Lattice Design and Advanced Modeling to Guide the Design of High-Performance Lightweight Structural Materials

Abstract

1. Introduction

2. Methods

2.1. Lattice Structure Design

2.1.1. Creo

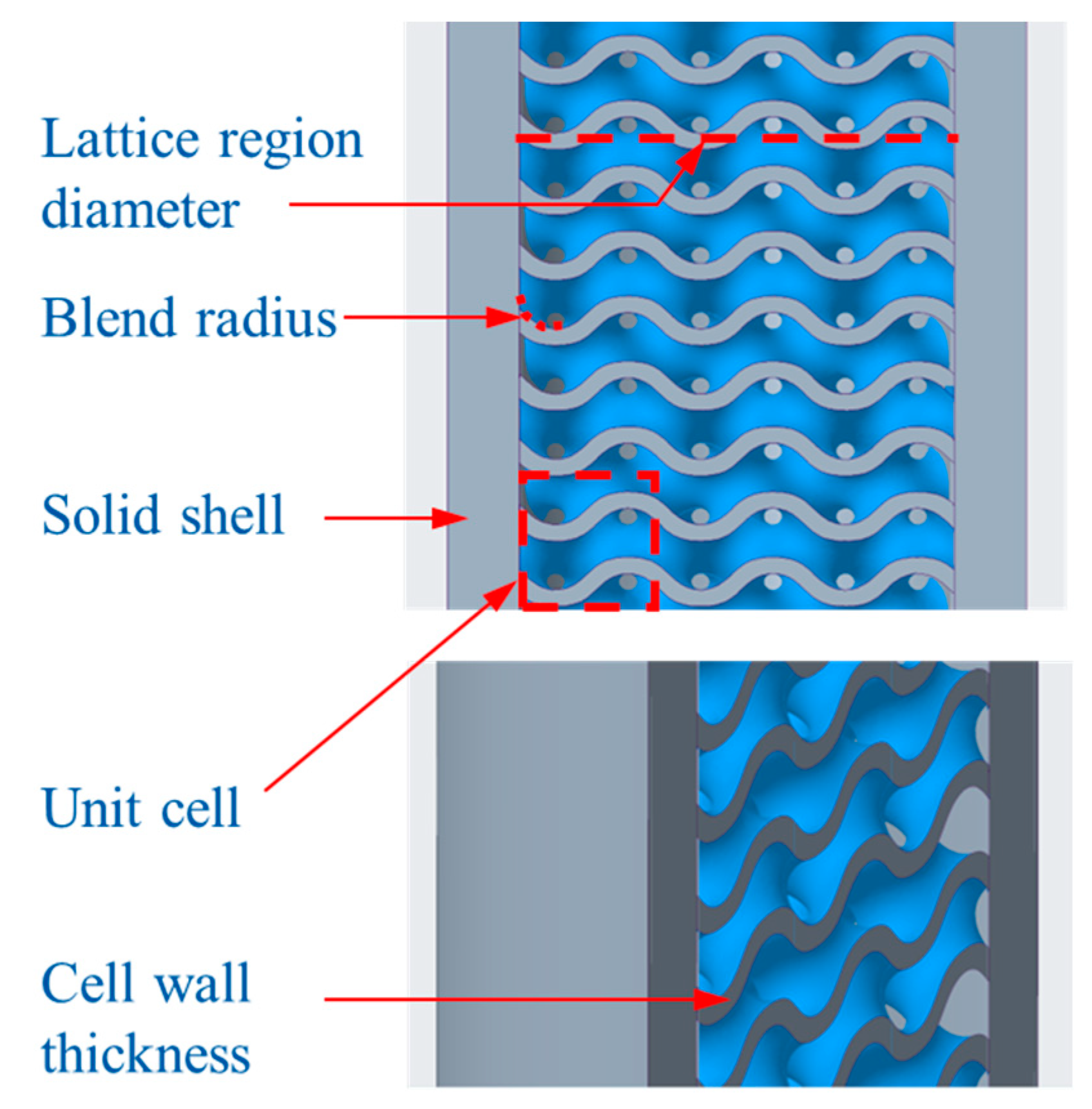

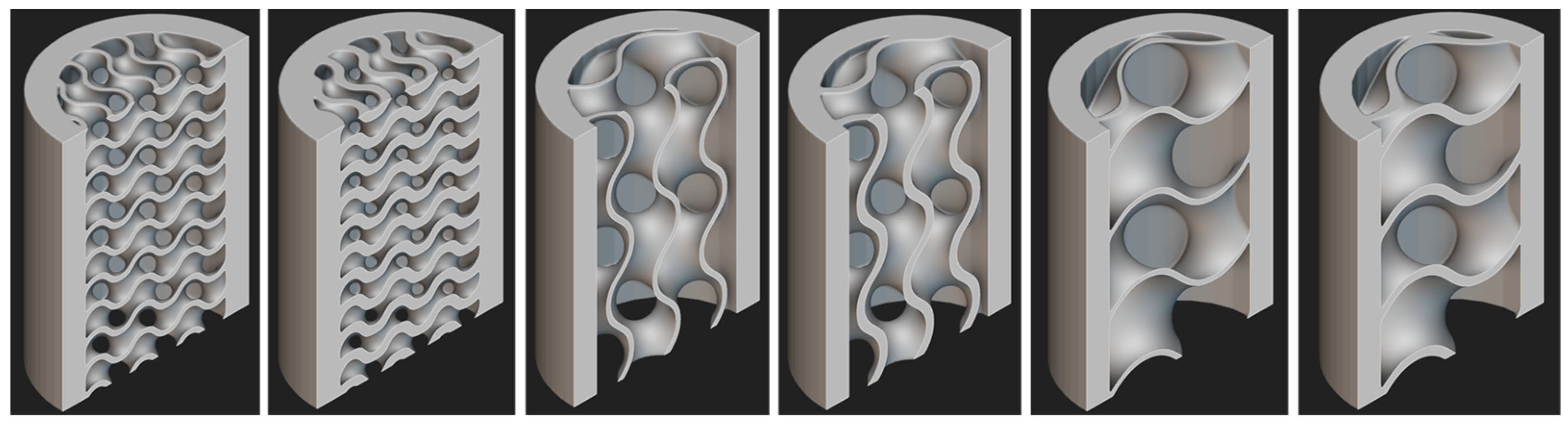

