVA systems (Table 5).

According to the definition of the amplitude, , the TVA effective peak-peak travel distance has to be regarded as , i.e., twice the value from Table 5 and Figure 11 and Figure 12. Thus, passive TVA solutions with 10-ton absorber mass (including the TVA-TN solution with 5.414 m TVA total travel distance) as well as the Mod.GH-H solution cannot be implemented along the demanding side–side direction in the nacelle without enforcing end-stop collision bumpers, which limit the TVA stroke but result in efficiency deterioration concerning the results presented in Table 5 and Figure 7, Figure 8, Figure 9 and Figure 10. Therefore, the promising tower deflection indexes of the passive TVA-TN system are hardly realisable, considering the NREL 5MW nacelle dimensions (Table 1) [28]. The H-MR-TVA travel distance values’ admissibility must be confirmed before implementation. However, control case III-H may be regarded as applicable with proper weight selection (i.e., a possible increase concerning assumed here).

The superiority of the newly developed optimal-based solutions (control case I(-H), II(-H), III(-H)) over the baseline Mod.GH(-H) control law is evident, especially regarding maximum tower deflection amplitude (up to 10.3% reduction) and TVA stroke amplitude (up to 25.7% reduction) values, and the MR damper force amplitudes to even further extend (up to 36.9% reduction). The modified ground-hook approach is devoted to the case when only the protected structure’s relative displacement (tower deflection) has to be minimised. In contrast, the redeveloped control case I(-H), II(-H), and III(-H) uses various optimisation fields (i.a., the nacelle relative velocity and acceleration, or the TVA stroke length) embedded in quality function (8), and the MR damper/force actuator constraints embedded in state and co-state Equations (4) and (11), to produce more favourable results.

Figure 16, Figure 17 and Figure 18 present selected time characteristics obtained for the exemplary wave/wind realisation no. 7: the excitations (TLP surge combined with the nacelle horizontal load ), the relative displacements of the tower tip (tower deflection ) and the TVA (), the nacelle acceleration , the force produced by the MR damper (and the electromagnetic actuator for the H-MR-TVA system only), and the MR damper electric current , obtained for the TVA tuned to the NREL 5MW tower-nacelle 1st bending mode vs. the structure without the TVA (tower deflection for the latter only; mind the signals multipliers in the legends). Figure 16a–c present the excitations’ time patterns and the corresponding tower tip relative displacement and nacelle acceleration responses obtained for the system without the TVA and two (H-)MR-TVA solutions: MR-TN (control case I) and H-MR-TN (control case I-H). Figure 17a vs. Figure 17b vs. Figure 17c show comparable time histories, zoomed in along the time axis to illustrate the control action for the MR-TVA system, while Figure 18a vs. Figure 18b vs. Figure 18c—for the H-MR-TVA system. As is evident in Figure 16, both MR-TVA and H-MR-TVA substantially reduce tower deflection and nacelle acceleration amplitudes, although the additional force actuator operation of the latter yields preferable protected structure vibration mitigation results. The operation of the MR-TVA system (Figure 17), control case II vs. control case I, is characterised by the slightly increased MR damper force modulus mostly during time intervals of high absorber velocity (both and ) values and the appropriate sign, opposing the absorber’s drawing away from the primary structure. On the other hand, the operation of the control case III solution vs. control case I and control case II is indicated with nonzero MR damper current during time intervals when force opposes the maximum acceleration values. The optimal control task quality function (8) is aimed to minimise the H2 norm of the included quantities; thus, the maximum amplitude of the TVA stroke is, in fact, not reduced for control case II solution vs. control case I (Figure 12 and Table 5), as for control case III. However, the TVA stroke RMS value is actually slightly lower for control case II vs. control case I and control case III (0.346 m vs. 0.353 m and 0.348 m, respectively, for the regarded exemplary Realisation 7 response, see Figure 17). The operation of the H-MR-TVA system (Figure 18), control case II-H and control case III-H vs. control case I-H, exhibits similar MR damper control conditions as described for the MR-TVA system. However, TVA stroke amplitude and RMS values are both reduced for control case II-H and control case III-H with regard to control case I-H, thanks to the active force actuator support. When analysing Figure 18a–c, it is evident that both actuators’ forces are used in cooperation by the vibration control system, e.g., in Figure 18c, the modulus increased due to the increased (concerning Figure 18a,b) MR damper current is reflected by the decreased modulus. Moreover, most transients are accompanied by the support, as the MR damper response (27) is faster than the assumed electromagnetic force actuator’s (28). The MR damper force support for the control case II-H solution, as visible in Figure 18b, also leads to the mean actuator power reduction (see Figure 15, H-MR-TN g13 = 3 × 1019 legend).

