Operation, Maintenance, and Decommissioning Cost in Life-Cycle Cost Analysis of Floating Wind Turbines

Abstract

1. Introduction

Literature Review of Life Cycle Cost Analysis for Offshore and Floating Wind Energy

2. Methods

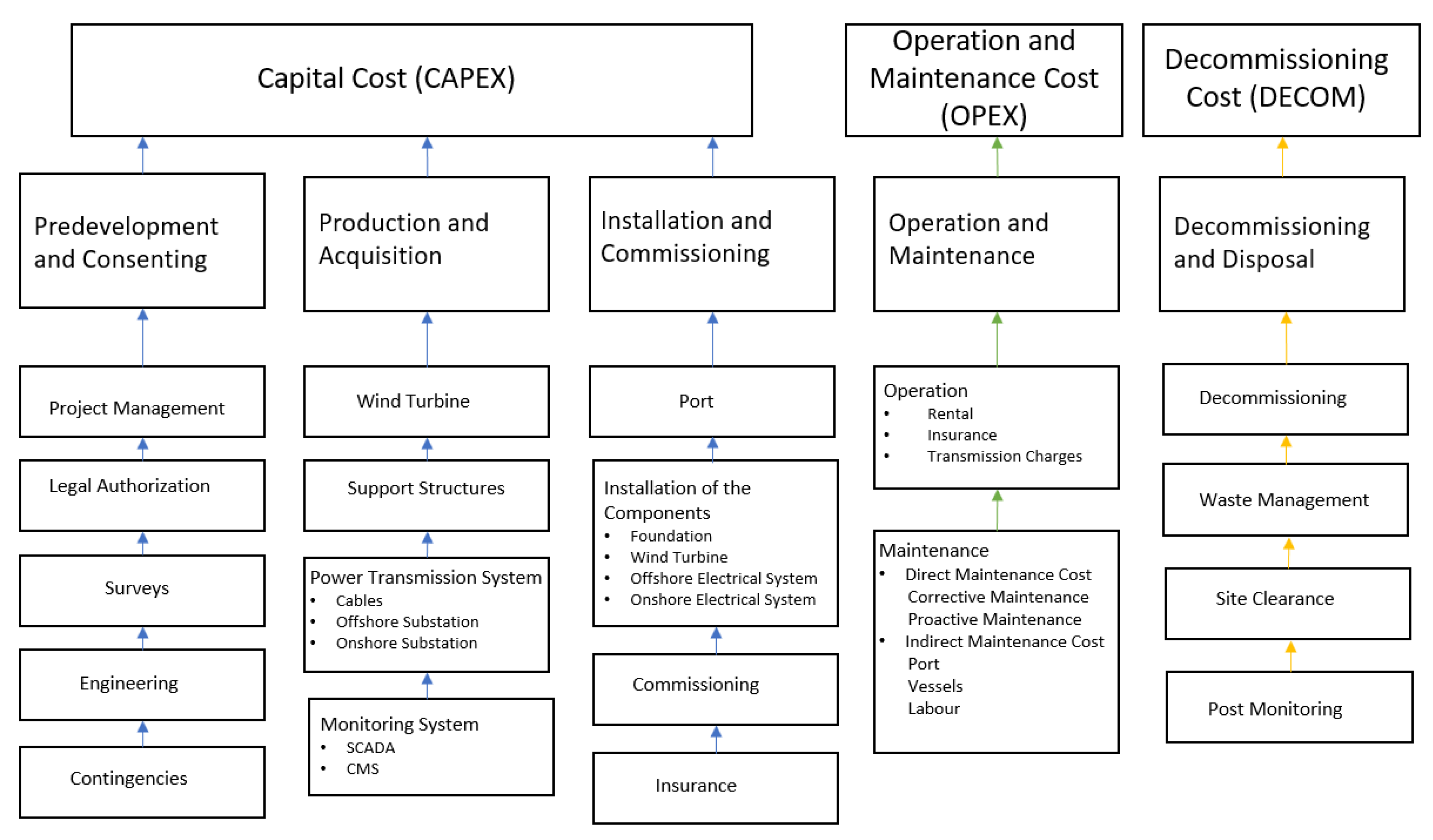

2.1. CAPEX

2.1.1. Predevelopment and Consenting

- Project management: All administrative services, prefeasibility studies, funding, tenders, internal control systems, and agreements with subcontractors are included in the project management activities. It is common to express the overall cost of project management during CAPEX. Project management costs approximately 3% of the CAPEX, according to a study by Shafiee et al. [15].