2.1.2. nTopology

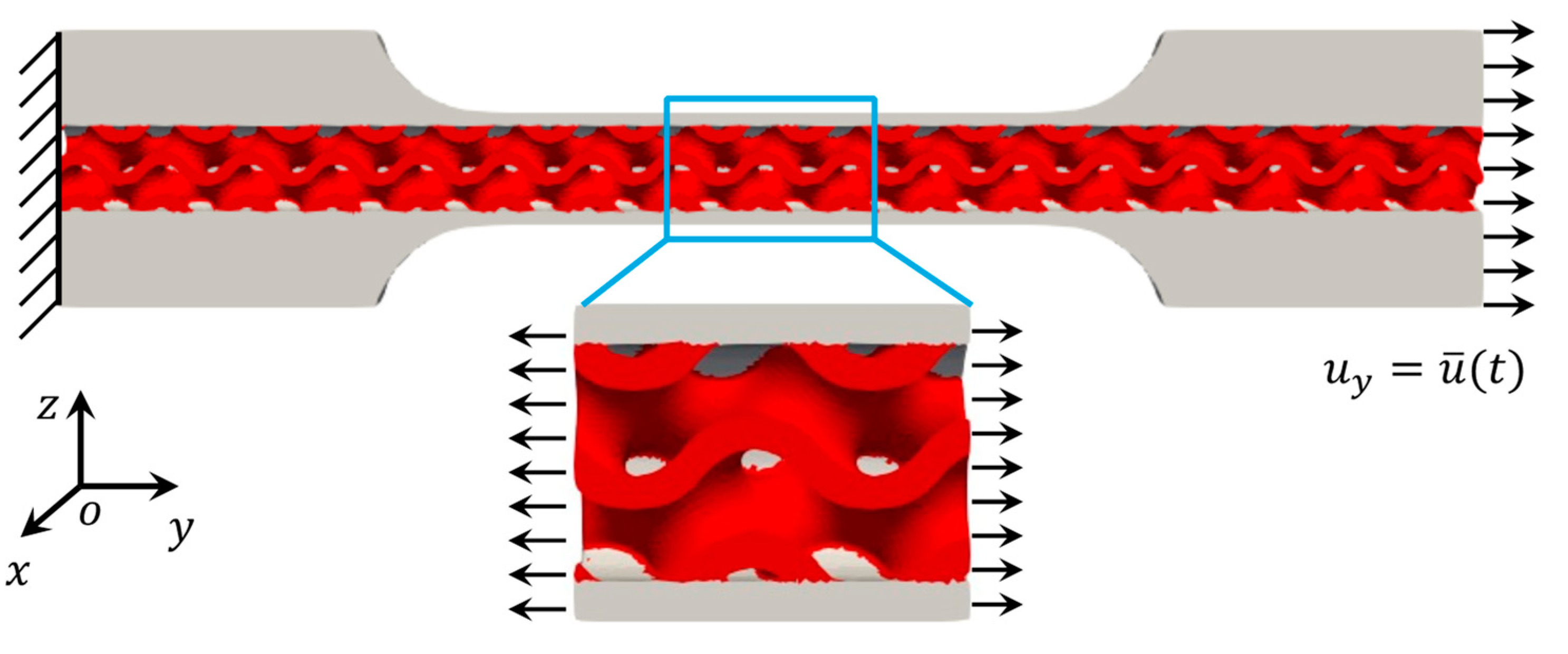

2.2. Interface with Moose

2.3. Finite Element Modeling

3. Results

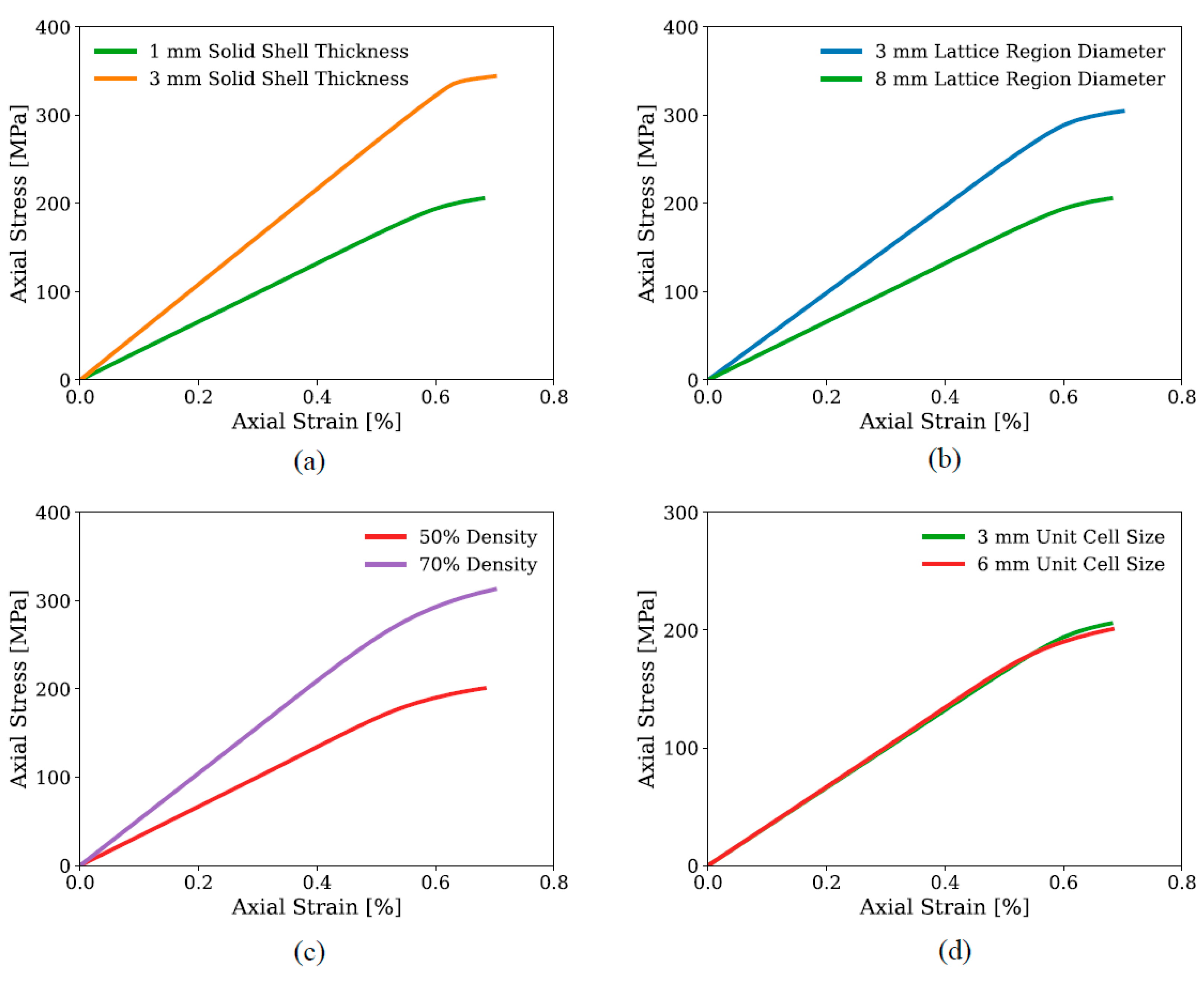

3.1. Macro-Mechanical Response

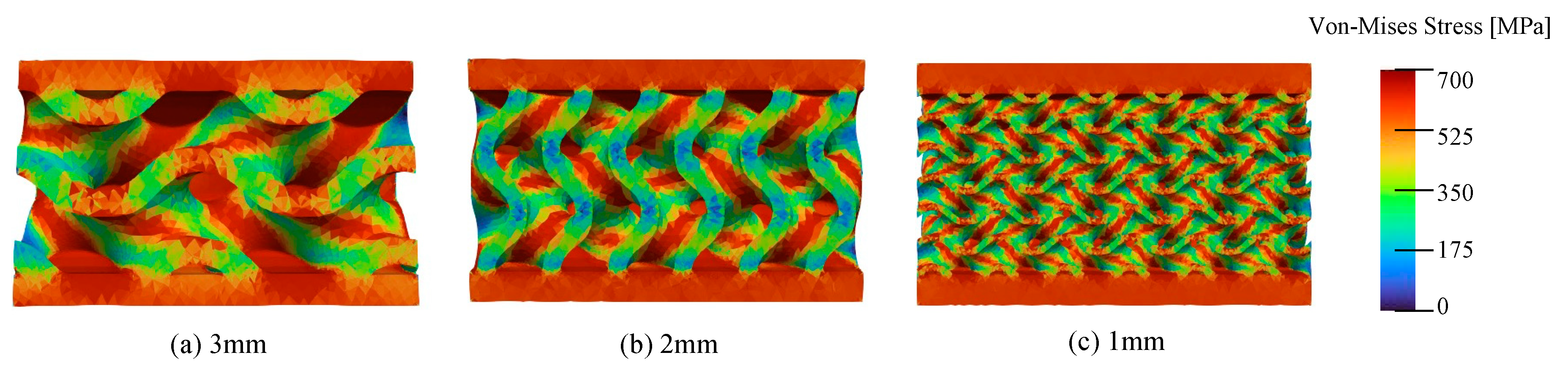