Implementing the protected structure’s acceleration term in the quality index (8) reduces the TVA stroke amplitude more effectively than using the term and, apart from that, the required MR damper force amplitude is also reduced, as reflected in Figure 12, Figure 14, Figure 17 and Figure 18 and Table 5. It also is worth to mention that the term used here for the MR-TVA system (control case II) is ineffective in minimisation (see Figure 12 and Figure 17b and Table 5); at the same time, it marginally deteriorates the primary structure response (Figure 8, Figure 10 and Figure 17a,b and Table 5). For the H-MR-TVA, control case II-H yields both less favourable primary structure deflection and less favourable TVA stroke length than control case III-H, i.e., similar mean tower deflection RMS values but 4.3% higher maximum tower deflection amplitude, and 4.3% higher maximum TVA stroke amplitude over all wave/wind realisations (see Table 5). On the contrary, the term implementation for the MR-TVA (control case III) results in 9.0% and 5.7% maximum TVA stroke amplitude reduction over all wave/wind realisations with regard to control case II and control case I, respectively, while its primary structure response differences with regard to the preferable control case I (Figure 8, Figure 10 and Figure 17 and Table 5) are negligible (within 0.2%). The implementation of the term for the H-MR-TVA system (control case III-H) results in 6.0% maximum TVA stroke amplitude reduction concerning the baseline control case I-H, while the primary structure response differences are negligible (within 0.3%), as for the MR-TVA system. The TVA travel distance reductions are obtained thanks to the sole control algorithm alteration. Thus, no additional hardware/software resources are necessary, while this pure advantage is accompanied by up to 4.4% reduction in the MR damper force amplitude vs. the control case I(-H) solutions.

Concerning the limited TVA stroke, the most favourable vibration control solution is the semi-active MR-TVA control case III implementation, providing favourable cumulative primary structure deflection indexes (over all wave/wind realisations) at the lowest obtained TVA travel distance. A possible alternative is the hybrid H-MR-TVA control case III-H implementation, providing even more favourable cumulative primary structure deflection indexes and reduced nacelle acceleration levels thanks to the utilisation of the force actuator of relatively low mean power (up to 6.15 kW), of which one side effect is, however, the increased TVA travel distance.

8. Conclusions

The purpose of this research was the implementation and numerical study of the nonlinear optimal-based vibration control solutions for the full-scale TLP–NREL 5MW wind turbine tower-nacelle model with the (H-)MR-TVA vibration reduction system under excessive wave/wind polyperiodic excitations yielding continual transient vibration states. The selection of the tuning frequency was initially investigated, and the TVAs were tuned to the tower-nacelle 1st bending mode (TVA-TN) or the TLP surge frequency (TVA-TLP). Simulations using experimentally derived platform motion realisations were performed, and the two approaches were compared based on tower deflection amplitude/RMS and TVA stroke values. It was concluded that the TVA-TN approach is superior to the TVA-TLP one. All the considered TVA-TN solutions provide a tower deflection safety factor of ca. 2, while the structure without any vibration reduction solutions or with the TVA tuned to the TLP surge frequency (especially passive and hybrid TVA-TLPs) are at risk of tower structural failure.

TVAs utilising magnetorheological dampers (MR-TVAs) either without or with additional small-scale active actuators (forming hybrid H-MR-TVAs) were examined, considering three control strategies for each TVA type. The control case I/I-H includes weighting factors for the minimisation of tower deflection and deflection rate. The control case II/II-H additionally assumes the nonzero weighting factor for the TVA stroke; in contrast, the control case III/III-H adds the nonzero weighting factor for the nacelle (tower tip) acceleration. The performance of these solutions was compared against the well-proven baseline modified ground-hook law (Mod.GH/Mod.GH-H), which uses the minimisation of the primary structure deflection as the single objective in the control strategy. The comparisons revealed that the newly proposed implementation of the protected structure’s acceleration and nonzero relative velocity terms (control case III/III-H) in the quality function results in 25.7%/22.0% maximum TVA stroke amplitude reduction along with 3.6%/10.3% maximum tower deflection amplitude reduction for the MR-TVA/H-MR-TVA systems, respectively. Furthermore, the sole usage of the protected structure’s acceleration term yields ca. 6% maximum TVA stroke amplitude reduction with regard to the control case I and I-H approaches, while the tower deflection response differences are negligible. The TVA travel distance reductions are obtained thanks to the sole control algorithm enhancement. Thus, no additional resources are necessary, while reducing the MR damper force necessary for the TVA operation accompanies this pure advantage. The utilisation of the protected structure’s acceleration term reduces the TVA stroke amplitude more efficiently than standard TVA relative displacement term usage, as in the previously developed approach (the latter being ineffective for the MR-TVA implementation), which, in turn, efficiently reduces the TVA stroke RMS (H2 norm) values and, apart from that, the required mean actuator power for the H-MR-TVA implementation.