- Legal authorization: The government or a regulatory authority must approve the establishment of a wind farm. The legal authorisation procedure is included in certain research as an element of project management. The cost of legal authorisation is expected to be around 0.13% of the CAPEX [15]. Thus,

- Surveys: In evaluating the viability of offshore wind projects, several site-specific surveys should be performed. The sort of survey completed normally changes depending to the amount of information requested. Environmental (), coastal process (), seabed (), and metocean conditions () surveys are now applied for offshore and floating wind farm projects [15]. The cost of surveying is determined by the following formulation:

- Engineering: Once a project is accepted and the final investment decision has been made, a multidisciplinary and experienced team is formed to design the offshore and floating wind farms. Many of the operations that are conducted throughout this phase encompass the aspects of structural design and selection of substructure, design of wind farm planning, and design of electrical system and grid connection [15,42]. Thus, the cost of engineering is given by the following formulation:where , and present the sum of a fixed base cost, design verification process, the cost of a unit term, and the installation capacity [19].

- Contingencies: The contingency cost compensates for uncertain annual costs and provides for the replacement of the most expensive components prone to catastrophic failure. It is projected to constitute 10% of CAPEX costs [2].

2.1.2. Production and Acquisition

- Wind Turbines: The cost of wind turbine procurements is stated as a function of the total number of wind turbines (NWT) erected in the farm and can be obtained by the following equation:

- Support structures: The cost of a support structure is split into two parts: the material cost ) and the transportation and assembly costs (). Thus,

- Power transmission system: The electricity transmission system is made up of many cables that link wind turbines to the grid as well as onshore/offshore substations () [15]. As a result, the cost of the power transmission system is provided by

- Monitoring system: To record condition data, a vast number of sensors and control devices are installed across offshore wind farms (sea-state, deterioration data, etc.). The information gathered is often sent to a supervisory control and data acquisition (SCADA) system and saved in databases. These condition data can be used by system analysts to arrange maintenance and inspection activities. The cost of offshore and floating wind farms’ SCADA and condition monitoring systems () is determined by the number of wind turbines deployed [43]. Hence,

2.1.3. Installation and Commissioning

- Port cost: The port is critical to the management of the supply chain for offshore and floating wind projects. Yearly fees must be paid to local governments for the use of port facilities, quayside docking, and crane usage authorization [44]. Furthermore, the annual fee to wind farm labourers who conduct project tasks (for example, pre-assembling the components) must be considered.

- = Average labour-day

- = Daily labour rate

- Installation of the components: Some procedures must be carried out throughout the erection of offshore wind farm projects. The expenditure of any such installation is split into four categories based on the kind of components installed: foundation, wind turbine, and offshore and onshore electrical systems [15,34]. The costs associated with hiring chartered ships and technicians are included in all of the aforementioned cost categories. Hence,

- Commissioning: In order to discover early faults and enhance dependability, offshore wind farms must undergo extensive testing before to being put into operation. This includes testing the wind turbines, electrical systems, SCADA, and CMSs. In most cases, the expenses involved with renting vessels and staff personnel make up the bulk of the cost of commissioning [45].

- Insurance: Insurance is necessary at this stage to mitigate the effects of any unexpected occurrences. The insurance cost (CI&C-ins) is included in the capital cost. Insurance costs are calculated using the average worldwide cost for installation insurance of wind turbines, foundations, and electrical systems (including offshore and onshore electrical substations) [34,45,46].

2.2. OPEX

2.2.1. Operational Expenditures

- Insurance: It is necessary to contract operational insurance coverage in order to protect offshore wind facilities from design flaws, collision accidents, and substation outages. When it comes to insurance packages, the cost is determined by the size of the wind farm in question [15].

2.2.2. Maintenance

- Direct maintenance cost: Direct maintenance expenses include the costs of transporting malfunctioning components, maintenance specialists who conduct repair/replacement procedures, and all consumables and spare parts necessary for wind farm maintenance. Corrective maintenance (CM) and proactive maintenance (PM) are the two primary types of the wind farm maintenance process (ProM) [47,48]. These are described as corrective maintenance, which occurs when a component fails, and proactive maintenance, which occurs before the component fails [48].

- Indirect maintenance: The cost of actions required to maintain the direct effort involved in delivering repair services is known as indirect maintenance cost. Port costs for replacement parts storage and quayside amenities must be paid regardless of the number of maintenance jobs to be accomplished. Aside from this, different procedures (such as weather forecasts and repair work scheduling) should need to be carried out onshore to coordinate maintenance tasks [47,48]. Thus, the cost of indirect maintenance can be expressed by,

2.3. DECOM

2.3.1. Decommissioning

2.3.2. Waste Management

- Salvage value: The salvage value represents the anticipated value of a property at the end of its operational life. A considerable volume of the materials used in wind turbines, such as stainless steel and aluminium, can be recycled. The salvage value of materials recovered from a wind farm depends on the type, quantity (weight or volume), and quality (condition) of recyclable materials [2,39,50].