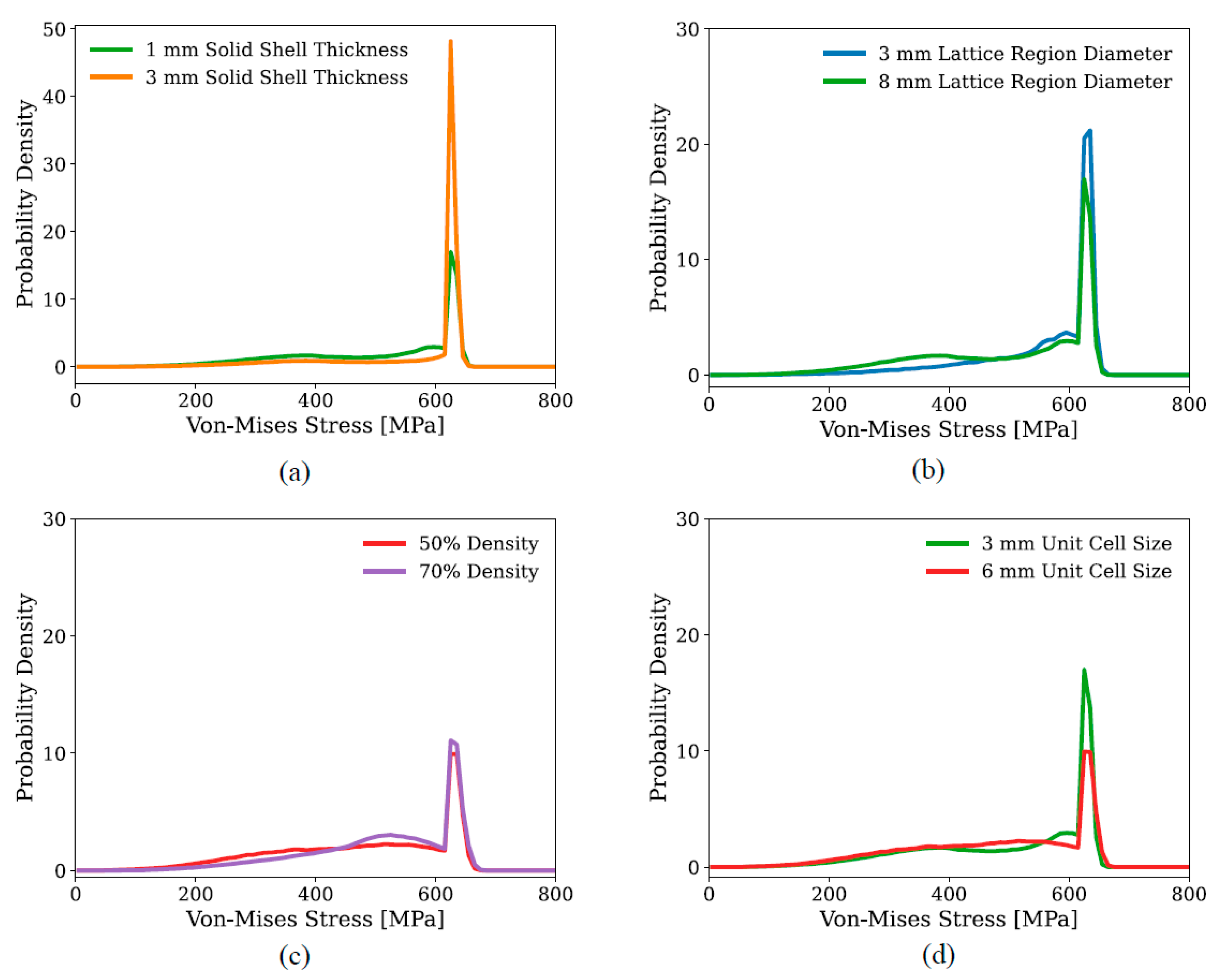

3.2. Micro-Mechanical Response

4. Discussion

5. Conclusions

- It is important to use the appropriate software for lattice design. nTopology could successfully mesh the unit cell, cell wall, solid shell, blend radius, and lattice type.

- A generalized pipeline and workflow were developed to construct the interface from Creo, using nTopology, to geometries and meshes that could be imported into MOOSE for FEM analysis.

- FEM analysis proves valuable for assessing the influence of a wide range of factors on the design of gyroid structures.

- Enhancing the mechanical performance at both macro- and micro-scales was facilitated by increasing the blend radius and solid shell thickness, while simultaneously decreasing the lattice region diameter within practical constraints.