Regarding the limited TVA stroke, the most favourable solution is the semi-active control case III, guarantying favourable cumulative primary structure deflection indexes at the lowest obtained TVA travel distance. A possible alternative may be the hybrid control case III-H, providing even more favourable primary structure deflection qualities (8% lower deflection amplitude) and reduced nacelle acceleration levels thanks to the utilisation of the force actuator of the relatively low power (ca. 6 kW). However, this has the side effect of an increased TVA stroke amplitude. The analysed passive TVA systems (both TVA-TN and TVA-TLP) with a relatively small 10-ton absorber mass can hardly be implemented in the nacelle, especially along the demanding side–side direction, without enforcing end-stop collision bumpers, which result in efficiency deterioration.

The results of the current study may be used in the design process of the full-scale vibration reduction system attached to the real-world NREL 5MW-class floating, TLP-based wind turbine structure. No offline calculations, MR damper or actuator (servomotor) force tracking, disturbances, or dominant frequency assumption are necessary for proper real-time implementation of the proposed method. This implementation includes complex polyperiodic vibration states arising from the variable waves and wind excitations. However, the developed approach may be directly applied to transient and steady-state structural vibration control under various other stochastic and deterministic disturbances. This crucial problem will be further investigated considering the FOWT model extension utilising a dedicated finite element environment in combination with the MATLAB/Simulink simulation platform.

Author Contributions

Conceptualization, P.M.; Methodology, P.M.; Software, P.M. and G.M.K.; Validation, P.M., G.M.K. and S.A.M.; Formal analysis, P.M.; Investigation, P.M.; Resources, P.M., G.M.K. and S.A.M.; Data curation, P.M.; Writing—original draft, P.M.; Writing—review & editing, P.M. and G.M.K.; Visualization, P.M. and G.M.K.; Supervision, P.M.; Project administration, P.M.; Funding acquisition, P.M. All authors have read and agreed to the published version of the manuscript.

Funding

The research project was supported by the program “Excellence initiative–research university” for the AGH University.

Data Availability Statement

The data presented in this study are available on request.

Conflicts of Interest

The authors declare no conflict of interest.

List of Symbols Used

| Symbol | Value | Unit | Description |

| m1 | 428.8 × 103 | kg | modal mass of the NREL 5MW tower 1st bending mode |

| m2 | 10.0 × 103 | kg | mass of the absorber |

| k1 | 1.546 × 106 | N/m | modal stiffness of the NREL 5MW tower 1st bending mode |

| k2 | 34.42 × 103 | N/m | stiffness coefficient of the absorber tuned to the NREL 5MW tower 1st bending mode |

| 3.770 × 103 | N/m | stiffness coefficient of the absorber tuned to the TLP surge | |

| c1 | 3.542 × 103 | Ns/m | modal damping of the NREL 5MW tower 1st bending mode |

| c2 | 3.352 × 103 | Ns/m | damping coefficient of the passive absorber tuned to the NREL 5MW tower 1st bending mode |

| 1.109 × 103 | Ns/m | damping coefficient of the passive absorber tuned to the TLP surge | |