2.3.3. Site Clearing

2.3.4. Post Monitoring

3. Levelized Cost of Energy Calculation

4. Case Study

5. Results and Discussion

6. Conclusions

- Based on the findings of the total operating expenses scenarios and whole LCOE results, the OPEX scenario that includes off-site maintenance and a wind turbine lifetime of 30 years, is the most cost-effective (£/MWh). The main reasons for this result are that the rental costs of the equipment used for on-site maintenance (motherships, etc.) are higher than those used for onshore maintenance, and sea conditions (wind, weather, etc.) increase the duration of on-site maintenance.

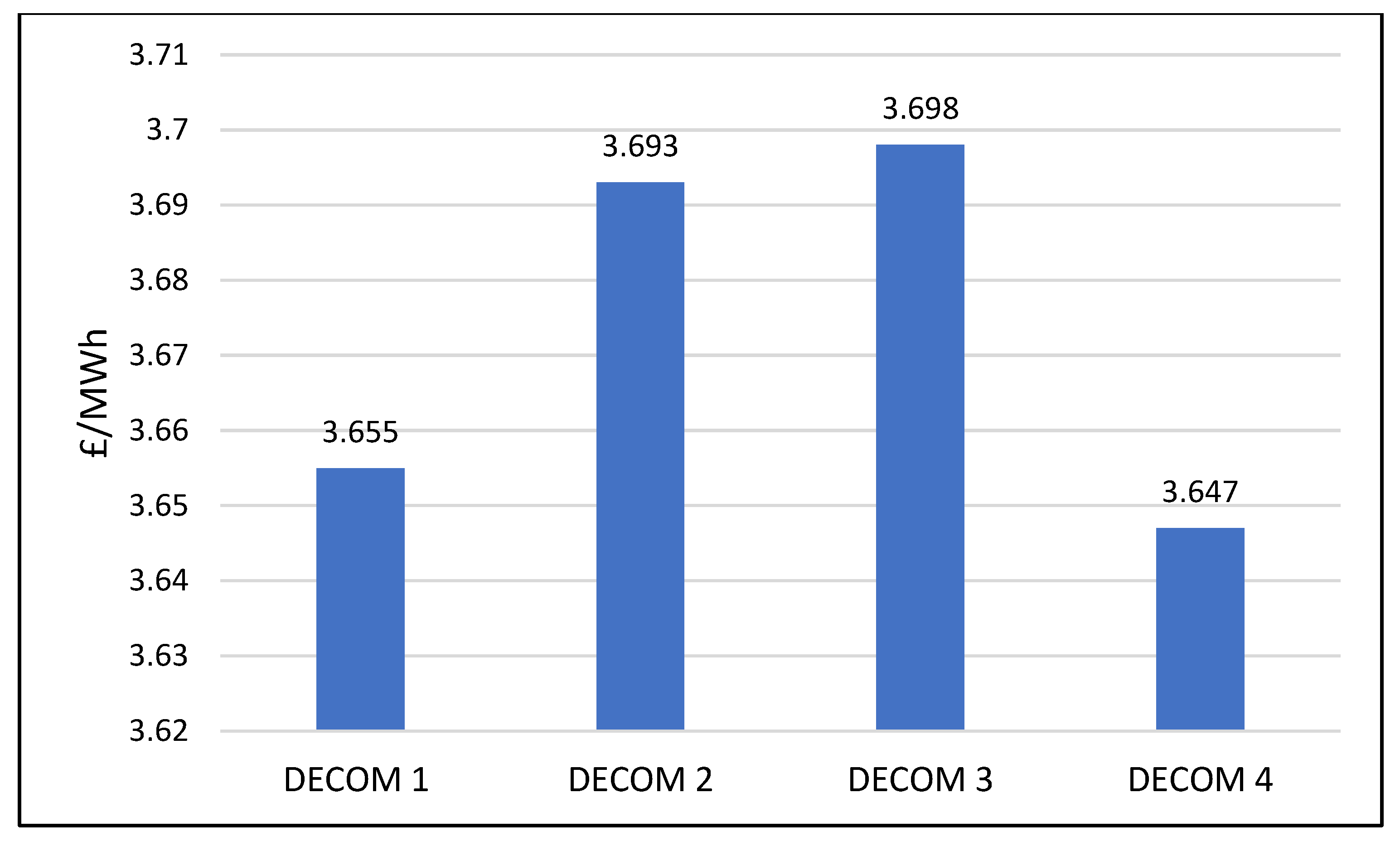

- In terms of decommissioning and disposal scenarios, the incineration scenario was found to contribute the least to DECOM’s LCOE compared to the other scenarios. However, increasing the recycling rate in the mechanical process and reducing the cost per tonne of the process could lead to a scenario with a lower LCOE.