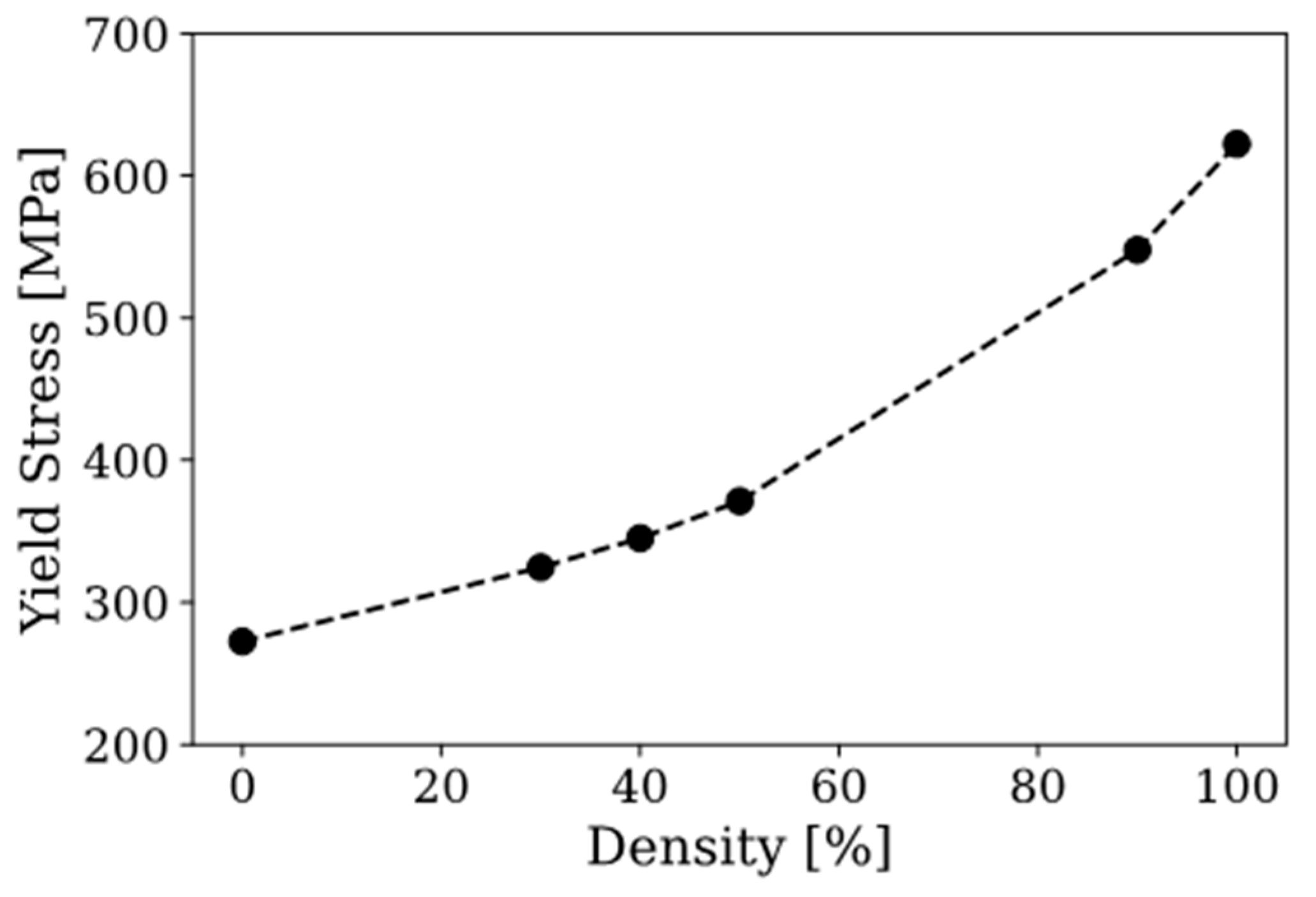

- Density plays a crucial role in macro-scale performance by improving the elastic modulus and yield point.

- Decreasing the unit cell size promotes a more uniform stress distribution at the micro scale.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Agarwal, V.; Ballout, Y.; Gehin, J. Fission Battery Initiative: Research and Development Plan. January 2021, INL/EXT-21-61275, DE-AC07-05ID14517. Available online: https://www.osti.gov/servlets/purl/1834302 (accessed on 9 January 2024).

- Forsberg, C.; Foss, A.W. Fission battery markets and economic requirements. Appl. Energy 2023, 329, 120266. [Google Scholar] [CrossRef]

- Hailu, Y.M.; Nazir, A.; Lin, S.C.; Jeng, J.Y. The Effect of Functional Gradient Material Distribution and Patterning on Torsional Properties of Lattice Structures Manufactured Using MultiJet Fusion Technology. Materials 2021, 14, 6521. [Google Scholar] [CrossRef] [PubMed]

- Pan, C.; Han, Y.; Lu, J. Design and Optimization of Lattice Structures: A Review. Appl. Sci. 2020, 10, 6374. [Google Scholar] [CrossRef]

- Seharing, A.; Azman, A.H.; Abdullah, S. A review on integration of lightweight gradient lattice structures in additive manufacturing parts. Adv. Mech. Eng. 2020, 12, 1687814020916951. [Google Scholar] [CrossRef]