| imax | 1.0 | A | maximum current of the magnetorheological damper |

| C1 | 1581 | N/A | current-dependent friction coefficient |

| C2 | 38.25 | N | friction coefficient |

| C3 | 12,240 | Ns/Am current-dependent viscous damping coefficient | |

| C4 | 3570 | Ns/m | viscous damping coefficient |

| ν | 1300 | s/m | friction scaling parameter |

| p | 1 | 1/s | hysteresis scaling parameter |

| Fnom | 7125 | N | nominal force of the actuator |

| g11 | 1021 | 1/m2 | weight of the protected structure relative displacement |

| g12 | 1019 | s2/m2 | weight of the protected structure relative velocity |

| g13 | 3 × 1019 | 1/m2 | weight of the absorber relative displacement |

| g14 | 0 | s2/m2 | weight of the absorber relative velocity |

| g15 | 10 | s4/m2 | weight of the protected structure acceleration |

| g21 | 4 | 1/A2 | weight of the magnetorheological damper current |

| g221 | 0 | 1/N2 | weight of the magnetorheological damper force |

| g222 | 4 × 10–12 | 1/N2 | weight of the actuator force |

| g23 | 0 | 1/W2 | weight of the actuator power |

| Fmr | N | force generated by the magnetorheological damper | |

| Fa | N | force generated by the actuator | |

| Pa | N | power of the actuator | |

| Fe | N | rotor force excitation | |

| m | TLP surge excitation | ||

| m | horizontal displacement of the nacelle | ||

| m/s | horizontal velocity of the nacelle | ||

| m | horizontal displacement of the absorber | ||

| m/s | horizontal velocity of the absorber |

References

- Weber, F.; Maślanka, M. Precise stiffness and damping emulation with MR dampers and its application to semi-active tuned mass dampers of Wolgograd Bridge. Smart Mater. Struct. 2014, 23, 15019. [Google Scholar] [CrossRef]

- Kavyashree, B.G.; Patil, S.; Rao, V.S. Review on vibration control in tall buildings: From the perspective of devices and applications. Int. J. Dyn. Control 2020, 9, 1316–1331. [Google Scholar] [CrossRef]

- Caterino, N. Semi-active control of a wind turbine via magnetorheological dampers. J. Sound Vib. 2015, 345, 1–17. [Google Scholar] [CrossRef]

- Kirkegaard, P.H.; Nielsen, S.R.K.; Poulsen, B.L.; Andersen, J.; Pedersen, L.H.; Pedersen, B.J. Semiactive vibration control of a wind turbine tower using an MR damper. In Structural Dynamics—EURODYN; Grundmann, H., Schueller, G.I., Eds.; Swets & Zeitlinger: Lisse, The Netherlands, 2002. [Google Scholar]

- Yung-Yen, K. A simplified structural model for monopile-supported offshore wind turbines with tapered towers. Renew. Energy 2020, 156, 777–790. [Google Scholar]

- Alotta, G.; Biondo, C.; Giaralis, A.; Failla, G. Seismic protection of land-based wind turbine towers using the tuned inerter damper. Structures 2023, 51, 640–656. [Google Scholar] [CrossRef]

- Rotea, M.A.; Lackner, M.A.; Saheba, R. Active Structural Control of Offshore Wind turbines. In Proceedings of the 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2010. [Google Scholar]

- Tsouroukdissian, A.; Carcangiu, C.E.; Pineda, A.I.; Martin, M.; Fischer, T.; Kuhnle, B.; Scheu, M. Wind Turbine Tower Load Reduction using Passive and Semiactive Dampers. In Proceedings of the European Wind Energy Association Annual Event, Brussels, Belgium, 14–17 March 2011. [Google Scholar]

- Spencer, B.F., Jr.; Soong, T.T. New Applications and Development of Active, Semi-Active and Hybrid Control Techniques for Seismic and Non-Seismic Vibration in the USA. In Proceedings of the International Post-SMiRT Conference Seminar on Seismic Isolation, Passive Energy Dissipation and Active Control of Vibration of Structures, Cheju, Republic of Korea, 23–25 August 1999. [Google Scholar]

- Zhang, Z.; Staino, A.; Basu, B.; Nielsen, S.R.K. Performance evaluation of full-scale tuned liquid dampers (TLDs) for vibration control of large wind turbines using real-time hybrid testing. Eng. Struct. 2016, 126, 417–431. [Google Scholar] [CrossRef]

- Den Hartog, J.P. Mechanical Vibrations; Dover Publications: Mineola, NY, USA, 1985. [Google Scholar]

- Nakamura, Y.; Tanaka, K.; Nakayama, M.; Fujita, T. Hybrid mass dampers using two types of electric servomotors: AC servomotors and linear-induction servomotors. Earthq. Eng. Struct. Dyn. 2001, 30, 1719–1743. [Google Scholar] [CrossRef]