- The lowest cost alternatives are OPEX 6 for maintenance and DECOM 4 for end-of-life, according to the total cost analysis. The total LCOE of these two scenarios is calculated at £50.66/MWh. Compared to the baseline scenario, a cost re-duction of approximately 24.08% was achieved with these two scenarios.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salah Alaloul, W.; Ali Musarat, M. Impact of Zero Energy Building: Sustainability Perspective. In Sustainable Sewage Sludge Management and Resource Efficiency; IntechOpen: Rijeka, Croatia, 2020. [Google Scholar]

- Alsubal, S.; Alaloul, W.S.; Shawn, E.L.; Liew, M.S.; Palaniappan, P.; Musarat, M.A. Life Cycle Cost Assessment of Offshore Wind Farm: Kudat Malaysia Case. Sustainability 2021, 13, 7943. [Google Scholar] [CrossRef]

- Kucaj, E.; Susaj, E.; Qaja, B. Renewable Energy—A Great Energizing Potential that Eliminates Environmental Pollution. Eur. J. Econ. Bus. Stud. 2017, 9, 40–45. [Google Scholar] [CrossRef]

- Wang, C.M.; Utsunomiya, T.; Wee, S.C.; Choo, Y.S. The IES Journal Part A: Civil & Structural Engineering Research on Floating Wind Turbines: A Literature Survey. Science (1979). IES J. Part A Civ. Struct. Eng. 2010, 3, 267–277. [Google Scholar]

- IRENA Insights on Renewables: Installed Capacity Trends. 2022. Available online: https://www.irena.org/Data (accessed on 10 January 2024).

- Pantusa, D.; Francone, A.; Tomasicchio, G.R. Floating Offshore Renewable Energy Farms. A Life-Cycle Cost Analysis at Brindisi, Italy. Energies 2020, 13, 6150. [Google Scholar] [CrossRef]

- European Commission. An EU Strategy to Harness the Potential of Offshore Renewable Energy for a Climate Neutral Future; European Comission: Brussels, Belgium, 2020. [Google Scholar]

- GWEC Global Wind Report 2019. 2020. Available online: https://gwec.net. (accessed on 20 January 2023).

- IRENA Offshore Renewables: An Action Agenda for Deployment. 2021. Available online: https://www.irena.org/Publications/2021/Jul/Offshore-Renewables-An-Action-Agenda-for-Deployment (accessed on 10 May 2022).

- Viselli, A.M.; Goupee, A.J.; Dagher, H.J. Model Test of a 1:8-Scale Floating Wind Turbine Offshore in the Gulf of Maine1. J. Offshore Mech. Arct. Eng. 2015, 137. [Google Scholar] [CrossRef]

- Liu, Z.; Fan, Y.; Wang, W.; Qian, G. Numerical Study of a Proposed Semi-Submersible Floating Platform with Different Numbers of Offset Columns Based on the DeepCwind Prototype for Improving the Wave-Resistance Ability. Appl. Sci. 2019, 9, 1255. [Google Scholar] [CrossRef]

- Liu, Y.; Ishihara, T. Numerical Study on Sectional Loads and Structural Optimization of an Elastic Semi-Submersible Floating Platform. Energies 2021, 14, 182. [Google Scholar] [CrossRef]

- Yildiz, N.; Hemida, H.; Baniotopoulos, C. Life Cycle Assessment of a Barge-Type Floating Wind Turbine and Comparison with Other Types of Wind Turbines. Energies 2021, 14, 5656. [Google Scholar] [CrossRef]

- Fuller, S.K.; Petersen, S.R. Life-Cycle Costing Manual of the US Federal Energy Management Program 1995. In NIST Handbook; US Department of Energy: Gaithersburg, MD, USA, 1996; p. 135. [Google Scholar]

- Shafiee, M.; Brennan, F.; Espinosa, I.A. A parametric whole life cost model for offshore wind farms. Int. J. Life Cycle Assess. 2016, 21, 961–975. [Google Scholar] [CrossRef]

- Maienza, C.; Avossa, A.M.; Ricciardelli, F.; Scherillo, F.; Georgakis, C.T. A Comparative Analysis of Construction Costs of Onshore and Shallow- and Deep-Water Offshore Wind Farms. In Lecture Notes in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2019; Volume 25, pp. 440–453. [Google Scholar]

- Blanco, M.I. The Economics of Wind Energy. Renew. Sustain. Energy Rev. 2009, 13, 1372–1382. [Google Scholar] [CrossRef]

- Ioannou, A.; Angus, A.; Brennan, F. Parametric CAPEX, OPEX, and LCOE expressions for offshore wind farms based on global deployment parameters. Energy Sources Part B Econ. Plan. Policy 2018, 13, 281–290. [Google Scholar] [CrossRef]

- Laura, C.-S.; Vicente, D.-C. Life-cycle cost analysis of floating offshore wind farms. Renew. Energy 2014, 66, 41–48. [Google Scholar] [CrossRef]