- Doodi, R.; Gunji, B.M. Prediction and experimental validation approach to improve performance of novel hybrid bio-inspired 3D printed lattice structures using artifcial neural networks. Sci. Rep. 2023, 13, 7763. [Google Scholar] [CrossRef] [PubMed]

- Charkaluk, E.; Chastand, V. Fatigue of Additive Manufacturing Specimens: A Comparison with Casting Processes. Proceedings 2018, 2, 474. [Google Scholar] [CrossRef]

- Chen, S.G.; Gao, H.J.; Zhang, Y.D.; Wu, Q.; Gao, Z.H.; Zhou, X. Review on residual stresses in metal additive manufacturing: Formation mechanisms, parameter dependencies, prediction and control approaches. J. Mater. Res. Technol. 2022, 17, 2950–2974. [Google Scholar] [CrossRef]

- Al-Maharma, A.; Patil, S.P.; Markert, B. Effects of porosity on the mechanical properties of additively manufactured components: A critical review. Mater. Res. Express 2020, 7, 122001. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Lam, T.N.; Chen, K.M.; Tsai, C.H.; Tsai, P.I.; Wu, M.H.; Hsu, C.C.; Jain, J.; Huang, E.W. Effect of Porosity and Heat Treatment on Mechanical Properties of Additive Manufactured CoCrMo Alloys. Materials 2023, 16, 751. [Google Scholar] [CrossRef] [PubMed]

- Kan, W.H.; Chiu, L.N.S.; Lim, C.V.S.; Zhu, Y.; Tian, Y.; Jiang, D.; Huang, A. A critical review on the effects of process-induced porosity on the mechanical properties of alloys fabricated by laser powder bed fusion. J. Mater. Sci. 2022, 57, 9818–9865. [Google Scholar] [CrossRef]

- Weeger, O.; Valizadeh, I.; Mistry, Y.; Bhate, D. Inelastic finite deformation beam modeling, simulation, and validation of additively manufactured lattice structures. Addit. Manuf. Lett. 2023, 1, 100111. [Google Scholar] [CrossRef]

- Yang, L.; Mertens, R.; Ferrucci, M.; Yan, C.; Shi, Y.; Yang, S. Continuous graded Gyroid cellular structures fabricated by selective laser melting: Design, manufacturing and mechanical properties. Mater. Des. 2019, 162, 394–404. [Google Scholar] [CrossRef]

- Yin, H.; Zhang, W.; Zhu, L.F.; Meng, F.; Liu, J.; Wen, G. Review on lattice structures for energy absorption properties. Compos. Struct. 2023, 304, 116397. [Google Scholar] [CrossRef]

- Lindsay, A.D.; Gaston, D.R.; Permann, C.J.; Miller, J.M.; Andrš, D.; Slaughter, A.E.; Kong, F.; Hansel, J.; Carlsen, R.W.; Icenhour, C.; et al. 2.0-MOOSE: Enabling massively parallel multiphysics simulation. SoftwareX 2022, 20, 101202. [Google Scholar] [CrossRef]

- BS EN ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. British Standards Institution Standards Limited: London, UK, 2022. Available online: https://www.iso.org/obp/ui/#iso:std:iso-astm:52900:ed-2:v1:en (accessed on 9 January 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, R.; Moorehead, M.; Yushu, D.; Ke, J.-H. Lattice Design and Advanced Modeling to Guide the Design of High-Performance Lightweight Structural Materials. Energies 2024, 17, 1468. https://doi.org/10.3390/en17061468

Song R, Moorehead M, Yushu D, Ke J-H. Lattice Design and Advanced Modeling to Guide the Design of High-Performance Lightweight Structural Materials. Energies. 2024; 17(6):1468. https://doi.org/10.3390/en17061468

Chicago/Turabian StyleSong, Rongjie, Michael Moorehead, Dewen Yushu, and Jia-Hong Ke. 2024. "Lattice Design and Advanced Modeling to Guide the Design of High-Performance Lightweight Structural Materials" Energies 17, no. 6: 1468. https://doi.org/10.3390/en17061468

APA StyleSong, R., Moorehead, M., Yushu, D., & Ke, J.-H. (2024). Lattice Design and Advanced Modeling to Guide the Design of High-Performance Lightweight Structural Materials. Energies, 17(6), 1468. https://doi.org/10.3390/en17061468