- Preumont, A.; Alaluf, D.; Bastaits, R. Hybrid Mass Damper: A Tutorial Example. In Active and Passive Vibration Control of Structures; Hagedorn, P., Spelsberg-Korspeter, G., Eds.; CISM International Centre for Mechanical Sciences: Udine, Italy, 2014. [Google Scholar] [CrossRef]

- Demetriou, D.; Nikitas, N. A Novel Hybrid Semi-Active Mass Damper Configuration for Structural Applications. Appl. Sci. 2016, 6, 397. [Google Scholar] [CrossRef]

- Koo, J.H.; Ahmadian, M. Qualitative Analysis of Magneto-Rheological Tuned Vibration Absorbers: Experimental Approach. J. Intell. Mater. Syst. Struct. 2007, 18, 1137–1142. [Google Scholar] [CrossRef]

- Wang, L.; Liang, Z.; Cai, M.; Zhang, Y.; Yan, J. Adaptive Structural Control of Floating Wind Turbine with Application of MR Damper. Energy Procedia 2019, 158, 254–259. [Google Scholar] [CrossRef]

- Martynowicz, P. Control of an MR Tuned Vibration Absorber for Wind Turbine Application Utilising the Refined Force Tracking Algorithm. J. Low Freq. Noise Vib. Act. Control 2017, 36, 339–353. [Google Scholar] [CrossRef]

- Martynowicz, P. Nonlinear optimal-based vibration control for systems with MR tuned vibration absorbers. J. Low Freq. Noise Vib. Act. Control 2019, 38, 1607–1628. [Google Scholar] [CrossRef]

- Martynowicz, P. Real-time implementation of nonlinear optimal-based vibration control for a wind turbine model. J. Low Freq. Noise Vib. Act. Control 2019, 38, 1635–1650. [Google Scholar] [CrossRef]

- Martynowicz, P. Nonlinear Optimal-Based Vibration Control of a Wind Turbine Tower Using Hybrid vs. Magnetorheological Tuned Vibration Absorber. Energies 2021, 14, 5145. [Google Scholar] [CrossRef]

- Martynowicz, P. Experimental study on the optimal-based vibration control of a wind turbine tower using a small-scale electric drive with MR damper support. Energies 2022, 15, 9530. [Google Scholar] [CrossRef]

- GWEC. Global Offshore Wind Report, 2022; GWEC Asia Ltd.: Singapore, 2022. [Google Scholar]

- Jonkman, J.; Matha, D. A Quantitative Comparison of the Responses of Three Floating Platform Concepts. In Proceedings of the European Offshore Wind 2009 Conference and Exhibition, Stockholm, Sweden, 14–16 September 2009; Conference Paper NREL/CP-500-46726. National Renewable Energy Laboratory: Golden, CO, USA, 2010. [Google Scholar]

- Katsaounis, G.M.; Polyzos, S.; Mavrakos, S.A. An Experimental Study of the Hydrodynamic Behavior of a TLP Platform for a 5MW Wind Turbine with OWC Devices. In Proceedings of the VII International Conference on Computational Methods in Marine Engineering (MARINE 2017), Nantes, France, 15–17 May 2017. [Google Scholar]

- Konispoliatis, D.; Katsaounis, G.M.; Manolas, D.; Soukissian, T.; Polyzos, S.; Mazarakos, T.P.; Voutsinas, S.G.; Mavrakos, S.A. REFOS: A Renewable Energy Multi-Purpose Floating Offshore System. Energies 2021, 14, 3126. [Google Scholar] [CrossRef]

- Jonkman, J.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-MW Reference Wind Turbine for Offshore System Development; Technical Report NREL/TP-500-38060; National Renewable Energy Laboratory: Golden, CO, USA, 2009. [Google Scholar]

- Bir, G.; Jonkman, J. Modal Dynamics of Large Wind Turbines with Different Support Structures. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Estoril, Portugal, 15–20 June 2008; Conference Paper NREL/CP-500-43045. National Renewable Energy Laboratory: Golden, CO, USA, 2008. [Google Scholar]

- Stewart, G.; Lackner, M. Offshore Wind Turbine Load Reduction Employing Optimal Passive Tuned Mass Damping Systems. IEEE Trans. Control Syst. Technol. 2013, 21, 1090–1104. [Google Scholar] [CrossRef]