- Topham, E.; McMillan, D. Sustainable decommissioning of an offshore wind farm. Renew. Energy 2017, 102, 470–480. [Google Scholar] [CrossRef]

- Madariaga, A.; De Alegría, I.M.; Martín, J.L.; Eguía, P.; Ceballos, S. Current Facts about Offshore Wind Farms. Renew. Sustain. Energy Rev. 2012, 16, 3105–3116. [Google Scholar] [CrossRef]

- Mekhilef, S.; Safari, A.; Chandrasegaran, D. Feasibility Study of Off-Shore Wind Farms in Malaysia. Energy Educ. Sci. Technol. Part A Energy Sci. Res. 2012, 28, 519–530. [Google Scholar]

- Ibrahim, M.; Albani, A. The Potential of Wind Energy in Malaysian Renewable Energy Policy: Case Study in Kudat, Sabah. Energy Environ. 2014, 25, 881–898. [Google Scholar] [CrossRef]

- Nian, V.; Liu, Y.; Zhong, S. Life cycle cost-benefit analysis of offshore wind energy under the climatic conditions in Southeast Asia – Setting the bottom-line for deployment. Appl. Energy 2018, 233, 1003–1014. [Google Scholar] [CrossRef]

- Mytilinou, V.; Kolios, A.J. Techno-economic optimisation of offshore wind farms based on life cycle cost analysis on the UK. Renew. Energy 2019, 132, 439–454. [Google Scholar] [CrossRef]

- Junginger, M.; Faaij, A.; Turkenburg, W.C. Cost Reduction Prospects for Offshore Wind Farms. Wind. Eng. 2004, 28, 97–118. [Google Scholar] [CrossRef]

- Valpy, B.; Hundleby, G.; Freeman, K.; Roberts, A.; Logan, A. Future Renewable Energy Costs: Offshore Wind; BVG Associates, Inno Energy: Swindon, UK, 2017. [Google Scholar]

- McAuliffe, F.D.; Murphy, J.; Lynch, K.; Desmond, C.; Norbeck, J.A.; Nonås, L.M.; Attari, Y.; Doherty, P.; Sorensen, J.D.; Giebhardt, J.; et al. Driving Cost Reductions in Offshore Wind: The Leanwind Project Final Publication; Driving Cost Reduction on Offshore Wind; Leanwind: Brussels, Belgium, 2017; p. 72. [Google Scholar]

- Darwish, A.S. Floating Offshore Wind Technology Development: Current State and Future Vision. In Sustainable Energy Development and Innovation: Selected Papers from the World Renewable Energy Congress (WREC) 2020; Springer International Publishing: Berlin/Heidelberg, Germany, 2022; pp. 651–659. [Google Scholar] [CrossRef]

- Ebenhoch, R.; Matha, D.; Marathe, S.; Muñoz, P.C.; Molins, C. Comparative Levelized Cost of Energy Analysis. Proc. Energy Procedia 2015, 80, 108–122. [Google Scholar] [CrossRef]

- Rinne, E.; Holttinen, H.; Kiviluoma, J.; Rissanen, S. Effects of turbine technology and land use on wind power resource potential. Nat. Energy 2018, 3, 494–500. [Google Scholar] [CrossRef]

- Cavazzi, S.; Dutton, A. An Offshore Wind Energy Geographic Information System (OWE-GIS) for assessment of the UK’s offshore wind energy potential. Renew. Energy 2016, 87, 212–228. [Google Scholar] [CrossRef]

- Hdidouan, D.; Staffell, I. The impact of climate change on the levelised cost of wind energy. Renew. Energy 2017, 101, 575–592. [Google Scholar] [CrossRef]

- Kaiser, M.J.; Snyder, B.F. Offshore Wind Energy Cost Modeling: Installation and Decommissioning. Green Energy Technol. 2012, 85, 135–154. [Google Scholar]

- Nilsson, J.; Bertling, L. Maintenance Management of Wind Power Systems Using Condition Monitoring Systems—Life Cycle Cost Analysis for Two Case Studies. IEEE Trans. Energy Convers. 2007, 22, 223–229. [Google Scholar] [CrossRef]

- Judge, F.; McAuliffe, F.D.; Sperstad, I.B.; Chester, R.; Flannery, B.; Lynch, K.; Murphy, J. A lifecycle financial analysis model for offshore wind farms. Renew. Sustain. Energy Rev. 2019, 103, 370–383. [Google Scholar] [CrossRef]

- Myhr, A.; Bjerkseter, C.; Ågotnes, A.; Nygaard, T.A. Levelised cost of energy for offshore floating wind turbines in a life cycle perspective. Renew. Energy 2014, 66, 714–728. [Google Scholar] [CrossRef]

- Baita-Saavedra, E.; Cordal-Iglesias, D.; Filgueira-Vizoso, A.; Castro-Santos, L. Economic Aspects of a Concrete Floating Offshore Wind Platform in the Atlantic Arc of Europe. Int. J. Environ. Res. Public Health 2019, 16, 4122. [Google Scholar] [CrossRef] [PubMed]

- Maienza, C.; Avossa, A.; Ricciardelli, F.; Coiro, D.; Troise, G.; Georgakis, C. A life cycle cost model for floating offshore wind farms. Appl. Energy 2020, 266, 114716. [Google Scholar] [CrossRef]

- Levitt, A.C.; Kempton, W.; Smith, A.P.; Musial, W.; Firestone, J. Pricing offshore wind power. Energy Policy 2011, 39, 6408–6421. [Google Scholar] [CrossRef]

- Castro-Santos, L.; Martins, E.; Soares, C.G. Methodology to Calculate the Costs of a Floating Offshore Renewable Energy Farm. Energies 2016, 9, 324. [Google Scholar] [CrossRef]

- Effiom, S.; Nwankwojike, B.; Abam, F. Economic cost evaluation on the viability of offshore wind turbine farms in Nigeria. Energy Rep. 2016, 2, 48–53. [Google Scholar] [CrossRef]

- TTavner, P. Offshore Wind Turbines Reliability, Availability and Maintenance; The Institution of Engineering and Technology: London, UK, 2012. [Google Scholar] [CrossRef]

- Maples, B.; Saur, G.; Hand, M.; Pietermen, R.; van Obdam, T. Installation, Operation, and Maintenance Strategies to Reduce the Cost of Offshore Wind Energy; Technical Report Nrel/Tp-5000-57403; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2013.

- Dinmohammadi, F.; Shafiee, M. A Fuzzy-FMEA Risk Assessment Approach for Offshore Wind Turbines. Int. J. Progn. Health Manag. 2013, 4, 59–68. [Google Scholar] [CrossRef]

- Ahn, D.; Shin, S.-C.; Kim, S.-Y.; Kharoufi, H.; Kim, H.-C. Comparative evaluation of different offshore wind turbine installation vessels for Korean west–south wind farm. Int. J. Nav. Arch. Ocean Eng. 2017, 9, 45–54. [Google Scholar] [CrossRef]

- Kang, J.; Sobral, J.; Soares, C.G. Review of Condition-Based Maintenance Strategies for Offshore Wind Energy. J. Mar. Sci. Appl. 2019, 18, 1–16. [Google Scholar] [CrossRef]

- Ren, Z.; Verma, A.S.; Li, Y.; Teuwen, J.J.; Jiang, Z. Offshore wind turbine operations and maintenance: A state-of-the-art review. Renew. Sustain. Energy Rev. 2021, 144, 110886. [Google Scholar] [CrossRef]

- European Council Directive 2008/98/EC on Waste (Waste Framework Directive)—Environment—European Commission. Off. J. Eur. Union 2008, 312, 6–36.

- Topham, E.; McMillan, D.; Bradley, S.; Hart, E. Recycling offshore wind farms at decommissioning stage. Energy Policy 2019, 129, 698–709. [Google Scholar] [CrossRef]

- James Floating Offshore Wind: Installation, Operation & Maintenance Challenges. Available online: https://blackfishengineering.com/2020/07/29/floating-offshore-wind-installation-operation-maintenance-challenges/ (accessed on 10 November 2023).

- Yildiz, N.; Hemida, H.; Baniotopoulos, C. Floating Versus Offshore Wind Turbines: A Comparative Life Cycle Assessment. In Proceedings of the CESARE Conference Publications; University of Birmingham: Birmingham, UK, 2022. [Google Scholar]

- Yildiz, N.; Hemida, H.; Baniotopoulos, C. Maintenance and End-of-Life Analysis in LCA for Barge-Type Floating Wind Turbine. Wind 2022, 2, 246–259. [Google Scholar] [CrossRef]

- Vargas, A.; Zenón, E.; Oswald, U.; Islas, J.; Güereca, L.; Manzini, F. Life cycle assessment: A case study of two wind turbines used in Mexico. Appl. Therm. Eng. 2015, 75, 1210–1216. [Google Scholar] [CrossRef]

- Martínez, E.; Sanz, F.; Pellegrini, S.; Jiménez, E.; Blanco, J. Life cycle assessment of a multi-megawatt wind turbine. Renew. Energy 2009, 34, 667–673. [Google Scholar] [CrossRef]

- Ortegon, K.; Nies, L.F.; Sutherland, J.W. Preparing for end of service life of wind turbines. J. Clean. Prod. 2013, 39, 191–199. [Google Scholar] [CrossRef]