- Park, S.; Lackner, M.A.; Cross-Whiter, J.; Tsouroukdissian, A.R.; La Cava, W. An investigation of passive and semi-active tuned mass dampers for a tension leg platform floating offshore wind turbine in ULS conditions. In Proceedings of the ASME 2016 35th International Conference on Ocean, Offshore and Arctic Engineering, Busan, Republic of Korea, 19–24 June 2016. [Google Scholar]

- Park, S.; Lackner, M.A.; Pourazarm, P.; Tsouroukdissian, A.R.; Cross-Whiter, J. An investigation on the impacts of passive and semiactive structural control on a fixed bottom and a floating offshore wind turbine. Wind Energy 2019, 22, 1451–1471. [Google Scholar] [CrossRef]

- Asareh, M.A.; Schonberg, W.; Volz, J. Fragility Analysis of a 5-MW NREL Wind Turbine Considering Aero-Elastic and Seismic Interaction Using Finite Element Method. Finite Elem. Anal. Des. 2016, 120, 57–67. [Google Scholar] [CrossRef]

- Hu, Y.; He, E. Active structural control of a floating wind turbine with a stroke-limited hybrid mass damper. J. Sound Vib. 2017, 410, 447–472. [Google Scholar] [CrossRef]

- Martynowicz, P.; Santos, M. Structural vibration control of NREL 5.0 MW FOWT using optimal-based MR tuned vibration absorber. In Proceedings of the 21st IFAC World Congress, Berlin, Germany, 11–17 July 2020. [Google Scholar]

- Vardaroglu, M.; Gao, Z.; Avossa, A.M.; Ricciardelli, F. Validation of a TLP wind turbine numerical model against model-scale tests under regular and irregular waves. Ocean Eng. 2022, 256, 111491. [Google Scholar] [CrossRef]

- Madsen, F.J.; Nielsen, T.R.L.; Kim, T.; Bredmose, H.; Pegalajar-Jurado, A.; Mikkelsen, R.F.; Lomholt, A.K.; Borg, M.; Mirzaei, M.; Shin, P. Experimental analysis of the scaled DTU10MW TLP floating wind turbine with different control strategies. Renew. Energy 2020, 155, 330–346. [Google Scholar] [CrossRef]

- Larsen, T.G.; Zhang, Z.; Høgsberg, J. Vibration damping of an offshore wind turbine by optimally calibrated pendulum absorber with shunted electromagnetic transducer. J. Sound Vib. 2021, 505, 116144. [Google Scholar] [CrossRef]

- Shen, Y.J.; Wang, L.; Yang, S.P.; Gao, G.S. Nonlinear dynamical analysis and parameters optimization of four semi-active on-off dynamic vibration absorbers. J. Vib. Control 2013, 19, 143–160. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, M.Z.Q.; Li, C. Active structural control for load mitigation of wind turbines via adaptive sliding-mode approach. J. Frankl. Inst. 2017, 354, 4311–4330. [Google Scholar] [CrossRef]

- Bryson, A.E.; Ho, Y.C. Applied Optimal Control; Taylor & Francis: Abingdon, UK, 1975. [Google Scholar]

- Shukla, P.; Ghodki, D.; Manjarekar, N.S.; Singru, P.M. A Study of H infinity and H2 synthesis for Active Vibration Control. IFAC-PapersOnLine 2016, 49, 623–628. [Google Scholar] [CrossRef]

- Itik, M. Optimal control of nonlinear systems with input constraints using linear time varying approximations. Nonlinear Anal. Model. Control 2016, 21, 400–412. [Google Scholar] [CrossRef]

- Snamina, J.; Martynowicz, P. Prediction of characteristics of wind turbine’s tower-nacelle system from investigation of its scaled model. In Proceedings of the 6WCSCM: Sixth World Conference on Structural Control and Monitoring—Proceedings of the 6th Edition of the World Conference of the International Association for Structural Control and Monitoring (IACSM), Barcelona, Spain, 15–17 July 2014. [Google Scholar]

- Ioffe, A.D.; Tihomirov, V.M. Theory of Extremal Problems. Studies in Mathematics and Its Applications; North-Holland Publishing Company: Amsterdam, The Netherland, 1979. [Google Scholar]

- Länger-Möller, A. Simulation of transient gusts on the NREL 5MW wind turbine using the URANS solver THETA. Wind Energy Sci. 2018, 3, 461–474. [Google Scholar] [CrossRef]

- Maślanka, M. Optimised semi-active tuned mass damper with acceleration and relative motion feedbacks. Mech. Syst. Signal Process. 2019, 130, 707–731. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).