- Echavarria, E.; Hahn, B.; Van Bussel, G.J.W.; Tomiyama, T. Reliability of Wind Turbine Technology through Time. J. Sol. Energy Eng. 2008, 130, 031005. [Google Scholar] [CrossRef]

| Costs | Formulation |

|---|---|

| The total cost over a lifetime | |

| Predevelopment and consenting | |

| Project management | × |

| Legal authorization | × |

| Surveys | |

| Engineering | × |

| Contingencies | × |

| Production and acquisition | |

| Wind turbines | × |

| Support structures | × |

| Power transmission system | |

| Monitoring system | × |

| Installation and commissioning | |

| Port cost | |

| Installation of the components | |

| Operation and maintenance (O&M) | |

| Operational expenditures | |

| Maintenance | |

| Indirect maintenance | |

| Decommissioning and disposal | |

| Decommissioning | |

| Waste management | |

| Levelized cost of energy |

| Components | Unit | Value |

|---|---|---|

| Rotor | ton | 28.5 |

| Nacelle | ton | 64 |

| Tower | ton | 183 |

| Platform | ton | 5472.5 |

| Scenario Name | Place of Maintenance Scenarios | Prevention Maintenance and Inspections (Year) | Unscheduled Maintenance (Year) | Lifetime of the Wind Turbine (Year) | Vehicles Used | Components Replaced |

|---|---|---|---|---|---|---|

| OPEX 1 | On-site | 12 | 1 | 20 | Workboat | - |

| OPEX 2 | On-site | 12 | 1 | 25 | Workboat and mother vessel | Gearbox |

| OPEX 3 | On-site | 12 | 1 | 25 | Workboat and mother vessel | Gearbox and blades |

| OPEX 4 | On-site | 12 | 1 | 30 | Workboat and mother vessel | Gearbox and blades |

| OPEX 5 | Off-site | 12 | 1 | 25 | Workboat, crane, and tugboats | Gearbox |

| OPEX 6 | Off-site | 12 | 1 | 30 | Workboat, crane, and tugboats | Gearbox and blades |

| Scenario Name | First Process | Second Process | Third Process | Last Process |

|---|---|---|---|---|

| DECOM 1 | Cutting | - | - | Landfill |

| DECOM 2 | Cutting | Mechanical recycling | - | Landfill |

| DECOM 3 | Cutting | Mechanical recycling | Incineration | Landfill |

| DECOM 4 | Cutting | Incineration | - | Landfill |

| Cost Element | Cost (£) | Contribution of Phase (%) | Contribution of CAPEX (%) |

|---|---|---|---|

| Project Management (CprojM) | 166,896 | 20.57% | 3.09% |

| Legal Authorizing (Clegal) | 65,842 | 8.12% | 1.22% |

| Surveys (Csurveys) | 75,556 | 9.31% | 1.40% |

| Engineering Activities (Ceng) | 4510 | 0.56% | 0.08% |

| Contingencies (Ccontingency) | 498,472 | 61.44% | 9.23% |

| Predevelopment and Consenting (P&C) | 811,276 | 100% | 15.02% |

| Support Structures (CSS) | 1,332,662 | 39.36% | 24.67% |

| Wind Turbines (CWT) | 1,417,041 | 41.85% | 26.23% |

| Power Transmission Systems (CPTS) | 625,914 | 18.48% | 11.59% |

| Monitoring Systems (Cmonitoring) | 9888 | 0.29% | 0.18% |

| Production and Acquisition (P&A) | 3,385,505 | 100% | 62.67% |

| Support Structures and Electrical Systems (CI&C-comp) | 58,756 | 4.87% | 1.09% |

| Ports Charges (Cport) | 1,063,076 | 88.15% | 19.68% |

| Commissioning Cost (Ccomm) | 960 | 0.08% | 0.02% |

| Insurance Cost (CI&C-ins) | 83,200 | 6.90% | 1.54% |

| Installation and Commissioning (I&C) | 1,205,992 | 100% | 22.33% |

| CAPEX | 5,402,773 |

| Scenario Name and Cost Element for OPEX | Cost (£) | % Contribution | LCOE for OPEX 1 (£/MWh) | Total LCOE (£/MWh) |

|---|---|---|---|---|

| Crent | 46,740 | 2.15% | 0.388 | |

| CO&M-ins | 174,610 | 8.04% | 1.452 | |

| Ctransmission | 860,700 | 39.67% | 7.168 | |

| CM-indirect | 390,000 | 17.97% | 3.247 | |

| CProM | 376,200 | 17.34% | 3.133 | |

| CCM | 321,100 | 14.80% | 2.674 | |

| Total OPEX 1 | 2,169,350 | 100% | 18.07 | 66.73 |

| Crent | 58,425 | 2.17% | 0.389 | |

| CO&M-ins | 218,262.5 | 8.11% | 1.454 | |

| Ctransmission | 1,075,875 | 40.00% | 7.172 | |

| CM-indirect | 487,500 | 18.12% | 3.248 | |

| CProM | 448,100 | 16.66% | 2.987 | |

| CCM | 401,375 | 14.92% | 2.675 | |

| Total OPEX 2 | 2,689,537.5 | 100% | 17.93 | 56.85 |

| Crent | 58,425 | 1.95% | 0.388 | |

| CO&M-ins | 218,262.5 | 7.30% | 1.454 | |

| Ctransmission | 1,075,875 | 35.98% | 7.170 | |

| CM-indirect | 487,500 | 16.30% | 3.248 | |

| CProM | 748,100 | 25.02% | 4.986 | |

| CCM | 401,375 | 13.42% | 2.674 | |

| Total OPEX 3 | 2,989,537.5 | 100% | 19.93 | 58.85 |

| Crent | 70,110 | 2.03% | 0.387 | |

| CO&M-ins | 261,915 | 7.61% | 1.452 | |

| Ctransmission | 1,291,050 | 37.55% | 7.168 | |

| CM-indirect | 58,5000 | 17.01% | 3.247 | |

| CProM | 748,100 | 21.76% | 4.153 | |

| CCM | 481,650 | 14.01% | 2.674 | |

| Total OPEX 4 | 3,437,825 | 100% | 19.09 | 51.54 |

| Crent | 58,425 | 2.30% | 0.388 | |

| CO&M-ins | 218,262.5 | 8.61% | 1.454 | |

| Ctransmission | 1,075,875 | 42.46% | 7.171 | |

| CM-indirect | 487,500 | 19.24% | 3.249 | |

| CProM | 292,100 | 11.52% | 1.945 | |

| CCM | 401,375 | 15.84% | 2.675 | |

| Total OPEX 5 | 2,533,537.5 | 100% | 16.89 | 55.81 |

| Crent | 70,110 | 2.13% | 0.388 | |

| CO&M-ins | 261,915 | 7.98% | 1.454 | |

| Ctransmission | 1,291,050 | 39.33% | 7.169 | |

| CM-indirect | 585,000 | 17.82% | 3.248 | |

| CProM | 592,100 | 18.04% | 3.288 | |

| CCM | 481,650 | 14.67% | 2.674 | |

| Total OPEX 6 | 3,281,825 | 100% | 18.23 | 50.67 |

| Scenario Names and Cost Element for DECOM | Cost (£) | % Contribution | LCOE for DECOM 1 (£/MWh) |

|---|---|---|---|

| CD&D-port | 99,278 | 22.63% | 0.827 |

| Cremove | 729,190.8 | 166.23% | 6.075 |

| CWM | −407,008 | −92.78% | −3.391 |

| CpostM | 17,178 | 3.91% | 0.142 |

| Total DECOM 1 | 438,638.8 | 100% | 3.655 |

| CD&D-port | 99,278 | 22.40% | 0.827 |

| Cremove | 729,190.8 | 164.53% | 6.076 |

| CWM | −402,462.775 | −90.81% | −3.353 |

| CpostM | 17,178 | 3.87% | 0.142 |

| Total DECOM 2 | 443,184.025 | 100% | 3.693 |

| CD&D-port | 99,278 | 22.37% | 0.827 |

| Cremove | 729,190.8 | 164.31% | 6.076 |

| CWM | −401,870.05 | −90.55% | −3.348 |

| CpostM | 17,178 | 3.87% | 0.143 |

| Total DECOM 3 | 443,776.75 | 100% | 3.698 |

| CD&D-port | 99,278 | 22.68% | 0.8271 |

| Cremove | 729,190.8 | 166.58% | 6.075 |

| CWM | −407,917.4 | −93.18% | −3.398 |

| CpostM | 17,178 | 3.92% | 0.142 |

| Total DECOM 4 | 437,729.4 | 100% | 3.647 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yildiz, N.; Hemida, H.; Baniotopoulos, C. Operation, Maintenance, and Decommissioning Cost in Life-Cycle Cost Analysis of Floating Wind Turbines. Energies 2024, 17, 1332. https://doi.org/10.3390/en17061332

Yildiz N, Hemida H, Baniotopoulos C. Operation, Maintenance, and Decommissioning Cost in Life-Cycle Cost Analysis of Floating Wind Turbines. Energies. 2024; 17(6):1332. https://doi.org/10.3390/en17061332

Chicago/Turabian StyleYildiz, Nurullah, Hassan Hemida, and Charalampos Baniotopoulos. 2024. "Operation, Maintenance, and Decommissioning Cost in Life-Cycle Cost Analysis of Floating Wind Turbines" Energies 17, no. 6: 1332. https://doi.org/10.3390/en17061332

APA StyleYildiz, N., Hemida, H., & Baniotopoulos, C. (2024). Operation, Maintenance, and Decommissioning Cost in Life-Cycle Cost Analysis of Floating Wind Turbines. Energies, 17(6), 1332. https://doi.org/10.3390/en17061332